Microstructure and Mechanical Properties of Severely Deformed Polypropylene in ECAE (Equal Channel Angular Extrusion) via Routes A and C

Abstract

1. Introduction

2. Material and Methods

2.1. Material and Specimens

2.2. ECAE Experiments

2.3. Mechanical Tests and Specimens

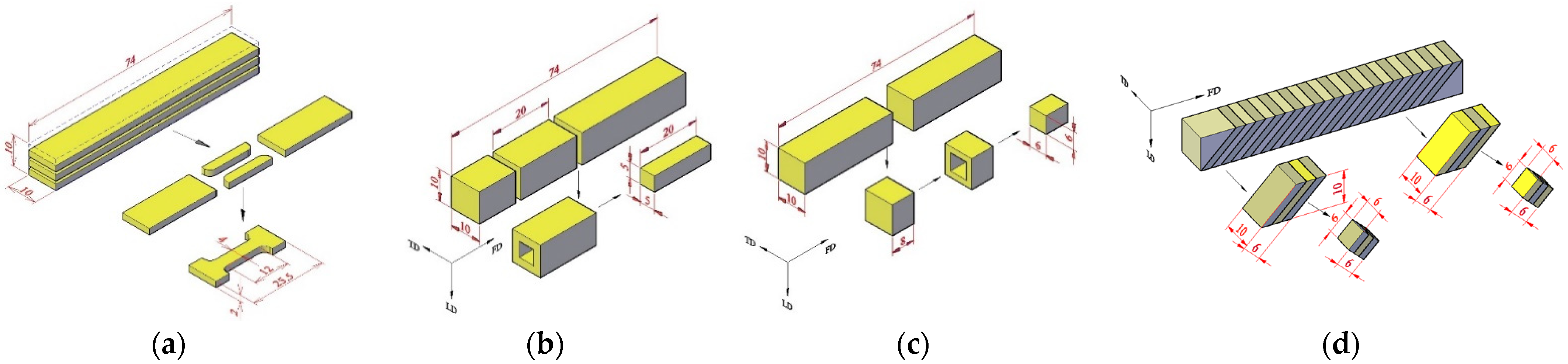

2.3.1. Specimens

2.3.2. Mechanical Tests

2.4. WAXS Measurements

3. Results and Discussion

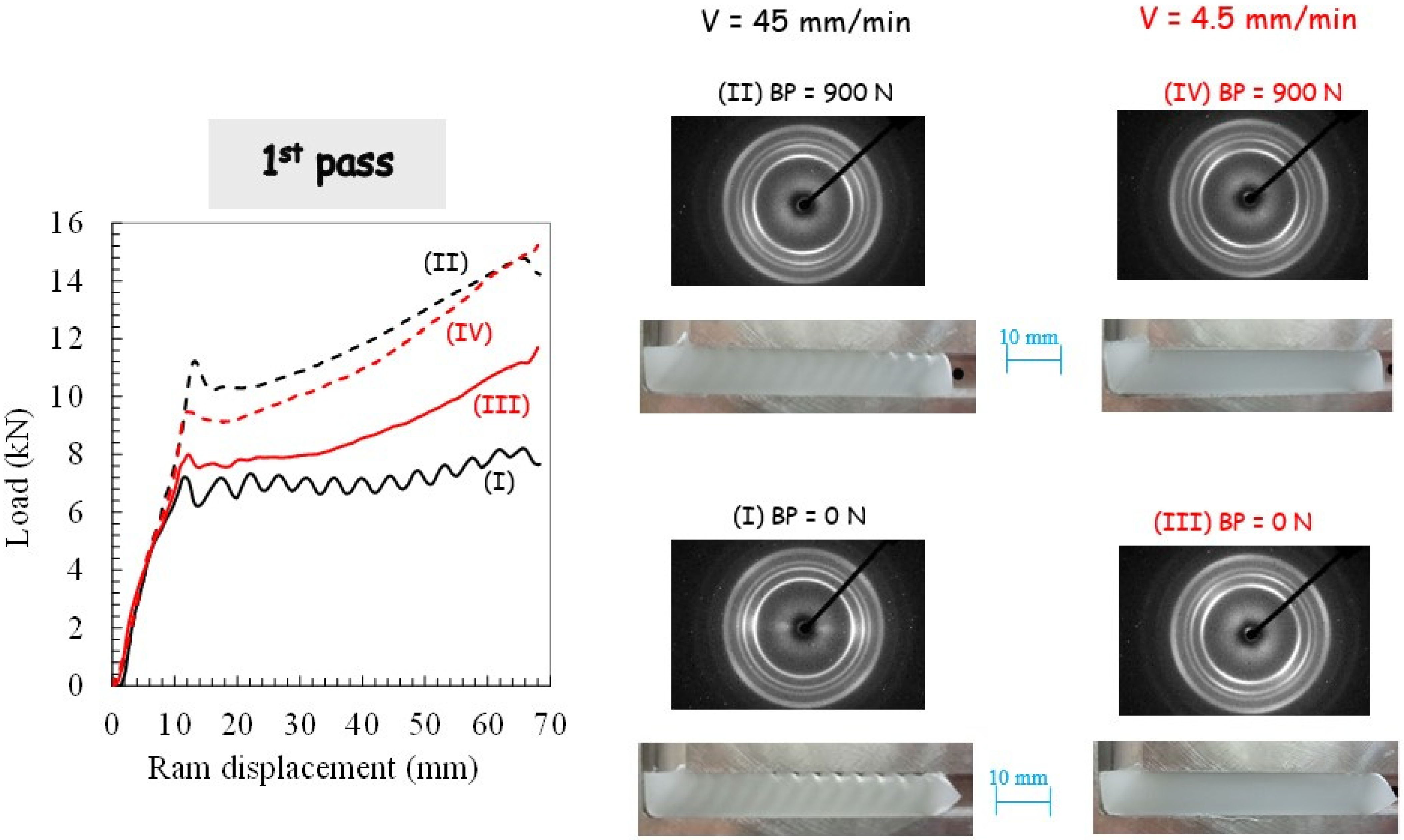

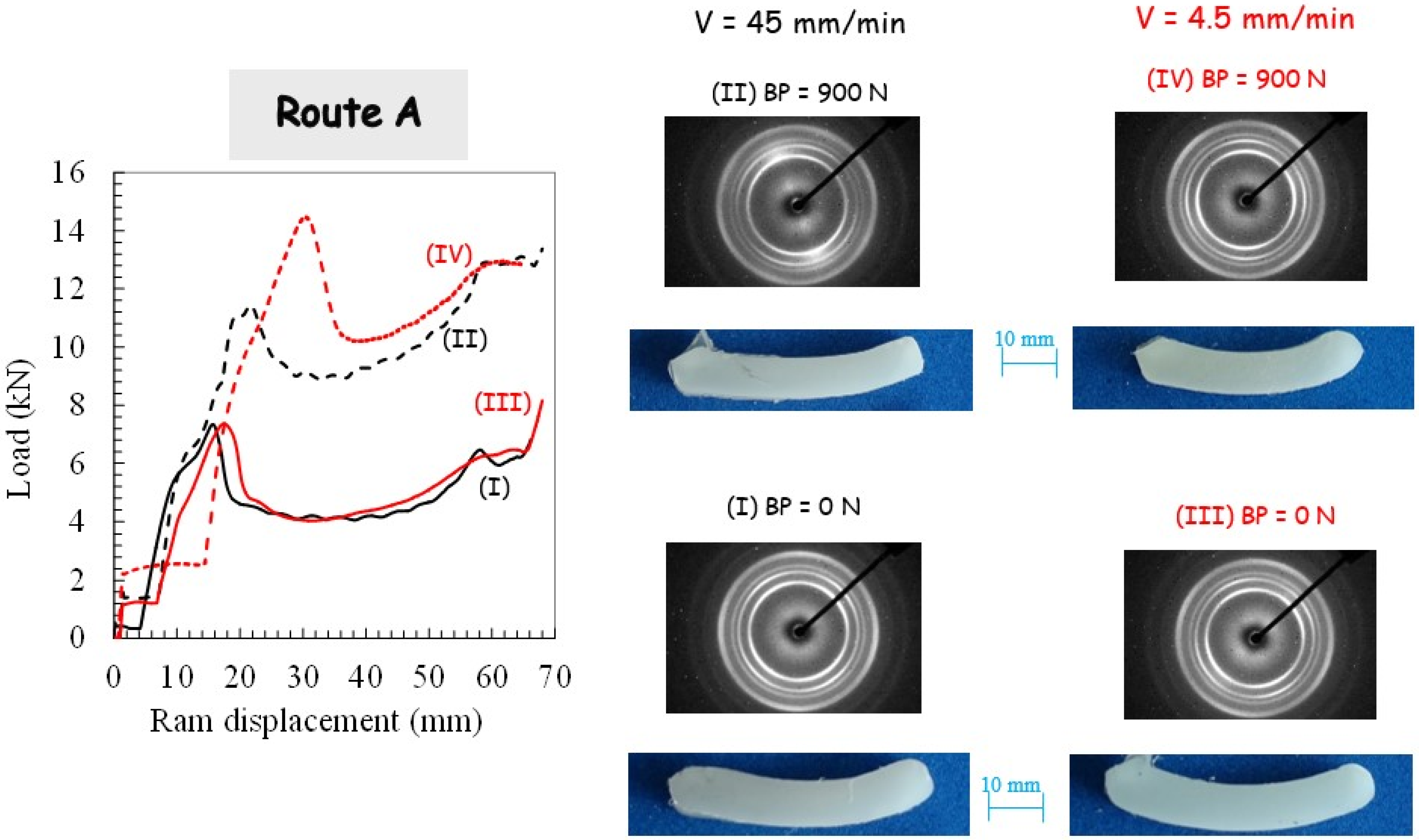

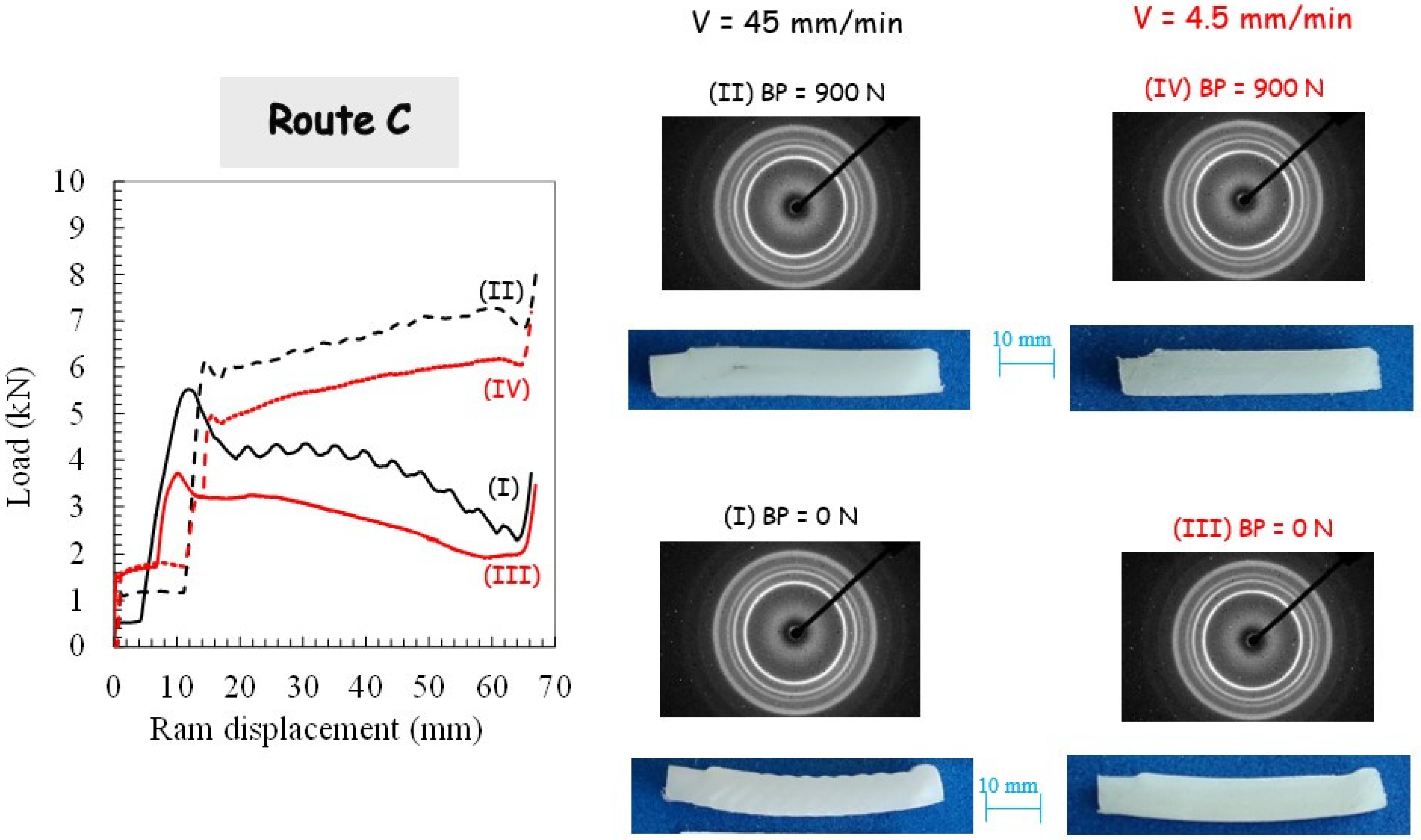

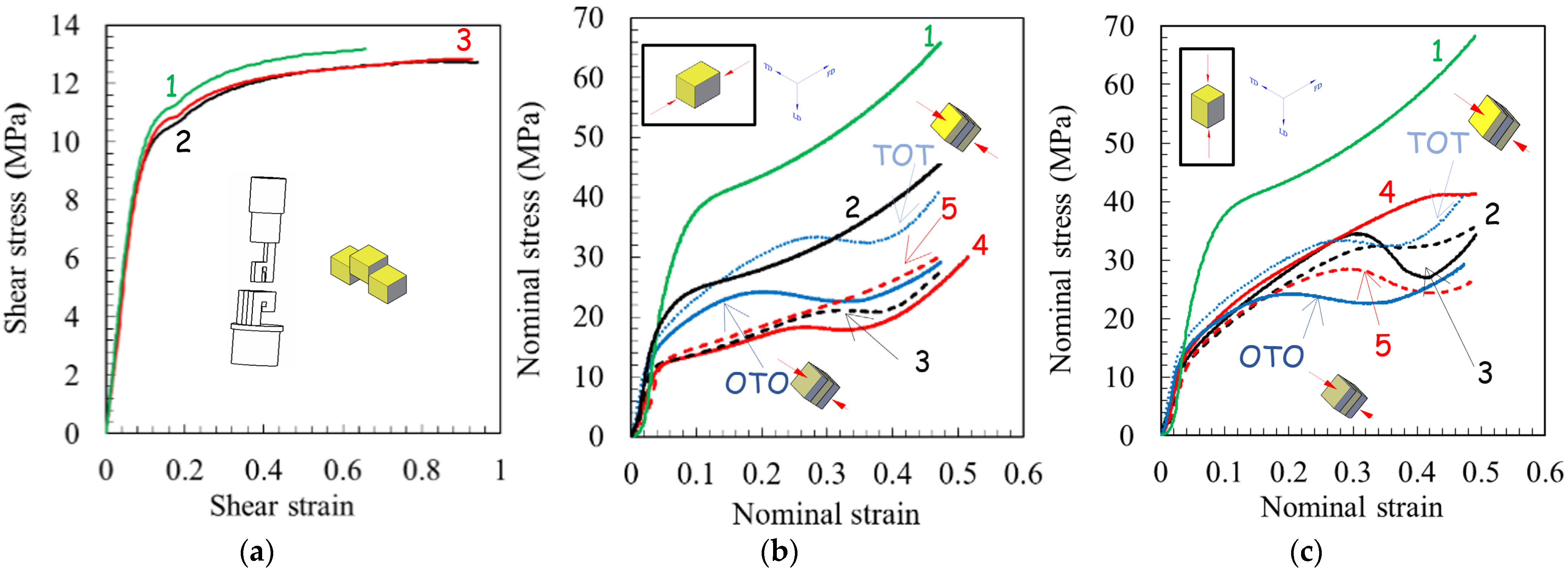

3.1. Deformation Behavior

3.2. Crystallographic Texturing

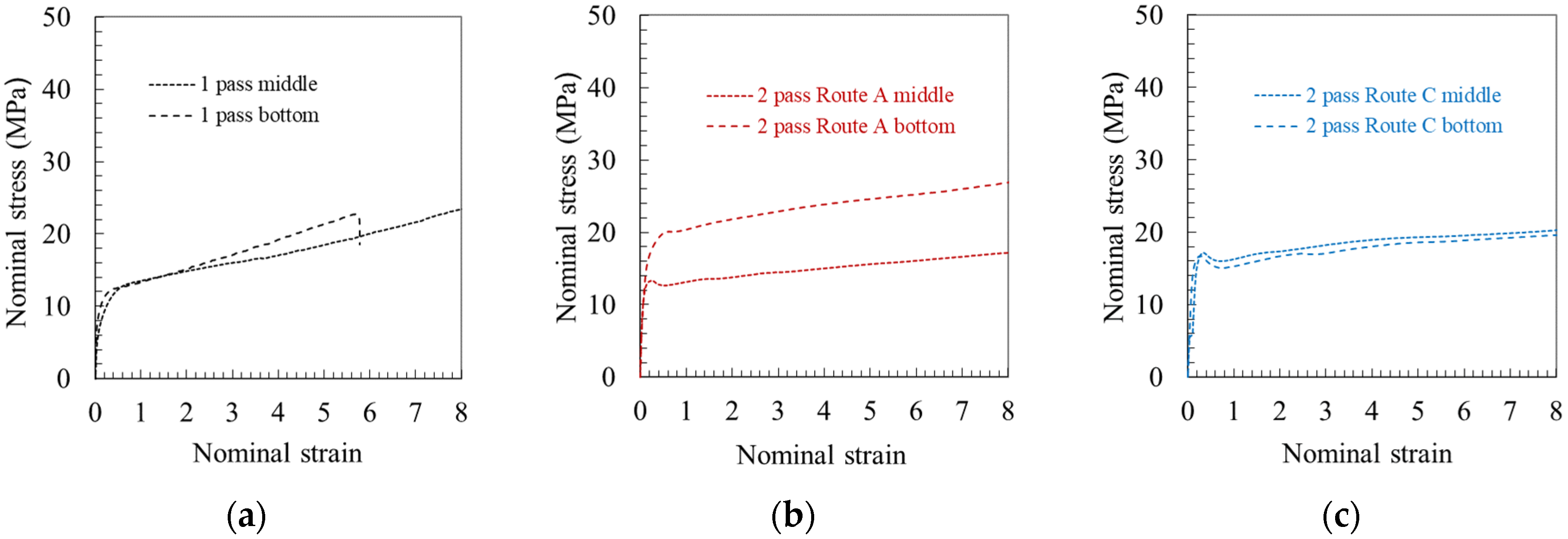

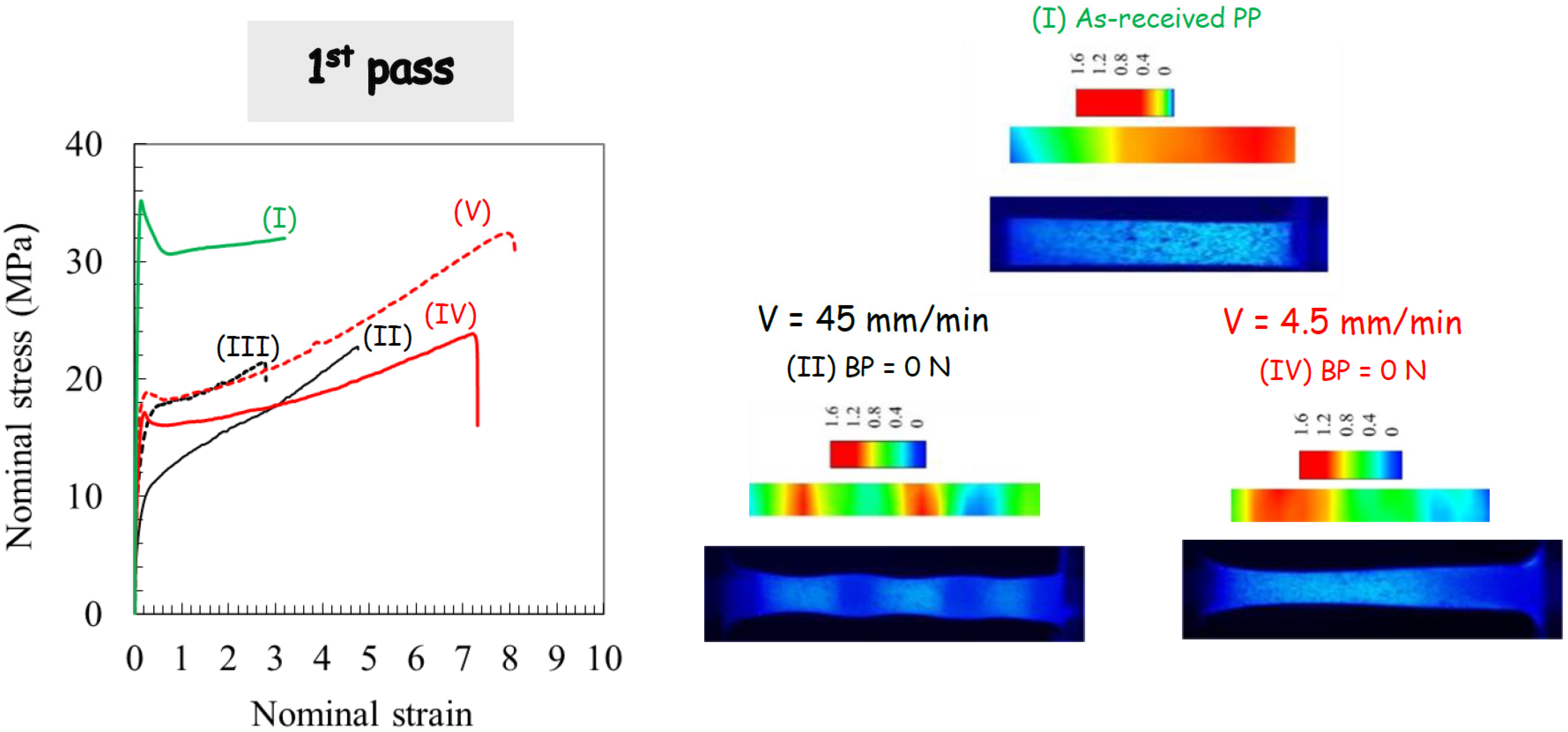

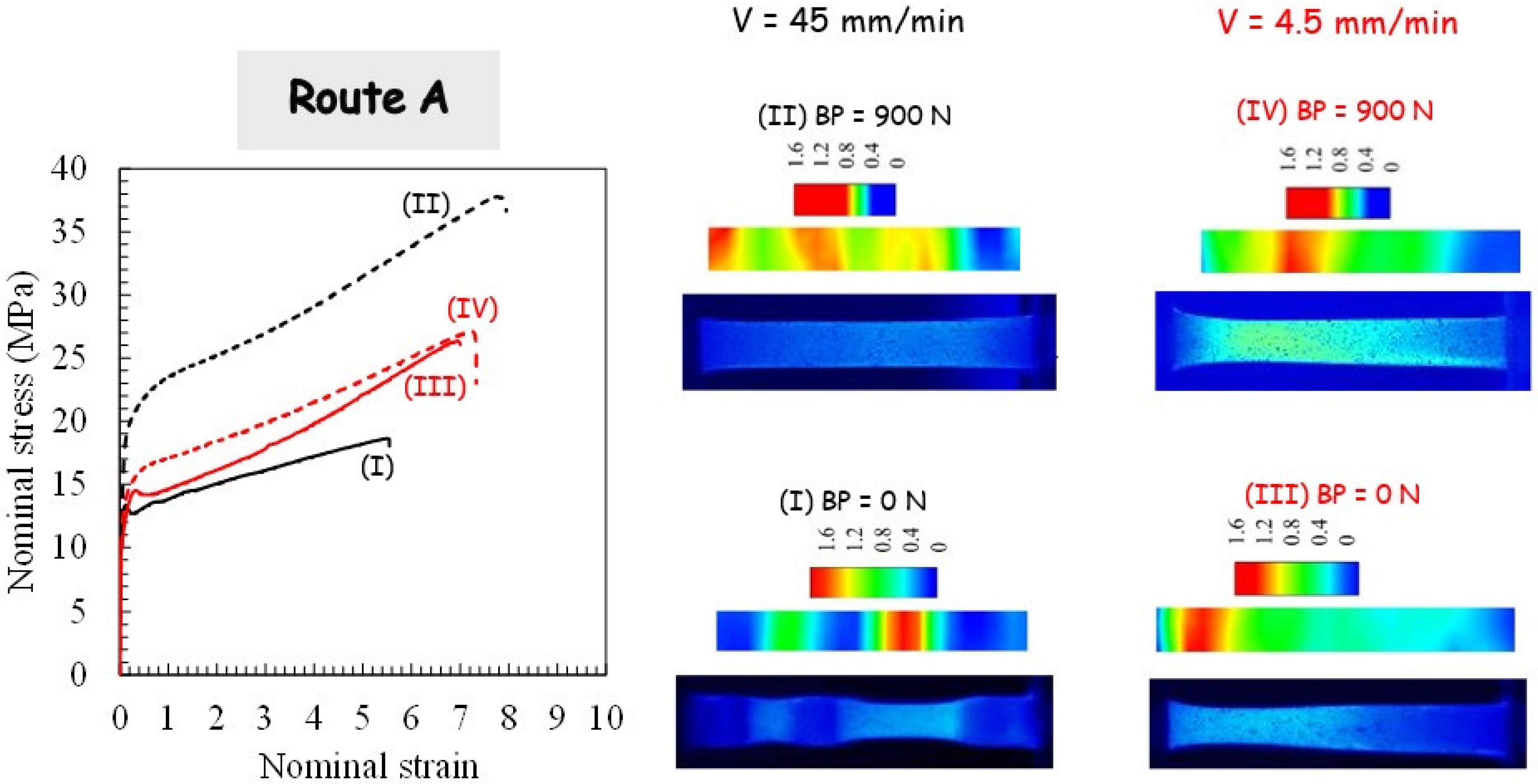

3.3. Mechanical Properties

3.4. Tensile Deformation Mechanisms

4. Concluding Remarks

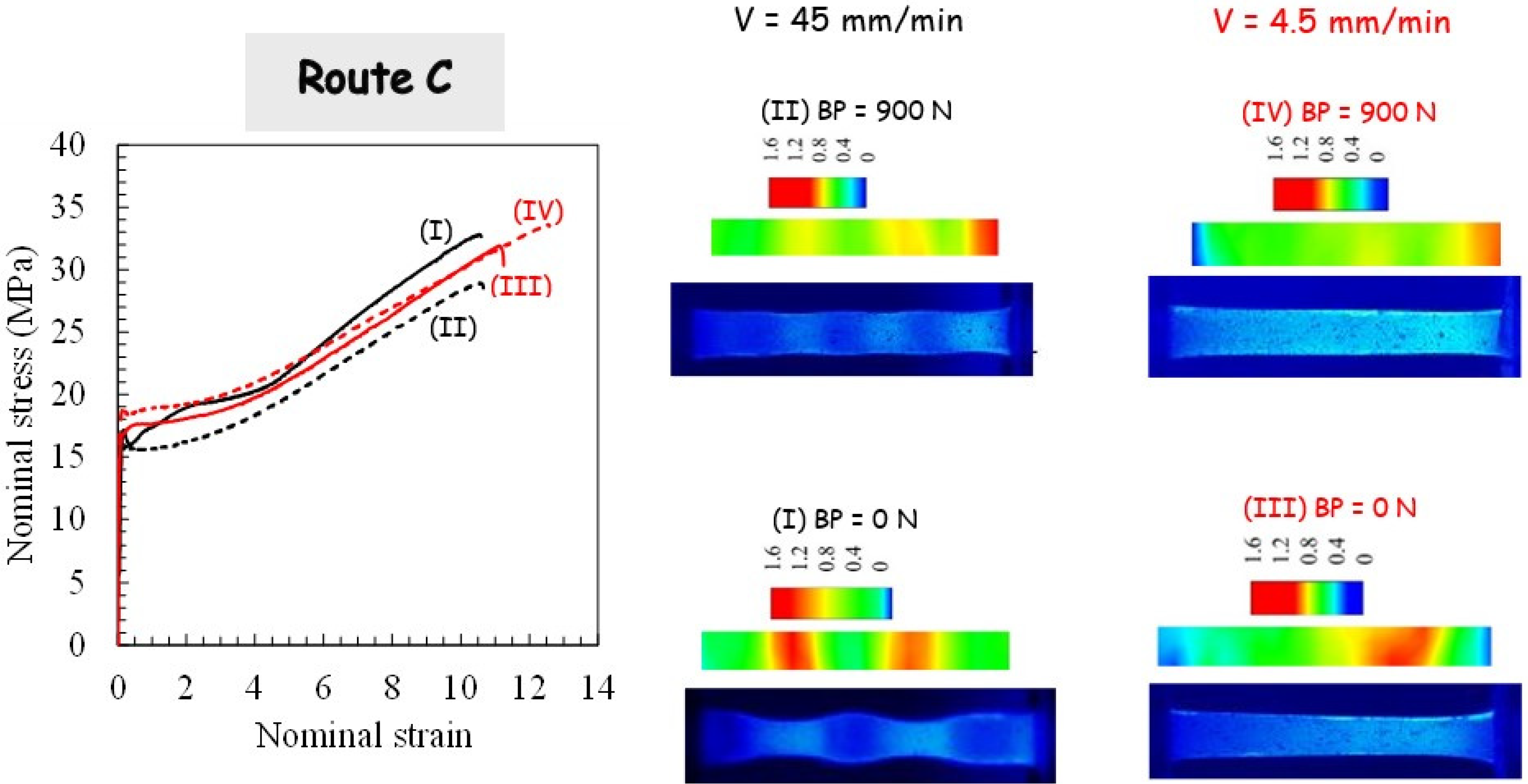

- The homogeneous simple shear expected undergone by the extruded piece was found to be a heterogeneous deformation manifested by periodic shear banding and warping. Both pressing force and deformation heterogeneity were observed to be strongly dependent on the processing route in terms of BP and ram velocity. The results obtained by route A showed significant warping. The flow localization persisted in route C but significantly lower warping was observed; the results via this route become more homogeneous with the application of BP.

- Microstructural observations using WAXS experiments gave useful information about the evolution of the crystalline microstructure showing how different crystalline textures developed according to the processing parameters. Texturing changed from single-shear to twin-like shear orientation in the shear direction.

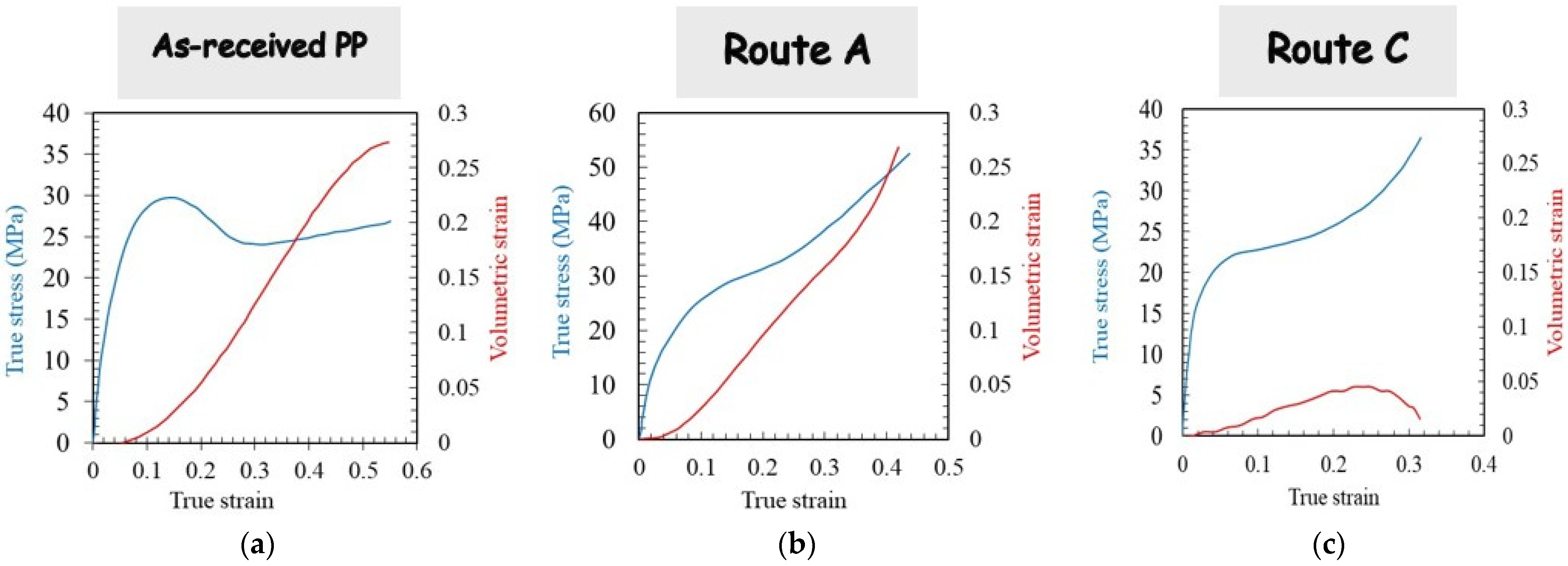

- The flow behavior was examined with the help of shear tests, compression tests and tension tests of specimens machined from the ECAE pieces. Important changes in tensile properties are observed between the first pass and the second pass with a significant effect of the processing route on the yield strength and the post-yield response.

- The tensile deformation mechanisms were altered by the processing route passing from a dominant cavitation mechanism for route A to a dominant shear yielding mechanism for route C.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sue, H.J.; Dilan, H.; Li, C.K.Y. Simple shear plastic deformation behavior of polycarbonate plate due to the equal channel angular extrusion process. I: Finite element methods modeling. Polym. Eng. Sci. 1999, 39, 2505–2515. [Google Scholar] [CrossRef]

- Zaïri, F.; Aour, B.; Gloaguen, J.M.; Naït-Abdelaziz, M.; Lefebvre, J.M. Influence of the initial yield strain magnitude on the materials flow in equal-channel angular extrusion process. Scr. Mater. 2007, 56, 105–108. [Google Scholar] [CrossRef]

- Zaïri, F.; Aour, B.; Gloaguen, J.M.; Naït-Abdelaziz, M.; Lefebvre, J.M. Steady plastic flow of a polymer during equal channel angular extrusion process: Experiments and numerical modeling. Polym. Eng. Sci. 2008, 48, 1015–1021. [Google Scholar] [CrossRef]

- Aour, B.; Zaïri, F.; Naït-Abdelaziz, M.; Gloaguen, J.M.; Rahmani, O.; Lefebvre, J.M. A computational study of die geometry and processing conditions effects on equal channel angular extrusion of a polymer. Int. J. Mech. Sci. 2008, 50, 589–602. [Google Scholar] [CrossRef]

- Aour, B.; Zaïri, F.; Naït-Abdelaziz, M.; Gloaguen, J.M.; Lefebvre, J.M. Finite element analysis of plastic strain distribution in multipass ECAE process of high density polyethylene. J. Manuf. Sci. Eng. 2009, 131, 031016. [Google Scholar] [CrossRef]

- Bouaksa, F.; Rodas, C.O.; Zaïri, F.; Stoclet, G.; Naït-Abdelaziz, M.; Gloaguen, J.M.; Tamine, T.; Lefebvre, J.M. Molecular chain orientation in polycarbonate during equal channel angular extrusion: Experiments and simulations. Comput. Mater. Sci. 2014, 85, 244–252. [Google Scholar] [CrossRef]

- Vasylevskyi, K.; Tsukrov, I.; Miroshnichenko, K.; Buklovskyi, S.; Grover, H.; Van Citters, D. Finite element model of equal channel angular extrusion of ultra high molecular weight polyethylene. J. Manuf. Sci. Eng. 2021, 143, 121007. [Google Scholar] [CrossRef]

- Yan, Z.; Guo, Q.; Zaïri, F.; Zaoui, A.; Jiang, Q.; Liu, X. Continuum-based modeling large-strain plastic deformation of semi-crystalline polyethylene systems: Implication of texturing and amorphicity. Mech. Mater. 2021, 162, 104060. [Google Scholar] [CrossRef]

- Yan, Z.; Guo, Q.; Zaïri, F.; Zaoui, A. A multi-scale plastic-damage model for strain-induced morphological anisotropy in semi-crystalline polyethylene. Int. J. Non-Linear Mech. 2022, 147, 104238. [Google Scholar]

- Li, C.K.Y.; Xia, Z.Y.; Sue, H.J. Simple shear plastic deformation behavior of polycarbonate plate. II: Mechanical property characterization. Polymer 2000, 41, 6285–6293. [Google Scholar] [CrossRef]

- Xia, Z.; Sue, H.J.; Hsieh, A.J. Impact fracture behavior of molecularly orientated polycarbonate sheets. J. Appl. Polym. Sci. 2001, 79, 2060–2066. [Google Scholar] [CrossRef]

- Yoshioka, S.; Tsukamoto, K. Effects of ECAE on plastic deformation behavior of glassy polymers. J. Soc. Mater. Sci. 2009, 58, 29–34. [Google Scholar] [CrossRef][Green Version]

- Beloshenko, V.A.; Voznyak, A.V.; Voznyak, Y.V. Effects of equal-channel, multiple-angular extrusion on the physical and mechanical properties of glassy polymers. J. Appl. Polym. Sci. 2015, 132, 42180. [Google Scholar] [CrossRef]

- Weon, J.I.; Creasy, T.S.; Sue, H.J.; Hsieh, A.J. Mechanical behavior of polymethylmethacrylate with molecules oriented via simple shear. Polym. Eng. Sci. 2005, 45, 314–324. [Google Scholar] [CrossRef]

- Sue, H.J.; Li, C.K.Y. Control of orientation of lamellar structure in linear low density polyethylene via a novel equal channel angular extrusion process. J. Mater. Sci. Lett. 1998, 17, 853–856. [Google Scholar] [CrossRef]

- Beloshenko, V.A.; Varyukhin, V.N.; Voznyak, A.V.; Voznyak, Y. Equal-channel multiangular extrusion of semicrystalline polymers. Polym. Eng. Sci. 2010, 50, 1000–1006. [Google Scholar] [CrossRef]

- Campbell, B.; Edward, G. Equal channel angular extrusion of polyalkenes. Plast. Rubber Compos. 1999, 28, 467–475. [Google Scholar] [CrossRef]

- Beloshenko, V.A.; Voznyak, A.V.; Voznyak, Y.V. Control of the mechanical and thermal properties of semicrystalline polymers via a new processing route of the equal channel multiple angular extrusion. Polym. Eng. Sci. 2014, 54, 531–539. [Google Scholar] [CrossRef]

- Voznyak, Y. The effect of radiation treatment on mechanical and thermal properties of semicrystalline polymers processed by severe plastic deformation. Macromol. Res. 2017, 25, 38–44. [Google Scholar] [CrossRef]

- Wu, X.; Pu, L.; Xu, Y.; Shi, J.; Liu, X.; Zhong, Z.; Luo, S.N. Deformation of high density polyethylene by dynamic equal-channel-angular pressing. RSC Adv. 2018, 8, 22583–22591. [Google Scholar] [CrossRef]

- Shirazi, M.M.H.; Khajouei-Nezhad, M.; Zebarjad, S.M.; Ebrahimi, R. Evolution of the crystalline and amorphous phases of high-density polyethylene subjected to equal-channel angular pressing. Polym. Bull. 2020, 77, 1681–1694. [Google Scholar] [CrossRef]

- Kitagawa, M.; Kozaki, T. ECAP process in polypropylene. J. Soc. Mater. Sci. 2006, 55, 37–41. [Google Scholar] [CrossRef][Green Version]

- Phillips, A.; Zhu, P.W.; Edward, G. Simple shear deformation of polypropylene via the equal channel angular extrusion process. Macromolecules 2006, 39, 5796–5803. [Google Scholar] [CrossRef]

- Aour, B.; Zaïri, F.; Boulahia, R.; Naït-Abdelaziz, M.; Gloaguen, J.M.; Lefebvre, J.M. Experimental and numerical study of ECAE deformation of polyolefins. Comput. Mater. Sci. 2009, 45, 646–652. [Google Scholar] [CrossRef]

- Boulahia, R.; Gloaguen, J.M.; Zaïri, F.; Naït-Abdelaziz, M.; Seguela, R.; Boukharouba, T.; Lefebvre, J.M. Deformation behaviour and mechanical properties of polypropylene processed by equal channel angular extrusion: Effects of back-pressure and extrusion velocity. Polymer 2009, 50, 5508–5517. [Google Scholar] [CrossRef]

- Wang, T.; Tang, S.; Chen, J. Effects of processing route on morphology and mechanical behavior of polypropylene in equal channel angular extrusion. J. Appl. Polym. Sci. 2011, 122, 2146–2158. [Google Scholar] [CrossRef]

- Qiu, J.; Murata, T.; Wu, X.; Kitagawa, M.; Kudo, M. Plastic deformation mechanism of crystalline polymer materials in the equal channel angular extrusion process. J. Mater. Process. Technol. 2012, 212, 1528–1536. [Google Scholar] [CrossRef]

- Wang, T.L.; Tang, S.C.; Chen, J.D. Microstructural evolution and its effect on mechanical properties of isotactic polypropylene by shear plastic deformation at elevated temperatures. J. Macromol. Sci. Part B 2015, 54, 1309–1322. [Google Scholar] [CrossRef]

- Boulahia, R.; Zaïri, F.; Voznyak, Y.; Gloaguen, J.M. Repeated equal-channel angular extrusion of polypropylene: Processing routes and back-pressure influence. Mater. Today Commun. 2021, 26, 101754. [Google Scholar] [CrossRef]

- Ma, J.; Simon, G.P.; Edward, G.H. The effect of shear deformation on nylon-6 and two types of nylon-6/clay nanocomposite. Macromolecules 2008, 41, 409–420. [Google Scholar] [CrossRef]

- Kumar, P.; Panda, S.S. Joining of two similar PA-6 rods through equal channel angular press based Y-shape extrusion channel. CIRP J. Manuf. Sci. Technol. 2022, 36, 133–142. [Google Scholar] [CrossRef]

- Xia, Z.; Sue, H.J.; Rieker, T.P. Morphological evolution of poly(ethylene terephthalate) during equal channel angular extrusion process. Macromolecules 2000, 33, 8746–8755. [Google Scholar] [CrossRef]

- Xia, Z.; Sue, H.J.; Hsieh, A.J.; Huang, J.W.L. Dynamic mechanical behavior of oriented semicrystalline polyethylene terephthalate. J. Polym. Sci. Part B Polym. Phys. 2001, 39, 1394–1403. [Google Scholar] [CrossRef]

- Wang, Z.G.; Xia, Z.Y.; Yu, Z.Q.; Chen, E.Q.; Sue, H.J.; Han, C.C.; Hsiao, B.S. Lamellar formation and relaxation in simple sheared poly(ethylene terephthalate) by small-angle X-ray scattering. Macromolecules 2006, 39, 2930–2939. [Google Scholar] [CrossRef]

- Beloshenko, V.A.; Beygelzimer, Y.E.; Voznyak, Y.V.; Savchenko, B.M.; Dmitrenko, V.Y. Reinforcing effect caused by equal channel multiple angular extrusion of polymers manufactured by the FDM process: Experimental investigation and mathematical modeling. J. Appl. Polym. Sci. 2018, 135, 45727. [Google Scholar] [CrossRef]

- Reinitz, S.D.; Engler, A.J.; Carlson, E.M.; Van Citters, D.W. Equal channel angular extrusion of ultra-high molecular weight polyethylene. Mater. Sci. Eng. C 2016, 67, 623–628. [Google Scholar] [CrossRef] [PubMed]

- Hongxiang, C.; Lianhong, Z.; Jianguo, G.; Yuchun, M.; Wang, Y. Reinforcement of biodegradable poly(DL-lactic acid) material by equal-channel angular extrusion. Macromol. Symp. 2006, 242, 55–59. [Google Scholar]

- Vozniak, I.; Beloshenko, V.; Savchenko, B.; Voznyak, A. Improvement of mechanical properties of polylactide by equal channel multiple angular extrusion. J. Appl. Polym. Sci. 2021, 138, 49720. [Google Scholar] [CrossRef]

- Creasy, T.S.; Kang, Y.S. Fibre fracture during equal-channel angular extrusion of short fibre-reinforced thermoplastics. J. Mater. Process. Technol. 2005, 160, 90–98. [Google Scholar] [CrossRef]

- Weon, J.I.; Sue, H.J. Effects of clay orientation and aspect ratio on mechanical behavior of nylon-6 nanocomposite. Polymer 2005, 46, 6325–6334. [Google Scholar] [CrossRef]

- Seo, Y.R.; Weon, J.I. Manipulation of nanofiller and polymer structures by using equal channel angular extrusion. J. Korean Phys. Soc. 2013, 63, 114–119. [Google Scholar] [CrossRef]

- Cook, D.J.; Chun, H.H.; Van Citters, D.W. Mechanical and electrical characterization of two carbon/ultra high molecular weight polyethylene composites created via equal channel angular processing. J. Eng. Mater. Technol. 2019, 141, 0210031. [Google Scholar] [CrossRef]

- Favreau, H.J.; Miroshnichenko, K.I.; Solberg, P.C.; Tsukrov, I.I.; Van Citters, D.W. Shear enhancement of mechanical and microstructural properties of synthetic graphite and ultra-high molecular weight polyethylene carbon composites. J. Appl. Polym. Sci. 2022, 139, 52175. [Google Scholar] [CrossRef]

- Beloshenko, V.A.; Voznyak, Y.V.; Reshidova, I.Y.; Naït-Abdelaziz, M.; Zaïri, F. Equal-channel angular extrusion of polymers. J. Polym. Res. 2013, 20, 322–334. [Google Scholar] [CrossRef]

- Beloshenko, V.; Vozniak, I.; Beygelzimer, Y.; Estrin, Y.; Kulagin, R. Severe plastic deformation of polymers. Mater. Trans. 2019, 60, 1192–1202. [Google Scholar] [CrossRef]

- Voznyak, A.; Pogrebnyak, A.; Tsys, O.; Torina, V. Solid-state extrusion of polymers using simple shear deformation. J. Polym. Eng. 2022, 42, 899–903. [Google Scholar] [CrossRef]

- Sternstein, S.S.; Ongchin, L.; Silverman, A. Inhomogeneous deformation and yielding of glasslike high polymers. Appl. Polym. Symp. 1968, 7, 175–199. [Google Scholar]

- Quinson, R.; Perez, J.; Rink, M.; Pavan, A. Yield criteria for amorphous glassy polymers. J. Mater. Sci. 1997, 32, 1371–1379. [Google Scholar] [CrossRef]

- G’sell, C.; Favier, V.; Hiver, J.M.; Dahoun, A.; Philippe, M.J.; Canova, G.R. Microstructure transformation and stress-strain behavior of isotactic polypropylene under large plastic deformation. Polym. Eng. Sci. 1997, 37, 1702–1711. [Google Scholar] [CrossRef]

- Bartczak, Z.; Argon, A.S.; Cohen, R.E. Texture evolution in large strain simple shear deformation of high density polyethylene. Polymer 1994, 35, 3427–3441. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Q.; Boulahia, R.; Zaïri, F.; Vozniak, I.; Qu, Z.; Gloaguen, J.-M.; Liu, X. Microstructure and Mechanical Properties of Severely Deformed Polypropylene in ECAE (Equal Channel Angular Extrusion) via Routes A and C. Polymers 2022, 14, 5287. https://doi.org/10.3390/polym14235287

Jiang Q, Boulahia R, Zaïri F, Vozniak I, Qu Z, Gloaguen J-M, Liu X. Microstructure and Mechanical Properties of Severely Deformed Polypropylene in ECAE (Equal Channel Angular Extrusion) via Routes A and C. Polymers. 2022; 14(23):5287. https://doi.org/10.3390/polym14235287

Chicago/Turabian StyleJiang, Qifeng, Ramdane Boulahia, Fahmi Zaïri, Iurii Vozniak, Zhengwei Qu, Jean-Michel Gloaguen, and Xiaobing Liu. 2022. "Microstructure and Mechanical Properties of Severely Deformed Polypropylene in ECAE (Equal Channel Angular Extrusion) via Routes A and C" Polymers 14, no. 23: 5287. https://doi.org/10.3390/polym14235287

APA StyleJiang, Q., Boulahia, R., Zaïri, F., Vozniak, I., Qu, Z., Gloaguen, J.-M., & Liu, X. (2022). Microstructure and Mechanical Properties of Severely Deformed Polypropylene in ECAE (Equal Channel Angular Extrusion) via Routes A and C. Polymers, 14(23), 5287. https://doi.org/10.3390/polym14235287