Evaluation of the Shape Memory Effect of Random and Aligned Electrospun Polyurethane Mats with Different Fibers Diameter

Abstract

1. Introduction

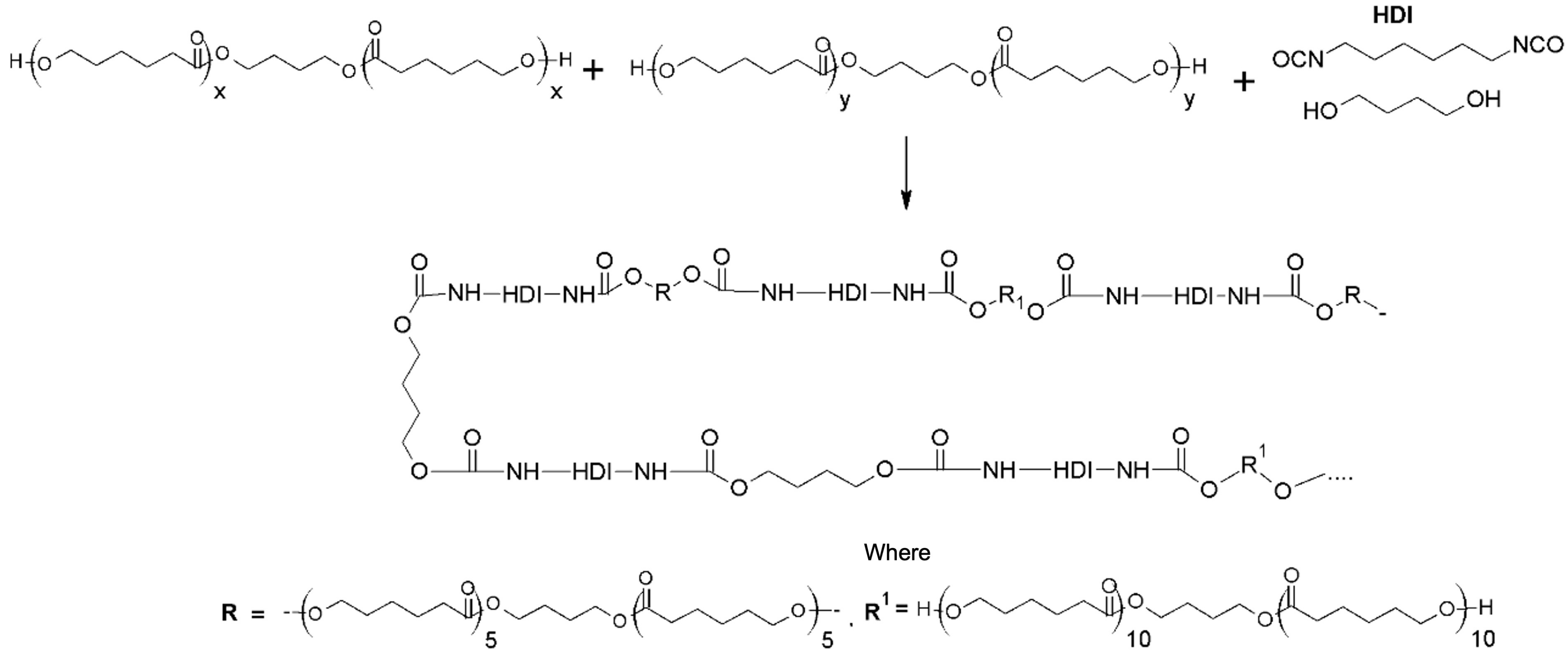

2. Materials and Methods

2.1. Materials

2.2. Electrospinning of Polyurethane Mats with Random and Aligned Structure

2.3. Characterization of the Electrospun Mats

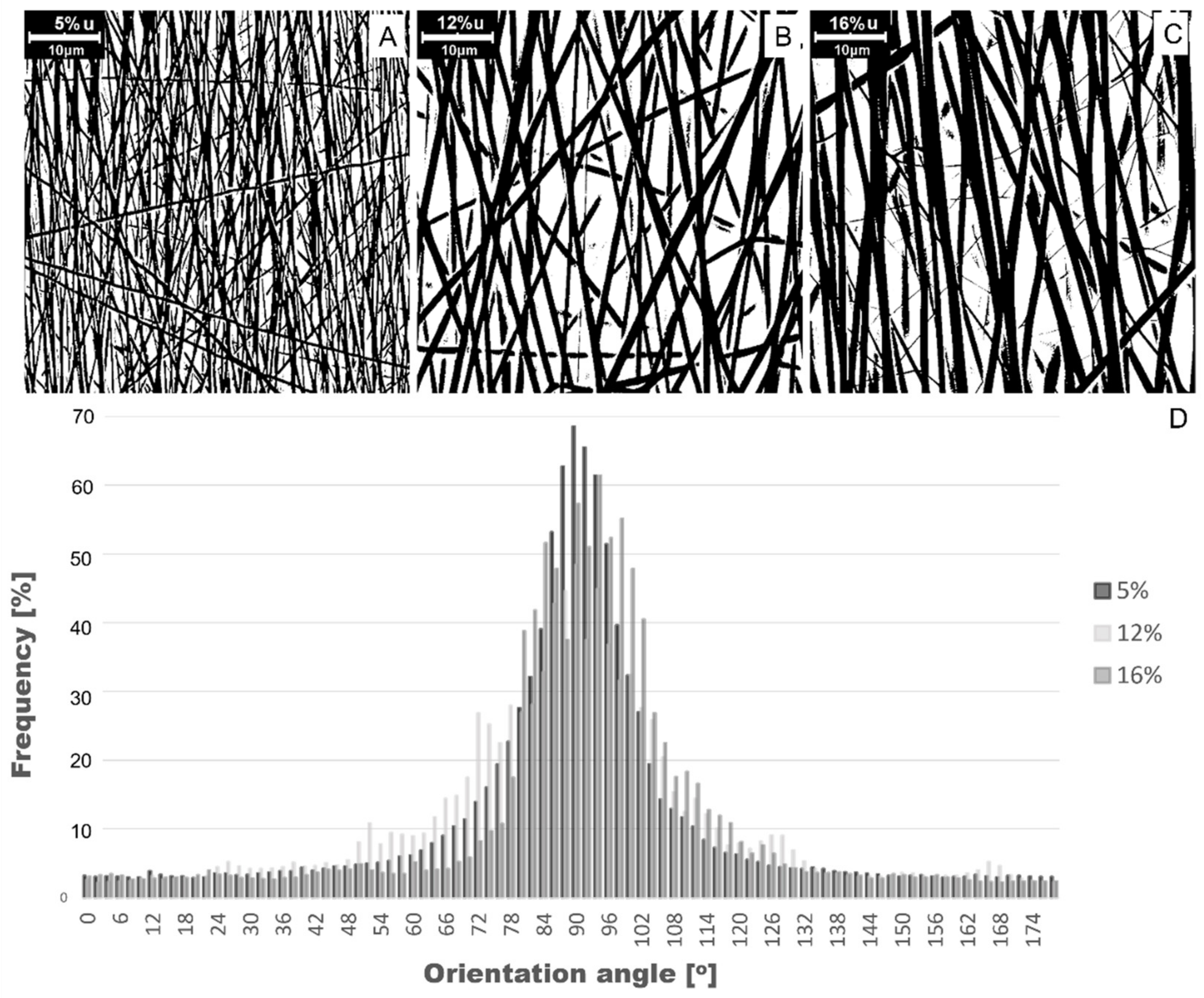

2.3.1. Morphology Evaluation

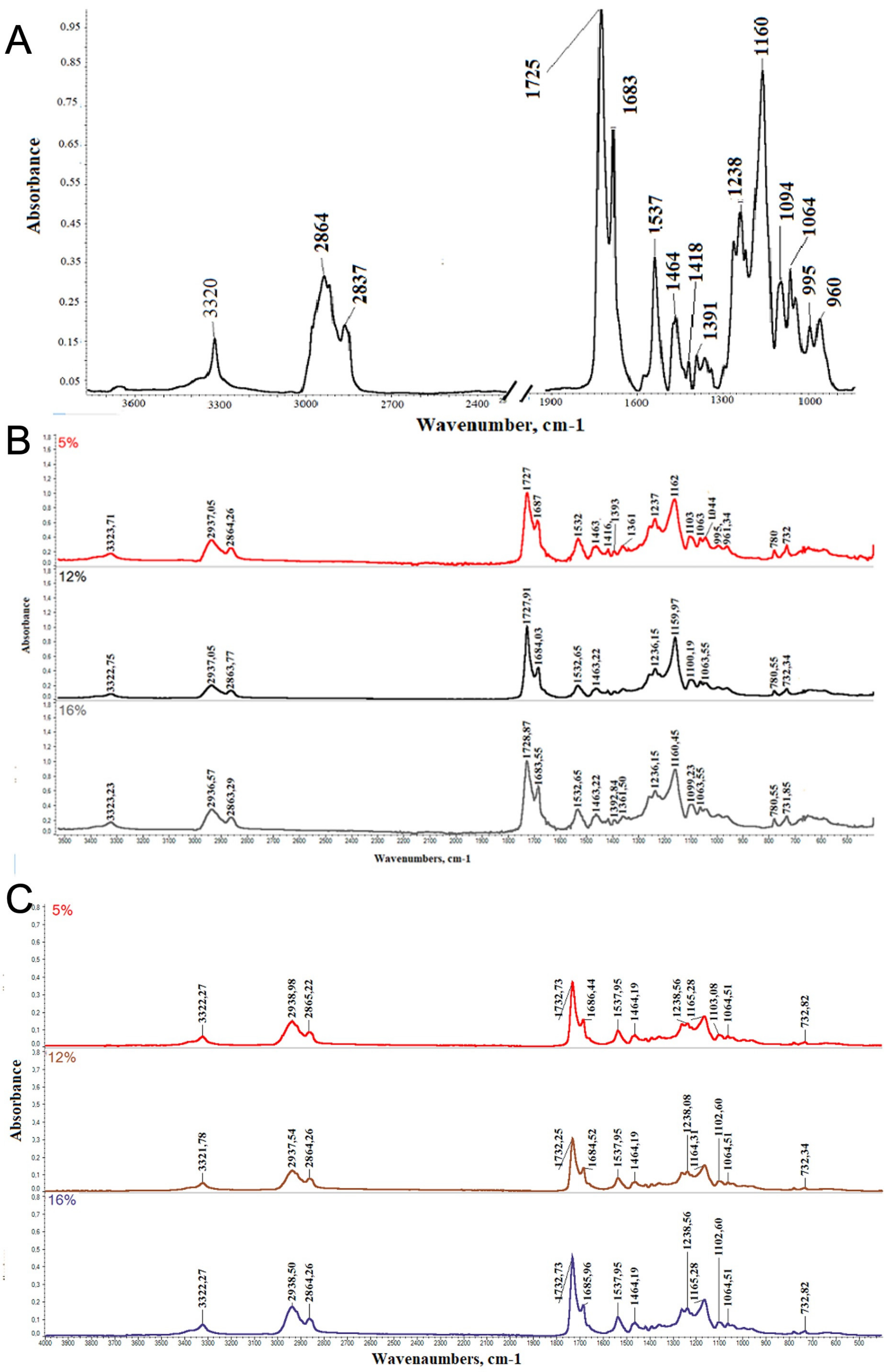

2.3.2. Molecular Structure

2.3.3. Thermal Analysis

2.3.4. Surface Hydrophilicity

2.3.5. Mechanical Properties Evaluation

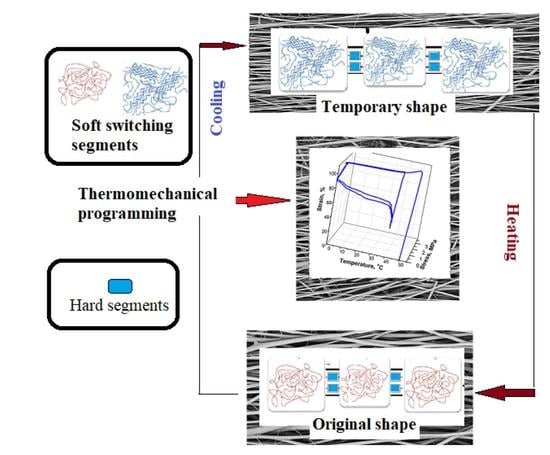

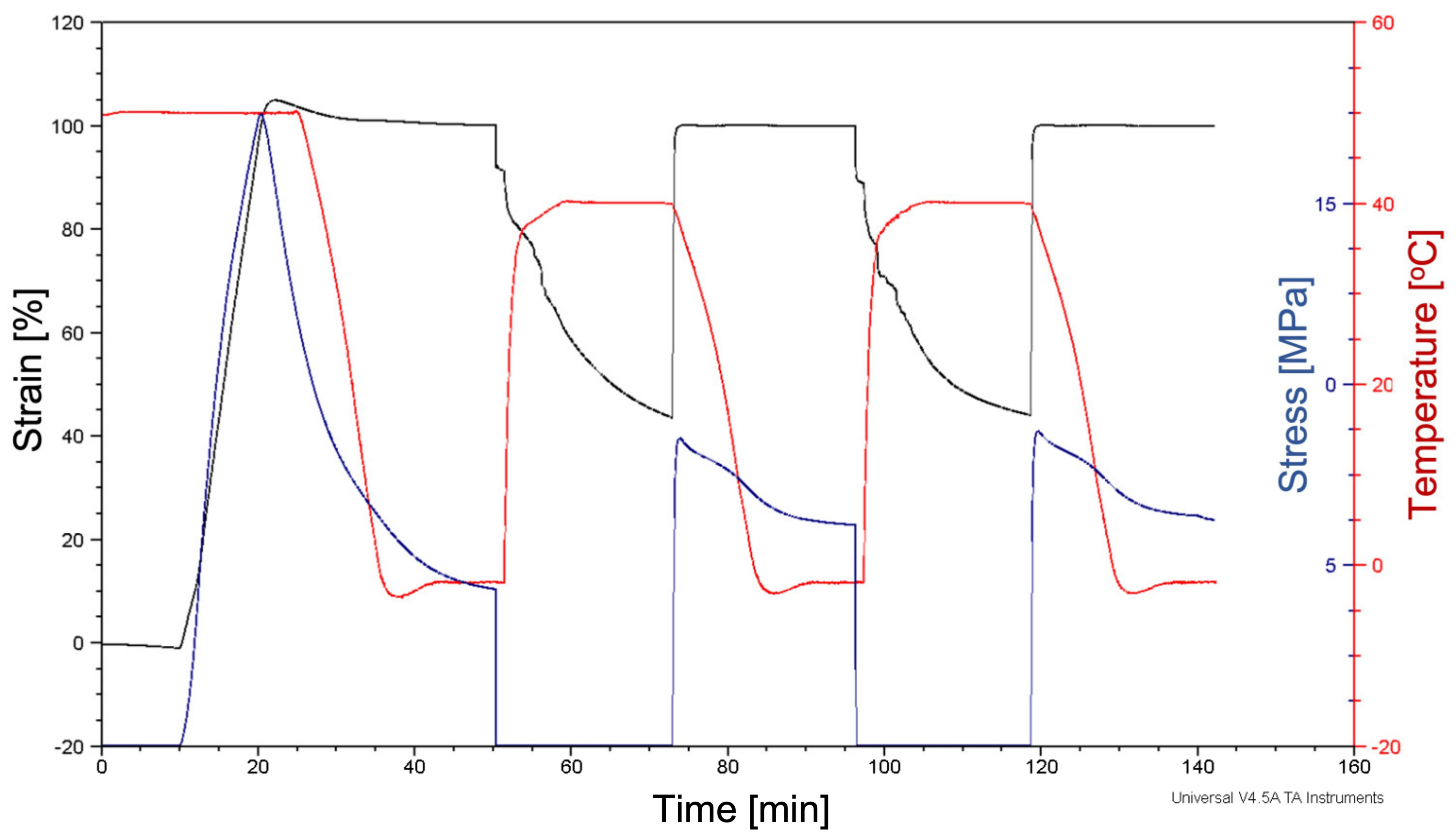

2.3.6. Shape Memory Effect Analysis

3. Results and Discussion

Chemo-Physical Properties of the Obtained Electrospun Mats

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Delaey, J.; Dubruel, P.; Van Vlierberghe, S. Shape-Memory Polymers for Biomedical Applications. Adv. Funct. Mater. 2020, 30, 1909047. [Google Scholar] [CrossRef]

- Bil, M.; Kijeńska-Gawrońska, E.; Głodkowska-Mrówka, E.; Manda-Handzlik, A.; Mrówka, P. Design and in Vitro Evaluation of Electrospun Shape Memory Polyurethanes for Self-Fitting Tissue Engineering Grafts and Drug Delivery Systems. Mater. Sci. Eng. C 2020, 110, 110675. [Google Scholar] [CrossRef] [PubMed]

- Wong, Y.S.; Stachurski, Z.H.; Venkatraman, S.S. Modeling Shape Memory Effect in Uncrosslinked Amorphous Biodegradable Polymer. Polymer 2011, 52, 874–880. [Google Scholar] [CrossRef]

- Salaris, V.; Leonés, A.; Lopez, D.; Kenny, J.M.; Peponi, L. Shape-Memory Materials via Electrospinning: A Review. Polymers 2022, 14, 995. [Google Scholar] [CrossRef] [PubMed]

- Gupta, A.; Maharjan, A.; Kim, B.S. Shape Memory Polyurethane and Its Composites for Various Applications. Appl. Sci. 2019, 9, 4694. [Google Scholar] [CrossRef]

- Paik, I.H.; Goo, N.S.; Jung, Y.C.; Cho, J.W. Development and Application of Conducting Shape Memory Polyurethane Actuators. Smart Mater. Struct. 2006, 15, 1476. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, Y.; Dong, H.; Xu, R.; Jiang, S. Flame-Retardant Shape Memory Polyurethane/MXene Paper and the Application for Early Fire Alarm Sensor. Compos. Part B Eng. 2021, 223, 109149. [Google Scholar] [CrossRef]

- Sáenz-Pérez, M.; Bashir, T.; Laza, J.M.; García-Barrasa, J.; Vilas, J.L.; Skrifvars, M.; León, L.M. Novel Shape-Memory Polyurethane Fibers for Textile Applications. Text. Res. J. 2019, 89, 1027–1037. [Google Scholar] [CrossRef]

- Gabriel, L.P.; Rodrigues, A.A.; Macedo, M.; Jardini, A.L.; Maciel Filho, R. Electrospun Polyurethane Membranes for Tissue Engineering Applications. Mater. Sci. Eng. C 2017, 72, 113–117. [Google Scholar] [CrossRef]

- Bil, M.; Hipś, I.; Mrówka, P.; Święszkowski, W. Studies on Enzymatic Degradation of Multifunctional Composite Consisting of Chitosan Microspheres and Shape Memory Polyurethane Matrix. Polym. Degrad. Stab. 2020, 182, 109392. [Google Scholar] [CrossRef]

- Puszka, A. Poliuretany—Surowce, Właściwości Oraz Modyfikacje. Available online: https://docplayer.pl/6805689-Poliuretany-surowce-wlasciwosci-oraz-modyfikacje.html (accessed on 25 October 2022).

- Gu, L.; Cui, B.; Wu, Q.-Y.; Yu, H. Bio-Based Polyurethanes with Shape Memory Behavior at Body Temperature: Effect of Different Chain Extenders. RSC Adv. 2016, 6, 17888–17895. [Google Scholar] [CrossRef]

- Garg, H.; Mohanty, J.; Gupta, P.; Das, A.; Tripathi, B.P.; Kumar, B. Polyethylenimine-Based Shape Memory Polyurethane with Low Transition Temperature and Excellent Memory Performance. Macromol. Mater. Eng. 2020, 305, 2000215. [Google Scholar] [CrossRef]

- Mao, H.-I.; Chen, C.-W.; Guo, L.-Y.; Rwei, S.-P. Tunable Shape Memory Property Polyurethane with High Glass Transition Temperature Composed of Polycarbonate Diols. J. Appl. Polym. Sci. 2022, 139, e52986. [Google Scholar] [CrossRef]

- Zhu, Y.; Hu, J.; Choi, K.-F.; Yeung, K.-W.; Meng, Q.; Chen, S. Crystallization and Melting Behavior of the Crystalline Soft Segment in a Shape-Memory Polyurethane Ionomer. J. Appl. Polym. Sci. 2008, 107, 599–609. [Google Scholar] [CrossRef]

- Zhuo, H.; Hu, J.; Chen, S. Electrospun Polyurethane Nanofibres Having Shape Memory Effect. Mater. Lett. 2008, 62, 2074–2076. [Google Scholar] [CrossRef]

- Sauter, T.; Kratz, K.; Heuchel, M.; Lendlein, A. Fiber Diameter as Design Parameter for Tailoring the Macroscopic Shape-Memory Performance of Electrospun Meshes. Mater. Des. 2021, 202, 109546. [Google Scholar] [CrossRef]

- Xi, J.; Shahab, S.; Mirzaeifar, R. Qualifying the Contribution of Fiber Diameter on the Acrylate-Based Electrospun Shape Memory Polymer Nano/Microfiber Properties. RSC Adv. 2022, 12, 29162–29169. [Google Scholar] [CrossRef]

- Mujica-Garcia, A.; Navarro-Baena, I.; Kenny, J.; Peponi, L. Influence of the Processing Parameters on the Electrospinning of Biopolymeric Fibers. J. Renew. Mater. 2014, 2, 23–34. [Google Scholar] [CrossRef]

- Kolbuk, D.; Guimond-Lischer, S.; Sajkiewicz, P.; Maniura-Weber, K.; Fortunato, G. The Effect of Selected Electrospinning Parameters on Molecular Structure of Polycaprolactone Nanofibers. Int. J. Polym. Mater. Polym. Biomater. 2015, 64, 365–377. [Google Scholar] [CrossRef]

- Ero-Phillips, O.; Jenkins, M.; Stamboulis, A. Tailoring Crystallinity of Electrospun Plla Fibres by Control of Electrospinning Parameters. Polymers 2012, 4, 1331–1348. [Google Scholar] [CrossRef]

- Kijeńska, E.; Prabhakaran, M.P.; Swieszkowski, W.; Kurzydlowski, K.J.; Ramakrishna, S. Electrospun Bio-Composite P(LLA-CL)/Collagen I/Collagen III Scaffolds for Nerve Tissue Engineering. J. Biomed. Mater. Res. Part B Appl. Biomater. 2012, 100B, 1093–1102. [Google Scholar] [CrossRef] [PubMed]

- Kijeńska-Gawrońska, E.; Swieszkowski, W. General Requirements of Electrospun Materials for Tissue Engineering. In Electrospun Materials for Tissue Engineering and Biomedical Applications: Research, Design and Commercialization; Woodhead Publishing: Sawston, UK, 2017; pp. 43–56. ISBN 978-0-08-101022-8. [Google Scholar]

- Kijeńska-Gawrońska, E.; Bolek, T.; Bil, M.; Swieszkowski, W. Alignment and Bioactive Molecule Enrichment of Bio-Composite Scaffolds towards Peripheral Nerve Tissue Engineering. J. Mater. Chem. B 2019, 7, 4509–4519. [Google Scholar] [CrossRef]

- Katta, P.; Alessandro, M.; Ramsier, R.D.; Chase, G.G. Continuous Electrospinning of Aligned Polymer Nanofibers onto a Wire Drum Collector. Nano Lett. 2004, 4, 2215–2218. [Google Scholar] [CrossRef]

- Borisova, I.; Stoilova, O.; Manolova, N.; Rashkov, I. Effect of Coating on the Mechanical Properties of Electrospun Poly(3-Hydroxybutyrate) Materials with Targeted Fibers Alignment. J. Polym. Res. 2021, 28, 10. [Google Scholar] [CrossRef]

- Zhu, G.; Xu, Q.; Qin, R.; Yan, H.; Liang, G. Effect of γ-Radiation on Crystallization of Polycaprolactone. Radiat. Phys. Chem. 2005, 74, 42–50. [Google Scholar] [CrossRef]

- Doshi, J.; Reneker, D.H. Electrospinning Process and Applications of Electrospun Fibers. J. Electrost. 1995, 35, 151–160. [Google Scholar] [CrossRef]

- Deitzel, J.M.; Kleinmeyer, J.; Harris, D.; Beck Tan, N.C. The Effect of Processing Variables on the Morphology of Electrospun Nanofibers and Textiles. Polymer 2001, 42, 261–272. [Google Scholar] [CrossRef]

- Theron, A.; Zussman, E.; Yarin, A.L. Electrostatic Field-Assisted Alignment of Electrospun Nanofibres. Nanotechnology 2001, 12, 384. [Google Scholar] [CrossRef]

- Kim, K.W.; Lee, K.H.; Khil, M.S.; Ho, Y.S.; Kim, H.Y. The Effect of Molecular Weight and the Linear Velocity of Drum Surface on the Properties of Electrospun Poly(Ethylene Terephthalate) Nonwovens. Fibers Polym. 2004, 5, 122–127. [Google Scholar] [CrossRef]

- Bil, M.; Mrówka, P.; Kołbuk, D.; Święszkowski, W. Multifunctional Composite Combining Chitosan Microspheres for Drug Delivery Embedded in Shape Memory Polyester-Urethane Matrix. Compos. Sci. Technol. 2021, 201, 108481. [Google Scholar] [CrossRef]

- Bil, M.; Ryszkowska, J.; Woźniak, P.; Kurzydłowski, K.J.; Lewandowska-Szumieł, M. Optimization of the Structure of Polyurethanes for Bone Tissue Engineering Applications. Acta Biomater. 2010, 6, 2501–2510. [Google Scholar] [CrossRef] [PubMed]

- Son, T.W.; Lee, D.W.; Lim, S.K. Thermal and Phase Behavior of Polyurethane Based on Chain Extender, 2,2-Bis-[4-(2-Hydroxyethoxy)Phenyl]Propane. Polym. J. 1999, 31, 563–568. [Google Scholar] [CrossRef]

- Echeverría, C.; Limón, I.; Muñoz-Bonilla, A.; Fernández-García, M.; López, D. Development of Highly Crystalline Polylactic Acid with β-Crystalline Phase from the Induced Alignment of Electrospun Fibers. Polymers 2021, 13, 2860. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Green, T.B.; Joo, Y.L. The Thermal Effects on Electrospinning of Polylactic Acid Melts. Polymer 2006, 47, 7497–7505. [Google Scholar] [CrossRef]

- Szycher, M. Structure–Property Relations in Polyurethanes. In Szycher’s Handbook of Polyurethanes; CRC Press: Boca Raton, FL, USA, 2012; ISBN 978-1-4398-6313-8. [Google Scholar]

- Areias, A.C.; Ribeiro, C.; Sencadas, V.; Garcia-Giralt, N.; Diez-Perez, A.; Gómez Ribelles, J.L.; Lanceros-Méndez, S. Influence of Crystallinity and Fiber Orientation on Hydrophobicity and Biological Response of Poly(l-Lactide) Electrospun Mats. Soft Matter 2012, 8, 5818–5825. [Google Scholar] [CrossRef]

- Banikazemi, S.; Rezaei, M.; Rezaei, P.; Babaie, A.; Eyvazzadeh-Kalajahi, A. Preparation of Electrospun Shape Memory Polyurethane Fibers in Optimized Electrospinning Conditions via Response Surface Methodology. Polym. Adv. Technol. 2020, 31, 2199–2208. [Google Scholar] [CrossRef]

- Zhao, Q.; Qi, H.J.; Xie, T. Recent Progress in Shape Memory Polymer: New Behavior, Enabling Materials, and Mechanistic Understanding. Prog. Polym. Sci. 2015, 49–50, 79–120. [Google Scholar] [CrossRef]

| Concentration [%] | Average Diameter for Random Fibers [nm] | Average Diameter for Aligned Fibers [nm] |

|---|---|---|

| 5 | 410 ± 90 | 360 ± 70 |

| 12 | 1160 ± 260 | 890 ± 130 |

| 16 | 1760 ± 540 | 1200 ± 210 |

| Fibers | Dominant Direction [°] | Contribution in Range of 60–120° [%] |

|---|---|---|

| aPU5 | 89.21 ± 8.14 | 78 ± 2 |

| aPU12 | 87.54 ± 12.19 | 74 ± 1 |

| aPU16 | 86.72 ± 9.10 | 80 ± 2 |

| Temperature | Tg [°C] | Tms [°C] | Tmh [°C] | ΔHms [J/g] | Χ, % | ΔHmh [J/g] | |

|---|---|---|---|---|---|---|---|

| Pristine polyurethane | −49.0 | 30.8 | 130.8 | 11.7 | 8,6 | 11.1 | |

| Random | rPU5 | −50.7 | 27.5 | 130.9 | 8.9 | 6.5 | 11.1 |

| rPU12 | −52.7 | 26.8 | 126.9 | 10.8 | 7.9 | 12.3 | |

| rPU16 | −51.4 | 27.4 | 128.9 | 10.9 | 8.0 | 10.5 | |

| Aligned | aPU5 | −52.4 | 28.4 | 127.1 | 10.9 | 8.0 | 11.0 |

| aPU12 | −51.8 | 28.8 | 127.1 | 9.7 | 7.1 | 12.1 | |

| aPU16 | −51.5 | 27.4 | 135.4 | 10.6 | 7.8 | 11.9 | |

| Sample | Contact Angle [°] | Shape of the Water Droplet |

|---|---|---|

| rPU5 | 114 ± 4 |  |

| rPU12 | 132 ± 5 |  |

| rPU16 | 133 ± 3 |  |

| aPU5 | 106 ± 7 |  |

| aPU12 | 126 ± 2 |  |

| aPU15 | 122 ± 4 |  |

| Sample | Arrangement of Fibers | Cycle I | Cycle II | Cycle III (in Water) |

|---|---|---|---|---|

| rPU5 | Random | 60.0 ± 5.9 | 59.0 ± 6.46 | 73.8 ± 4.36 |

| aPU5 | Longitudinal direction * | 58.5 ± 2.12 | 57.4 ± 1.62 | 84.8 ± 3.21 |

| rPU12 | Random | 58.7 ± 0.91 | 58.5 ± 0.99 | 75.6 ± 3.10 |

| aPU12 | Longitudinal direction * | 60.1 ± 1.48 | 59.4 ± 1.36 | 86.9 ± 0.64 |

| rPU16 | Random | 57.3 ± 2.59 | 56.4 ± 3.21 | 74.3 ± 3.66 |

| aPU16 | Longitudinal direction * | 60.0 ± 3.59 | 58.9 ± 5.96 | 95.67 ± 1.36 |

| Sample | Arrangement of Fibers | Cycle I | Cycle II | Cycle III |

|---|---|---|---|---|

| rPU5 | Random | 93.10 ± 2.05 | 94.15 ± 0.39 | 91.0 |

| aPU5 | Longitudinal direction * | 95.18 ± 0.99 | 94.76 ± 0.61 | 93.52 ± 1.69 |

| rPU12 | Random | 95.49 ± 0.35 | 93.66 ± 2.04 | 87.26 ± 3.64 |

| aPU12 | Longitudinal direction * | 95.12 ± 0.36 | 94.15 ± 0.40 | 95.72 ± 1.24 |

| rPU16 | Random | 92.69 ± 2.03 | 93.30 ± 1.91 | 87.0 ± 3.41 |

| aPU16 | Longitudinal direction * | 93.75 ± 1.10 | 92.97 ± 3.24 | 96.95 ± 1.57 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kijeńska-Gawrońska, E.; Maliszewski, A.; Bil, M. Evaluation of the Shape Memory Effect of Random and Aligned Electrospun Polyurethane Mats with Different Fibers Diameter. Polymers 2022, 14, 5468. https://doi.org/10.3390/polym14245468

Kijeńska-Gawrońska E, Maliszewski A, Bil M. Evaluation of the Shape Memory Effect of Random and Aligned Electrospun Polyurethane Mats with Different Fibers Diameter. Polymers. 2022; 14(24):5468. https://doi.org/10.3390/polym14245468

Chicago/Turabian StyleKijeńska-Gawrońska, Ewa, Adrian Maliszewski, and Monika Bil. 2022. "Evaluation of the Shape Memory Effect of Random and Aligned Electrospun Polyurethane Mats with Different Fibers Diameter" Polymers 14, no. 24: 5468. https://doi.org/10.3390/polym14245468

APA StyleKijeńska-Gawrońska, E., Maliszewski, A., & Bil, M. (2022). Evaluation of the Shape Memory Effect of Random and Aligned Electrospun Polyurethane Mats with Different Fibers Diameter. Polymers, 14(24), 5468. https://doi.org/10.3390/polym14245468