Towards Circular Economy by the Valorization of Different Waste Subproducts through Their Incorporation in Composite Materials: Ground Tire Rubber and Chicken Feathers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Composite Preparation

2.3. Tensile Tests

2.4. Structural Characterization by Fourier Transform Infrared Spectroscopy (FTIR)

2.5. Characterization by Scanning Electron Microscopy (SEM)

2.6. Characterization by Thermogravimetricy Analysis (TGA)

2.7. Characterization of Acoustic Properties by Impedance Tube

3. Results and Discussion

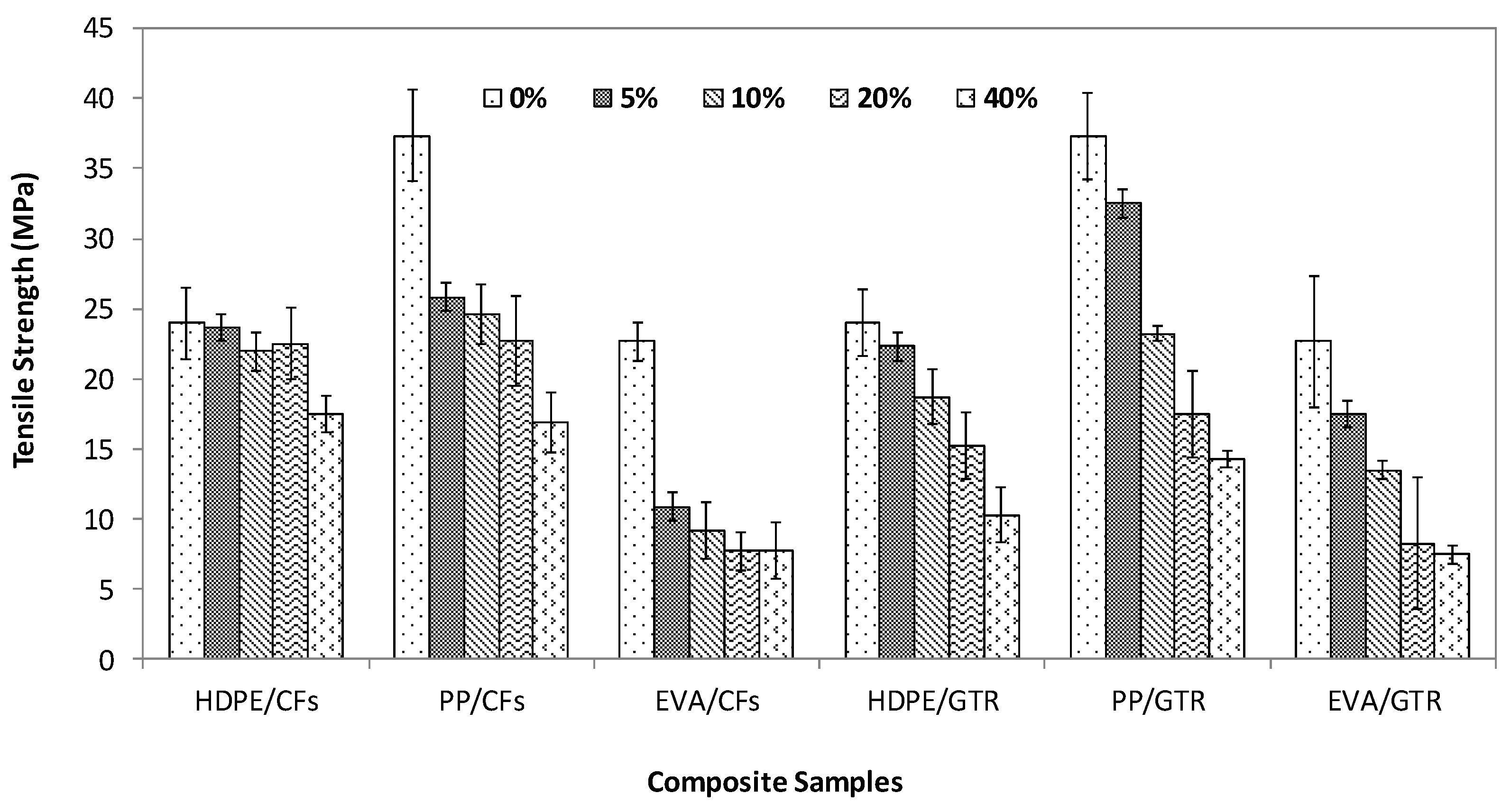

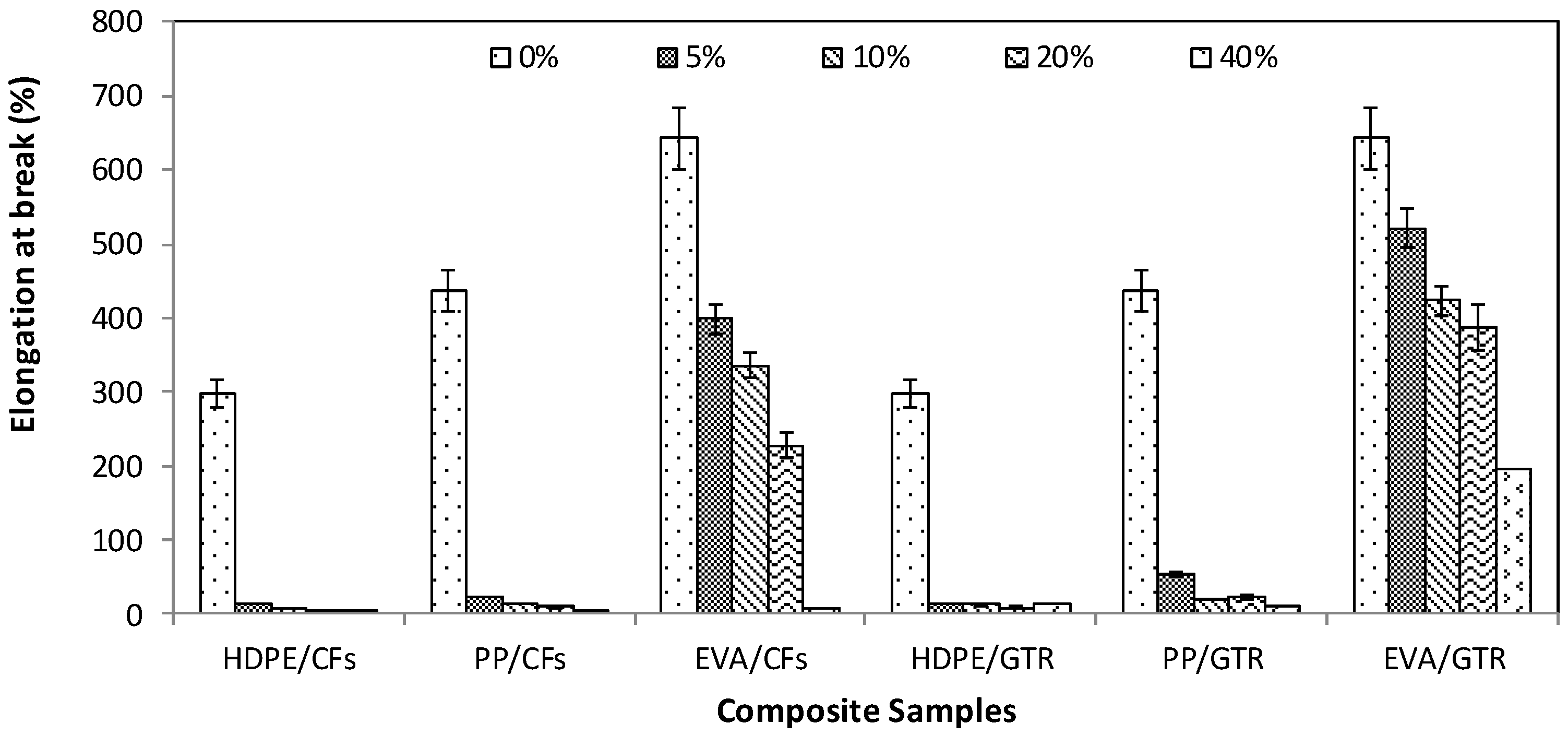

3.1. Mechanical Properties

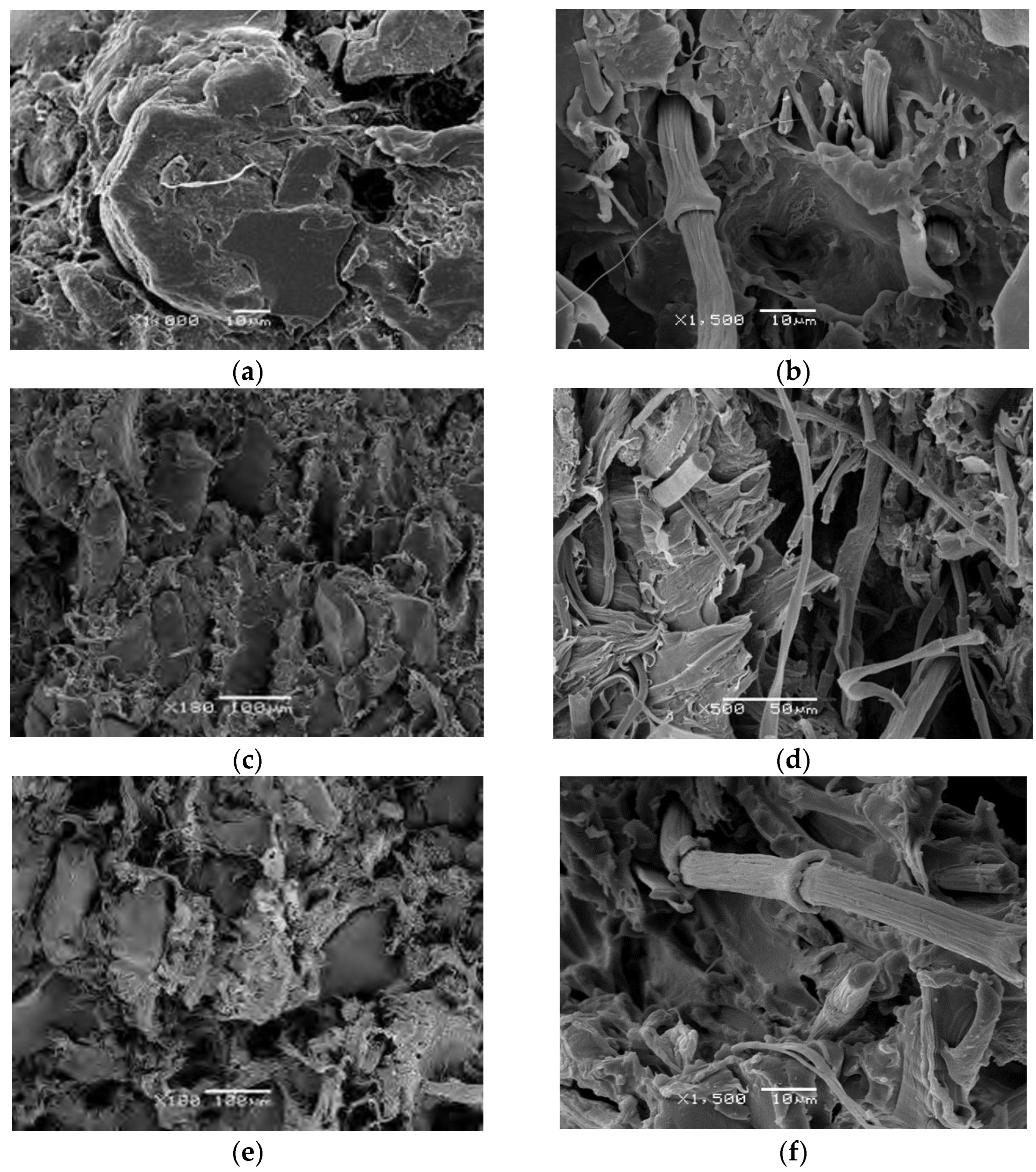

3.2. SEM Characterization of Interfacial Adhesion

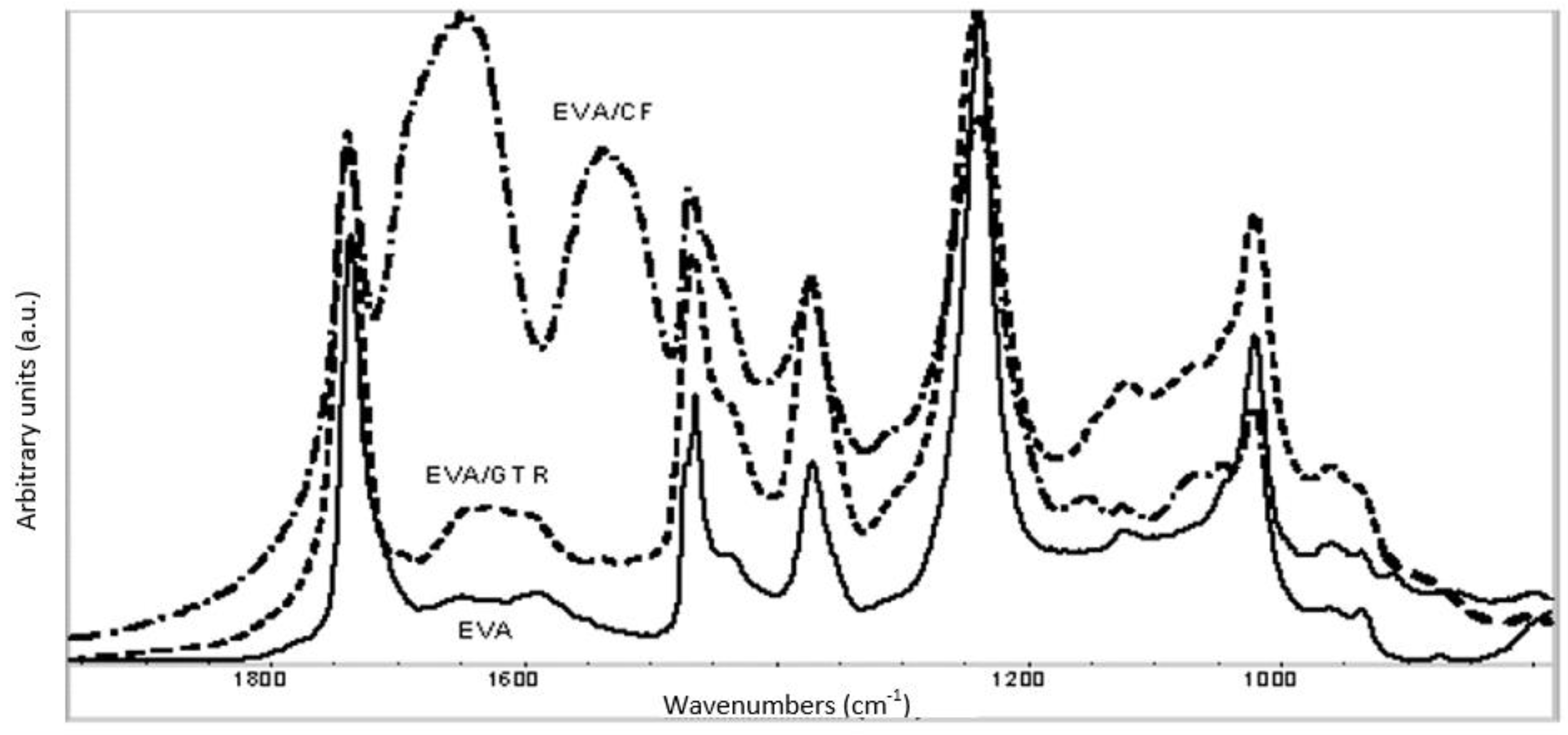

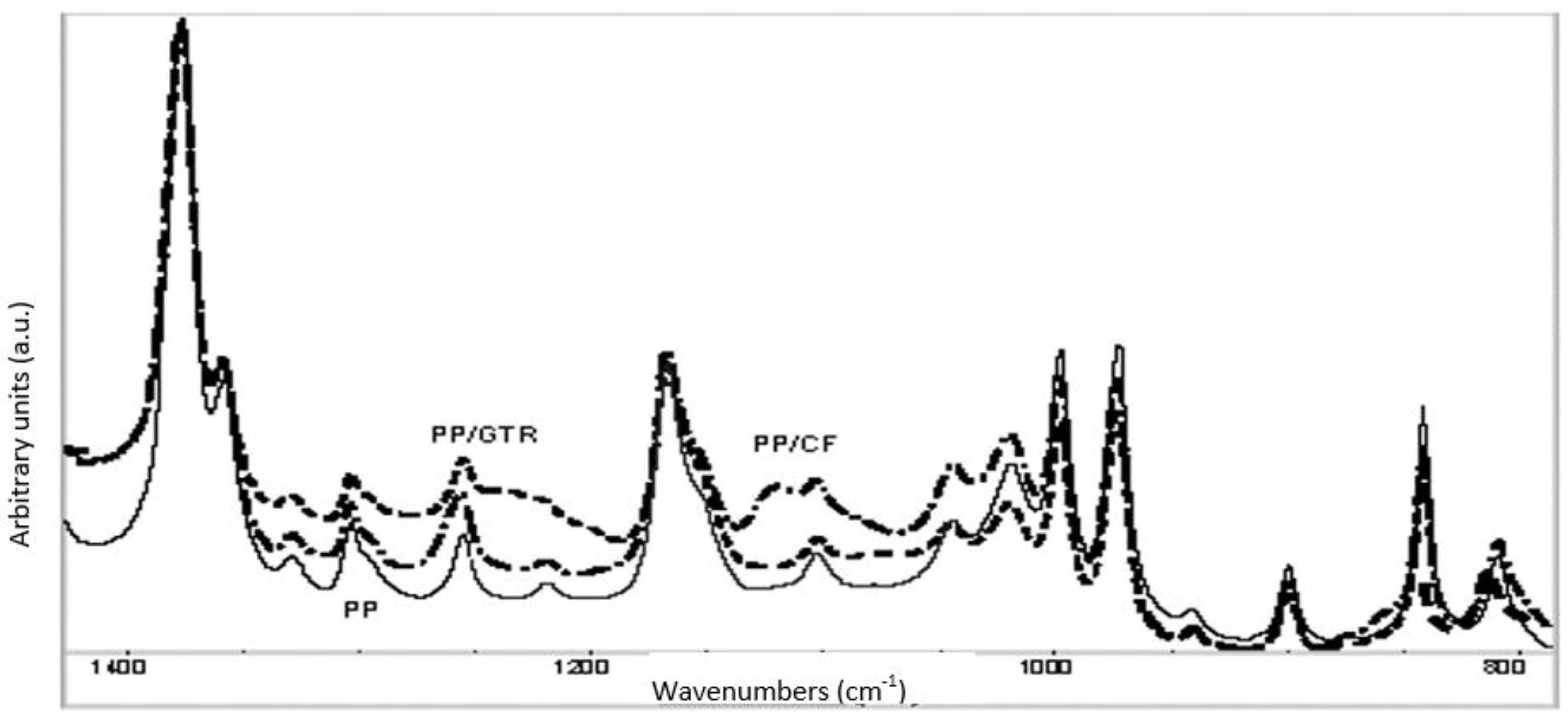

3.3. FTIR Characterization

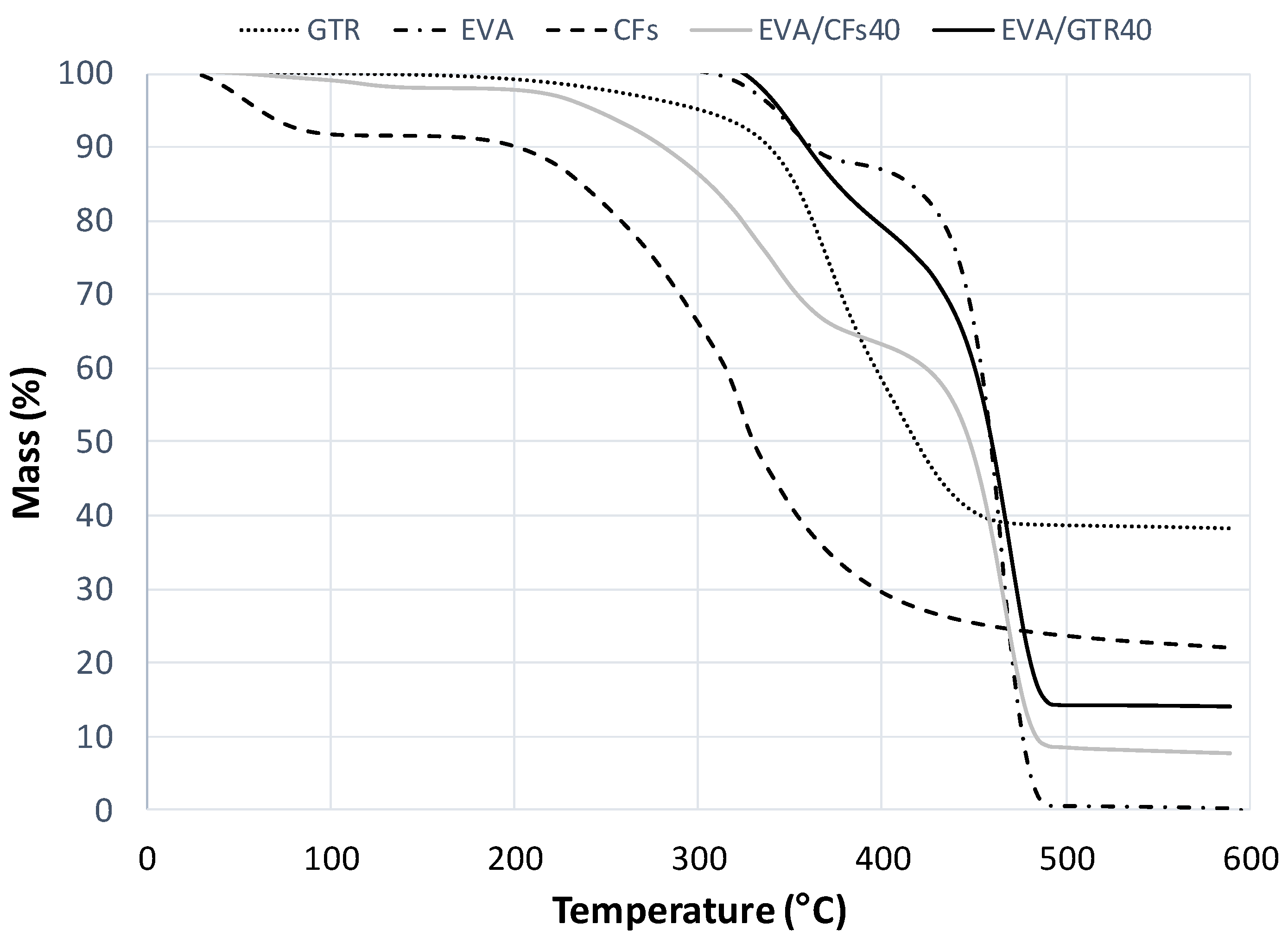

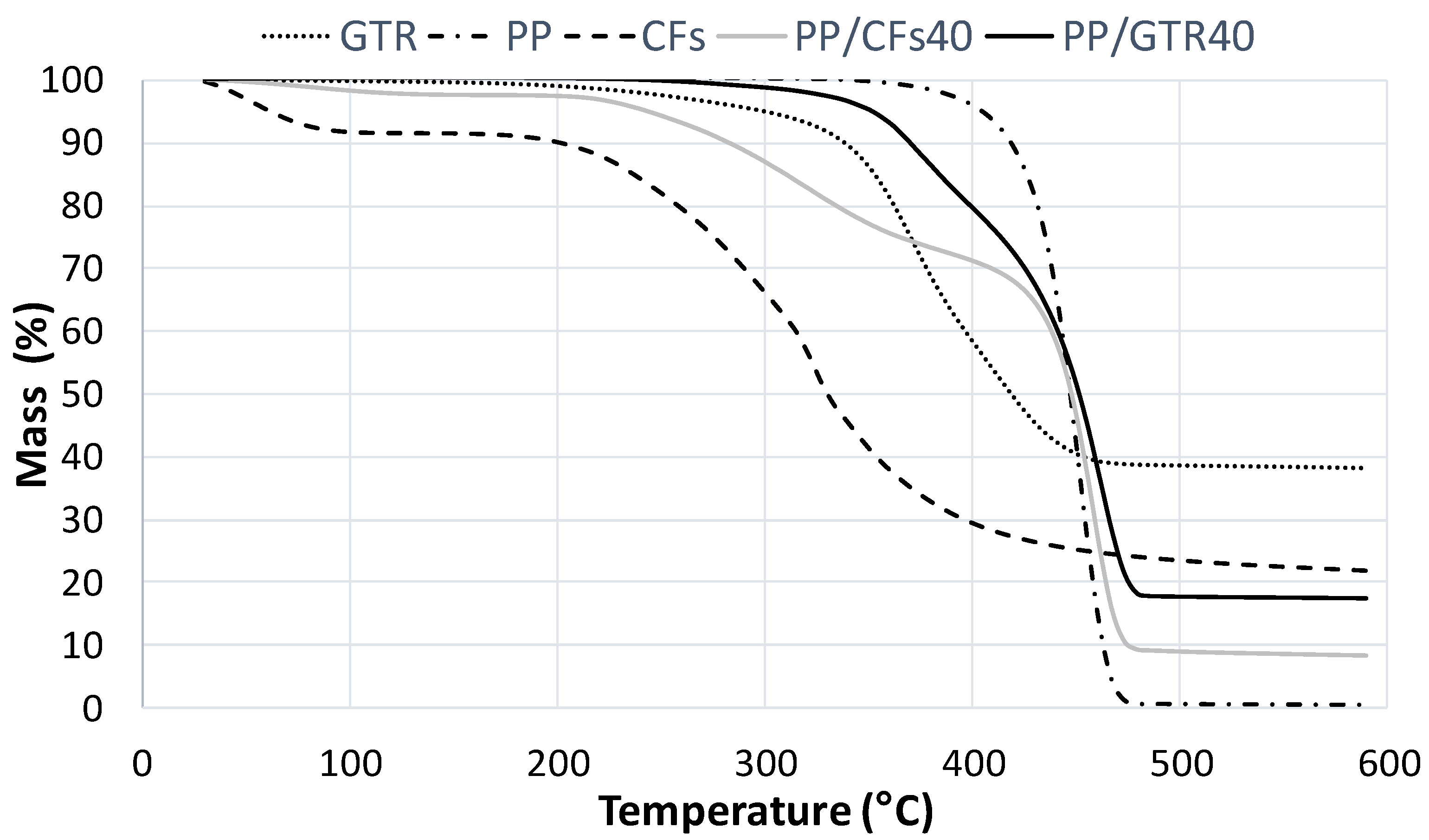

3.4. Thermogravimetric Analysis (TGA)

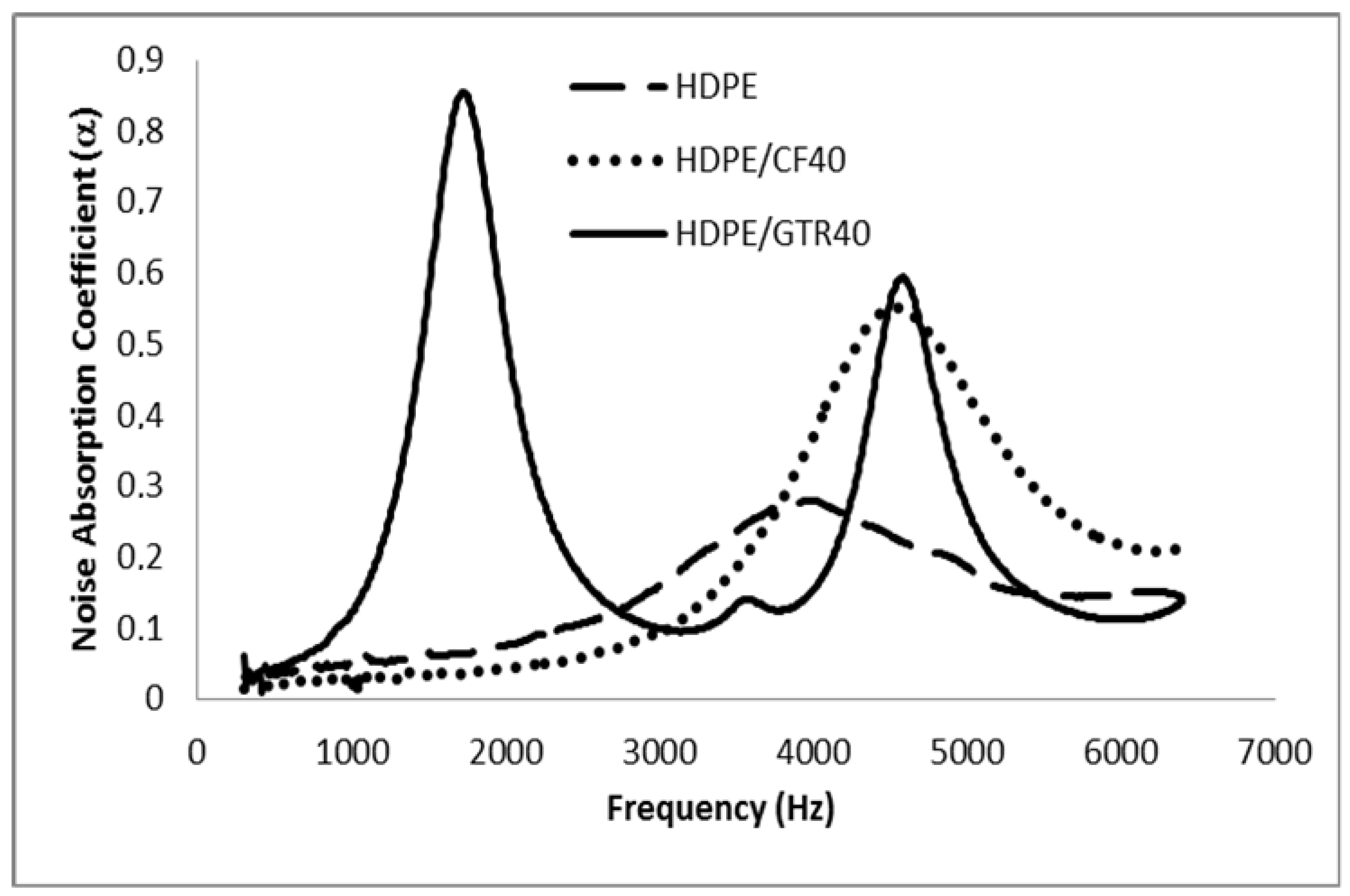

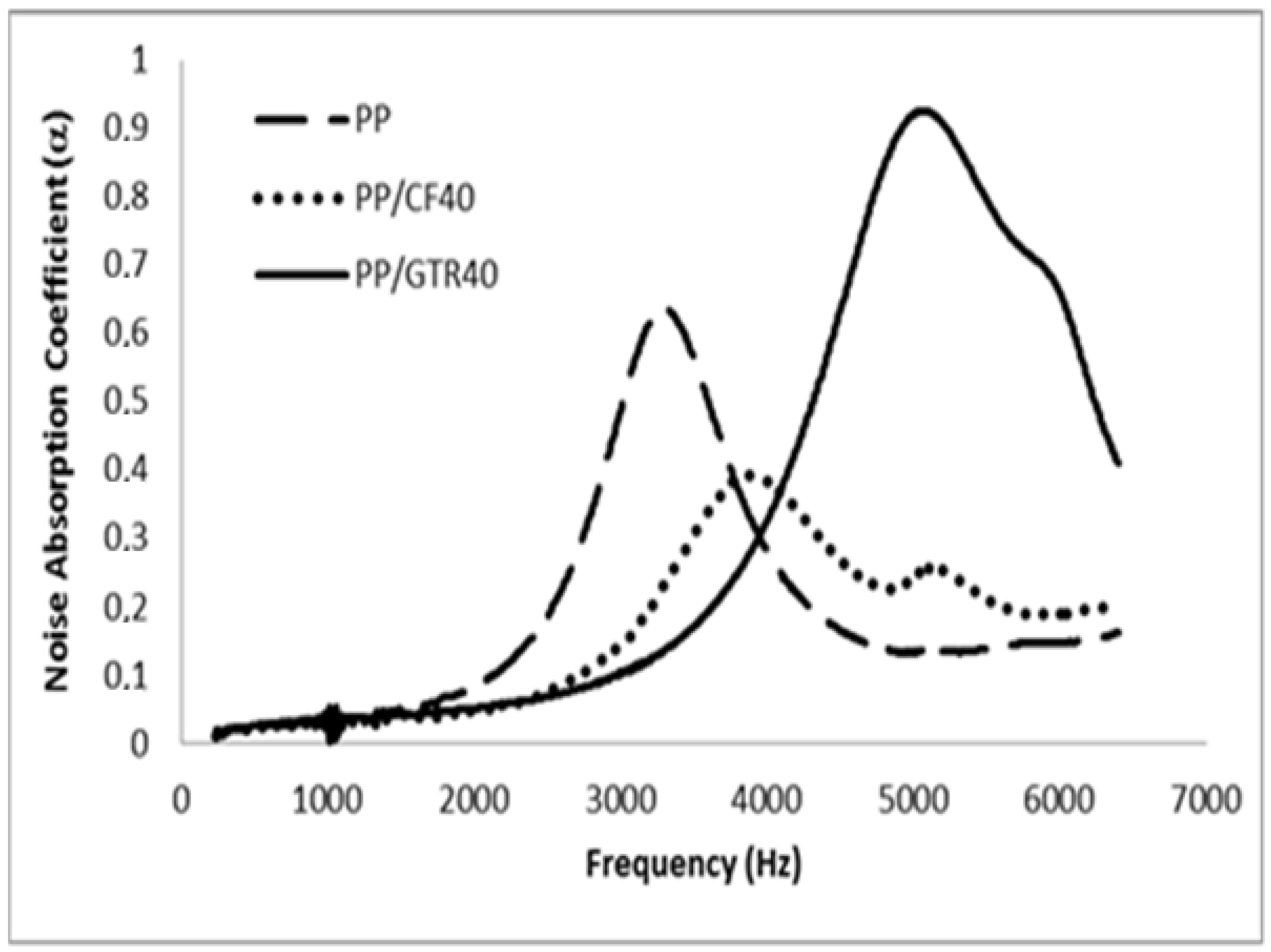

3.5. Acoustical Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Blanco, I.; Siracusa, V. The Use of Thermal Techniques in the Characterization of Bio-Sourced Polymers. Materials 2021, 14, 1686. [Google Scholar] [CrossRef] [PubMed]

- Blanco, I.; Ingrao, C.; Siracusa, V. Life-Cycle Assessment in the Polymeric Sector: A Comprehensive Review of Application Experiences on the Italian Scale. Polymers 2020, 12, 1212. [Google Scholar] [CrossRef] [PubMed]

- Roy, P.S.; Garnier, G.; Allais, F.; Saito, K. Strategic Approach Towards Plastic Waste Valorization: Challenges and Promising Chemical Upcycling Possibilities. ChemSusChem 2021, 14, 4007–4027. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.-L.; He, P.-J.; Peng, W.; Yi, S.-X.; Lü, F.; Shao, L.-M.; Zhang, H. Upcycling waste polyvinyl chloride: One-pot synthesis of valuable carbon materials and pipeline-quality syngas via pyrolysis in a closed reactor. J. Hazard. Mater. 2022, 427, 128210. [Google Scholar] [CrossRef]

- Schüch, A.; Morscheck, G.; Nelles, M. Technological Options for Biogenic Waste and Residues-Overview of Current Solutions and Developments. In Waste Valorisation and Recycling; Ghosh, S., Ed.; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar] [CrossRef]

- Shen, L.; Worrell, E. Chapter 13—Plastic Recycling. In Handbook of Recycling; Worrell, E., Reuter, M.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 179–190. [Google Scholar] [CrossRef]

- Zhao, X.; Boruah, B.; Chin, K.F.; Đokić, M.; Modak, J.M.; Soo, H.S. Upcycling to Sustainably Reuse Plastics. Adv. Mater. 2021, 2100843. [Google Scholar] [CrossRef]

- Ashori, A. Hybrid Composites from Waste Materials. J. Polym. Environ. 2009, 18, 65–70. [Google Scholar] [CrossRef]

- Seghiri, M.; Boutoutaou, D.; Kriker, A.; Hachani, M.I. The Possibility of Making a Composite Material from Waste Plastic. Energy Procedia 2017, 119, 163–169. [Google Scholar] [CrossRef]

- Mohammed, L.; Ansari, M.N.M.; Pua, G.; Jawaid, M.; Islam, M.S. A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. Int. J. Polym. Sci. 2015, 2015, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Girijappa, Y.G.T.; Rangappa, S.M.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review. Front. Mater. 2019, 6, 226. [Google Scholar] [CrossRef]

- Davoodi, M.; Sapuan, M.S.; Ahmad, D.; Aidy, A.; Ali, A.; Jonoobi, M. Concept selection of car bumper beam with developed hybrid bio-composite material. Mater. Des. 2011, 32, 4857–4865. [Google Scholar] [CrossRef]

- Senthilkumar, K.; Saba, N.; Rajini, N.; Chandrasekar, M.; Jawaid, M.; Siengchin, S.; Alotman, O.Y. Mechanical properties evaluation of sisal fibre reinforced polymer composites: A review. Constr. Build. Mater. 2018, 174, 713–729. [Google Scholar] [CrossRef]

- Girge, A.; Goel, V.; Gupta, G.; Fuloria, D.; Pati, P.R.; Sharma, A.; Mishra, V.K. Industrial waste filled polymer composites—A review. Mater. Today Proc. 2021, 47, 2852–2863. [Google Scholar] [CrossRef]

- Tasnim, S.; Shaikh, F.U.A. Effect of chemical exposure on mechanical properties and microstructure of lightweight polymer composites containing solid waste fillers. Constr. Build. Mater. 2021, 309, 125192. [Google Scholar] [CrossRef]

- Mujal-Rosas, R.; Orrit-Prat, J.; Ramis-Juan, X.; Marin-Genesca, M.; Rahhali, A. Study on Dielectric, Mechanical and Thermal Properties of Polypropylene (PP) Composites with Ground Tyre Rubber (GTR). Polym. Polym. Compos. 2012, 20, 797–808. [Google Scholar] [CrossRef]

- Colom, X.; Cañavate, J.; Carrillo, F.; Lis, M. Acoustic and mechanical properties of recycled polyvinyl chloride/ground tyre rubber composites. J. Compos. Mater. 2013, 48, 1061–1069. [Google Scholar] [CrossRef]

- Sienkiewicz, M.; Janik, H.; Borzędowska-Labuda, K.; Kucinska-Lipka, J. Environmentally friendly polymer-rubber composites obtained from waste tyres: A review. J. Clean. Prod. 2017, 147, 560–571. [Google Scholar] [CrossRef]

- Casadesús, M.; Macanás, J.; Colom, X.; Cañavate, J.; Álvarez, M.D.; Garrido, N.; Molins, G.; Carrillo, F. Effect of chemical treatments and additives on properties of chicken feathers thermoplastic biocomposites. J. Compos. Mater. 2018, 52, 3637–3653. [Google Scholar] [CrossRef]

- Colom, X.; Cañavate, J.; Carrillo, F.; Suñol, J.J. Effect of the particle size and acid pretreatments on compatibility and properties of recycled HDPE plastic bottles filled with ground tyre powder. J. Appl. Polym. Sci. 2009, 112, 1882–1890. [Google Scholar] [CrossRef]

- Yagneswaran, S.; Storer, W.J.; Tomar, N.; Chaur, M.N.; Echegoyen, L.; Smith, D.W., Jr. Surface-grafting of ground rubber tire by poly acrylic acid via self-initiated free radical polymerization and composites with epoxy thereof. Polym. Compos. 2013, 34, 769–777. [Google Scholar] [CrossRef]

- ASTM D412-16; Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers-Tension. ASTM International: West Conshohocken, PA, USA, 2021.

- Archibong, F.N.; Sanusi, O.M.; Médéric, P.; Hocine, N.A. An overview on the recycling of waste ground tyre rubbers in thermoplastic matrices: Effect of added fillers. Resour. Conserv. Recycl. 2021, 175, 105894. [Google Scholar] [CrossRef]

- Sonnier, R.; Leroy, E.; Clerc, L.; Bergeret, A.; Lopez-Cuesta, J.-M.; Bretelle, A.-S.; Lenny, P. Compatibilizing thermoplastic/ground tyre rubber powder blends: Efficiency and limits. Polym. Test. 2008, 27, 901–907. [Google Scholar] [CrossRef]

- Tesfaye, T.; Sithole, B.; Ramjugernath, D.; Mokhothu, T. Valorisation of chicken feathers: Characterisation of thermal, mechanical and electrical properties. Sustain. Chem. Pharm. 2018, 9, 27–34. [Google Scholar] [CrossRef]

- Aranberri, I.; Montes, S.; Azcune, I.; Rekondo, A.; Grande, H.-J. Fully Biodegradable Biocomposites with High Chicken Feather Content. Polymers 2017, 9, 593. [Google Scholar] [CrossRef] [Green Version]

- Januszewicz, K.; Klein, M.; Klugmann-Radziemska, E.; Kardas, D. Thermogravimetric analysis/pyrolysis of used tyres and waste rubber. Physicochem. Probl. Miner. Pro. 2017, 53, 802–811. [Google Scholar] [CrossRef]

- Colom, X.; Faliq, A.; Formela, K.; Cañavate, J. FTIR spectroscopic and thermogravimetric characterization of ground tyre rubber devulcanized by microwave treatment. Polym. Test. 2016, 52, 200–208. [Google Scholar] [CrossRef]

- Badiee, A.; Ashcroft, I.; Wildman, R. The thermo-mechanical degradation of ethylene vinyl acetate used as a solar panel adhesive and encapsulant. Int. J. Adhes. Adhes. 2016, 68, 212–218. [Google Scholar] [CrossRef]

- Koffi, A.; Mijiyawa, F.; Koffi, D.; Erchiqui, F.; Toubal, L. Mechanical Properties, Wettability and Thermal Degradation of HDPE/Birch Fiber Composite. Polymers 2021, 13, 1459. [Google Scholar] [CrossRef]

- Gao, Z.; Kaneko, T.; Amasaki, I.; Nakada, M. A kinetic study of thermal degradation of polypropylene. Polym. Degrad. Stab. 2003, 80, 269–274. [Google Scholar] [CrossRef]

- Brennan, M.; To, W. Acoustic properties of rigid-frame porous materials—An engineering perspective. Appl. Acoust. 2001, 62, 793–811. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Colom, X.; Cañavate, J.; Carrillo-Navarrete, F. Towards Circular Economy by the Valorization of Different Waste Subproducts through Their Incorporation in Composite Materials: Ground Tire Rubber and Chicken Feathers. Polymers 2022, 14, 1090. https://doi.org/10.3390/polym14061090

Colom X, Cañavate J, Carrillo-Navarrete F. Towards Circular Economy by the Valorization of Different Waste Subproducts through Their Incorporation in Composite Materials: Ground Tire Rubber and Chicken Feathers. Polymers. 2022; 14(6):1090. https://doi.org/10.3390/polym14061090

Chicago/Turabian StyleColom, Xavier, Javier Cañavate, and Fernando Carrillo-Navarrete. 2022. "Towards Circular Economy by the Valorization of Different Waste Subproducts through Their Incorporation in Composite Materials: Ground Tire Rubber and Chicken Feathers" Polymers 14, no. 6: 1090. https://doi.org/10.3390/polym14061090

APA StyleColom, X., Cañavate, J., & Carrillo-Navarrete, F. (2022). Towards Circular Economy by the Valorization of Different Waste Subproducts through Their Incorporation in Composite Materials: Ground Tire Rubber and Chicken Feathers. Polymers, 14(6), 1090. https://doi.org/10.3390/polym14061090