Structure of Waste Hemp Stalks and Their Sound Absorbing Properties

Abstract

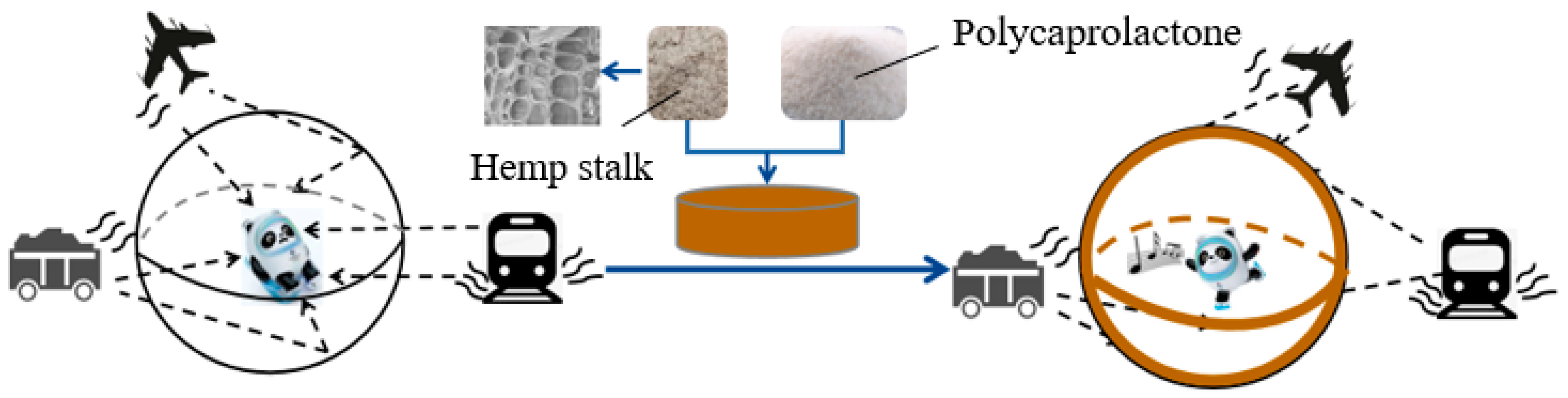

1. Introduction

2. Experiment

2.1. Materials

2.2. Equipment

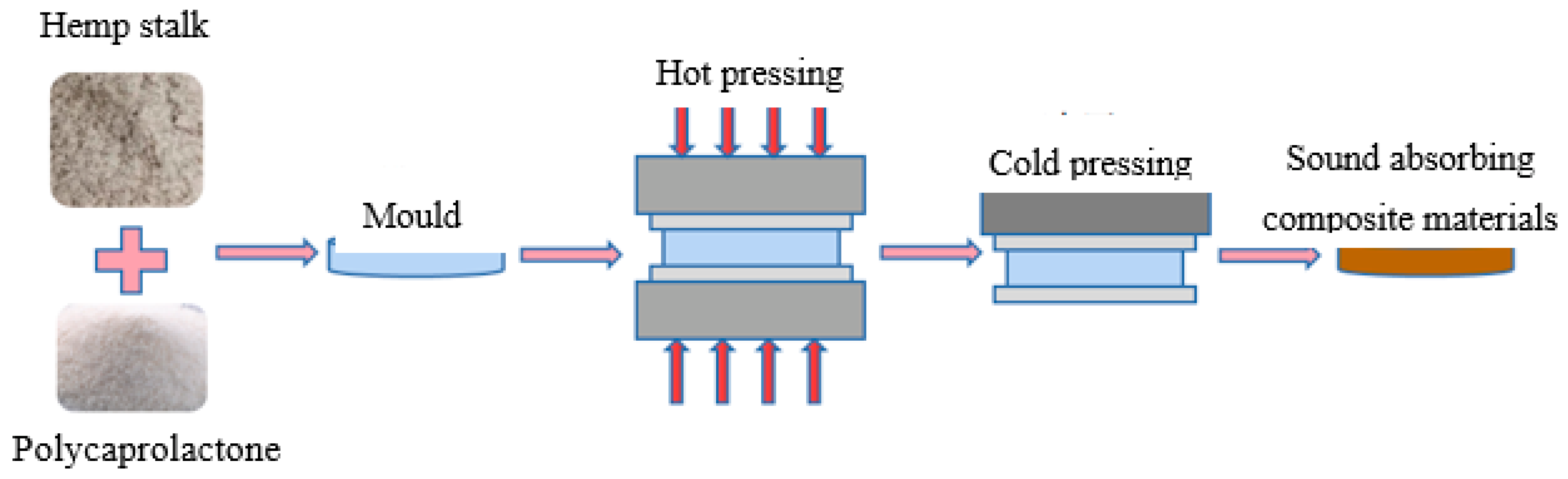

2.3. Preparation of Hemp Stalk/Polycaprolactone Sound-Absorbing Composite Materials

2.4. Test Indicators

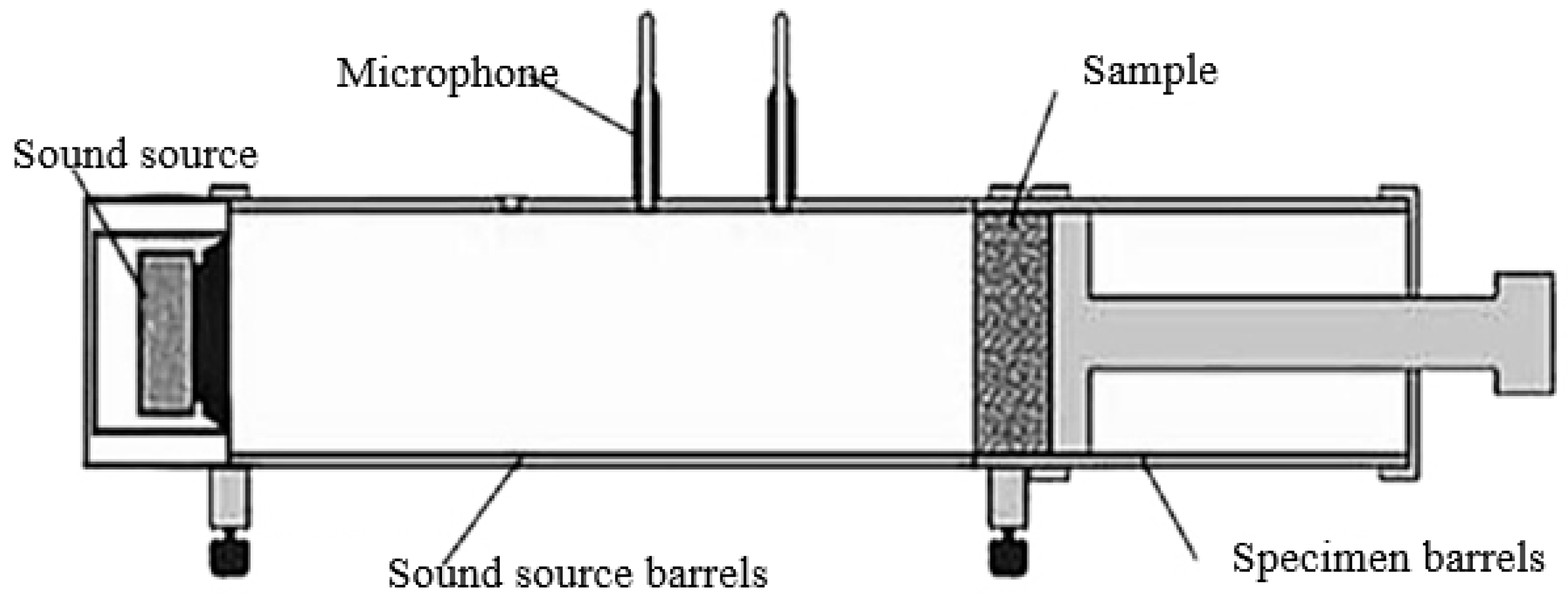

2.4.1. Sound Absorption Coefficient

2.4.2. Macromolecular Structure

2.4.3. Supramolecular Structure

2.4.4. Morphological Structure

3. Results and Discussion

3.1. Relationships between Structural Characteristics and Sound-Absorbing Properties of Hemp Stalks

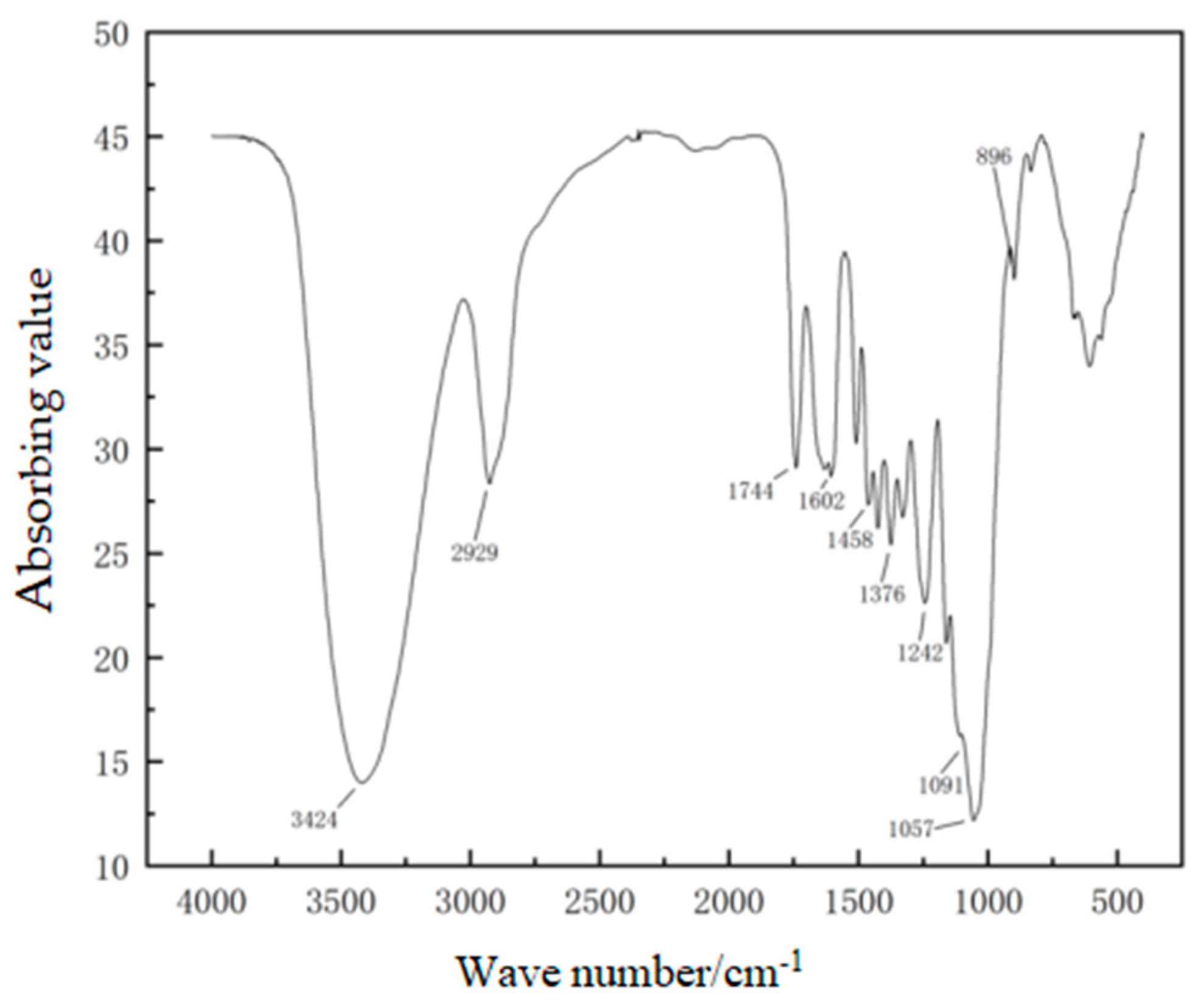

3.1.1. Macromolecular Structure

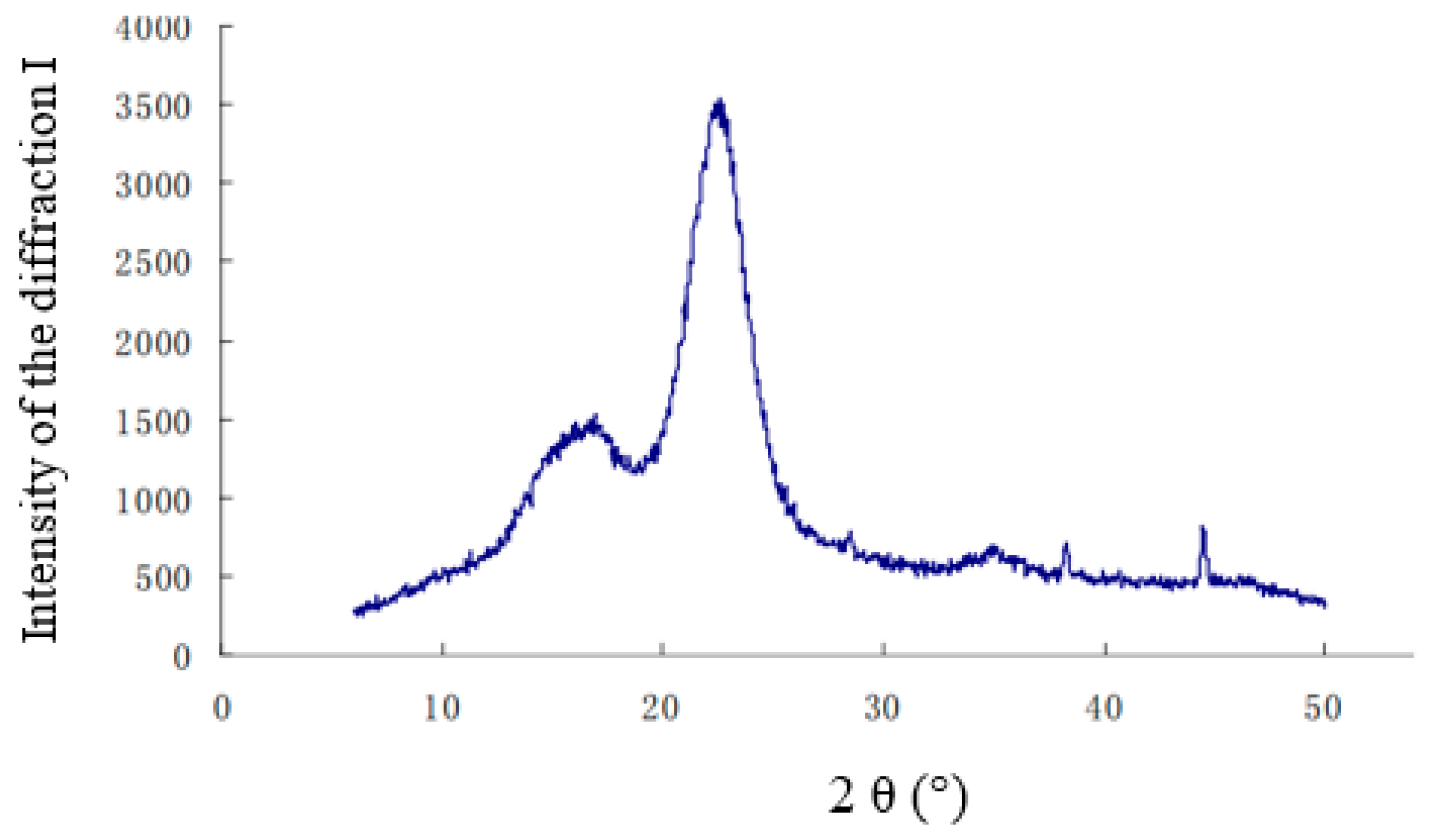

3.1.2. Supramolecular Structure

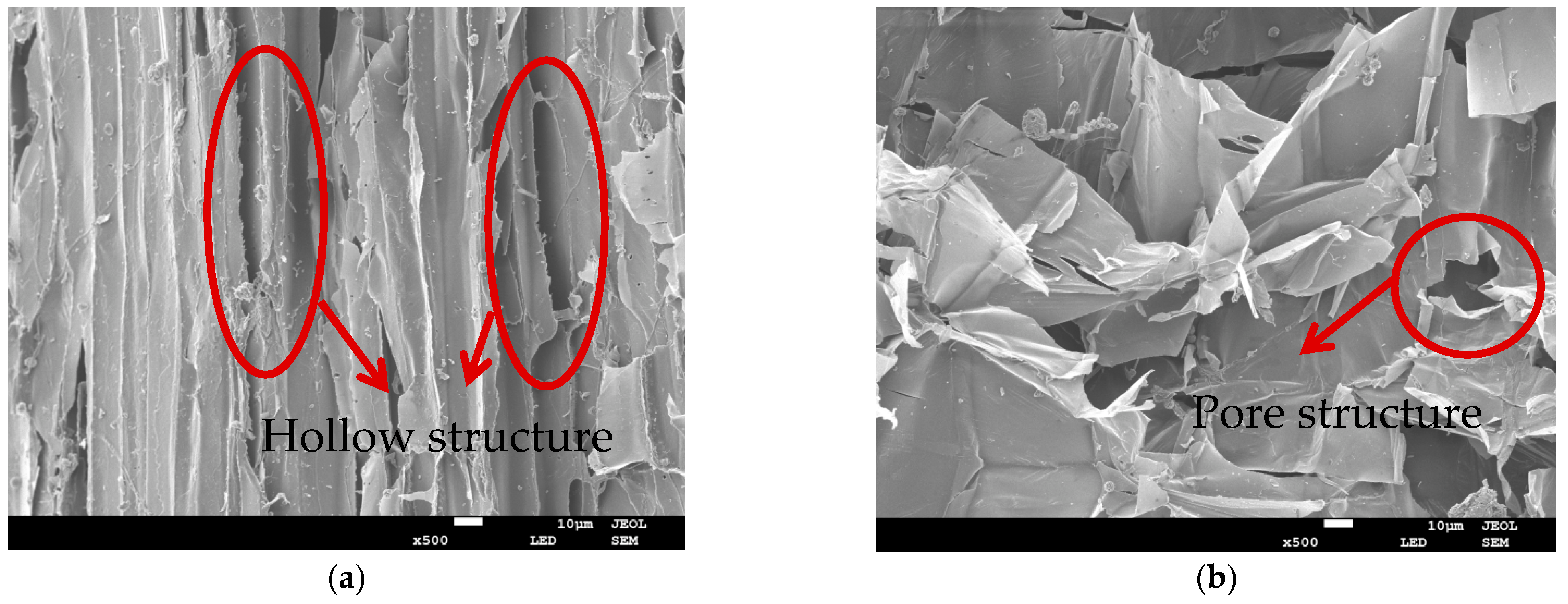

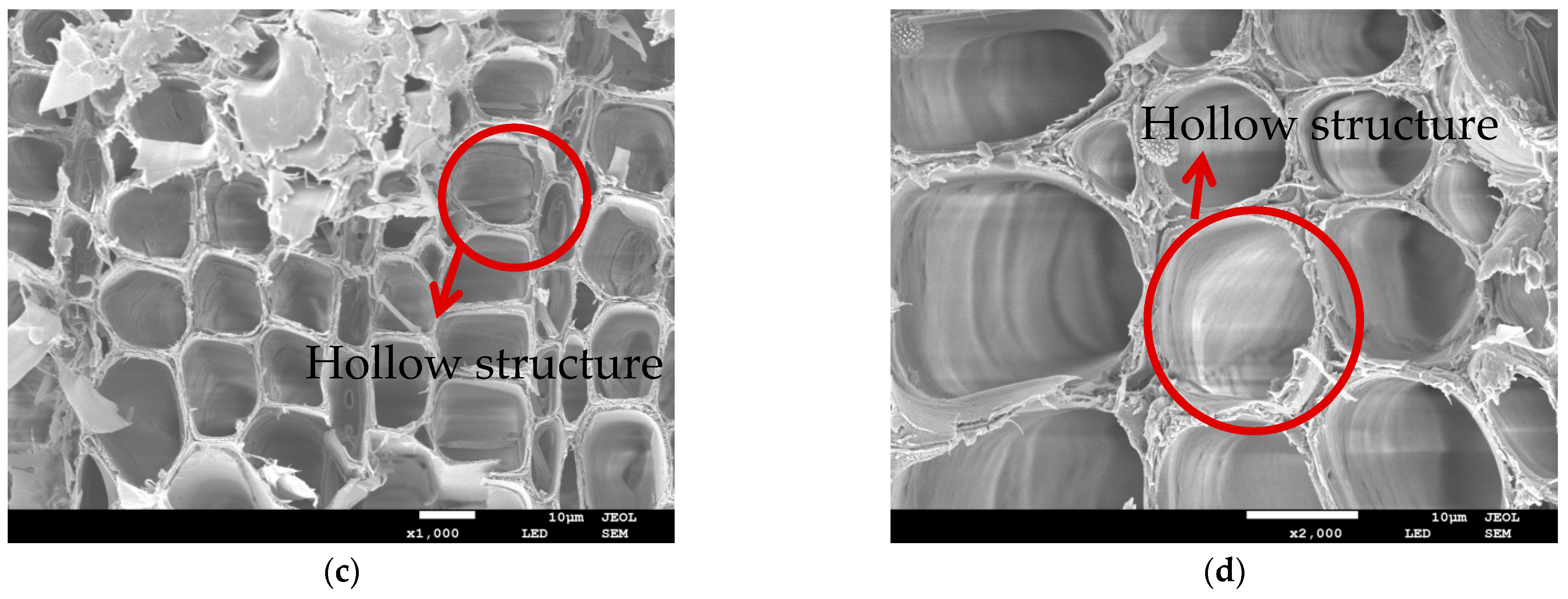

3.1.3. Morphological Structure

3.2. Sound-Absorbing Composite Materials of Waste Hemp Stalks and Their Sound Absorption Properties

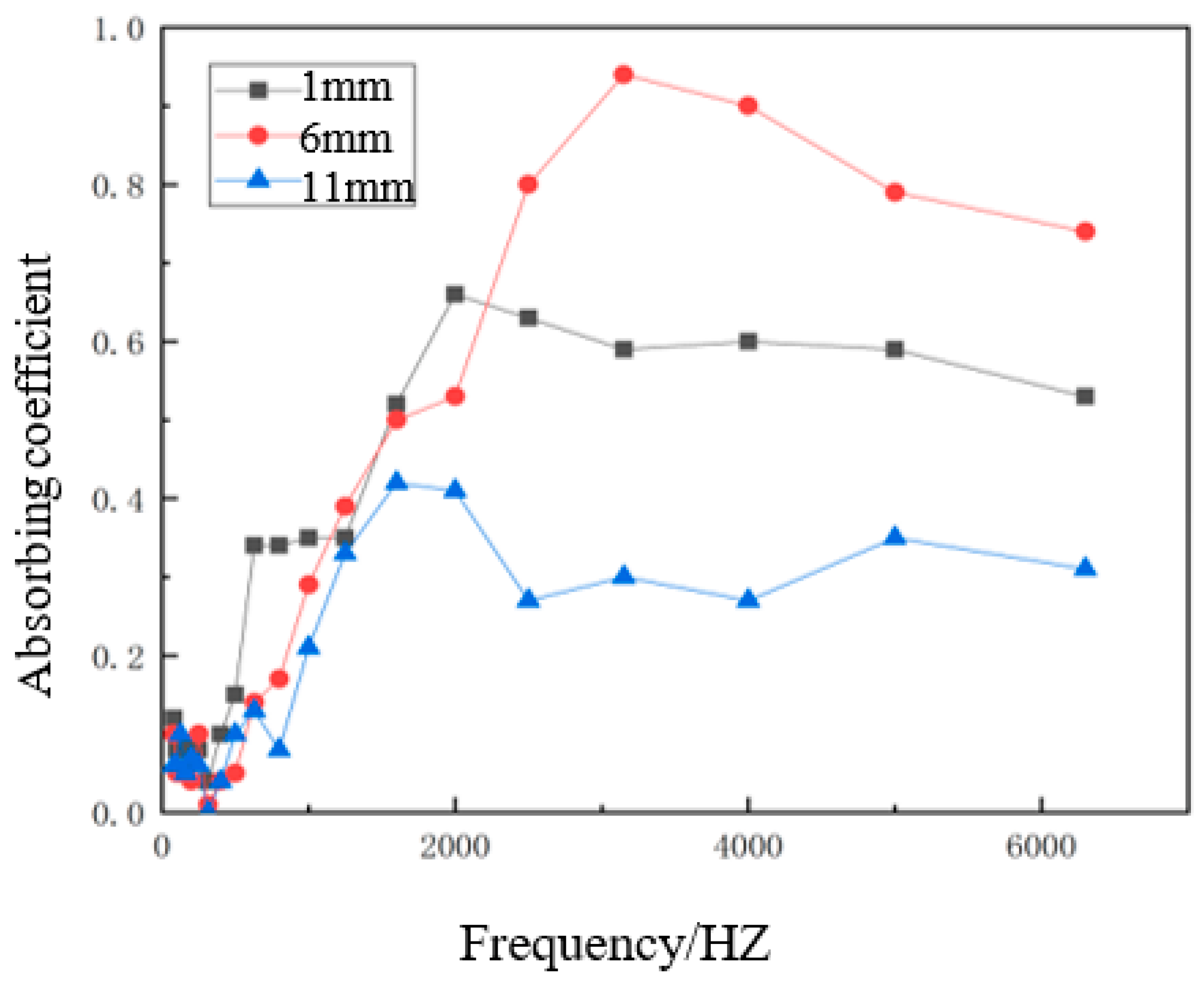

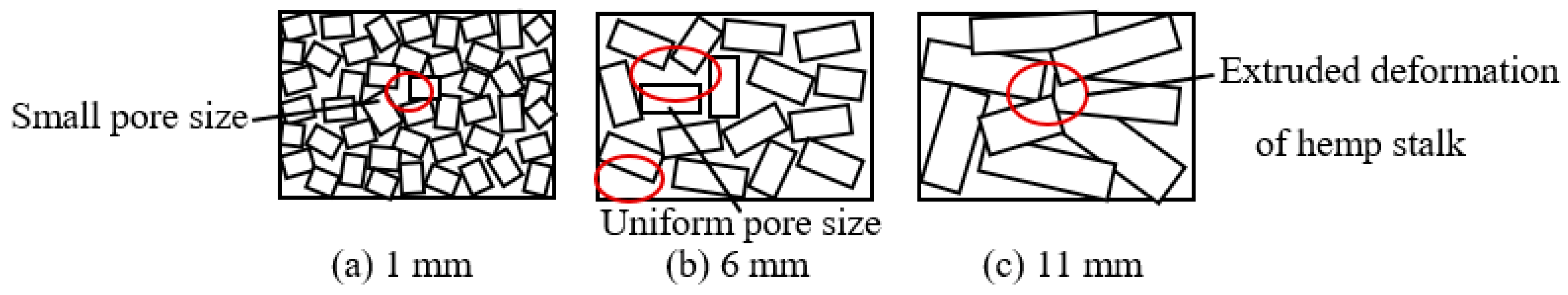

3.2.1. Effect of Hemp Stalk Length on Sound Absorption Properties

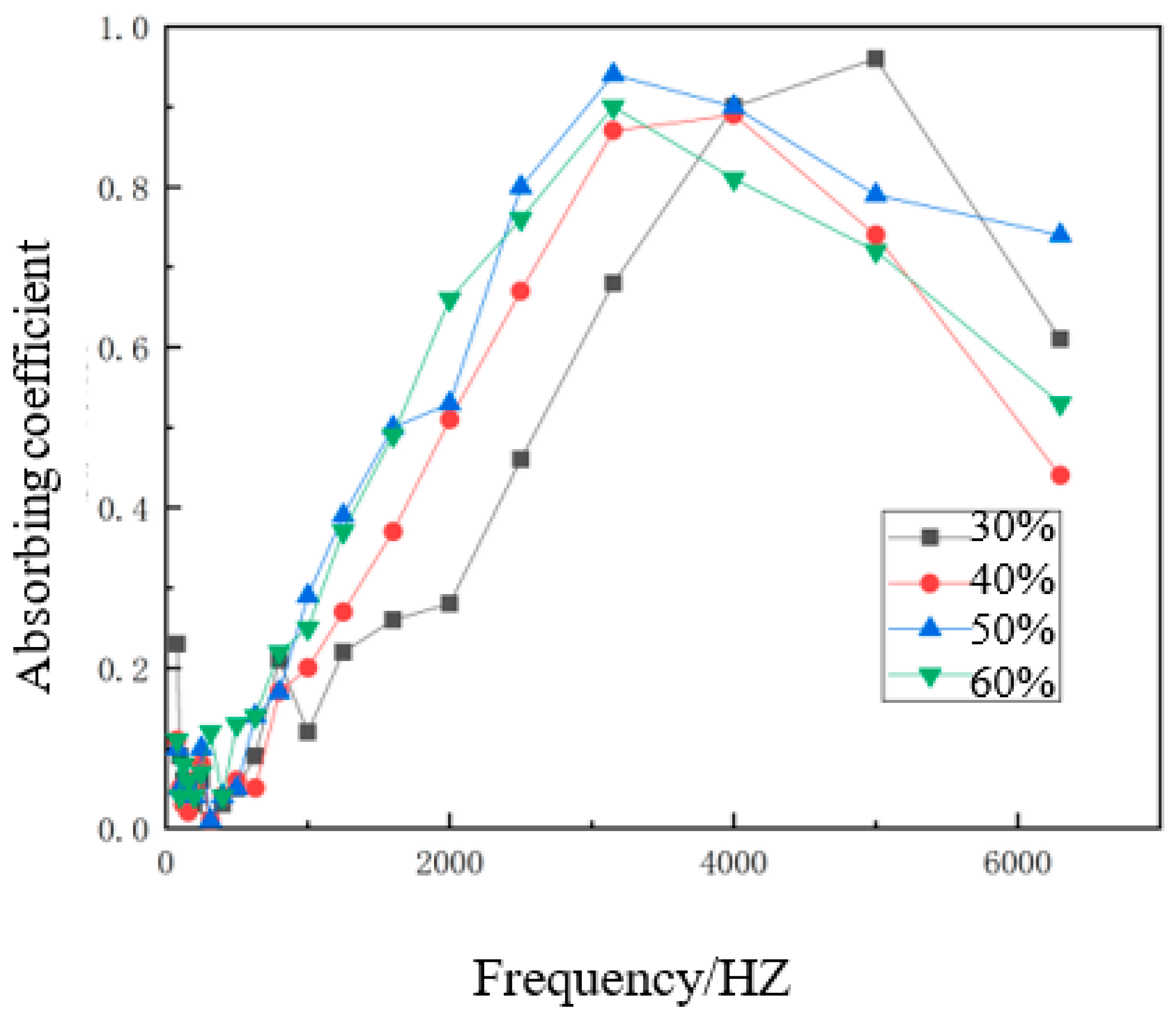

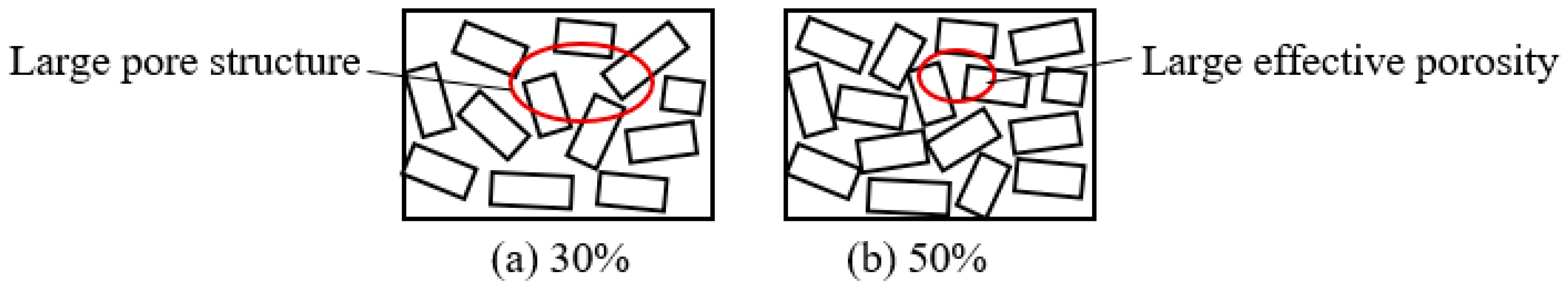

3.2.2. Influence of Hemp Stalk Mass Fraction on Sound Absorption Properties

3.2.3. Effect of the Density of the Composite Materials on Sound Absorption Properties

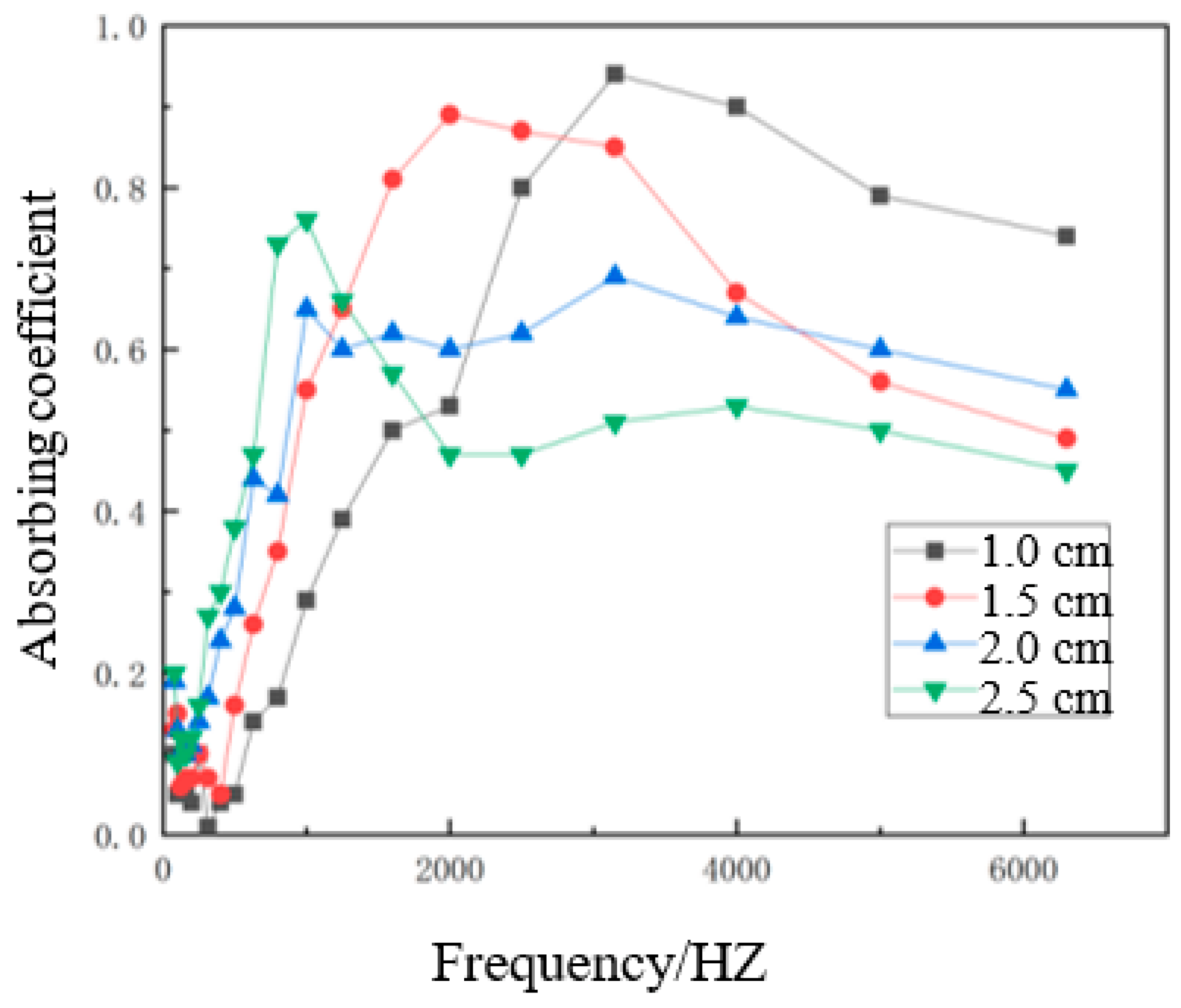

3.2.4. Effect of Material Thickness on Sound Absorption Properties

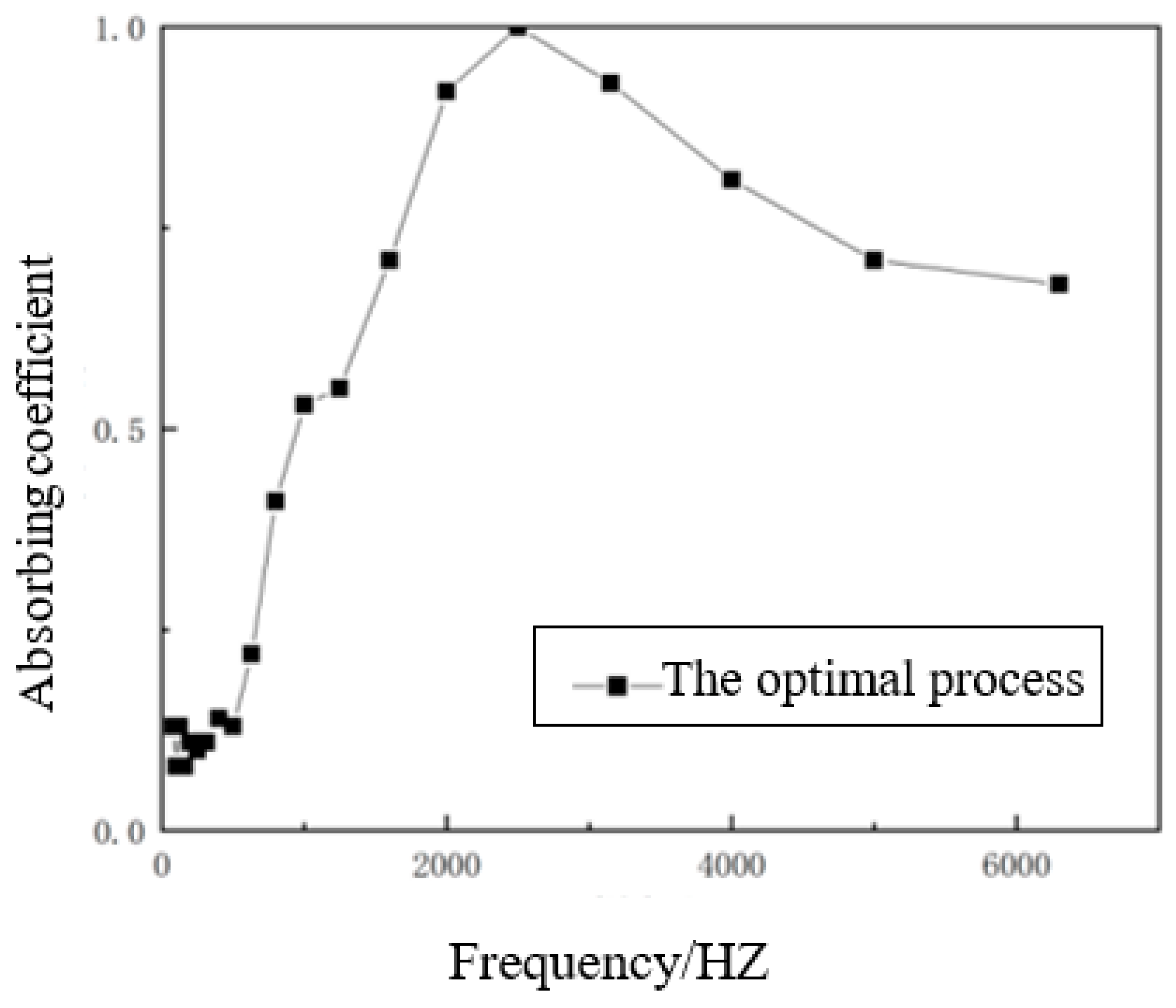

3.2.5. Optimal Process Samples and Comprehensive Analysis

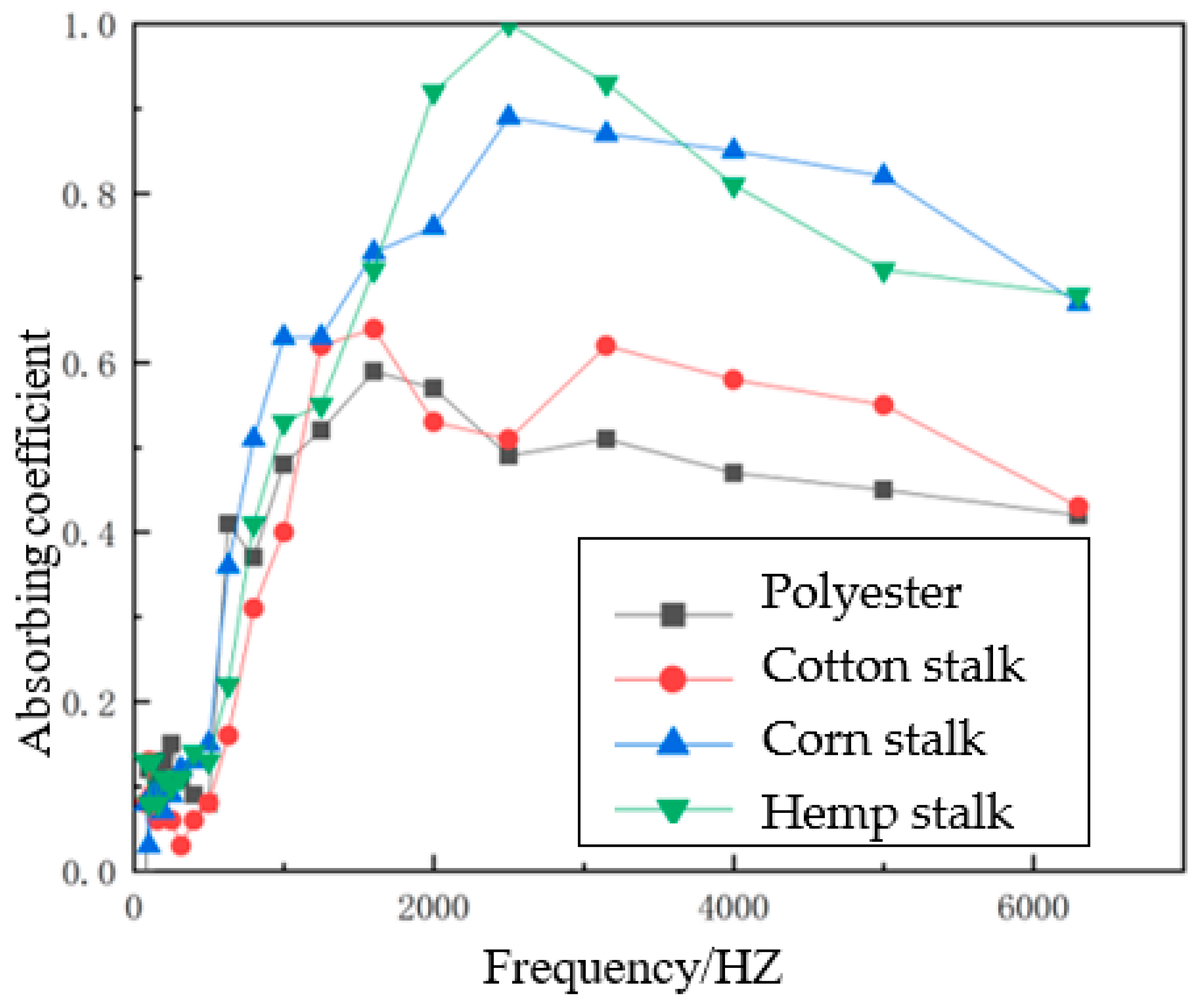

3.2.6. Sound Absorption Coefficient Curves of Different Types of Reinforcers

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Juang, D.F.; Lee, C.H.; Yang, T.; Chang, M.C. Noise pollution and its effects on medical were workers and patients in hospitals. Int. J. Environ. Sci. Technol. 2010, 7, 705–716. [Google Scholar] [CrossRef]

- Du, Y. The current situation of stalk burning and the exploration of stalk utilization and prospect. Mod. Agric. 2020, 7, 90–91. [Google Scholar]

- Xu, Z.Z.; Yang, L.; Ni, Q.Q.; Ruan, H.T.; Wang, H. Fabrication of high-performance green hemp/polylactic acid fibre composites. J. Eng. Fibers Fabr. 2019, 14, 1558925019834497. [Google Scholar] [CrossRef]

- Viel, M.; Collet, F.; Prétot, S.; Lanos, C. Hemp-stalk composite materials: Gluing Study and Multi-Physical Characterizations. Compos. Mater. 2019, 12, 1199. [Google Scholar]

- Lyu, L.H.; Lu, J.; Guo, J.; Qian, Y.; Li, H.; Zhao, X.; Xiong, X. Sound absorbing properties of multi-layer structural composite materials composite materials based on waste corn husk fibers. J. Eng. Fibers Fabr. 2020, 15, 155892502091086. [Google Scholar]

- Samaei, S.E.; Berardi, U.; Taban, E.; Soltani, P.; Mousavi, S.M. Natural fibre-granular composite as a novel sustainable sound-absorbing material. Appl. Acoust. 2021, 181, 108157. [Google Scholar] [CrossRef]

- Wang, H.Z.; Zhao, H.; Lian, Z.Z.; Tan, B.; Zheng, Y.; Erdun, E. Numerical simulation for porous hemp plastic composite materials sound absorbing properties. J. Compos. Mater. Res. Technol. 2022, 19, 2458–2469. [Google Scholar] [CrossRef]

- Agirgan, M.; Agirgan, A.O.; Taskin, V. Investigation of Thermal Conductivity and Sound Absorption Properties of Rice Straw Fiber/Polylactic Acid Biocomposite Material. J. Nat. Fibers 2022, 1–14. [Google Scholar] [CrossRef]

- Desmond, D.C.V.; Musli, N.B.Y.; Nazli, B.C.D. Sound absorbing of Microperforated Panel Made from Coconut Fiber and Polylactic Acid Composite. J. Nat. Fibers 2020, 19, 2719–2729. [Google Scholar]

- Dhandapania, N.; Megalingam, A. Mechanical and Sound absorbing Behavior of Swasal and Palm Fiber Reinforced Hybrid Composites. J. Nat. Fibers 2021, 19, 1530–4543. [Google Scholar]

- Andrea, S.; Paolo, B.; Patrizio, F. Improving the sound absorbing properties of sustainable thermal insulation composite materials: Natural hemp fibers. Appl. Sounds 2019, 150, 279–289. [Google Scholar]

- Olcay, H.; Kocak, E.D. Rice plant waste reinforced polyurethane composite materials for use as the sound absorbing material. Appl. Sounds 2021, 173, 107733. [Google Scholar]

- Platnieks, O.; Gaidukovs, S.; Thakur, V.K.; Barkāne, A.; Beluns, S. Bio-based poly (butylene succinate): Recent progress, challenges and future opportunities. Eur. Polym. J. 2021, 161, 110855. [Google Scholar] [CrossRef]

- Rajesh, D.A.; Sunshine, B. Composites from Bast Fibres—Prospects and Potential in the Changing Market Environment. J. Nat. Fibers 2014, 4, 91–109. [Google Scholar]

- Bogard, F.; Bach, T.; Abbes, B.; Bliard, C.; Maalouf, C.; Bogard, V.; Beaumont, F.; Polidori, G. A comparative review of Nettle and Ramie fiber and their use in biocomposites, particularly with a PLA matrix. J. Nat. Fibers 2021, 1–25. [Google Scholar] [CrossRef]

- GB/T 18696.2-2002; Sounds Measurement of Sound Absorbing Coefficient and Sound Impedance in Impedance Tubes Part 2: Transfer Function Method. China Standard Press: Beijing, China, 2002.

- Li, M. Research on Preparation and Application of Magnetic Iron Oxide Based Nanocomposites; Hangzhou University of Electronic Science and Technology: Hangzhou, China, 2020. [Google Scholar]

- Pei, J.C. Lignocellulosic Chenistry, 4th ed.; China Light Industry Press: Beijing, China, 2012; pp. 166–167. [Google Scholar]

- GB/T 16731-1997; Standard for Grading the Sound Absorbing Properties of Building Sound Pstalkucts. China Standard Press: Beijing, China, 1997.

- Moryganov, A.P.; Zavadskii, A.E.; Stokozenko, V.G. Special Features of X-ray analysis of Cellulose Crystallinity and Content in Flax fibers. Fibre Chem. 2018, 49, 382–387. [Google Scholar] [CrossRef]

- Yu, W.D. Textile Material Science, 1st ed.; China Textile Press: Beijing, China, 2006. [Google Scholar]

- Liu, Y.J.; Lv, L.H.; Xiong, X.Q.; Qian, Y.F. Structural characteristics and sound absorbing properties of poplar seed fibers. Text. Res. J. 2020, 90, 2467–2477. [Google Scholar] [CrossRef]

- Ao, Q.B.; Wang, J.Z.; Li, Y.; Ma, J.; Wu, C. Research progress of low frequency sound absorption materials. J. Funct. Mater. 2020, 51, 12045–12050. [Google Scholar]

- Li, W.; Zhao, F.R. Experimental study on sound absorption properties of several commonly used sound-absorbing materials. Urban Resid. 2019, 26, 117–120. [Google Scholar]

- Qi, M.; Liu, L.; Chen, Q.G.; Lu, C.; Chen, W.Y. Research on acoustic performance of composite micro-perforated plate structure based on porous materials. Nat. Sci. Ed. 2022, 41, 83–90. [Google Scholar]

- Ju, Z.H. Study on Sound Insulation of Wood Composite Partition Board. Master’s Thesis, Nanjing Forestry University, Nanjing, China, 2018. [Google Scholar]

| Factors | ||||

|---|---|---|---|---|

| Hemp Stalk Length | Hemp Stalk Mass Fraction | Density of Materials | Thickness of Materials | |

| Level | 1 mm | 30% | 0.25 g/cm3 | 1.0 cm |

| 6 mm | 40% | 0.30 g/cm3 | 1.5 cm | |

| 11 mm | 50% | 0.35 g/cm3 | 2.0 cm | |

| 60% | 0.40 g/cm3 | 2.5 cm | ||

| Wave Number/cm−1 | Absorbing Band Attribution and Description |

|---|---|

| 3424 | O-H stretching vibration |

| 2929 | C-H stretching vibrations (polysaccharides, lignin, fatty acids, saturated hydroxyl groups) |

| 1744 | C=O stretching vibrations (carboxylic acids, esters, anhydrides, aldehydes, ketones, amides, acyl halides, etc.) |

| 1602 | Carbon skeleton vibrations of benzene rings (lignin) |

| 1458 | C-H bending vibrations (lignin, CH in polysaccharides) and benzene ring skeleton vibrations (lignin) |

| 1376 | C-H In-plane bending vibration (cellulose and hemicellulose) |

| 1242 | Guaiacyl propane structure and acyl-oxygen bond CO-O stretching vibrations |

| 1091 | C-O stretch, secondary alcohols, and aliphatic ethers |

| 1057 | Alkoxy bond stretching vibrations and C-O stretching vibrations in acetyl groups (cellulose and hemicellulose) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, S.; Gao, Y.; Zhou, X.; Xiong, X.; Wang, Y.; Lyu, L. Structure of Waste Hemp Stalks and Their Sound Absorbing Properties. Polymers 2022, 14, 4844. https://doi.org/10.3390/polym14224844

Su S, Gao Y, Zhou X, Xiong X, Wang Y, Lyu L. Structure of Waste Hemp Stalks and Their Sound Absorbing Properties. Polymers. 2022; 14(22):4844. https://doi.org/10.3390/polym14224844

Chicago/Turabian StyleSu, Shuang, Yuan Gao, Xinghai Zhou, Xiaoqing Xiong, Ying Wang, and Lihua Lyu. 2022. "Structure of Waste Hemp Stalks and Their Sound Absorbing Properties" Polymers 14, no. 22: 4844. https://doi.org/10.3390/polym14224844

APA StyleSu, S., Gao, Y., Zhou, X., Xiong, X., Wang, Y., & Lyu, L. (2022). Structure of Waste Hemp Stalks and Their Sound Absorbing Properties. Polymers, 14(22), 4844. https://doi.org/10.3390/polym14224844