Consecutive Ink Writing of Conducting Polymer and Graphene Composite Electrodes for Foldable Electronics-Related Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Direct Ink Writing with PEDOT:PSS Ink

2.3. Consecutive Ink Writing with PEDOT:PSS and Graphene Inks

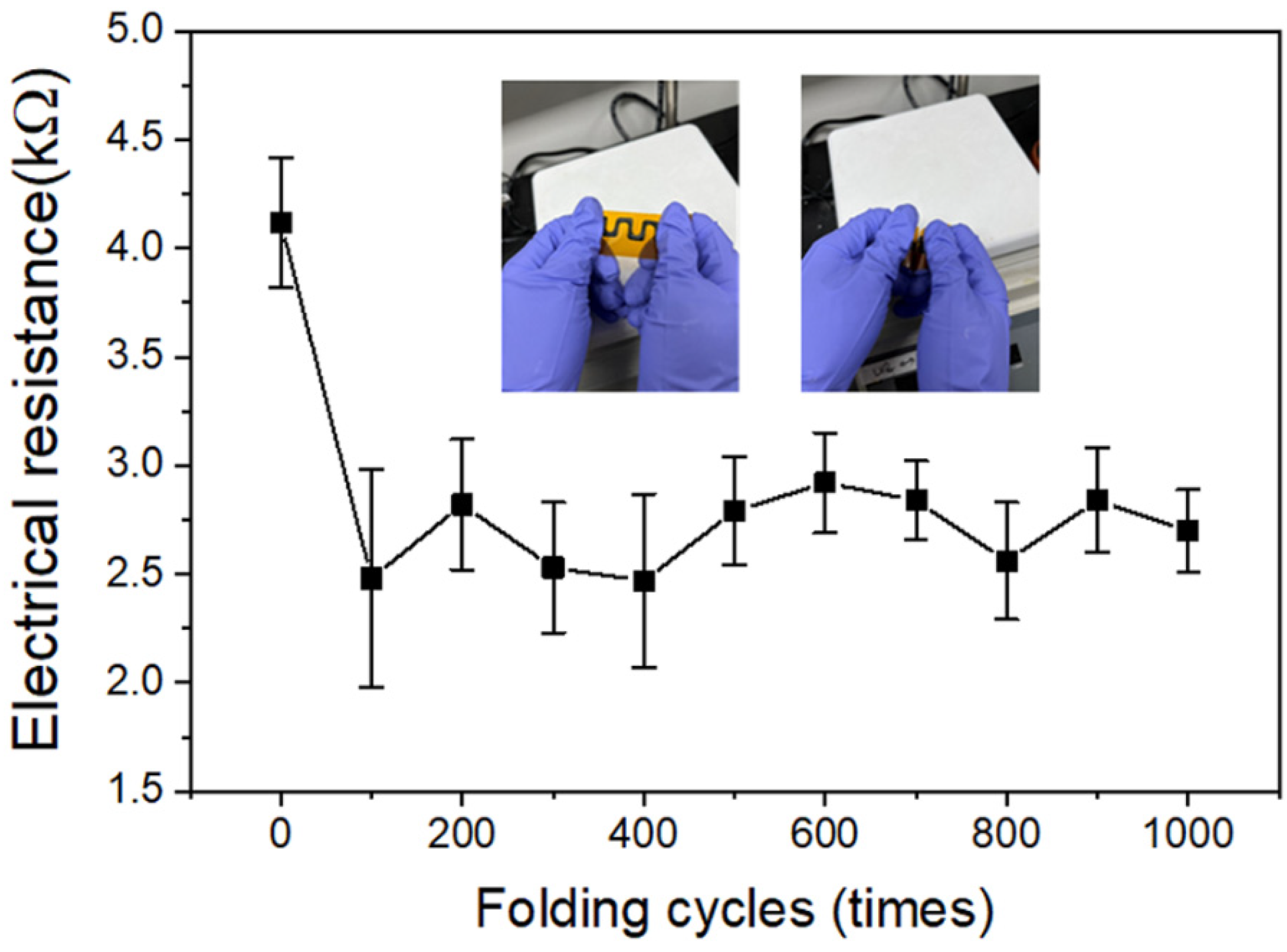

2.4. Folding Test of 3D-Printed EEG/PEDOT:PSS Composite Electrodes on Flexible Substrates

2.5. Characterization

3. Results and Discussion

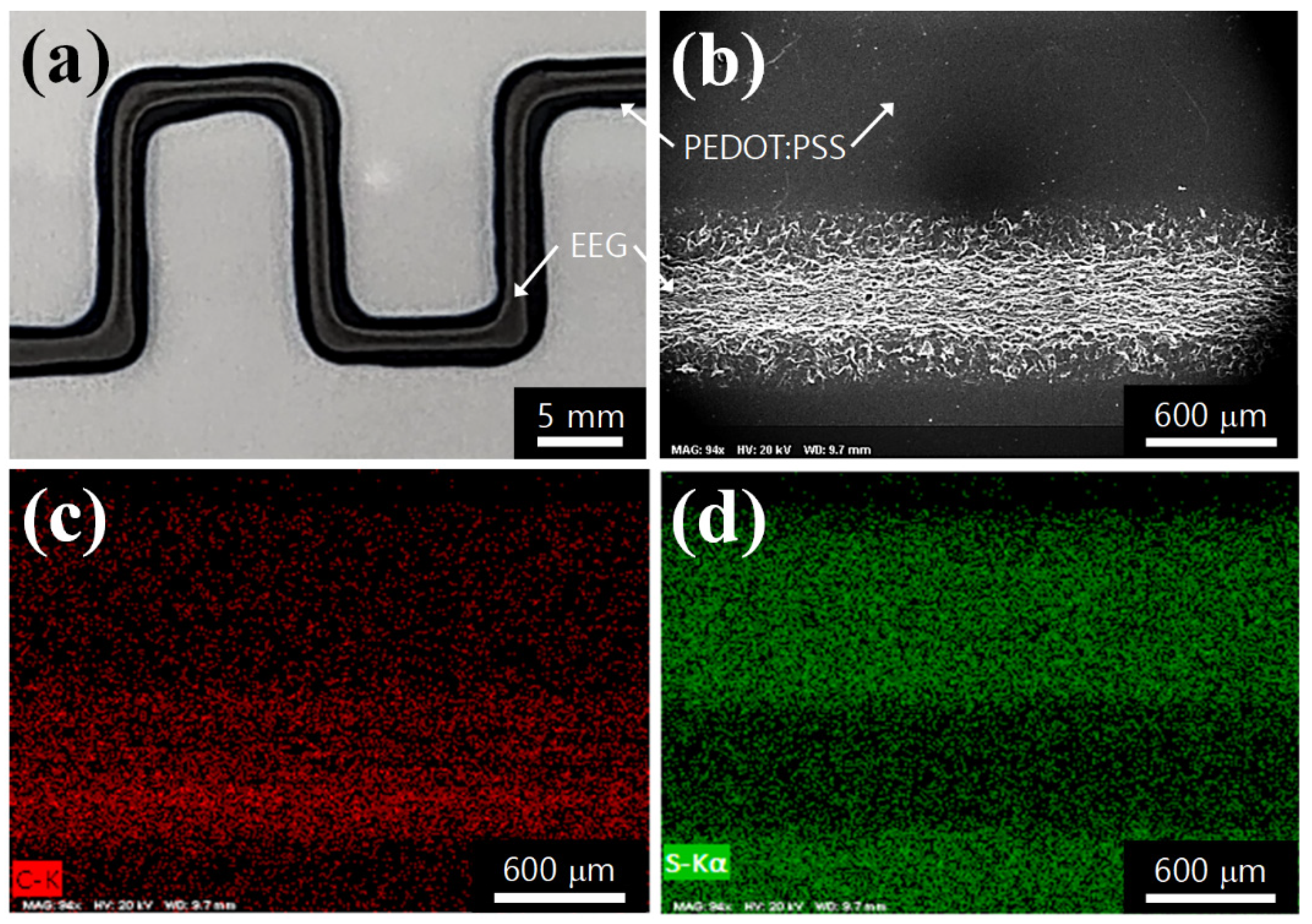

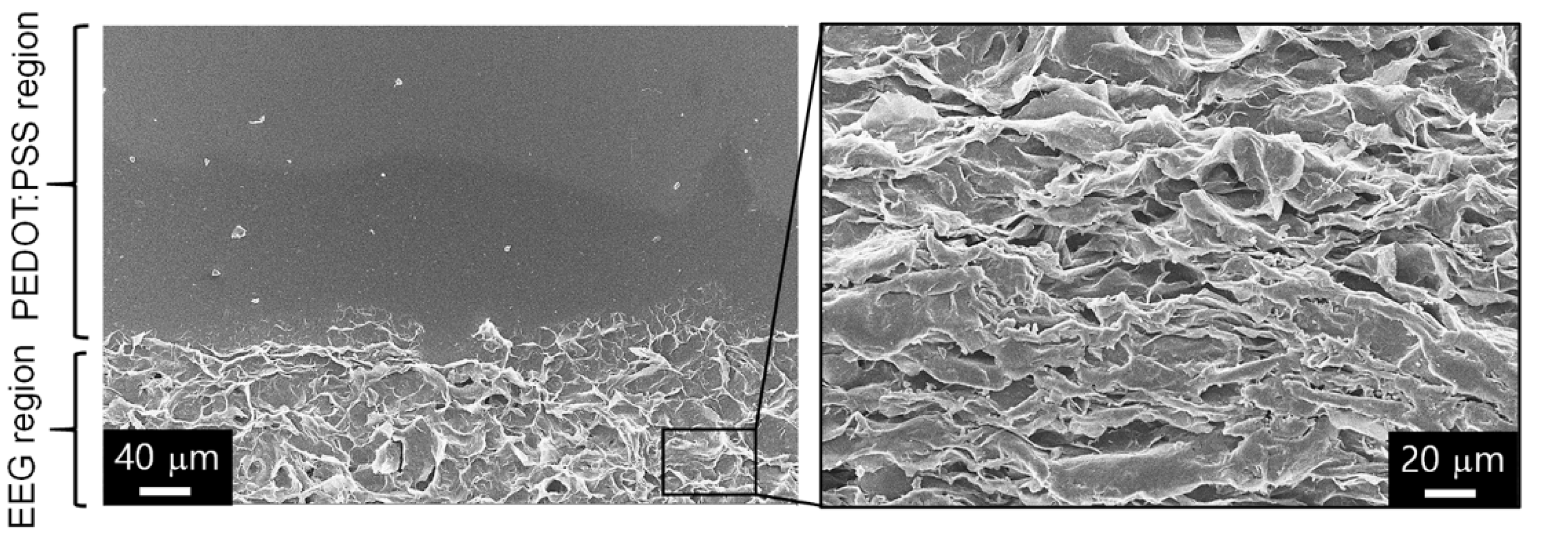

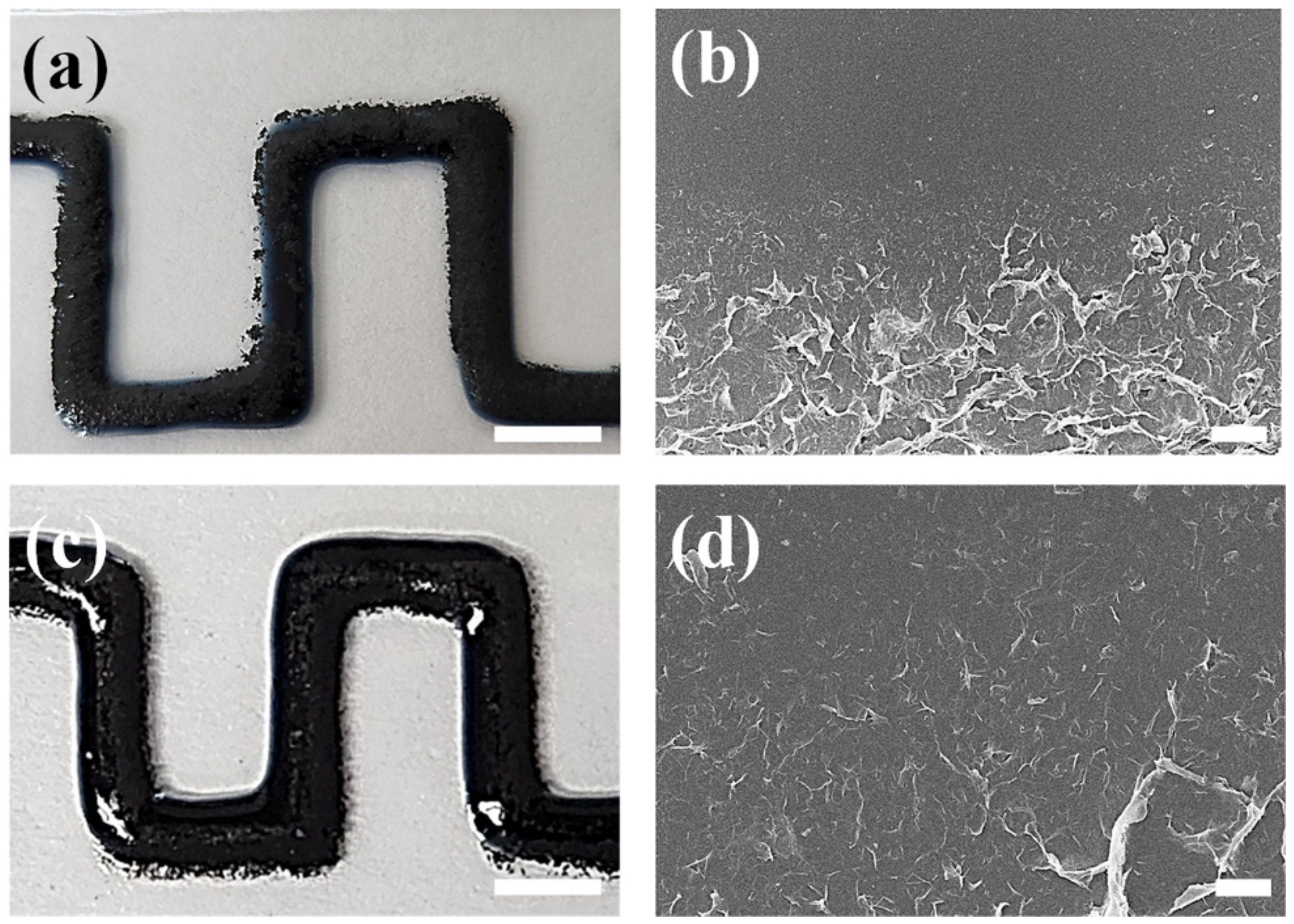

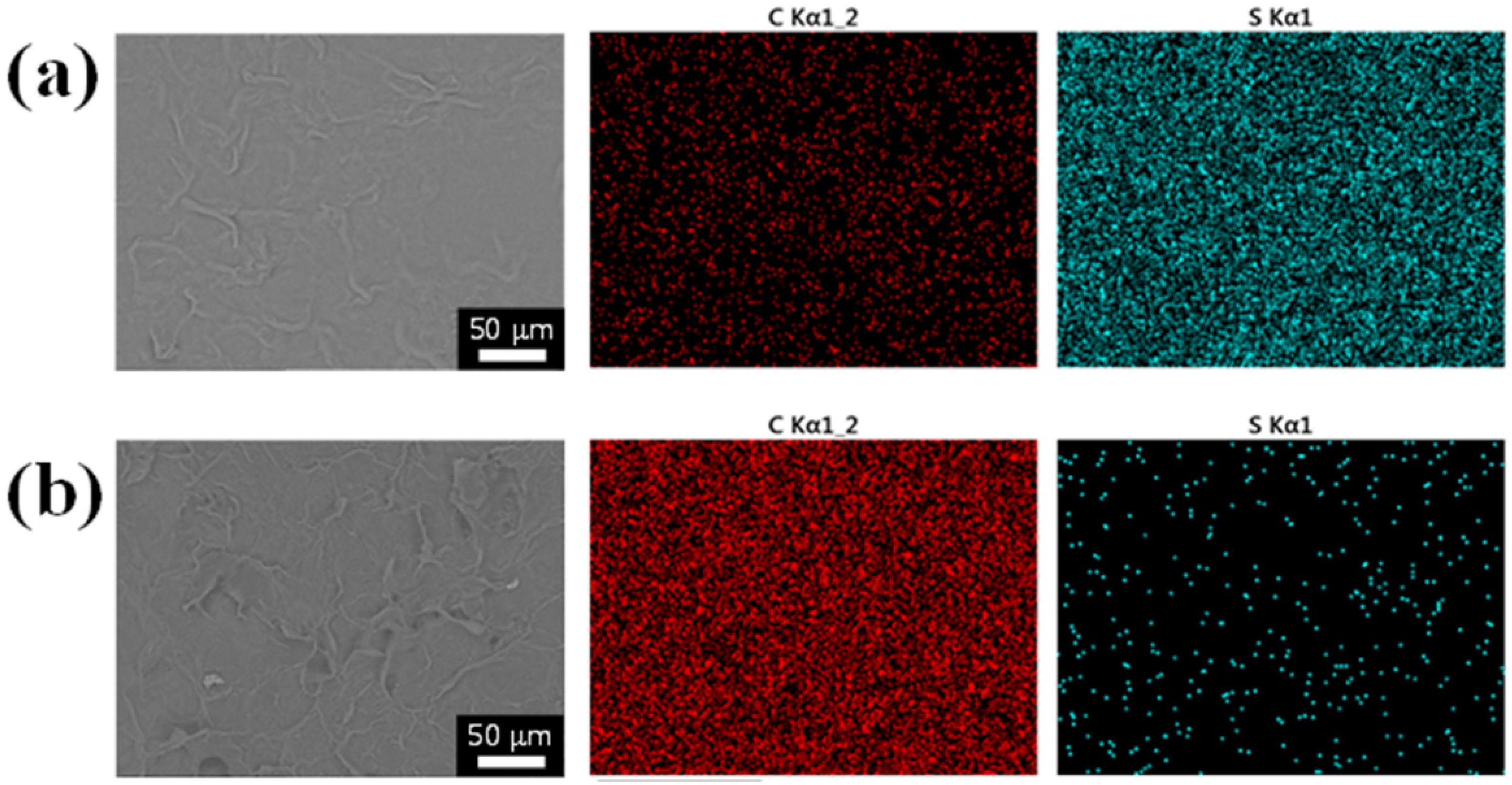

3.1. CIW of PEDOT:PSS/EEG Inks on Glass Substrates

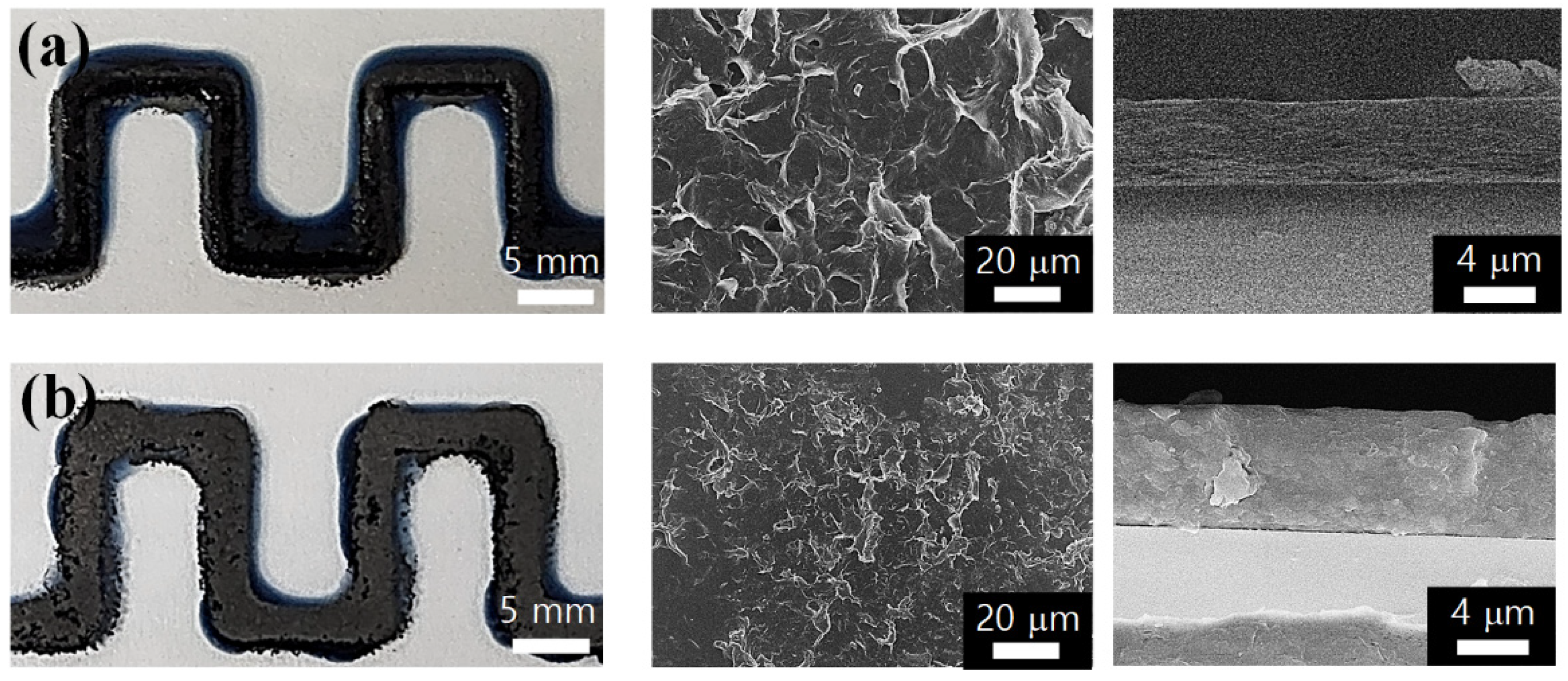

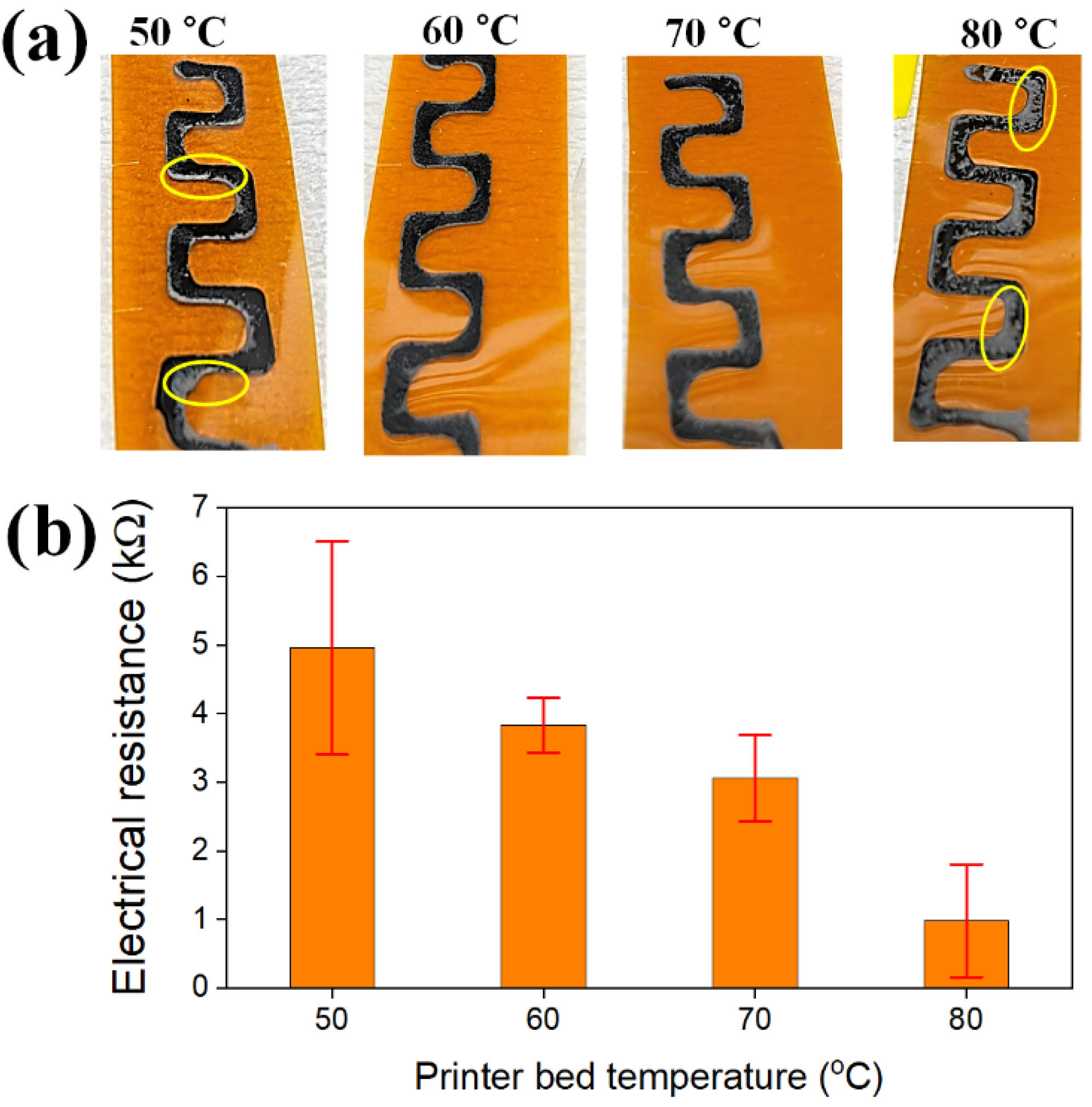

3.2. CIW of PEDOT:PSS/EEG Inks on the Flexible Polyimide Substrate

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Seymour, S. Fashionable Technology, the Intersection of Design, Fashion, Science, and Technology; Springer: New York, NY, USA, 2008. [Google Scholar]

- Post, E.R.; Gershenfeld, N. Massachusetts Institute of Technology, Assignee. Method of Making Flexible Electroniccircuitry. United States Patent US 6,493,933, 18 October 2000. [Google Scholar]

- Azani, M.R.; Hassanpour, A.; Torres, T. Benefits, Problems, and Solutions of Silver Nanowire Transparent Conductive Electrodes in Indium Tin Oxide (ITO)-Free Flexible Solar Cells. Adv. Energy Mater. 2020, 10, 2002536. [Google Scholar] [CrossRef]

- Hu, L.; Kim, H.S.; Lee, J.Y.; Peumans, P.; Cui, Y. Scalable Coating and Properties of Transparent, Flexible, Silver Nanowire Electrodes. Scalable Coating and Properties of Transparent, Flexible, Silver Nanowire Electrodes. ACS Nano 2010, 4, 2955–2963. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhu, C.; Pfattner, R.; Yan, H.; Jin, L.; Chen, S.; Bao, Z. A highly stretchable, transparent, and conductive polymer. Sci. Adv. 2017, 3, e1602076. [Google Scholar] [CrossRef]

- Yuk, H.; Lu, B.; Zhao, X. Hydrogel bioelectronics. Chem. Soc. Rev. 2019, 48, 1642–1667. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Peng, L.; Ding, Y.; Zhao, Y.; Yu, G. Nanostructured conductive polymers for advanced energy storage. Chem. Soc. Rev. 2015, 44, 6684–6696. [Google Scholar] [CrossRef] [PubMed]

- Hu, L.; Song, J.; Yin, X.; Su, Z.; Li, Z. Research Progress on Polymer Solar Cells Based on PEDOT:PSS Electrodes. Polymers 2020, 12, 145. [Google Scholar] [CrossRef]

- Sun, K.; Zhang, S.P.; Li, P.C.; Xia, Y.J.; Zhang, X.; Du, D.H.; Isikgor, F.H.; Ouyang, J.Y. Review on application of PEDOTs and PEDOT:PSS in energy conversion and storage devices. J. Mater. Sci. Mater Electron. 2015, 26, 4438–4462. [Google Scholar] [CrossRef]

- Fan, X.; Nie, W.; Tsai, H.; Wang, N.; Huang, H.; Cheng, Y.; Wen, R.; Ma, L.; Yan, F.; Xia, Y. PEDOT:PSS for Flexible and Stretchable Electronics: Modifications, Strategies, and Applications. Adv. Sci. 2019, 6, 1900813. [Google Scholar] [CrossRef]

- Worfolk, B.J.; Andrews, S.C.; Park, S.; Reinspach, J.; Liu, N.; Toney, M.F.; Mannsfeld, S.C.B.; Bao, Z.N. Ultrahigh electrical conductivity in solution-sheared polymeric transparent films. Proc. Natl. Acad. Sci. USA 2015, 112, 14138. [Google Scholar] [CrossRef]

- Xia, Y.; Sun, K.; Ouyang, J. Solution-processed metallic conducting polymer films as transparent electrode of optoelectronic devices. Adv. Mater. 2012, 24, 2436. [Google Scholar] [CrossRef]

- Gao, N.; Yu, J.; Tian, Q.; Shi, J.; Zhang, M.; Chen, S.; Zang, L. Application of PEDOT:PSS and Its Composites in Electrochemical and Electronic. Chemosensors 2021, 9, 79. [Google Scholar] [CrossRef]

- Anwar, A.; Chang, T.P.; Chen, C.T. Graphene oxide synthesis using a top–down approach and discrete characterization techniques: A holistic review. Carbon Lett. 2022, 32, 1–38. [Google Scholar] [CrossRef]

- Chadha, N.; Sharma, R.; Saini, P. A new insight into the structural modulation of graphene oxide upon chemical reduction probed by Raman spectroscopy and X-ray diffraction. Carbon Lett. 2021, 31, 1125–1131. [Google Scholar] [CrossRef]

- Shin, Y.; Park, S. Production of B-doped reduced graphene oxide using wet-process in tetrahydrofuran. Carbon Lett. 2021, 31, 887–893. [Google Scholar] [CrossRef]

- Zhang, Z.; Cai, R.; Long, F.; Wang, J. Development and application of tetrabromobisphenol A imprinted electrochemical sensor based on graphene/carbon nanotubes three-dimensional nanocomposites modified carbon electrode. Talanta 2015, 134, 435–442. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Z.; Liao, J.; He, B.; Zhang, F.; Zhang, F.; Huang, X.; Zhou, L. One-Step Fabrication of Graphene Oxide Enhanced Magnetic Composite Gel for Highly Efficient Dye Adsorption and Catalysis. ACS Sustain. Chem. Eng. 2015, 3, 1677–1685. [Google Scholar] [CrossRef]

- Chen, H.; Chen, Z.; Yang, H.; Wen, L.; Yi, Z.; Zhou, Z.; Dai, B.; Zhang, J.; Wu, X.; Wu, P. Multi-mode surface plasmon resonance absorber based on dart-type single-layer graphene. RSC Adv. 2022, 12, 7821. [Google Scholar] [CrossRef]

- Shangguan, Q.; Chen, Z.; Yang, H.; Cheng, S.; Yang, W.; Yi, Z.; Wu, X.; Wang, S.; Yi, Y.; Wu, P. Design of Ultra-Narrow Band Graphene Refractive Index Sensor. Sensors 2022, 22, 6483. [Google Scholar] [CrossRef]

- Chen, Y.C.; O’Hare, D. Exhaled breath condensate based breath analyser-a disposable hydrogen peroxide sensor and smart analyser. Analyst 2020, 145, 3549–3556. [Google Scholar] [CrossRef] [PubMed]

- Li, S.Y.; Chen, S.J.; Zhuo, B.G.; Li, Q.F.; Liu, W.J.; Guo, X.J. Flexible ammonia sensor based on PEDOT:PSS/silver nanowire composite film for meat freshness monitoring. IEEE Electron Device Lett. 2017, 38, 975–978. [Google Scholar] [CrossRef]

- Kayser, L.V.; Lipomi, D.J. Stretchable Conductive polymers and composites based on PEDOT and PEDOT: PSS. Adv. Mater. 2019, 31, 1806133. [Google Scholar] [CrossRef]

- Sirringhaus, H.; Kawase, T.A.K.E.O.; Friend, R.H.; Shimoda, T.; Inbasekaran, M.; Wu, W.; Woo, E.P. High-resolution inkjet printing of all-polymer transistor circuits. Science 2000, 290, 2123–2126. [Google Scholar] [CrossRef] [PubMed]

- Seekaew, Y.; Lokavee, S.; Phokharatkul, D.; Wisitsoraat, A.; Kerdcharoen, T.; Wongchoosuk, C. Low-cost and flexible printed graphene–PEDOT:PSS gas sensor for ammonia detection. Org. Electron. 2014, 15, 2971–2981. [Google Scholar] [CrossRef]

- Wu, X.; Li, F.; Wu, W.; Guo, T. Flexible organic light emitting diodes based on double-layered graphene/PEDOT:PSS conductive film formed by spray-coating. Vacuum 2014, 101, 53–56. [Google Scholar] [CrossRef]

- Yuk, H.; Lu, B.; Lin, S.; Qu, K.; Xu, J.; Luo, J.; Zhao, X. 3D printing of conducting polymers. Nat. Commun. 2020, 11, 1604. [Google Scholar] [CrossRef]

- Jeon, H.; Kim, Y.; Yu, W.-R.; Lee, J.U. Exfoliated graphene/thermoplastic elastomer nanocomposites with improved wear properties for 3D printing. Compos. Part B 2020, 189, 107912. [Google Scholar] [CrossRef]

- Kwon, Y.J.; Kwon, Y.; Park, H.S.; Lee, J.U. Mass-Produced Electrochemically Exfoliated Graphene for Ultrahigh Thermally Conductive Paper Using a Multimetal Electrode System. Adv. Mater. Interfaces 2019, 6, 1900095. [Google Scholar] [CrossRef]

- Pakravan, H.R.; Jamshidi, M.; Latifi, M. Relationship between the surface free energy of hardened cement paste and chemical phase composition. J. Ind. Eng. Chem. 2014, 20, 1737–1740. [Google Scholar] [CrossRef]

- Yoon, S.S.; Lee, K.E.; Cha, H.J.; Seong, D.G.; Um, M.K.; Byun, J.H.; Oh, Y.; Oh, J.H.; Lee, W.; Lee, J.U. Hybrid Fibers for Flexible Fiber-Type Transistors. Sci. Rep. 2015, 5, 16366. [Google Scholar] [CrossRef]

- Tang, S.; Liu, Z.; Xiang, X. Graphene oxide composite hydrogels for wearable devices. Carbon Lett. 2022, 32, 1395–1410. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, K.; Dixit, A.R. A review on the mechanical properties of polymer composites reinforced by carbon nanotubes and graphene. Carbon Lett. 2021, 31, 149–165. [Google Scholar] [CrossRef]

- Li, W.; Li, Y.; Su, M.; An, B.; Liu, J.; Su, D.; Li, L.; Fi, F.; Song, Y. Printing assembly and structural regulation of graphene towards three-dimensional flexible micro-supercapacitors. J. Mater. Chem. A 2017, 5, 16281. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Q.; Long, S.; Luo, Y.; Yu, P.; Tan, Z.; Bai, J.; Qu, B.; Yang, Y.; Shi, J.; et al. Three-Dimensional Printing of Polyaniline/Reduced Graphene Oxide Composite for High-Performance Planar Supercapacitor. ACS Appl. Mater. Interfaces 2018, 10, 10437–10444. [Google Scholar] [CrossRef] [PubMed]

- Tang, X.; Zhou, H.; Cai, Z.; Cheng, D.; He, P.; Xie, P.; Zhang, D.; Fan, T. Generalized 3D Printing of Graphene-Based Mixed-Dimensional Hybrid Aerogels. ACS Nano 2018, 12, 3502–3511. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Tian, X.; Li, L.; Lu, L.; Hou, S.; Cao, G.; Jin, H. 3D printing-based cellular microelectrodes for high-performance asymmetric quasi-solid-state micro-pseudocapacitors. J. Mater. Chem. A 2020, 8, 1749. [Google Scholar] [CrossRef]

- Prabhu, S.; Kavithayeni, V.; Suganthy, S.; Geetha, K. Graphene quantum dots synthesis and energy application: A review. Carbon Lett. 2021, 31, 1–12. [Google Scholar] [CrossRef]

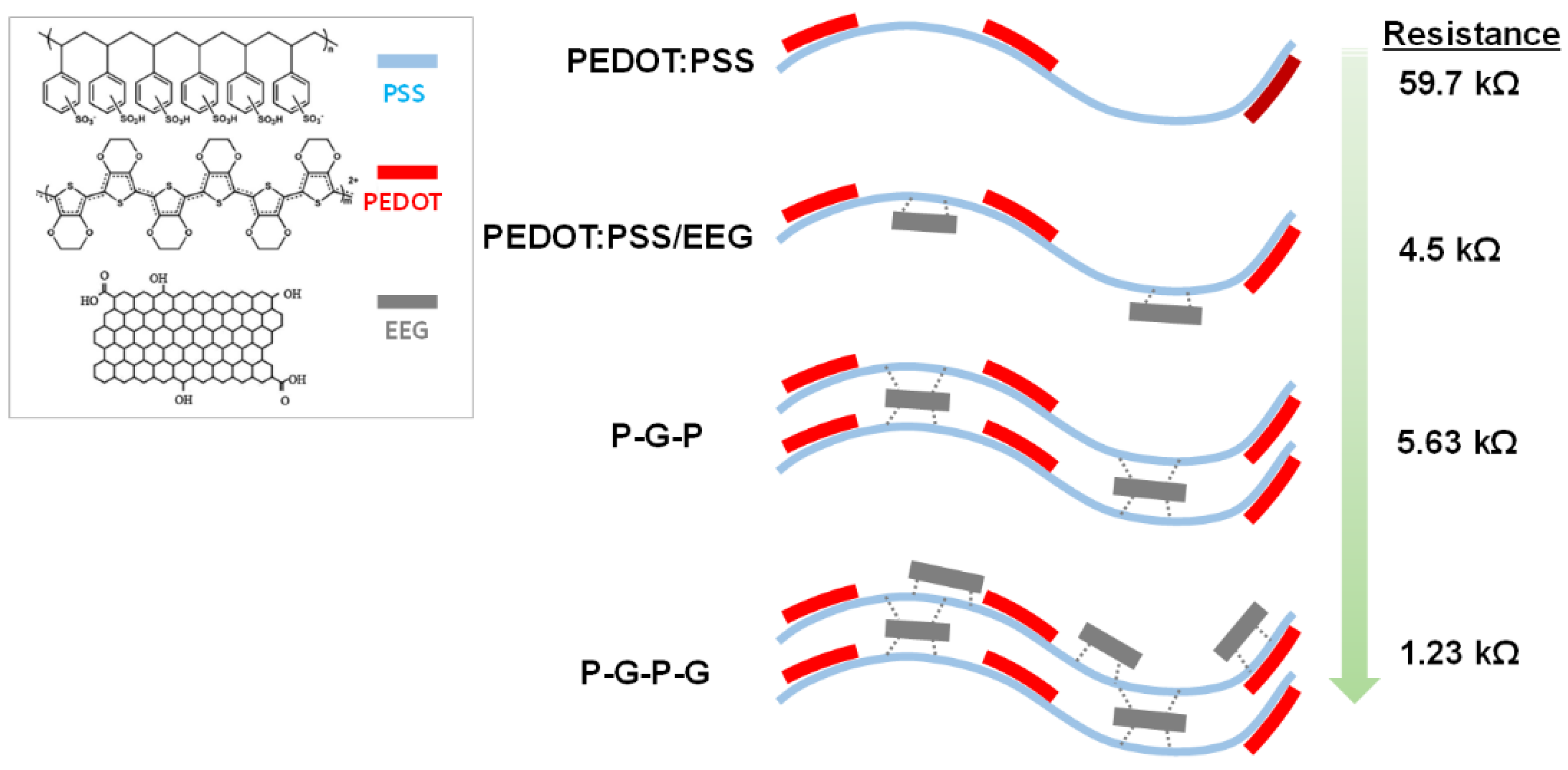

| Sample | Measuring Part | Electrical Resistance (kΩ) |

|---|---|---|

| PEDOT:PSS/EEG (after drying) | PEDOT:PSS region | 59.7 |

| EEG region | 0.05 | |

| PEDOT:PSS/EEG (before drying) | - | 4.5 |

| P-G-P | - | 5.63 |

| P-G-P-G | - | 1.23 |

| Graphene | Hybrid Materials | Ink Writing Process | Flexibility Test | Ref. |

|---|---|---|---|---|

| Graphene oxide | - | Direct ink writing | Bending test (angle ± 60°, 200 cycles) | [34] |

| Graphene oxide | Polyaniline | Direct ink writing | - | [35] |

| Graphene oxide | Urea + Gluconic-δ-lactone | Direct ink writing | Hand rolling with PET substrate | [36] |

| Graphene oxide | Ni-Co-O nanosheets | Direct ink writing | - | [37] |

| Electrochemically exfoliated graphene | PEDOT:PSS | Consecutive ink writing | Folding test (1000 cycles) | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.; Kim, Y.; Kim, J.; Moon, S.Y.; Lee, J.U. Consecutive Ink Writing of Conducting Polymer and Graphene Composite Electrodes for Foldable Electronics-Related Applications. Polymers 2022, 14, 5294. https://doi.org/10.3390/polym14235294

Lee H, Kim Y, Kim J, Moon SY, Lee JU. Consecutive Ink Writing of Conducting Polymer and Graphene Composite Electrodes for Foldable Electronics-Related Applications. Polymers. 2022; 14(23):5294. https://doi.org/10.3390/polym14235294

Chicago/Turabian StyleLee, Heechan, Youngdo Kim, Jiwoo Kim, Su Young Moon, and Jea Uk Lee. 2022. "Consecutive Ink Writing of Conducting Polymer and Graphene Composite Electrodes for Foldable Electronics-Related Applications" Polymers 14, no. 23: 5294. https://doi.org/10.3390/polym14235294

APA StyleLee, H., Kim, Y., Kim, J., Moon, S. Y., & Lee, J. U. (2022). Consecutive Ink Writing of Conducting Polymer and Graphene Composite Electrodes for Foldable Electronics-Related Applications. Polymers, 14(23), 5294. https://doi.org/10.3390/polym14235294