Improved Wood-Bond Strengths Using Soy and Canola Flours with pMDI and PAE

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Soy and Canola Flour Adhesives

2.3. Evaluation of Shear Strength of Synthesized Adhesives

2.3.1. ABES

2.3.2. Plywood

2.4. ATR-FTIR

3. Results and Discussion

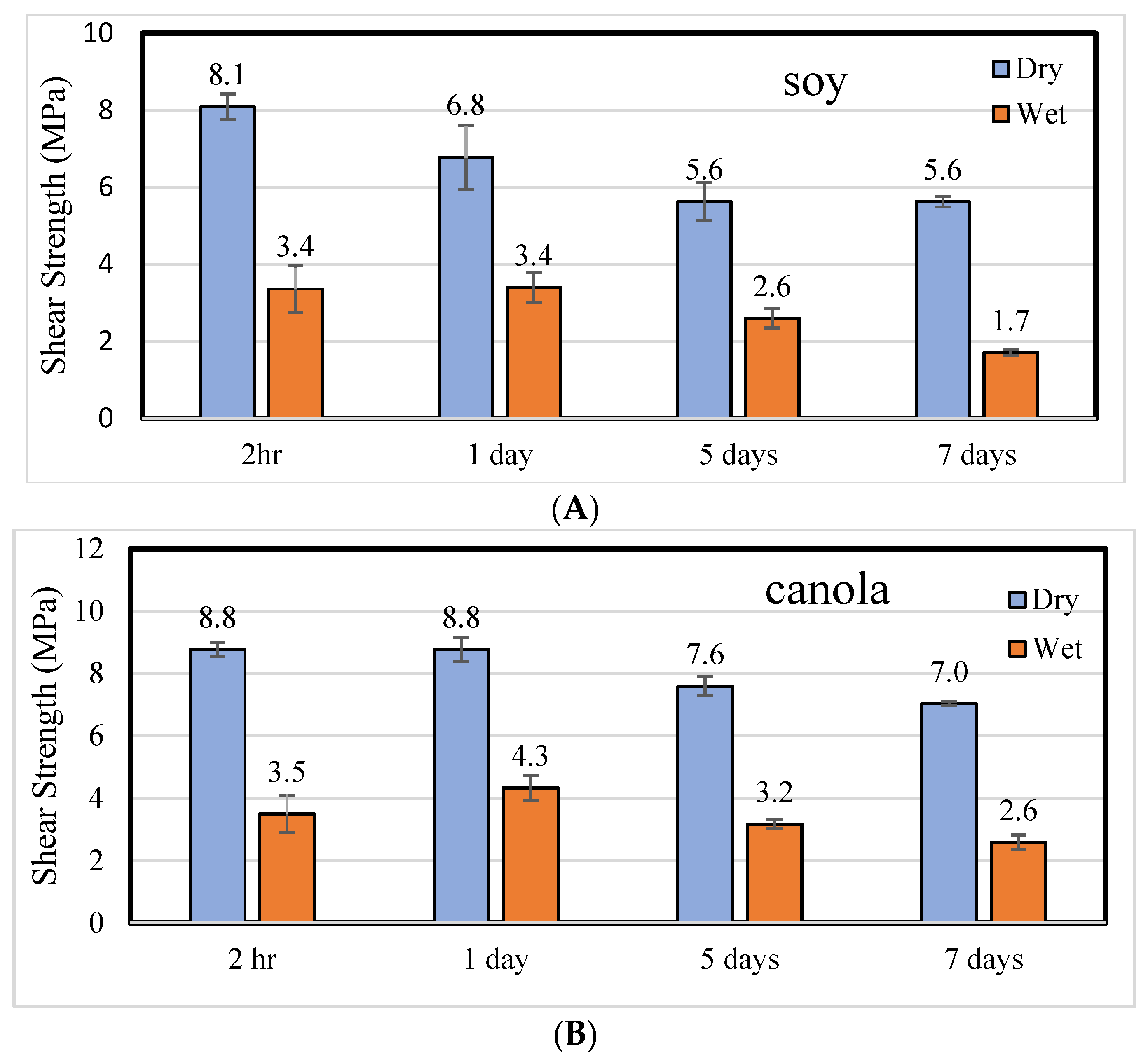

3.1. Results of Evaluation of ABES Shear Strength

3.1.1. Reaction of Soy and Canola Flour with pMDI

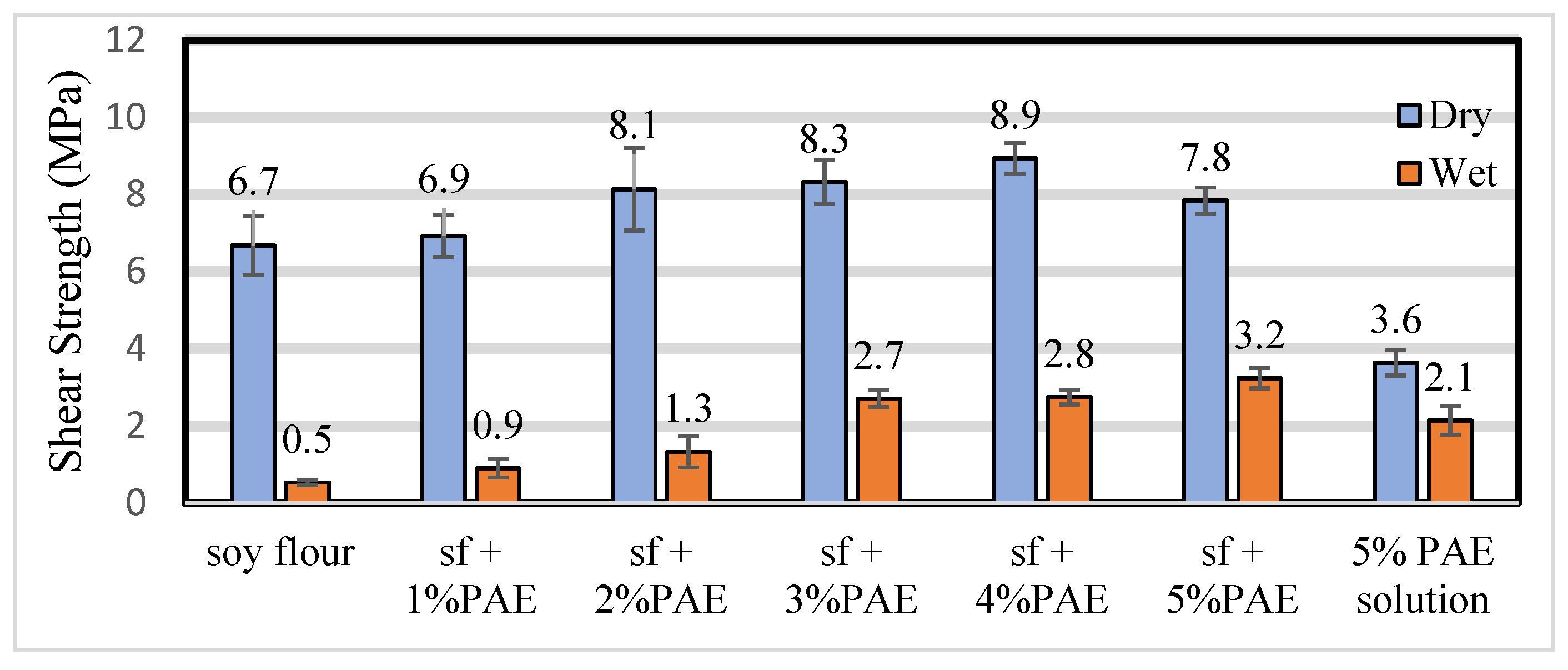

3.1.2. Reaction of Soy Flour with PAE

3.1.3. Reaction of Soy Flour and Canola with pMDI and PAE

3.2. Plywood Adhesive Tests

3.3. ATR-FTIR Spectroscopy of pMDI Plus Soy or Canola Flour

4. Conclusions

5. Patent

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dunky, M. Wood Adhesives Based on Natural Resources: A Critical Review Part I. Protein-Based Adhesives. Rev. Adhes. Adhes. 2020, 8, 199–332. [Google Scholar] [CrossRef]

- Frihart, C.R.; Lorenz, L.F. Protein Adhesives. In Handbook of Adhesive Technology, 3nd ed.; Pizzi, A., Mittal, K., Eds.; Taylor & Francis Group: Abingdon, UK, 2017; pp. 145–176. [Google Scholar]

- Dunky, M. Adhesives in the Wood Industry. In Handbook of Adhesive Technology, 3nd ed.; Pizzi, A., Mittal, K., Eds.; Taylor & Francis Group: Abingdon, UK, 2017; pp. 511–574. [Google Scholar]

- Adhikari, B.; Appadu, P.; Chae, M.; Bressler, D. Protein-based wood adhesives: Current trnds of preparation and application. In Bio-Based Wood Adhesives: Preparation, Characterization, and Testing; He, Z., Ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- He, Z. (Ed.) Bio-Based Wood Adhesives: Preparation, Characterization, and Testing; CRC Press: Boca Raton, FL, USA, 2017; 366p. [Google Scholar]

- He, Z.; Wan, H. Bio-based wood adhesive research: Advances and outlooks. In Bio-Based Wood Adhesives: Preparation, Characterization, and Testing; He, Z., Ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Frihart, C.R.; Satori, H.; Rongxian, Z.; Birkeland, M.J. Ovalbumin as a wood adhesive. In Proceedings of the 37th Annual Meeting of The Adhesion Society, San Diego, CA, USA, 23–26 February 2014. [Google Scholar]

- Vnucec, D.; Kutnar, A.; Gorsek, A. Soy-based adhesives for wood-bonding—A review. J. Adhes. Sci. Technol. 2017, 31, 910–931. [Google Scholar] [CrossRef]

- Humphrey, P.E. Outline Standard for Adhesion Dynamics Evaluation Employing the ABES (Automated Bonding Evaluation System) Technique. In Proceedings of the International Conference on Wood Adhesives 2009, Lake Tahoe, NV, USA, 28–30 September 2009; pp. 213–223. [Google Scholar]

- ASTM D 7998-19; Standard Test Method for Measuring the Effect of Temperature on the Cohesive Strength Development of Adhesives Using Lap Shear Bonds under Tensile Loading. ASTM International: West Conshohocken, PA, USA, 2020.

- Frihart, C.R.; Coolidge, T.; Mock, C.; Valle, E. High Bonding Temperatures Greatly Improve Soy Adhesive Wet Strength. Polymers 2016, 8, 394. [Google Scholar] [CrossRef] [PubMed]

- Lorenz, L.; Birkeland, M.; Daurio, C.; Frihart, C.R. Soy flour adhesive strength compared with that of purified soy proteins. For. Prod. J. 2015, 65, 26–30. [Google Scholar] [CrossRef]

- Adams, R.D. Adhesive Bonding: Science, Technology and Applications; CRC Press: Boca Raton, FL, USA, 2005; 543p. [Google Scholar]

- Allen, A.J.; Wescott, J.M.; Varnell, D.F.; Evans, M.A. Protein Adhesive Formulations with Amne-Epchlorohydrin and Isocyanate Additives. U.S. Patent 8,845,851, 30 September 2014. [Google Scholar]

- Asafu-Adjaye, O.; Via, B.; Banerjee, S. Soy Flour Substitution in Polymeric Methylene Diphenyl Diisocyanate Resin for Composite Panel Applications. For. Prod. J. 2020, 70, 350–355. [Google Scholar] [CrossRef]

- Cheng, Q.; Essien, C.; Via, B.; Banerjee, S. Cost Savings from Soy Flour Substitution in Methylene Diphenyl Diisocyanate for Bonding Flakes and Particle. For. Prod. J. 2019, 69, 154–158. [Google Scholar] [CrossRef]

- Barzegar, M.; Behrooz, R.; Mansouri, H.R.; Najafi, S.K.; Lorenz, L.F.; Frihart, C.R. Comparison of Canola and Soy Flour with Added Isocyanate as Wood Adhesives. J. Am. Oil Chem. Soc. 2020, 97, 1371–1383. [Google Scholar] [CrossRef]

- ASTM D 906-20; Standard Test Method for Strength Properties of Adhesives in Plywood Type Construction in Shear by Tension Loading. ASTM International: West Conshohocken, PA, USA, 2020.

- Sun, X.S. Soy Protein Adhesives. In Bio-Based Polymers and Composites; Wool, R.P., Sun, X.S., Eds.; Elsevier-Academic Press: Burlington, MA, USA, 2005; pp. 327–368. [Google Scholar]

- Utsumi, S.; Matsumura, Y.; Mori, T. Structure-function relationships of soy proteins. In Food Proteins and Their Applications; Damodaran, S., Paraf, A., Eds.; Marcel Dekker, Inc.: New York, NY, USA, 1997; pp. 257–291. [Google Scholar]

- Gordon, A.J.; Ford, R.A. The Chemist’s Companion: A Handbook of Practical Data, Techniques, and References; Wiley: New York, NY, USA, 1974; 560p. [Google Scholar]

| Adhesives | Dry (MPa) | stdv | Wet | stdv |

|---|---|---|---|---|

| soy flour | 5.3 | 0.8 | 0.3 | 0.09 |

| canola flour | 4.4 | 0.5 | 0.2 | 0.002 |

| CSPI | 8.2 | 1.6 | 3.2 | 0.3 |

| minimum | 3.0 |

| Soy Flour 100 g | Dry | stdv | Wet | stdv | Canola Flour 100 g | Dry | stdv | Wet | stdv |

|---|---|---|---|---|---|---|---|---|---|

| + pMDI 2.5 g | 6.7 | 0.3 | 1.3 | 0.2 | + pMDI 2.5 g | 5.6 | 0.4 | 1.4 | 0.2 |

| + pMDI 5 g | 8.2 | 0.6 | 2.5 | 0.3 | + pMDI 5 g | 6.6 | 0.2 | 1.8 | 0.0 |

| + pMDI 25 g | 7.4 | 0.5 | 2.3 | 0.1 | + pMDI 25 g | 7.5 | 0.1 | 2.4 | 0.1 |

| + pMDI 50 g 1 | 8.3 | 0.2 | 3.9 | 0.3 | + pMDI 50 g | 8.8 | 0.2 | 3.5 | 0.6 |

| Adhesives | Dry | stdv | Wet | stdv |

|---|---|---|---|---|

| soy flour + 50 g pMDI | 8.3 | 0.2 | 3.9 | 0.3 |

| soy flour + 50 g pMDI + 5 g PAE | 7.9 | 0.5 | 4.9 | 1.2 |

| canola + 50 g pMDI | 8.8 | 0.2 | 3.5 | 0.6 |

| canola + 50 g pMDI + 5 g PAE | 9.8 | 0.2 | 5.6 | 0.3 |

| D 906 Samples | Dry (MPa) | Wet (MPa) | ||

|---|---|---|---|---|

| ave | stdv | ave | stdv | |

| soy flour + 50 g pMDI + 5 g PAE | 0.97 | 0.08 | 0.48 | 0.09 |

| soy flour + 50 g pMDI | 0.87 | 0.07 | 0.44 | 0.06 |

| canola flour + 50 g pMDI + 5 g PAE | 1.12 | 0.06 | 0.63 | 0.06 |

| canola flour + 50 g pMDI | 0.91 | 0.10 | 0.44 | 0.04 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barzegar, M.; Lorenz, L.F.; Behrooz, R.; Frihart, C.R. Improved Wood-Bond Strengths Using Soy and Canola Flours with pMDI and PAE. Polymers 2022, 14, 1272. https://doi.org/10.3390/polym14071272

Barzegar M, Lorenz LF, Behrooz R, Frihart CR. Improved Wood-Bond Strengths Using Soy and Canola Flours with pMDI and PAE. Polymers. 2022; 14(7):1272. https://doi.org/10.3390/polym14071272

Chicago/Turabian StyleBarzegar, Mahsa, Linda F. Lorenz, Rabi Behrooz, and Charles R. Frihart. 2022. "Improved Wood-Bond Strengths Using Soy and Canola Flours with pMDI and PAE" Polymers 14, no. 7: 1272. https://doi.org/10.3390/polym14071272

APA StyleBarzegar, M., Lorenz, L. F., Behrooz, R., & Frihart, C. R. (2022). Improved Wood-Bond Strengths Using Soy and Canola Flours with pMDI and PAE. Polymers, 14(7), 1272. https://doi.org/10.3390/polym14071272