Behaviour of Rectangular Hollow Thin Ply Carbon Thermoset and Thermoplastic Composite Tubes Subjected to Bending

Abstract

:1. Introduction

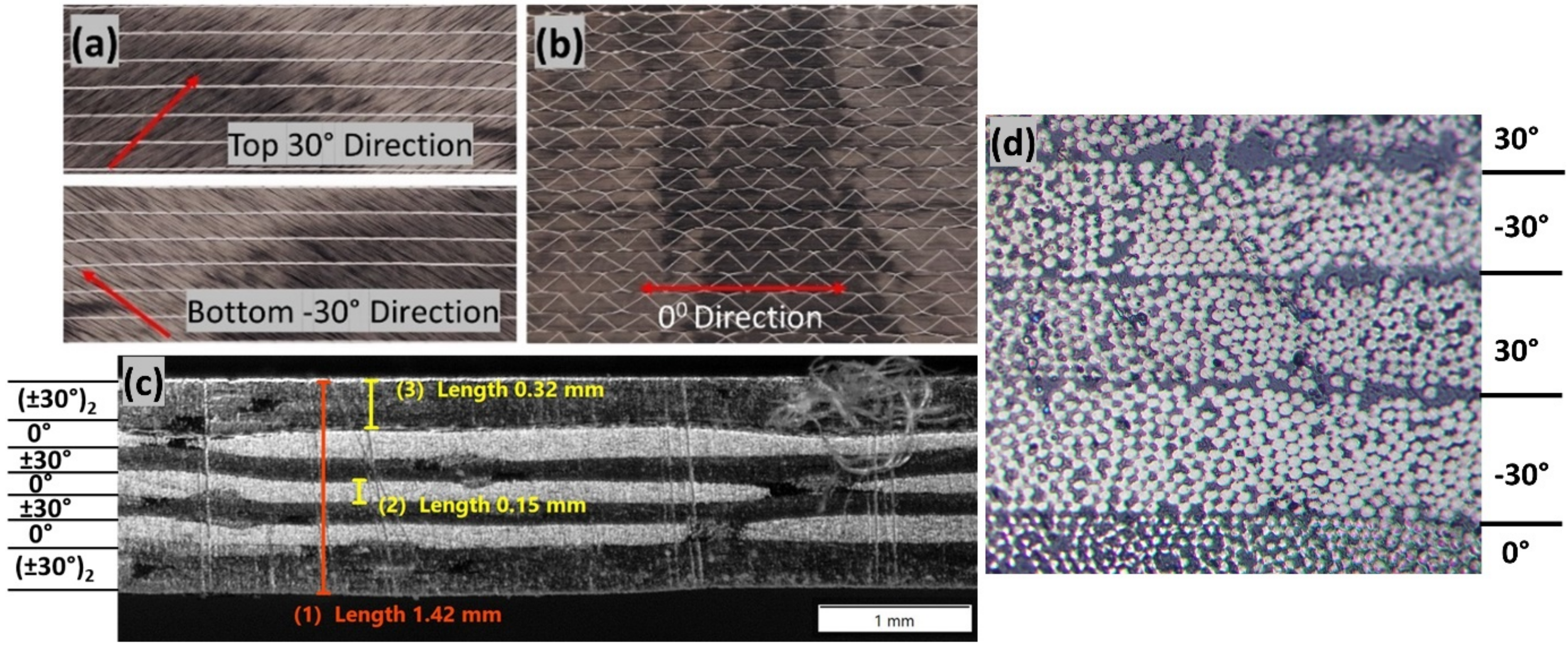

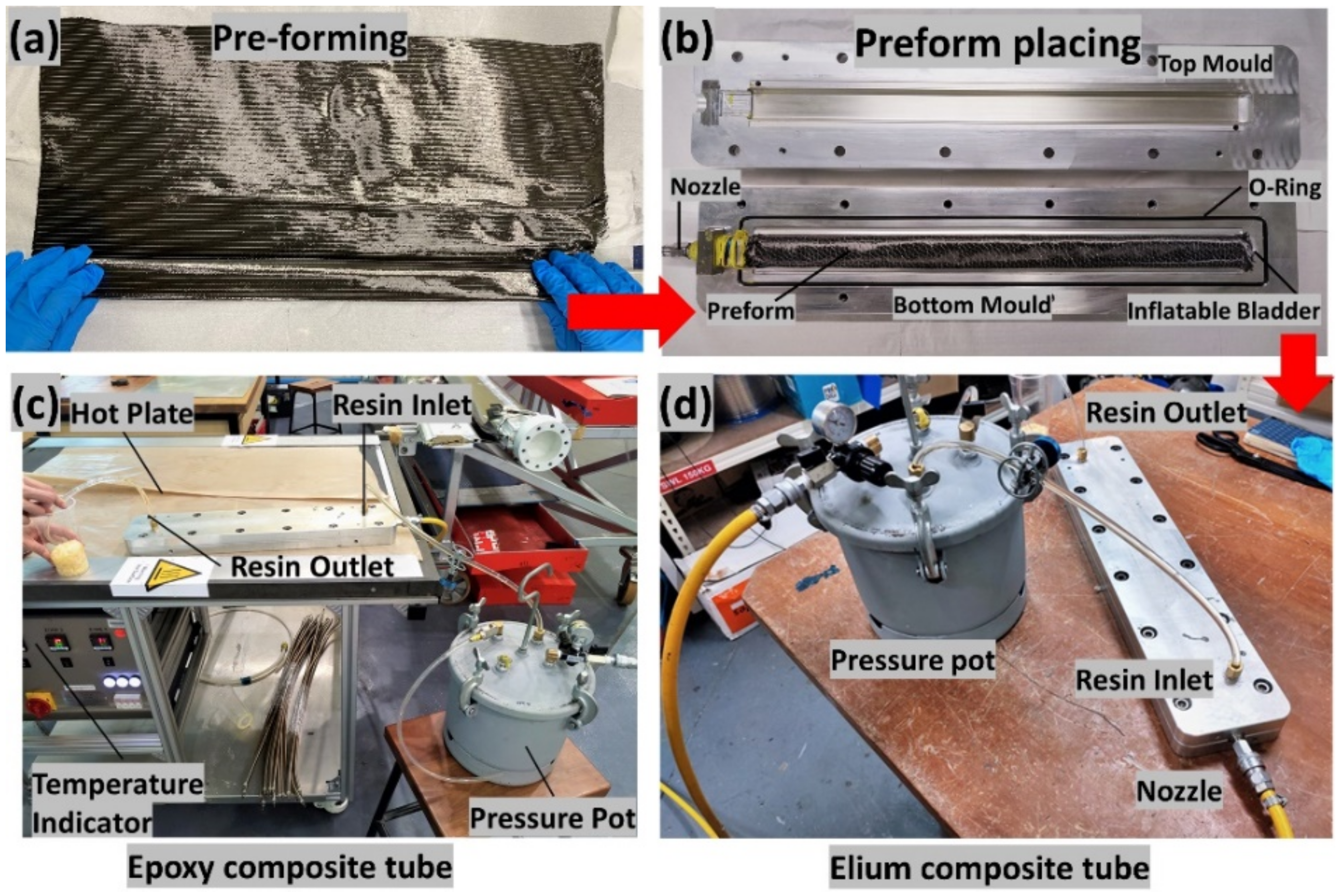

2. Materials and Manufacturing

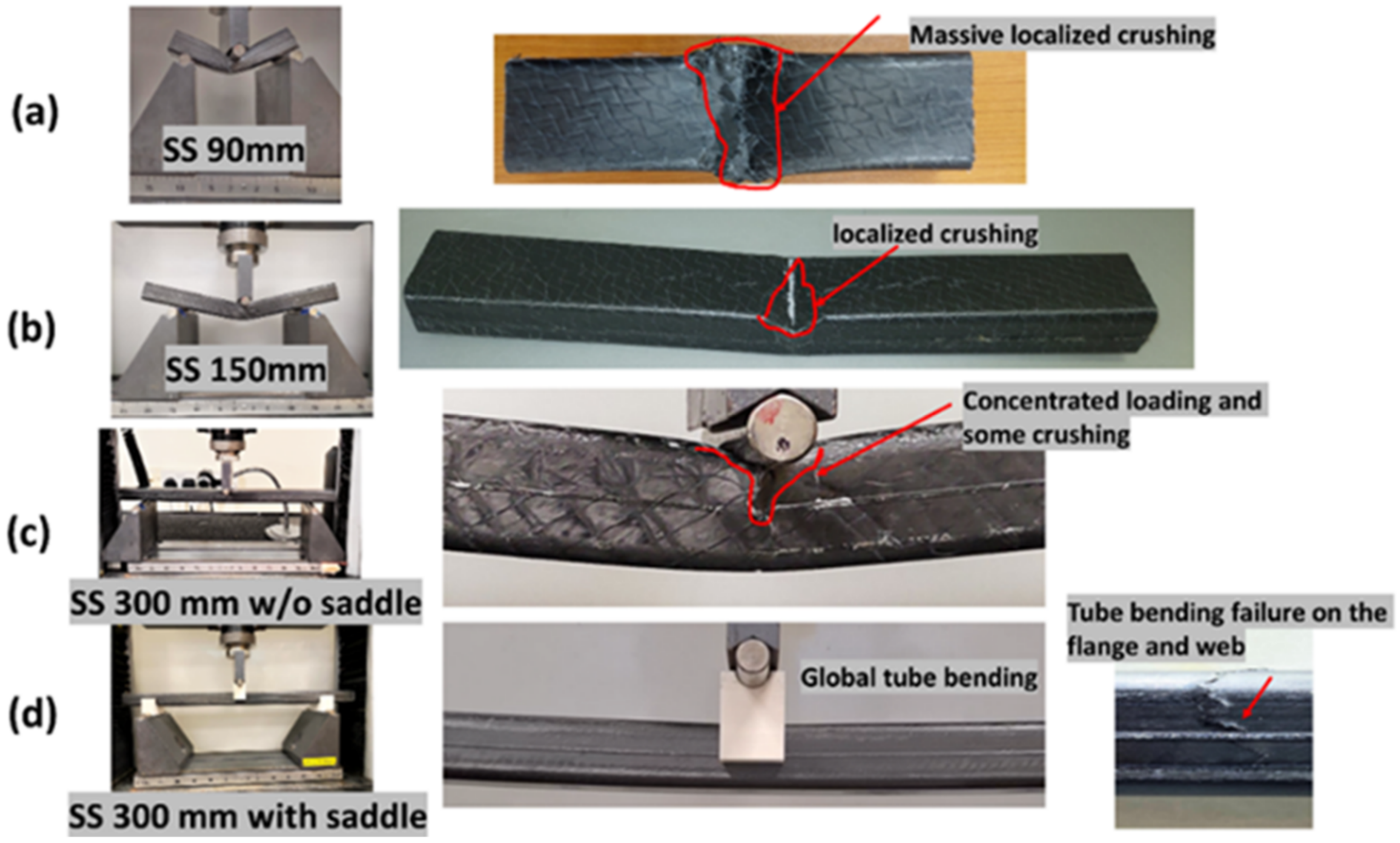

3. Experimental Setup

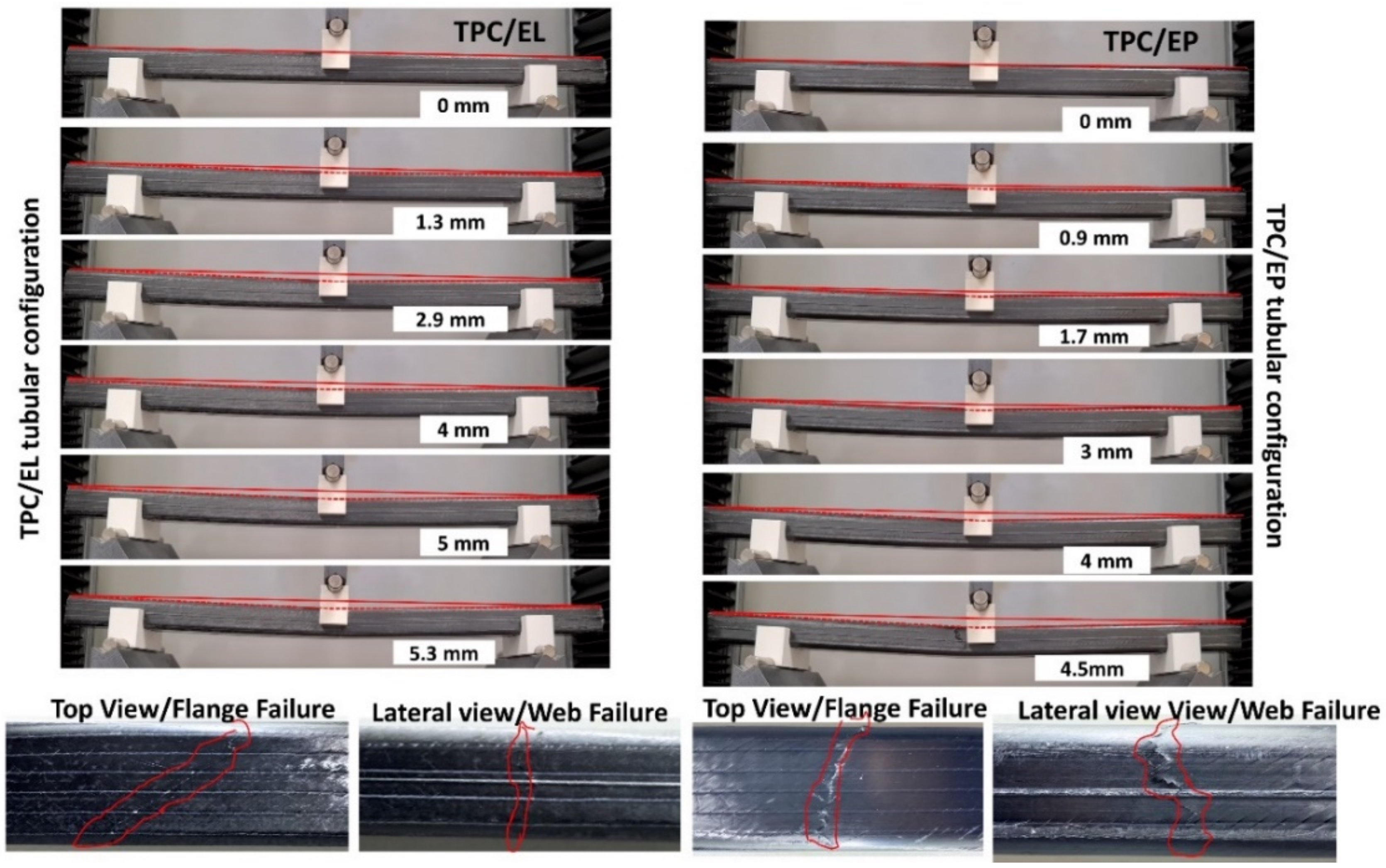

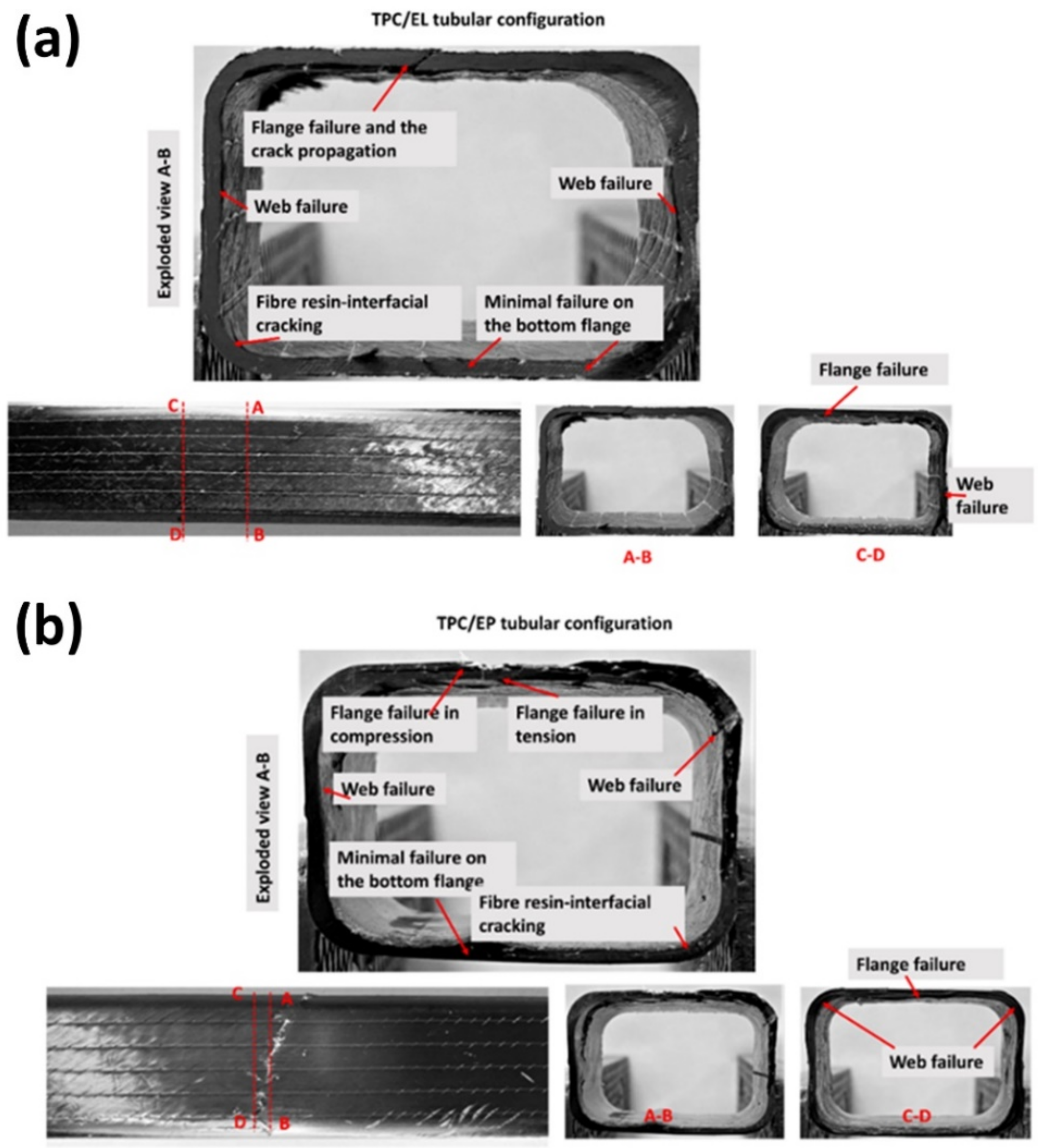

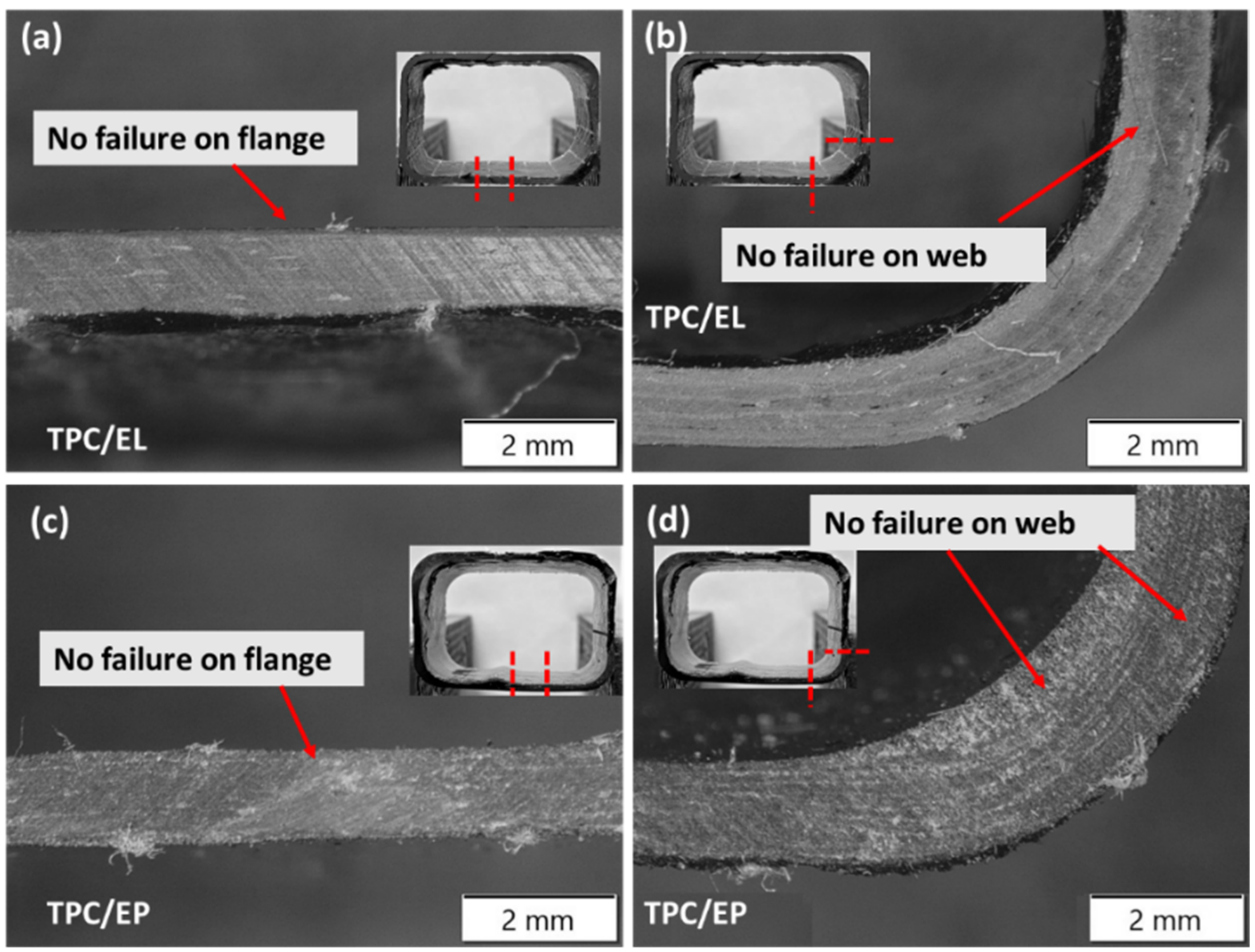

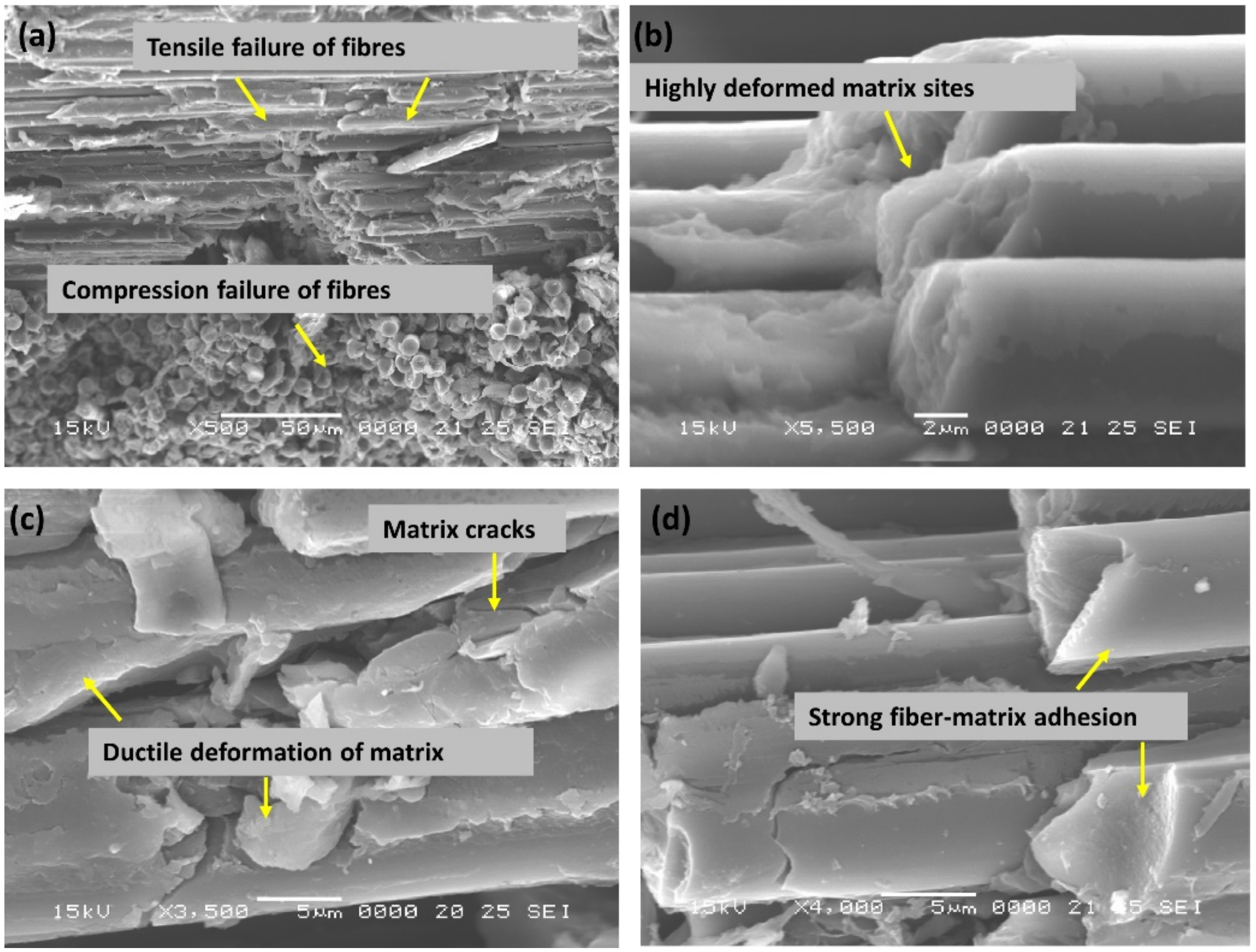

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, G.; Barocio, E.; Pipes, R.B.; Sterkenburg, R. 3D printed thermoplastic polyurethane bladder for manufacturing of fiber reinforced composites. Addit. Manuf. 2019, 29, 100809. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Perrotey, P.; Gohel, G.; Joshi, S.C.; Gerard, P.; Leong, K.F. Optimizing bladder resin transfer molding process to manufacture complex, thin-ply thermoplastic tubular composite structures: An experimental case study. Polymers 2021, 13, 4093. [Google Scholar] [CrossRef]

- Lehmann, U.; Michaeli, W. Cores lead to an automated production of hollow composite parts in resin transfer moulding. Compos. Part A Appl. Sci. Manuf. 1998, 29, 803–810. [Google Scholar] [CrossRef]

- Schillfahrt, C.; Fauster, E.; Schledjewski, R. Influence of process pressures on filling behavior of tubular fabrics in bladder-assisted resin transfer molding. Adv. Manuf. Polym. Compos. Sci. 2017, 3, 148–158. [Google Scholar] [CrossRef] [Green Version]

- Tsai, S.W. Thin ply composites. In Proceedings of the 46th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics & Materials Conference, Austin, TX, USA, 18–21 April 2005. [Google Scholar]

- Sihn, S.; Kim, R.Y.; Kawabe, K.; Tsai, S.W. Experimental studies of thin-ply laminated composites. Compos. Sci. Technol. 2007, 67, 996–1008. [Google Scholar] [CrossRef]

- Yokozeki, T.; Aoki, Y.; Ogasawara, T. Experimental characterization of strength and damage resistance properties of thin-ply carbon fiber/toughened epoxy laminates. Compos. Struct. 2008, 82, 382–389. [Google Scholar] [CrossRef]

- Yokozeki, T.; Kuroda, A.; Yoshimura, A.; Ogasawara, T.; Aoki, T. Damage characterization in thin-ply composite laminates under out-of-plane transverse loadings. Compos. Struct. 2010, 93, 49–57. [Google Scholar] [CrossRef]

- Lystrup, A.; Andersen, T.L. Autoclave consolidation of fibre composites with a high temperature thermoplastic matrix. J. Mater. Proc. Technol. 1998, 77, 80–85. [Google Scholar] [CrossRef]

- Díaz, J.; Rubio, L. Developments to manufacture structural aeronautical parts in carbon fibre reinforced thermoplastic materials. J. Mater. Proc. Technol. 2003, 143–144, 342–346. [Google Scholar] [CrossRef]

- Chou, P.J.C.; Ding, D.; Chen, W.S. Damping of moisture-absorbed composite rackets. J. Reinf. Plast. Compos. 2000, 19, 848–862. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Gohel, G.; Leong, K.F.; Joshi, S.C. Damping, impact and flexural performance of novel carbon/elium® thermoplastic tubular composites. Compos. Part B Eng. 2020, 203, 108480. [Google Scholar] [CrossRef]

- Friedrich, K.; Gogeva, T.; Fakirov, S. Thermoplastic impregnated fiber bundles: Manufacturing of laminates and fracture mechanics characterization. Compos. Sci. Technol. 1988, 33, 97–120. [Google Scholar] [CrossRef]

- Barbosa, L.C.M.; Bortoluzzi, D.B.; Ancelotti, A.C. Analysis of fracture toughness in mode ii and fractographic study of composites based on elium® 150 thermoplastic matrix. Compos. Part B Eng. 2019, 175, 107082. [Google Scholar] [CrossRef]

- Sadighi, M.; Rabizadeh, E.; Kermansaravi, F. Effects of laminate sequencing on thermoforming of thermoplastic matrix composites. J. Mater. Proc. Technol. 2008, 201, 725–730. [Google Scholar] [CrossRef]

- Taillemite, S. Arkema Gains Ground in Composites and Launches a Revolutionary Range of Elium Liquid Resins. Available online: http://www.arkema.com/en/media/news/news-details/Arkema-gains-ground-in-composites-and-launches-a-revolutionary-range-of-Elium-liquid-resins/ (accessed on 12 February 2017).

- Matadi Boumbimba, R.; Coulibaly, M.; Khabouchi, A.; Kinvi-Dossou, G.; Bonfoh, N.; Gerard, P. Glass fibres reinforced acrylic thermoplastic resin-based tri-block copolymers composites: Low velocity impact response at various temperatures. Compos. Struct. 2017, 160, 939–951. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Joshi, S.C. Low-velocity impact response of carbon fibre composites with novel liquid methylmethacrylate thermoplastic matrix. Compos. Struct. 2018, 203, 696–708. [Google Scholar] [CrossRef]

- Obande, W.; Ray, D.; O’Brádaigh, C.M. Viscoelastic and drop-weight impact properties of an acrylic-matrix composite and a conventional thermoset composite—A comparative study. Mater. Lett. 2019, 238, 38–41. [Google Scholar] [CrossRef]

- Kinvi-Dossou, G.; Matadi Boumbimba, R.; Bonfoh, N.; Garzon-Hernandez, S.; Garcia-Gonzalez, D.; Gerard, P.; Arias, A. Innovative acrylic thermoplastic composites versus conventional composites: Improving the impact performances. Compos. Struct. 2019, 217, 1–13. [Google Scholar] [CrossRef]

- Kinvi-Dossou, G.; Matadi Boumbimba, R.; Bonfoh, N.; Koutsawa, Y.; Eccli, D.; Gerard, P. A numerical homogenization of e-glass/acrylic woven composite laminates: Application to low velocity impact. Compos. Struct. 2018, 200, 540–554. [Google Scholar] [CrossRef]

- Gohel, G.; Bhudolia, S.K.; Kantipudi, J.; Leong, K.F.; Barsotti, R.J. Ultrasonic welding of novel carbon/elium® with carbon/epoxy composites. Compos. Commun. 2020, 22, 100463. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Gohel, G.; Kah Fai, L.; Barsotti, R.J. Fatigue response of ultrasonically welded carbon/elium® thermoplastic composites. Mater. Lett. 2020, 264, 127362. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Gohel, G.; Kantipudi, J.; Leong, K.F.; Barsotti, R.J. Ultrasonic welding of novel carbon/elium® thermoplastic composites with flat and integrated energy directors: Lap shear characterisation and fractographic investigation. Materials 2020, 13, 1634. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bhudolia, S.K.; Gohel, G.; Leong, K.F.; Barsotti, R.J. Investigation on ultrasonic welding attributes of novel carbon/elium® composites. Materials 2020, 13, 1117. [Google Scholar] [CrossRef] [Green Version]

- Campbell, F.C. Chapter 10—Thermoplastic composites: An unfulfilled promise. In Manufacturing Processes for Advanced Composites; Campbell, F.C., Ed.; Elsevier Science: Amsterdam, The Netherlands, 2003; pp. 357–397. [Google Scholar]

- Offringa, A.R. Thermoplastic composites—Rapid processing applications. Compos. Part A Appl. Sci. Manuf. 1996, 27, 329–336. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Joshi, S.C.; Bert, A.; Yi Di, B.; Makam, R.; Gohel, G. Flexural characteristics of novel carbon methylmethacrylate composites. Compos. Commun. 2019, 13, 129–133. [Google Scholar] [CrossRef]

- Cousins, D.S.; Suzuki, Y.; Murray, R.E.; Samaniuk, J.R.; Stebner, A.P. Recycling glass fiber thermoplastic composites from wind turbine blades. J. Clean. Prod. 2019, 209, 1252–1263. [Google Scholar] [CrossRef]

- Khalili, P.; Blinzler, B.; Kádár, R.; Bisschop, R.; Försth, M.; Blomqvist, P. Flammability, smoke, mechanical behaviours and morphology of flame retarded natural fibre/elium® composite. Materials 2019, 12, 2648. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khalili, P.; Blinzler, B.; Kádár, R.; Blomqvist, P.; Sandinge, A.; Bisschop, R.; Liu, X. Ramie fabric elium® composites with flame retardant coating: Flammability, smoke, viscoelastic and mechanical properties. Compos. Part A Appl. Sci. Manuf. 2020, 137, 105986. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Gohel, G.; Joshi, S.C.; Leong, K.F. Quasi-static indentation response of core-shell particle reinforced novel nccf/elium® composites at different feed rates. Compos. Commun. 2020, 21, 100383. [Google Scholar] [CrossRef]

- Shah, S.Z.H.; Megat-Yusoff, P.S.M.; Karuppanan, S.; Choudhry, R.S.; Ud Din, I.; Othman, A.R.; Sharp, K.; Gerard, P. Compression and buckling after impact response of resin-infused thermoplastic and thermoset 3d woven composites. Compos. Part B Eng. 2021, 207, 108592. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Joshi, S.C.; Bert, A.; Gohel, G.R.; Raama, M. Energy characteristics and failure mechanisms for textile spread tow thin ply thermoplastic composites under low-velocity impact. Fibers Polym. 2019, 20, 1716–1725. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Gohel, G.; Joshi, S.C.; Leong, K.F. Manufacturing optimization and experimental investigation of ex-situ core-shell particles toughened carbon/elium® thermoplastic composites. Fibers Polym. 2021, 13, 4093. [Google Scholar] [CrossRef]

- Yin, D.; Zheng, J.; Xiong, C.; Yin, J.; Li, B.; Deng, H.; Zhu, X. Analytical, numerical, and experimental investigations on transverse bending responses of cfrp square tube filled with aluminum foam. Math. Probl. Eng. 2020, 2020, 8764349. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. On energy absorption capacity, flexural and dynamic properties of flax/epoxy composite tubes. Fibers Polym. 2014, 15, 1270–1277. [Google Scholar] [CrossRef]

- Amiri, A.; Krosbakken, T.; Schoen, W.; Theisen, D.; Ulven, C.A. Design and manufacturing of a hybrid flax/carbon fiber composite bicycle frame. Proc. Inst. Mech. Eng. Part P J. Sports Eng. Technol. 2017, 232, 28–38. [Google Scholar] [CrossRef] [Green Version]

- Stefanovska, M.; Risteska, S.; Samakoski, B.; Maneski, G.; Kostadinoska, B. Theoretical and Experimental Bending Properties of Composite Pipes. Int. J. Environ. Ecol. Eng. 2015, 9, 706–710. [Google Scholar]

- Wu, Z.; Shen, Y.; Pan, Z.; Hu, X. Three-point bending behavior and energy absorption capacity of composite tube reinforced by gradient braided structure in radial direction. Fibers Polym. 2019, 20, 1455–1466. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Gohel, G.; Kantipudi, J.; Leong, K.F.; Gerard, P. Manufacturing and investigating the load, energy and failure attributes of thin ply carbon/elium® thermoplastic hollow composites under low-velocity impact. Mater. Des. 2021, 206, 109814. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Gohel, G.; Kantipudi, J.; Leong, K.F.; Gerard, P. Mechanical performance and damage mechanisms of thin rectangular carbon/elium® tubular thermoplastic composites under flexure and low-velocity impact. Thin-Walled Struct. 2021, 165, 107971. [Google Scholar] [CrossRef]

- Van Rijswijk, K.; Bersee, H.E.N. Reactive processing of textile fiber-reinforced thermoplastic composites—An overview. Compos. Part A Appl. Sci. Manuf. 2007, 38, 666–681. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Perrotey, P.; Joshi, S.C. Mode I fracture toughness and fractographic investigation of carbon fibre composites with liquid methylmethacrylate thermoplastic matrix. Compos. Part B Eng. 2018, 134, 246–253. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Perrotey, P.; Joshi, S.C. Optimizing polymer infusion process for thin ply textile composites with novel matrix system. Materials 2017, 10, 293. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Astm-D792-2020; Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. ASTM International: West Conshohocken, PA, USA, 2020.

- Astm D2734-09; Standard Test Methods for Void Content of Reinforced Plastics. ASTM International: West Conshohocken, PA, USA, 2011.

- Scărlătescu, D.D.; Modrea, A.; Stanciu, M.D. Three-point bend test to determine the mechanical behavior of the tubes used in water supply networks. Procedia Manuf. 2019, 32, 179–186. [Google Scholar] [CrossRef]

- Bakavos, D.; Prangnell, P.B. Mechanisms of joint and microstructure formation in high power ultrasonic spot welding 6111 aluminium automotive sheet. Mater. Sci. Eng. A 2010, 527, 6320–6334. [Google Scholar] [CrossRef]

- Gohel, G.; Bhudolia, S.K.; Elisetty, S.B.S.; Leong, K.F.; Gerard, P. Development and impact characterization of acrylic thermoplastic composite bicycle helmet shell with improved safety and performance. Compos. Part B Eng. 2021, 221, 109008. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Gohel, G.; Subramanyam, E.S.B.; Leong, K.F.; Gerard, P. Enhanced impact energy absorption and failure characteristics of novel fully thermoplastic and hybrid composite bicycle helmet shells. Mater. Des. 2021, 209, 110003. [Google Scholar] [CrossRef]

- Gohel, G.; Bhudolia, S.K.; Leong, K.F.; Gerard, P. On the structural damping response of hollow carbon composite shafts with room temperature curable novel acrylic liquid thermoplastic resin. Compos. Commun. 2021, 29, 100990. [Google Scholar] [CrossRef]

| Tubular Configuration | Thickness (mm)/Vf (%) | Slope (from L vs. d Curve) | Maximum Bending Stress (σmax) (Mpa) | Flexural Modulus (E) (Gpa) | Bending Stiffness/Flexural Rigidity (EI) (Nmm2) |

|---|---|---|---|---|---|

| TPC/EL | 1.4/54 | 756.61 | 522.42 ± 3.7 | 36.16 ± 1.78 | 425,595.2 ± 234.7 |

| TPC/EP | 1.4/54 | 778.90 | 473.31 ± 2.8 | 37.23 ± 1.23 | 438,135.8 ± 398.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bhudolia, S.K.; Gohel, G.; Vasudevan, D.; Leong, K.F.; Gerard, P. Behaviour of Rectangular Hollow Thin Ply Carbon Thermoset and Thermoplastic Composite Tubes Subjected to Bending. Polymers 2022, 14, 1386. https://doi.org/10.3390/polym14071386

Bhudolia SK, Gohel G, Vasudevan D, Leong KF, Gerard P. Behaviour of Rectangular Hollow Thin Ply Carbon Thermoset and Thermoplastic Composite Tubes Subjected to Bending. Polymers. 2022; 14(7):1386. https://doi.org/10.3390/polym14071386

Chicago/Turabian StyleBhudolia, Somen K., Goram Gohel, Durga Vasudevan, Kah Fai Leong, and Pierre Gerard. 2022. "Behaviour of Rectangular Hollow Thin Ply Carbon Thermoset and Thermoplastic Composite Tubes Subjected to Bending" Polymers 14, no. 7: 1386. https://doi.org/10.3390/polym14071386

APA StyleBhudolia, S. K., Gohel, G., Vasudevan, D., Leong, K. F., & Gerard, P. (2022). Behaviour of Rectangular Hollow Thin Ply Carbon Thermoset and Thermoplastic Composite Tubes Subjected to Bending. Polymers, 14(7), 1386. https://doi.org/10.3390/polym14071386