Experimental Investigation and Numerical Simulation of a Self-Wiping Corotating Parallel Octa-Screw Extruder

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

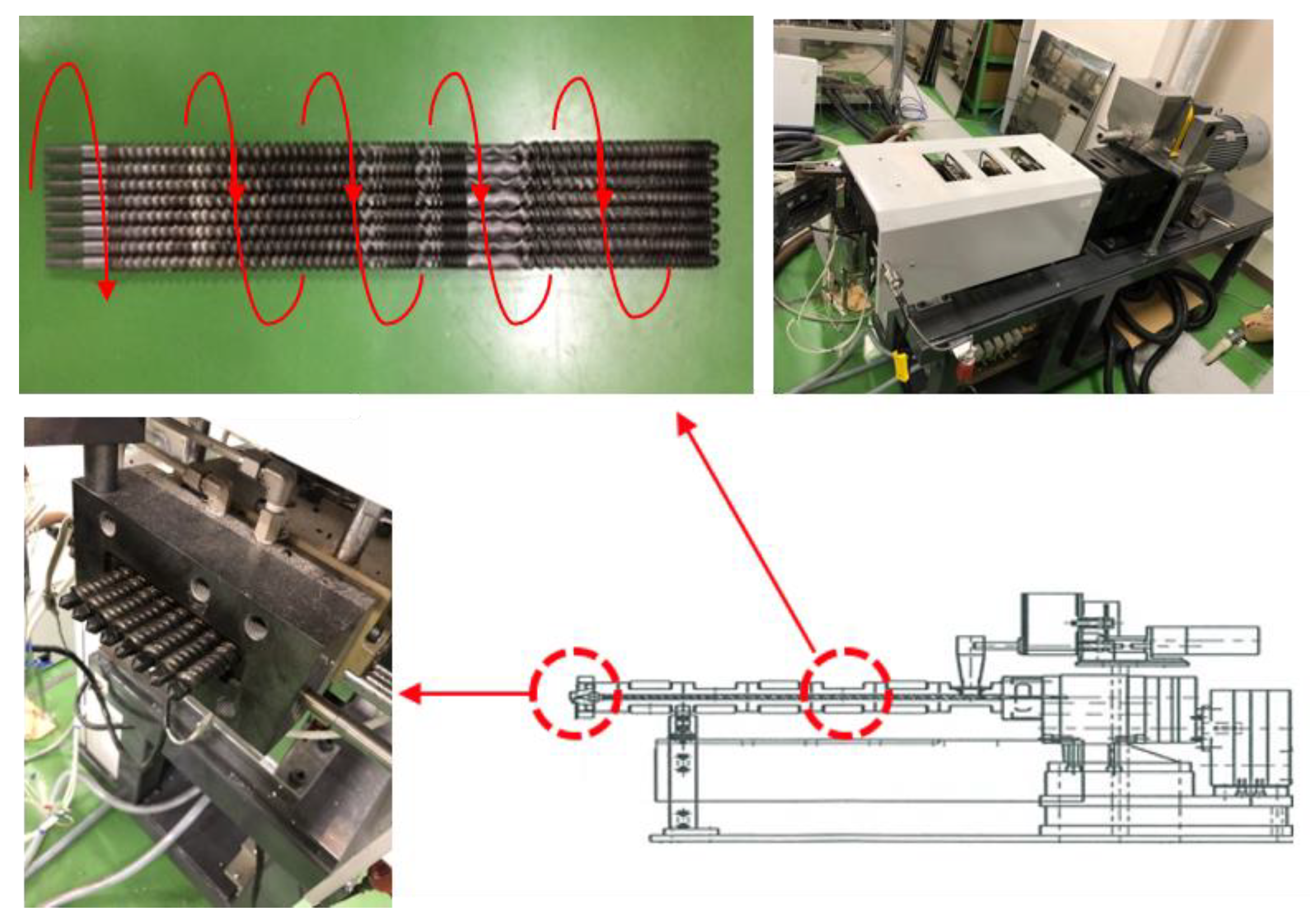

2.2. Octa-Screw and Twin-Screw Extrusions

2.3. Determining the Degree of Fill

2.4. Assessment of Residence Time Distribution

3. Numerical Analysis

3.1. Formulation of Numerical Model

3.2. Estimating the Fill Factor

4. Results and Discussion

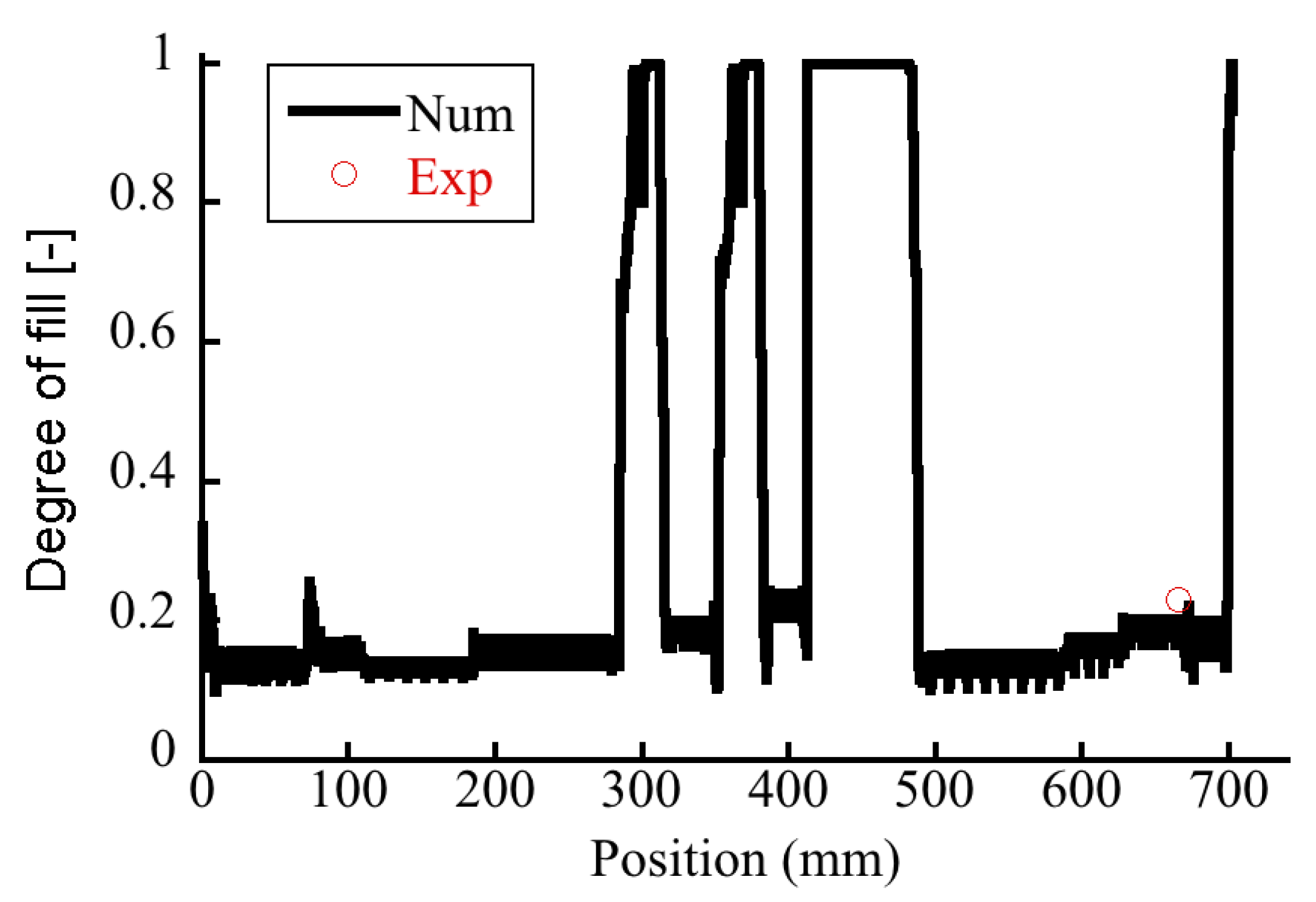

4.1. Degree of Fill

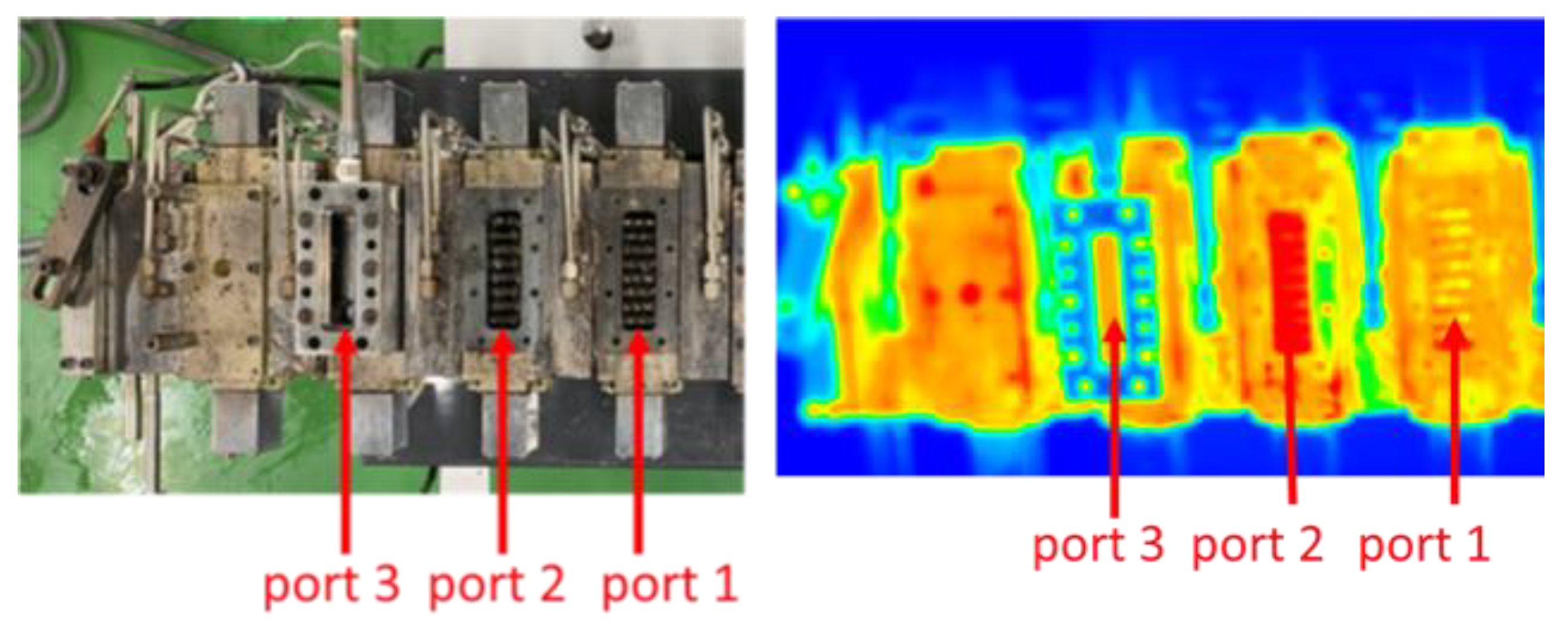

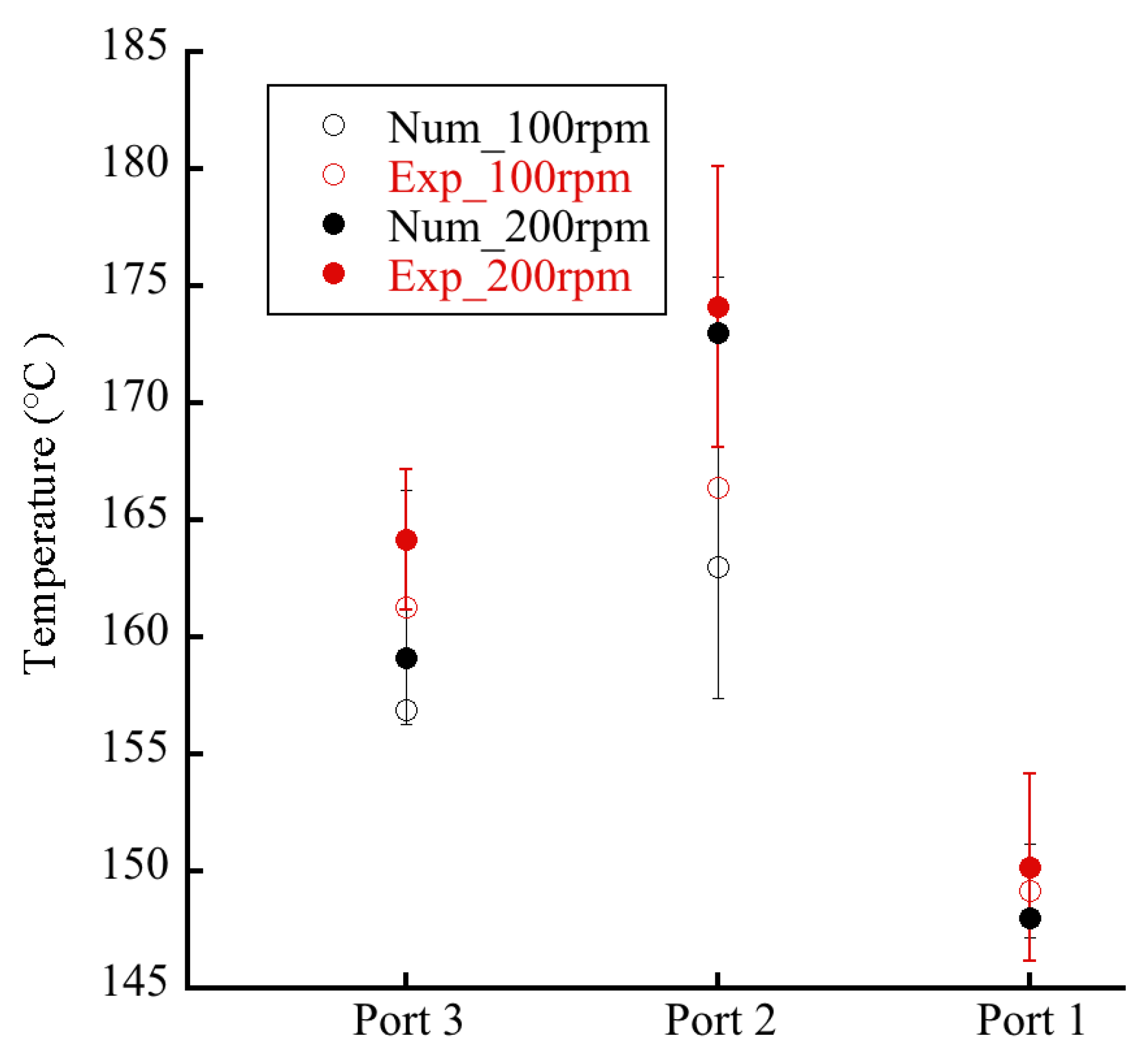

4.2. Temperature Distribution

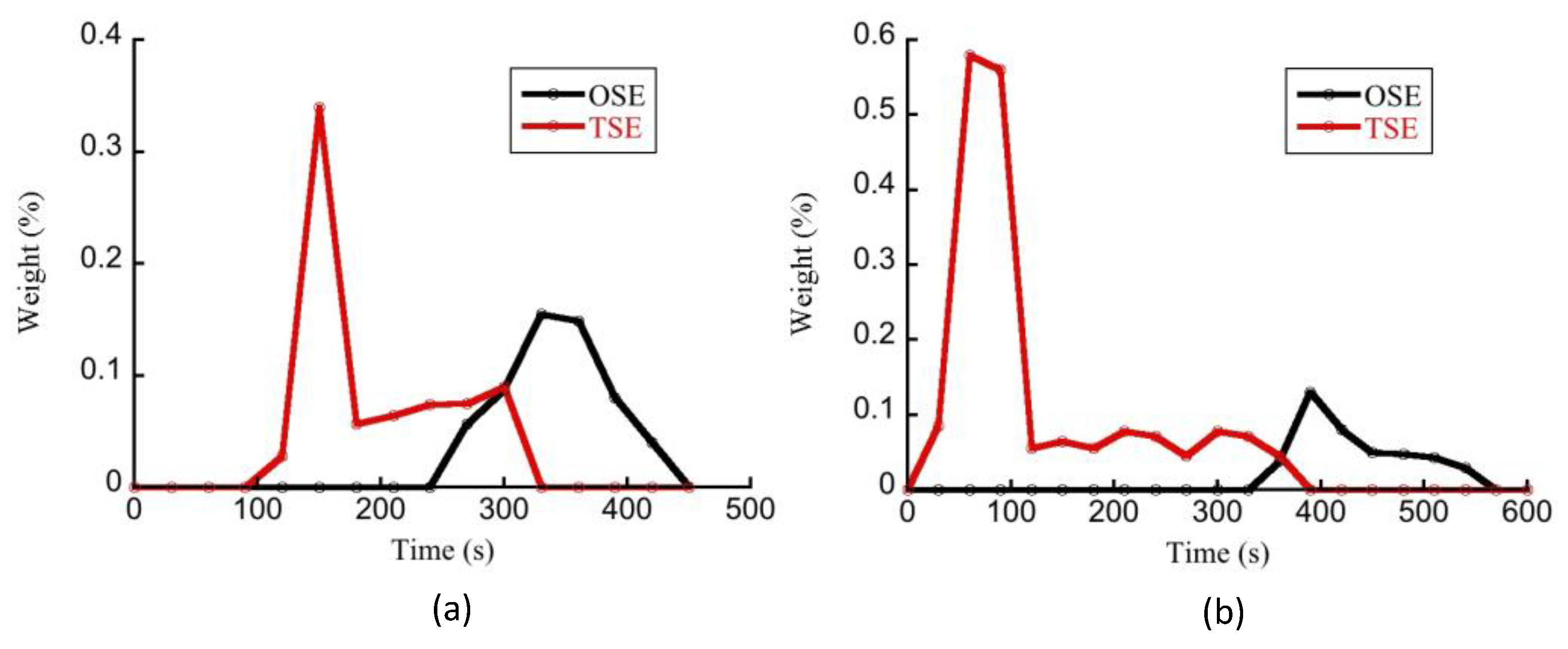

4.3. Residence Time Distribution

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- White, J.L. Twin Screw Extrusion: Technology and Principles; Hanser: Munich, Germany, 1991. [Google Scholar]

- Bourque, A.J.; Locker, C.R.; Tsou, A.H.; Vadlamudi, M. Nucleation and mechanical enhancements in polyethylene-graphene nanoplate composites. Polymer 2016, 99, 263–272. [Google Scholar] [CrossRef]

- Honaker, K.; Vautard, F.; Drzal, L. Investigating the mechanical and barrier properties to oxygen and fuel of high density polyethylene–graphene nanoplatelet composites. Mater. Sci. Eng. B 2017, 216, 23–30. [Google Scholar] [CrossRef]

- Khanam, P.N.; AlMaadeed, M.; Ouederni, M.; Harkin-Jones, E.; Mayoral, B.; Hamilton, A.; Sun, D. Melt processing and properties of linear low density polyethylene-graphene nanoplatelet composites. Vacuum 2016, 130, 63–71. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, E.; Vieira, A.; Vieira, L.; Fechine, G. High-Tribological-Performance Polymer Nanocomposites: An Approach Based on the Superlubricity State of the Graphene Oxide Agglomerates. Polymers 2021, 13, 2237. [Google Scholar] [CrossRef] [PubMed]

- Batista, N.L.; Helal, E.; Kurusu, R.S.; Moghimian, N.; David, E.; Demarquette, N.R.; Hubert, P. Mass-produced graphene—HDPE nanocomposites: Thermal, rheological, electrical, and mechanical properties. Polym. Eng. Sci. 2019, 59, 675–682. [Google Scholar] [CrossRef]

- Hyvärinen, M.; Jabeen, R.; Kärki, T. The Modelling of Extrusion Processes for Polymers—A Review. Polymers 2020, 12, 1306. [Google Scholar] [CrossRef] [PubMed]

- White, J.L.; Coran, A.Y.; Moet, A. (Eds.) Polymer Mixing: Technology and Engineering; Hanser: Munich, Germany, 2001. [Google Scholar]

- Kretschmer, K.; Schubert, M.; Bastian, M. A new online measurement technique for the evaluation of the degree of dispersion. In Proceedings of the 21st Annual Meeting of the Polymer Processing Society (PPS21), Leipzig, Germany, 19–23 June 2005. [Google Scholar]

- Vergnes, B.; Della Valle, G.; Delamare, L. A global computer software for polymer flows in corotating twin screw extruders. Polym. Eng. Sci. 1998, 38, 1781–1792. [Google Scholar] [CrossRef]

- Canedo, E.L.; Valsamis, L. Mixing in corotating intermeshing twin-screw extruders with Farrel asymmetric modular mixing elements (Famme). ANTEC’95 1995, 1, 312–320. [Google Scholar]

- Tomiyama, H.; Takamoto, S.; Shintani, H.; Inoue, S. Devolatilization analysis in a twin screw extruder by using the flow analysis network (FAN) method. Seikei-Kakou 2009, 19, 565–574. [Google Scholar] [CrossRef]

- Crochet, M.; Keunings, R. Finite element analysis of die swell of a highly elastic fluid. J. Non-Newton. Fluid Mech. 1982, 10, 339–356. [Google Scholar] [CrossRef]

- Ohara, M.; Tanifuji, S.; Sasai, Y.; Sugiyama, T.; Umemoto, S.; Murata, J.; Tsujimura, I.; Kihara, S.; Taki, K. Resin distribution along axial and circumferential directions of self-wiping co-rotating parallel twin-screw extruder. AIChE J. 2020, 66, e17018. [Google Scholar] [CrossRef]

- Van Der Goot, A.J.; Poorter, O.; Janssen, L.P.B.M. Determination of the degree of fill in a counter-rotating twin screw extruder. Polym. Eng. Sci. 1998, 38, 1193–1198. [Google Scholar] [CrossRef] [Green Version]

- White, J.L.; Bernhardt, E.C. Computer Aided Engineering for Injection Molding, 2nd ed.; Hanser: New York, NY, USA, 1983. [Google Scholar]

- Wang, K.K.; Wang, V.W.; Isayev, A.I. (Eds.) Injection and Compression Molding Fundamentals; Marcel Dekker: New York, NY, USA, 1987. [Google Scholar]

- Taki, K.; Sugiyama, T.; Ohara, M.; Umemoto, S.; Tanifuji, S.I.; Murata, J.I.; Tsujimura, I.; Kihara, S.I. Online Monitoring of the Degree of Fill in a Rotating Full-Flight Screw of a Corotating Twin-Screw Extruder. AIChE J. 2019, 65, 326–333. [Google Scholar] [CrossRef] [Green Version]

- Robinson, M.; Cleary, P.W. Effect of geometry and fill level on the transport and mixing behaviour of a co-rotating twin screw extruder. Comput. Part. Mech. 2018, 6, 227–247. [Google Scholar] [CrossRef]

- Sombatsompop, N.; Panapoy, M. Effect of screw rotating speed on polymer melt temperature profiles in twin screw extruder. J. Mater. Sci. 2000, 35, 6131–6137. [Google Scholar] [CrossRef]

- Wilczyński, K.; Nastaj, A.; Lewandowski, A.; Wilczyński, K.J.; Buziak, K. Fundamentals of Global Modeling for Polymer Extrusion. Polymers 2019, 11, 2106. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kelly, A.; Brown, E.C.; Howell, K.; Coates, P.D. Melt temperature field measurements in extrusion using thermocouple meshes. Plast. Rubber Compos. 2008, 37, 151–157. [Google Scholar] [CrossRef]

- De Melo, T.J.A.; Pinheiro, L.A.; Canevarolo, S.V. Factorial design to quantify the influence of extrusion parameters in the mean residence time. Polímeros 2010, 20, 322–326. [Google Scholar] [CrossRef] [Green Version]

- Kao, S.V.; Allison, G.R. Residence time distribution in a twin screw extruder. Polym. Eng. Sci. 1984, 24, 645–651. [Google Scholar] [CrossRef]

- Limper, A.; Seibel, S.; Fattmann, G. Compounding Unit Planetary Roller Extruder. Macromol. Mater. Eng. 2002, 287, 815–823. [Google Scholar] [CrossRef]

- Schmidt, C.; Lindner, H.; Kleinebudde, P. Comparison between a twin-screw extruder and a rotary ring die press. I. Influence of formulation variables. Eur. J. Pharm. Biopharm. 1997, 44, 169–176. [Google Scholar] [CrossRef]

- Schmidt, C.; Kleinebudde, P. Comparison between a twin-screw extruder and a rotary ring die press. Part II: Influence of process variables. Eur. J. Pharm. Biopharm. 1998, 45, 173–179. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.-Y.; Mikoshiba, S.; Kobayashi, Y.; Ishigami, A.; Yorifuji, D.; Tanifuji, S.-i.; Ito, H. Experimental Investigation and Numerical Simulation of a Self-Wiping Corotating Parallel Octa-Screw Extruder. Polymers 2022, 14, 1201. https://doi.org/10.3390/polym14061201

Liu C-Y, Mikoshiba S, Kobayashi Y, Ishigami A, Yorifuji D, Tanifuji S-i, Ito H. Experimental Investigation and Numerical Simulation of a Self-Wiping Corotating Parallel Octa-Screw Extruder. Polymers. 2022; 14(6):1201. https://doi.org/10.3390/polym14061201

Chicago/Turabian StyleLiu, Cheng-Ying, Shota Mikoshiba, Yutaka Kobayashi, Akira Ishigami, Daisuke Yorifuji, Shin-ichiro Tanifuji, and Hiroshi Ito. 2022. "Experimental Investigation and Numerical Simulation of a Self-Wiping Corotating Parallel Octa-Screw Extruder" Polymers 14, no. 6: 1201. https://doi.org/10.3390/polym14061201

APA StyleLiu, C.-Y., Mikoshiba, S., Kobayashi, Y., Ishigami, A., Yorifuji, D., Tanifuji, S.-i., & Ito, H. (2022). Experimental Investigation and Numerical Simulation of a Self-Wiping Corotating Parallel Octa-Screw Extruder. Polymers, 14(6), 1201. https://doi.org/10.3390/polym14061201