Fabrication and Characterization of Transparent and Uniform Cellulose/Polyethylene Composite Films from Used Disposable Paper Cups by the “One-Pot Method”

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

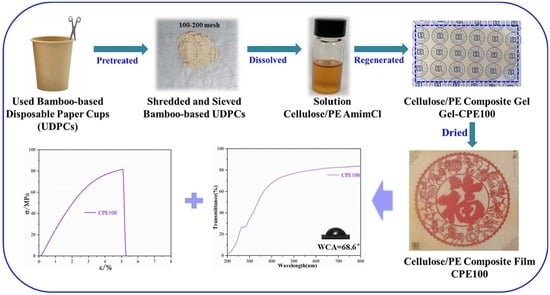

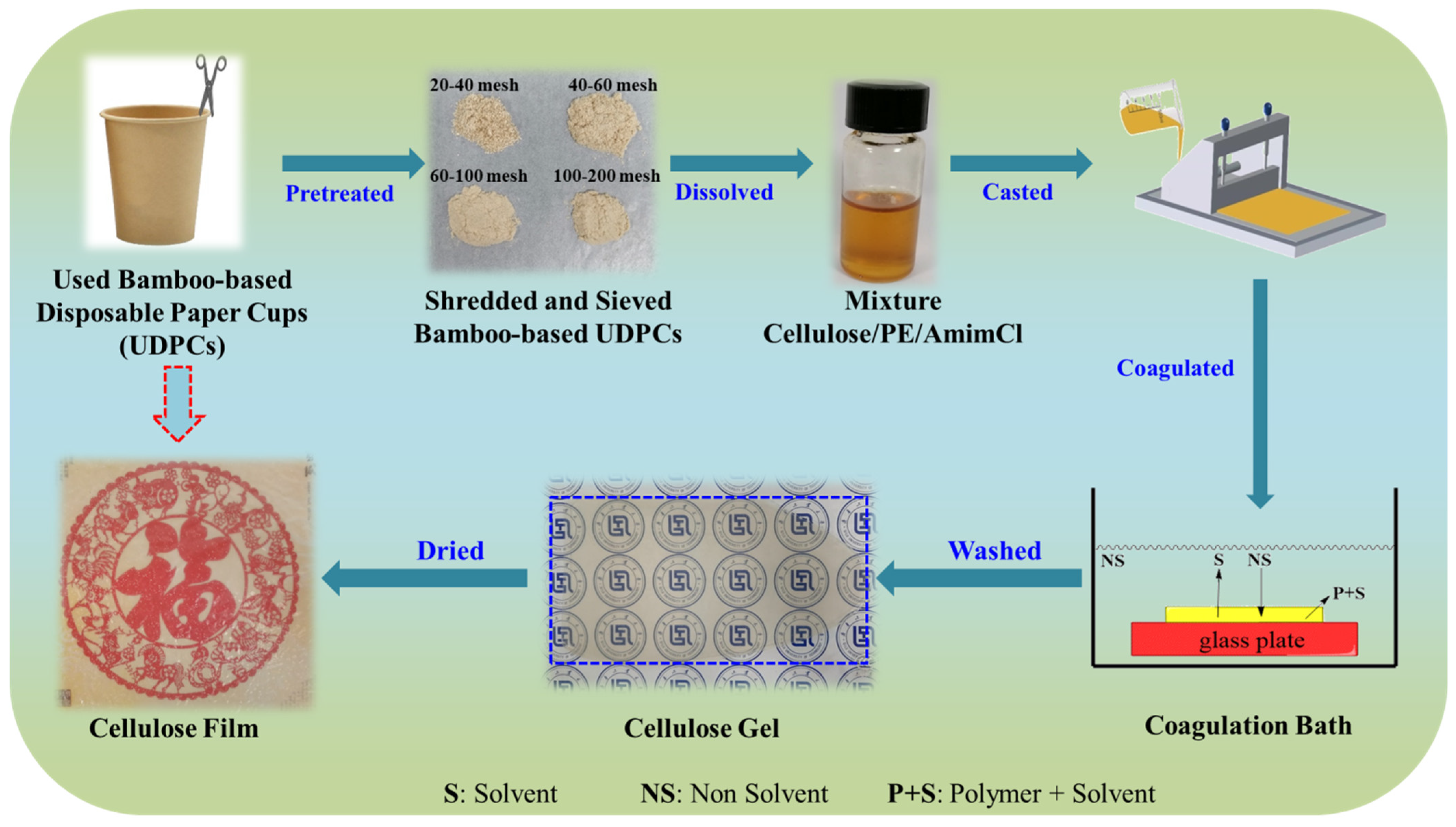

2.2. Dissolution of UDPCs and Fabrication of Cellulose/Polyethylene Composite Films

2.3. Characterization

2.3.1. The Chemical Components in UDPCs

2.3.2. The Degree of Polymerization (DP) of Cellulose in UDPCs

2.3.3. Polarized Optical Microscopy of UDPCs/AmimCl Solution

2.3.4. Ultraviolet and Visible (UV-Vis) Spectra of the Cellulose/Polyethylene Composite Films

2.3.5. The Surface Hydrophilicity of the Cellulose/Polyethylene Composite Films

2.3.6. Wide-Angle X-ray Diffraction (WAXD) of the CPs, UDPCs, Commercial PE film, and Cellulose/Polyethylene Composite Films

2.3.7. Fourier Transform Infrared (FTIR) Spectra of the CPs, UDPCs, Commercial PE film, and Cellulose/Polyethylene Composite Films

2.3.8. Mechanical Tests of the Cellulose/polyethylene Composite Films

2.3.9. Thermogravimetric Analysis (TGA) of the CPs, UDPCs, Commercial PE Film, and Cellulose/Polyethylene Composite Films

2.3.10. Morphology of Cellulose/Polyethylene Composite Films

3. Results

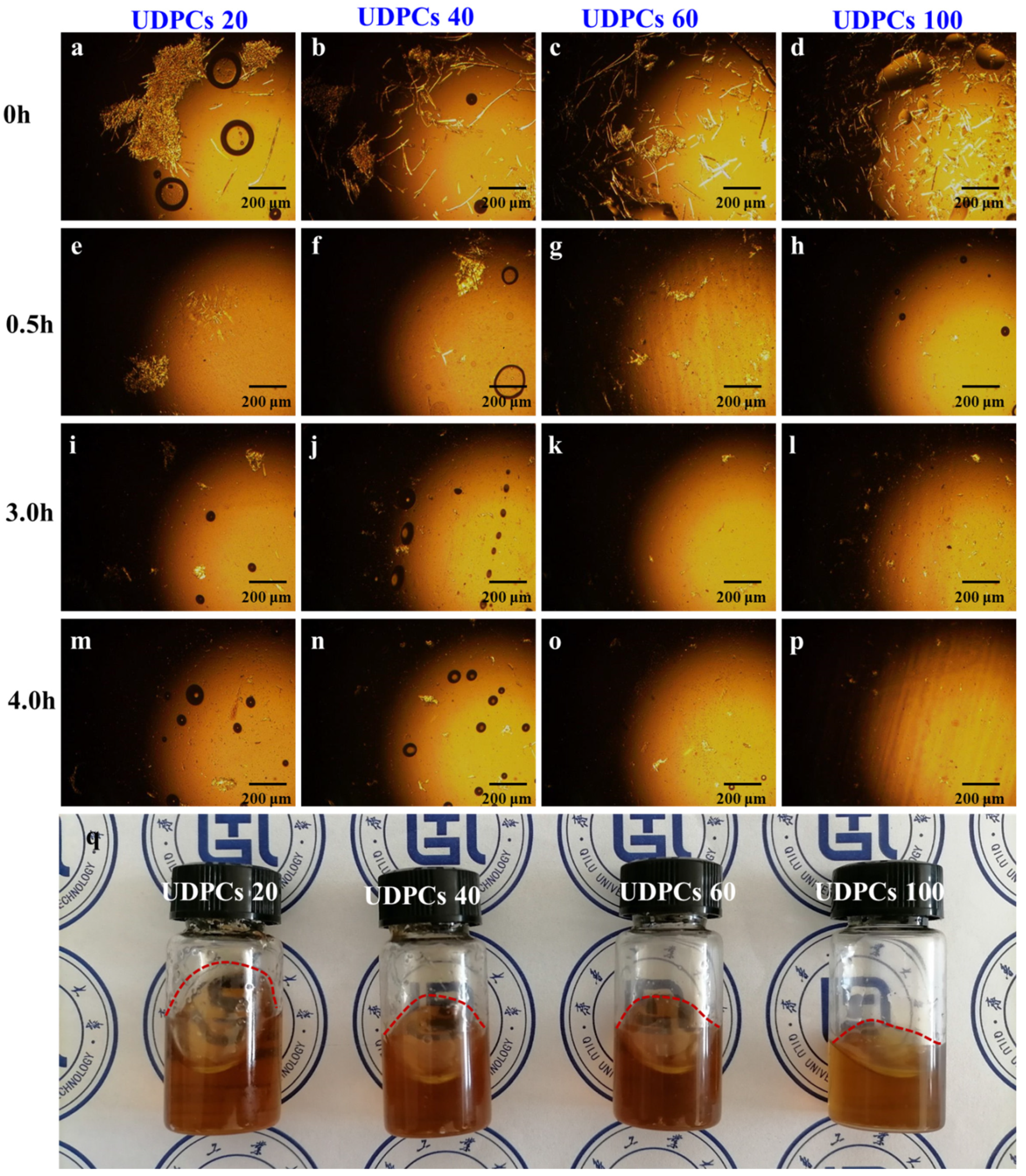

3.1. Dissolution of Bamboo-Based Used Disposable Paper Cups

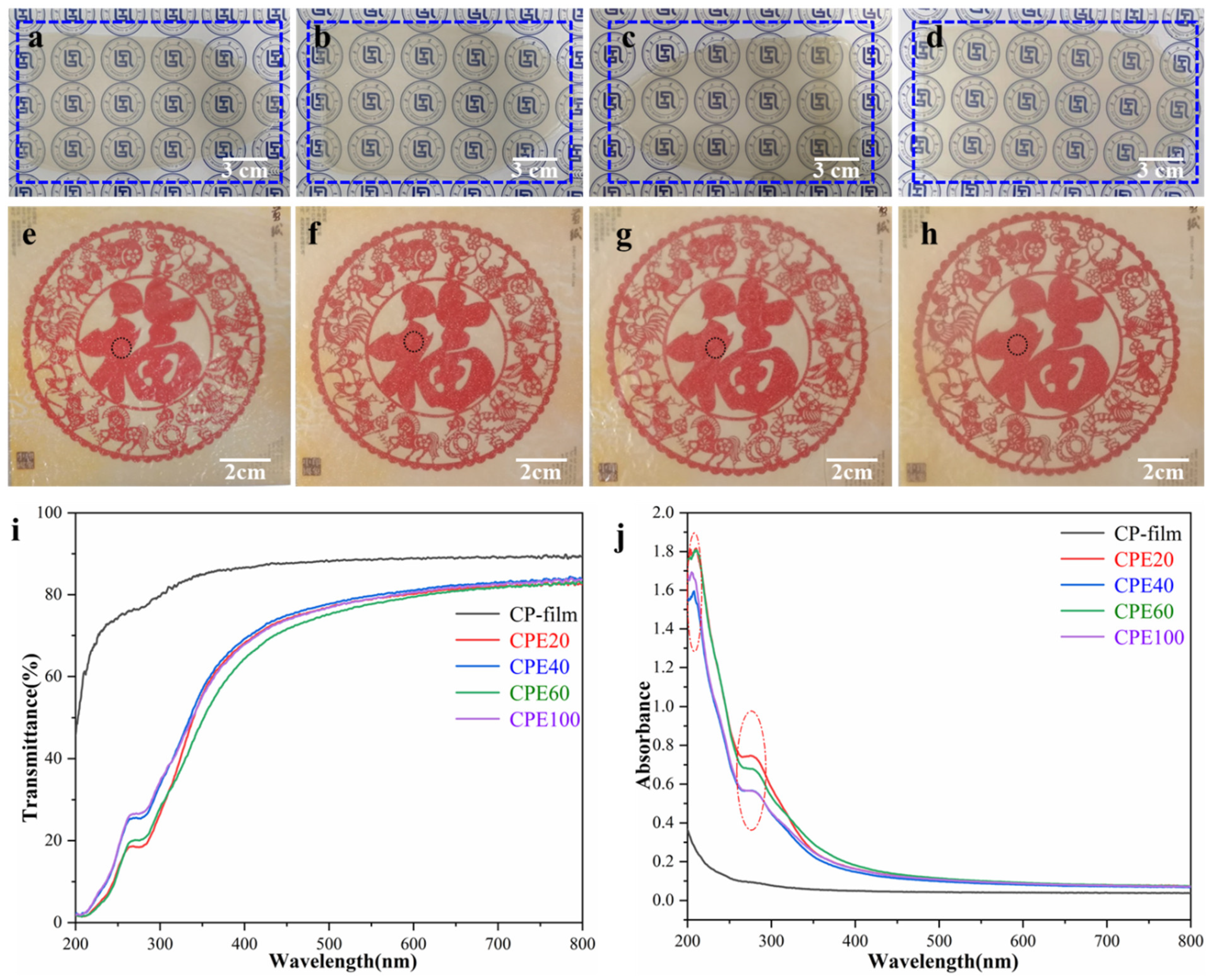

3.2. Transparency of Cellulose/PE Composite Films

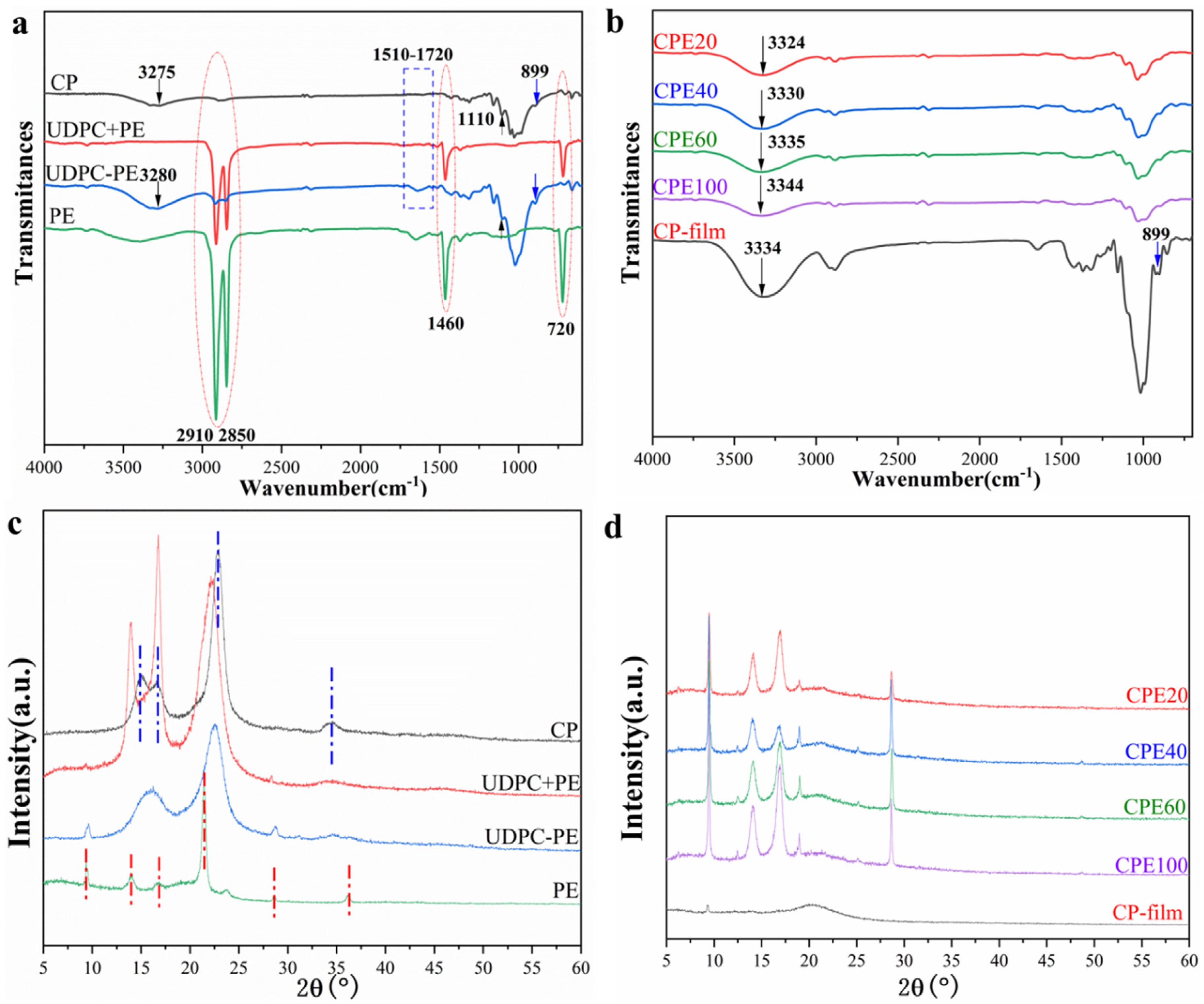

3.3. Structure and Crystallinity

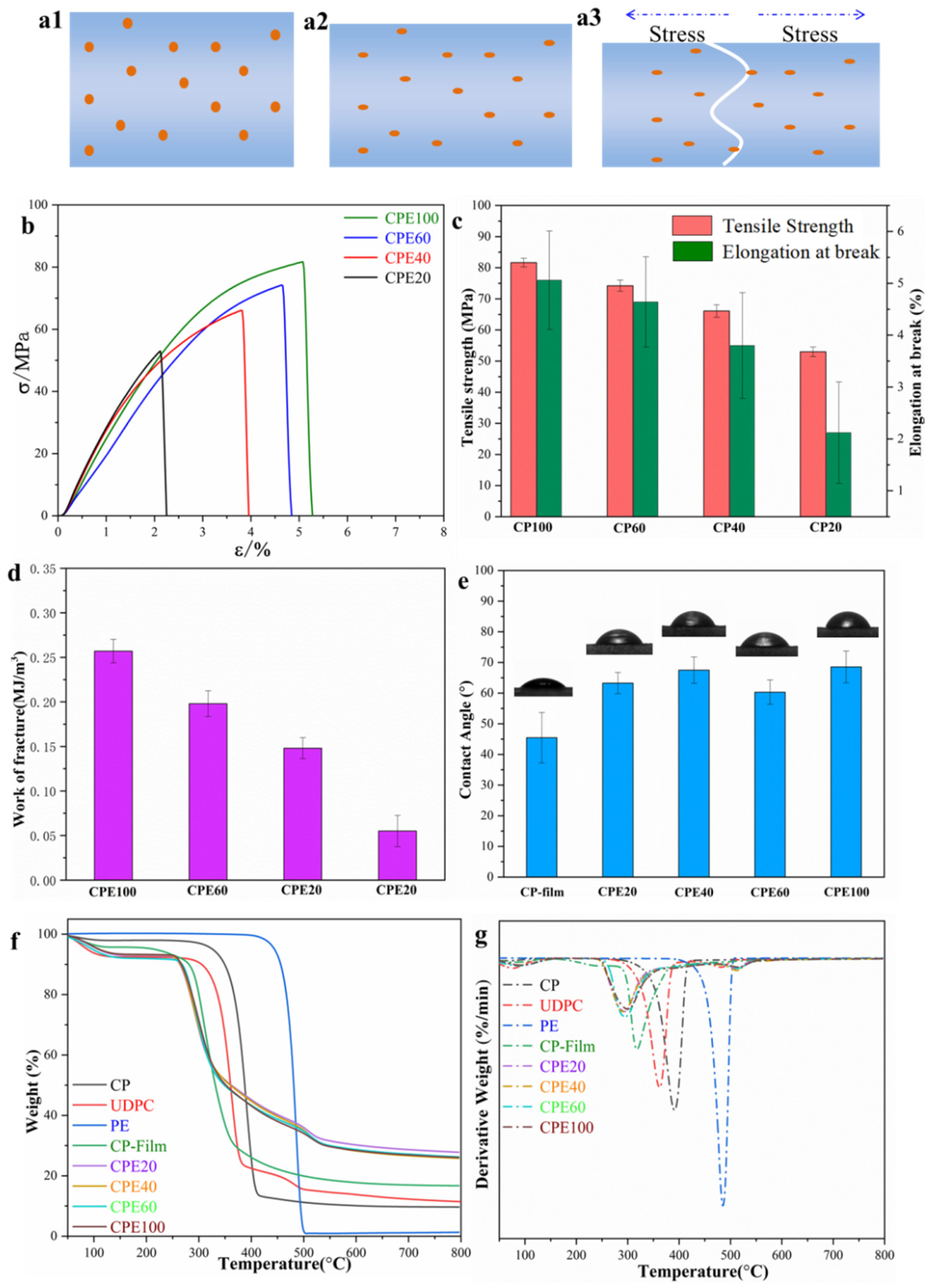

3.4. Mechanical Property, Hydrophilicity and Thermal Degradation

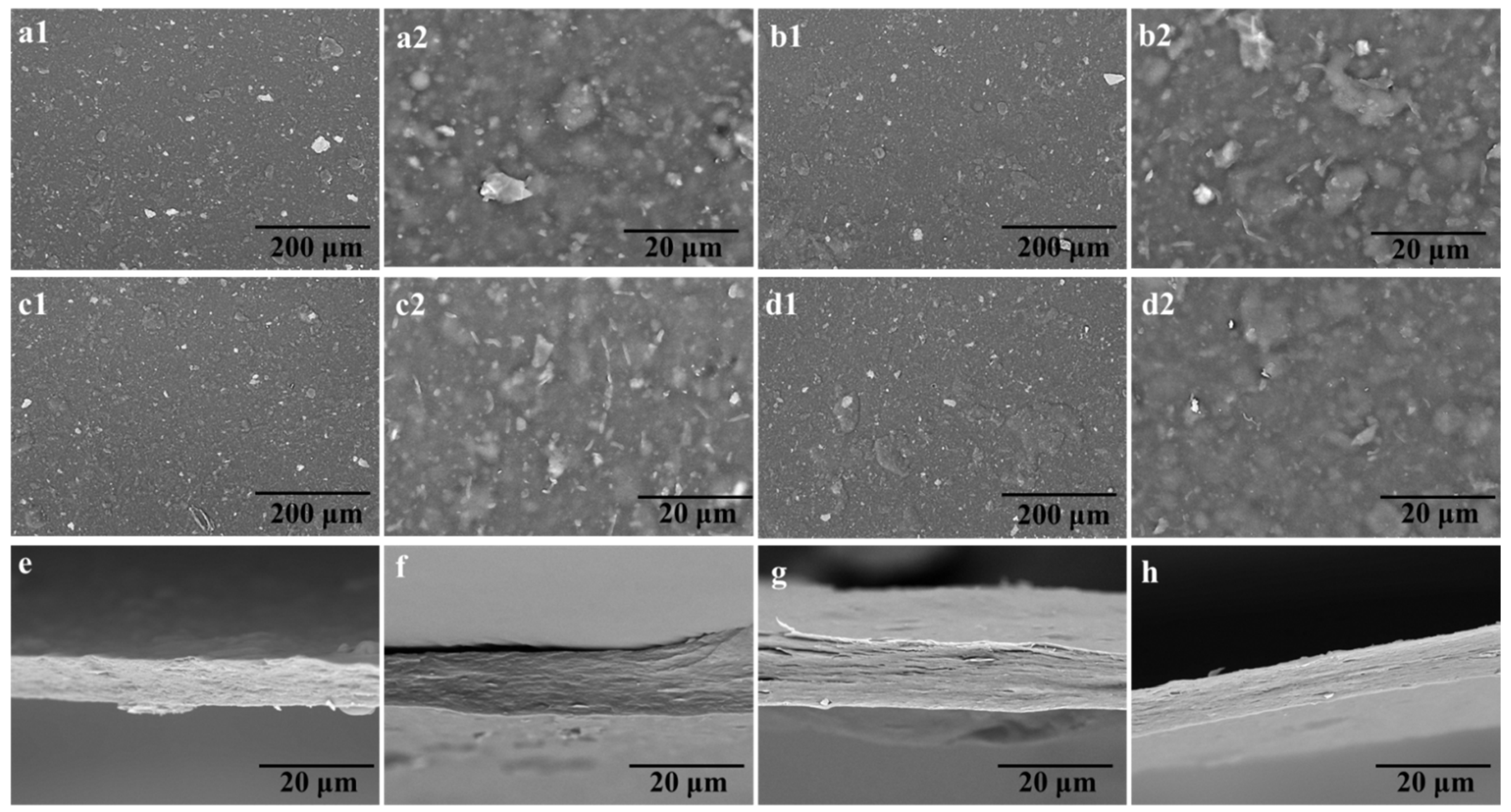

3.5. Morphology of Cellulose/Polyethylene Composite Films

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- EI Bhilat, H.; Hachim, A.; Salmi, H.; Mabchour, H.; EI Had, K. Characterization and processability of post-consumer, double-recycled high impact polystyrene from disposable cups. Mater. Today Proc. 2021, 45, 7264–7270. [Google Scholar] [CrossRef]

- Liu, G.; Wang, J.; Wang, M.; Ying, R.; Li, X.; Hu, Z.; Zhang, Y. Disposable plastic materials release microplastics and harmful substances in hot water. Sci Total Environ. 2021, 151685. [Google Scholar] [CrossRef] [PubMed]

- Dintcheva, N.T.; Infurna, G.; D’Anna, F. End-of-life and waste management of disposable beverage cups. Sci. Total Environ. 2021, 763, 143044. [Google Scholar] [CrossRef]

- Keller, A.; Köhler, J.K.; Eisen, C.; Kleihauer, S.; Hanss, D. Why consumers shift from single-use to reusable drink cups: An empirical application of the stage model of self-regulated behavioural change. Sustain. Prod. Consump. 2021, 27, 1672–1687. [Google Scholar] [CrossRef]

- Van der Harst, E.; Potting, J. A critical comparison of ten disposable cup LCAs. Environ. Impact Assess. Rev. 2013, 43, 86–96. [Google Scholar] [CrossRef]

- Foteinis, S. How small daily choices play a huge role in climate change: The disposable paper cup environmental bane. J. Clean. Prod. 2020, 255, 120294. [Google Scholar] [CrossRef]

- Bilek, M.A.; Salem, H.J.; Korehei, R.; Olson, J.A. Recycling Paper-Plastic laminate coffee cups using a Single-Disk Refiner: Energy requirements and recovered fiber quality. Waste Manag. 2021, 136, 104–112. [Google Scholar] [CrossRef]

- Karthika, A.; Seenivasagan, R.; Kasimani, R.; Babalola, O.O.; Vasanthy, M. Cellulolytic bacteria isolation, screening and optimization of enzyme production from vermicompost of paper cup waste. Waste Manag. 2020, 116, 58–65. [Google Scholar] [CrossRef]

- Ranjan, V.P.; Joseph, A.; Goel, S. Microplastics and other harmful substances released from disposable paper cups into hot water. J. Hazard. Mater. 2021, 404, 124118. [Google Scholar] [CrossRef]

- Ma, Y. Problems and resolutions in dealing with waste disposable paper cups. Sci. Prog. 2018, 101, 1–7. [Google Scholar]

- Arumugam, K.; Renganathan, S.; Babalola, O.O.; Muthunarayanan, V. Investigation on paper cup waste degradation by bacterial consortium and Eudrillus eugeinea through vermicomposting. Waste Manag. 2018, 74, 185–193. [Google Scholar] [CrossRef] [PubMed]

- Notaro, S.; Lovera, E.; Paletto, A. Consumers’ preferences for bioplastic products: A discrete choice experiment with a focus on purchase drivers. J. Clean. Prod. 2022, 330, 129870. [Google Scholar] [CrossRef]

- Loschelder, D.D.; Siepelmeyer, H.; Fischer, D.; Rubel, J.A. Dynamic norms drive sustainable consumption: Norm-based nudging helps café customers to avoid disposable to-go-cups. J. Econ. Psychol. 2019, 75, 102146. [Google Scholar] [CrossRef]

- Novoradovskaya, E.; Mullan, B.; Hasking, P.; Uren, H.V. My cup of tea: Behaviour change intervention to promote use of reusable hot drink cups. J. Clean. Prod. 2021, 284, 124675. [Google Scholar] [CrossRef]

- Gill, M.B.; Jensen, K.L.; Lambert, D.M.; Upendram, S.; English, B.C.; Labbé, N.; Jackson, S.W.; Menard, R.J. Consumer preferences for eco-friendly attributes in disposable dinnerware. Resour. Conserv. Recycl. 2020, 161, 104965. [Google Scholar] [CrossRef]

- Sandhu, S.; Lodhia, S.; Potts, A.; Crocker, R. Environment friendly takeaway coffee cup use: Individual and institutional enablers and barriers. J. Clean. Prod. 2021, 291, 125271. [Google Scholar] [CrossRef]

- Ramanathan, S.; Sasikumar, M.; Prince Makarios Paul, S.; Obadiah, A.; Angamuthu, A.; Santhoshkumar, P.; Durairaj, A.; Vasanthkumar, S. Low cost electrochemical composite material of paper cup waste carbon (P-carbon) and Fluorescein for supercapacitor application. Mater. Today Proc. 2021, 47, 825–836. [Google Scholar] [CrossRef]

- Nagarajan, K.J.; Balaji, A.N.; Kasi Rajan, S.T.; Ramanujam, N.R. Preparation of bio-eco based cellulose nanomaterials from used disposal paper cups through citric acid hydrolysis. Carbohydr. Polym. 2020, 235, 115997. [Google Scholar] [CrossRef]

- Chen, J.; Li, H.; Fang, C.; Cheng, Y.; Tan, T.; Han, H. Synthesis and structure of carboxymethylcellulose with a high degree of substitution derived from waste disposable paper cups. Carbohydr. Polym. 2020, 237, 116040. [Google Scholar] [CrossRef]

- Biswal, B.; Kumar, S.; Singh, R.K. Production of Hydrocarbon Liquid by Thermal Pyrolysis of Paper Cup Waste. Waste Manag. 2013, 2013, 731858. [Google Scholar] [CrossRef]

- Mitchell, J.; Vandeperre, L.; Dvorak, R.; Kosior, E.; Tarverdi, K.; Cheeseman, C. Recycling disposable cups into paper plastic composites. Waste Manag. 2014, 34, 2113–2119. [Google Scholar] [CrossRef] [PubMed]

- Ikram, R.; Jan, B.M.; Ahmad, W. Advances in synthesis of graphene derivatives using industrial wastes precursors; prospects and challenges. J. Mater. Res. Technol. 2020, 9, 15924–15951. [Google Scholar] [CrossRef]

- Xia, Q.; Chen, C.; Yao, Y.; Li, J.; He, S.; Zhou, Y.; Li, T.; Pan, X.; Yao, Y.; Hu, L. A strong, biodegradable and recyclable lignocellulosic bioplastic. Nat. Sustain. 2021, 4, 627–635. [Google Scholar] [CrossRef]

- Jiang, B.; Chen, C.; Liang, Z.; He, S.; Kuang, Y.; Song, J.; Mi, R.; Chen, G.; Jiao, M.; Hu, L. Lignin as a Wood-Inspired Binder Enabled Strong, Water Stable, and Biodegradable Paper for Plastic Replacement. Adv. Funct. Mater. 2019, 30, 1906307. [Google Scholar] [CrossRef]

- Zhang, J.; Luo, N.; Wan, J.; Xia, G.; Yu, J.; He, J.; Zhang, J. Directly Converting Agricultural Straw into All-Biomass Nanocomposite Films Reinforced with Additional in Situ-Retained Cellulose Nanocrystals. Acs. Sustain. Chem. Eng. 2017, 5, 5127–5133. [Google Scholar] [CrossRef]

- Liu, Y.; Ahmed, S.; Sameen, D.E.; Wang, Y.; Lu, R.; Dai, J.; Li, S.; Qin, W. A review of cellulose and its derivatives in biopolymer-based for food packaging application. Trends Food Sci. Tech. 2021, 112, 532–546. [Google Scholar] [CrossRef]

- Xia, G.; Zhou, Q.; Xu, Z.; Zhang, J.; Zhang, J.; Wang, J.; You, J.; Wang, Y.; Nawaz, H. Transparent cellulose/aramid nanofibers films with improved mechanical and ultraviolet shielding performance from waste cotton textiles by in-situ fabrication. Carbohydr. Polym. 2021, 273, 118569. [Google Scholar] [CrossRef]

- Huang, K.; Wang, Y. Recent applications of regenerated cellulose films and hydrogels in food packaging. Curr. Opin. Food Sci. 2022, 43, 7–17. [Google Scholar] [CrossRef]

- Nawaz, H.; Zhang, X.; Chen, S.; You, T.; Xu, F. Recent studies on cellulose-based fluorescent smart materials and their applications: A comprehensive review. Carbohydr. Polym. 2021, 267, 118135. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; Huang, X.; Jiang, S.; Wang, G. Anisotropy-functionalized cellulose-based phase change materials with reinforced solar-thermal energy conversion and storage capacity. Chem. Eng. J. 2021, 415, 129086. [Google Scholar] [CrossRef]

- Shen, Z.; Oh, K.; Kwon, S.; Toivakka, M.; Lee, H.L. Use of cellulose nanofibril (CNF)/silver nanoparticles (AgNPs) composite in salt hydrate phase change material for efficient thermal energy storage. Int. J. Biol. Macromol. 2021, 174, 402–412. [Google Scholar] [CrossRef] [PubMed]

- Xia, G.; Wan, J.; Zhang, J.; Zhang, X.; Xu, L.; Wu, J.; He, J.; Zhang, J. Cellulose-based films prepared directly from waste newspapers via an ionic liquid. Carbohydr. Polym. 2016, 151, 223–229. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wong, L.C.; Leh, C.P.; Goh, C.F. Designing cellulose hydrogels from non-woody biomass. Carbohydr. Polym. 2021, 264, 118036. [Google Scholar] [CrossRef] [PubMed]

- Cavalcanti, D.K.K.; Banea, M.D.; Neto, J.S.S.; Lima, R.A.A. Comparative analysis of the mechanical and thermal properties of polyester and epoxy natural fibre-reinforced hybrid composites. J. Compos. Mater. 2020, 55, 1683–1692. [Google Scholar] [CrossRef]

- Neto, J.S.S.; de Queiroz, H.F.M.; Aguiar, R.A.A.; Banea, M.D. A Review on the Thermal Characterisation of Natural and Hybrid Fiber Composites. Polymers 2021, 13, 4425. [Google Scholar] [CrossRef]

- Jawaid, M.; Awad, S.; Fouad, H.; Asim, M.; Saba, N.; Dhakal, H.N. Improvements in the thermal behaviour of date palm/bamboo fibres reinforced epoxy hybrid composites. Compos. Struct. 2021, 277, 114644. [Google Scholar] [CrossRef]

- Awad, S.A.; Jawaid, M.; Fouad, H.; Saba, N.; Dhakal, H.N.; Alothman, O.Y.; Khalaf, E.M. A comparative assessment of chemical, mechanical, and thermal characteristics of treated oil palm/pineapple fiber/bio phenolic composites. Polym. Compos. 2022, 1–14. [Google Scholar] [CrossRef]

- Zhang, L.; Ruan, D.; Gao, S. Dissolution and regeneration of cellulose in NaOH/thiourea aqueous solution. J. Polym. Sci. Pol. Phys. 2002, 40, 1521–1529. [Google Scholar] [CrossRef]

- Swatloski, R.P.; Spear, S.K.; Holbrey, J.D.; Rogers, R.D. Dissolution of Cellose with Ionic Liquids. J. Am. Chem. Soc. 2002, 124, 4974–4975. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, J.; Zhang, J.; He, J. 1-Allyl-3-methylimidazolium Chloride Room Temperature Ionic Liquid: A New and Powerful Nonderivatizing Solvent for Cellulose. Macromolecules 2005, 38, 8272–8277. [Google Scholar] [CrossRef]

- Sun, N.; Rahman, M.; Qin, Y.; Maxim, M.L.; Rodríguez, H.; Rogers, R.D. Complete dissolution and partial delignification of wood in the ionic liquid 1-ethyl-3-methylimidazolium acetate. Green Chem. 2009, 11, 646–655. [Google Scholar] [CrossRef]

- Xia, G.; Han, W.; Xu, Z.; Zhang, J.; Kong, F.; Zhang, J.; Zhang, X.; Jia, F. Complete recycling and valorization of waste textiles for value-added transparent films via an ionic liquid. J. Environ. Chem. Eng. 2021, 9, 106182. [Google Scholar] [CrossRef]

- Xia, G.; Zhou, Q.; Xu, Z.; Zhang, J.; Ji, X.; Zhang, J.; Nawaz, H.; Wang, J.; Peng, J. Cellulose-Based Films with Ultraviolet Shielding Performance Prepared Directly from Waste Corrugated Pulp. Polymers 2021, 13, 3359. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Zhou, Q.; Wang, L.; Xia, G.; Ji, X.; Zhang, J.; Zhang, J.; Nawaz, H.; Wang, J.; Peng, J. Transparent Cellulose-Based Films Prepared from Used Disposable Paper Cups via an Ionic Liquid. Polymers 2021, 13, 4209. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.; Li, Y.; Liu, X.; Zhang, X.; Wang, J.; Yao, X.; Zhang, S. Mechanistic study on the cellulose dissolution in ionic liquids by density functional theory. Chin. J. Chem. Eng. 2015, 23, 1894–1906. [Google Scholar] [CrossRef]

- Luo, N.; Lv, Y.; Wang, D.; Zhang, J.; Wu, J.; He, J.; Zhang, J. Direct visualization of solution morphology of cellulose in ionic liquids by conventional TEM at room temperature. Chem. Commun. 2012, 48, 6283–6285. [Google Scholar] [CrossRef]

- Kaur, R.; Bhardwaj, S.K.; Chandna, S.; Kim, K.H.; Bhaumik, J. Lignin-based metal oxide nanocomposites for UV protection applications: A review. J. Clean. Prod. 2021, 317, 128300. [Google Scholar] [CrossRef]

- Kaparaju, P.; Felby, C. Characterization of lignin during oxidative and hydrothermal pre-treatment processes of wheat straw and corn stover. Bioresour. Technol. 2010, 101, 3175–3181. [Google Scholar] [CrossRef]

- Cao, Y.; Li, H.; Zhang, Y.; Zhang, J.; He, J. Structure and properties of novel regenerated cellulose films prepared from cornhusk cellulose in room temperature ionic liquids. J. Appl. Polym. Sci. 2010, 116, 547–554. [Google Scholar] [CrossRef]

- Cao, Y.; Wu, J.; Meng, T.; Zhang, J.; He, J.; Li, H.; Zhang, Y. Acetone-soluble cellulose acetates prepared by one-step homogeneous acetylation of cornhusk cellulose in an ionic liquid 1-allyl-3-methylimidazolium chloride (AmimCl). Carbohydr. Polym. 2007, 69, 665–672. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Zhou, Q.; Ji, X.; Peng, J.; Nawaz, H.; Xia, G.; Ji, X.; Zhang, J.; Zhang, J. Fabrication and Characterization of Transparent and Uniform Cellulose/Polyethylene Composite Films from Used Disposable Paper Cups by the “One-Pot Method”. Polymers 2022, 14, 1070. https://doi.org/10.3390/polym14061070

Wang L, Zhou Q, Ji X, Peng J, Nawaz H, Xia G, Ji X, Zhang J, Zhang J. Fabrication and Characterization of Transparent and Uniform Cellulose/Polyethylene Composite Films from Used Disposable Paper Cups by the “One-Pot Method”. Polymers. 2022; 14(6):1070. https://doi.org/10.3390/polym14061070

Chicago/Turabian StyleWang, Lixiang, Qiwen Zhou, Xiaoqian Ji, Jianfeng Peng, Haq Nawaz, Guangmei Xia, Xingxiang Ji, Jinming Zhang, and Jun Zhang. 2022. "Fabrication and Characterization of Transparent and Uniform Cellulose/Polyethylene Composite Films from Used Disposable Paper Cups by the “One-Pot Method”" Polymers 14, no. 6: 1070. https://doi.org/10.3390/polym14061070

APA StyleWang, L., Zhou, Q., Ji, X., Peng, J., Nawaz, H., Xia, G., Ji, X., Zhang, J., & Zhang, J. (2022). Fabrication and Characterization of Transparent and Uniform Cellulose/Polyethylene Composite Films from Used Disposable Paper Cups by the “One-Pot Method”. Polymers, 14(6), 1070. https://doi.org/10.3390/polym14061070