Non-Isothermal Crystallization of Titanium-Dioxide-Incorporated Rice Straw Fiber/Poly(butylene succinate) Biocomposites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Removal of Rice Straw Extractives

2.3. Preparation of PBS-Containing Nucleating Agent

2.4. Synthesis of Maleic Anhydride-Grafted PBS

2.5. Preparation of RS/PBS Composites

2.6. Analysis

2.6.1. Mechanical Property Test

2.6.2. Differential Scanning Calorimetry (DSC) Analysis

2.6.3. X-ray Diffraction (XRD) Analysis

2.6.4. Morphological Analysis

3. Results

3.1. Mechanical Properties of PBS and the Composites

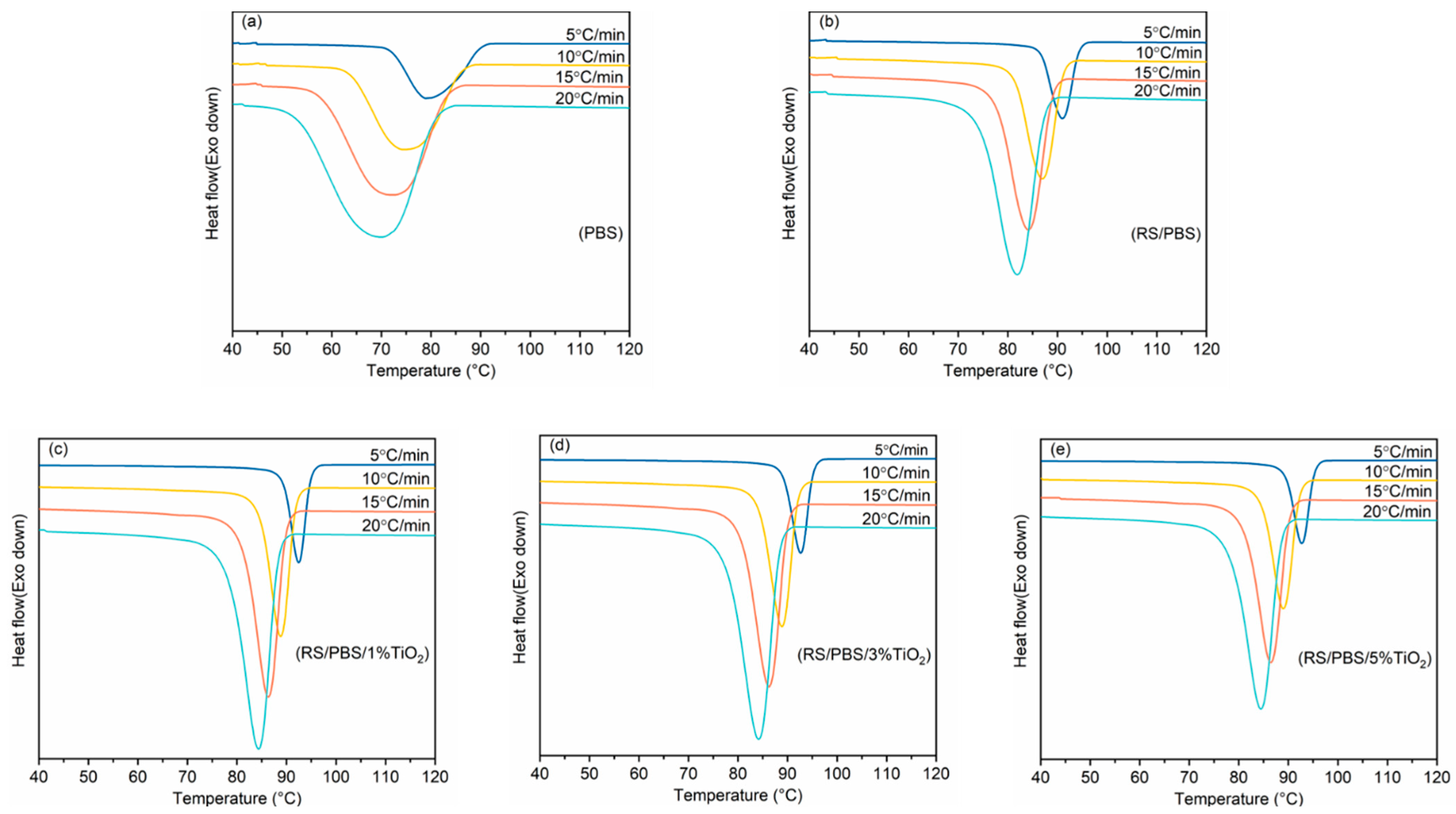

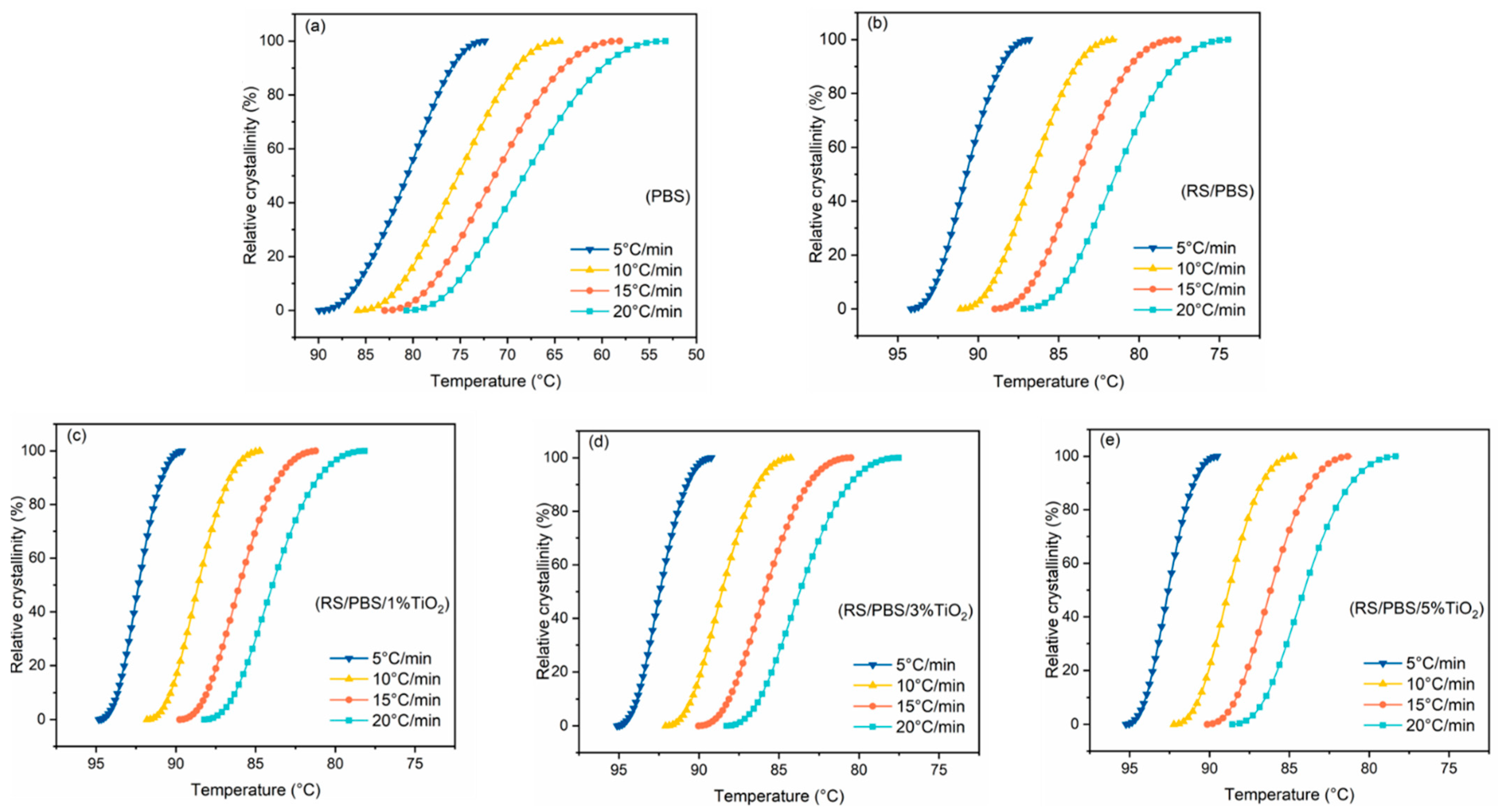

3.2. Non-Isothermal Crystallization Analysis

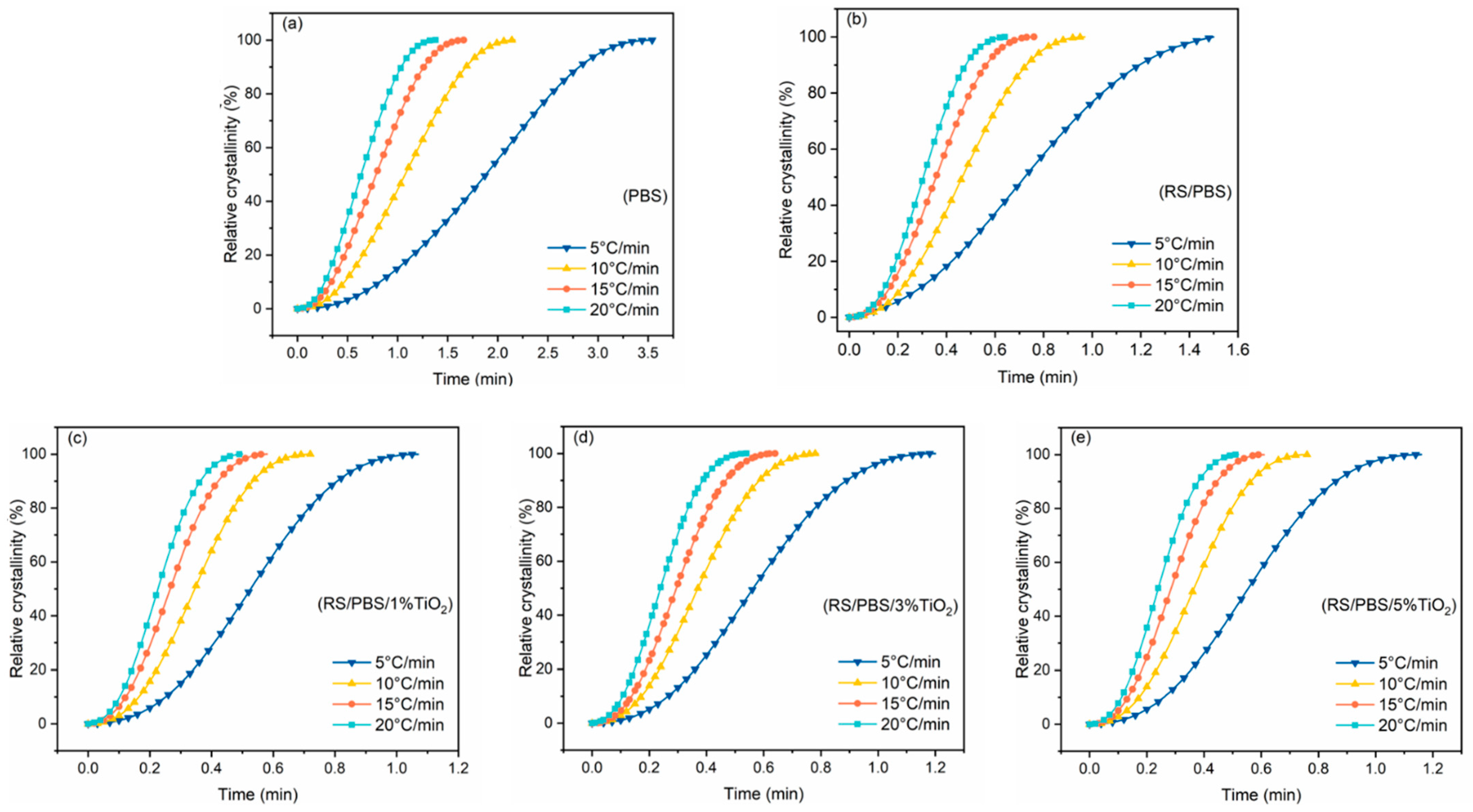

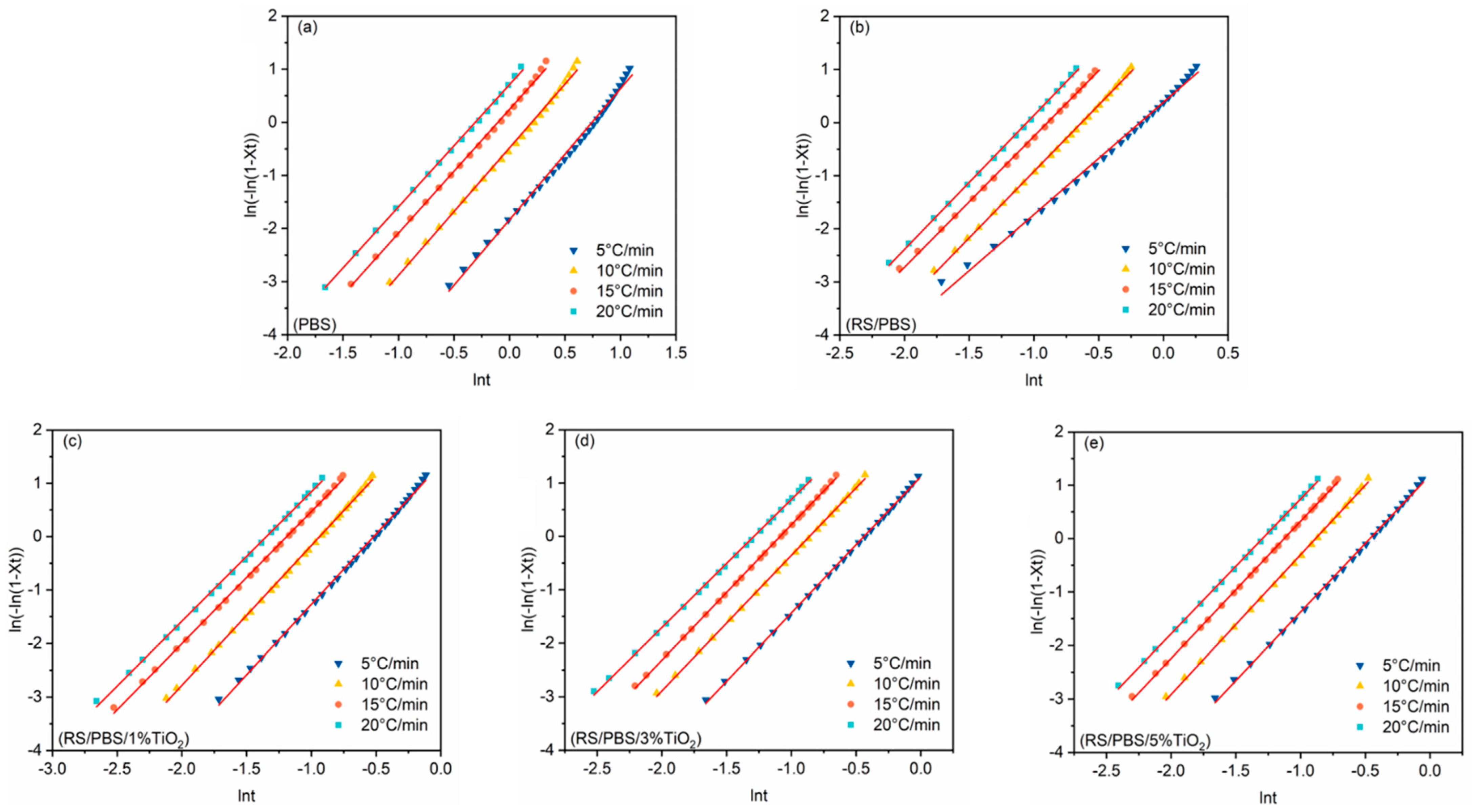

3.3. Non-Isothermal Crystallization Kinetics

3.3.1. Avrami Model

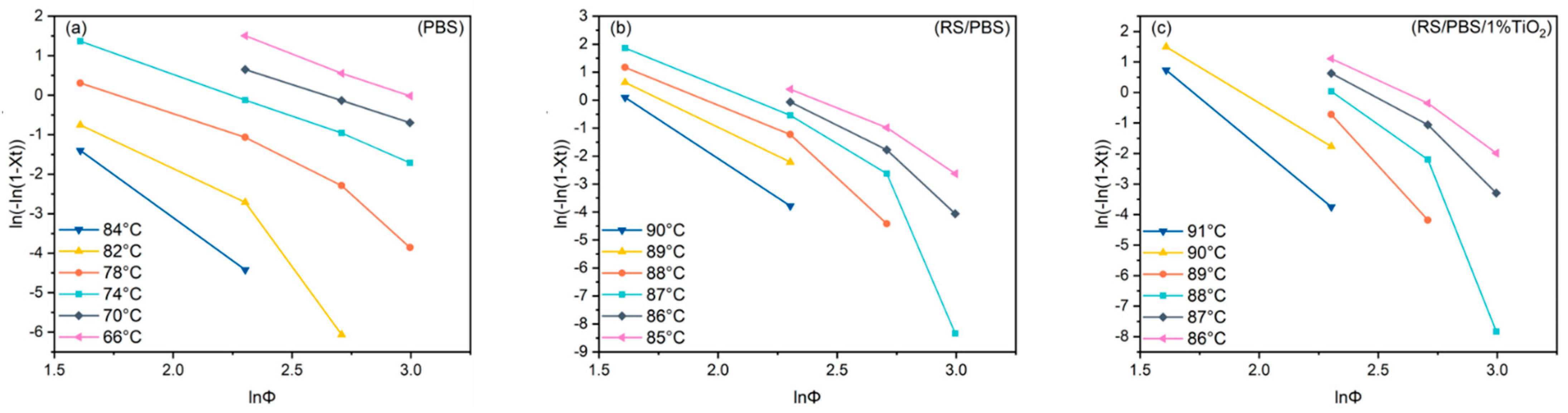

3.3.2. Ozawa Method

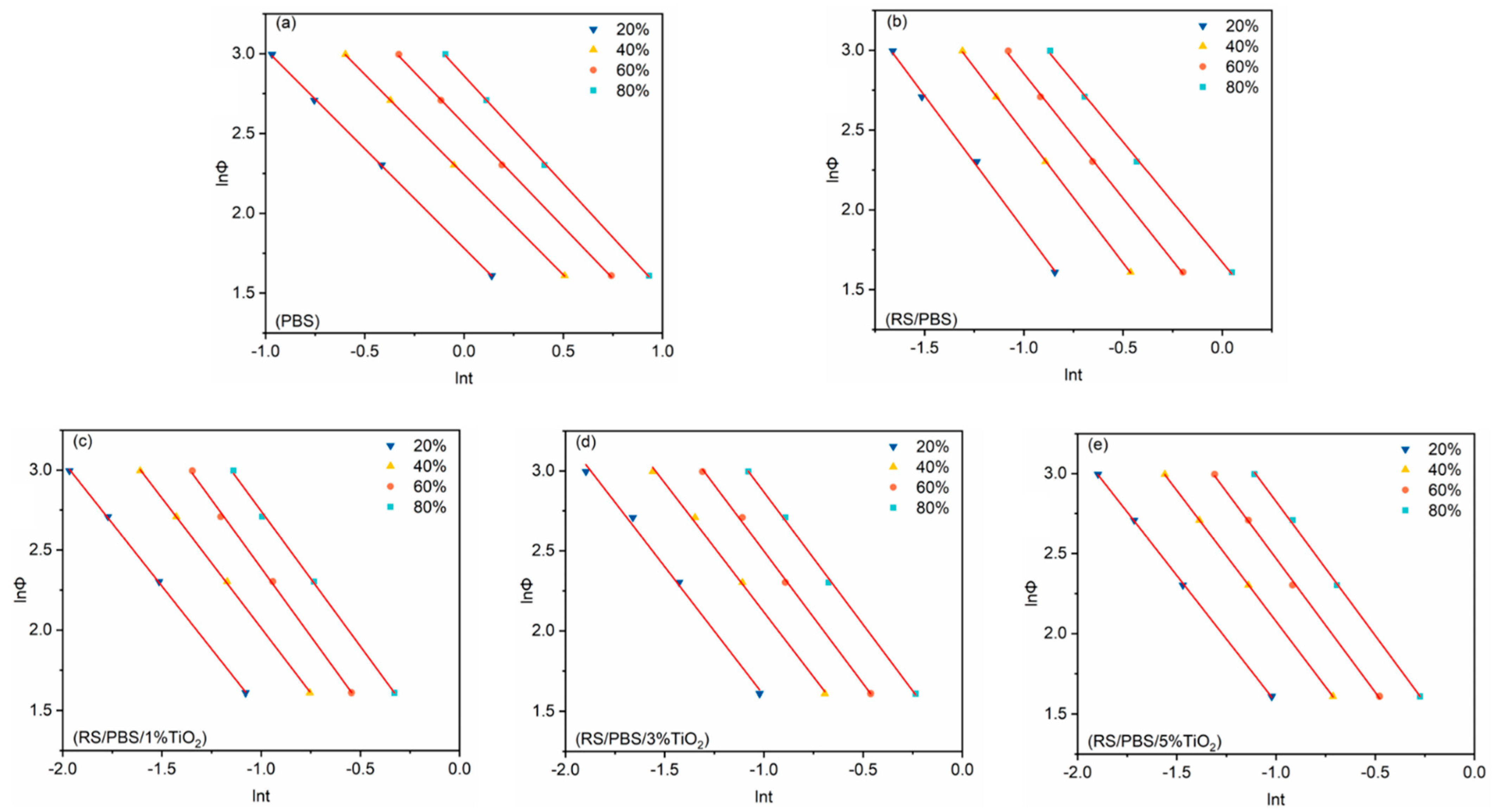

3.3.3. Mo Method

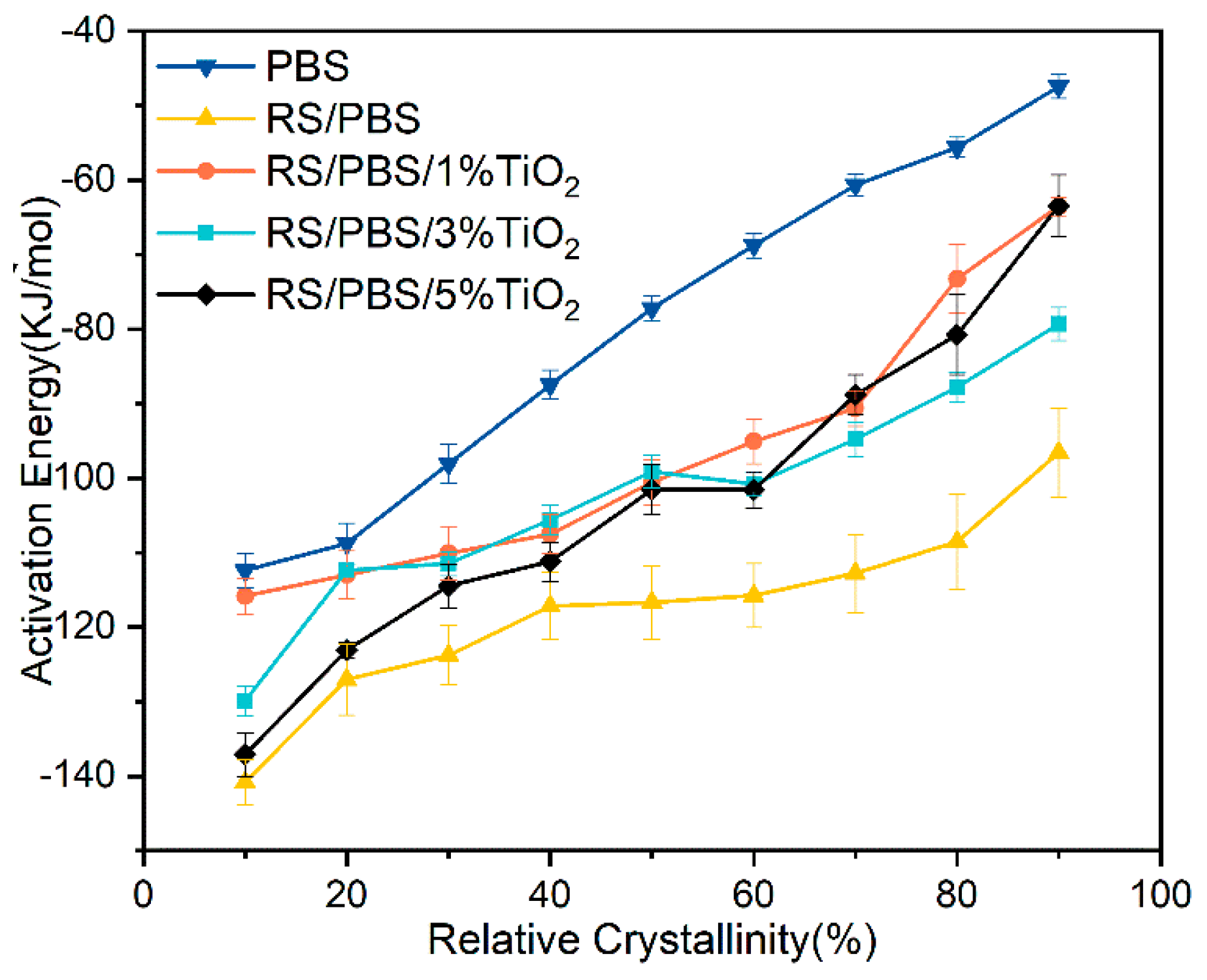

3.4. Non-Isothermal Crystallization Activation Energy

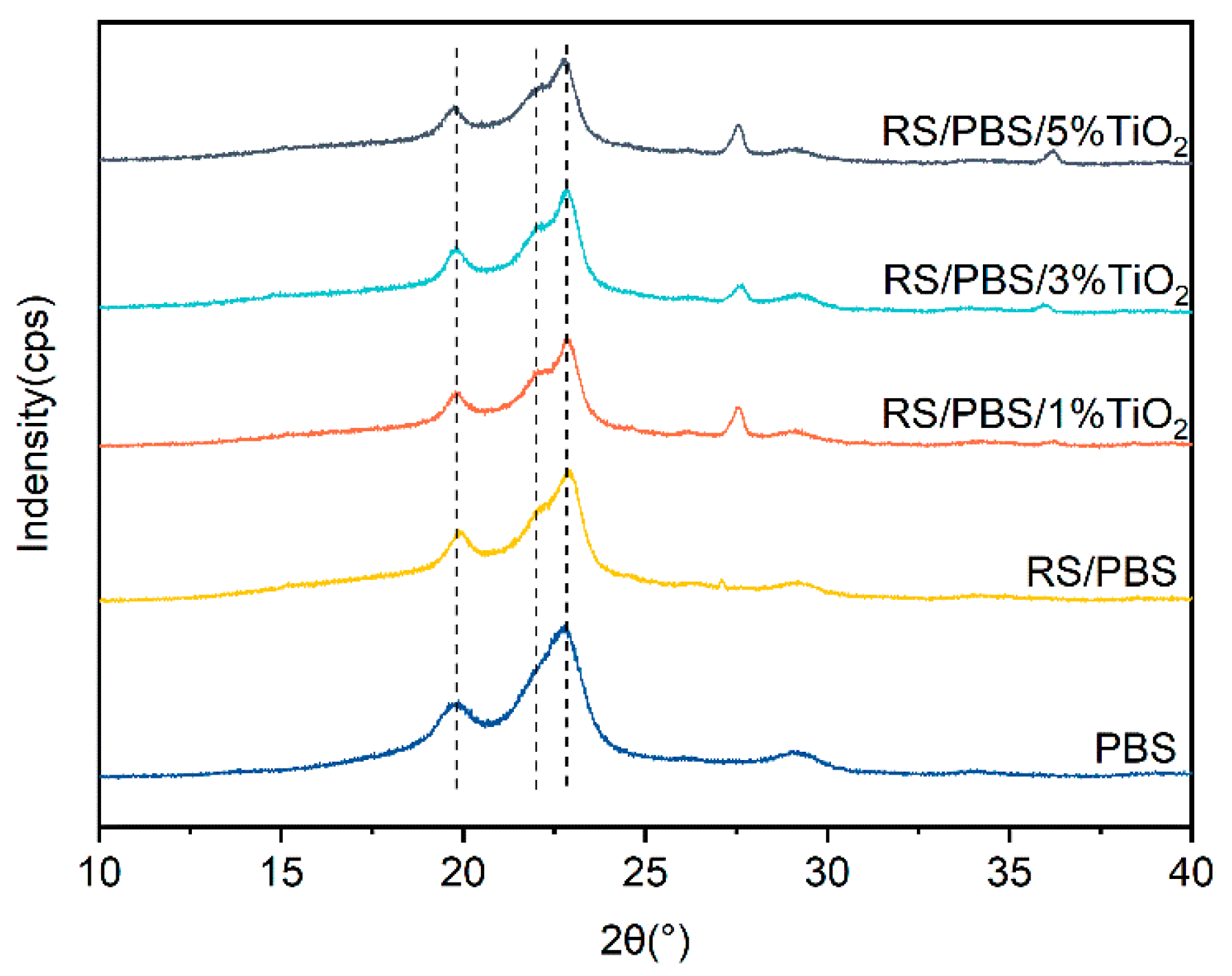

3.5. X-ray Diffraction of PBS and the Composites

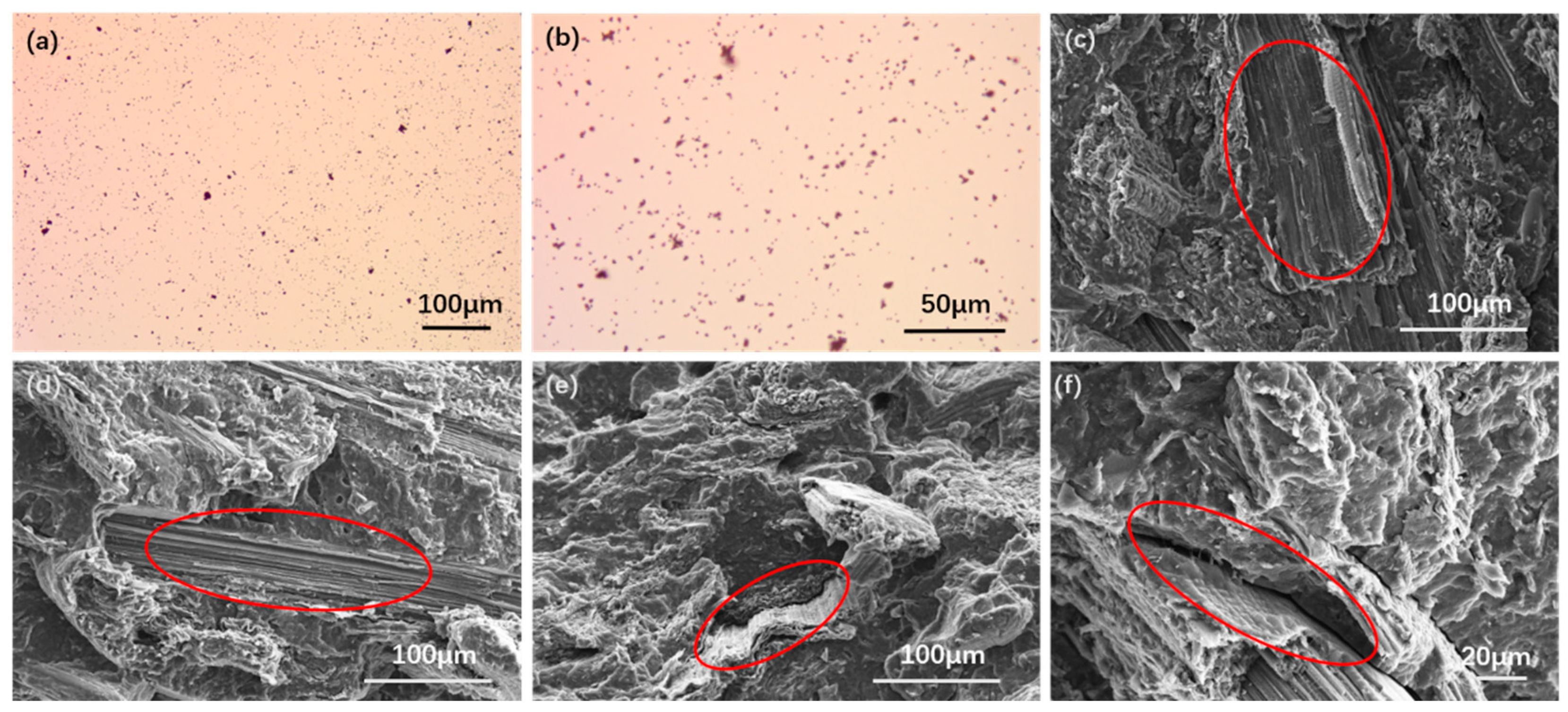

3.6. Morphological Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mochane, M.J.; Magagula, S.I.; Sefadi, J.S.; Mokhena, T.C. A Review on Green Composites Based on Natural Fiber-Reinforced Polybutylene Succinate (PBS). Polymers 2021, 13, 1200. [Google Scholar] [CrossRef] [PubMed]

- Shah, A.A.; Kato, S.; Shintani, N.; Kamini, N.R.; Nakajima-Kambe, T. Microbial degradation of aliphatic and aliphatic-aromatic co-polyesters. Appl. Microbiol. Biotechnol. 2014, 98, 3437–3447. [Google Scholar] [CrossRef] [PubMed]

- Raquez, J.-M.; Narayan, R.; Dubois, P. Recent advances in reactive extrusion processing of biodegradable polymer-based compositions. Macromol. Mater. Eng. 2008, 293, 447–470. [Google Scholar] [CrossRef]

- Dong, C. Review of natural fibre-reinforced hybrid composites. J. Reinf. Plast. Compos. 2018, 37, 331–348. [Google Scholar] [CrossRef] [Green Version]

- Gholampour, A.; Ozbakkaloglu, T. A review of natural fiber composites: Properties, modification and processing techniques, characterization, applications. J. Reinf. Plast. Compos. 2020, 55, 829–892. [Google Scholar] [CrossRef]

- Azhar, S.W.; Xu, F.; Zhang, Y.; Qiu, Y. Fabrication and mechanical properties of flaxseed fiber bundle-reinforced polybutylene succinate composites. J. Ind. Text. 2020, 50, 98–113. [Google Scholar] [CrossRef]

- Pivsa-Art, S.; Pivsa-Art, W. Eco-friendly bamboo fiber-reinforced poly(butylene succinate) biocomposites. Polym. Compos. 2021, 42, 1752–1759. [Google Scholar] [CrossRef]

- Ghani, M.U.; Siddique, A.; Abraha, K.G.; Yao, L.; Li, W.; Khan, M.Q.; Kim, I.-S. Performance Evaluation of Jute/Glass-Fiber-Reinforced Polybutylene Succinate (PBS) Hybrid Composites with Different Layering Configurations. Materials 2022, 15, 1055. [Google Scholar] [CrossRef] [PubMed]

- Sasimowski, E.; Majewski, Ł.; Grochowicz, M. Analysis of Selected Properties of Injection Moulded Sustainable Biocomposites from Poly(butylene succinate) and Wheat Bran. Materials 2021, 14, 7049. [Google Scholar] [CrossRef] [PubMed]

- Yue, X.; Li, J.; Liu, P.; Lin, Y.; Du, X. Study on the performance of flame-retardant esterified starch-modified cassava dregs-PBS composites. J. Appl. Polym. Sci. 2018, 135, 46210. [Google Scholar] [CrossRef]

- Lopusiewicz, L.; Zdanowicz, M.; Macieja, S.; Kowalczyk, K.; Bartkowiak, A. Development and Characterization of Bioactive Poly(butylene-succinate) Films Modified with Quercetin for Food Packaging Applications. Polymers 2021, 13, 1798. [Google Scholar] [CrossRef]

- Pantaloni, D.; Shah, D.; Baley, C.; Bourmaud, A. Monitoring of mechanical performances of flax non-woven biocomposites during a home compost degradation. Polym. Degrad. Stabil. 2020, 177, 109166. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A.; Rafidah, M.; Razman, M.R. Potential Application of Green Composites for Cross Arm Component in Transmission Tower: A Brief Review. Int. J. Polym. Sci. 2020, 2020, 8878300. [Google Scholar] [CrossRef]

- Abraham, A.; Mathew, A.K.; Sindhu, R.; Pandey, A.; Binod, P. Potential of rice straw for bio-refining: An overview. Bioresour. Technol. 2016, 215, 29–36. [Google Scholar] [CrossRef] [PubMed]

- Pędzik, M.; Janiszewska, D.; Rogoziński, T. Alternative lignocellulosic raw materials in particleboard production: A review. Ind. Crop. Prod. 2021, 174, 114162. [Google Scholar] [CrossRef]

- Sahu, S.K.; Mangaraj, P.; Beig, G.; Samal, A.; Pradhan, C.; Dash, S.; Tyagi, B. Quantifying the high resolution seasonal emission of air pollutants from crop residue burning in India. Environ. Pollut. 2021, 286, 117165. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.X.; Huang, D.; Ji, J.H.; Volker, C.; Wurm, F.R. Seawater-Degradable Polymers-Fighting the Marine Plastic Pollution. Adv. Sci. 2021, 8, 2001121. [Google Scholar] [CrossRef]

- Kandemir, A.; Pozegic, T.R.; Hamerton, I.; Eichhorn, S.J.; Longana, M.L. Characterisation of Natural Fibres for Sustainable Discontinuous Fibre Composite Materials. Materials 2020, 13, 2129. [Google Scholar] [CrossRef]

- Suriani, M.J.; Ilyas, R.A.; Zuhri, M.Y.M.; Khalina, A.; Sultan, M.T.H.; Sapuan, S.M.; Ruzaidi, C.M.; Wan, F.N.; Zulkifli, F.; Harussani, M.M.; et al. Critical Review of Natural Fiber Reinforced Hybrid Composites: Processing, Properties, Applications and Cost. Polymers 2021, 13, 3514. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Chen, D.; Sun, X.; Xu, Z.; Yang, Y.; Song, Y.; Jiang, F. An environmentally tolerant, highly stable, cellulose nanofiber-reinforced, conductive hydrogel multifunctional sensor. Carbohydr. Polym. 2022, 284, 119199. [Google Scholar] [CrossRef] [PubMed]

- Picard, M.C.; Rodriguez-Uribe, A.; Thimmanagari, M.; Misra, M.; Mohanty, A.K. Sustainable Biocomposites from Poly(butylene succinate) and Apple Pomace: A Study on Compatibilization Performance. Waste Biomass Valorization 2020, 11, 3775–3787. [Google Scholar] [CrossRef]

- Yu, T.; Jiang, N.; Li, Y. Study on short ramie fiber/poly(lactic acid) composites compatibilized by maleic anhydride. Compos. Pt. A-Appl. Sci. Manuf. 2014, 64, 139–146. [Google Scholar] [CrossRef]

- Lin, F.; Wang, H.; Yue, T.; Qiu, P.; Liu, T. Inner defects elimination and significant reinforcement of rice straw/high-density polyethylene composites by extractives removal process. J. Appl. Polym. Sci. 2021, 138, 50137. [Google Scholar] [CrossRef]

- Ou, R.; Guo, C.; Xie, Y.; Wang, Q. Non-isothermal crystallization kinetics of kevlar fiber-reinforced wood flour/HDPE composites. BioResources 2011, 6, 4547–4565. [Google Scholar]

- Tolga, S.; Kabasci, S.; Duhme, M. Progress of Disintegration of Polylactide (PLA)/Poly(Butylene Succinate) (PBS) Blends Containing Talc and Chalk Inorganic Fillers under Industrial Composting Conditions. Polymers 2021, 13, 10. [Google Scholar] [CrossRef] [PubMed]

- Behera, K.; Sivanjineyulu, V.; Chang, Y.-H.; Chiu, F.-C. Thermal properties, phase morphology and stability of biodegradable PLA/PBSL/HAp composites. Polym. Degrad. Stabil. 2018, 154, 248–260. [Google Scholar] [CrossRef]

- Gao, C.; Li, Z.; Liu, Y.; Zhang, X.; Wang, J.; Wu, Y. Thermal, Crystallographic, and Mechanical Properties of Poly(butylene succinate)/Magnesium Hydroxide Sulfate Hydrate Whisker Composites Modified by in Situ Polymerization. Ind. Eng. Chem. 2017, 56, 3516–3526. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, S.; Zhang, S.; Ma, L.; Shi, G.; Yang, L. Crystallization and melting behavior of poly(butylene succinate)/silicon nitride composites: The influence of filler’s phase structure. Thermochim. Acta 2016, 627–629, 68–76. [Google Scholar] [CrossRef]

- Cazan, C.; Enesca, A.; Andronic, L. Synergic Effect of TiO2 Filler on the Mechanical Properties of Polymer Nanocomposites. Polymers 2021, 13, 2017. [Google Scholar] [CrossRef] [PubMed]

- Deka, B.K.; Maji, T.K. Effect of TiO2 and nanoclay on the properties of wood polymer nanocomposite. Compos. Pt. A-Appl. Sci. Manuf. 2011, 42, 2117–2125. [Google Scholar] [CrossRef]

- Zhan, J.; Chen, Y.; Tang, G.; Pan, H.; Zhang, Q.; Song, L.; Hu, Y. Crystallization and Melting Properties of Poly(butylene succinate) Composites with Titanium Dioxide Nanotubes or Hydroxyapatite Nanorods. J. Appl. Polym. Sci. 2014, 131, 40335–40344. [Google Scholar] [CrossRef]

- Pan, S.Y.; Qiu, Z.B. Fully Biodegradable Poly(hexamethylene succinate)/Cellulose Nanocrystals Composites with Enhanced Crystallization Rate and Mechanical Property. Polymers 2021, 13, 667. [Google Scholar] [CrossRef] [PubMed]

- Shazleen, S.S.; Yasim-Anuar, T.A.T.; Ibrahim, N.A.; Hassan, M.A.; Ariffin, H. Functionality of Cellulose Nanofiber as Bio-Based Nucleating Agent and Nano-Reinforcement Material to Enhance Crystallization and Mechanical Properties of Polylactic Acid Nanocomposite. Polymers 2021, 13, 389. [Google Scholar] [CrossRef] [PubMed]

- Naffakh, M.; Rica, P.; Moya-Lopez, C.; Castro-Osma, J.A.; Alonso-Moreno, C.; Moreno, D.A. The Effect of WS2 Nanosheets on the Non-Isothermal Cold- and Melt-Crystallization Kinetics of Poly(l-lactic acid) Nanocomposites. Polymers 2021, 13, 2214. [Google Scholar] [CrossRef] [PubMed]

- Muthuraj, R.; Misra, M.; Mohanty, A.K. Injection Molded Sustainable Biocomposites From Poly(butylene succinate) Bioplastic and Perennial Grass. ACS Sustain. Chem. Eng. 2015, 3, 2767–2776. [Google Scholar] [CrossRef]

- Nabar, Y.; Raquez, J.M.; Dubois, P.; Narayan, R. Production of starch foams by twin-screw extrusion: Effect of maleated poly(butylene adipate-co-terephthalate) as a compatibilizer. Biomacromolecules 2005, 6, 807–817. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.S.; Yang, H.S.; Kim, H.J. Biodegradability and mechanical properties of Agro-Flour-filled polybutylene succinate biocomposites. J. Appl. Polym. Sci. 2005, 97, 1513–1521. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M.; Díez-Vicente, A.L. Nano-TiO2 Reinforced PEEK/PEI Blends as Biomaterials for Load-Bearing Implant Applications. ACS Appl. Mater. Interfaces 2015, 7, 5561–5573. [Google Scholar] [CrossRef] [PubMed]

- Ojijo, V.; Sinha Ray, S.; Sadiku, R. Effect of Nanoclay Loading on the Thermal and Mechanical Properties of Biodegradable Polylactide/Poly[(butylene succinate)-co-adipate] Blend Composites. ACS Appl. Mater. Interfaces 2012, 4, 2395–2405. [Google Scholar] [CrossRef] [PubMed]

- Sattari, M.; Molazemhosseini, A.; Naimi-Jamal, M.R.; Khavandi, A. Nonisothermal crystallization behavior and mechanical properties of PEEK/SCF/nano-SiO2 composites. Mater. Chem. Phys. 2014, 147, 942–953. [Google Scholar] [CrossRef]

- Phua, Y.J.; Chow, W.S.; Ishak, Z.A.M. The hydrolytic effect of moisture and hygrothermal aging on poly(butylene succinate)/organo-montmorillonite nanocomposites. Polym. Degrad. Stabil. 2011, 96, 1194–1203. [Google Scholar] [CrossRef]

- Yan, X.; Liu, C.; Qiao, L.; Zhu, K.; Tan, H.; Dong, S.; Lin, Z. Crystallization and Dynamic Mechanical Behavior of Coir Fiber Reinforced Poly(Butylene Succinate) Biocomposites. J. Renew. Mater. 2022, 10, 1039–1048. [Google Scholar] [CrossRef]

- Jiasheng, Q.; Pingsheng, H. Non-isothermal crystallization of HDPE/nano-SiO2 composite. J. Mater. Sci. 2003, 38, 2299–2304. [Google Scholar] [CrossRef]

- Chen, R.-Y.; Zou, W.; Zhang, H.-C.; Zhang, G.-Z.; Yang, Z.-T.; Jin, G.; Qu, J.-P. Thermal behavior, dynamic mechanical properties and rheological properties of poly(butylene succinate) composites filled with nanometer calcium carbonate. Polym. Test 2015, 42, 160–167. [Google Scholar] [CrossRef]

- Kuo, M.C.; Huang, J.C.; Chen, M. Non-isothermal crystallization kinetic behavior of alumina nanoparticle filled poly(ether ether ketone). Mater. Chem. Phys. 2006, 99, 258–268. [Google Scholar] [CrossRef]

- Yang, Z.; Huang, S.; Liu, T.X. Crystallization Behavior of Polyamide 11/Multiwalled Carbon Nanotube Composites. J. Appl. Polym. Sci. 2011, 122, 551–560. [Google Scholar] [CrossRef]

- Han, H.Y.; Wang, X.D.; Wu, D.Z. Mechanical properties, morphology and crystallization kinetic studies of bio-based thermoplastic composites of poly(butylene succinate) with recycled carbon fiber. J. Chem. Technol. Biotechnol. 2013, 88, 1200–1211. [Google Scholar] [CrossRef]

- Wang, H.; Lin, F.; Qiu, P.; Liu, T. Effects of Extractives on Dimensional Stability, Dynamic Mechanical Properties, Creep, and Stress Relaxation of Rice Straw/High-Density Polyethylene Composites. Polymers 2018, 10, 1176. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Papageorgiou, G.Z.; Papageorgiou, D.G.; Chrissafis, K.; Bikiaris, D.; Will, J.; Hoppe, A.; Roether, J.A.; Boccaccini, A.R. Crystallization and Melting Behavior of Poly(Butylene Succinate) Nanocomposites Containing Silica-Nanotubes and Strontium Hydroxyapatite Nanorods. Ind. Eng. Chem. Res. 2014, 53, 678–692. [Google Scholar] [CrossRef]

- Zhang, Z.; Xiao, C.; Dong, Z. Comparison of the Ozawa and modified Avrami models of polymer crystallization under nonisothermal conditions using a computer simulation method. Thermochim. Acta 2007, 466, 22–28. [Google Scholar] [CrossRef]

- Ozawa, T. Kinetics of non-isothermal crystallization. Polymer 1971, 12, 150–158. [Google Scholar] [CrossRef]

- Yarici, T.; Kodal, M.; Ozkoc, G. Non-isothermal crystallization kinetics of Poly(Butylene succinate) (PBS) nanocomposites with different modified carbon nanotubes. Polymer 2018, 146, 361–377. [Google Scholar] [CrossRef]

- Qu, D.; Gao, H.; Wang, Q.; Bai, Y.; Li, N. Non-isothermal crystallization kinetics of bio-based poly(butylene-co-isosorbide succinate) (PBIS). J. Therm. Anal. Calorim. 2020, 139, 1931–1939. [Google Scholar] [CrossRef]

- Liu, T.; Mo, Z.; Wang, S.; Zhang, H. Nonisothermal melt and cold crystallization kinetics of poly(aryl ether ether ketone ketone). Polym. Eng. Sci. 1997, 37, 568–575. [Google Scholar] [CrossRef]

- Bian, J.; Han, L.; Wang, X.; Wen, X.; Han, C.; Wang, S.; Dong, L. Nonisothermal Crystallization Behavior and Mechanical Properties of Poly(butylene succinate)/Silica Nanocomposites. J. Appl. Polym. Sci. 2010, 116, 902–912. [Google Scholar] [CrossRef]

- Friedman, H.L. Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. J. Polym. Sci. Part C Polym. Symp. 1964, 6, 183–195. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, Z.; Guo, B.; Xu, J. Secondary nucleation in polymer crystallization: A kinetic view. Polym. Cryst. 2021, 4, e10173. [Google Scholar] [CrossRef]

- Filizgok, S.; Kodal, M.; Ozkoc, G. Non-isothermal crystallization kinetics and dynamic mechanical properties of poly(Butylene succinate) nanocomposites with different type of carbonaceous nanoparticles. Polym. Compos. 2018, 39, 2705–2721. [Google Scholar] [CrossRef]

- Ichikawa, Y.; Kondo, H.; Igarashi, Y.; Noguchi, K.; Okuyama, K.; Washiyama, J. Crystal structures of α and β forms of poly(tetramethylene succinate). Polymer 2000, 41, 4719–4727. [Google Scholar] [CrossRef]

- Bin, T.; Qu, J.-P.; Liu, L.-M.; Feng, Y.-H.; Hu, S.-X.; Yin, X.-C. Non-isothermal crystallization kinetics and dynamic mechanical thermal properties of poly(butylene succinate) composites reinforced with cotton stalk bast fibers. Thermochim. Acta 2011, 525, 141–149. [Google Scholar] [CrossRef]

- Gowman, A.; Wang, T.; Rodriguez-Uribe, A.; Mohanty, A.K.; Misra, M. Bio-poly(butylene succinate) and Its Composites with Grape Pomace: Mechanical Performance and Thermal Properties. ACS Omega 2018, 3, 15205–15216. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Samples | Rice Straw (wt%) | Matrix (wt%) | MA-g-PBS (wt%) | TiO2 (wt%) 1 |

|---|---|---|---|---|

| PBS | 0 | 100 | 0 | 0 |

| RS/PBS | 40 | 50 | 10 | 0 |

| RS/PBS/1%TiO2 | 40 | 50 | 10 | 0.6 |

| RS/PBS/3%TiO2 | 40 | 50 | 10 | 1.8 |

| RS/PBS/5%TiO2 | 40 | 50 | 10 | 3.0 |

| Sample | Flexural Strength (MPa) | Flexural Modulus (GPa) | Tensile Strength (MPa) | Tensile Modulus (GPa) | Notched Izod Impact Strength (J/m) |

|---|---|---|---|---|---|

| PBS | 36.50 ± 0.41 | 0.54 ± 0.02 | 31.76 ± 0.59 | 0.33 ± 0.02 | 17.39 ± 4.34 |

| RS/PBS | 66.14 ± 1.71 | 2.43 ± 0.03 | 36.85 ± 0.41 | 1.34 ± 0.02 | 14.01 ± 0.01 |

| RS/PBS/1%TiO2 | 86.21 ± 1.81 | 3.12 ± 0.05 | 39.58 ± 0.16 | 1.34 ± 0.01 | 14.06 ± 0.02 |

| RS/PBS/3%TiO2 | 87.90 ± 1.16 | 3.08 ± 0.06 | 39.37 ± 0.30 | 1.30 ± 0.03 | 14.04 ± 0.02 |

| RS/PBS/5%TiO2 | 85.91 ± 2.02 | 3.36 ± 0.03 | 38.88 ± 0.30 | 1.42 ± 0.02 | 14.04 ± 0.03 |

| Sample | Φ (°C/min) | |||||||

|---|---|---|---|---|---|---|---|---|

| PBS | 5 | 89.9 | 72.2 | 78.9 | 114.5 | 60.63 | 1.88 | 52.29 |

| 10 | 85.8 | 64.2 | 74.5 | 114.3 | 60.04 | 1.08 | 54.32 | |

| 15 | 83.0 | 58.0 | 72.0 | 114.4 | 59.55 | 0.79 | 52.28 | |

| 20 | 80.7 | 53.0 | 70.0 | 114.7 | 57.27 | 0.64 | 51.76 | |

| RS/PBS | 5 | 94.2 | 86.7 | 91.0 | 114.3 | 35.30 | 0.72 | 55.22 |

| 10 | 91.1 | 81.4 | 86.9 | 114.2 | 32.84 | 0.47 | 56.50 | |

| 15 | 88.9 | 77.6 | 84.1 | 114.3 | 30.62 | 0.36 | 55.49 | |

| 20 | 87.2 | 74.3 | 81.8 | 114.5 | 29.05 | 0.31 | 55.67 | |

| RS/PBS/1%TiO2 | 5 | 94.8 | 89.5 | 92.4 | 113.9 | 34.83 | 0.53 | 54.38 |

| 10 | 91.8 | 84.6 | 88.8 | 113.5 | 31.03 | 0.35 | 56.67 | |

| 15 | 89.8 | 81.1 | 86.3 | 113.3 | 28.17 | 0.27 | 55.52 | |

| 20 | 88.3 | 78.2 | 84.2 | 113.4 | 26.09 | 0.23 | 55.13 | |

| RS/PBS/3%TiO2 | 5 | 95.1 | 89.1 | 92.6 | 114.0 | 36.22 | 0.57 | 60.36 |

| 10 | 92.0 | 84.2 | 88.8 | 113.7 | 32.42 | 0.37 | 58.42 | |

| 15 | 90.0 | 80.6 | 86.2 | 113.6 | 29.34 | 0.29 | 58.44 | |

| 20 | 88.3 | 77.6 | 84.1 | 113.6 | 27.12 | 0.23 | 58.72 | |

| RS/PBS/5%TiO2 | 5 | 95.2 | 89.4 | 92.7 | 114.0 | 31.56 | 0.55 | 50.09 |

| 10 | 92.2 | 84.7 | 89.0 | 113.7 | 28.31 | 0.36 | 51.72 | |

| 15 | 90.2 | 81.2 | 86.4 | 113.6 | 25.81 | 0.29 | 50.13 | |

| 20 | 88.6 | 78.3 | 84.4 | 113.6 | 23.91 | 0.23 | 50.12 |

| Sample | Φ (°C/min) | ||||

|---|---|---|---|---|---|

| PBS | 5 | 2.47 | 0.1597 | 0.6929 | 0.9956 |

| 10 | 2.40 | 0.6182 | 0.9530 | 0.9974 | |

| 15 | 2.33 | 1.2754 | 1.0163 | 0.9983 | |

| 20 | 2.30 | 2.0314 | 1.0361 | 0.9989 | |

| RS/PBS | 5 | 2.11 | 1.4669 | 1.0796 | 0.9956 |

| 10 | 2.50 | 4.8684 | 1.1715 | 0.9989 | |

| 15 | 2.47 | 9.0954 | 1.1586 | 0.9988 | |

| 20 | 2.52 | 14.3265 | 1.1424 | 0.9993 | |

| RS/PBS/1%TiO2 | 5 | 2.63 | 3.8956 | 1.3126 | 0.9987 |

| 10 | 2.61 | 11.5237 | 1.2769 | 0.9991 | |

| 15 | 2.47 | 18.9134 | 1.2165 | 0.9991 | |

| 20 | 2.42 | 26.1445 | 1.1773 | 0.9992 | |

| RS/PBS/3%TiO2 | 5 | 2.55 | 3.0536 | 1.2502 | 0.9995 |

| 10 | 2.53 | 8.7891 | 1.2428 | 0.9994 | |

| 15 | 2.53 | 15.6325 | 1.2012 | 0.9996 | |

| 20 | 2.40 | 21.9619 | 1.1670 | 0.9995 | |

| RS/PBS/5%TiO2 | 5 | 2.56 | 3.2814 | 1.2683 | 0.9990 |

| 10 | 2.61 | 10.0287 | 1.2593 | 0.9992 | |

| 15 | 2.57 | 17.9755 | 1.2124 | 0.9995 | |

| 20 | 2.52 | 26.1241 | 1.1772 | 0.9996 |

| Sample | ||||

|---|---|---|---|---|

| PBS | 20% | 1.24 | 5.94 | 0.9997 |

| 40% | 1.25 | 9.42 | 0.9999 | |

| 60% | 1.29 | 12.95 | 0.9986 | |

| 80% | 1.35 | 17.49 | 0.9990 | |

| RS/PBS | 20% | 1.67 | 1.23 | 0.9975 |

| 40% | 1.63 | 2.34 | 0.9999 | |

| 60% | 1.56 | 3.64 | 0.9990 | |

| 80% | 1.51 | 5.32 | 0.9989 | |

| RS/PBS/1%TiO2 | 20% | 1.57 | 0.93 | 0.9997 |

| 40% | 1.62 | 1.48 | 0.9997 | |

| 60% | 1.71 | 1.98 | 0.9983 | |

| 80% | 1.69 | 2.87 | 0.9986 | |

| RS/PBS/3%TiO2 | 20% | 1.61 | 0.99 | 0.9959 |

| 40% | 1.62 | 1.65 | 0.9974 | |

| 60% | 1.65 | 2.33 | 0.9981 | |

| 80% | 1.66 | 3.36 | 0.9986 | |

| RS/PBS/5%TiO2 | 20% | 1.59 | 0.98 | 0.9997 |

| 40% | 1.64 | 1.55 | 0.9999 | |

| 60% | 1.67 | 2.22 | 0.9986 | |

| 80% | 1.68 | 3.16 | 0.9990 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yue, T.; Wang, H.; Fu, Y.; Guo, S.; Zhang, X.; Liu, T. Non-Isothermal Crystallization of Titanium-Dioxide-Incorporated Rice Straw Fiber/Poly(butylene succinate) Biocomposites. Polymers 2022, 14, 1479. https://doi.org/10.3390/polym14071479

Yue T, Wang H, Fu Y, Guo S, Zhang X, Liu T. Non-Isothermal Crystallization of Titanium-Dioxide-Incorporated Rice Straw Fiber/Poly(butylene succinate) Biocomposites. Polymers. 2022; 14(7):1479. https://doi.org/10.3390/polym14071479

Chicago/Turabian StyleYue, Tianqi, Huanbo Wang, Yuan Fu, Shiyu Guo, Xuefeng Zhang, and Tian Liu. 2022. "Non-Isothermal Crystallization of Titanium-Dioxide-Incorporated Rice Straw Fiber/Poly(butylene succinate) Biocomposites" Polymers 14, no. 7: 1479. https://doi.org/10.3390/polym14071479

APA StyleYue, T., Wang, H., Fu, Y., Guo, S., Zhang, X., & Liu, T. (2022). Non-Isothermal Crystallization of Titanium-Dioxide-Incorporated Rice Straw Fiber/Poly(butylene succinate) Biocomposites. Polymers, 14(7), 1479. https://doi.org/10.3390/polym14071479