Performance Analysis of Full Assembly Glass Fiber-Reinforced Polymer Composite Cross-Arm in Transmission Tower

Abstract

1. Introduction

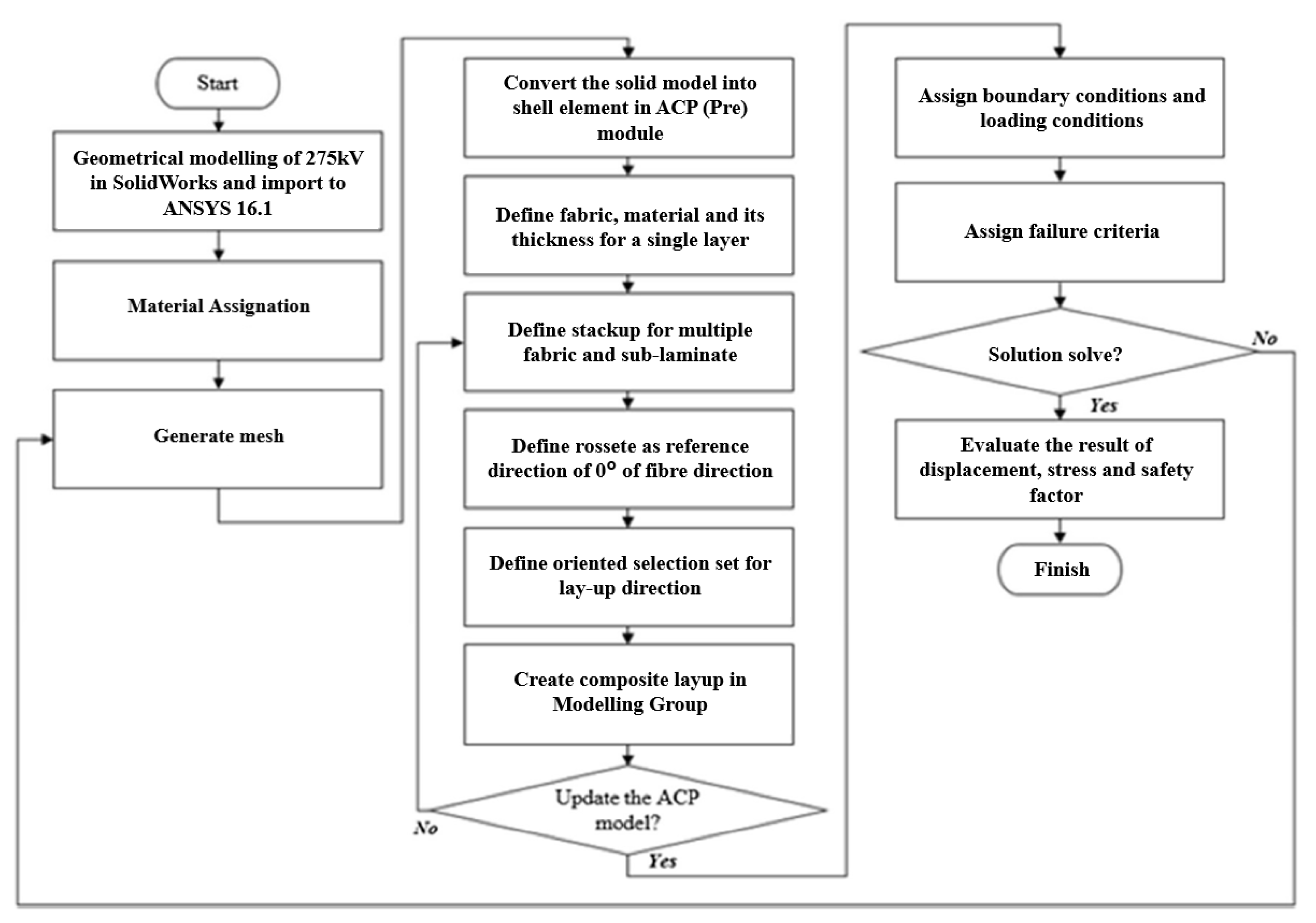

2. Methodology

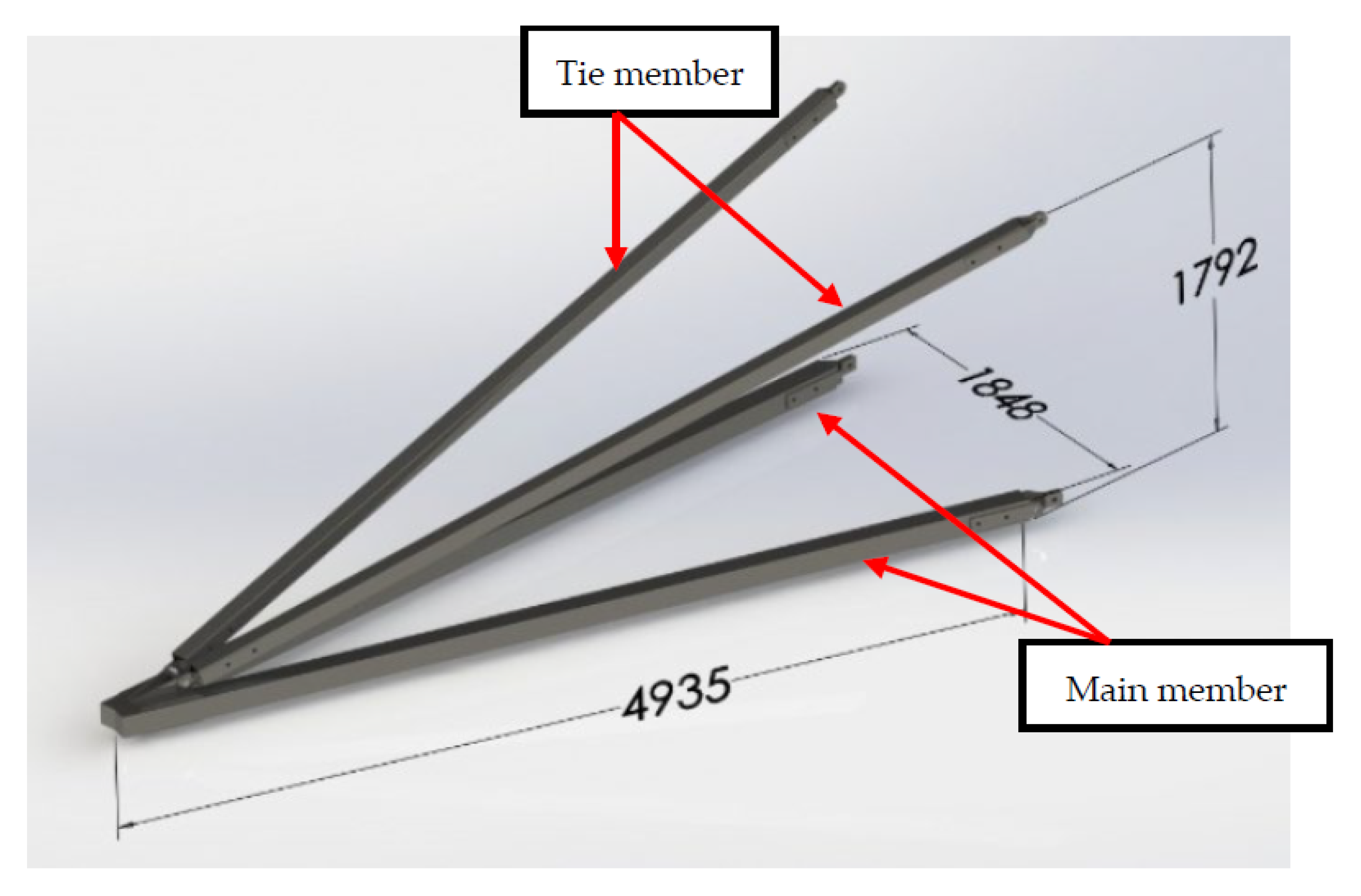

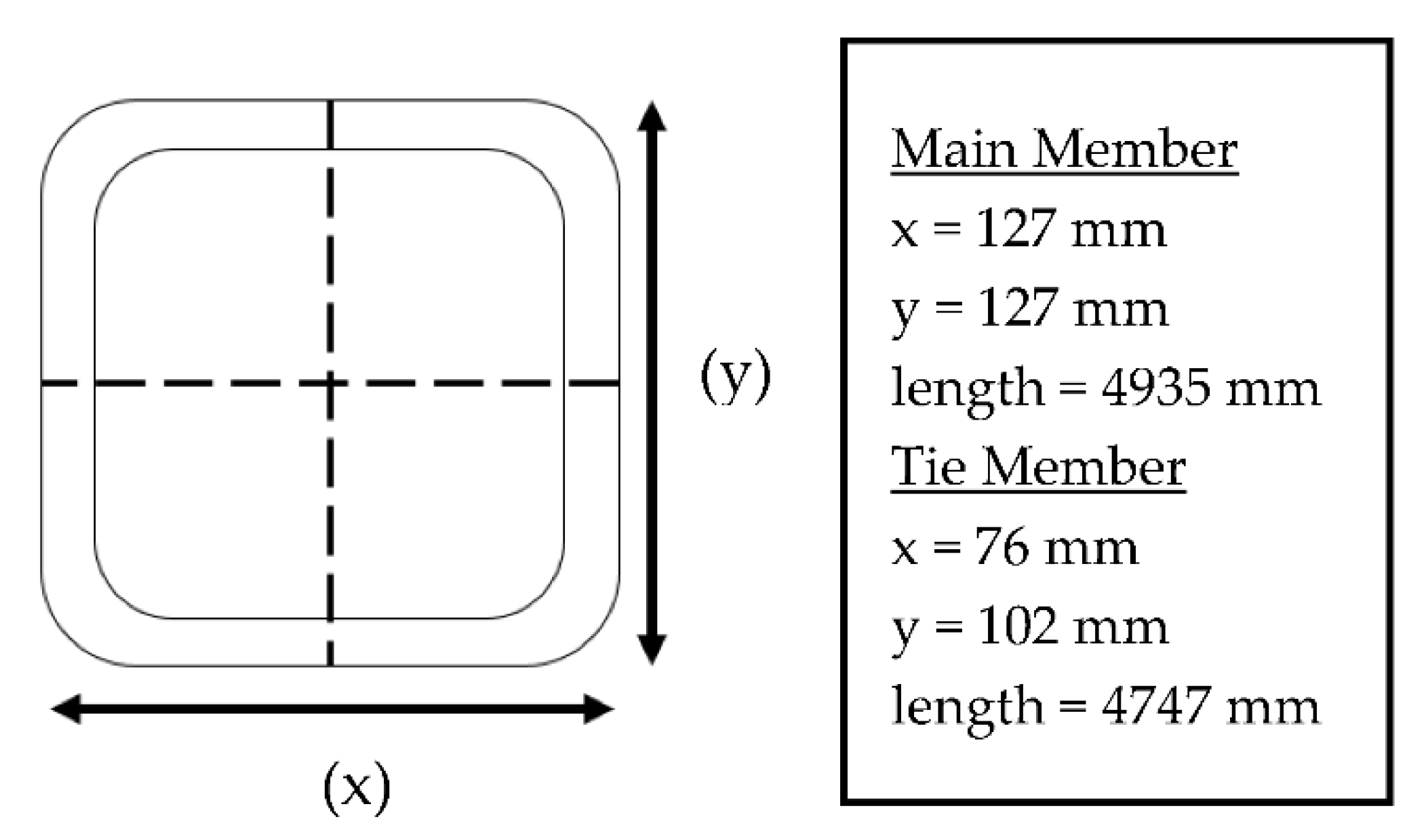

2.1. Geometrical Configurations

2.2. Material Assignation

2.3. Mesh Generation

2.4. Experimental Program

2.5. FE Analysis

2.5.1. Finite Element Model and Validation

2.5.2. Parametric Studies

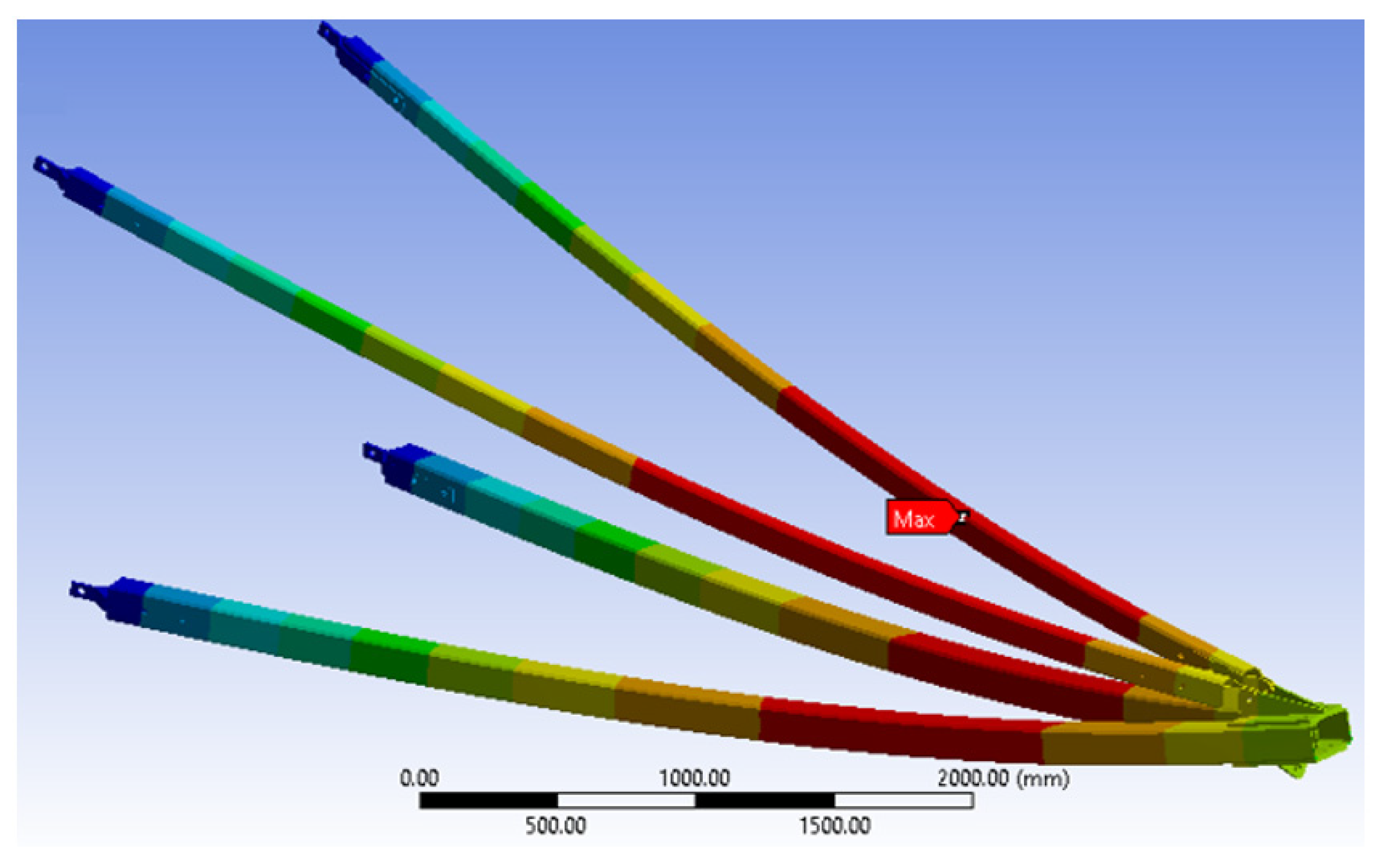

3. Results and Discussions

3.1. Analysis for Normal Condition

3.2. Analysis for Broken Wire Condition

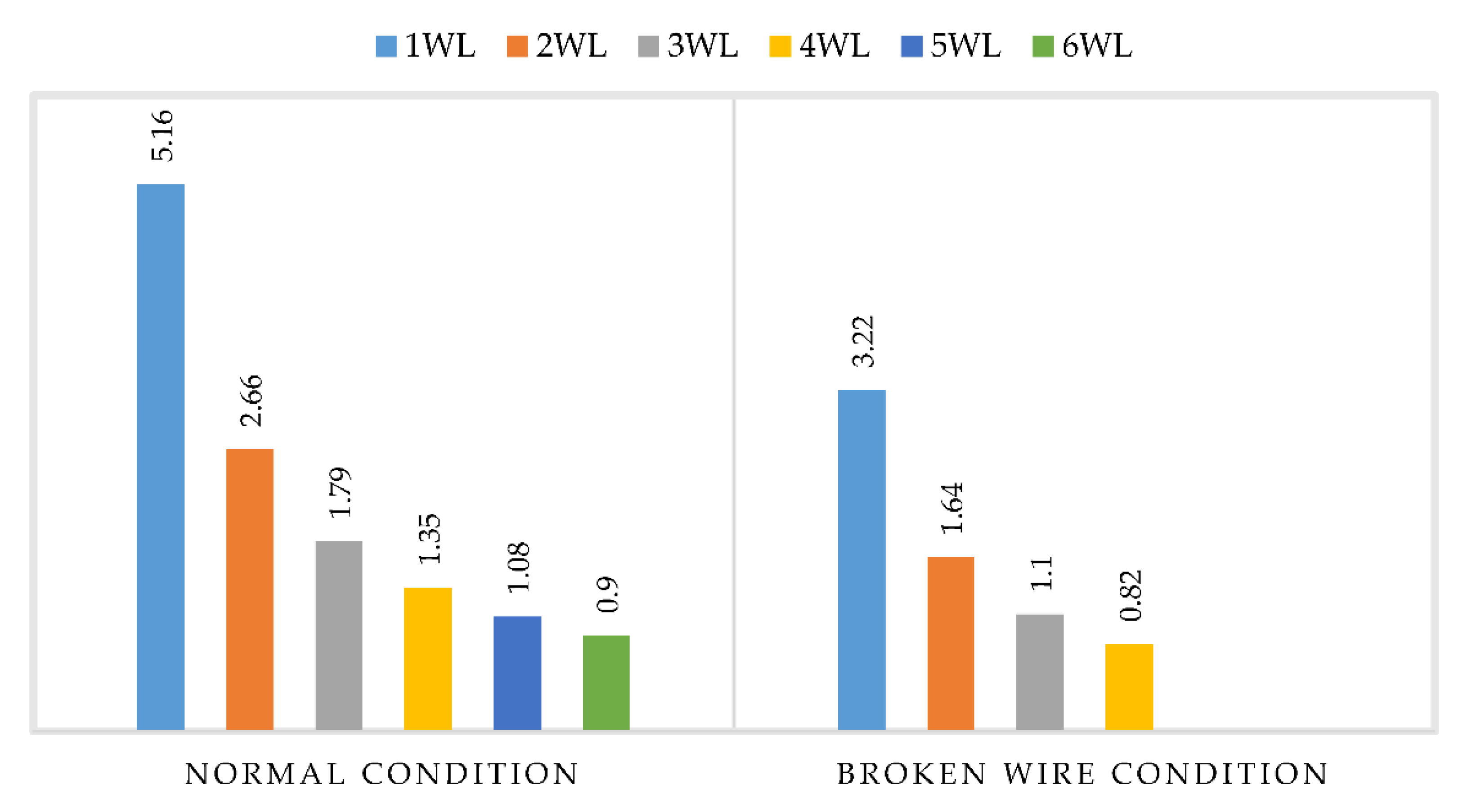

3.3. Factor of Safety

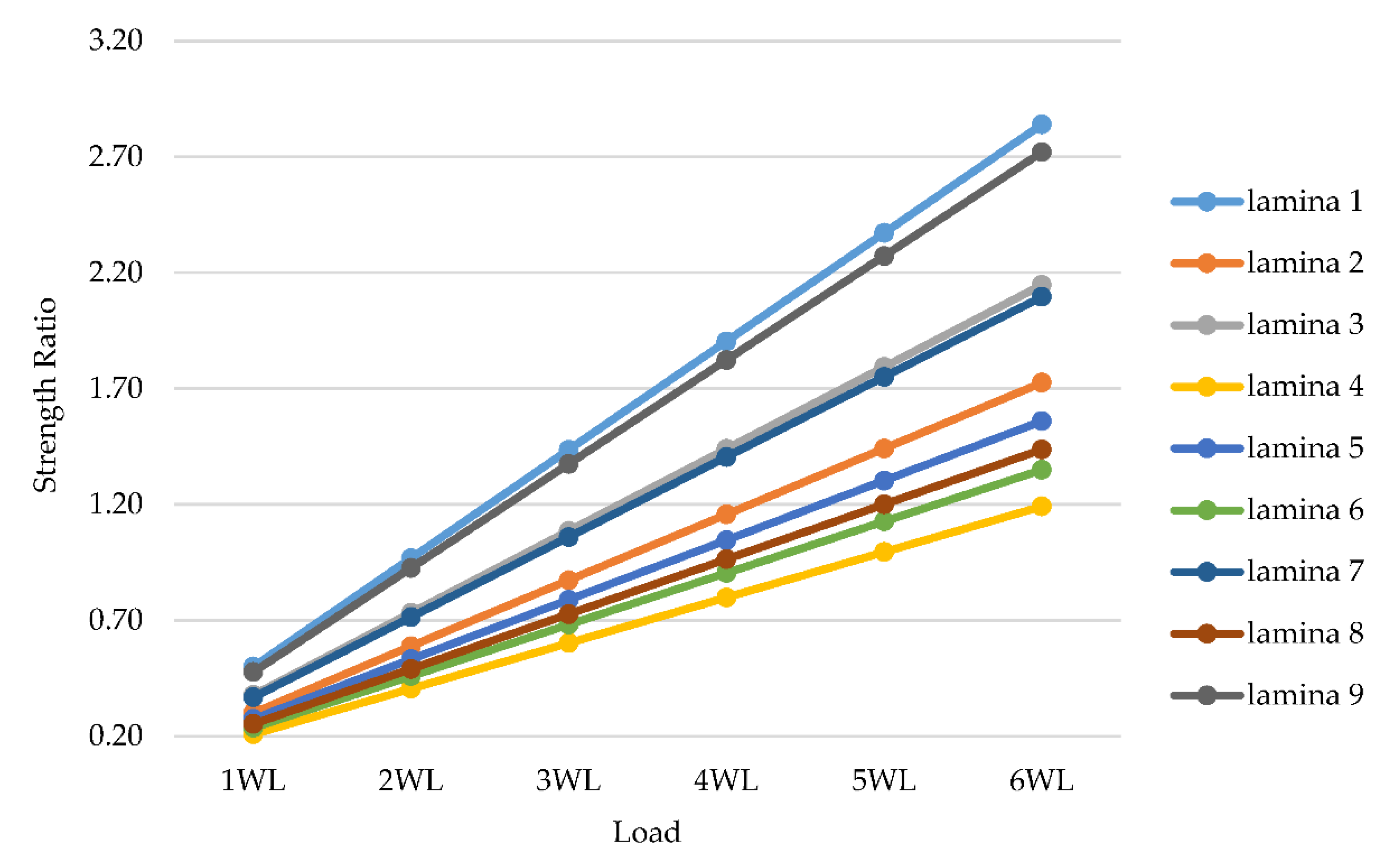

3.4. Failure Criteria (Hashin Theory)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ali, S.S.S.; Razman, M.R.; Awang, A.; Asyraf, M.R.M.; Ishak, M.R.; Ilyas, R.A.; Lawrence, R.J. Critical Determinants of Household Electricity Consumption in a Rapidly Growing City. Sustainability 2021, 13, 4441. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A.; Rafidah, M.; Razman, M.R. Evaluation of design and simulation of creep test rig for full-scale cross arm structure. Adv. Civ. Eng. 2020, 2020, 6980918. [Google Scholar] [CrossRef]

- Zhu, J.J.; Schoenoff, M.S. Effects of natural sunlight on fiberglass reinforced polymers for crossarms. In Proceedings of the IEEE Rural Electric Power Conference (REPC), Memphis, TN, USA, 6–9 May 2018; Volume 2018-May, pp. 101–105. [Google Scholar]

- Selvaraj, M.; Kulkarni, S.; Babu, R.R. Analysis and experimental testing of a built-up composite cross arm in a transmission line tower for mechanical performance. Compos. Struct. 2013, 96, 1–7. [Google Scholar] [CrossRef]

- Yang, X.; Li, N.; Peng, Z.; Liao, J.; Wang, Q. Potential distribution computation and structure optimization for composite cross-arms in 750 kV AC transmission line. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1660–1669. [Google Scholar] [CrossRef]

- Rawi, I.M.; Ab Kadir, M.Z.A. Investigation on the 132kV overhead lines lightning-related flashovers in Malaysia. In Proceedings of the International Symposium on Lightning Protection, XIII SIPDA, Balneario Camboriu, Brazil, 28 September–2 October 2015; pp. 239–243. [Google Scholar]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Shahroze, R.M.; Johari, A.N.; Rafidah, M.; Ilyas, R.A. Creep test rig for cantilever beam: Fundamentals, prospects and present views. J. Mech. Eng. Sci. 2020, 14, 6869–6887. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Razman, M.R.; Chandrasekar, M. Fundamentals of creep, testing methods and development of test rig for the full-scale crossarm: A review. J. Teknol. 2019, 81, 155–164. [Google Scholar] [CrossRef]

- Grzybowski, S.; Disyadej, T. Electrical performance of fiberglass crossarm in distribution and transmission lines. In Proceedings of the Transmission and Distribution Exposition Conference: 2008 IEEE PES Powering Toward the Future, PIMS, Chicago, IL, USA, 21–24 April 2008. [Google Scholar]

- Asyraf, M.R.M.; Ishak, M.R.; Syamsir, A.; Amir, A.L.; Nurazzi, N.M.; Norrrahim, M.N.F.; Asrofi, M.; Rafidah, M.; Ilyas, R.A.; Rashid, M.Z.A.; et al. Filament-wound glass-fibre reinforced polymer composites: Potential applications for cross arm structure in transmission towers. Polym. Bull. 2022, 1–26. [Google Scholar] [CrossRef]

- Rawi, I.M.; Rahman, M.S.A.; Ab Kadir, M.Z.A.; Izadi, M. Wood and fiberglass crossarm performance against lightning strikes on transmission towers. In Proceedings of the International Conference on Power Systems Transient (IPST), Seoul, Korea, 26–29 June 2017; pp. 1–6. [Google Scholar]

- Alias, A.H.; Norizan, M.N.; Sabaruddin, F.A.; Asyraf, M.R.M.; Norrrahim, M.N.F.; Ilyas, A.R.; Kuzmin, A.M.; Rayung, M.; Shazleen, S.S.; Nazrin, A.; et al. Hybridization of MMT/Lignocellulosic Fiber Reinforced Polymer Nanocomposites for Structural Applications: A Review. Coatings 2021, 11, 1355. [Google Scholar] [CrossRef]

- Huzaifah, M.R.M.; Sapuan, S.M.; Leman, Z.; Ishak, M.R. Effect of Soil Burial on Physical, Mechanical and Thermal Properties of Sugar Palm Fibre Reinforced Vinyl Ester Composites. Fibers Polym. 2019, 20, 1893–1899. [Google Scholar] [CrossRef]

- Ishak, M.R.; Leman, Z.; Sapuan, S.M.; Edeerozey, A.M.M.; Othman, I.S. Mechanical properties of kenaf bast and core fibre reinforced unsaturated polyester composites. IOP Conf. Ser. Mater. Sci. Eng. 2010, 11, 012006. [Google Scholar] [CrossRef]

- Kadier, A.; Ilyas, R.A.; Huzaifah, M.R.M.; Harihastuti, N.; Sapuan, S.M.; Harussani, M.M.; Azlin, M.N.M.; Yuliasni, R.; Ibrahim, R.; Atikah, M.S.N.; et al. Use of Industrial Wastes as Sustainable Nutrient Sources for Bacterial Cellulose (BC) Production: Mechanism, Advances, and Future Perspectives. Polymers 2021, 13, 3365. [Google Scholar] [CrossRef] [PubMed]

- Yallappa, S.; Deepthi, D.R.; Yashaswini, S.; Hamsanandini, R.; Chandraprasad, M.; Ashok Kumar, S.; Hegde, G. Natural biowaste of Groundnut shell derived nano carbons: Synthesis, characterization and itsin vitro antibacterial activity. Nano-Struct. Nano-Objects 2017, 12, 84–90. [Google Scholar] [CrossRef]

- Syafiq, R.; Sapuan, S.M.; Zuhri, M.Y.M.; Ilyas, R.A.; Nazrin, A.; Sherwani, S.F.K.; Khalina, A. Antimicrobial Activities of Starch-Based Biopolymers and Biocomposites Incorporated with Plant Essential Oils: A Review. Polymers 2020, 12, 2403. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, R.A.; Aisyah, H.A.; Nordin, A.H.; Ngadi, N.; Zuhri, M.Y.M.; Asyraf, M.R.M.; Sapuan, S.M.; Zainudin, E.S.; Sharma, S.; Abral, H.; et al. Natural-Fiber-Reinforced Chitosan, Chitosan Blends and Their Nanocomposites for Various Advanced Applications. Polymers 2022, 14, 874. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Comparison of Static and Long-term Creep Behaviors between Balau Wood and Glass Fiber Reinforced Polymer Composite for Cross-arm Application. Fibers Polym. 2021, 22, 793–803. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Influence of Additional Bracing Arms as Reinforcement Members in Wooden Timber Cross-Arms on Their Long-Term Creep Responses and Properties. Appl. Sci. 2021, 11, 2061. [Google Scholar] [CrossRef]

- Borukaev, T. Wood-Based Composite Material-Panel Products, Glued-Laminated Timber, Structural Composite Lumber, and Wood-Nonwood Composite Materials. In Polybutilene Therephthalate (PBT), Synthesis and Properties; CRC Press/Taylor & Francis Group: Boca Raton, FL, USA, 2006. [Google Scholar]

- Balau and Chengal Supply in Malaysia. Available online: https://www.aathaworld.com/single-post/Balau-Chengal-Timber-Wood-Supplier-Malaysia (accessed on 12 January 2020).

- Beddu, S.; Syamsir, A.; Arifin, Z.; Ishak, M. Creep behavior of glass fibre reinforced polymer structures in crossarms transmission line towers. In AIP Conference Proceedings; AIP Publishing: College Park, MD, USA, 2018; Volume 2031, p. 020039. [Google Scholar]

- Johari, A.N.; Ishak, M.R.; Leman, Z.; Yusoff, M.Z.M.; Asyraf, M.R.M. Influence of CaCO3 in pultruded glass fibre/unsaturated polyester composite on flexural creep behaviour using conventional and TTSP methods. Polimery 2020, 65, 46–54. [Google Scholar] [CrossRef]

- Roslan, Z.B.; Ramli, Z.; Razman, M.R.; Asyraf, M.R.M.; Ishak, M.R.; Ilyas, R.A.; Nurazzi, N.M. Reflections on Local Community Identity by Evaluating Heritage Sustainability Protection in Jugra, Selangor, Malaysia. Sustainability 2021, 13, 8705. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Zuhri, M.Y.M.; Norrrahim, M.N.F.; Misenan, M.S.M.; Jenol, M.A.; Samsudin, S.A.; Nurazzi, N.M.; Asyraf, M.R.M.; Supian, A.B.M.; Bangar, S.P.; et al. Natural Fiber-Reinforced Polycaprolactone Green and Hybrid Biocomposites for Various Advanced Applications. Polymers 2022, 14, 182. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Zuhri, M.Y.M.; Aisyah, H.A.; Asyraf, M.R.M.; Hassan, S.A.; Zainudin, E.S.; Sapuan, S.M.; Sharma, S.; Bangar, S.P.; Jumaidin, R.; et al. Natural Fiber-Reinforced Polylactic Acid, Polylactic Acid Blends and Their Composites for Advanced Applications. Polymers 2022, 14, 202. [Google Scholar] [CrossRef] [PubMed]

- Nurazzi, N.M.; Asyraf, M.R.M.; Khalina, A.; Abdullah, N.; Aisyah, H.A.; Rafiqah, S.A.; Sabaruddin, F.A.; Kamarudin, M.N.F.; Ilyas, R.A.; Sapuan, S.M. A Review on Natural Fiber Reinforced Polymer Composite for Bullet Proof and Ballistic Applications. Polymers 2021, 13, 646. [Google Scholar] [CrossRef] [PubMed]

- Alsubari, S.; Zuhri, M.Y.M.; Sapuan, S.M.; Ishak, M.R.; Ilyas, R.A.; Asyraf, M.R.M. Potential of Natural Fiber Reinforced Polymer Composites in Sandwich Structures: A Review on Its Mechanical Properties. Polymers 2021, 13, 423. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, R.A.; Sapuan, S.M.; Asyraf, M.R.M.; Dayana, D.A.Z.N.; Amelia, J.J.N.; Rani, M.S.A.; Norrrahim, M.N.F.; Nurazzi, N.M.; Aisyah, H.A.; Sharma, S.; et al. Polymer composites filled with metal derivatives: A review of flame retardants. Polymers 2021, 13, 1701. [Google Scholar] [CrossRef] [PubMed]

- Asyraf, M.R.M.; Ishak, M.R.; Syamsir, A.; Nurazzi, N.M.; Sabaruddin, F.A.; Shazleen, S.S.; Norrrahim, M.N.F.; Rafidah, M.; Ilyas, R.A.; Rashid, M.Z.A.; et al. Mechanical properties of oil palm fibre-reinforced polymer composites: A review. J. Mater. Res. Technol. 2022, 17, 33–65. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Norrrahim, M.N.F.; Nurazzi, N.M.; Shazleen, S.S.; Ilyas, R.A.; Rafidah, M.; Razman, M.R. Recent advances of thermal properties of sugar palm lignocellulosic fibre reinforced polymer composites. Int. J. Biol. Macromol. 2021, 193, 1587–1599. [Google Scholar] [CrossRef] [PubMed]

- Supian, A.B.M.; Sapuan, S.M.; Jawaid, M.; Zuhri, M.Y.M.; Ilyas, R.A.; Syamsir, A. Crashworthiness Response of Filament Wound Kenaf/Glass Fibre-reinforced Epoxy Composite Tubes with Influence of Stacking Sequence under Intermediate-velocity Impact Load. Fibers Polym. 2021, 23, 222–233. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Rafidah, M.; Azrina, A.; Razman, M.R. Dynamic mechanical behaviour of kenaf cellulosic fibre biocomposites: A comprehensive review on chemical treatments. Cellulose 2021, 28, 2675–2695. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Rafidah, M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A.; Razman, M.R. Integration of TRIZ, Morphological Chart and ANP method for development of FRP composite portable fire extinguisher. Polym. Compos. 2020, 41, 2917–2932. [Google Scholar] [CrossRef]

- Mazani, N.; Sapuan, S.M.; Sanyang, M.L.; Atiqah, A.; Ilyas, R.A. Design and Fabrication of a Shoe Shelf From Kenaf Fiber Reinforced Unsaturated Polyester Composites. In Lignocellulose for Future Bioeconomy; Ariffin, H., Sapuan, S.M., Hassan, M.A., Eds.; Elsevier Inc.: Amsterdam, The Netherland, 2019; pp. 315–332. ISBN 9780128163542. [Google Scholar]

- Norizan, M.N.; Alias, A.H.; Sabaruddin, F.A.; Asyraf, M.R.M.; Shazleen, S.S.; Mohidem, N.A.; Kamarudin, S.H.; Norrrahim, M.N.F.; Rushdan, A.I.; Ishak, M.R.; et al. Effect of Silane Treatments on Mechanical Performance of Kenaf Fibre Reinforced Polymer Composites: A Review. Funct. Compos. Struct. 2021, 3, 4. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S.; Atikah, M.S.N. Characterization of Sugar Palm Nanocellulose and Its Potential for Reinforcement with a Starch-Based Composite. In Sugar Palm Biofibers, Biopolymers, and Biocomposites, 1st ed.; CRC Press/Taylor & Francis Group: Boca Raton, FL, USA, 2018; pp. 189–220. [Google Scholar]

- Hasan, K.M.F.; Horváth, P.G.; Alpár, T. Potential natural fiber polymeric nanobiocomposites: A review. Polymers 2020, 12, 1072. [Google Scholar] [CrossRef]

- Tian, X.; Liu, T.; Yang, C.; Wang, Q.; Li, D. Interface and performance of 3D printed continuous carbon fiber reinforced PLA composites. Compos. Part A Appl. Sci. Manuf. 2016, 88, 198–205. [Google Scholar] [CrossRef]

- Amir, N.; Abidin, K.A.Z.; Shiri, F.B.M. Effects of Fibre Configuration on Mechanical Properties of Banana Fibre/PP/MAPP Natural Fibre Reinforced Polymer Composite. Procedia Eng. 2017, 184, 573–580. [Google Scholar] [CrossRef]

- Rafique, I.; Kausar, A.; Anwar, Z.; Muhammad, B. Exploration of Epoxy Resins, Hardening Systems, and Epoxy/Carbon Nanotube Composite Designed for High Performance Materials: A Review. Polym. Plast. Technol. Eng. 2016, 55, 312–333. [Google Scholar] [CrossRef]

- Mansor, M.R.; Sapuan, S.M.; Zainudin, E.S.; Nuraini, A.A. Conceptual design of kenaf fiber polymer composite automotive parking brake lever using integrated TRIZ-Morphological Chart-Analytic Hierarchy Process method. Mater. Des. 2014, 54, 473–482. [Google Scholar] [CrossRef]

- Mansor, M.R.; Sapuan, S.M.; Zainudin, E.S.; Nuraini, A.A.; Hambali, A. Hybrid natural and glass fibers reinforced polymer composites material selection using Analytical Hierarchy Process for automotive brake lever design. Mater. Des. 2013, 51, 484–492. [Google Scholar] [CrossRef]

- Azammi, A.M.N.; Sapuan, S.M.; Ishak, M.R.; Sultan, M.T.H. Conceptual design of automobile engine rubber mounting composite using TRIZ-Morphological chart-analytic network process technique. Def. Technol. 2018, 14, 268–277. [Google Scholar] [CrossRef]

- Bakar, M.S.A.; Mohamad, D.; Ishak, Z.A.M.; Yusof, Z.M.; Salwi, N. Durability control of moisture degradation in GFRP cross arm transmission line towers. In AIP Conference Proceedings; AIP Publishing: College Park, MD, USA, 2018; p. 020027. [Google Scholar]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Conceptual design of creep testing rig for full-scale cross arm using TRIZ-Morphological chart-analytic network process technique. J. Mater. Res. Technol. 2019, 8, 5647–5658. [Google Scholar] [CrossRef]

- Sharaf, H.K.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Fattahi, A. Experimental and numerical investigation of the mechanical behavior of full-scale wooden cross arm in the transmission towers in terms of load-deflection test. J. Mater. Res. Technol. 2020, 9, 7937–7946. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Utilization of Bracing Arms as Additional Reinforcement in Pultruded Glass Fiber-Reinforced Polymer Composite Cross-Arms: Creep Experimental and Numerical Analyses. Polymers 2021, 13, 620. [Google Scholar] [CrossRef] [PubMed]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Conceptual design of multi-operation outdoor flexural creep test rig using hybrid concurrent engineering approach. J. Mater. Res. Technol. 2020, 9, 2357–2368. [Google Scholar] [CrossRef]

- Sharaf, H.K.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Conceptual design of the cross-arm for the application in the transmission towers by using TRIZ–morphological chart–ANP methods. J. Mater. Res. Technol. 2020, 9, 9182–9188. [Google Scholar] [CrossRef]

- Cardoso, D.C.T.; Harries, K.A.; Batista, E.D.M. Compressive strength equation for GFRP square tube columns. Compos. Part B Eng. 2014, 59, 1–11. [Google Scholar] [CrossRef]

- Nadhirah, A.; Mohamad, D.; Zainoodin, M.; Nabihah, S.; Mubin, N.; Itam, Z.; Mansor, H.; Kamal, N.M.; Muda, Z.C.; Nasional, U.T.; et al. Properties of fiberglass crossarm in transmission tower—A review. Int. J. Appl. Eng. Res. 2017, 12, 15228–15233. [Google Scholar]

- Amir, A.L.; Ishak, M.R.; Yidris, N.; Zuhri, M.Y.M.; Asyraf, M.R.M. Potential of Honeycomb-Filled Composite Structure in Composite Cross-Arm Component: A Review on Recent Progress and Its Mechanical Properties. Polymers 2021, 13, 1341. [Google Scholar] [CrossRef]

- Amir, A.L.; Ishak, M.R.; Yidris, N.; Zuhri, M.Y.M.; Asyraf, M.R.M. Advances of composite cross arms with incorporation of material core structures: Manufacturability, recent progress and views. J. Mater. Res. Technol. 2021, 13, 1115–1131. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Syamsir, A.; Zahari, N.M.; Supian, A.B.M.; Ishak, M.R.; Sapuan, S.M.; Rashedi, A.; Sharma, S.; Razman, M.R.; Ilyas, R.A.; et al. Product Development of Natural Fibre-Composites for Various Applications: Design for Sustainability. Polymers 2022, 14, 920. [Google Scholar] [CrossRef]

- Azman, M.A.; Asyraf, M.R.M.; Khalina, A.; Petrů, M.; Ruzaidi, C.M.; Sapuan, S.M.; Wan Nik, W.B.; Ishak, M.R.; Ilyas, R.A.; Suriani, M.J. Natural Fiber Reinforced Composite Material for Product Design: A Short Review. Polymers 2021, 13, 1917. [Google Scholar] [CrossRef]

- Muttashar, M.; Manalo, A.; Karunasena, W.; Lokuge, W. Flexural behaviour of multi-celled GFRP composite beams with concrete infill: Experiment and theoretical analysis. Compos. Struct. 2017, 159, 21–33. [Google Scholar] [CrossRef]

- Jahangiri, T.; Wang, Q.; da Silva, F.F.; Leth Bak, C. Fiber Reinforced Plastic (FRP) Composite Selection for the Composite Cross-Arm Core. In Electrical Design of a 400 kV Composite Tower; Jahangiri, T., Wang, Q., Silva, F.F., da Bak, C.L., Eds.; Springer Cham: Cham, Switzerland, 2020; Volume 557, pp. 15–65. [Google Scholar]

- Peesapati, V.; Zachariades, C.; Li, Q.; Rowland, S.M.; Cotton, I.; Allison, F.; Chambers, D. 3D electric field computation of a composite cross-arm. In Proceedings of the IEEE International Symposium on Electrical Insulation, San Juan, PR, USA, 10–13 June 2012; Densley, J., Ed.; IEEE: San Juan, PR, USA, 2012; pp. 464–468. [Google Scholar]

- Meira Castro, A.C.; Carvalho, J.P.; Ribeiro, M.C.S.; Meixedo, J.P.; Silva, F.J.G.; Fiúza, A.; Dinis, M.L. An integrated recycling approach for GFRP pultrusion wastes: Recycling and reuse assessment into new composite materials using Fuzzy Boolean Nets. J. Clean. Prod. 2014, 66, 420–430. [Google Scholar] [CrossRef]

- Bodros, E.; Pillin, I.; Montrelay, N.; Baley, C. Could biopolymers reinforced by randomly scattered flax fibre be used in structural applications? Compos. Sci. Technol. 2007, 67, 462–470. [Google Scholar] [CrossRef]

- Fairuz, A.M.; Sapuan, S.M.; Zainudin, E.S.; Jaafar, C.N.A. Polymer composite manufacturing using a pultrusion process: A review. Am. J. Appl. Sci. 2014, 11, 1798–1810. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Rafidah, M.; Ilyas, R.A.; Razman, M.R. Potential application of green composites for cross arm component in transmission tower: A brief review. Int. J. Polym. Sci. 2020, 2020, 8878300. [Google Scholar] [CrossRef]

- Johari, A.N.; Ishak, M.R.; Leman, Z.; Yusoff, M.Z.M.; Asyraf, M.R.M. Creep behaviour monitoring of short-term duration for fiber-glass reinforced composite cross-arms with unsaturated polyester resin samples using conventional analysis. J. Mech. Eng. Sci. 2020, 14, 7361–7368. [Google Scholar] [CrossRef]

- Kanesan, G.; Mansor, S.; Abdul-Latif, A. Validation of UAV wing structural model for finite element analysis. J. Teknol. 2014, 71, 1–5. [Google Scholar] [CrossRef][Green Version]

- Mohamad, D.; Syamsir, A.; Beddu, S.; Abas, A.; Ng, F.C.; Razali, M.F.; Seman, S.A.H.A. Numerical Study of Composite Fiberglass Cross Arms under Statics Loading and Improvement with Sleeve Installation. IOP Conf. Ser. Mater. Sci. Eng. 2019, 530, 012027. [Google Scholar] [CrossRef]

- Tian, L.; Pan, H.; Ma, R.; Zhang, L.; Liu, Z. Full-scale test and numerical failure analysis of a latticed steel tubular transmission tower. Eng. Struct. 2020, 208, 109919. [Google Scholar] [CrossRef]

- Sayahi, M.; Sghaier, S.; Belhadjsalah, H. Finite element analysis of ball burnishing process: Comparisons between numerical results and experiments. Int. J. Adv. Manuf. Technol. 2013, 67, 1665–1673. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, W.; Zhai, Z.J.; Chen, Q.Y. Evaluation of various turbulence models in predicting airflow and turbulence in enclosed environments by CFD: Part 2—comparison with experimental data from literature. HVAC R Res. 2007, 13, 871–886. [Google Scholar] [CrossRef]

- Agusril; Nor, N.M.; Zaidi, A.M.A. Failure analysis of Carbon Fiber Reinforced Polymer (CFRP) bridge using composite material failure theories. Adv. Mater. Res. 2012, 488–489, 525–529. [Google Scholar] [CrossRef]

- Alhayek, A.; Syamsir, A.; Anggraini, V.; Muda, Z.C.; Nor, N.M. Numerical Modelling of Glass Fiber Reinforced Polymer (GFRP) Cross Arm. Int. J. Recent Technol. Eng. 2019, 8, 6484–6489. [Google Scholar] [CrossRef]

- Kasiviswanathan, S.; Santhanam, K.; Kumaravel, A. Evaluation of mechanical properties of natural hybrid fibers, reinforced polyester composite materials. Carbon-Sci. Technol. 2015, 7, 43–49. [Google Scholar]

- Mohamad, D.; Beddu, S.; Syamsir, A.; Zahari, N.M.; Abu Seman, S.A.H.; Razali, M.F.; Abas, A.; Ng, F.C. Performance Evaluation of Composite Cross-Arm Structure under Different Magnitude of Loading. In IOP Conference Series: Materials Science and Engineering; IOP Publishing Ltd.: Bristol, UK, 2020; Volume 920. [Google Scholar]

- Mei, M.; He, Y.; Yang, X.; Wei, K.; Qu, Z.; Fang, D. Shear deformation characteristics and defect evolution of the biaxial ±45° and 0/90° glass non-crimp fabrics. Compos. Sci. Technol. 2020, 193, 108137. [Google Scholar] [CrossRef]

- Riccio, A.; Di Felice, G.; Saputo, S.; Scaramuzzino, F. Stacking sequence effects on damage onset in composite laminate subjected to low velocity impact. Procedia Eng. 2014, 88, 222–229. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Khalina, A.; Chandrasekar, M.; Aisyah, H.A.; Rafiqah, S.A.; Ilyas, R.A.; Hanafee, Z.M. Effect of fiber orientation and fiber loading on the mechanical and thermal properties of sugar palm yarn fiber reinforced unsaturated polyester resin composites. Polimery 2020, 65, 115–124. [Google Scholar] [CrossRef]

| Mode of Study | Research | Findings | Ref |

|---|---|---|---|

| Mechanical test rigs development specialized for cross-arms | Conceptual design of creep testing rig for full-scale cross-arm. |

| [2,47] |

| Conceptual design of multi-operation outdoor flexural creep test rig | [50] | ||

| Design of GFRP cross-arms | Conceptual design of a braced composite cross-arm |

| [51] |

| Experiments | Experimental testing on the compressive strength equation for GFRP square tube columns |

| [52] |

| Mechanical evaluation on composite cross-arm performance |

| [4] |

| Parameter | Value |

|---|---|

| Density | 2.03 g/cm3 |

| Young’s modulus in x, Ex | 34,000 MPa |

| Young’s modulus y, Ey | 10,200 MPa |

| Young’s modulus z, Ez | 3100 MPa |

| Poisson’s ratio (vxy = vyz = vxz) | 0.28 |

| Shear modulus (Gxy = Gyz = Gxz) | 4280 MPa |

| Ultimate tensile stress, σt,x | 429 MPa |

| Ultimate compressive stress, σc,x | 320 MPa |

| Ultimate tensile stress, σt,y | 100 MPa |

| Ultimate compressive stress, σc,y | 76 MPa |

| Ultimate shear stress, Sxy | 95 MPa |

| Ultimate shear stress, (Sxz = Syz) | 70 MPa |

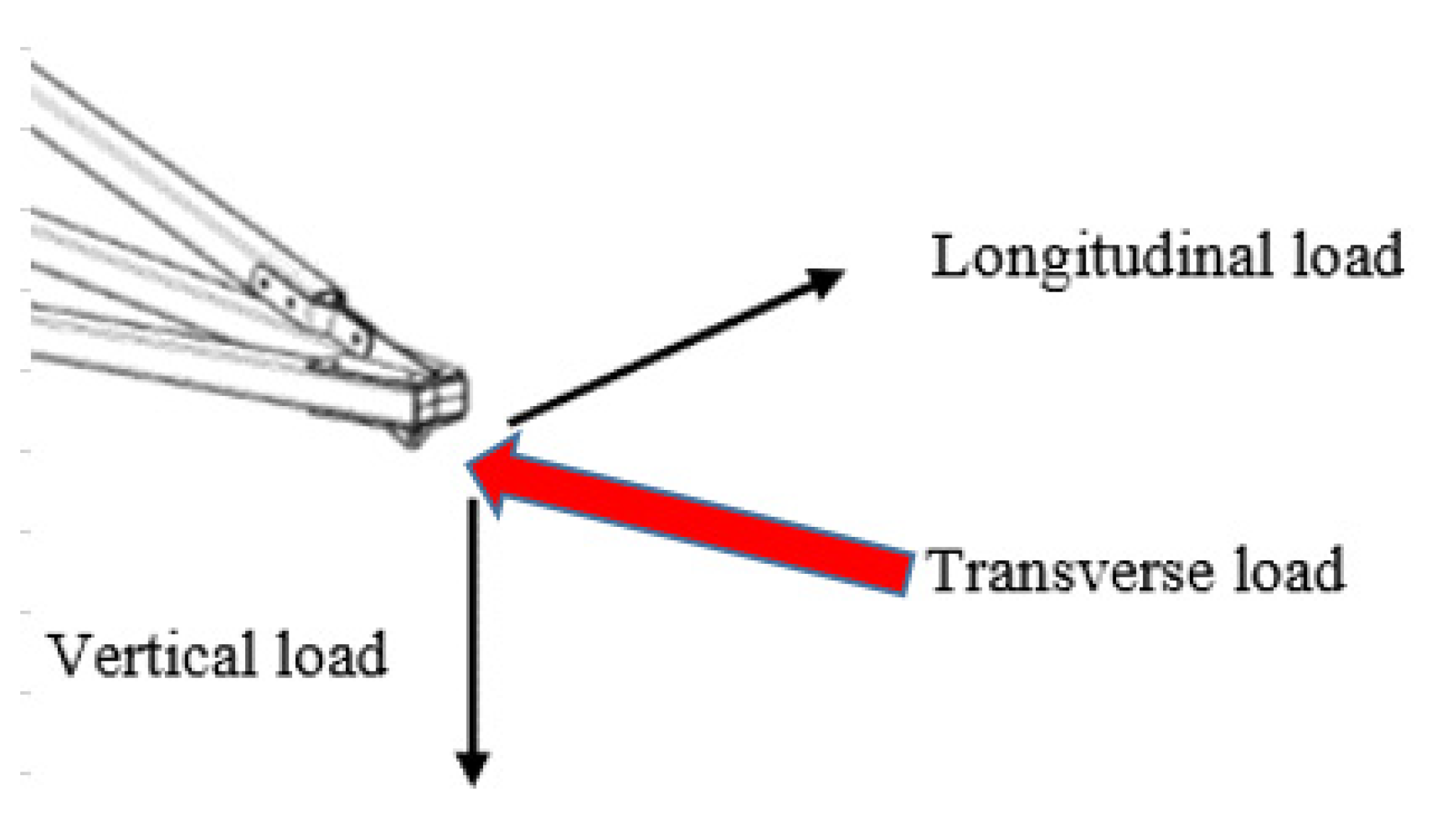

| Normal Condition (All Wires Intact), (N) | Broken Wire Condition, (N) | |

|---|---|---|

| Vertical | 21,248 | 16,436 |

| Transverse | 11,718 | 8667 |

| Longitudinal | 0 | 25,779 |

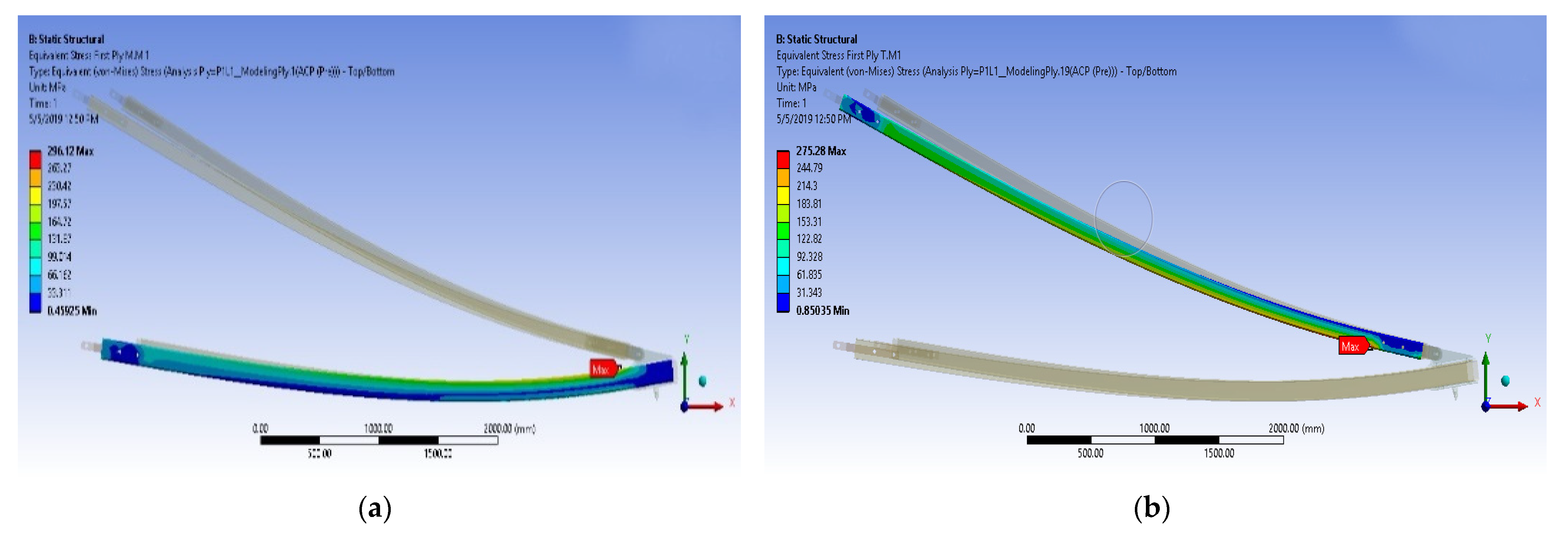

| Load Designation | Normal Loads (N) | Deformation (mm) | Stress ply (N/mm2) First Layer | Compressive Strength (N/mm2) | Minimum Factor of Safety (Strength /Stress) | ||

|---|---|---|---|---|---|---|---|

| Vertical | Transverse | Main | Tie | ||||

| 1 WL | 21,248 | 11,718 | 49.60 | 61.98 | 56.89 | 320 | 5.16 |

| 2 WL | 42,496 | 23,436 | 93.77 | 120.52 | 111.49 | 320 | 2.66 |

| 3 WL | 63,744 | 35,154 | 137.96 | 179.05 | 166.09 | 320 | 1.79 |

| 4 WL | 84,992 | 46,872 | 182.15 | 237.59 | 220.69 | 320 | 1.35 |

| 5 WL | 106,240 | 58,590 | 226.35 | 296.12 | 275.28 | 320 | 1.08 |

| 6 WL | 127,488 | 70,308 | 270.54 | 354.66 | 329.88 | 320 | 0.90 |

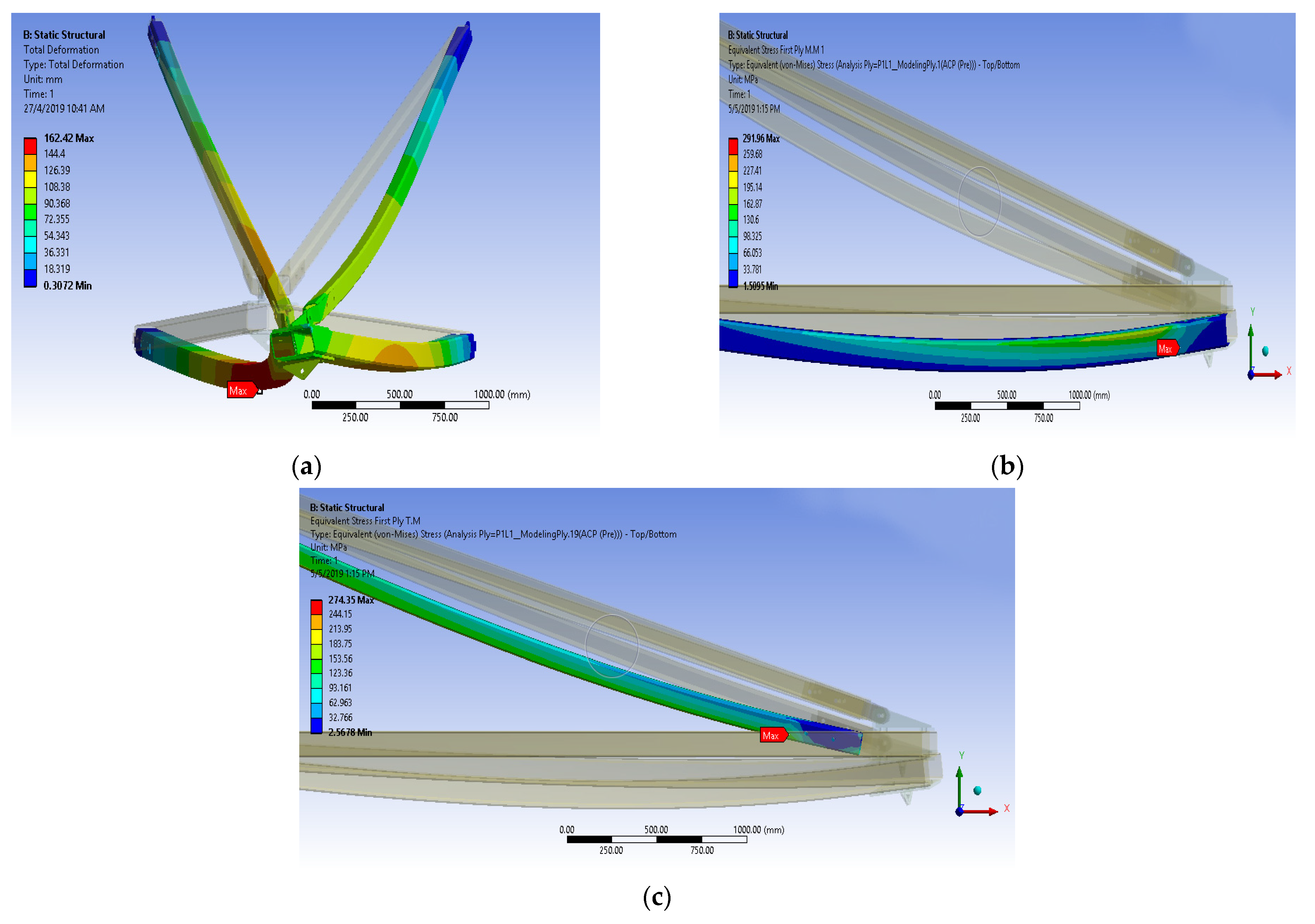

| Load Designation | Broken Wire Loads (N) | Deformation (mm) | Stress ply (N/mm2) First Layer | Compressive Strength (N/mm2) | Minimum Factor of Safety (Strength /Stress) | |||

|---|---|---|---|---|---|---|---|---|

| Vertical | Transverse | Longitudinal | Main | Tie | ||||

| 1 WL | 16,436 | 8667 | 25,779 | 55.70 | 99.24 | 92.67 | 320 | 3.22 |

| 2 WL | 32,872 | 17,334 | 51,558 | 109.05 | 195.60 | 183.51 | 320 | 1.64 |

| 3 WL | 49,308 | 26,001 | 77,337 | 162.42 | 291.96 | 274.35 | 320 | 1.10 |

| 4 WL | 65,744 | 34,668 | 103,116 | 215.79 | 388.32 | 365.19 | 320 | 0.82 |

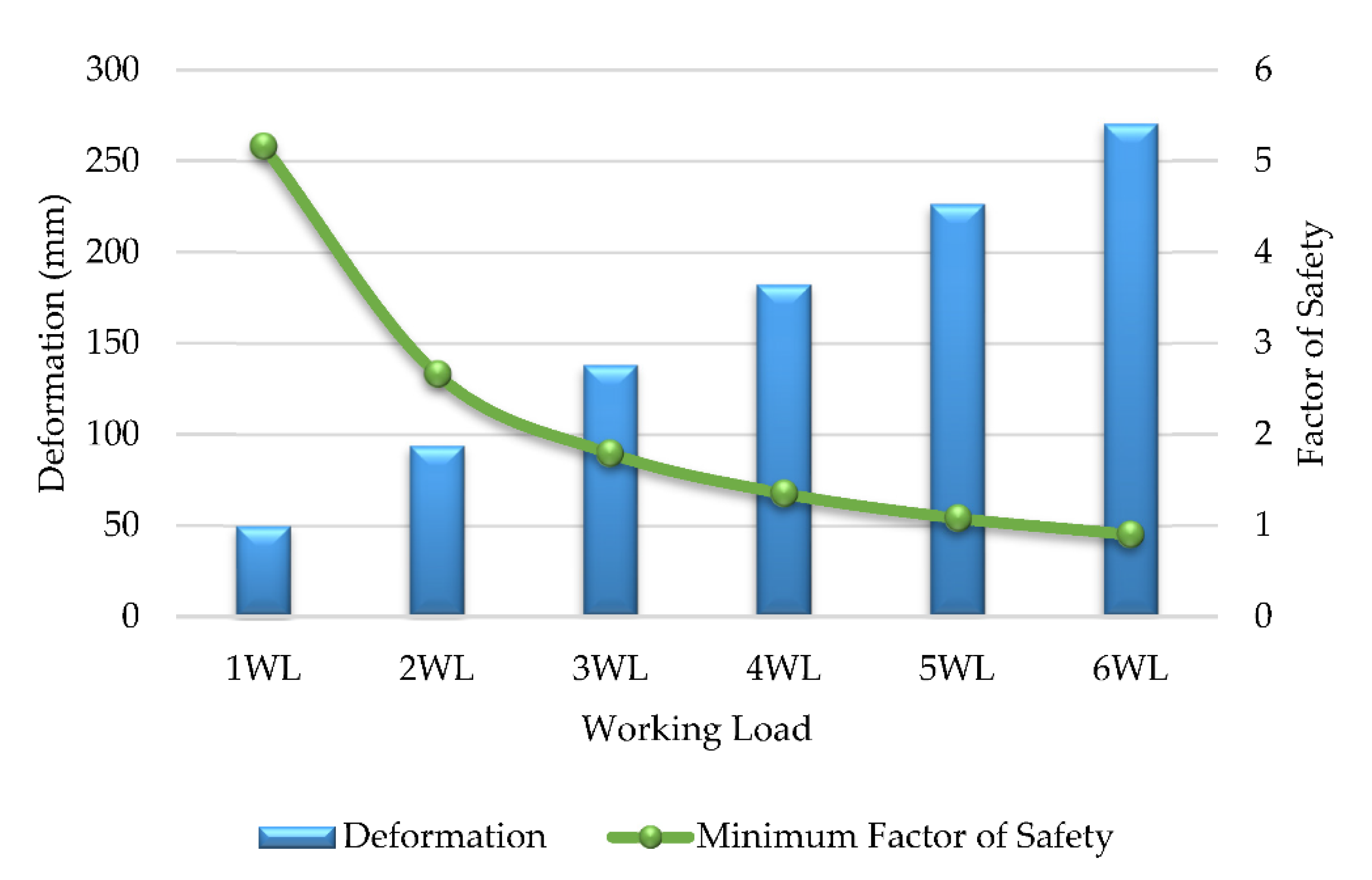

| Load | Deformation (mm) | Minimum Factor of Safety (Strength/Stress) | ||

|---|---|---|---|---|

| Normal Condition | Broken Wire Condition | Normal Condition | Broken Wire Condition | |

| 1 WL | 49.60 | 55.07 | 5.16 | 3.22 |

| 2 WL | 93.77 | 109.05 | 2.66 | 1.64 |

| 3 WL | 137.96 | 162.42 | 1.79 | 1.10 |

| 4 WL | 182.15 | 215.79 | 1.35 | 0.82 |

| 5 WL | 226.35 | 1.08 | ||

| 6 WL | 270.54 | 0.90 | ||

| Lamina | Fiber Orientation (°) | 1 WL | 2 WL | 3 WL | 4 WL | 5 WL | 6 WL |

|---|---|---|---|---|---|---|---|

| lamina 1 | 0 | 0.50 | 0.97 | 1.44 | 1.90 | 2.37 | 2.84 |

| lamina 2 | 45 | 0.30 | 0.59 | 0.87 | 1.16 | 1.44 | 1.73 |

| lamina 3 | 0 | 0.38 | 0.73 | 1.09 | 1.44 | 1.79 | 2.15 |

| lamina 4 | −45 | 0.21 | 0.40 | 0.60 | 0.80 | 0.99 | 1.19 |

| lamina 5 | 0 | 0.27 | 0.53 | 0.79 | 1.05 | 1.30 | 1.56 |

| lamina 6 | −45 | 0.24 | 0.46 | 0.68 | 0.90 | 1.13 | 1.35 |

| lamina 7 | 0 | 0.37 | 0.71 | 1.06 | 1.40 | 1.75 | 2.10 |

| lamina 8 | 45 | 0.25 | 0.49 | 0.73 | 0.96 | 1.20 | 1.44 |

| lamina 9 | 0 | 0.48 | 0.93 | 1.37 | 1.82 | 2.27 | 2.72 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Syamsir, A.; Nadhirah, A.; Mohamad, D.; Beddu, S.; Asyraf, M.R.M.; Itam, Z.; Anggraini, V. Performance Analysis of Full Assembly Glass Fiber-Reinforced Polymer Composite Cross-Arm in Transmission Tower. Polymers 2022, 14, 1563. https://doi.org/10.3390/polym14081563

Syamsir A, Nadhirah A, Mohamad D, Beddu S, Asyraf MRM, Itam Z, Anggraini V. Performance Analysis of Full Assembly Glass Fiber-Reinforced Polymer Composite Cross-Arm in Transmission Tower. Polymers. 2022; 14(8):1563. https://doi.org/10.3390/polym14081563

Chicago/Turabian StyleSyamsir, Agusril, Afiqah Nadhirah, Daud Mohamad, Salmia Beddu, Muhammad Rizal Muhammad Asyraf, Zarina Itam, and Vivi Anggraini. 2022. "Performance Analysis of Full Assembly Glass Fiber-Reinforced Polymer Composite Cross-Arm in Transmission Tower" Polymers 14, no. 8: 1563. https://doi.org/10.3390/polym14081563

APA StyleSyamsir, A., Nadhirah, A., Mohamad, D., Beddu, S., Asyraf, M. R. M., Itam, Z., & Anggraini, V. (2022). Performance Analysis of Full Assembly Glass Fiber-Reinforced Polymer Composite Cross-Arm in Transmission Tower. Polymers, 14(8), 1563. https://doi.org/10.3390/polym14081563