Additive Manufacturing of Polyolefins

Abstract

1. Introduction

2. Additive Manufacturing Techniques Used for Polymers

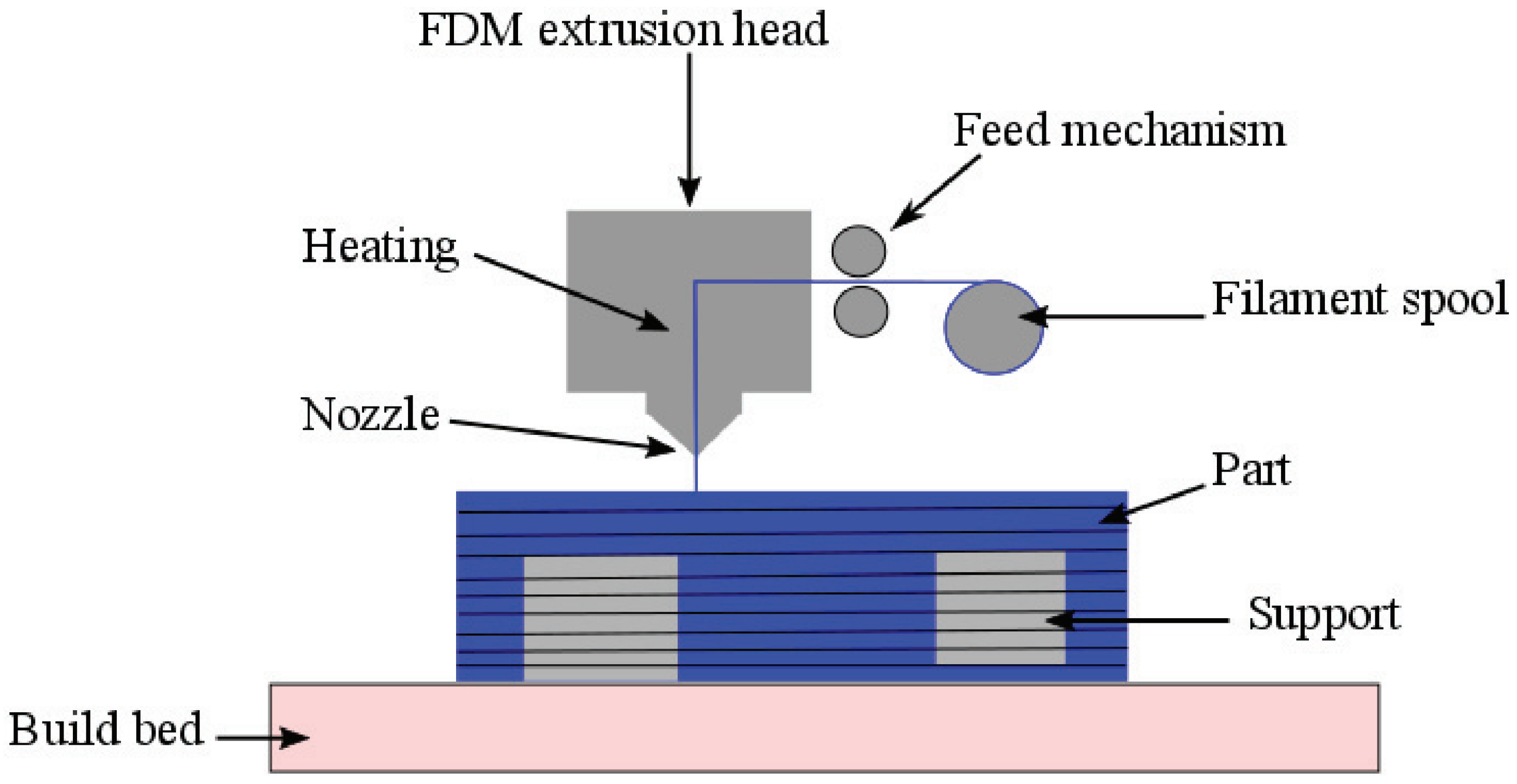

2.1. Fused Filament Fabrication

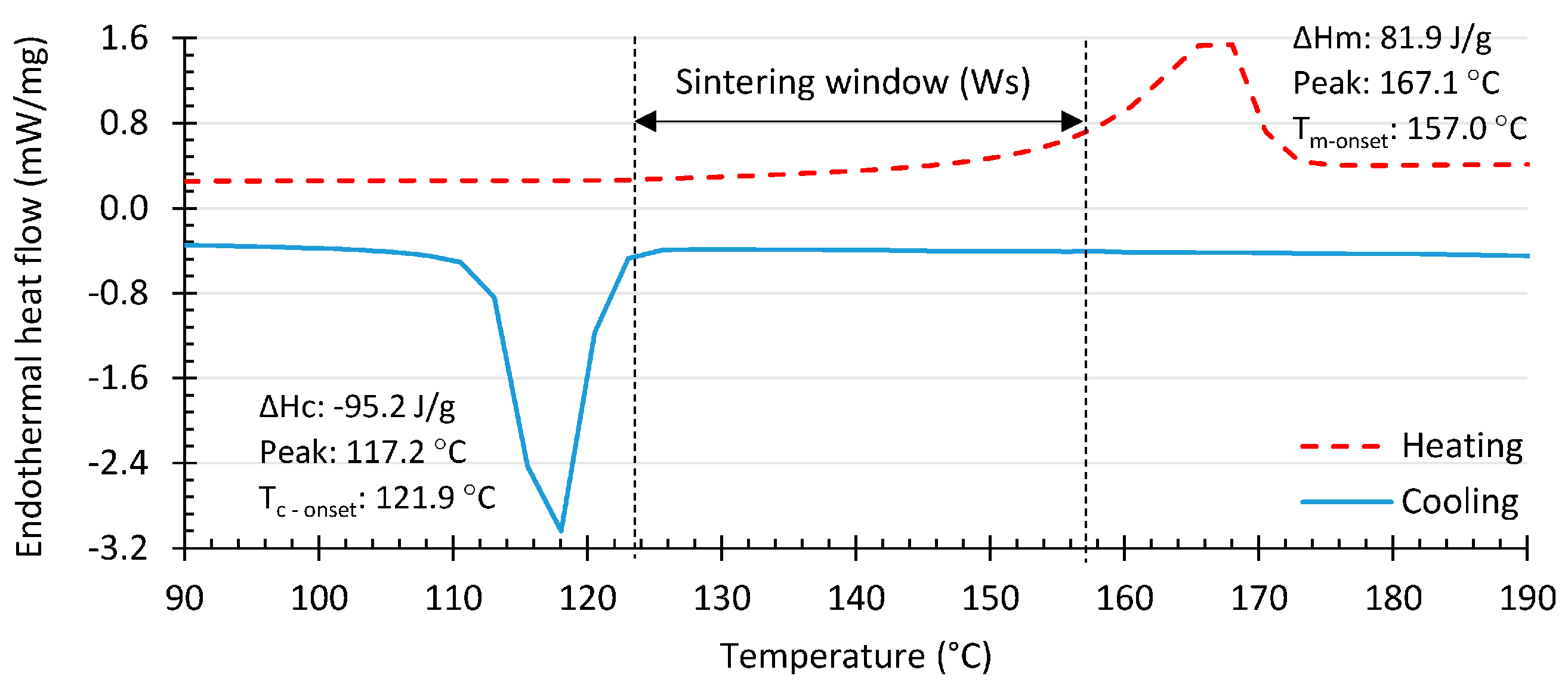

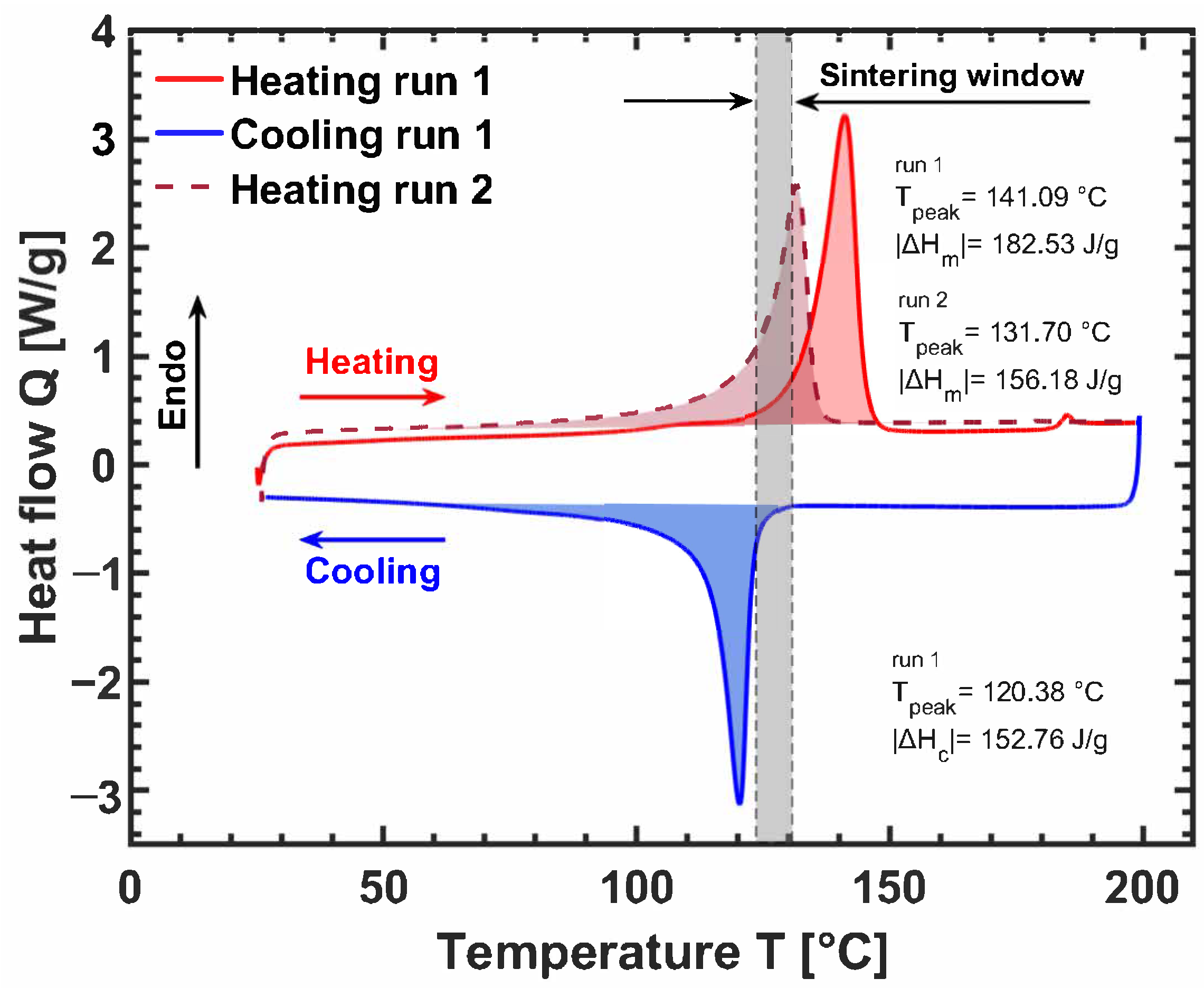

2.2. Selective Laser Sintering

3. Approaches Used for the Additive Manufacturing of Polyolefins

3.1. Polypropylene

3.2. Low- and High-Density Polyethylene

3.3. Ultra-High Molecular Weight Polyethylene

4. Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nielsen, T.D.; Hasselbalch, J.; Holmberg, K.; Stripple, J. Politics and the plastic crisis: A review throughout the plastic life cycle. Wiley Interdiscip. Rev. Energy Environ. 2020, 9, e360. [Google Scholar] [CrossRef]

- Amadei, A.M.; Sanyé-Mengual, E.; Sala, S. Modeling the EU plastic footprint: Exploring data sources and littering potential. Resour. Conserv. Recycl. 2022, 178, 106086. [Google Scholar] [CrossRef]

- Agboola, O.; Sadiku, R.; Mokrani, T.; Amer, I.; Imoru, O. Polyolefins and the environment. In Polyolefin Fibres: Structure, Properties and Industrial Applications: Second Edition; Woodhead Publishing: Sawston, UK, 2017; pp. 89–133. [Google Scholar] [CrossRef]

- Shonnard, D.; Tipaldo, E.; Thompson, V.; Pearce, J.; Caneba, G.; Handler, R. Systems analysis for PET and olefin polymers in a circular economy. Procedia CIRP 2019, 80, 602–606. [Google Scholar] [CrossRef]

- Vollmer, I.; Jenks, M.J.; Roelands, M.C.; White, R.J.; van Harmelen, T.; de Wild, P.; van der Laan, G.P.; Meirer, F.; Keurentjes, J.T.; Weckhuysen, B.M. Beyond Mechanical Recycling: Giving New Life to Plastic Waste. Angew. Chem. Int. Ed. 2020, 59, 15402–15423. [Google Scholar] [CrossRef]

- Eijssen, M. Offshore wind farm construction; Easier, safer and more cost effective. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Rotterdam, The Netherlands, 19–24 June 2011; Volume 5, pp. 701–709. [Google Scholar] [CrossRef]

- Zhang, T.G.; Satapathy, S.S.; Vargas-Gonzalez, L.R.; Walsh, S.M. Ballistic impact response of Ultra-High-Molecular-Weight Polyethylene (UHMWPE). Compos. Struct. 2015, 133, 191–201. [Google Scholar] [CrossRef]

- Singletary, J.; Lauke, B. Advanced Fibrous Composite Materials for Ballistic Protection; Woodhead Publishing: Sawston, UK, 2016; pp. 71–107. [Google Scholar] [CrossRef]

- Hustad, P.D.; Kuhlman, R.L.; Li Pi Shan, C. Chain Shuttling Catalysis and Olefin Block Copolymers. In Polymer Science: A Comprehensive Reference, 10 Volume Set; Elsevier: Amsterdam, The Netherlands, 2012; Volume 3, pp. 699–737. [Google Scholar] [CrossRef]

- Posch, D.W. Polyolefins. In Applied Plastics Engineering Handbook: Processing, Materials, and Applications: Second Edition; William Andrew Publishing: Norwich, NY, USA, 2016; pp. 27–52. [Google Scholar] [CrossRef]

- Pukanszk, B. Polyolefin Composites: Interfacial Phenomena and Properties. In Handbook of Polyolefins, 2nd ed.; Vasile, C., Ed.; CRC Press: Boca Raton, FL, USA, 2000; pp. 689–722. [Google Scholar] [CrossRef]

- Gahleitner, M. Melt rheology of polyolefins. Prog. Polym. Sci. 2001, 26, 895–944. [Google Scholar] [CrossRef]

- Hoffman, J.D.; Davis, G.T.; Lauritzen, J.I. The Rate of Crystallization of Linear Polymers with Chain Folding. In Treatise on Solid State Chemistry; Springer: Boston, MA, USA, 1976; pp. 497–614. [Google Scholar] [CrossRef]

- Cerpentier, R.R.; van Vliet, T.; Pastukhov, L.V.; van Drongelen, M.; Boerakker, M.J.; Tervoort, T.A.; Govaert, L.E. Fatigue-Crack Propagation of High-Density Polyethylene Homopolymers: Influence of Molecular Weight Distribution and Temperature. Macromolecules 2021, 54, 11508–11521. [Google Scholar] [CrossRef]

- Cerpentier, R.R.J.; Boerakker, M.J.; Tervoort, T.A.; Drongelen, M.; Govaert, L.E. Influence of electron-beam irradiation on plasticity-controlled and crack-growth-controlled failure in high-density polyethylene. J. Polym. Sci. 2022, 60, 701–714. [Google Scholar] [CrossRef]

- Kumar, S. Selective Laser Sintering: A Qualitative and Objective Approach. JOM 2003, 55, 43–47. [Google Scholar] [CrossRef]

- Kruth, J.P.; Mercelis, P.; Van Vaerenbergh, J.; Froyen, L.; Rombouts, M. Binding mechanisms in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2005, 11, 26–36. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Brighenti, R.; Cosma, M.P.; Marsavina, L.; Spagnoli, A.; Terzano, M. Laser-based additively manufactured polymers: A review on processes and mechanical models. J. Mater. Sci. 2021, 56, 961–998. [Google Scholar] [CrossRef]

- Johnson, M. A Review on Selective Laser Sintering. United Int. J. Res. Technol. 2020, 1, 2582–6832. [Google Scholar]

- Costabile, G.; Fera, M.; Fruggiero, F.; Lambiase, A.; Pham, D. Cost models of additive manufacturing: A literature review. Int. J. Ind. Eng. Comput. 2016, 8, 263–282. [Google Scholar] [CrossRef]

- Gao, X.; Qi, S.; Zhang, D.; Su, Y.; Wang, D. The role of poly (ethylene glycol) on crystallization, interlayer bond and mechanical performance of polylactide parts fabricated by fused filament fabrication. Addit. Manuf. 2020, 35, 101414. [Google Scholar] [CrossRef]

- Ho, Q.B.; Kontopoulou, M. Improving the adhesion and properties in the material extrusion of polypropylene by blending with a polyolefin elastomer. Addit. Manuf. 2022, 55, 102818. [Google Scholar] [CrossRef]

- Zhang, W.; Tong, M.; Harrison, N.M. Scanning strategies effect on temperature, residual stress and deformation by multi-laser beam powder bed fusion manufacturing. Addit. Manuf. 2020, 36, 101507. [Google Scholar] [CrossRef]

- Wang, W.; Liang, S.Y. Physics-based analytical modeling of keyhole mode in laser powder bed fusion. Int. J. Adv. Manuf. Technol. 2022, 123, 2809–2818. [Google Scholar] [CrossRef]

- Sola, A.; Nouri, A. Microstructural porosity in additive manufacturing: The formation and detection of pores in metal parts fabricated by powder bed fusion. J. Adv. Manuf. Process. 2019, 1, e10021. [Google Scholar] [CrossRef]

- Gong, H.; Rafi, K.; Gu, H.; Starr, T.; Stucker, B. Analysis of defect generation in Ti-6Al-4V parts made using powder bed fusion additive manufacturing processes. Addit. Manuf. 2014, 1, 87–98. [Google Scholar] [CrossRef]

- Davis, C.S.; Hillgartner, K.E.; Han, S.H.; Seppala, J.E. Mechanical strength of welding zones produced by polymer extrusion additive manufacturing. Addit. Manuf. 2017, 16, 162–166. [Google Scholar] [CrossRef] [PubMed]

- Salehi, A.; Pircheraghi, G.; Foudazi, R. Pore structure evolution during sintering of HDPE particles. Polymer 2019, 183, 121865. [Google Scholar] [CrossRef]

- Moretti, M.; Senin, N. In-process monitoring of part warpage in fused filament fabrication through the analysis of the repulsive force acting on the extruder. Addit. Manuf. 2022, 49, 102505. [Google Scholar] [CrossRef]

- Stansbury, J.W.; Idacavage, M.J. 3D printing with polymers: Challenges among expanding options and opportunities. Dent. Mater. 2016, 32, 54–64. [Google Scholar] [CrossRef] [PubMed]

- Schmid, M.; Amado, A.; Wegener, K. Materials perspective of polymers for additive manufacturing with selective laser sintering. J. Mater. Res. 2014, 29, 1824–1832. [Google Scholar] [CrossRef]

- Wendel, B.; Rietzel, D.; Kühnlein, F.; Feulner, R.; Hülder, G.; Schmachtenberg, E. Additive processing of polymers. Macromol. Mater. Eng. 2008, 293, 799–809. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef]

- Lakhdar, Y.; Tuck, C.; Binner, J.; Terry, A.; Goodridge, R. Additive manufacturing of advanced ceramic materials. Prog. Mater. Sci. 2021, 116, 100736. [Google Scholar] [CrossRef]

- Minas, C.; Carnelli, D.; Tervoort, E.; Studart, A.R. 3D Printing of Emulsions and Foams into Hierarchical Porous Ceramics. Adv. Mater. 2016, 28, 9993–9999. [Google Scholar] [CrossRef]

- Rimell, J.T.; Marquis, P.M. Selective laser sintering of ultra high molecular weight polyethylene for clinical applications. J. Biomed. Mater. Res. 2000, 53, 414–420. [Google Scholar] [CrossRef]

- Rhodes, M.L.; Kuo, Y.M.; Rothman, S.L.; Woznick, C. An Application of Computer Graphics and Networks to Anatomic Model and Prosthesis Manufacturing. IEEE Comput. Graph. Appl. 1987, 7, 12–25. [Google Scholar] [CrossRef]

- Crump, S.S. Apparatus and Method for Creating Three-Dimensional Objects. US5121329A, 1992. [Google Scholar]

- Alafaghani, A.; Qattawi, A.; Alrawi, B.; Guzman, A. Experimental Optimization of Fused Deposition Modelling Processing Parameters: A Design-for-Manufacturing Approach. Procedia Manuf. 2017, 10, 791–803. [Google Scholar] [CrossRef]

- Shaffer, S.; Yang, K.; Vargas, J.; Di Prima, M.A.; Voit, W. On reducing anisotropy in 3D printed polymers via ionizing radiation. Polymer 2014, 55, 5969–5979. [Google Scholar] [CrossRef]

- Yang, K.; Grant, J.C.; Lamey, P.; Joshi-Imre, A.; Lund, B.R.; Smaldone, R.A.; Voit, W. Diels–Alder Reversible Thermoset 3D Printing: Isotropic Thermoset Polymers via Fused Filament Fabrication. Adv. Funct. Mater. 2017, 27, 1700318. [Google Scholar] [CrossRef]

- Prager, S.; Tirrell, M. The healing process at polymer-polymer interfaces. J. Chem. Phys. 1981, 75, 5194–5198. [Google Scholar] [CrossRef]

- McIlroy, C.; Olmsted, P.D. Disentanglement effects on welding behaviour of polymer melts during the fused-filament-fabrication method for additive manufacturing. Polymer 2017, 123, 376–391. [Google Scholar] [CrossRef]

- Xue, Y.Q.; Tervoort, T.A.; Rastogi, S.; Lemstra, P.J. Welding behavior of semicrystalline polymers. 2. Effect of cocrystallization on autoadhesion. Macromolecules 2000, 33, 7084–7087. [Google Scholar] [CrossRef]

- Gantenbein, S.; Masania, K.; Woigk, W.; Sesseg, J.P.W.; Tervoort, T.A.; Studart, A.R. Three-dimensional printing of hierarchical liquid-crystal-polymer structures. Nature 2018, 561, 226–230. [Google Scholar] [CrossRef]

- Mackay, M.E. The importance of rheological behavior in the additive manufacturing technique material extrusion. J. Rheol. 2018, 62, 1549–1561. [Google Scholar] [CrossRef]

- Sun, Q.; Rizvi, G.M.; Bellehumeur, C.T.; Gu, P. Effect of processing conditions on the bonding quality of FDM polymer filaments. Rapid Prototyp. J. 2008, 14, 72–80. [Google Scholar] [CrossRef]

- Yang, F.; Pitchumani, R. Healing of thermoplastic polymers at an interface under nonisothermal conditions. Macromolecules 2002, 35, 3213–3224. [Google Scholar] [CrossRef]

- Seppala, J.E.; Migler, K.D. Infrared thermography of welding zones produced by polymer extrusion additive manufacturing. Addit. Manuf. 2016, 12, 71–76. [Google Scholar] [CrossRef]

- Hofstätter, T.; Pimentel, R.; Pedersen, D.B.; Mischkot, M.; Hansen, H.N. Simulation of a Downsized FDM Nozzle. In Proceedings of the COMSOL Conference 2015, Grenoble, France, 14–16 October 2015. [Google Scholar]

- Vaes, D.; Van Puyvelde, P. Semi-crystalline feedstock for filament-based 3D printing of polymers. Prog. Polym. Sci. 2021, 118, 101411. [Google Scholar] [CrossRef]

- Jarrousse, G. Self Adhesion of Semi-Crystalline Polymers between Their Glass Transition Temperature and Their Melting Temperature. PhD Thesis, Université Pierre et Marie Curie, Paris, France, 2004. [Google Scholar]

- Buj-Corral, I.; Domínguez-Fernández, A.; Durán-Llucià, R. Influence of Print Orientation on Surface Roughness in Fused Deposition Modeling (FDM) Processes. Materials 2019, 12, 3834. [Google Scholar] [CrossRef]

- Pérez, M.; Medina-Sánchez, G.; García-Collado, A.; Gupta, M.; Carou, D. Surface quality enhancement of fused deposition modeling (FDM) printed samples based on the selection of critical printing parameters. Materials 2018, 11, 1382. [Google Scholar] [CrossRef]

- Yan, C.; Shi, Y.; Hao, L. Investigation into the differences in the selective laser sintering between amorphous and semi-crystalline polymers. Int. Polym. Process. 2011, 26, 416–423. [Google Scholar] [CrossRef]

- Turner, B.N.; Gold, S.A. A review of melt extrusion additive manufacturing processes: II. Materials, dimensional accuracy, and surface roughness. Rapid Prototyp. J. 2015, 21, 250–261. [Google Scholar] [CrossRef]

- Spoerk, M.; Gonzalez-Gutierrez, J.; Sapkota, J.; Schuschnigg, S.; Holzer, C. Effect of the printing bed temperature on the adhesion of parts produced by fused filament fabrication. Plast. Rubber Compos. 2018, 47, 17–24. [Google Scholar] [CrossRef]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Deckard, C.R. Method and Apparatus for Producing Parts by Selective Sintering. U.S. Patent 4863538A, 5 September 1989. [Google Scholar]

- Hejmady, P.; Van Breemen, L.C.; Anderson, P.D.; Cardinaels, R. Laser sintering of polymer particle pairs studied by in situ visualization. Soft Matter 2019, 15, 1373–1387. [Google Scholar] [CrossRef] [PubMed]

- Goodridge, R.D.; Tuck, C.J.; Hague, R.J. Laser sintering of polyamides and other polymers. Prog. Mater. Sci. 2012, 57, 229–267. [Google Scholar] [CrossRef]

- Kruth, J.; Levy, G.; Schindel, R.; Craeghs, T.; Yasa, E. Consolidation of Polymer Powders by Selective Laser Sintering. In Proceedings of the International Conference on Polymers and Moulds Innovations, Gent, Belgium, 17–19 September 2008; pp. 15–30. [Google Scholar]

- Lupone, F.; Padovano, E.; Casamento, F.; Badini, C. Process phenomena and material properties in selective laser sintering of polymers: A review. Materials 2022, 1, 183. [Google Scholar] [CrossRef] [PubMed]

- Dotchev, K.; Yusoff, W. Recycling of polyamide 12 based powders in the laser sintering process. Rapid Prototyp. J. 2009, 15, 192–203. [Google Scholar] [CrossRef]

- Amado, A.; Schmid, M.; Wegener, K. Simulation of warpage induced by non-isothermal crystallization of co-polypropylene during the SLS process. AIP Conf. Proc. 2015, 1664, 160002. [Google Scholar] [CrossRef]

- Amado Becker, A.F. Characterization and Prediction of SLS Processability of Polymer Powders with Respect to Powder Flow and Part Warpage. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, 2016. [Google Scholar] [CrossRef]

- Schmid, M.; Amado, A.; Wegener, K. Polymer powders for selective laser sintering (SLS). AIP Conf. Proc. 2015, 1664, 160009. [Google Scholar] [CrossRef]

- Drummer, D.; Rietzel, D.; Kühnlein, F. Development of a characterization approach for the sintering behavior of new thermoplastics for selective laser sintering. Phys. Procedia 2010, 5, 533–542. [Google Scholar] [CrossRef]

- Schmid, M.; Amado, F.; Levy, G.; Wegener, K. Flowability of powders for Selective Laser Sintering (SLS) investigated by Round Robin Test. In Proceedings of the High Value Manufacturing: Proceedings of the 6th International Conference on Advanced Research in Virtual and Rapid Prototyping, Leiria, Portugal, 1–5 October 2013; Taylor & Francis: Abingdon, UK, 2014; pp. 95–99. [Google Scholar] [CrossRef]

- Calignano, F.; Giuffrida, F.; Galati, M. Effect of the build orientation on the mechanical performance of polymeric parts produced by multi jet fusion and selective laser sintering. J. Manuf. Process. 2021, 65, 271–282. [Google Scholar] [CrossRef]

- Kafle, A.; Luis, E.; Silwal, R.; Pan, H.M.; Shrestha, P.L.; Bastola, A.K. 3D/4D printing of polymers: Fused deposition modelling (FDM), selective laser sintering (SLS), and stereolithography (SLA). Polymers 2021, 13, 3101. [Google Scholar] [CrossRef]

- Carneiro, O.S.; Silva, A.F.; Gomes, R. Fused deposition modeling with polypropylene. Mater. Des. 2015, 83, 768–776. [Google Scholar] [CrossRef]

- Caelers, H.J.; Troisi, E.M.; Govaert, L.E.; Peters, G.W. Deformation-induced phase transitions in iPP polymorphs. Polymers 2017, 9, 547. [Google Scholar] [CrossRef] [PubMed]

- Varga, J. β-modification of isotactic polypropylene: Preparation, structure, processing, properties, and application. J. Macromol. Sci. Part B 2002, 41, 1121–1171. [Google Scholar] [CrossRef]

- Lotz, B.; Wittmann, J.C.; Lovinger, A.J. Structure and morphology of poly(propylenes): A molecular analysis. Polymer 1996, 37, 4979–4992. [Google Scholar] [CrossRef]

- Brückner, S.; Meille, S.V.; Petraccone, V.; Pirozzi, B. Polymorphism in isotactic polypropylene. Prog. Polym. Sci. 1991, 16, 361–404. [Google Scholar] [CrossRef]

- Jones, A.T.; Aizlewood, J.M.; Beckett, D.R. Crystalline forms of isotactic polypropylene. Die Makromol. Chem. 1964, 75, 134. [Google Scholar] [CrossRef]

- Keith, H.D.; Padden, F.J.; Walter, N.M.; Wyckoff, H.W. Evidence for a second crystal form of polypropylene. J. Appl. Phys. 1959, 30, 1485–1488. [Google Scholar] [CrossRef]

- Addink, E.J.; Beintema, J. Polymorphism of crystalline polypropylene. Polymer 1961, 2, 185–193. [Google Scholar] [CrossRef]

- Silva, A.F.; Carneiro, O.S.; Gomes, R. 3D printing of polypropylene using the fused filament fabrication technique. AIP Conf. Proc. 2017, 1896, 040014. [Google Scholar] [CrossRef]

- Charlon, S.; Le Boterff, J.; Soulestin, J. Fused filament fabrication of polypropylene: Influence of the bead temperature on adhesion and porosity. Addit. Manuf. 2021, 38, 101838. [Google Scholar] [CrossRef]

- Wang, L.; Sanders, J.E.; Gardner, D.J.; Han, Y. Effect of fused deposition modeling process parameters on the mechanical properties of a filled polypropylene. Prog. Addit. Manuf. 2018, 3, 205–214. [Google Scholar] [CrossRef]

- van Erp, T.B.; Balzano, L.; Spoelstra, A.B.; Govaert, L.E.; Peters, G.W.M. Quantification of non-isothermal, multiphase crystallization of isotactic polypropylene: The influence of shear and pressure. Polymer 2012, 53, 5896–5908. [Google Scholar] [CrossRef]

- Tordjeman, P.; Robert, C.; Marin, G.; Gerard, P. The effect of α, β crystalline structure on the mechanical properties of polypropylene. Eur. Phys. J. E 2001, 4, 459–465. [Google Scholar] [CrossRef]

- Fillon, B.; Thierry, A.; Wittmann, J.C.; Lotz, B. Self-nucleation and recrystallization of polymers. Isotactic polypropylene, β phase: β-α conversion and β-α growth transitions. J. Polym. Sci. Part B Polym. Phys. 1993, 31, 1407–1424. [Google Scholar] [CrossRef]

- Northcutt, L.A.; Orski, S.V.; Migler, K.B.; Kotula, A.P. Effect of processing conditions on crystallization kinetics during materials extrusion additive manufacturing. Polymer 2018, 154, 182–187. [Google Scholar] [CrossRef] [PubMed]

- Eder, G.; Janeschitz-Kriegl, H.; Krobath, G. Shear induced crystallization, a relaxation phenomenon in polymer melts. Relax. Polym. 1989, 80, 1–7. [Google Scholar] [CrossRef]

- Janeschitz-Kriegl, H.; Eder, G. Shear induced crystallization, a relaxation phenomenon in polymer melts: A re-collection. J. Macromol. Sci. Part B Phys. 2007, 46, 591–601. [Google Scholar] [CrossRef]

- Ituarte, I.F.; Wiikinkoski, O.; Jansson, A. Additive manufacturing of polypropylene: A screening design of experiment using laser-based powder bed fusion. Polymers 2018, 10, 1293. [Google Scholar] [CrossRef]

- Zhu, W.; Yan, C.; Shi, Y.; Wen, S.; Liu, J.; Shi, Y. Investigation into mechanical and microstructural properties of polypropylene manufactured by selective laser sintering in comparison with injection molding counterparts. Mater. Des. 2015, 82, 37–45. [Google Scholar] [CrossRef]

- Tan, L.J.; Zhu, W.; Sagar, K.; Zhou, K. Comparative study on the selective laser sintering of polypropylene homopolymer and copolymer: Processability, crystallization kinetics, crystal phases and mechanical properties. Addit. Manuf. 2021, 37, 101610. [Google Scholar] [CrossRef]

- Valdo Meille, S.; Brückner, S. Non-parallel chains in crystalline γ-isotactic polypropylene. Nature 1989, 340, 455–457. [Google Scholar] [CrossRef]

- Mezghani, K.; Phillips, P.J. The γ-phase of high molecular weight isotactic polypropylene: III. The equilibrium melting point and the phase diagram. Polymer 1998, 39, 3735–3744. [Google Scholar] [CrossRef]

- Lezak, E.; Bartczak, Z. Plastic deformation of the γ phase isotactic polypropylene in plane-strain compression at elevated temperatures. Macromolecules 2007, 40, 4933–4941. [Google Scholar] [CrossRef]

- Khanam, P.N.; AlMaadeed, M.A.A. Processing and characterization of polyethylene-based composites. Adv. Manuf. Polym. Compos. Sci. 2015, 1, 63–79. [Google Scholar] [CrossRef]

- Jordan, J.L.; Casem, D.T.; Bradley, J.M.; Dwivedi, A.K.; Brown, E.N.; Jordan, C.W. Mechanical Properties of Low Density Polyethylene. J. Dyn. Behav. Mater. 2016, 2, 411–420. [Google Scholar] [CrossRef]

- Olesik, P.; Godzierz, M.; Kozioł, M. Preliminary characterization of novel LDPE-based wear-resistant composite suitable for FDM 3D printing. Materials 2019, 12, 2520. [Google Scholar] [CrossRef]

- Bedi, P.; Singh, R.; Ahuja, I.P. Effect of SiC/Al2O3 particle size reinforcement in recycled LDPE matrix on mechanical properties of FDM feed stock filament. Virtual Phys. Prototyp. 2018, 13, 246–254. [Google Scholar] [CrossRef]

- Enderle, H. Polyethylene: High-density. In Encyclopedia of Materials: Science and Technology; Buschow, K.H.J., Cahn, R.W., Flemings, M.C., Ilschner, B., Kramer, E.J., Subhash Mahajan, P.V., Eds.; Elsevier: Amsterdam, The Netherlands, 2001; Chapter 2; pp. 7172–7180. [Google Scholar] [CrossRef]

- Mejia, E.B.; Al-Maqdi, S.; Alkaabi, M.; Alhammadi, A.; Alkaabi, M.; Cherupurakal, N.; Mourad, A.H.I. Upcycling of HDPE waste using additive manufacturing: Feasibility and challenges. In Proceedings of the 2020 Advances in Science and Engineering Technology International Conferences, Dubai, United Arab Emirates, 4 February–9 April 2020. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Maniadi, A. Sustainable additive manufacturing: Mechanical response of high-density polyethylene over multiple recycling processes. Recycling 2021, 6, 4. [Google Scholar] [CrossRef]

- Schirmeister, C.G.; Hees, T.; Licht, E.H.; Mülhaupt, R. 3D printing of high density polyethylene by fused filament fabrication. Addit. Manuf. 2019, 28, 152–159. [Google Scholar] [CrossRef]

- Salmoria, G.V.; Leite, J.L.; Paggi, R.A.; Lago, A.; Pires, A.T. Selective laser sintering of PA12/HDPE blends: Effect of components on elastic/plastic behavior. Polym. Test. 2008, 27, 654–659. [Google Scholar] [CrossRef]

- Lisi Leite, J.; Salmoria, G.V.; Paggi, R.A.; Ahrens, C.H.; Pouzada, A.S. Microstructural characterization and mechanical properties of functionally graded PA12/HDPE parts by selective laser sintering. Int. J. Adv. Manuf. Technol. 2012, 59, 583–591. [Google Scholar] [CrossRef]

- Salari, M.; Pircheraghi, G. Fabrication of sintered porous polymeric materials: Effect of chain interdiffusion time on mechanical properties. Polym. Int. 2018, 67, 422–430. [Google Scholar] [CrossRef]

- Rajamani, D.; Balasubramanian, E. Investigation of sintering parameters on viscoelastic behaviour of selective heat sintered HDPE parts. J. Appl. Sci. Eng. 2019, 22, 39–402. [Google Scholar] [CrossRef]

- Barham, P.J.; Sadler, D.M. A neutron scattering study of the melting behaviour of polyethylene single crystals. Polymer 1991, 32, 393–395. [Google Scholar] [CrossRef]

- Litvinov, V.; Deblieck, R.; Clair, C.; Van Den Fonteyne, W.; Lallam, A.; Kleppinger, R.; Ivanov, D.A.; Ries, M.E.; Boerakker, M. Molecular Structure, Phase Composition, Melting Behavior, and Chain Entanglements in the Amorphous Phase of High-Density Polyethylenes. Macromolecules 2020, 53, 5418–5433. [Google Scholar] [CrossRef]

- Hoelzel, B.; Herren, B.; Saha, M.C.; Liu, Y. Investigation of selective laser sintering of high-density polyethylene using optimized 3D printing parameters. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Proceedings (IMECE), Virtual, 1–5 November 2021; Volume 4. [Google Scholar] [CrossRef]

- Wencke, Y.L.; Proes, F.; Imgrund, P.; Luinstra, G.A. Toward the Direct Synthesis of HDPE Powders for Powder Bed Fusion Based Additive Manufacturing. Macromol. Mater. Eng. 2021, 306, 2100477. [Google Scholar] [CrossRef]

- Chanzy, H.D.; Bonjour, E.; Marchessault, R.H. Nascent structures during the polymerization of ethylene—II. Calorimetric study. Colloid Polym. Sci. 1974, 252, 8–14. [Google Scholar] [CrossRef]

- Wang, X.Y.; Salovey, R. Melting of ultrahigh molecular weight polyethylene. J. Appl. Polym. Sci. 1987, 34, 593–599. [Google Scholar] [CrossRef]

- Christakopoulos, F.; Troisi, E.M.; Sologubenko, A.S.; Friederichs, N.; Stricker, L.; Tervoort, T.A. Melting kinetics, ultra-drawability and microstructure of nascent ultra-high molecular weight polyethylene powder. Polymer 2021, 222. [Google Scholar] [CrossRef]

- Goodridge, R.D.; Hague, R.J.; Tuck, C.J. An empirical study into laser sintering of ultra-high molecular weight polyethylene (UHMWPE). J. Mater. Process. Technol. 2010, 210, 72–80. [Google Scholar] [CrossRef]

- Khalil, Y.; Kowalski, A.; Hopkinson, N. Influence of laser power on tensile properties and material characteristics of laser-sintered UHMWPE. Manuf. Rev. 2016, 3, 15. [Google Scholar] [CrossRef]

- Song, C.; Huang, A.; Yang, Y.; Xiao, Z.; Yu, J.K. Effect of energy input on the UHMWPE fabricating process by selective laser sintering. Rapid Prototyp. J. 2017, 23, 1069–1078. [Google Scholar] [CrossRef]

- Ullsperger, T.; Wencke, Y.L.; Yürekli, B.; Matthäus, G.; Rettenmayr, M.; Luinstra, G.A.; Nolte, S. Laser powder bed fusion of ultra-high molecular weight polyethylene (UHMWPE) using near-infrared ultrashort laser pulses. Mater. Des. 2021, 210, 110048. [Google Scholar] [CrossRef]

- Wool, R.P.; Yuan, B.L.; McGarel, O.J. Welding of polymer interfaces. Polym. Eng. Sci. 1989, 29, 1340–1367. [Google Scholar] [CrossRef]

- Wool, R.P. Self-healing materials: A review. Soft Matter 2008, 4, 400–418. [Google Scholar] [CrossRef]

- De Gennes, P.G. The formation of polymer/polymer junctions. Tribol. Ser. 1981, 7, 355–367. [Google Scholar] [CrossRef]

- Benkoski, J.J.; Fredrickson, G.H.; Kramer, E.J. Model for the fracture energy of glassy polymer-polymer interfaces. J. Polym. Sci. Part B Polym. Phys. 2002, 40, 2377–2386. [Google Scholar] [CrossRef]

- Bastiaansen, C.W.; Meyer, H.E.; Lemstra, P.J. Memory effects in polyethylenes: Influence of processing and crystallization history. Polymer 1990, 31, 1435–1440. [Google Scholar] [CrossRef]

- Gill, T.J.; Hon, K.K. Experimental investigation into the selective laser sintering of silicon carbide polyamide composites. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2004, 218, 1249–1256. [Google Scholar] [CrossRef]

- Visco, A.M.; Torrisi, L.; Galtieri, G.; Scolaro, C. Effect of the filler amount on the optical absorption properties and the surface features of polymeric joints based on biomedical UHMWPE welded by a Nd:YAG laser. J. Thermoplast. Compos. Mater. 2017, 30, 1675–1692. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Tzounis, L.; Maniadi, A.; Velidakis, E.; Mountakis, N.; Papageorgiou, D.; Liebscher, M.; Mechtcherine, V. Sustainable additive manufacturing: Mechanical response of polypropylene over multiple recycling processes. Sustainability 2021, 13, 159. [Google Scholar] [CrossRef]

- Christakopoulos, F.; Troisi, E.; Friederichs, N.; Vermant, J.; Tervoort, T.A. “Tying the Knot”: Enhanced Recycling through Ultrafast Entangling across Ultrahigh Molecular Weight Polyethylene Interfaces. Macromolecules 2021, 54, 9452–9460. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Christakopoulos, F.; van Heugten, P.M.H.; Tervoort, T.A. Additive Manufacturing of Polyolefins. Polymers 2022, 14, 5147. https://doi.org/10.3390/polym14235147

Christakopoulos F, van Heugten PMH, Tervoort TA. Additive Manufacturing of Polyolefins. Polymers. 2022; 14(23):5147. https://doi.org/10.3390/polym14235147

Chicago/Turabian StyleChristakopoulos, Fotis, Paul M. H. van Heugten, and Theo A. Tervoort. 2022. "Additive Manufacturing of Polyolefins" Polymers 14, no. 23: 5147. https://doi.org/10.3390/polym14235147

APA StyleChristakopoulos, F., van Heugten, P. M. H., & Tervoort, T. A. (2022). Additive Manufacturing of Polyolefins. Polymers, 14(23), 5147. https://doi.org/10.3390/polym14235147