Effects of Secondary Porosity on Microstructure and Mechanical Properties of SAP-Containing Lime-Based Plasters

Abstract

:1. Introduction

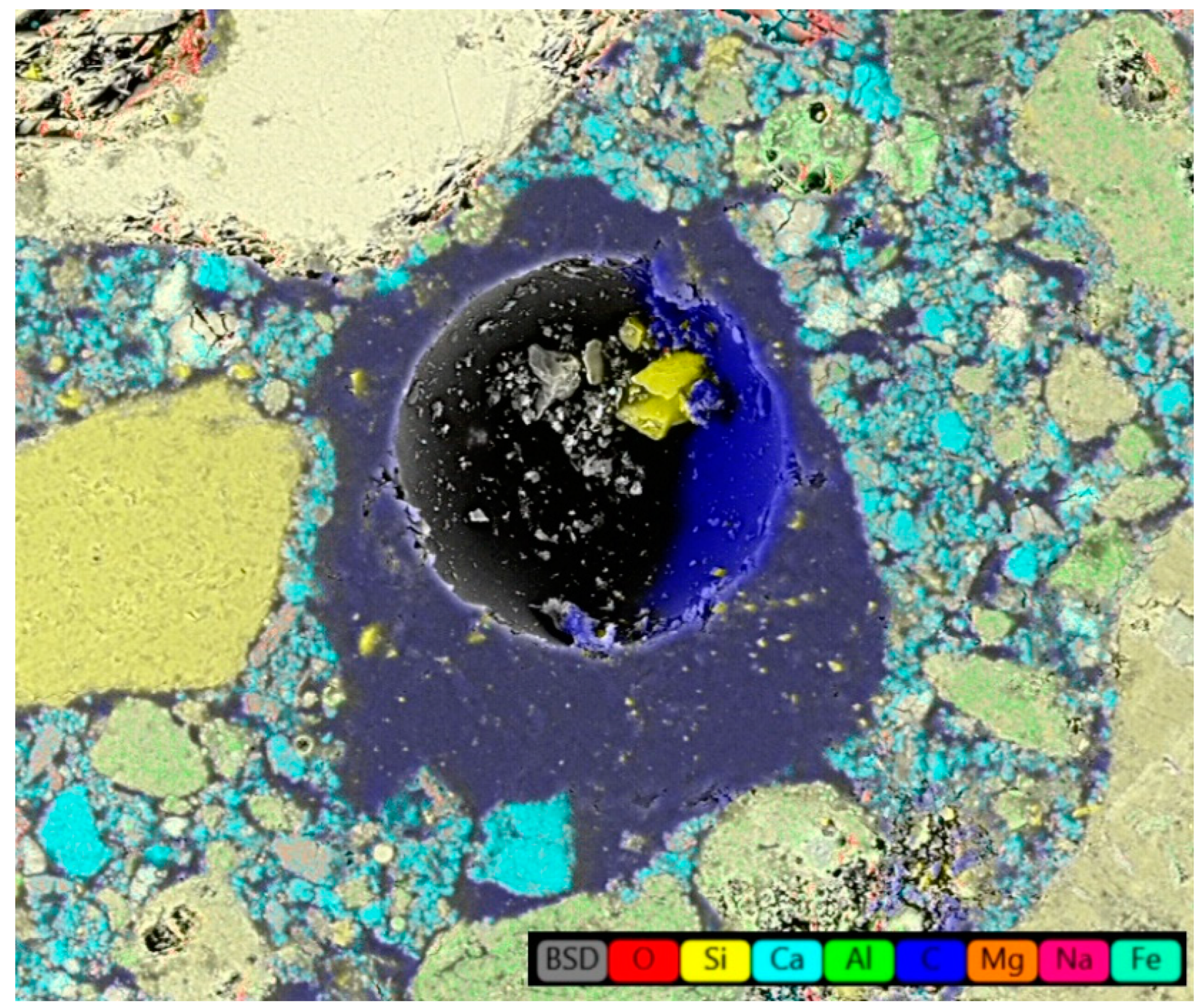

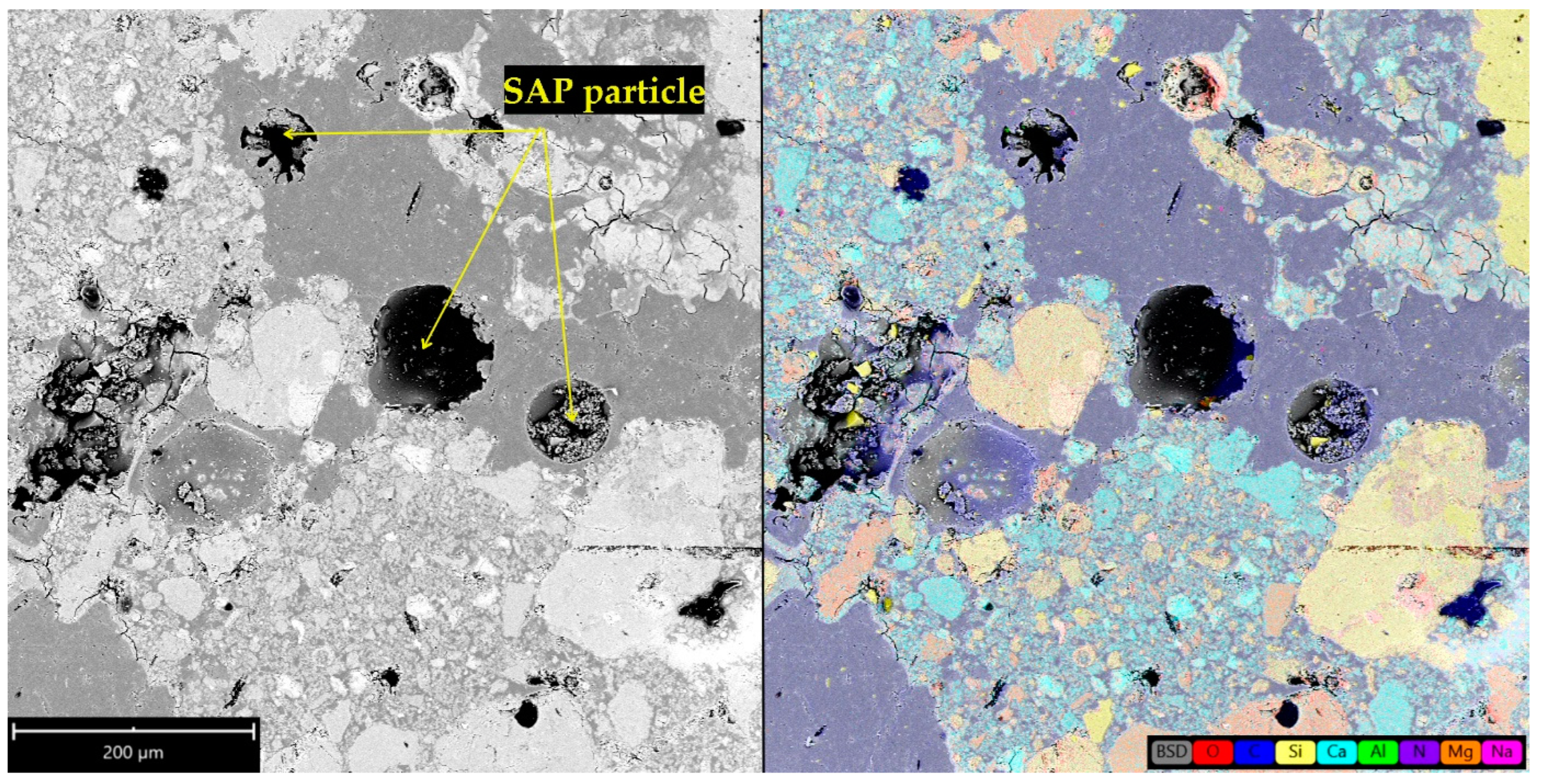

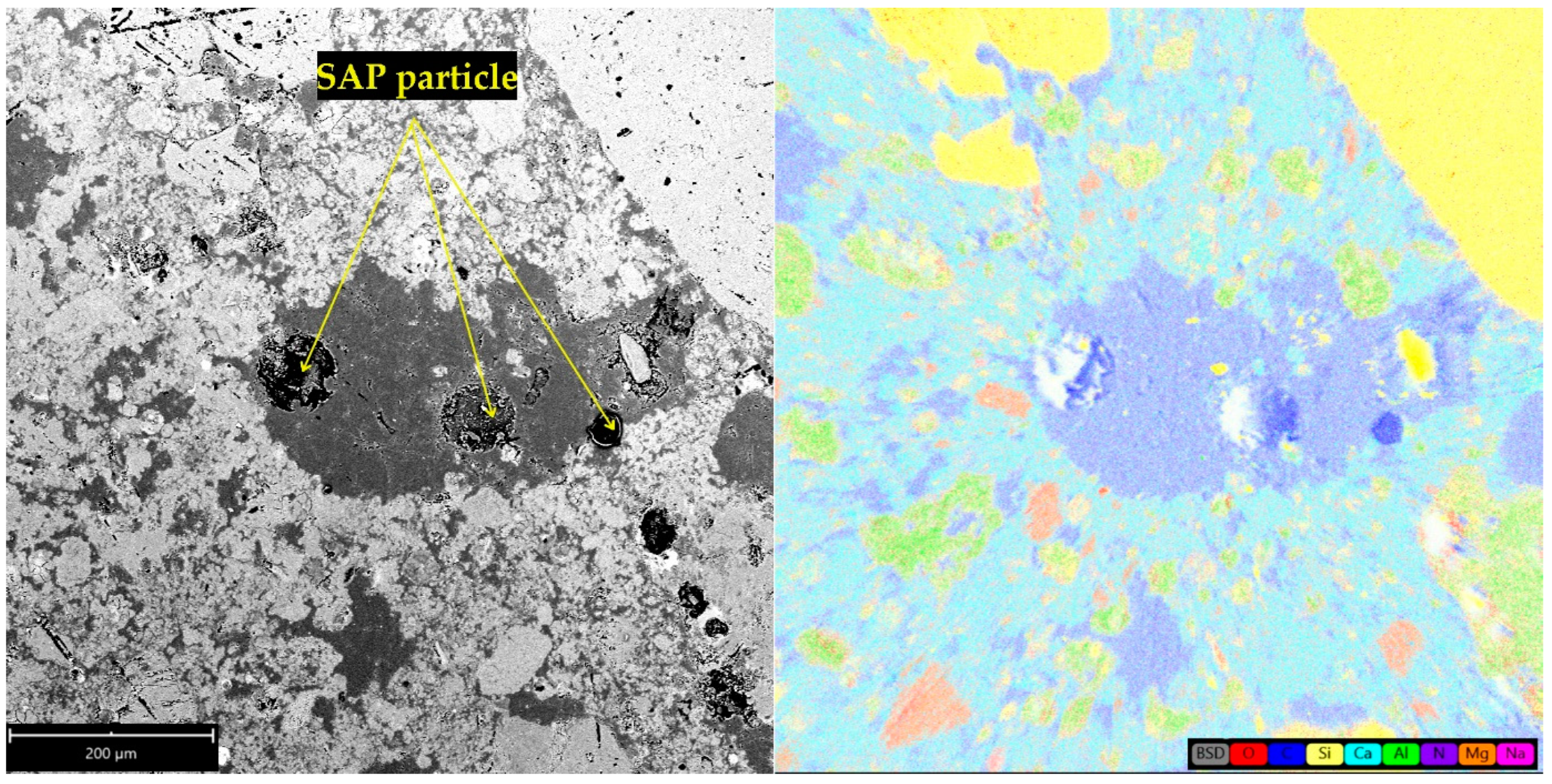

2. Materials and Methods

2.1. Materials

2.2. Experimental Methods

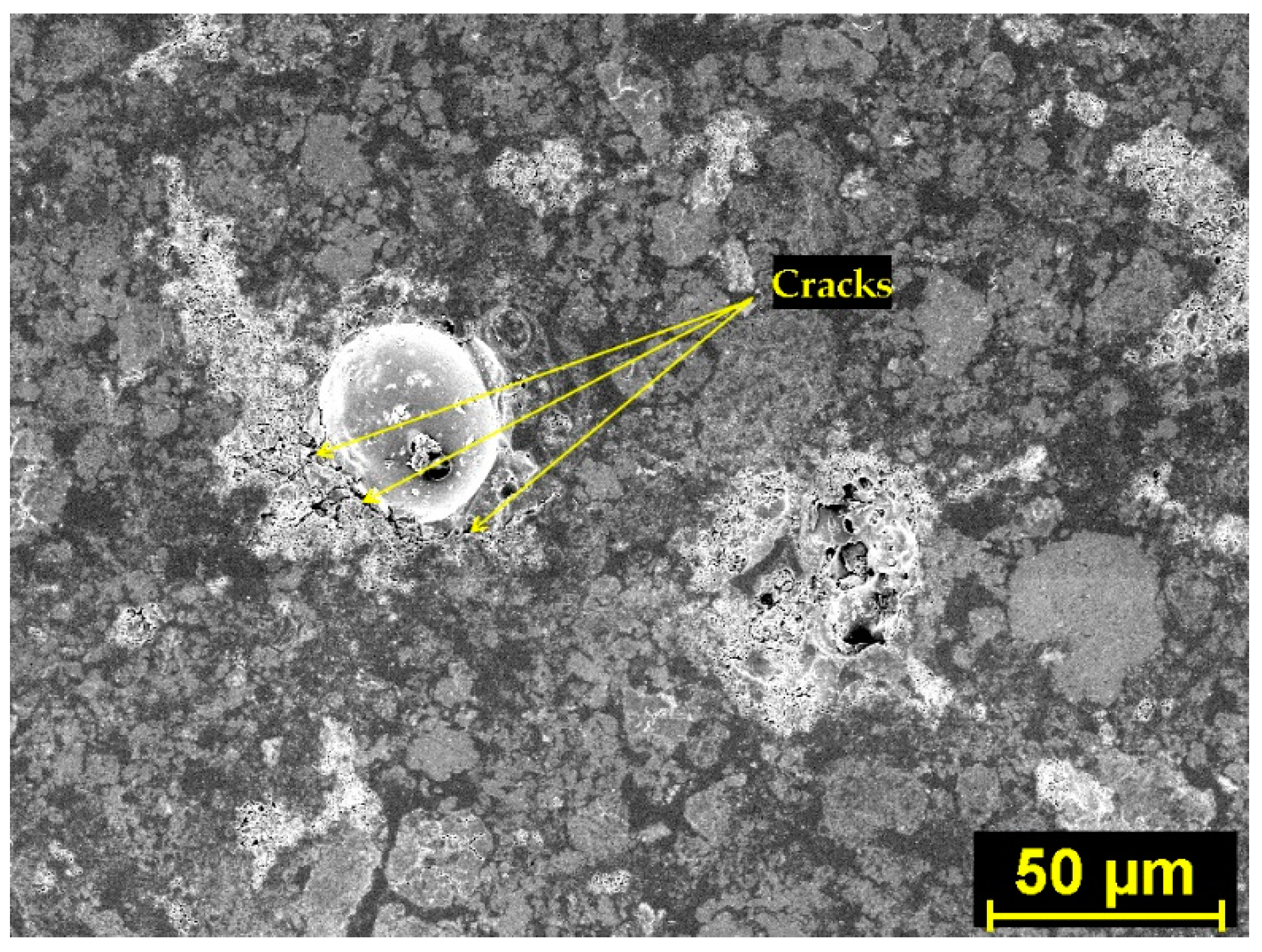

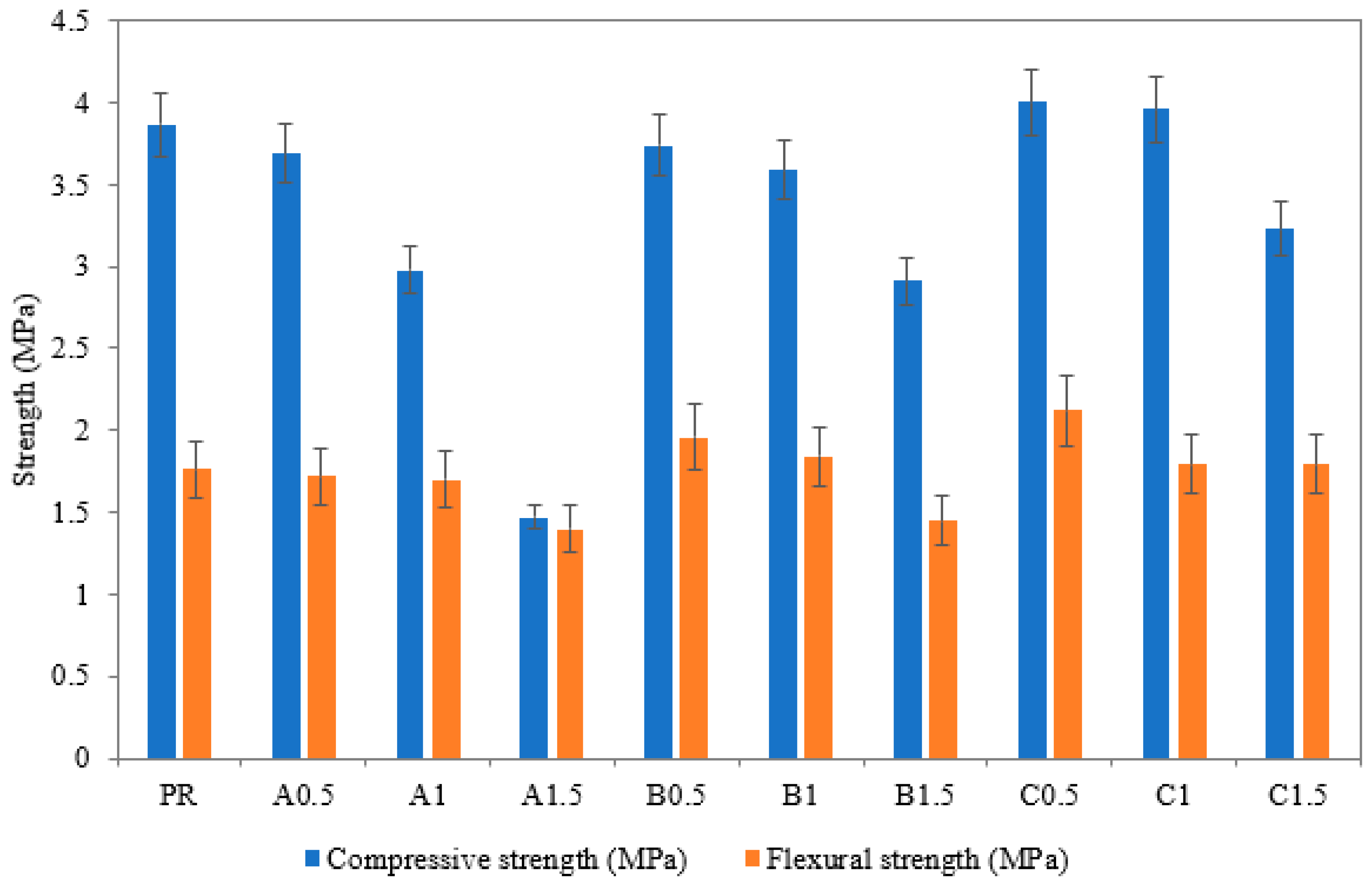

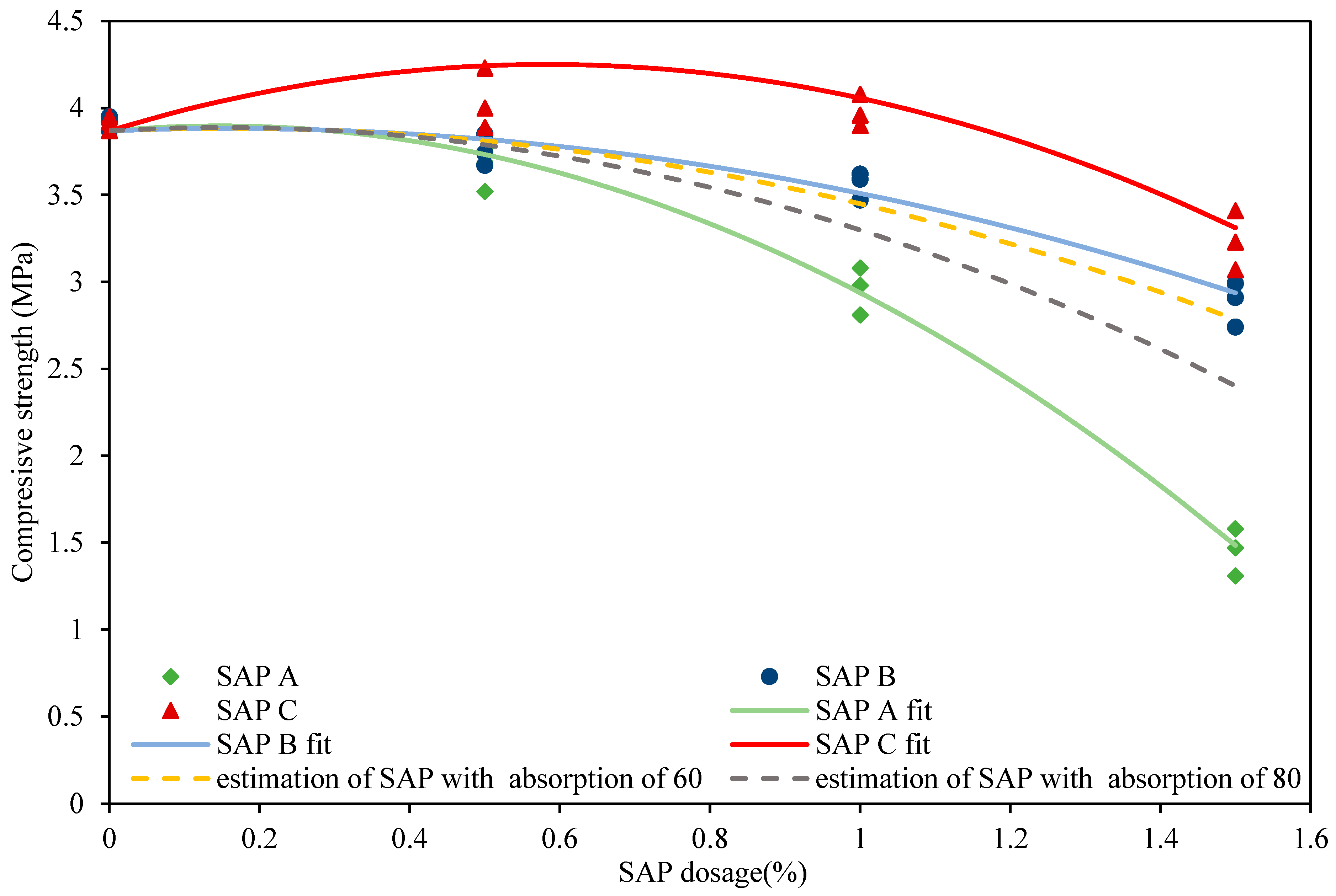

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fernandez, C.A.; Correa, M.; Nguyen, M.T.; Rod, K.A.; Dai, G.L.; Cosimbescu, L.; Rousseau, R.; Glezakou, V.A. Progress and challenges in self-healing cementitious materials. J. Mater. Sci. 2021, 56, 201–230. [Google Scholar] [CrossRef]

- Makul, N. Advanced smart concrete—A review of current progress, benefits and challenges. J. Clean. Prod. 2020, 274, 122899. [Google Scholar] [CrossRef]

- He, Z.M.; Shen, A.Q.; Guo, Y.C.; Lyu, Z.H.; Li, D.S.; Qin, X.; Zhao, M.; Wang, Z.L. Cement-based materials modified with superabsorbent polymers: A review. Constr. Build. Mater. 2019, 225, 569–590. [Google Scholar] [CrossRef]

- Lee, H.X.D.; Wong, H.S.; Buenfeld, N.R. Self-sealing of cracks in concrete using superabsorbent polymers. Cem. Concr. Res. 2016, 79, 194–208. [Google Scholar] [CrossRef] [Green Version]

- Hong, G.; Song, C.; Choi, S. Autogenous Healing of Early-Age Cracks in Cementitious Materials by Superabsorbent Polymers. Materials 2020, 13, 690. [Google Scholar] [CrossRef] [Green Version]

- Fort, J.; Koci, J.; Pokorny, J.; Cerny, R. Influence of Superabsorbent Polymers on Moisture Control in Building Interiors. Energies 2020, 13, 2009. [Google Scholar] [CrossRef]

- Fort, J.; Sal, J.; Koci, J.; Cerny, R. Energy Efficiency of Novel Interior Surface Layer with Improved Thermal Characteristics and Its Effect on Hygrothermal Performance of Contemporary Building Envelopes. Energies 2020, 13, 2012. [Google Scholar] [CrossRef] [Green Version]

- Vieira, J.; Senff, L.; Goncalves, H.; Silva, L.; Ferreira, V.M.; Labrincha, J.A. Functionalization of mortars for controlling the indoor ambient of buildings. Energy Build. 2014, 70, 224–236. [Google Scholar] [CrossRef]

- Senff, L.; Ascensao, G.; Hotza, D.; Ferreira, V.M.; Labrincha, J.A. Assessment of the single and combined effect of superabsorbent particles and porogenic agents in nanotitania-containing mortars. Energy Build. 2016, 127, 980–990. [Google Scholar] [CrossRef]

- Ma, S.W.; Huang, C.H.; Baah, P.; Nantung, T.; Lu, N. The influence of water-to-cement ratio and superabsorbent polymers (SAPs) on solid-like behaviors of fresh cement pastes. Constr. Build. Mater. 2021, 275, 122160. [Google Scholar] [CrossRef]

- Kanellopoulou, I.A.; Kartsonakis, I.A.; Charitidis, C.A. The Effect of Superabsorbent Polymers on the Microstructure and Self-Healing Properties of Cementitious-Based Composite Materials. Appl. Sci. 2021, 11, 700. [Google Scholar] [CrossRef]

- Luo, M.; Bai, J.Q.; Jing, K.; Ding, Z.Q.; Yang, D.Y.; Qian, C.X. Self-healing of early-age cracks in cement mortars with artificial functional aggregates. Constr. Build. Mater. 2021, 272, 121846. [Google Scholar] [CrossRef]

- Huang, H.L.; Ye, G. Self-healing of cracks in cement paste affected by additional Ca2+ ions in the healing agent. J. Intell. Mater. Syst. Struct. 2015, 26, 309–320. [Google Scholar] [CrossRef]

- Sidiq, A.; Gravina, R.; Setunge, S.; Giustozzi, F. The effectiveness of Super Absorbent polymers and superplasticizer in self-healing of cementitious materials. Constr. Build. Mater. 2020, 253, 15119175. [Google Scholar] [CrossRef]

- Zhao, S.Y.; Jensen, O.M.; Hasholt, M.T. Measuring absorption of superabsorbent polymers in cementitious environments. Mater. Struct. 2020, 53, 11. [Google Scholar] [CrossRef]

- Lefever, G.; Aggelis, D.G.; De Belie, N.; Raes, M.; Hauffman, T.; Van Hemelrijck, D.; Snoeck, D. The Influence of Superabsorbent Polymers and Nanosilica on the Hydration Process and Microstructure of Cementitious Mixtures. Materials 2020, 13, 5194. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.H.; Farzadnia, N.; Khayat, K.H.; Shi, C.J. Effects of SAP characteristics on internal curing of UHPC matrix. Constr. Build. Mater. 2021, 280, 122530. [Google Scholar] [CrossRef]

- Reis, P.F.O.; Evangelista, F.E.; Silva, E.F. Profile of internal relative humidity and depth of drying in cementitious materials containing superabsorbent polymer and nano-silica particles. Constr. Build. Mater. 2020, 237, 117412. [Google Scholar] [CrossRef]

- Yang, L.; Shi, C.J.; Wu, Z.M. Mitigation techniques for autogenous shrinkage of ultra-high-performance concrete—A review. Compos. Part B-Eng. 2019, 178, 107456. [Google Scholar] [CrossRef]

- Yang, J.B.; Sun, Z.P.; Zhao, Y.H.; Ji, Y.L.; Li, B.Y. The Water Absorption-release of Superabsorbent Polymers in Fresh Cement Paste: An NMR Study. J. Adv. Concr. Technol. 2020, 18, 139–145. [Google Scholar] [CrossRef] [Green Version]

- Mechtcherine, V.; Snoeck, D.; Schroefl, C.; De Belie, N.; Klemm, A.J.; Ichimiya, K.; Moon, J.; Wyrzykowski, M.; Lura, P.; Toropovs, N.; et al. Testing superabsorbent polymer (SAP) sorption properties prior to implementation in concrete: Results of a RILEM Round-Robin Test. Mater. Struct. 2018, 51, 28. [Google Scholar] [CrossRef]

- Senff, L.; Modolo, R.C.E.; Ascensao, G.; Hotza, D.; Ferreira, V.M.; Labrincha, J.A. Development of mortars containing superabsorbent polymer. Constr. Build. Mater. 2015, 95, 575–584. [Google Scholar] [CrossRef]

- Goncalves, H.; Goncalves, B.; Silva, L.; Raupp-Pereira, F.; Senff, L.; Labrincha, J.A. Development of porogene-containing mortars for levelling the indoor ambient moisture. Ceram. Int. 2014, 40, 15489–15495. [Google Scholar] [CrossRef]

- Goncalves, H.; Goncalves, B.; Silva, L.; Vieira, N.; Raupp-Pereira, F.; Senff, L.; Labrincha, J.A. The influence of porogene additives on the properties of mortars used to control the ambient moisture. Energy Build. 2014, 74, 61–68. [Google Scholar] [CrossRef]

- Isikdag, B.; Topcu, I.B. The effect of ground granulated blast-furnace slag on properties of Horasan mortar. Constr. Build. Mater. 2013, 40, 448–454. [Google Scholar] [CrossRef]

- Fort, J.; Madera, J.; Hotek, P.; Mildner, M.; Cerny, R. Optimization of Concrete Mixture Composition with Superabsorbent Polymer Admixture. In Proceedings of the International Conference on Numerical Analysis and Applied Mathematics (ICNAAM), Rhodes, Greece, 23–28 September 2019; Volume 2293. [Google Scholar] [CrossRef]

- Tenorio, J.R.; Snoeck, D.; De Belie, N. Mixing protocols for plant-scale production of concrete with superabsorbent polymers. Struct. Concr. 2020, 21, 983–991. [Google Scholar] [CrossRef]

- Kang, S.H.; Hong, S.G.; Moon, J. The effect of superabsorbent polymer on various scale of pore structure in ultra-high performance concrete. Constr. Build. Mater. 2018, 172, 29–40. [Google Scholar] [CrossRef]

- Choi, H.; Inoue, M.; Kim, D.; Sengoku, R. Effect of Addition of Ca2+ and CO32− Ions with Temperature Control on Self-Healing of Hardened Cement Paste. Materials 2019, 12, 2456. [Google Scholar] [CrossRef] [Green Version]

- Hu, M.M.; Guo, J.T.; Du, J.B.; Liu, Z.X.; Li, P.P.; Ren, X.K.; Feng, Y.K. Development of Ca2+-based, ion-responsive superabsorbent hydrogel for cement applications: Self-healing and compressive strength. J. Colloid Interface Sci. 2019, 538, 397–403. [Google Scholar] [CrossRef]

- Schrofl, C.; Mechtcherine, V.; Gorges, M. Relation between the molecular structure and the efficiency of superabsorbent polymers (SAP) as concrete admixture to mitigate autogenous shrinkage. Cem. Concr. Res. 2012, 42, 865–873. [Google Scholar] [CrossRef]

- Zhu, Q.; Barney, C.W.; Erk, K.A. Effect of ionic crosslinking on the swelling and mechanical response of model superabsorbent polymer hydrogels for internally cured concrete. Mater. Struct. 2015, 48, 2261–2276. [Google Scholar] [CrossRef]

- Yang, J.; Wang, F.Z.; He, X.Y.; Su, Y. Pore structure of affected zone around saturated and large superabsorbent polymers in cement paste. Cem. Concr. Compos. 2019, 97, 54–67. [Google Scholar] [CrossRef]

- Wang, F.Z.; Yang, J.; Hu, S.G.; Li, X.P.; Cheng, H. Influence of superabsorbent polymers on the surrounding cement paste. Cem. Concr. Res. 2016, 81, 112–121. [Google Scholar] [CrossRef]

- Snoeck, D.; Pel, L.; De Belie, N. Comparison of different techniques to study the nanostructure and the microstructure of cementitious materials with and without superabsorbent polymers. Constr. Build. Mater. 2019, 223, 244–253. [Google Scholar] [CrossRef]

- Liu, H.Z.; Zhang, Q.; Gu, C.S.; Su, H.Z.; Li, V. Influence of microcrack self-healing behavior on the permeability of Engineered Cementitious Composites. Cem. Concr. Compos. 2017, 82, 14–22. [Google Scholar] [CrossRef]

- Atahan, H.N.; Oktar, O.N.; Tasdemir, M.A. Effects of water-cement ratio and curing time on the critical pore width of hardened cement paste. Constr. Build. Mater. 2009, 23, 1196–1200. [Google Scholar] [CrossRef]

- Ma, X.W.; Liu, J.H.; Wu, Z.M.; Shi, C.J. Effects of SAP on the properties and pore structure of high performance cement-based materials. Constr. Build. Mater. 2017, 131, 476–484. [Google Scholar] [CrossRef]

- Jung, A.; Endres, M.B.; Weichold, O. Influence of Environmental Factors on the Swelling Capacities of Superabsorbent Polymers Used in Concrete. Polymers 2020, 12, 2185. [Google Scholar] [CrossRef]

- Farzanian, K.; Ghahremaninezhad, A. Desorption of superabsorbent hydrogels with varied chemical compositions in cementitious materials. Mater. Struct. 2018, 51, 15. [Google Scholar] [CrossRef]

- Wehbe, Y.; Ghahremaninezhad, A. Combined effect of shrinkage reducing admixtures (SRA) and superabsorbent polymers (SAP) on the autogenous shrinkage, hydration and properties of cementitious materials. Constr. Build. Mater. 2017, 138, 151–162. [Google Scholar] [CrossRef]

- Krafcik, M.J.; Erk, K.A. Characterization of superabsorbent poly(sodium-acrylate acrylamide) hydrogels and influence of chemical structure on internally cured mortar. Mater. Struct. 2016, 49, 4765–4778. [Google Scholar] [CrossRef]

- Patra, S.K.; Swain, S.K. Swelling Study of Superabsorbent PAA-co-PAM/Clay Nanohydrogel. J. Appl. Polym. Sci. 2011, 120, 1533–1538. [Google Scholar] [CrossRef]

- Snoeck, D.; Dewanckele, J.; Cnudde, V.; De Belie, N. X-ray computed microtomography to study autogenous healing of cementitious materials promoted by superabsorbent polymers. Cem. Concr. Compos. 2016, 65, 83–93. [Google Scholar] [CrossRef]

- Zhong, P.H.; Wyrzykowski, M.; Toropovs, N.; Li, L.; Liu, J.P.; Lura, P. Internal curing with superabsorbent polymers of different chemical structures. Cem. Concr. Res. 2019, 123, 105789. [Google Scholar] [CrossRef]

- Tan, Y.W.; Chen, H.X.; Wang, Z.D.; Xue, C.; He, R. Performances of Cement Mortar Incorporating Superabsorbent Polymer (SAP) Using Different Dosing Methods. Materials 2019, 12, 1619. [Google Scholar] [CrossRef] [Green Version]

- Danish, A.; Mosaberpanah, M.A.; Salim, M.U. Robust evaluation of superabsorbent polymers as an internal curing agent in cementitious composites. J. Mater. Sci. 2021, 56, 136–172, Review. [Google Scholar] [CrossRef]

- Paul, A.; Murgadas, S.; Delpiano, J.; Moreno-Casas, P.A.; Walczak, M.; Lopez, M. The role of moisture transport mechanisms on the performance of lightweight aggregates in internal curing. Constr. Build. Mater. 2021, 268, 121191. [Google Scholar] [CrossRef]

- Dang, J.T.; Zhao, J.; Du, Z.H. Effect of Superabsorbent Polymer on the Properties of Concrete. Polymers 2017, 9, 672. [Google Scholar] [CrossRef] [Green Version]

- Shen, D.J.; Wang, X.D.; Cheng, D.B.; Zhang, J.Y.; Jiang, G.Q. Effect of internal curing with super absorbent polymers on autogenous shrinkage of concrete at early age. Constr. Build. Mater. 2016, 106, 512–522. [Google Scholar] [CrossRef]

- Guo, S.C.; Forooshani, P.K.; Dai, Q.L.; Lee, B.P.; Si, R.Z.; Wang, J.Q. Design of pH-responsive SAP polymer for pore solution chemistry regulation and crack sealing in cementitious materials. Compos. Part B-Eng. 2020, 199, 108262. [Google Scholar] [CrossRef]

- Gwon, S.; Ahn, E.; Shin, M. Water permeability and rapid self-healing of sustainable sulfur composites using superabsorbent polymer and binary cement. Constr. Build. Mater. 2020, 265, 120306. [Google Scholar] [CrossRef]

- Olawuyi, B.J.; Babafemi, A.J.; Boshoff, W.P. Early-age and long-term strength development of high-performance concrete with SAP. Constr. Build. Mater. 2021, 267, 121798. [Google Scholar] [CrossRef]

- Tan, Y.W.; Lu, X.S.; He, R.; Chen, H.X.; Wang, Z.J. Influence of superabsorbent polymers (SAPs) type and particle size on the performance of surrounding cement-based materials. Constr. Build. Mater. 2021, 270, 121442. [Google Scholar] [CrossRef]

| Particle Size (µm) | Density (kg/m3) | Water Absorption Capacity (g/g) | Cross-Linking (wt.%) | Base | |

|---|---|---|---|---|---|

| SAP A | 285 | 600 | 128 | 1.2 | acrylamide/acrylic acid potassium salt |

| SAP B | 32 | 690 | 52 | 1 | sodium polyacrylate |

| SAP C | 84 | 605 | 45 | 0.3 | acrylamide/acrylic acid + sodium salt |

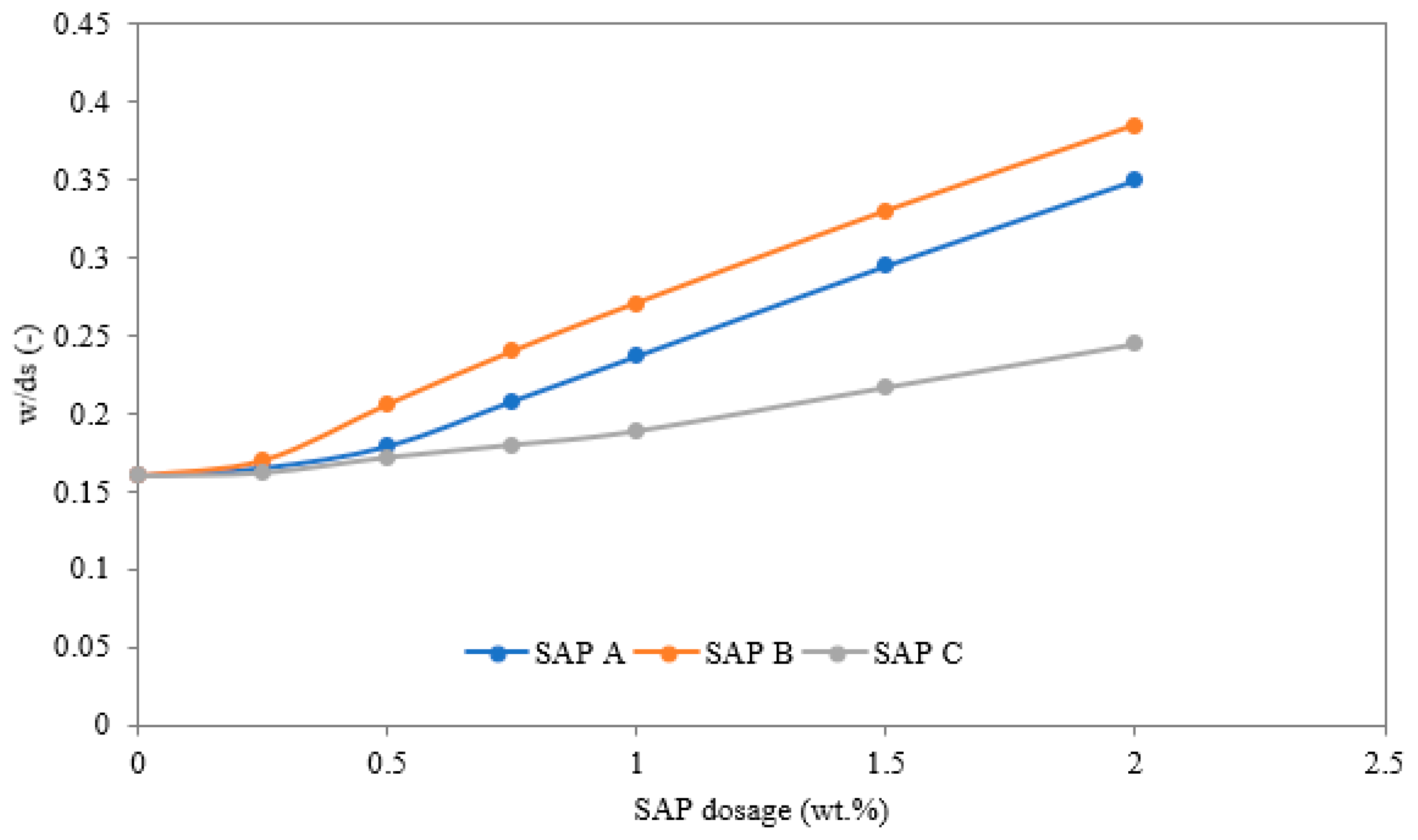

| Mixture | Dry Plaster Mixture (kg/m3) | w/ds | SAP |

|---|---|---|---|

| (-) | |||

| PR | 1351 | 0.16 | - |

| A0.5 | 1255 | 0.177 | 0.5% |

| A1 | 1161 | 0.225 | 1.0% |

| A1.5 | 1060 | 0.276 | 1.5% |

| B0.5 | 1230 | 0.205 | 0.5% |

| B1 | 1117 | 0.271 | 1.0% |

| B1.5 | 1004 | 0.326 | 1.5% |

| C0.5 | 1274 | 0.167 | 0.5% |

| C1 | 1277 | 0.175 | 1.0% |

| C1.5 | 1185 | 0.189 | 1.5% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fořt, J.; Böhm, M.; Medveď, I.; Mildner, M.; Černý, R. Effects of Secondary Porosity on Microstructure and Mechanical Properties of SAP-Containing Lime-Based Plasters. Polymers 2022, 14, 1162. https://doi.org/10.3390/polym14061162

Fořt J, Böhm M, Medveď I, Mildner M, Černý R. Effects of Secondary Porosity on Microstructure and Mechanical Properties of SAP-Containing Lime-Based Plasters. Polymers. 2022; 14(6):1162. https://doi.org/10.3390/polym14061162

Chicago/Turabian StyleFořt, Jan, Martin Böhm, Igor Medveď, Martin Mildner, and Robert Černý. 2022. "Effects of Secondary Porosity on Microstructure and Mechanical Properties of SAP-Containing Lime-Based Plasters" Polymers 14, no. 6: 1162. https://doi.org/10.3390/polym14061162

APA StyleFořt, J., Böhm, M., Medveď, I., Mildner, M., & Černý, R. (2022). Effects of Secondary Porosity on Microstructure and Mechanical Properties of SAP-Containing Lime-Based Plasters. Polymers, 14(6), 1162. https://doi.org/10.3390/polym14061162