Study of Aramid Yarns Sizing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Yarn

2.2. Sizing

2.2.1. Sizing Agents

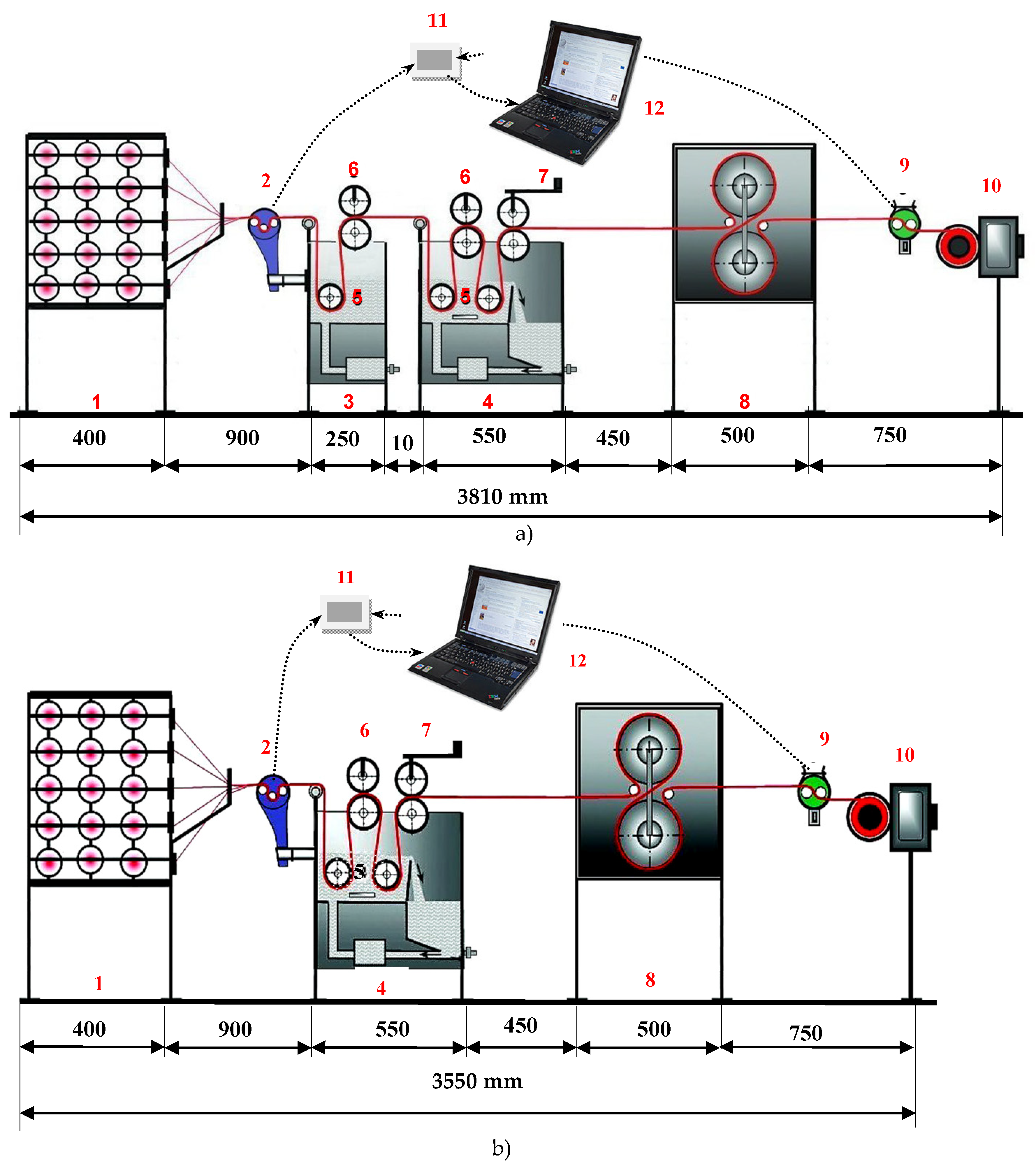

2.2.2. Sizing Equipment

2.2.3. Sizing Conditions

2.3. Mechanical Properties of Yarn

- The breaking properties of the yarn were tested according to ISO 2062, on the Statimat M Textechno tensile tester, which includes the following properties: breaking force F (cN), elongation at break ε (%) and breaking strength (cN/tex) and work to rupture (cN × cm).

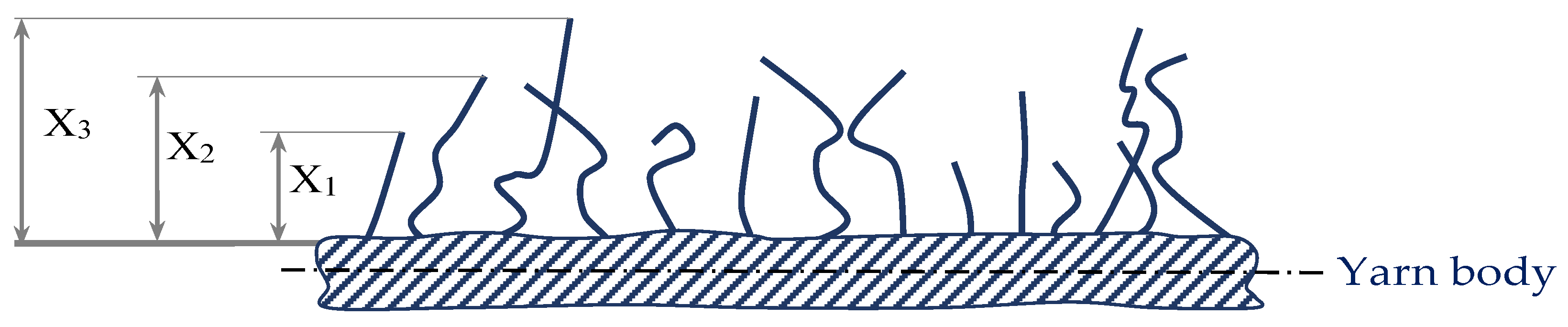

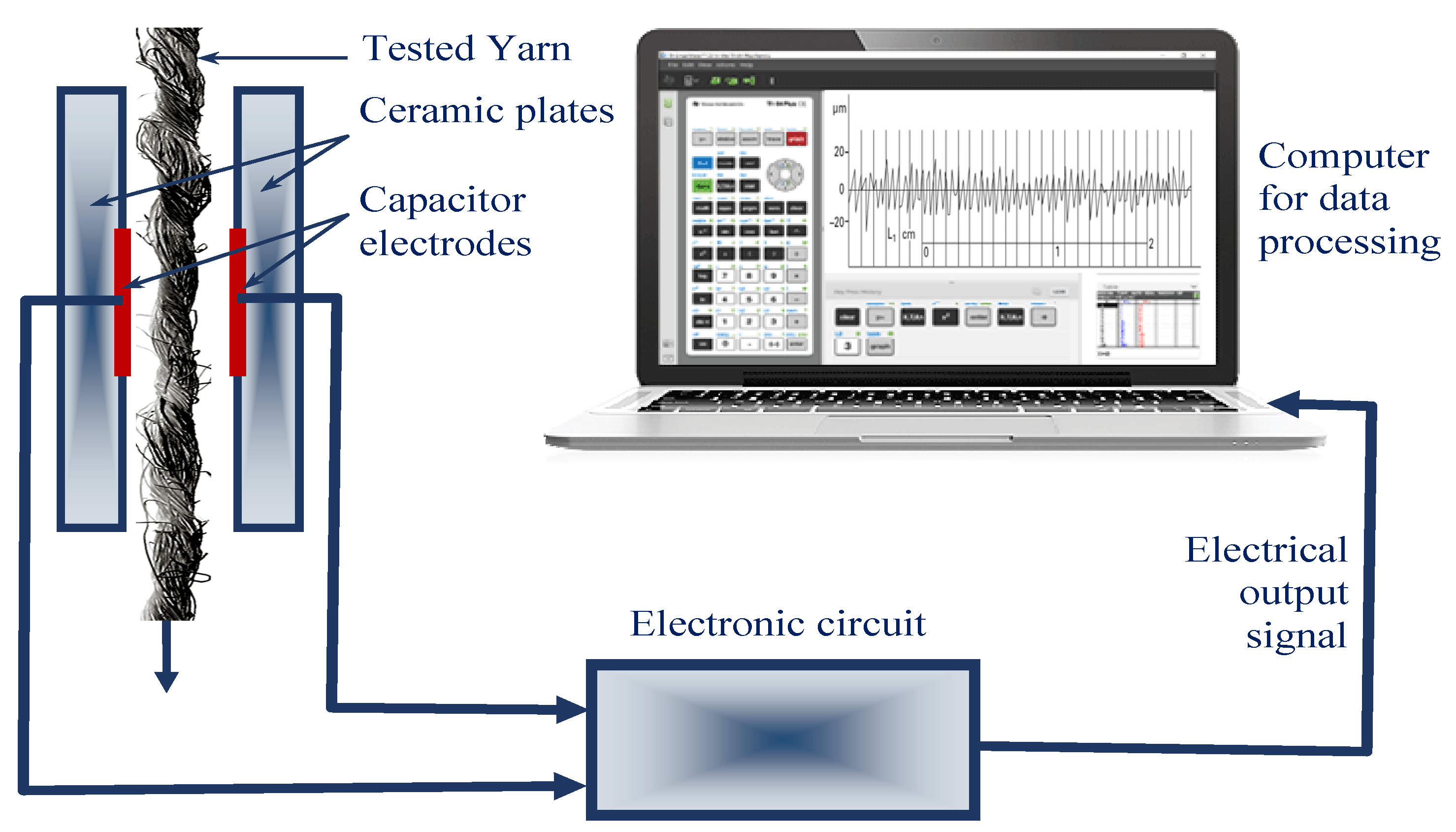

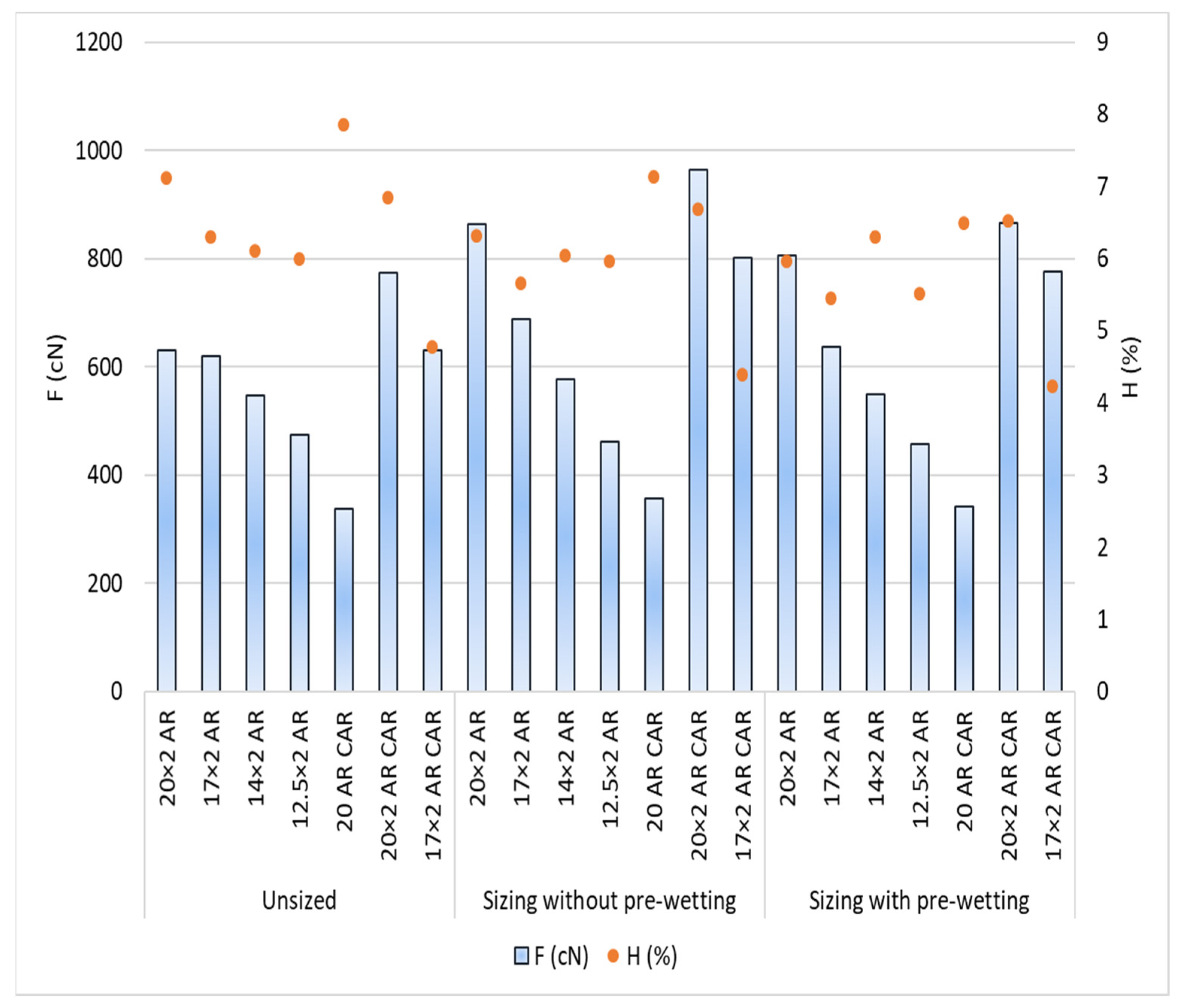

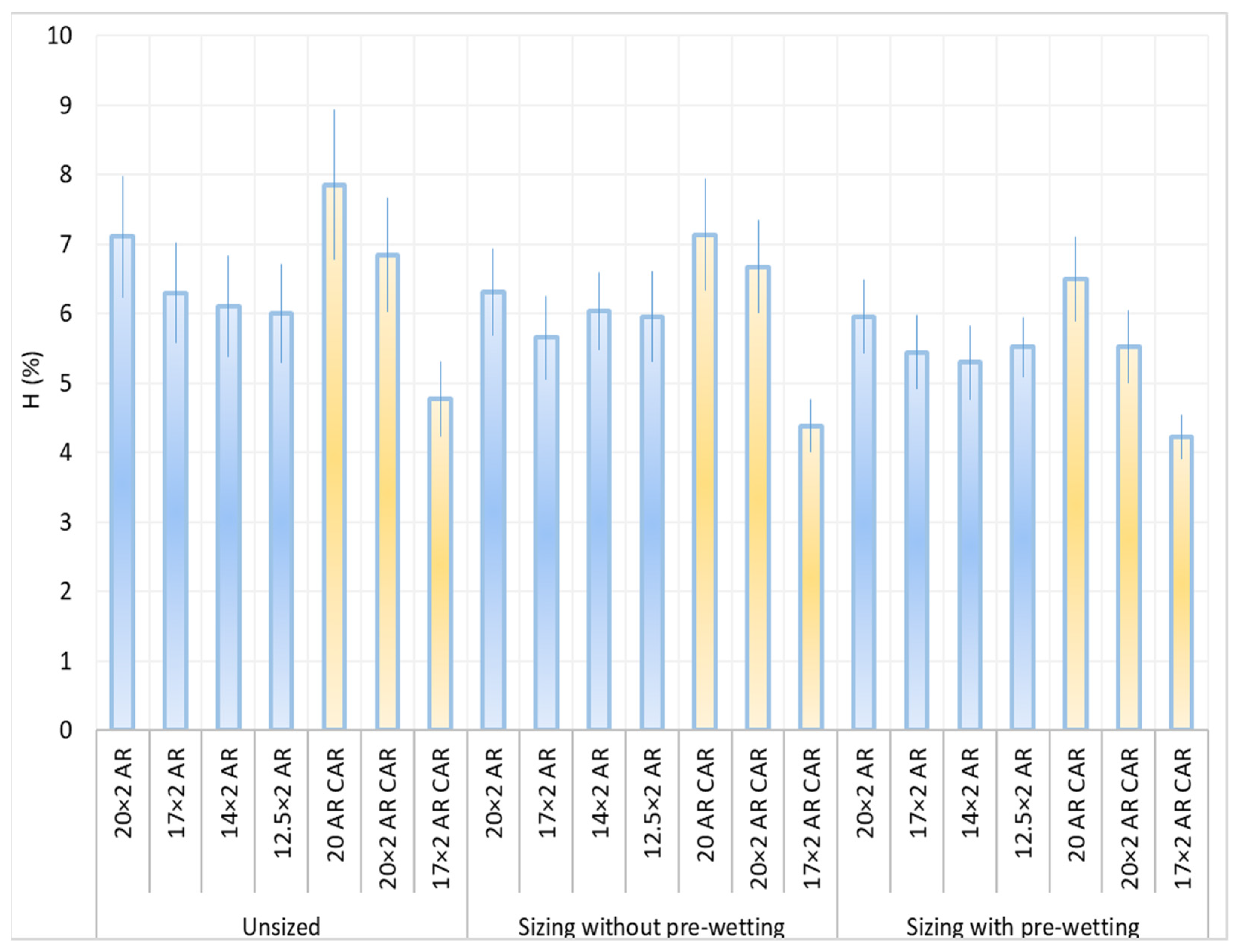

- Uster hairiness index (H)—total length of protruding fibre/cm length of yarn. It is also termed as the H-value and was tested on Uster Tester 4, Zellweger Uster, Switzerland, ISO 2649. USTER® TESTER with the hairiness metre attachment measures the hairiness index [30]. A parallel beam of infrared light is illuminated on the yarn as it runs past the measuring device, as depicted in Figure 2. Only the light that is scattered by the protruding fibres from the main body of the yarn reaches the detector. The hairiness measurement is done by the amount of scattered light that is converted to an electric signal by the apparatus. Therefore, this instrument monitors only the total hairiness. The testing speed of this instrument is 800 m/min. The measuring principle is based on evaluation with diffracted light. The hairiness value H is defined as the total length of all fibre ends sticking out in cm, related to a yarn section of 1 cm in length. The device gives information on the standard deviation of the hairiness value H and provides a hairiness diagram and spectrogram.

- Yarn twist was determined using a MesdanLab Twist Tester according standard ISO 17202.

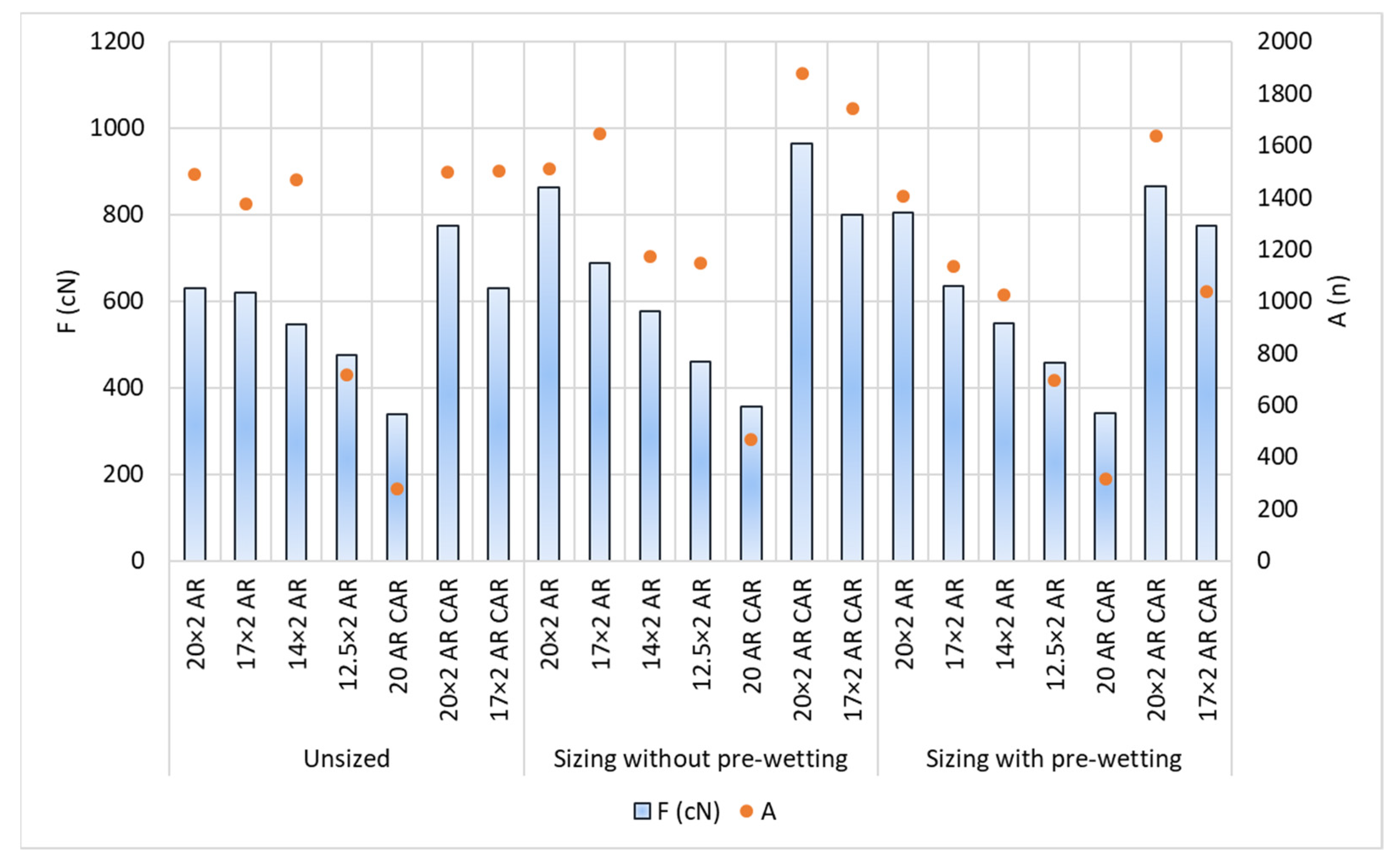

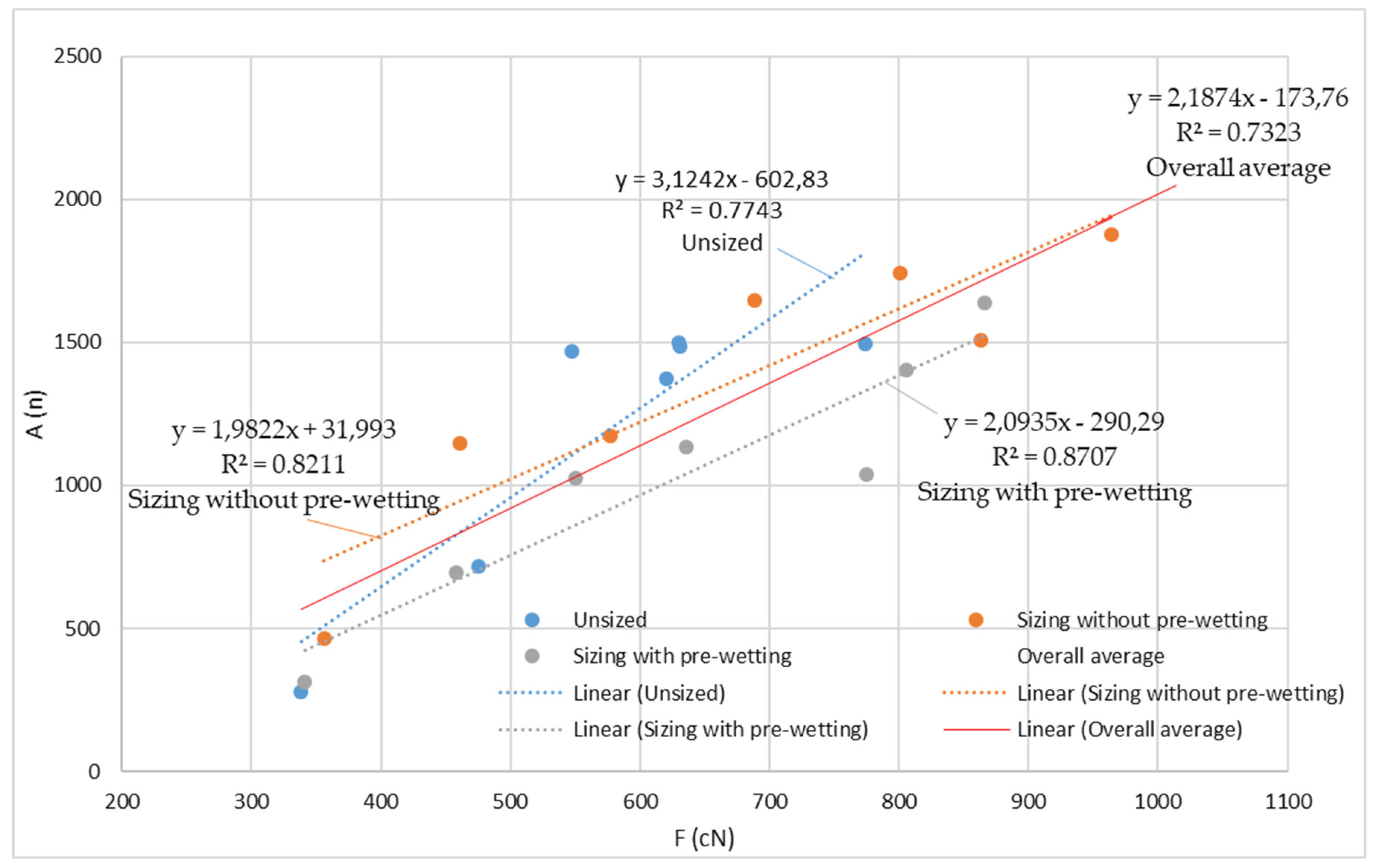

- Abrasion resistance (A) (number of cycles)—the abrasion resistance test was performed on the Zweigle G551 tester, where each of the 20 threads was simultaneously subjected to the abrasion process under a load of 20 g until the thread breaks. By moving the roller coated with 600 grit emery paper along the length of the thread and rotating it around its axis, a certain intensity of abrasion of thread and emery paper is achieved. During abrasion, the thread weakens and at the moment when the weight mass hung on the thread overcomes the strength of the thread, a break occurs and the number of movements of the roller (n) is registered until the break of each thread.

- The moisture content of the yarn after drying was measured with a contact moisture meter (K.P. Mundinger GmbH, type Aqua-boy), which was redesigned for continuous measurement and storage of the data in the computer.

- The yarn tension was measured with a tension meter (Schmidt, model ETM), which was redesigned for continuous measurement and storage of the data in the computer.

- The gravimetric method was used to determine the quantity of the size. Prior to the sizing process, the samples are dried to absolutely dry, after which the samples are weighed and then returned to climatic conditions and sized; after sizing the samples are dried again to absolutely dry and weighed. Size pick-up (Sp) on the yarn was determined using the mass technique according to the Equation (1):

- Sp (%)—amount of the size pick-up,

- GS (g)—mass of the absolutely dry sized yarn,

- GU (g)—mass of the absolutely dry unsized yarn.

3. Results and Discussion

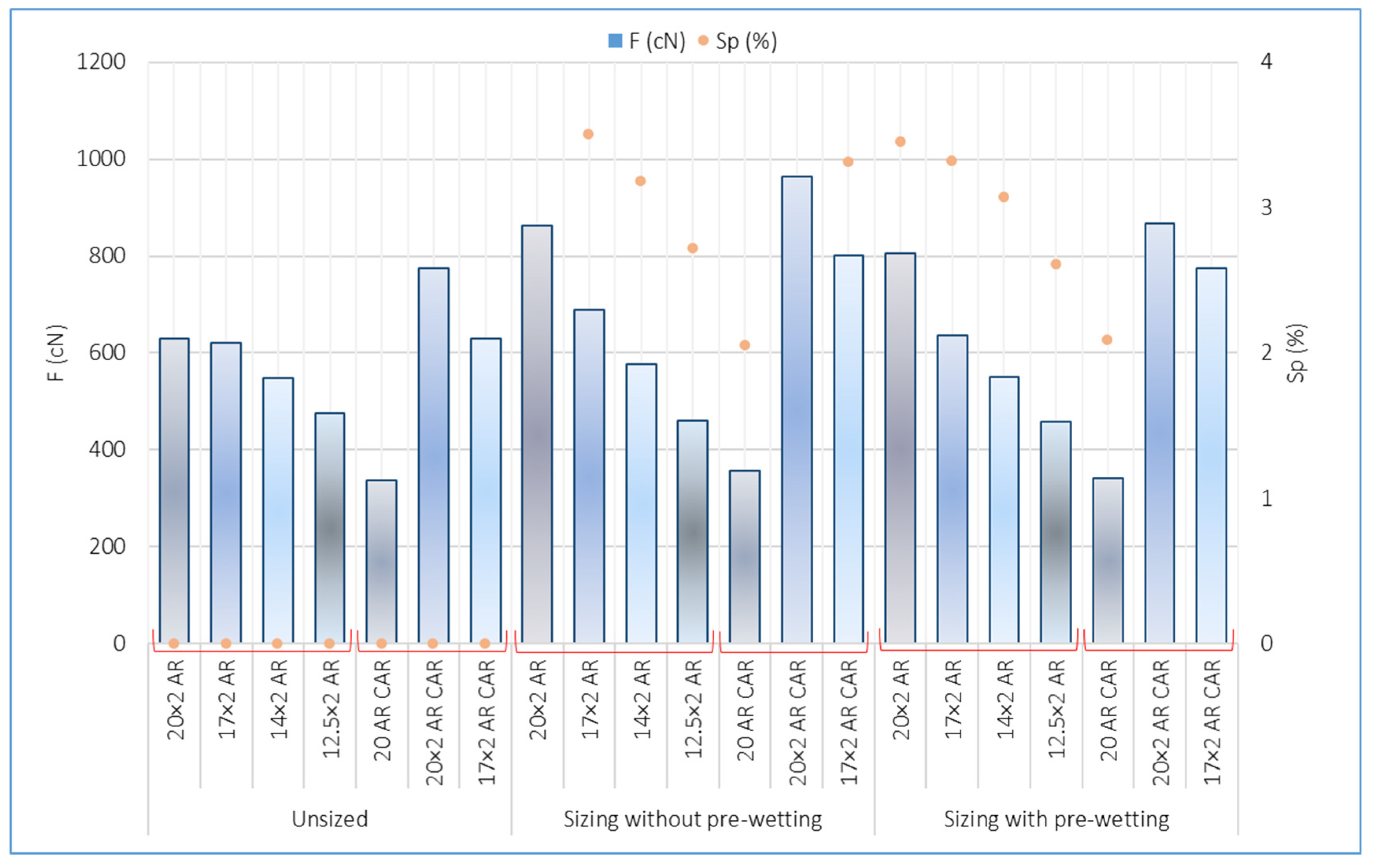

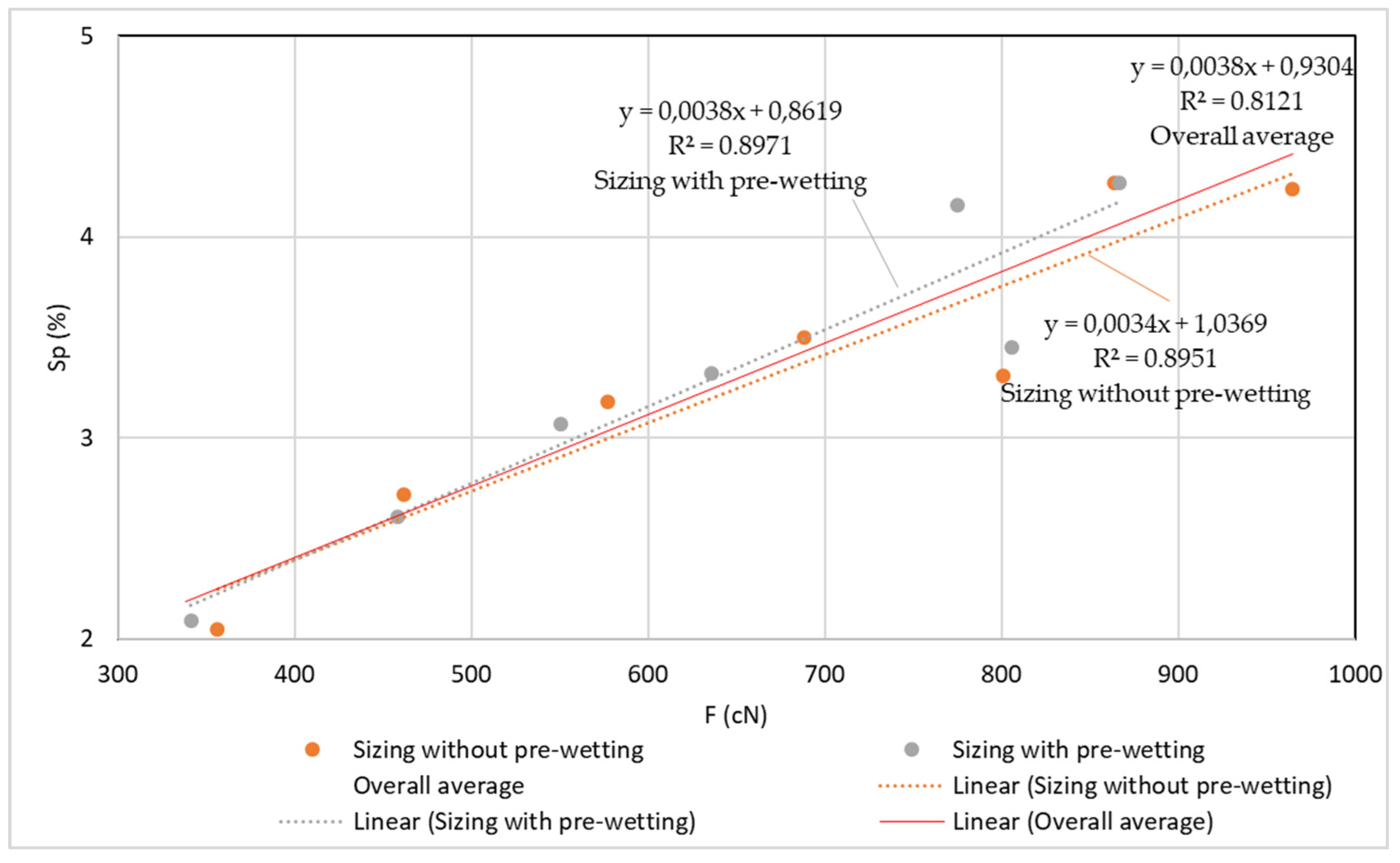

- Size pick-up is higher for yarns designated with AR with sizing without pre-wetting and for yarns designated with AR CAR with sizing with pre-wetting;

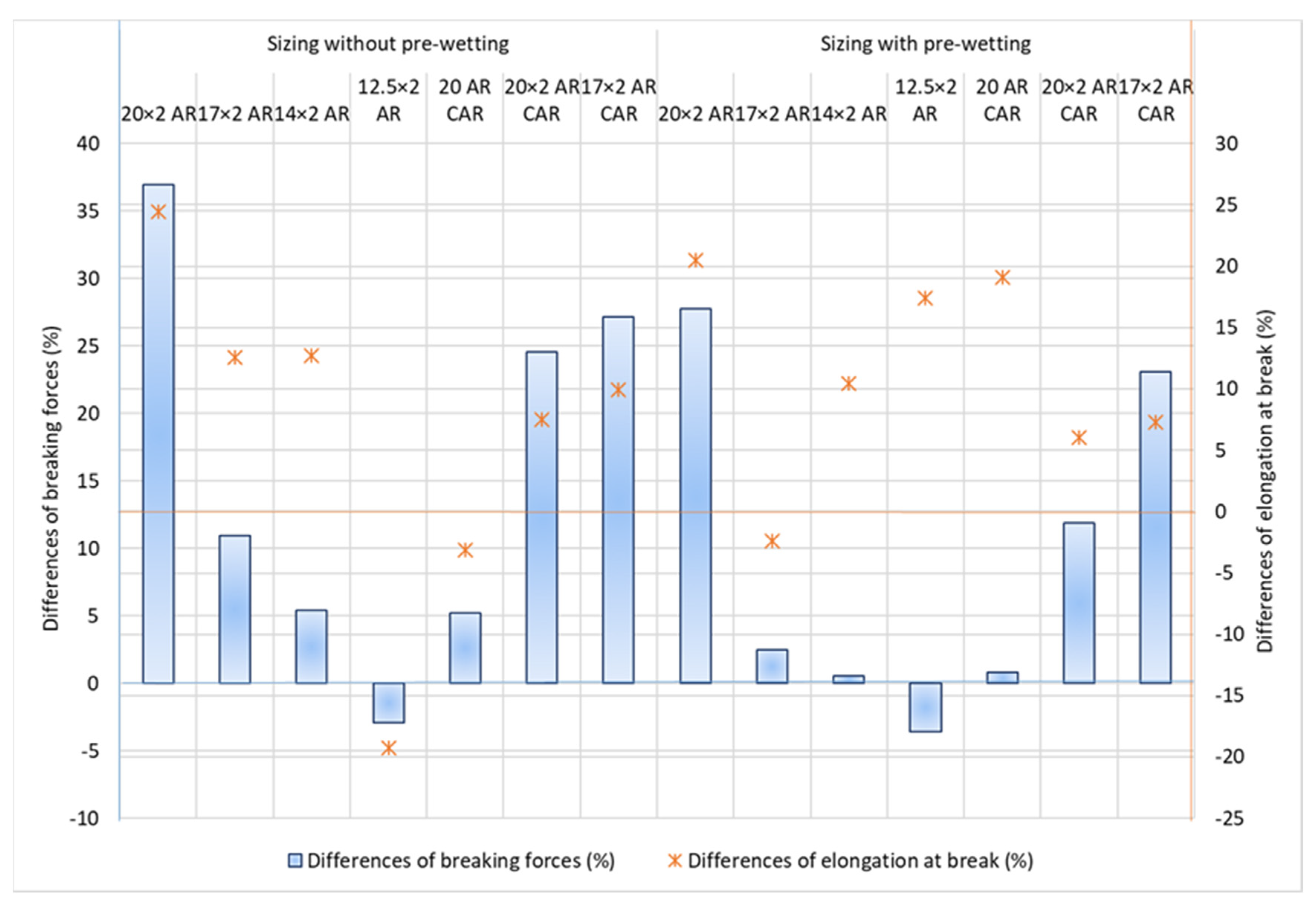

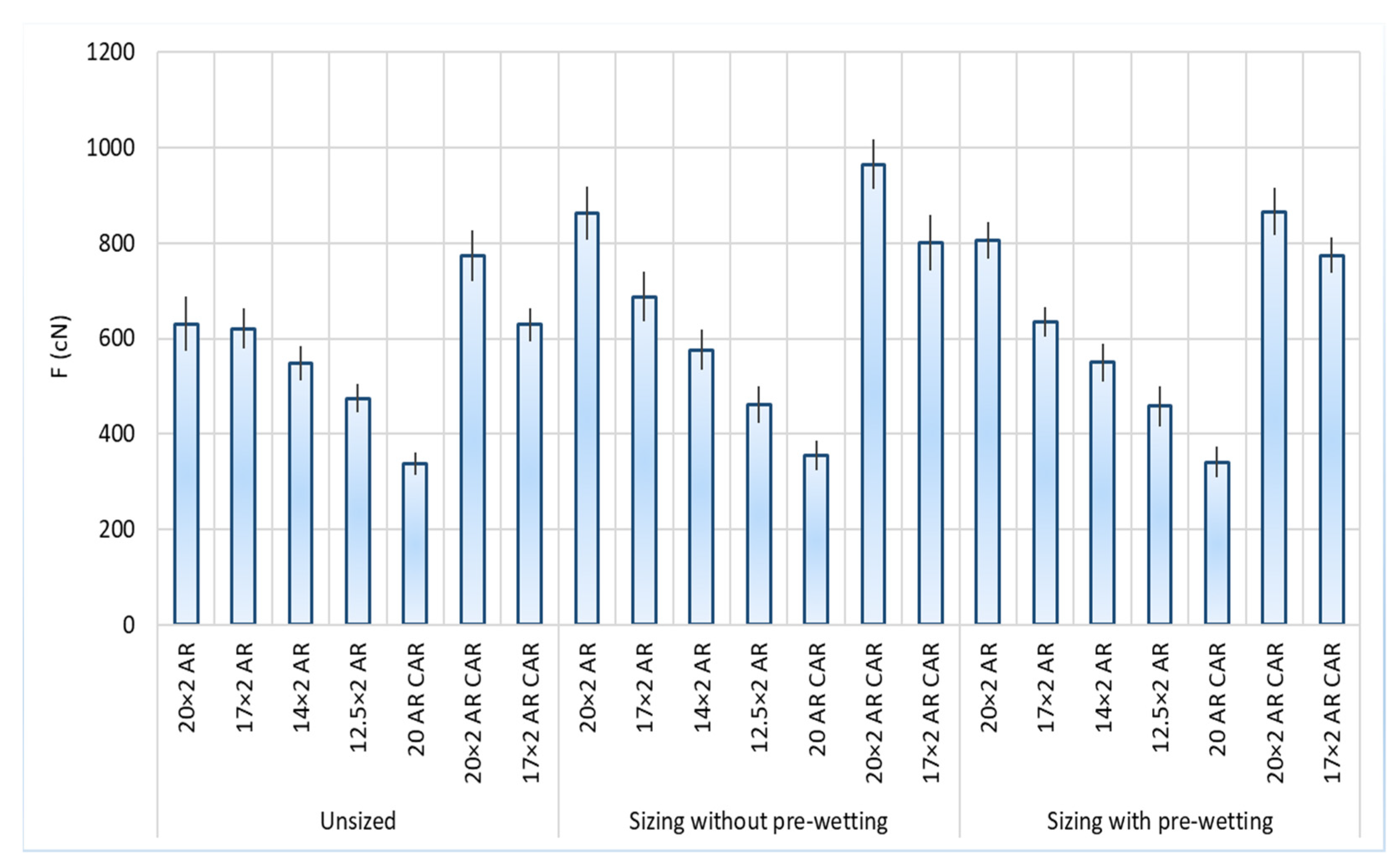

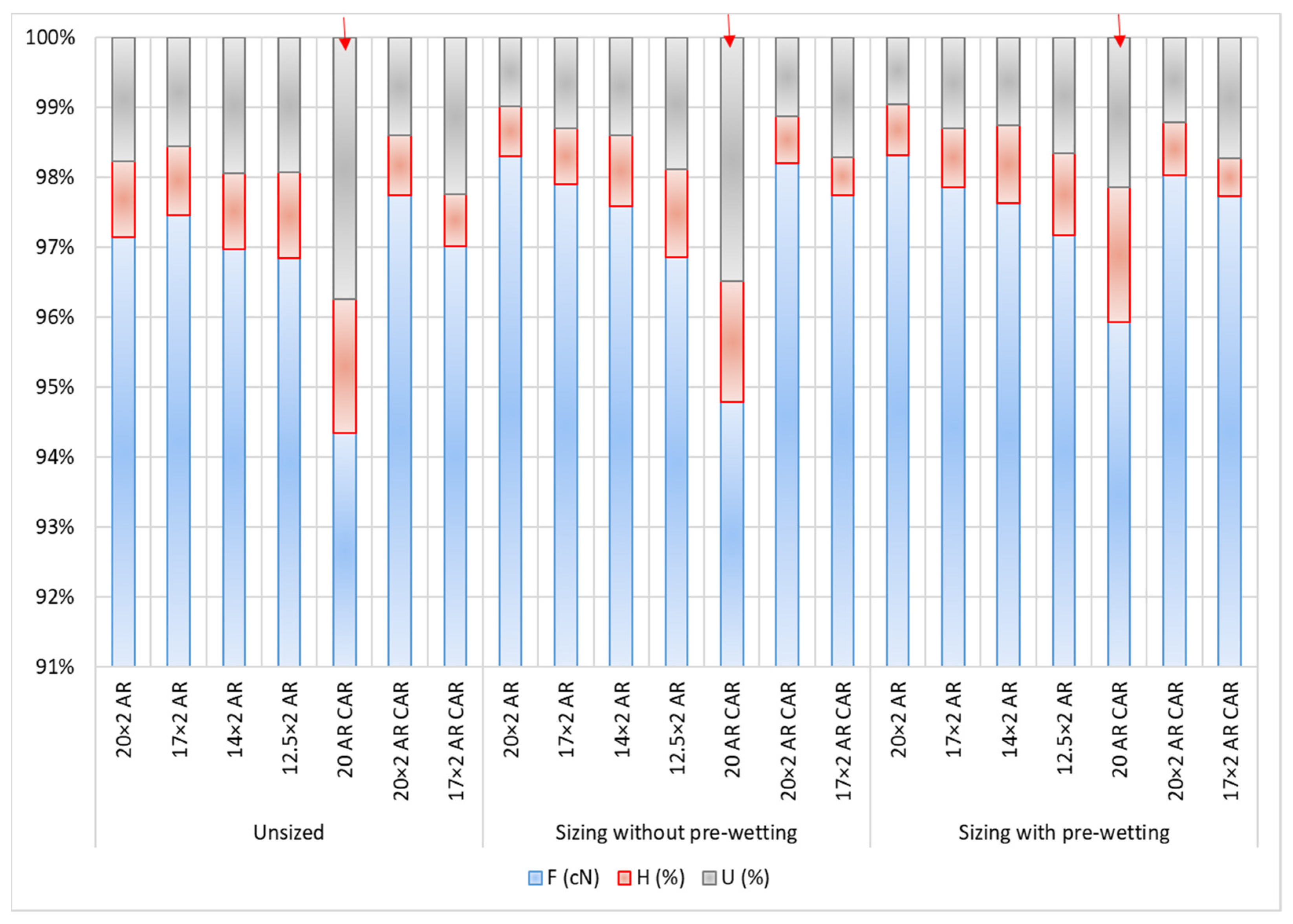

- The breaking forces are higher for all samples except for the yarn sample designated with 12.5 × 2 AR with and without sizing;

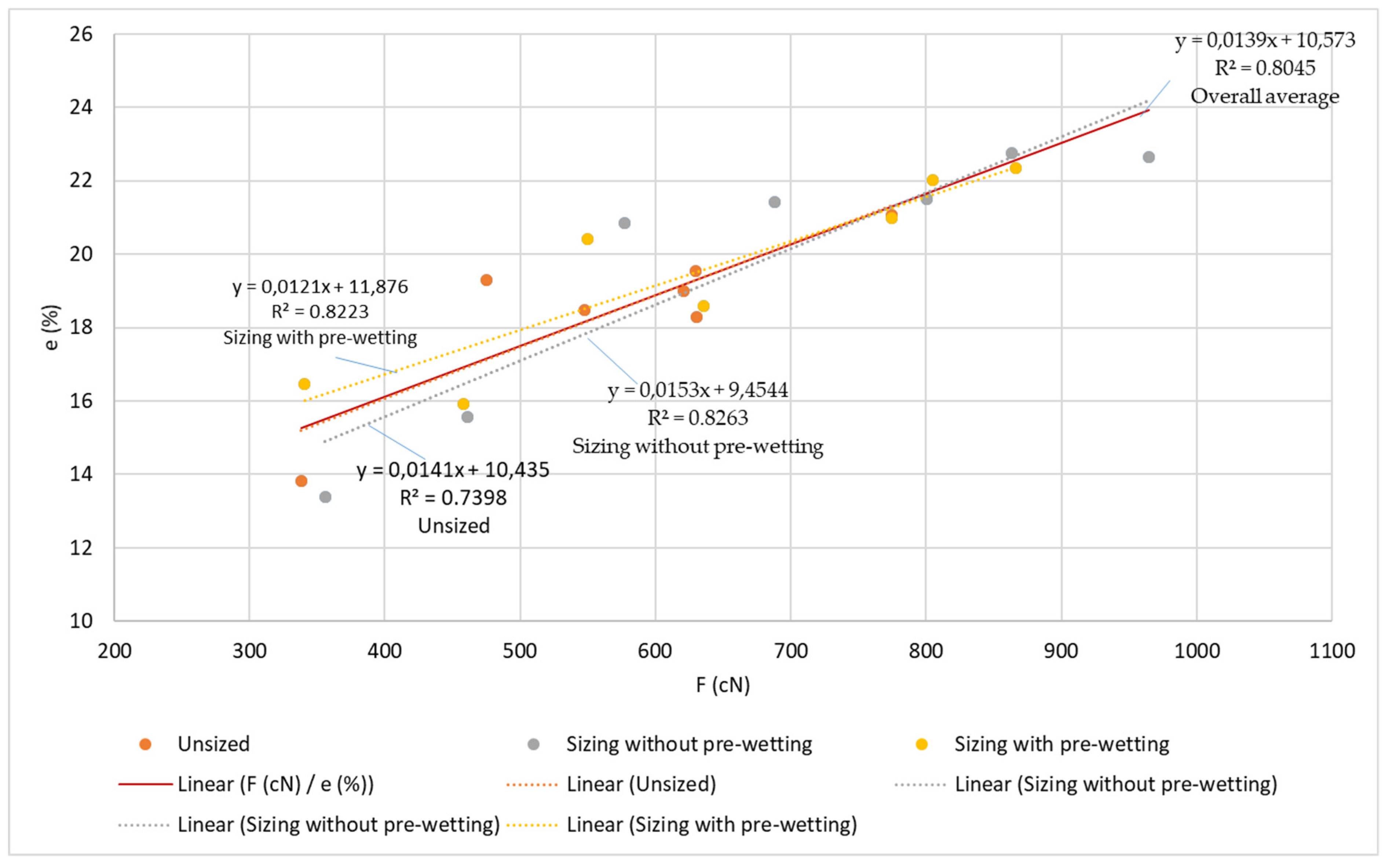

- The elongation at break is higher for all samples except for the sample 12.5 × 2 AR sized without pre-wetting and the sample 20 AR CAR sized with and without pre-wetting;

- The abrasion resistance of the yarn increased with sizing without pre-wetting, except for sample 14 × 2 AR, while only in two samples abrasion resistance increased with sizing with pre-wetting (20 AR CAR and 20 × 2 AR CAR);

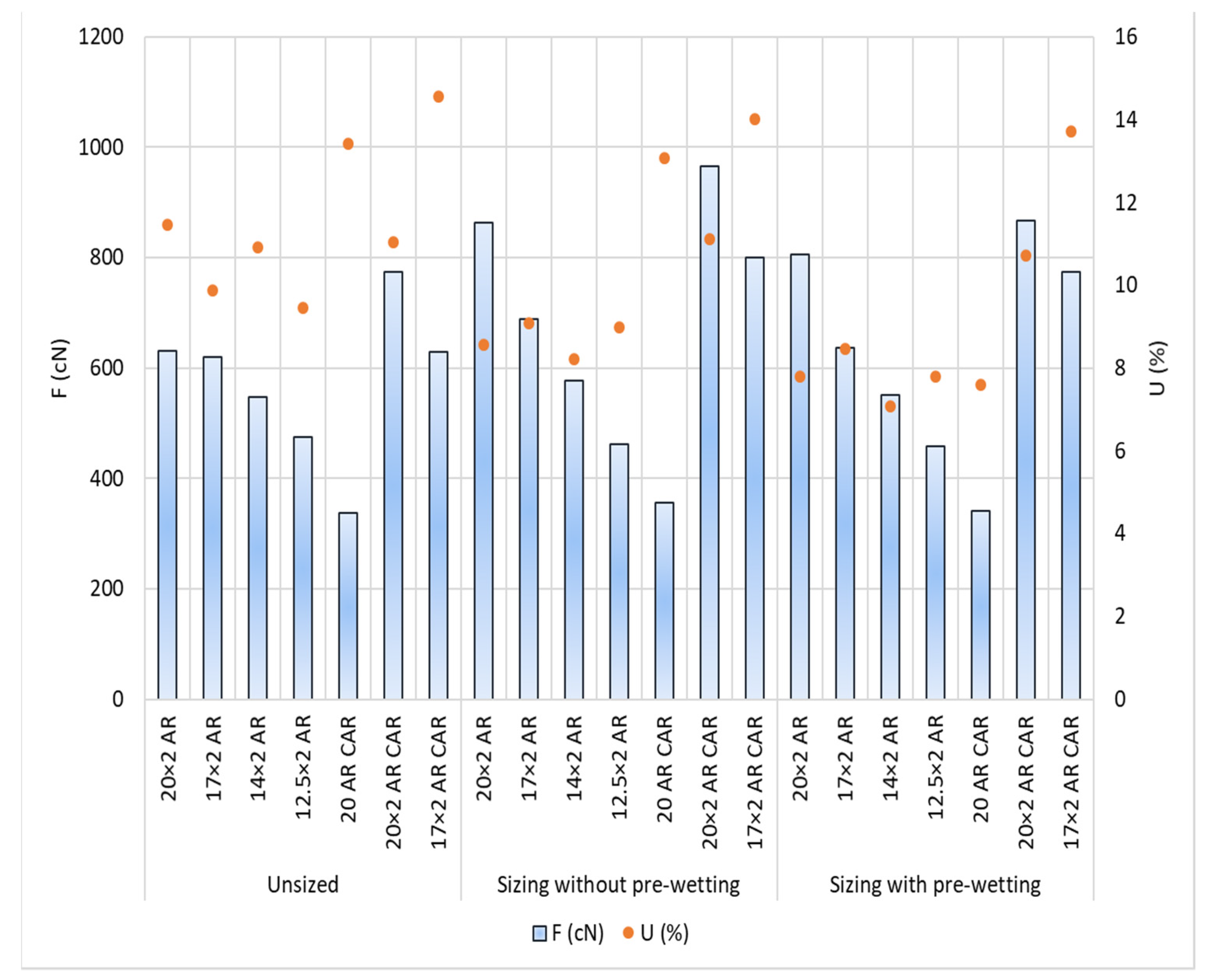

- The yarn irregularity is lower for all samples sized without and with pre-wetting, except for sample 14 × 2 AR, which was sized with pre-wetting;

- The hairiness of the yarn decreased in all samples except for the sample 14 × 2 AR sized with pre-wetting.

4. Conclusions

- The finer and single yarn has a lower size pick-up and breaking force;

- The yarn sized without pre-wetting designated with AR has a higher size pick-up and the yarn designated with AR CAR sized with pre-wetting has also a higher size pick-up;

- The results obtained for the breaking properties suggest that the sizing of aramid yarns is justified;

- Sizing increased the breaking forces by up to 40%. A higher breaking force results from the sizing without pre-watering. Increasing breaking forces are recorded in all samples and under sizing conditions, except for the finest sample designated with 12 × 2 AR, which proved to be the most sensitive in wet sizing processing and with a lower size pick-up. The yarns designated with AR CAR with a carbon fibre content had a higher breaking force before and after sizing;

- Elongation at break increased by sizing for the plied yarns except for the finest plied yarn designated with 12.5 × 2 AR sized without pre-wetting and the yarn designated with 17 × 2 AR sized with pre-wetting and except for the single yarn 20 AR CAR sized with pre-wetting;

- The abrasion resistance of the yarn is higher for all samples without pre-wetting, except for sample 14 × 2 AR, which was sized without pre-wetting. The samples sized with pre-wetting mostly demonstrate no increase in abrasion resistance, except for samples 20 AR CAR and 20 × 2 AR CAR, in which abrasion resistance increased. The finer the yarn after sizing, the lower the increase in abrasion resistance;

- The yarn irregularity was reduced by sizing in all samples, especially in yarns sized with pre-wetting, except for sample 20 AR CAR after sizing without pre-wetting. Analysing the samples of the groups AR and AR CAR after sizing, it was found that their mutual differences in irregularity decreased;

- Yarn hairiness or the frequency of protruding fibres due to sizing decreased in all samples and sizing conditions, except for the sample 14 × 2 AR after sizing with pre-wetting.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, X. Fabrication and Properties of Carbon Fibers. Materials 2009, 2, 2369–2403. [Google Scholar] [CrossRef]

- Vaidyal, S.; Allouche, E.N. Experimental evaluation of electrical conductivity of carbon fiber reinforced fly-ash based geopolymer. Smart Struct. Syst. 2011, 7, 27–40. [Google Scholar] [CrossRef]

- Šafářová, V.; Grégr, J. Electrical Conductivity Measurement of Fibers and Yarns. In Proceedings of the 7th International Conference, TEXSCI 2010, Liberec, Czech Republic, 6–8 September 2010. [Google Scholar]

- Morton, W.E.; Hearle, J.W.S. Physical Properties of Textile Fibres, 4th ed.; Woodhead Publishing: London, UK, 2008; ISBN 1845692209. [Google Scholar]

- European Agency for Safety and Health at Work, Legislation 89/686, HRN EN 531 I HRN EN 15613. Available online: https://osha.europa.eu/hr/legislation/directives/34 (accessed on 23 November 2021).

- Behera, B.K.; Joshi, V.K. Effect of sizing on weavability of dref yarns. Autex Res. J. 2006, 6, 142–147. [Google Scholar]

- Kovačević, S.; Dimitrovski, K.; Hađina, J. The Processes of Weaving; Faculty of Textile Technology, University of Zagreb: Zagreb, Croatia, 2008. [Google Scholar]

- Djordjevic, S.; Nikolic, L.; Urosevic, S.; Djordjevic, D. Importance of Polymer Size Rheology for Efficient Sizing of Cotton Warp Yarns. Tekst. Konfeksiyon 2012, 2, 77–82. [Google Scholar]

- Kovačević, S.; Schwarz, I.; Brnada, S. Analysis of size pick–up and mechanical and surface properties of multicolored warps. Text. Res. J. 2008, 78, 158–167. [Google Scholar] [CrossRef]

- Zhu, Z.; Cao, S. Modifications to improve the adhesion of crosslinked starch sizes to fiber substrates. Text. Res. J. 2004, 74, 253–258. [Google Scholar] [CrossRef]

- Clarkson, C.; March, J.; Palmer, J. GCSE Textiles Technology for OCR; Heinemann: Portsmouth, NH, USA, 2002. [Google Scholar]

- Šomođi, Ž.; Kovačević, S.; Dimitrovski, K. Fabric Distortion after Weaving—An Approximate Theoretical Model. In Proceedings of the 5th International Textile, Clothing & Design Conference—Magic World of Textiles, Dubrovnik, Croatia, 3–6 October 2010; pp. 729–734. [Google Scholar]

- Kovačević, S.; Orešković, V.; Grancarić, A.M. Optimising Size Layer As Related to Input Humidity. Tekstil 2000, 49, 689–697. [Google Scholar]

- Kovačević, S.; Dimitrovski, K.; Orešković, V. Optimization of size pick–up on yarn. In Proceedings of the 2nd International Textile, Clothing & Desing Conference—Magic World of Textiles, Dubrovnik, Croatia, 3–6 October 2004; pp. 210–215. [Google Scholar]

- Kovačević, S.; Grancarić, A.M.; Stipančić, M. Determination of the Size Coat. Fibres Text. East. Eur. 2002, 10, 63–67. [Google Scholar]

- Mostafa, K.M.; Morsy, M.S. Tailoring a new sizing agent via structural modification of pregelled starch molecules part 1: Carboxymethylation and grafting. Starch/Stärke 2004, 56, 254–261. [Google Scholar] [CrossRef]

- Kovačević, S.; Penava, Ž. Impact of Sizing on Physico-mechanical Properties of Yarn. Fibres Text. East. Eur. 2004, 4, 32–36. [Google Scholar]

- Ashdown, S.P. Sizing in Clothing: Developing Effective Sizing Systems for Ready-to-Wear Clothing; Woodhead Publishing Inassociation with The Textile Institute: Manchester, UK, 2007. [Google Scholar]

- Kovačević, S.; Mijović, B.; Grancarić, A.N. Influence of Rheological Size Parameters on Yarn Properties. Fibres Text. East. Eur. 2012, 4, 41–46. [Google Scholar]

- Wanga, Y.J.; Truongb, V.D.; Wang, L. Structures and rheological properties of corn starch as affected by acid hydrolysis. Carbohydr. Polym. 2003, 52, 327–333. [Google Scholar] [CrossRef]

- Zhu, Z.; Xiong, Z. Effect of starch/sio2 nanoparticle blends on the adhesion of starch to fibers for warp sizing. AATCC Rev. 2008, 10, 45–48. [Google Scholar]

- Zakrajšek, N.; Knez, S.; Ravnjak, D.; Golob, J. Analysis of modified starch adsorption kinetics on cellulose fibers via the modified langmuir adsorption theory. Chem. Biochem. Eng. Q. 2009, 23, 461–470. [Google Scholar]

- Zhu, Z.; Chen, P. Carbamoyl ethylation of starch for enhancing the adhesion capacity to fibers. J. Appl. Polym. Sci. 2007, 106, 2763–2768. [Google Scholar] [CrossRef]

- Gudlin Schwarz, I.; Kovačević, S.; Dimitrovski, K.; Katović, D. Investigation of the parameters of the yarns sized by the pre-wetting process. Tekstil 2010, 59, 279–286. [Google Scholar]

- Kovačević, S.; Đorđević, S.; Đorđević, D. Modified Natural Starch in the Function of Sizing with and without Pre-Wetting of the Yarn. Contemporary Trends and Innovations in the Textile Industry; Urošević., S., Ed.; Union of Engineers and Technicians of Serbia: Beograd, Serbia, 2018; pp. 315–327. [Google Scholar]

- Gudlin Schwarz, I.; Kovačević, S.; Dimitrovski, K. Comparative Analysis of the Standard and the Pre-wet Sizing Process. Fibres Text. East. Eur. 2011, 19, 135–141. [Google Scholar]

- Gudlin Schwarz, I.; Kovačević, S. A New Pre-Wet Sizing Process—Yes or No? Cutting Edge Research in New Technologies; Volosencu, C., Ed.; InTech-Open Access Publisher: London, UK, 2012; pp. 59–72. [Google Scholar]

- Sun, S.; Yu, H.; Williams, T.; Hicks, R.F.; Qiu, Y. Eco-friendly sizing technology of cotton yarns with He/O2 atmospheric pressure plasma treatment and green sizing recipes. Text. Res. J. 2013, 83, 2177–2190. [Google Scholar] [CrossRef]

- Kenar, J.A.; Eller, F.J.; Felker, F.C.; Jackson, M.A.; Fanta, G.F. Starch aerogel beads obtained from inclusion complexes prepared from high amylose starch and sodium palmitate. Green Chem. 2014, 16, 1921–1930. [Google Scholar] [CrossRef]

- Gudlin Schwarz, I.; Kovačević, S.; Dimitrovski, K. Analysis of changes in mechanical and deformation properties of yarn by sizing. Text. Res. J. 2011, 81, 545–555. [Google Scholar] [CrossRef]

- Mostafa, K.M.; El-Sanaba, A.A. Carboxyl–containing starch and hydrolyzed starch derivatives as size base materials for cotton textiles. Polym. Degrad. Stab. 1997, 55, 181–184. [Google Scholar] [CrossRef]

- Sandhu, K.S.; Kaur, M.; Singh, N.; Lim, S.T. A comparison of native and oxidized normal and waxy corn starches: Physicochemical, thermal, morphological and pasting properties. LWT-Food Sci. Technol. 2008, 41, 1000–1010. [Google Scholar] [CrossRef]

- Schwarz, I. Technological Justification and Optimization of Sizing with Pre-Wetting. Ph.D. Thesis, Faculty of Textile Technology, University of Zagreb, Zagreb, Croatia, 2012. [Google Scholar]

- Djordjevic, S. Synthesis of Derivates Based on Starch and Their Application in Yarn Sizing Process. Ph.D. Thesis, Faculty of technology, University of Niš, Leskovac, Serbia, 2014. [Google Scholar]

- Ghosh, A.; Mal, P. Testing of Fibres. Yarns and Fabrics and Their Recent Developments. In Fibres to Smart Textiles; CRC Press: Boca Raton, FL, USA, 2019; Volume 8, pp. 221–256. [Google Scholar]

- Methods of Evenness Testing. Available online: https://textilestudycenter.com/methods-evenness-testing/#google_vignette (accessed on 26 November 2021).

—highlighted differences.

—highlighted differences.

—highlighted differences.

—highlighted differences.

| Samples | Yarn Designation | Raw Material Composition | Percentage of Raw Materials (%) | Yarn Count (Tex) | Number of Twists (Twist/m) | CV Number of Twists (%) |

|---|---|---|---|---|---|---|

| 1 | 20 × 2 AR | Meta-aramid | 95 | 20 × 2 | 571.2 | 2.83 |

| Para-aramid | 5 | |||||

| 2 | 17 × 2 AR | Meta-aramid | 95 | 17 × 2 | 624.5 | 2.56 |

| Para-aramid | 5 | |||||

| 3 | 14 × 2 AR | Meta-aramid | 95 | 14 × 2 | 687.1 | 3.73 |

| Para-aramid | 5 | |||||

| 4 | 12.5 × 2 AR | Meta-aramid | 95 | 12.5 × 2 | 723.8 | 4.25 |

| Para-aramid | 5 | |||||

| 5 | 20 AR CAR | Meta-aramid | 93 | 20 | 705.1 | 3.70 |

| Para-aramid | 5 | |||||

| Carbon | 2 | |||||

| 6 | 20 × 2 AR CAR | Meta-aramid | 93 | 20 × 2 | 564.3 | 4.11 |

| Para-aramid | 5 | |||||

| Carbon | 2 | |||||

| 7 | 17 × 2 AR CAR | Meta-aramid | 93 | 17 × 2 | 580.2 | 7.07 |

| Para-aramid | 5 | |||||

| Carbon | 2 |

| Size Composition | Industrial Values | Laboratory Values | ||

|---|---|---|---|---|

| (L/kg) | % | (L/kg) | % | |

| Water (L) | 500 | 88.03 | 5 | 88.03 |

| Fibrostin C75 (kg) | 50 | 8.80 | 0.5 | 8.80 |

| Inex 773C (kg) | 15 | 2.64 | 0.15 | 2.64 |

| Avilor 308AS (kg) | 3 | 0.53 | 0.03 | 0.53 |

| Size (L) | 568 | 100 | 5.68 | 100 |

| Sizing Conditions | X | CV (%) |

|---|---|---|

| Thread tension between the creel with cross-wound packages and the pre-wetting box | 40 cN | 16.42 |

| Water temperature in the pre-wetting box | 60 °C | 7.81 |

| Size solution temperature in the size box | 80–85 °C | 5.27 |

| Sizing speed | 3.2 m/min | 11.54 |

| Pressure on the last pair of size solution squeezing rollers | 12.5 N/cm2 | 2.51 |

| Temperature of the cylinders of the contact dryer | 110 °C | 12.00 |

| Moisture of the yarn in the box entry | 4% | 4.40 |

| Moisture of the yarn in the dryer exit | 4% | 13.06 |

| Sizing Conditions | Yarn Designation | Breaking Force/ Differences after Sizing | Elongation at Break/ Differences after Sizing | Work of Rupture | Strength | ||||

|---|---|---|---|---|---|---|---|---|---|

| X (cN) | CV (%) | X (%) | CV (%) | X (cN × cm) | CV (%) | X (cN/tex) | CV (%) | ||

| Unsized yarn | 20 × 2 AR | 630.45 | 6.12 | 18.28 | 15.93 | 44.79 | 20.52 | 15.76 | 6.12 |

| 17 × 2 AR | 620.48 | 4.97 | 19.04 | 10.61 | 45.72 | 13.76 | 18.63 | 4.97 | |

| 14 × 2 AR | 547.36 | 7.12 | 18.49 | 13.43 | 38.76 | 18.53 | 19.16 | 7.12 | |

| 12.5 × 2 AR | 474.98 | 6.07 | 19.29 | 11.83 | 33.04 | 16.95 | 19.00 | 1.15 | |

| 20 AR CAR | 338.20 | 9.04 | 13.81 | 26.98 | 18.73 | 34.20 | 16.91 | 9.04 | |

| 20 × 2 AR CAR | 774.30 | 6.71 | 21.07 | 9.91 | 61.18 | 14.14 | 19.36 | 6.71 | |

| 17 × 2 AR CAR | 629.67 | 5.50 | 19.55 | 10.88 | 44.46 | 15.76 | 18.91 | 5.50 | |

| Sizing without pre-wetting | 20 × 2 AR | 863.40 +36.95 | 6.61 | 22.75 +24.45 | 11.10 | 70.10 | 16.73 | 21.58 | 6.61 |

| 17 × 2 AR | 688.28 +10.93 | 6.14 | 21.43 +12.55 | 10.97 | 53.11 | 16.24 | 20.67 | 6.14 | |

| 14 × 2 AR | 576.84 +5.39 | 6.21 | 20.84 +12.71 | 10.62 | 42.97 | 15.64 | 20.19 | 6.21 | |

| 12.5 × 2 AR | 461.15 −2.91 | 9.10 | 15.57 −19.28 | 25.10 | 28.70 | 31.56 | 18.45 | 9.10 | |

| 20 AR CAR | 355.96 +5.25 | 9.15 | 13.38 −3.11 | 25.75 | 19.15 | 32.31 | 17.80 | 9.15 | |

| 20 × 2 AR CAR | 964.54 +24.57 | 4.95 | 22.65 +7.50 | 19.47 | 39.15 | 24.06 | 34.97 | 6.95 | |

| 17 × 2 AR CAR | 800.49 +27.13 | 6.16 | 21.49 +9.92 | 11.94 | 64.20 | 15.71 | 20.01 | 6.16 | |

| Sizing with pre-wetting | 20 × 2 AR | 805.21 +27.72 | 6.92 | 22.02 +20.46 | 10.20 | 65.69 | 15.43 | 20.26 | 6.92 |

| 17 × 2 AR | 635.92 +2.49 | 8.34 | 18.59 −2.36 | 18.60 | 45.18 | 24.46 | 19.10 | 8.34 | |

| 14 × 2 AR | 550.16 +0.52 | 7.56 | 20.42 +10.44 | 13.06 | 42.32 | 18.43 | 19.26 | 7.56 | |

| 12.5 × 2 AR | 458.12 −3.55 | 8.47 | 15.93 +17.42 | 22.06 | 28.98 | 28.52 | 18.32 | 8.47 | |

| 20 AR CAR | 340.93 +0.81 | 6.77 | 16.45 −19.11 | 16.08 | 20.92 | 21.98 | 17.05 | 6.77 | |

| 20 × 2 AR CAR | 866.11 +11.86 | 4.28 | 22.35 +6.07 | 6.84 | 72.98 | 9.54 | 26.01 | 4.28 | |

| 17 × 2 AR CAR | 774.82 +23.05 | 6.89 | 20.98 +7.31 | 12.14 | 58.85 | 17.35 | 19.37 | 6.89 | |

| Sizing Conditions | Yarn Designation | Size Pick-Up (Sp/%) | Abrasion Resistance (A/n) | Irregularity (U/%) | Hairiness (H/%) | ||||

|---|---|---|---|---|---|---|---|---|---|

| X | CV | X | CV | X | CV | X | CV | ||

| Unsized | 20 × 2 AR | 1487.25 | 16.78 | 11.45 | 15.32 | 7.11 | 12.2 | ||

| 17 × 2 AR | 1374.35 | 16.89 | 9.87 | 12.79 | 6.3 | 11.45 | |||

| 14 × 2 AR | 1470.05 | 32.71 | 10.92 | 13.65 | 6.11 | 11.92 | |||

| 12.5 × 2 AR | 718.55 | 37.11 | 9.44 | 11.86 | 6 | 11.86 | |||

| 20 AR CAR | 277.75 | 31.57 | 13.42 | 17.72 | 6.86 | 13.79 | |||

| 20 × 2 AR CAR | 1495.95 | 30.46 | 11.03 | 14.81 | 6.85 | 11.9 | |||

| 17 × 2 AR CAR | 1501.2 | 19.12 | 14.55 | 20.35 | 4.78 | 11.27 | |||

| Sizing without pre-wetting | 20 × 2 AR | 4.27 | 6.55 | 1508.4 | 17.27 | 8.57 | 10.78 | 6.31 | 9.89 |

| 17 × 2 AR | 3.5 | 8.55 | 1645.65 | 26.78 | 9.08 | 11.54 | 5.66 | 10.68 | |

| 14 × 2 AR | 3.18 | 9.71 | 1172.1 | 18.31 | 8.22 | 10.44 | 6.04 | 9.11 | |

| 12.5 × 2 AR | 2.72 | 5.82 | 1145.25 | 38.65 | 8.98 | 11.19 | 5.96 | 10.87 | |

| 20 AR CAR | 2.05 | 8.49 | 466.95 | 30.38 | 13.08 | 17.73 | 6.84 | 11.16 | |

| 20 × 2 AR CAR | 4.24 | 10.11 | 1878.8 | 15.38 | 11.11 | 14.99 | 6.68 | 9.99 | |

| 17 × 2 AR CAR | 3.31 | 8.21 | 1744.1 | 16.89 | 14 | 18.84 | 4.39 | 8.6 | |

| Sizing with pre-wetting | 20 × 2 AR | 3.45 | 6.2 | 1403.2 | 20.02 | 7.8 | 9.87 | 5.96 | 8.87 |

| 17 × 2 AR | 3.32 | 5.44 | 1132.55 | 17.11 | 8.45 | 10.8 | 5.45 | 9.7 | |

| 14 × 2 AR | 3.07 | 3.91 | 1025.6 | 30.4 | 7.07 | 9.07 | 5.3 | 9.96 | |

| 12.5 × 2 AR | 2.61 | 7.09 | 695.05 | 21.21 | 7.8 | 9.87 | 5.52 | 7.7 | |

| 20 AR CAR | 2.09 | 7.12 | 314.4 | 26.31 | 7.6 | 9.48 | 6.5 | 9.04 | |

| 20 × 2 AR CAR | 4.27 | 4.73 | 1636.55 | 26.15 | 10.72 | 14.7 | 5.53 | 7.93 | |

| 17 × 2 AR CAR | 4.16 | 5.29 | 1037.3 | 20.21 | 13.72 | 18.46 | 4.23 | 7.47 | |

| Samp. | Yarn Designation | Size Pick-Up | Breaking Forces | Elongation at Break | Abrasion Resistance | Irregularity | Hairiness | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | A | B | A | B | A | B | A | B | A | B | ||

| 1 | 20 × 2 AR | ↑ | ↓ | ↑ | ↑ | ↑ | ↑ | ↑ | ↓ | ↓ | ↓ | ↓ | ↓ |

| 2 | 17 × 2 AR | ↑ | ↓ | ↑ | ↑ | ↑ | ↓ | ↑ | ↓ | ↓ | ↓ | ↓ | ↓ |

| 3 | 14 × 2 AR | ↑ | ↓ | ↑ | ↑ | ↑ | ↑ | ↓ | ↓ | ↓ | ↓ | ↓ | ↑ |

| 4 | 12.5 × 2 AR | ↑ | ↓ | ↓ | ↓ | ↓ | ↑ | ↑ | ↓ | ↓ | ↓ | ↓ | ↓ |

| 5 | 20 AR CAR | ↓ | ↑ | ↑ | ↑ | ↓ | ↓ | ↑ | ↑ | ↑ | ↓ | ↓ | ↓ |

| 6 | 20 × 2 AR CAR | ↓ | ↑ | ↑ | ↑ | ↑ | ↑ | ↑ | ↑ | ↓ | ↓ | ↓ | ↓ |

| 7 | 17 × 2 AR CAR | ↓ | ↑ | ↑ | ↑ | ↑ | ↑ | ↑ | ↓ | ↓ | ↓ | ↓ | ↓ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krstović, K.; Kovačević, S.; Schwarz, I.; Brnada, S. Study of Aramid Yarns Sizing. Polymers 2022, 14, 761. https://doi.org/10.3390/polym14040761

Krstović K, Kovačević S, Schwarz I, Brnada S. Study of Aramid Yarns Sizing. Polymers. 2022; 14(4):761. https://doi.org/10.3390/polym14040761

Chicago/Turabian StyleKrstović, Katarina, Stana Kovačević, Ivana Schwarz, and Snježana Brnada. 2022. "Study of Aramid Yarns Sizing" Polymers 14, no. 4: 761. https://doi.org/10.3390/polym14040761

APA StyleKrstović, K., Kovačević, S., Schwarz, I., & Brnada, S. (2022). Study of Aramid Yarns Sizing. Polymers, 14(4), 761. https://doi.org/10.3390/polym14040761