On Crashworthiness and Energy-Absorbing Mechanisms of Thick CFRP Structures for Railway Vehicles

Abstract

1. Introduction

2. Experimental Testing and Results

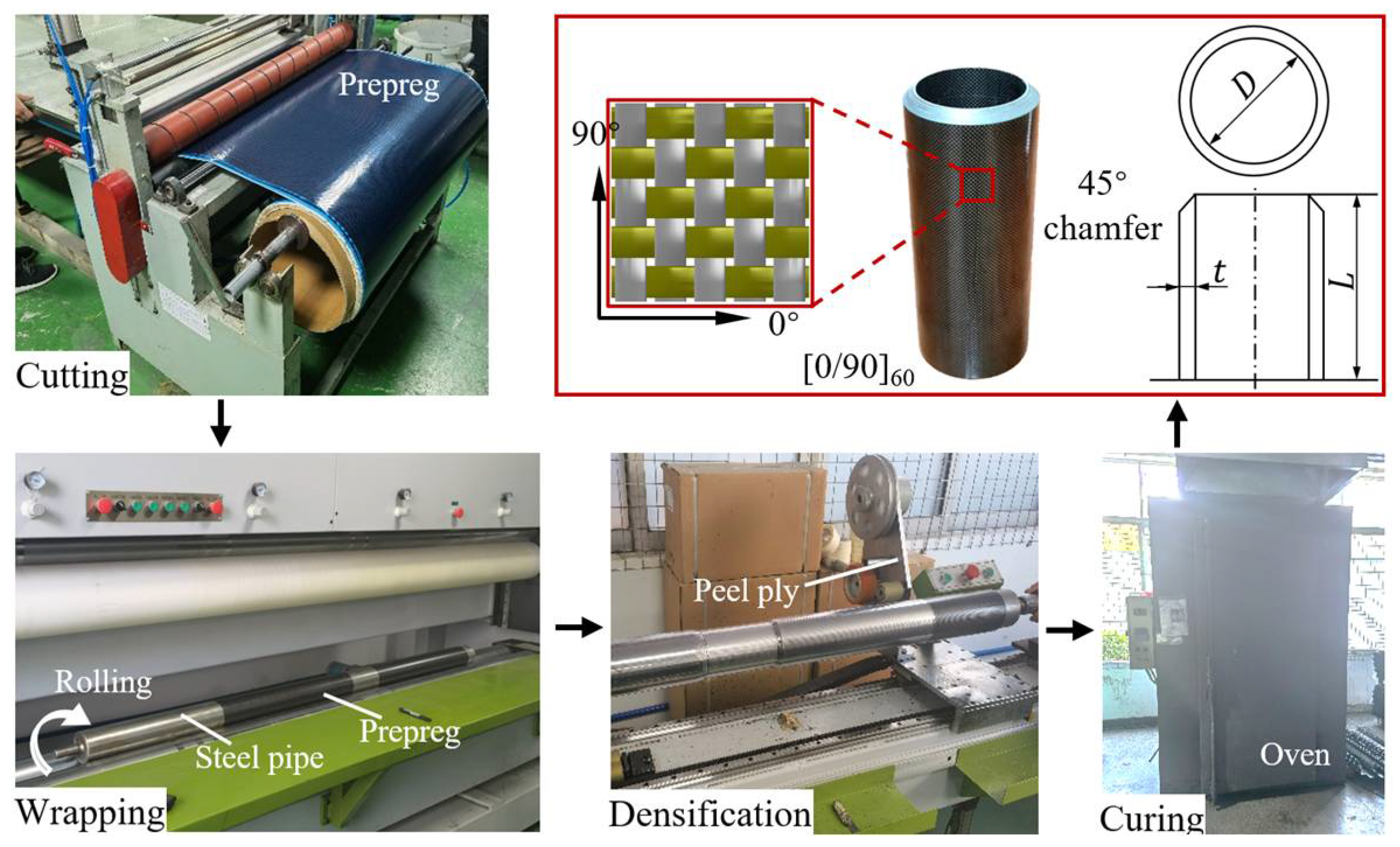

2.1. Specimen Preparation

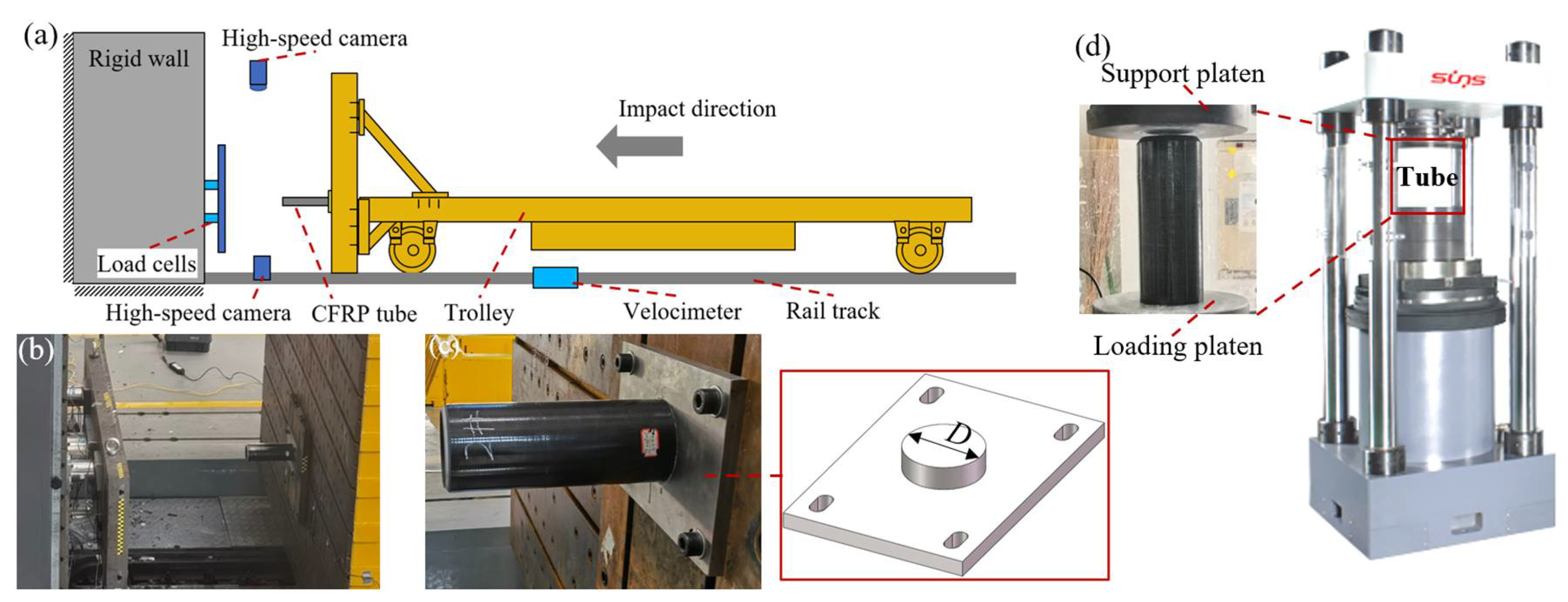

2.2. Test setup

2.3. Crashworthiness Indicators

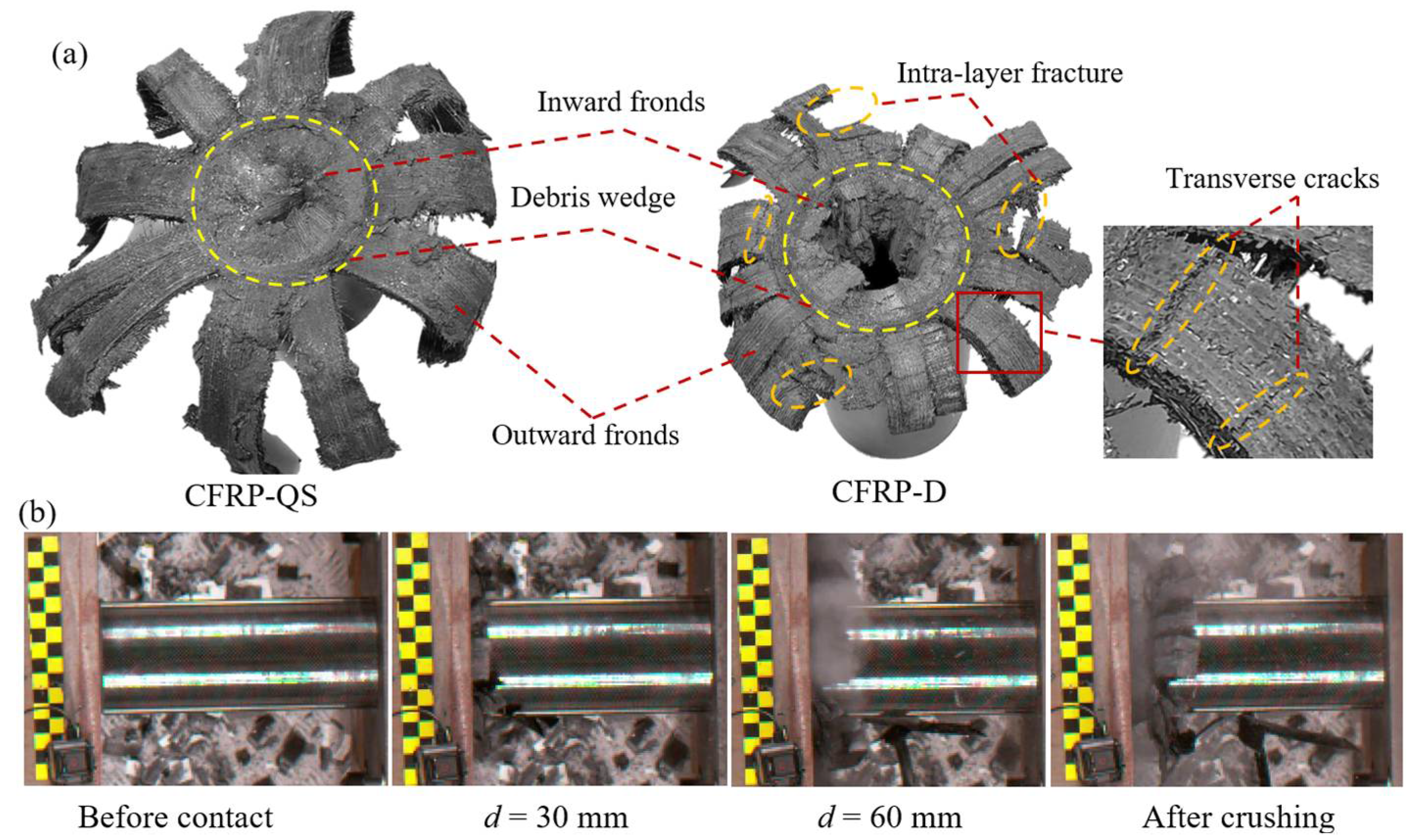

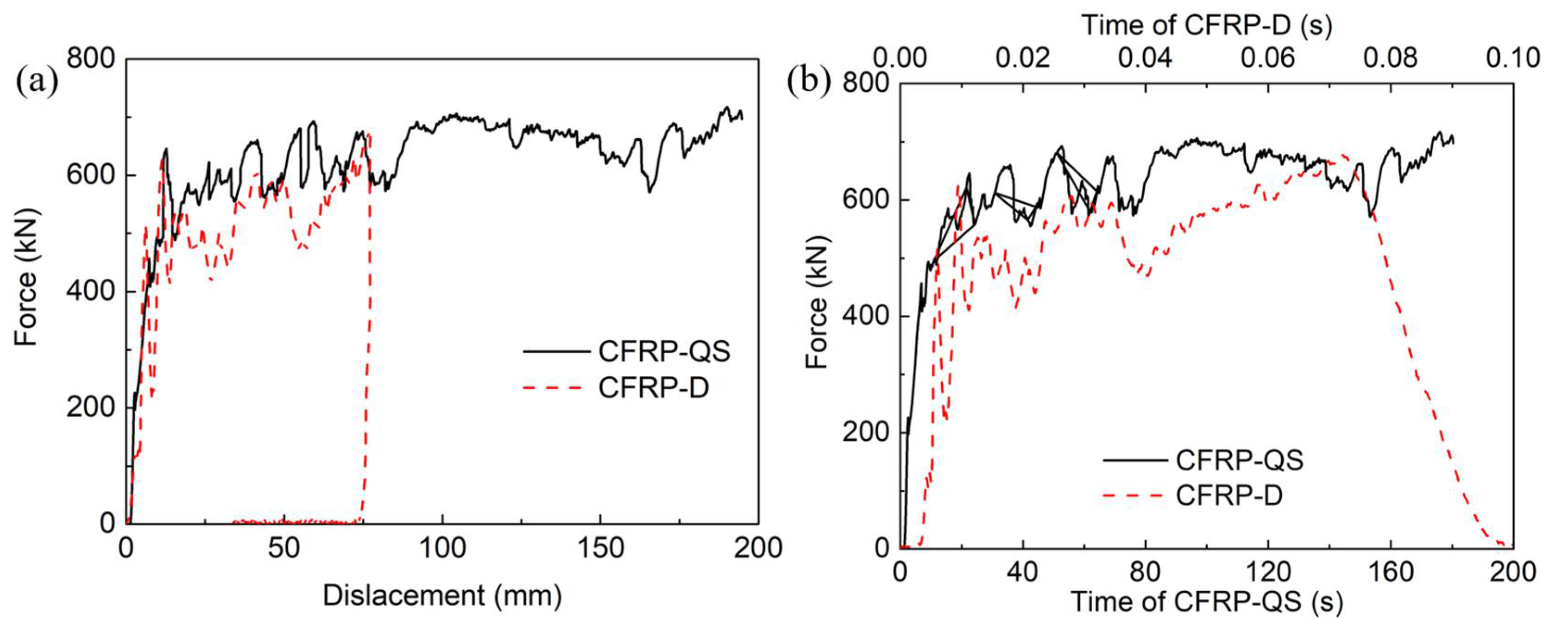

2.4. Experimental Results and Discussion

3. Numerical Simulations

3.1. Model Setup

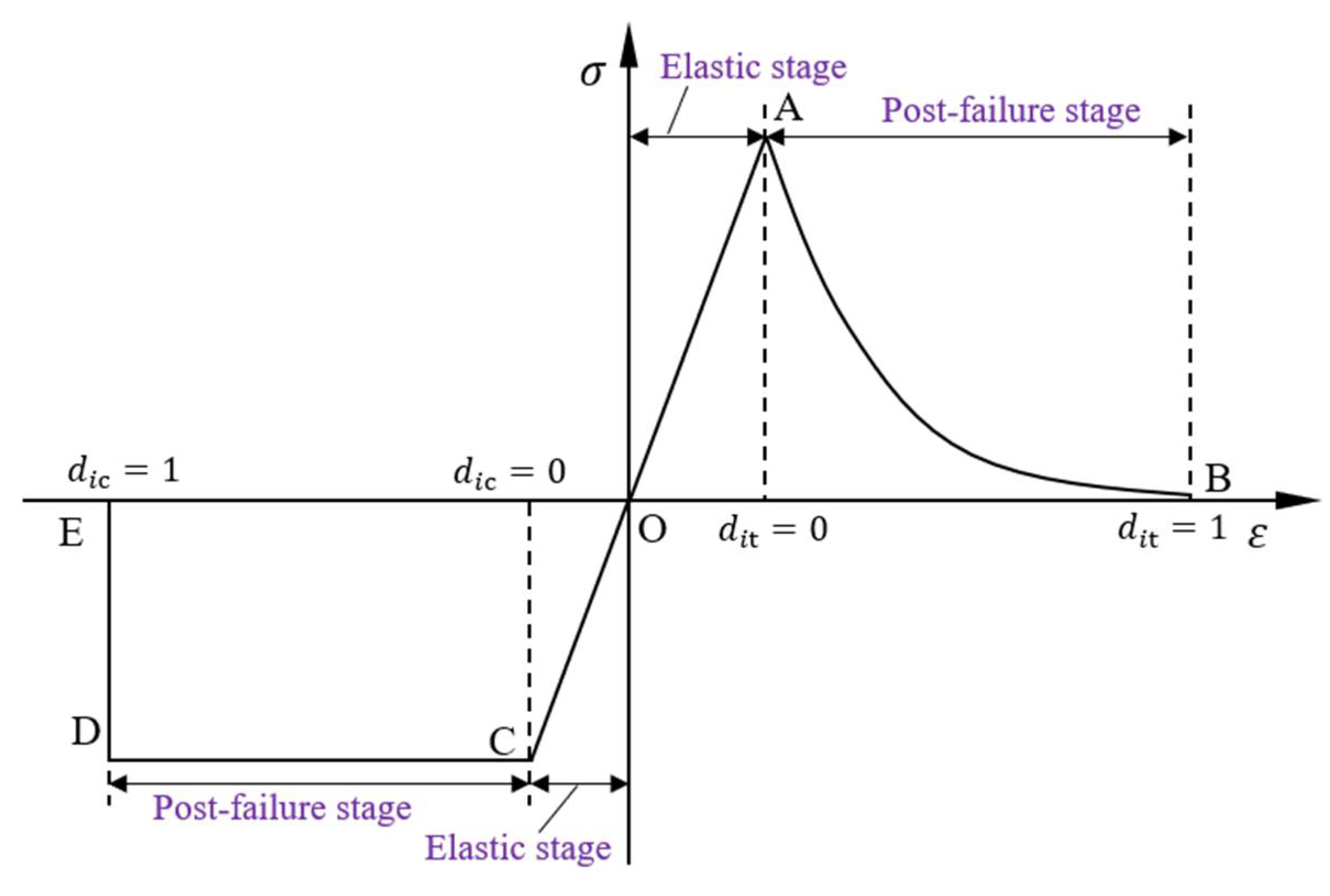

3.2. Constitutive Models

3.3. Simulated Results and Validation

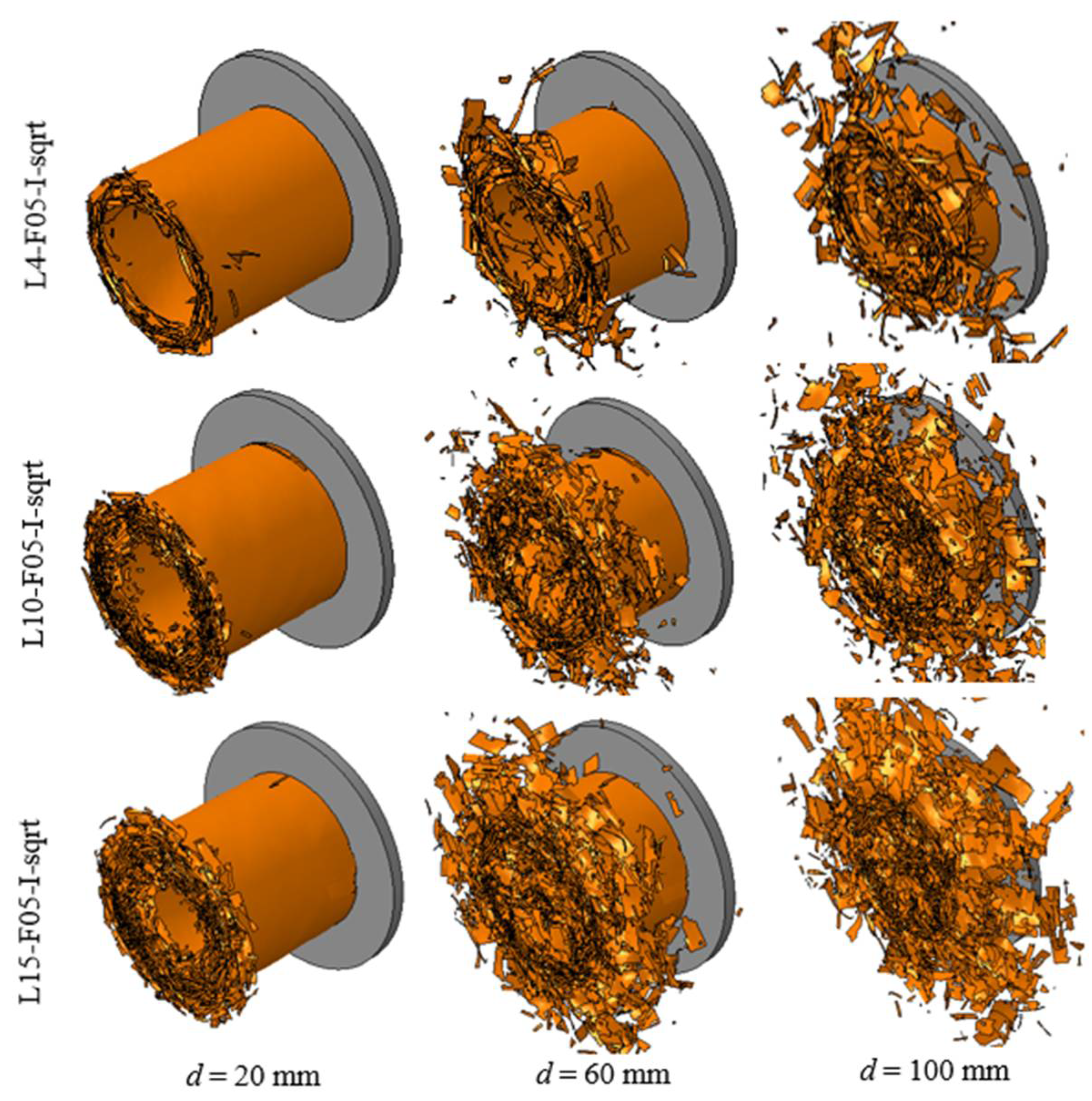

3.3.1. Influences of the Number of Shell Layers

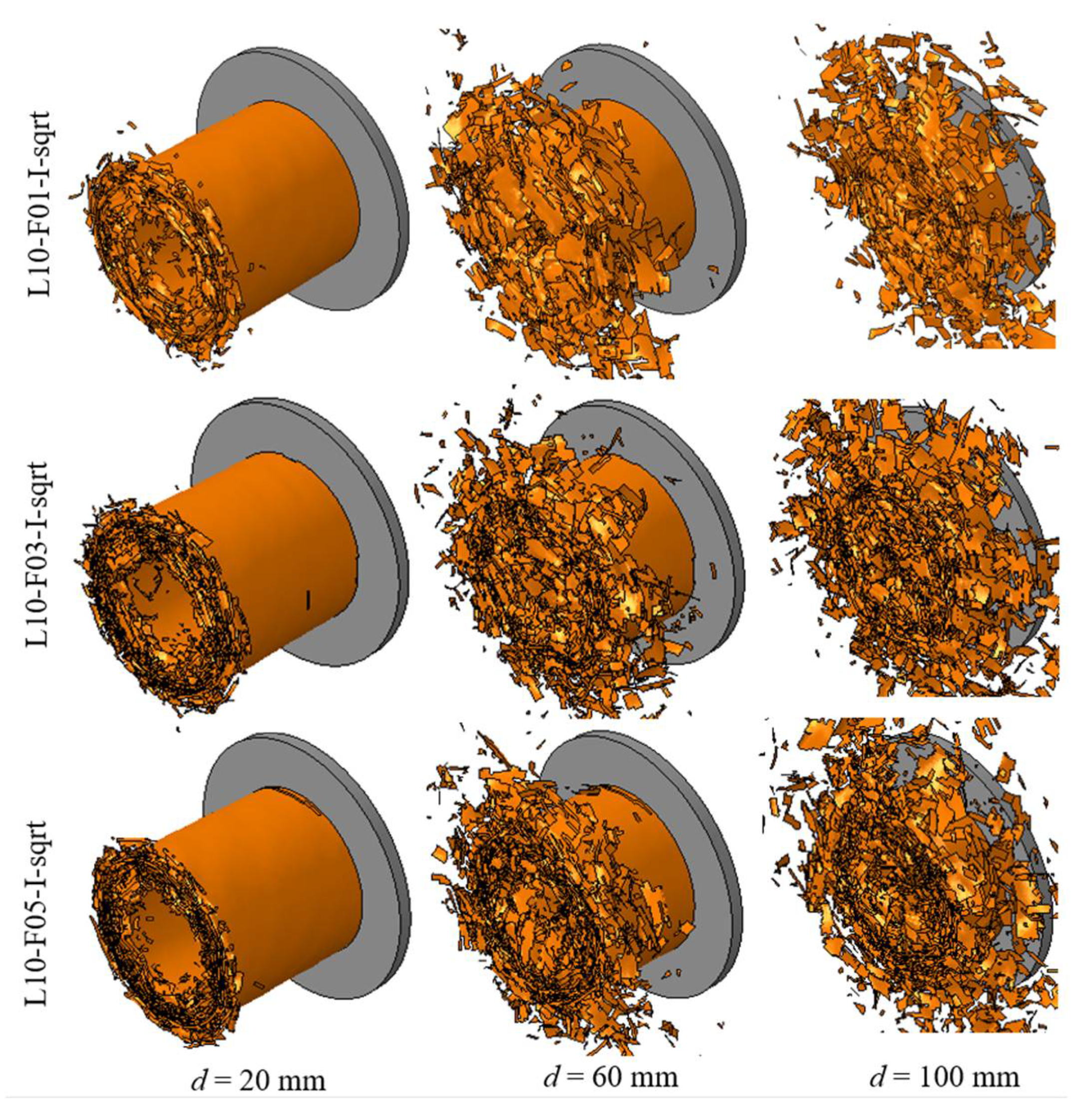

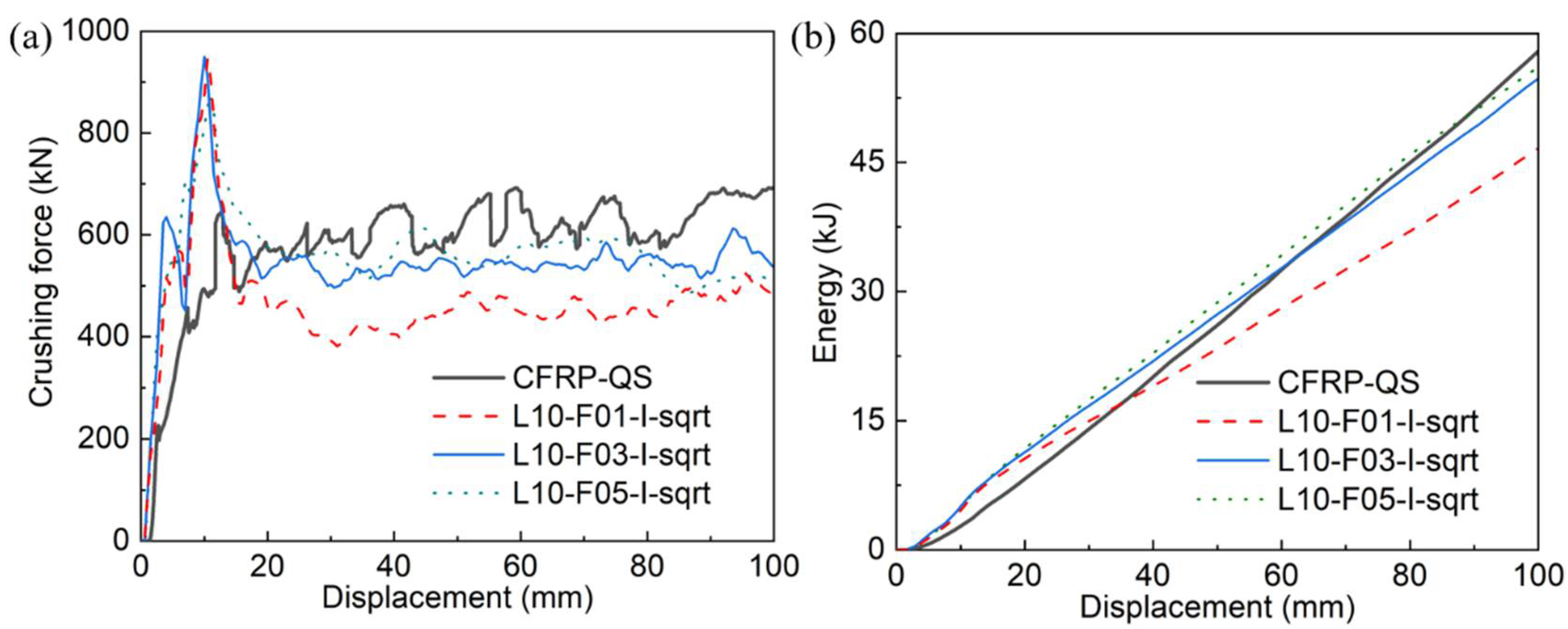

3.3.2. Influences of Friction Coefficient

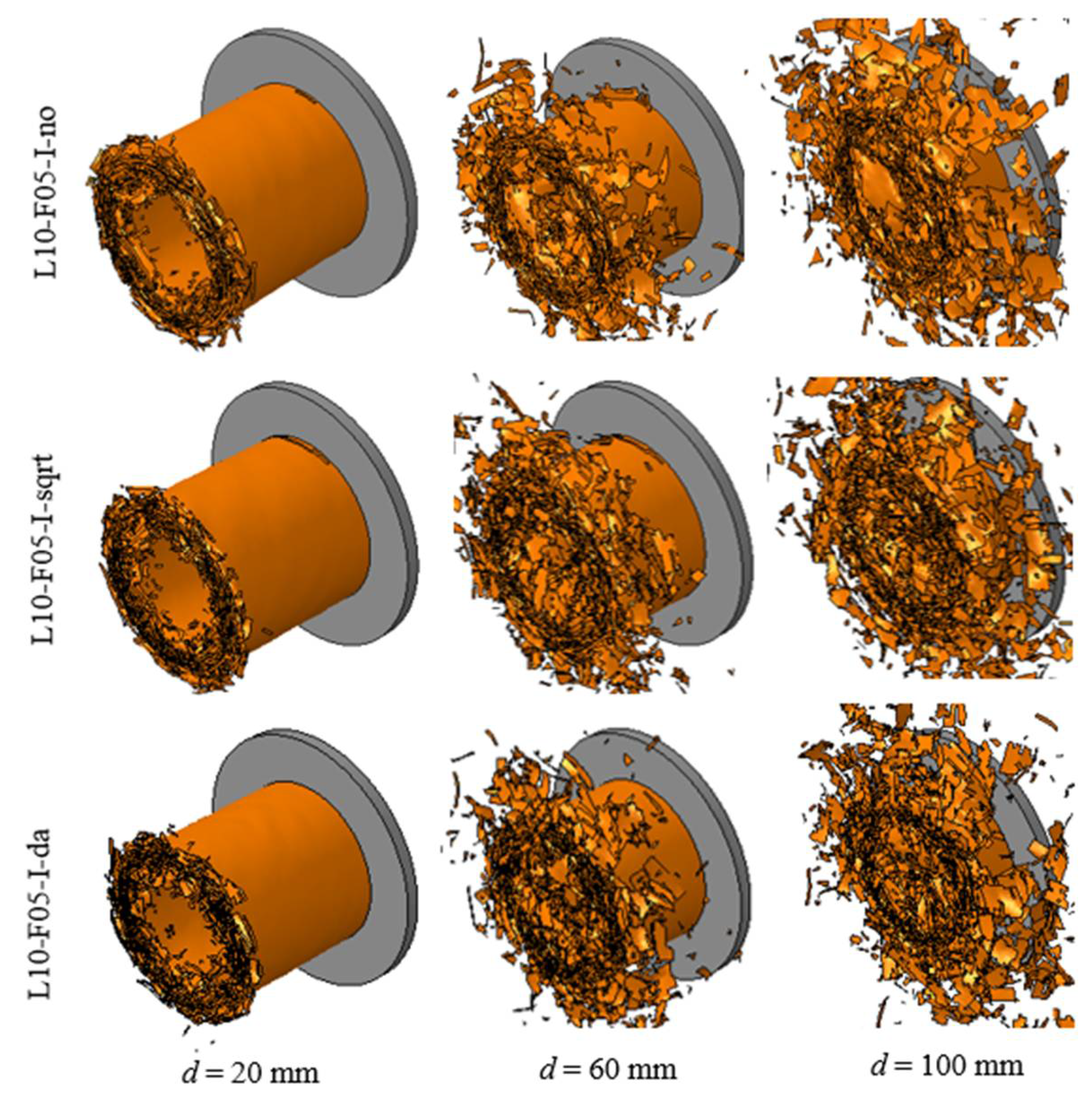

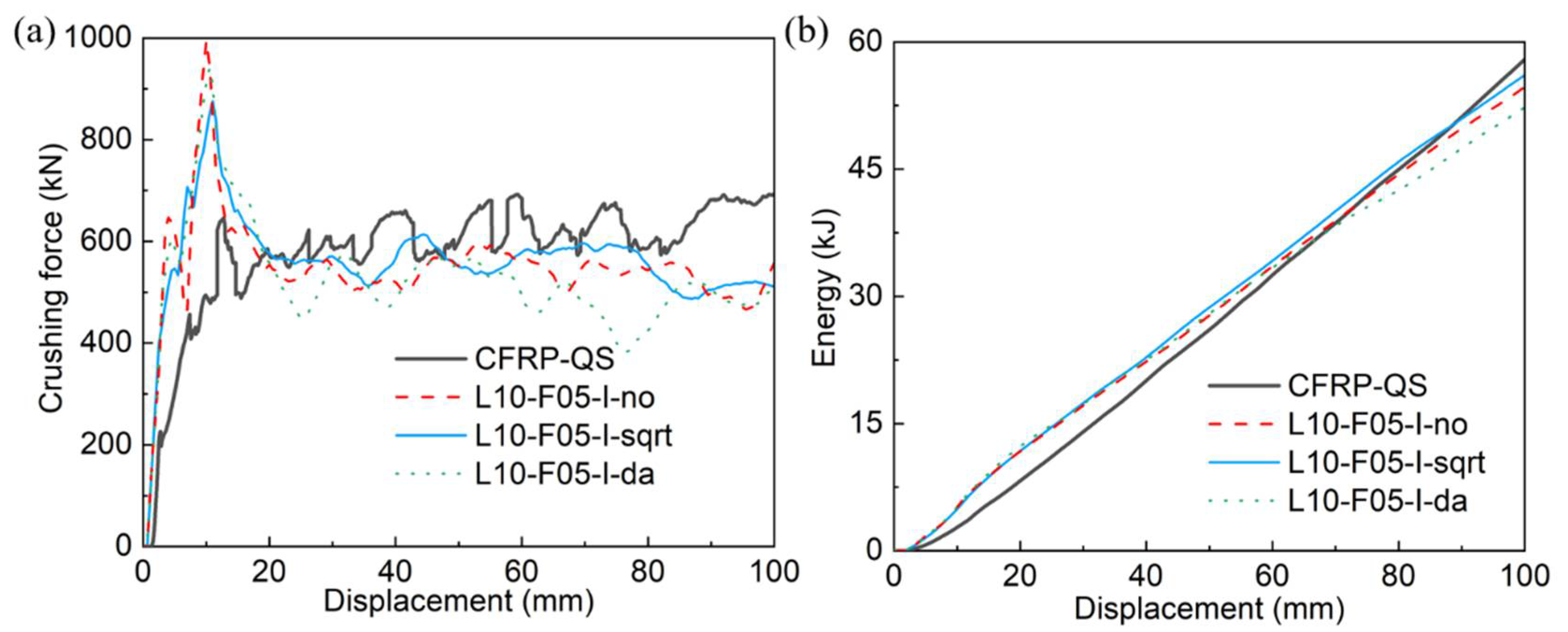

3.3.3. Influences of Interface Properties

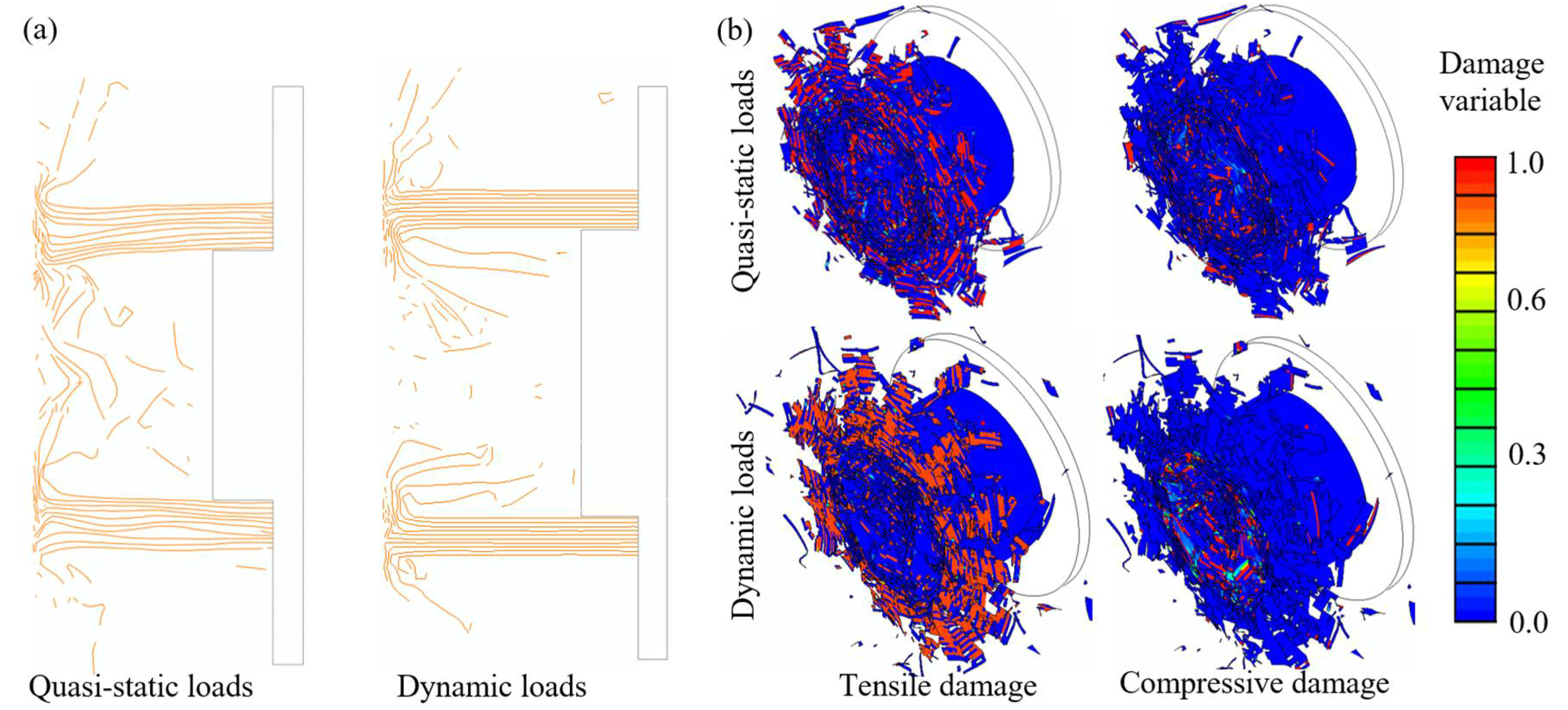

3.3.4. Dynamic Simulation Results

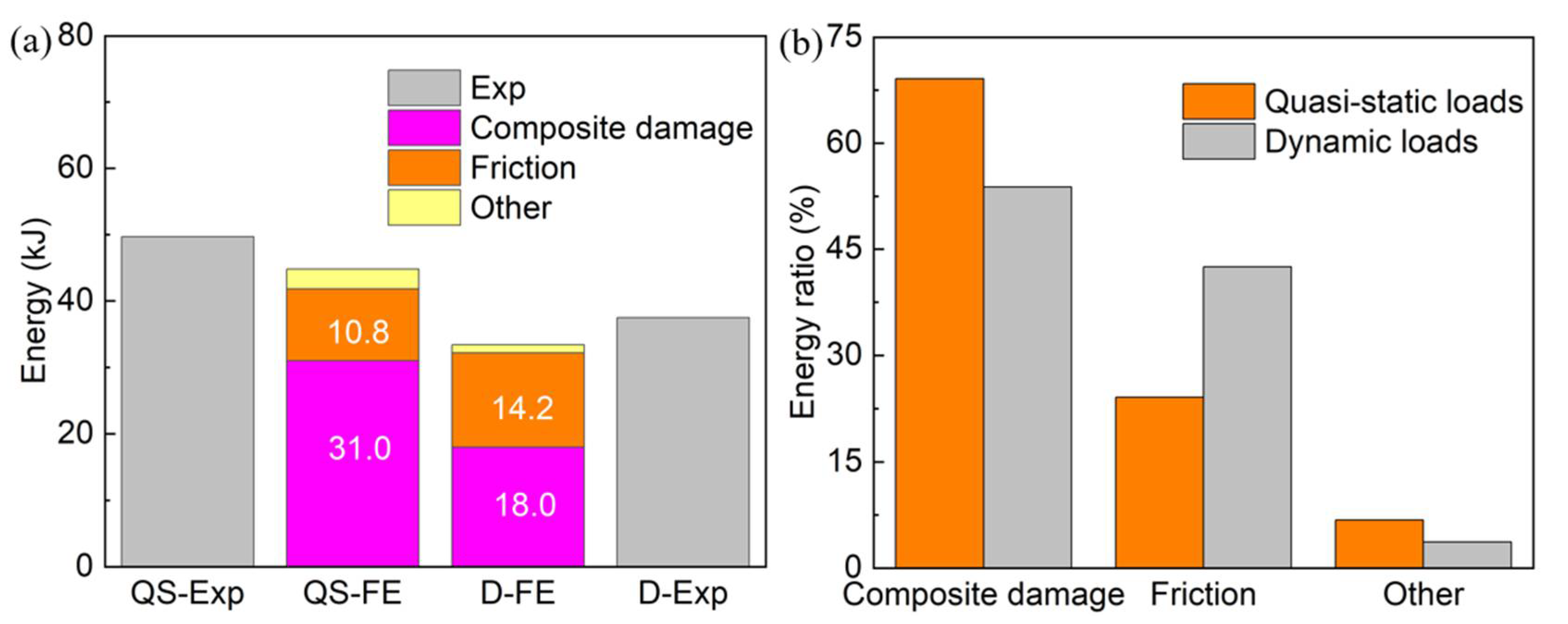

3.4. Energy-Absorbing Mechanisms’ Analysis

4. Conclusions

- (1)

- Under quasi-static and dynamic axial impact loads, the circular CFRP tubes exhibited a stable crushing response. However, the values of MCF and SEA under dynamic crushing loads were 485.7 kN and 78.7 kJ/kg, respectively, showing the same 21.8% reduction compared to the quasi-static cases.

- (2)

- A parametric study on modeling strategies showed that the predicted EA was sensitive to a series of modeling parameters, including the number of shell layers, friction coefficient, and interface properties. A small variation in these parameters can have a negligible influence on the failure mode but a significant change in the total EA.

- (3)

- The validated FE models showed good agreement in predicting the crushing response of circular CFRP tubes. The errors in crashworthiness indicators, such as MCF and SEA, were less than 10%.

- (4)

- Composite damage and friction interaction accounted for a major portion of the energy-absorbing behavior: their percentages in the EA were 69.1% and 24.1%, respectively, under quasi-static crushing loads. Dynamic crushing loads resulted in a 41.9% reduction in composite damage energy but a 31.4% increase in friction energy, resulting in a reduction in SEA compared to the quasi-static cases.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Constitutive Laws for Intra-Layer Material

References

- Sun, G.; Chen, D.; Zhu, G.; Li, Q. Lightweight hybrid materials and structures for energy absorption: A state-of-the-art review and outlook. Thin-Walled Struct. 2022, 172, 108760. [Google Scholar] [CrossRef]

- Wang, Z.; Luo, Q.; Li, Q.; Sun, G. Design optimization of bioinspired helicoidal CFRPP/GFRPP hybrid composites for multiple low-velocity impact loads. Int. J. Mech. Sci. 2022, 219, 107064. [Google Scholar] [CrossRef]

- Isaac, C.W.; Ezekwem, C. A review of the crashworthiness performance of energy absorbing composite structure within the context of materials, manufacturing and maintenance for sustainability. Compos. Struct. 2021, 257, 113081. [Google Scholar] [CrossRef]

- Supian, A.B.M.; Sapuan, S.M.; Zuhri, M.Y.M.; Zainudin, E.S.; Ya, H.H. Hybrid reinforced thermoset polymer composite in energy absorption tube application: A review. Def. Technol. 2018, 14, 291–305. [Google Scholar] [CrossRef]

- Baroutaji, A.; Sajjia, M.; Olabi, A.-G. On the crashworthiness performance of thin-walled energy absorbers: Recent advances and future developments. Thin-Walled Struct. 2017, 118, 137–163. [Google Scholar] [CrossRef]

- Xian, G.; Guo, R.; Li, C.; Wang, Y. Mechanical performance evolution and life prediction of prestressed cfrp plate exposed to hygrothermal and freeze-thaw environments. Compos. Struct. 2022, 293, 115719. [Google Scholar] [CrossRef]

- Mamalis, A.G.; Manolakos, D.E.; Ioannidis, M.B.; Papapostolou, D.P. On the response of thin-walled CFRP composite tubular components subjected to static and dynamic axial compressive loading: Experimental. Compos. Struct. 2005, 69, 407–420. [Google Scholar] [CrossRef]

- Mamalis, A.G.; Manolakos, D.E.; Ioannidis, M.B.; Papapostolou, D.P. Crashworthy characteristics of axially statically compressed thin-walled square CFRP composite tubes: Experimental. Compos. Struct. 2004, 63, 347–360. [Google Scholar] [CrossRef]

- Hussein, R.D.; Ruan, D.; Lu, G. An analytical model of square CFRP tubes subjected to axial compression. Compos. Sci. Technol. 2018, 168, 170–178. [Google Scholar] [CrossRef]

- Zhu, G.; Yu, Q.; Zhao, X.; Wei, L.; Chen, H. Energy-absorbing mechanisms and crashworthiness design of CFRP multi-cell structures. Compos. Struct. 2020, 233, 111631. [Google Scholar] [CrossRef]

- Ryzińska, G.; David, M.; Prusty, G.; Tarasiuk, J.; Wroński, S. Effect of fibre architecture on the specific energy absorption in carbon epoxy composite tubes under progressive crushing. Compos. Struct. 2019, 227, 111292. [Google Scholar] [CrossRef]

- Rabiee, A.; Ghasemnejad, H. Lightweight design to improve crushing behaviour of multi-stitched composite tubular structures under impact loading. Thin-Walled Struct. 2019, 135, 109–122. [Google Scholar] [CrossRef]

- Li, C.; Xian, G.; Li, H. Effect of postcuring immersed in water under hydraulic pressure on fatigue performance of large-diameter pultruded carbon/glass hybrid rod. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 1148–1160. [Google Scholar] [CrossRef]

- Hadavinia, H.; Ghasemnejad, H. Effects of Mode-I and Mode-II interlaminar fracture toughness on the energy absorption of CFRP twill/weave composite box sections. Compos. Struct. 2009, 89, 303–314. [Google Scholar] [CrossRef]

- Xin, Z.; Duan, Y.; Zhou, J.; Xiao, H. Effect of tailored plies on the energy absorption capability of square CFRP tubes with discontinuous fibers. Compos. Struct. 2019, 209, 150–159. [Google Scholar] [CrossRef]

- Dalli, D.; Varandas, L.F.; Catalanotti, G.; Foster, S.; Falzon, B.G. Assessing the current modelling approach for predicting the crashworthiness of Formula One composite structures. Compos. Part B-Eng. 2020, 201, 108242. [Google Scholar] [CrossRef]

- Liu, X.; Belkassem, B.; Jonet, A.; Lecompte, D.; Van Hemelrijck, D.; Pintelon, R.; Pyl, L. Experimental investigation of energy absorption behaviour of circular carbon/epoxy composite tubes under quasi-static and dynamic crush loading. Compos. Struct. 2019, 227, 111266. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, J.; Wu, J.; Hu, D. Effects of fiber orientation and wall thickness on energy absorption characteristics of carbon-reinforced composite tubes under different loading conditions. Compos. Struct. 2016, 153, 356–368. [Google Scholar] [CrossRef]

- Yang, H.; Lei, H.; Lu, G.; Zhang, Z.; Li, X.; Liu, Y. Energy absorption and failure pattern of hybrid composite tubes under quasi-static axial compression. Compos. Part B-Eng. 2020, 198, 108217. [Google Scholar] [CrossRef]

- Hamada, H.; Ramakrishna, S. Scaling effects in the energy absorption of carbon-fiber/PEEK composite tubes. Compos. Sci. Technol. 1995, 55, 211–221. [Google Scholar] [CrossRef]

- Xiao, Z.; Mo, F.; Zeng, D.; Yang, C. Experimental and numerical study of hat shaped CFRP structures under quasi-static axial crushing. Compos. Struct. 2020, 249, 112465. [Google Scholar] [CrossRef]

- Liu, Q.; Fu, J.; Ma, Y.; Zhang, Y.; Li, Q. Crushing responses and energy absorption behaviors of multi-cell CFRP tubes. Thin-Walled Struct. 2020, 155, 106930. [Google Scholar] [CrossRef]

- Palanivelu, S.; Van Paepegem, W.; Degrieck, J.; Vantomme, J.; Kakogiannis, D.; Van Ackeren, J.; Van Hemelrijck, D.; Wastiels, J. Crushing and energy absorption performance of different geometrical shapes of small-scale glass/polyester composite tubes under quasi-static loading conditions. Compos. Struct. 2011, 93, 992–1007. [Google Scholar] [CrossRef]

- Song, H.-W.; Du, X.-W.; Zhao, G.-F. Energy absorption behavior of double-chamfer triggered glass/epoxy circular tubes. J. Compos. Mater. 2002, 36, 2183–2198. [Google Scholar] [CrossRef]

- Alkbir, M.F.M.; Sapuan, S.M.; Nuraini, A.A.; Ishak, M.R. Fibre properties and crashworthiness parameters of natural fibre-reinforced composite structure: A literature review. Compos. Struct. 2016, 148, 59–73. [Google Scholar] [CrossRef]

- Yang, H.; Lei, H.; Lu, G. Crashworthiness of circular fiber reinforced plastic tubes filled with composite skeletons/aluminum foam under drop-weight impact loading. Thin-Walled Struct. 2021, 160, 107380. [Google Scholar] [CrossRef]

- Palanivelu, S.; Van Paepegem, W.; Degrieck, J.; Van Ackeren, J.; Kakogiannis, D.; Van Hemelrijck, D.; Wastiels, J.; Vantomme, J. Experimental study on the axial crushing behaviour of pultruded composite tubes. Polym. Test. 2010, 29, 224–234. [Google Scholar] [CrossRef]

- Chambe, J.E.; Bouvet, C.; Dorival, O.; Rivallant, S.; Ferrero, J.F. Effects of dynamics and trigger on energy absorption of composite tubes during axial crushing. Int. J. Crashworthiness 2020, 26, 549–567. [Google Scholar] [CrossRef]

- Zhu, G.; Liao, J.; Sun, G.; Li, Q. Comparative study on metal/CFRP hybrid structures under static and dynamic loading. Int. J. Impact Eng. 2020, 141, 103509. [Google Scholar] [CrossRef]

- Ataabadi, P.B.; Karagiozova, D.; Alves, M. Crushing and energy absorption mechanisms of carbon fiber-epoxy tubes under axial impact. Int. J. Impact Eng. 2019, 131, 174–189. [Google Scholar] [CrossRef]

- Zhu, G.; Sun, G.; Li, G.; Cheng, A.; Li, Q. Modeling for CFRP structures subjected to quasi-static crushing. Compos. Struct. 2018, 184, 41–55. [Google Scholar] [CrossRef]

- Sokolinsky, V.S.; Indermuehle, K.C.; Hurtado, J.A. Numerical simulation of the crushing process of a corrugated composite plate. Compos. Part A-Appl. Sci. Manuf. 2011, 42, 1119–1126. [Google Scholar] [CrossRef]

- Jiang, H.; Ren, Y.; Gao, B.; Xiang, J. Numerical investigation on links between the stacking sequence and energy absorption characteristics of fabric and unidirectional composite sinusoidal plate. Compos. Struct. 2017, 171, 382–402. [Google Scholar] [CrossRef]

- Ataabadi, P.B.; Karagiozova, D.; Alves, M. Finite element modeling of crushing of CFRP cylindrical tubes under low-velocity axial impact. Compos. Struct. 2022, 280, 114902. [Google Scholar] [CrossRef]

- Mamalis, A.G.; Manolakos, D.E.; Ioannidis, M.B.; Papapostolou, D.P. The static and dynamic axial collapse of CFRP square tubes: Finite element modelling. Compos. Struct. 2006, 74, 213–225. [Google Scholar] [CrossRef]

- McGregor, C.; Vaziri, R.; Xiao, X. Finite element modelling of the progressive crushing of braided composite tubes under axial impact. Int. J. Impact Eng. 2010, 37, 662–672. [Google Scholar] [CrossRef]

- Zhang, Z.; Hou, S.; Liu, Q.; Han, X. Winding orientation optimization design of composite tubes based on quasi-static and dynamic experiments. Thin-Walled Struct. 2018, 127, 425–433. [Google Scholar] [CrossRef]

- Shi, D.; Xiao, X. An enhanced continuum damage mechanics model for crash simulation of composites. Compos. Struct. 2018, 185, 774–785. [Google Scholar] [CrossRef]

- Sommer, D.E.; Thomson, D.; Falcó, O.; Quino, G.; Cui, H.; Petrinic, N. Damage modelling of carbon fibre composite crush tubes: Numerical simulation and experimental validation of drop weight impact. Compos. Part A-Appl. Sci. Manuf. 2022, 160, 107033. [Google Scholar] [CrossRef]

- Rondina, F.; Donati, L. Comparison and validation of computational methods for the prediction of the compressive crush energy absorption of CFRP structures. Compos. Struct. 2020, 254, 112848. [Google Scholar] [CrossRef]

- Joosten, M.W.; Dutton, S.; Kelly, D.; Thomson, R. Experimental and numerical investigation of the crushing response of an open section composite energy absorbing element. Compos. Struct. 2011, 93, 682–689. [Google Scholar] [CrossRef]

- Johnson, A.F.; David, M. Failure mechanisms and energy absorption in composite elements under axial crush. Key. Eng. Mater. 2012, 488–489, 638–641. [Google Scholar] [CrossRef]

- Reiner, J.; Feser, T.; Waimer, M.; Poursartip, A.; Voggenreiter, H.; Vaziri, R. Axial crush simulation of composites using continuum damage mechanics: FE software and material model independent considerations. Compos. Part B-Eng. 2021, 225, 109284. [Google Scholar] [CrossRef]

- Grotto, F.; Rivallant, S.; Bouvet, C. Development of a 3D finite element model at mesoscale for the crushing of unidirectional composites: Application to plates crushing. Compos. Struct. 2022, 287, 115346. [Google Scholar] [CrossRef]

- Cherniaev, A.; Butcher, C.; Montesano, J. Predicting the axial crush response of CFRP tubes using three damage-based constitutive models. Thin-Walled Struct. 2018, 129, 349–364. [Google Scholar] [CrossRef]

- Bussadori, B.P.; Schuffenhauer, K.; Scattina, A. Modelling of CFRP crushing structures in explicit crash analysis. Compos. Part B-Eng. 2014, 60, 725–735. [Google Scholar] [CrossRef]

- Song, Z.; Ming, S.; Du, K.; Feng, S.; Zhou, C.; Hao, P.; Xu, S.; Wang, B. A novel equivalent method for crashworthiness analysis of composite tubes. Compos. Part A-Appl. Sci. Manuf. 2022, 153, 106761. [Google Scholar] [CrossRef]

- Zhu, T.; Xiao, S.; Lei, C.; Wang, X.; Zhang, J.; Yang, B.; Yang, G.; Li, Y. Rail vehicle crashworthiness based on collision energy management: An overview. Int. J. Rail Transp. 2020, 9, 101–131. [Google Scholar] [CrossRef]

- Gao, G.; Zhuo, T.; Guan, W. Recent research development of energy-absorption structure and application for railway vehicles. J. Cent. South Univ. 2020, 27, 1012–1038. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, X.; Zhu, T.; Yang, B.; Xiao, S.; Yang, G.; Liu, Y.; Li, B.; Castejón, C. Research on Calculation Method for Maximum Mean Acceleration in Longitudinal Train Collision. Shock Vib. 2021, 2021, 1–16. [Google Scholar] [CrossRef]

- Guan, W.; Gao, G.; Yu, Y. Crushing analysis and multiobjective crashworthiness optimization of combined shrinking circular tubes under impact loading. Struct. Multidiscip. Optim. 2021, 64, 1649–1667. [Google Scholar] [CrossRef]

- Yao, S.; Li, Z.; Yan, J.; Xu, P.; Peng, Y. Analysis and parameters optimization of an expanding energy-absorbing structure for a rail vehicle coupler. Thin-Walled Struct. 2018, 125, 129–139. [Google Scholar] [CrossRef]

- Djabali, A.; Toubal, L.; Zitoune, R.; Rechak, S. Fatigue damage evolution in thick composite laminates: Combination of X-ray tomography, acoustic emission and digital image correlation. Compos. Sci. Technol. 2019, 183, 107815. [Google Scholar] [CrossRef]

- Gul, S.; Tabrizi, I.E.; Okan, B.S.; Kefal, A.; Yildiz, M. An experimental investigation on damage mechanisms of thick hybrid composite structures under flexural loading using multi-instrument measurements. Aerosp. Sci. Technol. 2021, 117, 106921. [Google Scholar] [CrossRef]

- Ge, X.; Zhang, P.; Zhao, F.; Liu, M.; Liu, J.; Cheng, Y. Experimental and numerical investigations on the dynamic response of woven carbon fiber reinforced thick composite laminates under low-velocity impact. Compos. Struct. 2022, 279, 114792. [Google Scholar] [CrossRef]

- Peng, Y.; Wang, S.; Yao, S.; Xu, P. Crashworthiness analysis and optimization of a cutting-style energy absorbing structure for subway vehicles. Thin-Walled Struct. 2017, 120, 225–235. [Google Scholar] [CrossRef]

- Farley, G. Relationship between Mechanical-Property and Energy-Absorption Trends for Composite Tubes; Technical Report NASA TP-3284, ARL-TR-29; Langley Research Center: Hampton, VA, USA, 1992. [Google Scholar]

- Farley, G.L. The effects of crushing speed on the energy-absorption capability of composite tubes. J. Compos. Mater. 1991, 25, 1314–1329. [Google Scholar] [CrossRef]

- Hu, D.; Zhang, C.; Ma, X.; Song, B. Effect of fiber orientation on energy absorption characteristics of glass cloth/epoxy composite tubes under axial quasi-static and impact crushing condition. Compos. Part A-Appl. Sci. Manuf. 2016, 90, 489–501. [Google Scholar] [CrossRef]

- David, M.; Johnson, A.F. Effect of strain rate on the failure mechanisms and energy absorption in polymer composite elements under axial loading. Compos. Struct. 2015, 122, 430–439. [Google Scholar] [CrossRef]

- Sun, G.; Li, S.; Liu, Q.; Li, G.; Li, Q. Experimental study on crashworthiness of empty/aluminum foam/honeycomb-filled CFRP tubes. Compos. Struct. 2016, 152, 969–993. [Google Scholar] [CrossRef]

- Chen, D.; Xiao, S.; Yang, B.; Yang, G.; Zhu, T.; Wang, M.; Zhang, Z. Axial crushing response of carbon/glass hybrid composite tubes: An experimental and multi-scale computational study. Compos. Struct. 2022, 294, 115640. [Google Scholar] [CrossRef]

- Pohl, C.; Toenjes, M.; Liebold, C.; Ploeckl, M.; Koerber, H.; Avila Gray, L.; Colin, D.; Drechsler, K. Numerical prediction of composite damage behavior: A modeling approach including the strain-rate-dependent material response. Compos. Struct. 2022, 292, 115628. [Google Scholar] [CrossRef]

- Jiang, H.; Ren, Y. Crashworthiness and failure analysis of steeple-triggered hat-shaped composite structure under the axial and oblique crushing load. Compos. Struct. 2019, 229, 111375. [Google Scholar] [CrossRef]

- Shi, D.; Xiao, X. A new shell-beam element modeling method and its use in crash simulation of triaxial braided composites. Compos. Struct. 2017, 160, 792–803. [Google Scholar] [CrossRef]

- Siromani, D.; Awerbuch, J.; Tan, T.-M. Finite element modeling of the crushing behavior of thin-walled CFRP tubes under axial compression. Compos. Part B-Eng. 2014, 64, 50–58. [Google Scholar] [CrossRef]

| Test Code | t/mm | D/mm | L/mm | Mass/kg | MCF/kN | EA/kJ | SEA/kJ/kg | |

|---|---|---|---|---|---|---|---|---|

| Initial | Crushed | |||||||

| CFRP-QS | 12.4 | 100 | 300 | 195 | 1.87 | 621.5 | 121.2 | 99.7 |

| CFRP-D | 12.4 | 100 | 300 | 77.2 | 1.85 | 485.7 | 37.5 | 78.7 |

| Property | Values | Property | Values |

|---|---|---|---|

| (GPa) | 59.2 [62] | (MPa) | 54 [32] |

| (GPa) | 3.7 [62] | (MPa) | 70 [32] |

| 0.067 [62] | (J/m2) | 504 [62] | |

| (MPa) | 679.1 [10] | (J/m2) | 1566 [62] |

| (MPa) | 512 [10] | 2.284 [32] | |

| (MPa) | 56.1 [10] | / | / |

| (kJ/m2) | 155 [62] | / | / |

| 0.36 [62] | / | / |

| Code | Layer Number | Friction Coefficient | Amplification of Interface Properties | Predicted EA (kJ) | Error for EA (%) |

|---|---|---|---|---|---|

| L4-F05-I-sqrt | 4 | 0.5 | Using Equation (7) | 54.7 | −5.5 |

| L10-F05-I-sqrt | 10 | 0.5 | Using Equation (7) | 56.0 | −3.3 |

| L15-F05-I-sqrt | 15 | 0.5 | Using Equation (7) | 46.5 | −19.7 |

| L10-F01-I-sqrt | 10 | 0.1 | Using Equation (7) | 46.6 | −19.5 |

| L10-F03-I-sqrt | 10 | 0.3 | Using Equation (7) | 54.7 | −5.5 |

| L10-F05-I-no | 10 | 0.5 | None | 54.6 | −5.7 |

| L10-F05-I-da | 10 | 0.5 | Using Equation (6) | 52.3 | −9.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, D.; Sun, X.; Li, B.; Liu, Y.; Zhu, T.; Xiao, S. On Crashworthiness and Energy-Absorbing Mechanisms of Thick CFRP Structures for Railway Vehicles. Polymers 2022, 14, 4795. https://doi.org/10.3390/polym14224795

Chen D, Sun X, Li B, Liu Y, Zhu T, Xiao S. On Crashworthiness and Energy-Absorbing Mechanisms of Thick CFRP Structures for Railway Vehicles. Polymers. 2022; 14(22):4795. https://doi.org/10.3390/polym14224795

Chicago/Turabian StyleChen, Dongdong, Xiaoyu Sun, Benhuai Li, Yanwen Liu, Tao Zhu, and Shoune Xiao. 2022. "On Crashworthiness and Energy-Absorbing Mechanisms of Thick CFRP Structures for Railway Vehicles" Polymers 14, no. 22: 4795. https://doi.org/10.3390/polym14224795

APA StyleChen, D., Sun, X., Li, B., Liu, Y., Zhu, T., & Xiao, S. (2022). On Crashworthiness and Energy-Absorbing Mechanisms of Thick CFRP Structures for Railway Vehicles. Polymers, 14(22), 4795. https://doi.org/10.3390/polym14224795