Study on Bending Creep Performance of GFRP-Reinforced PVC-Based Wood-Plastic Composite Panels

Abstract

1. Introduction

2. Experiments

2.1. Raw Materials

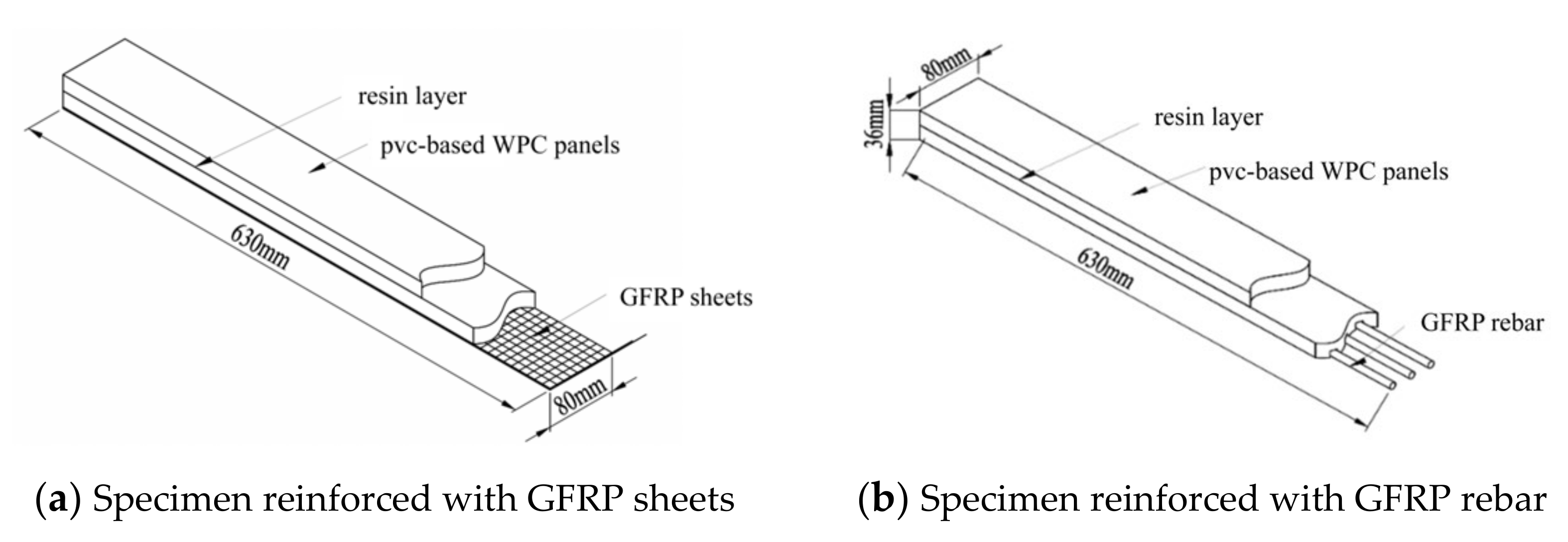

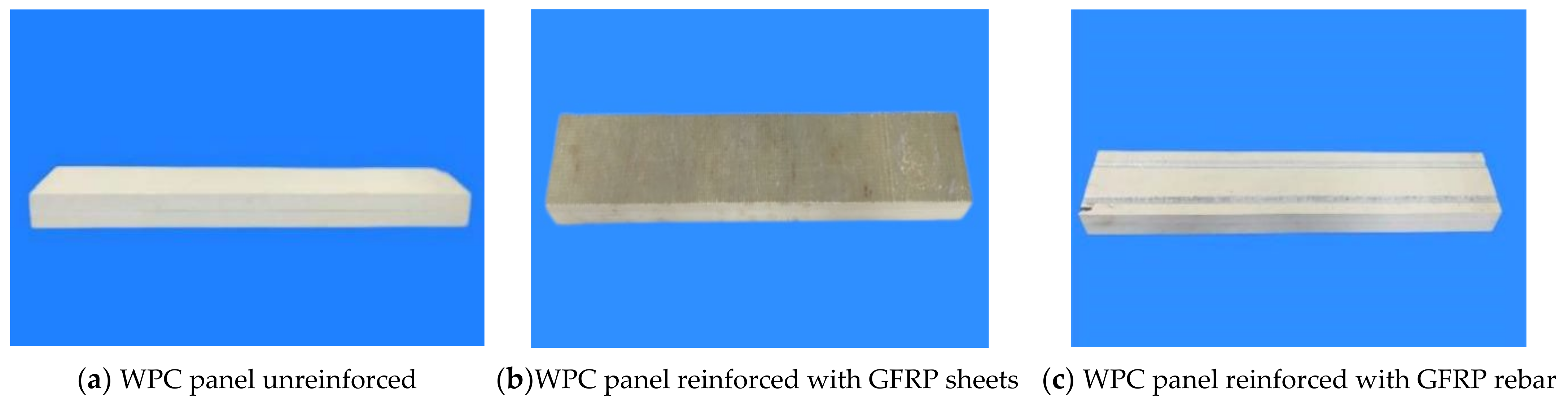

2.2. Samples’ Design and Preparation

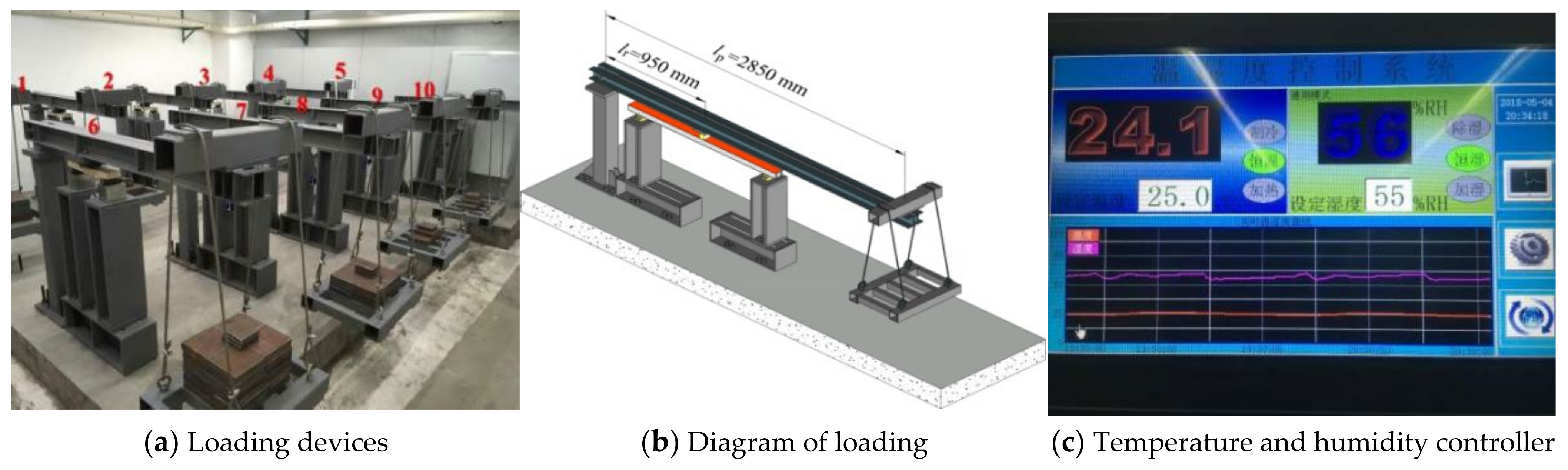

2.3. Bending Static Load Test

2.4. Bending Creep Test

3. Results and Analysis

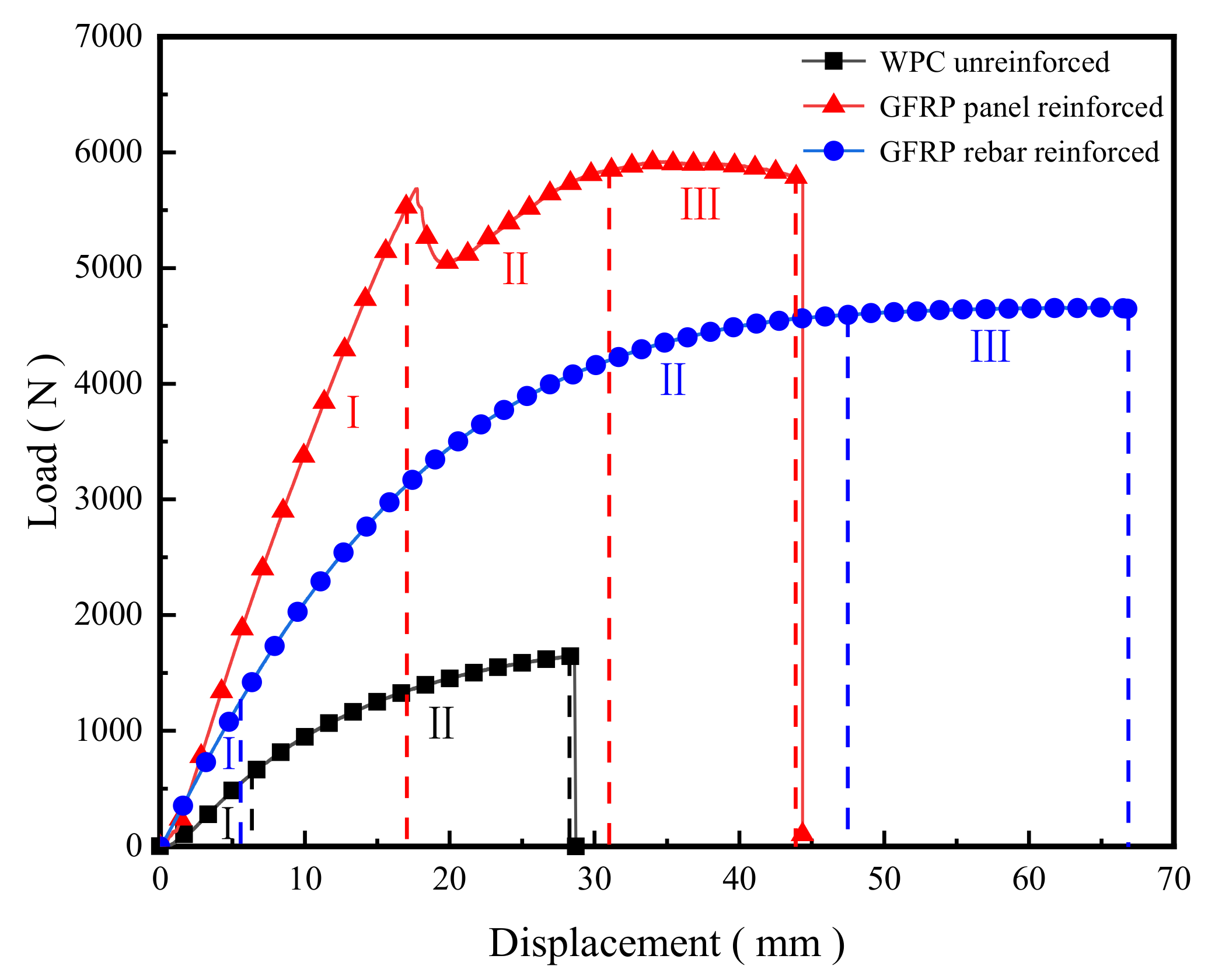

3.1. Results and Analysis of Bending Static Load Test

3.2. Results and Analysis of Bending Creep Test

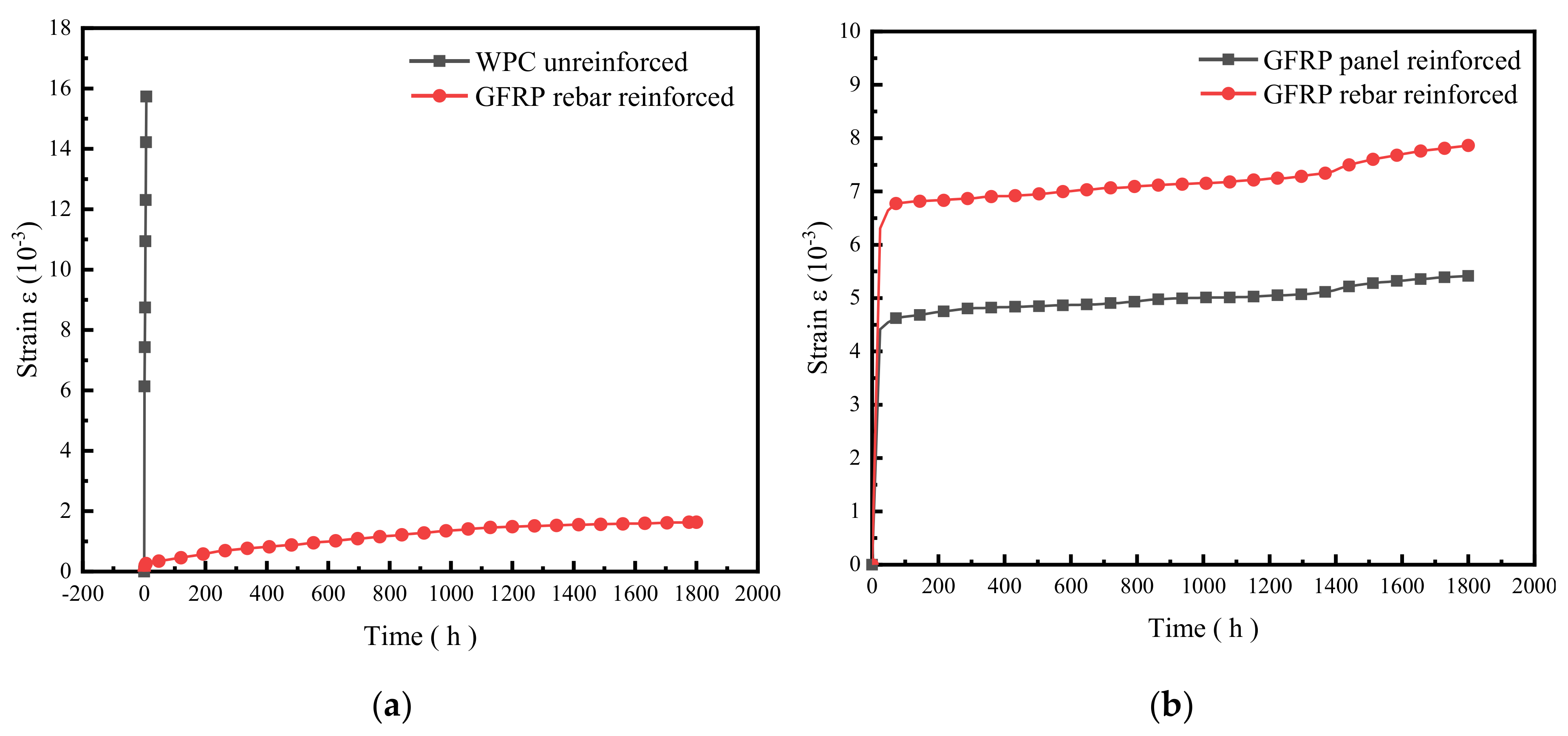

3.2.1. Failure Mode

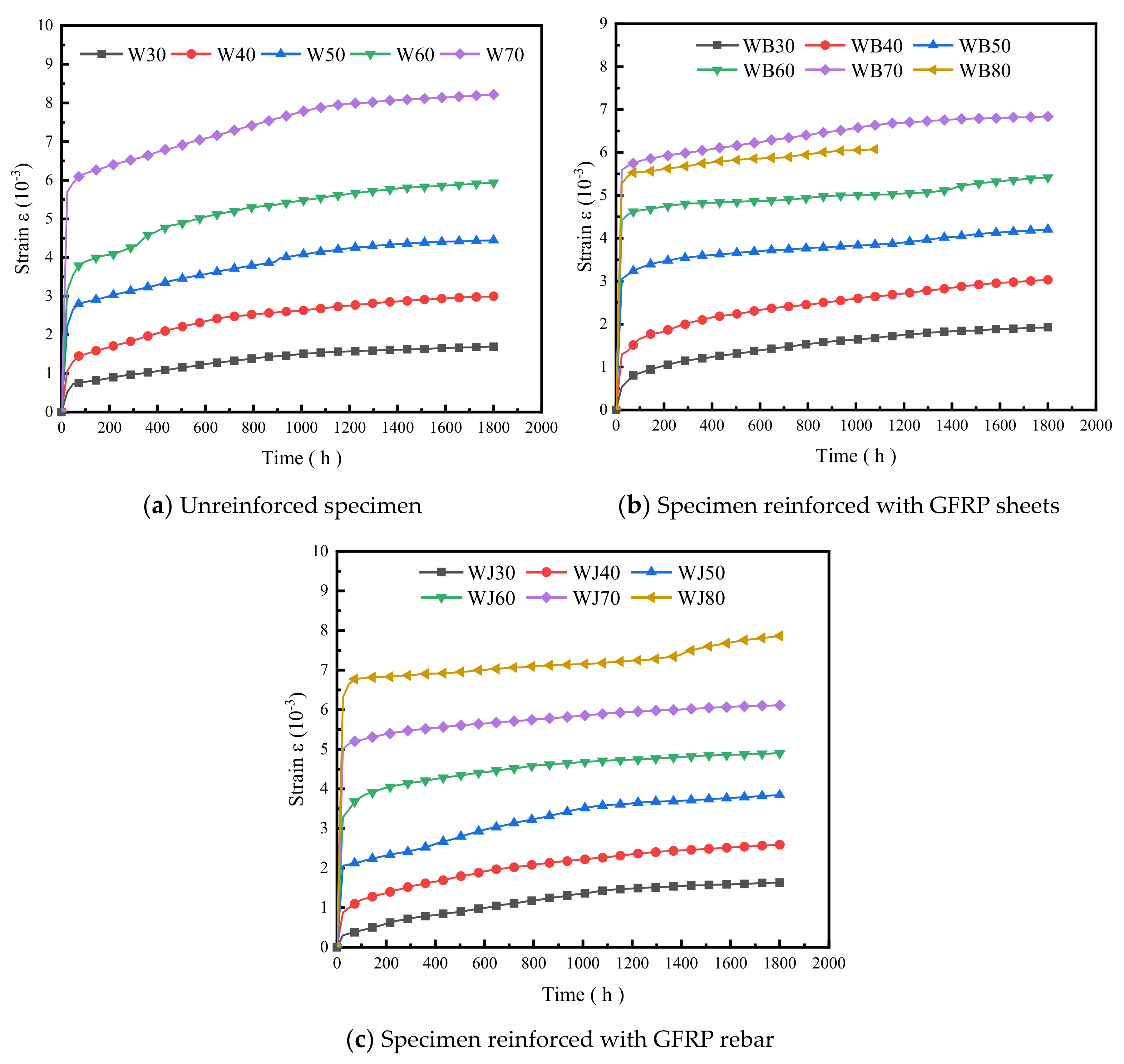

3.2.2. Creep Strain–Time Curves

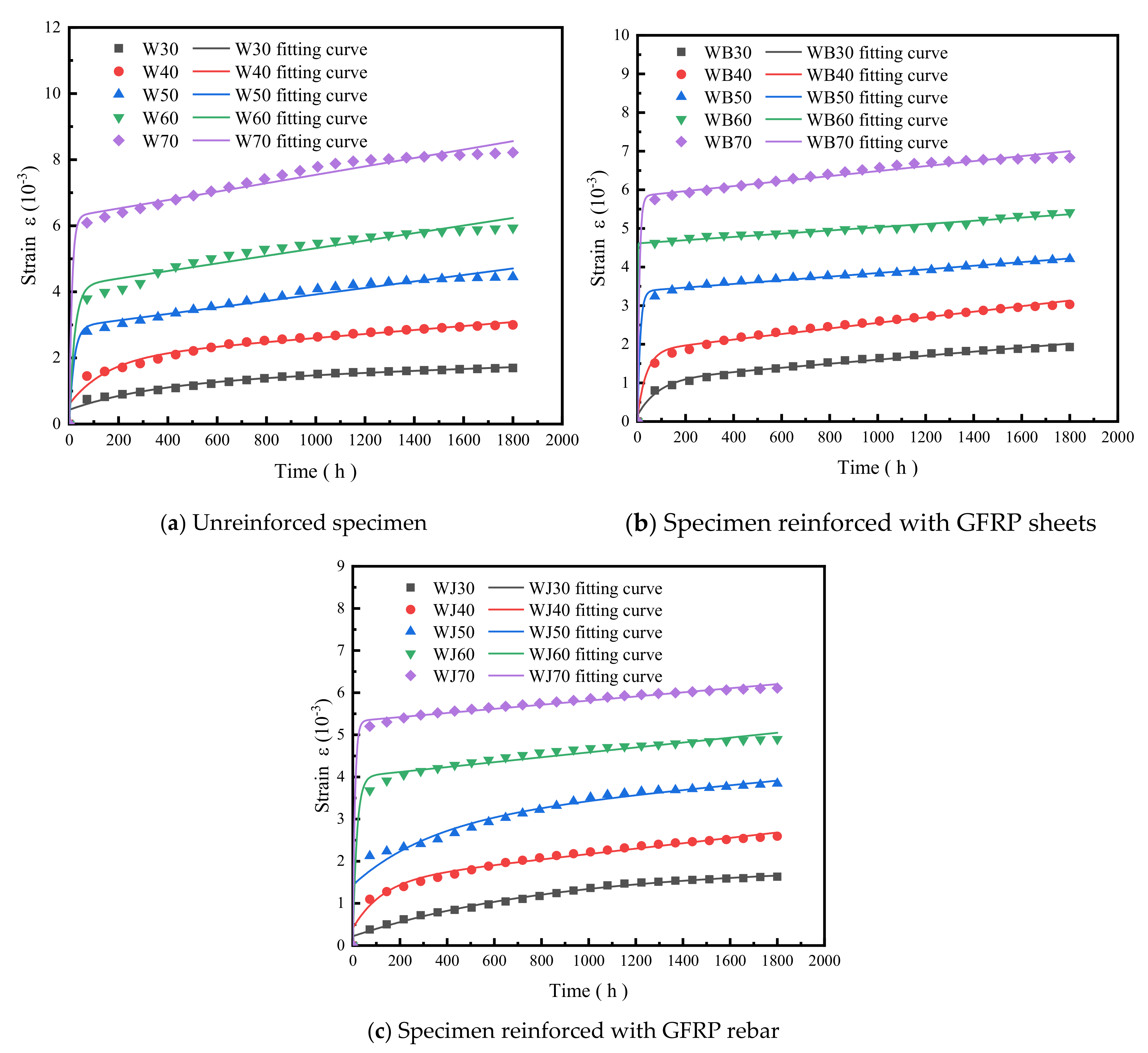

4. Four-Element Theoretical Model

5. Conclusions

- (1)

- The ultimate load-bearing capacity of WPC panels is greatly improved with GFRP sheets and rebar reinforcement, and the ultimate bearing capacity of the GFRP-sheets-reinforced specimen increased by 258% and the GFRP-rebar-reinforced specimen increased by 165%. Using GFRP to reinforce WPCs is effective.

- (2)

- The failure mode of PVC-based WPCs is closely related to the load level and the reinforcement method. After the transient stage, the creep kept decreasing and developed stably without damage under the low load level. When the loading level reached 80% of the ultimate load, unreinforced specimens suffered shear failure after 7 h, the maximum deflection in the span was 19.10 mm. The mid-span deflection of the GFRP-sheets-reinforced specimen increased significantly under transient loading, the GFRP sheets’ fibers were pulled out and bending shear failure occurred after 960 h, and the maximum deflection in the span was 7.03 mm. GFRP-rebar-reinforced specimens had significant deformation and were considered to fail due to their excessive mid-span deflection deformation, no cracks or fractures appeared, and the specimens had excellent ductility.

- (3)

- The creep strain change rules of specimens were obtained under different load levels. The strain increased and the strain growth rate decreased with time. The final strain rates of the unreinforced specimen increased by 226.67%, 182.11%, 99.61%, 88.74%, and 44.31% under the loading levels from 30% to 70%; those of the GFRP-sheets-reinforced specimen were 259.77%, 134.00%, 37.96%, 22.70%, 22.26%, and 15.25% under the loading levels from 30% to 80%; those of the GFRP-rebar-reinforced specimen were 440.00%, 194.12%, 86.97%, 49.21%, 22.11%, and 24.66% under the loading levels from 30% to 80%. The strain growth rates of the three types of specimens are generally decelerated. The relative creep decreased with increasing load levels. The final relative creep of unreinforced specimens was 327%, 282%, 199%, 189%, and 144% under the load levels from 30% to 70%; that of the GFRP-sheets-reinforced specimens was 360%, 234%, 138%, 123%, 122%, and 121%; and that of the GFRP-rebar-reinforced specimens was 540%, 294%, 187%, 149%, 122%, and 122% under the load levels from 30% to 80%.

- (4)

- Based on the test results, a four-element model was built. It is a simple, accurate, and reasonable classical model for describing the creep performance of WPC either reinforced by GFRP or not. The model can be used for long-term strain analysis and life prediction of specimens in the first two stages of transient creep and deceleration creep. GFRP-reinforced design methods can effectively improve the mechanical properties and creep resistance of WPCs and broaden the application field of WPC products.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alrubaie, M.A.A.; Lopez-Anido, R.A.; Gardner, D.J. Flexural creep behavior of high-density polyethylene lumber and wood plastic composite lumber made from thermally modified wood. Polymers 2020, 12, 262. [Google Scholar] [CrossRef] [PubMed]

- Abdullah, A.; Emin, S.; Hayrettin, D.; Ömer, S.S.; Mürsel, E. The effects of harsh aging environments on the properties of neat and MWCNT reinforced epoxy resins. Constr. Build. Mater. 2021, 272, 121929. [Google Scholar]

- Abouelregal, A.E.; Marin, M. The size-dependent thermoelastic vibrations of nanobeams subjected to harmonic excitation and rectified sine wave heating. Mathematics 2020, 8, 1128. [Google Scholar] [CrossRef]

- Wang, Q.W.; Wang, W.H. Wood-Plastic Composites and Products; Chemical Industry Press: Beijing, China, 2007. [Google Scholar]

- Wang, D.Z.; Zhu, M. Research progress of biomass WPCs. Sci. Technol. Innov. 2019, 22. [Google Scholar]

- Li, C.; Xian, G.; Li, H. Effect of postcuring immersed in water under hydraulic pressure on fatigue performance of large- diameter pultruded carbon/glass hybrid rod. Fatigue Fract. Eng. Mater. 2019, 42, 1148–1160. [Google Scholar] [CrossRef]

- Lal, H.M.; Uthaman, A.; Li, C.G.; Xian, G.J.; Thomas, S. Combined effects of cyclic/sustained bending loading and water immersion on the interface shear strength of carbon/glass fiber reinforced polymer hybrid rods for bridge cable. Constr. Build. Mater. 2022, 314, 125587. [Google Scholar] [CrossRef]

- Pan, Y.F.; Yan, D.M. Study on the durability of GFRP bars and carbon/glass hybrid fiber reinforced polymer (HFRP) bars aged in alkaline solution. Compos. Struct. 2021, 261, 113285. [Google Scholar] [CrossRef]

- Bledzki, K.; Andrzej; Omar, F. Creep and impact properties of wood fibre-polypropylene composites: Influence of temperature and moisture content composites. Sci. Technol. 2004, 64, 693–700. [Google Scholar] [CrossRef]

- Adrian, J.; Marcovich, E. Norma Analysis of the Creep Behavior of Poly propylene-Woodfiber Composites. Polym. Eng. Sci. 2004, 44, 1594–1603. [Google Scholar]

- Lee, S.Y.; Yang, H.S.; Kim, H.J.; Jeong, C.S.; Lim, B.S.; Lee, J.N. Creep behavior and manufacturing parameters of wood fiber filled poly propylene composites. Compos. Struct. 2004, 65, 459–469. [Google Scholar] [CrossRef]

- Hung, K.C.; Wu, L.T.; Chen, Y.L. Assessing the effect of wood acetylation on mechanical properties and extended creep behavior of wood/recycled-polypropylene composites. Constr. Build. Mater. 2016, 108, 139–145. [Google Scholar] [CrossRef]

- Pooler, D.J.; Smith, L.V. Nonlinear Viscoelastic Response of a Wood- Plastic Composite Including Temperature Effects. J. Thermoplast. Compos. 2004, 17, 425–450. [Google Scholar] [CrossRef]

- Park, P.D.; Balatinecz, J.J. Short term flexural creep behavior of wood- fiber/polypropylene composites. Polym. Compos. 2004, 19, 377–382. [Google Scholar] [CrossRef]

- Fang, H.; Sun, H.; Liu, W.; Wang, L.; Bai, Y.; Hui, D. Mechanical performance of innovative GFRP-bamboo-wood sandwich beams: Experimental and modelling investigation. Compos. Part B Eng. 2015, 79, 182–196. [Google Scholar] [CrossRef]

- Tuwair, H.; Hopkins, M.; Volz, J.; Eigawady, M.A.; Mohamed, M.; Chandrashekhara, K.; Birman, V. Evaluation of sandwich panels with various polyurethane foam-cores and ribs. Compos. Part B Eng. 2015, 79, 262–276. [Google Scholar] [CrossRef]

- Shi, H.; Liu, W.; Fang, H.; Bai, Y.; Hui, D. Flexural responses and pseudo-ductile performance of lattice-web reinforced GFRP-wood sandwich beams. Compos. Part B Eng. 2017, 108, 364–376. [Google Scholar] [CrossRef]

- Gigliotti, L.; Pinho, S.T. Prediction of the post-crushing compressive response of progressively crushable sandwich foam cores. Compos. Part A Appl. Sci. 2016, 80, 148–158. [Google Scholar] [CrossRef]

- Zhang, P.; Cheng, Y.; Liu, J.; Li, Y.; Zhang, C.; Hou, H.; Wang, C. Experimental study on the dynamic response of foam-fifilled corrugated core sandwich panels subjected to air blast loading. Compos. Part B Eng. 2016, 105, 67–81. [Google Scholar] [CrossRef]

- Chen, Q.; Linghu, T.; Gao, Y.; Wang, Z.; Liu, Y.; Du, R.; Zhao, G. Mechanical properties in glass fiber PVC-foam sandwich structures from different chopped fiber interfacial reinforcement through vacuum-assisted resin transfer molding (VARTM) processing. Compos. Sci. Technol. 2017, 144, 202–207. [Google Scholar] [CrossRef]

- Badaruzzaman, W.H.W.; Dabbagh, N.M.R.; Salleh, K.M.; Saharuddin, E.N.; Radzi, N.F.M.; Azham, M.A.A.; Sani, S.F.A.; Zakaria, S. Mechanical Properties and Water Absorption Capacity of Hybrid GFRP Composites. Polymers 2022, 14, 1394. [Google Scholar] [CrossRef]

- Zhou, Z.L.; Yang, Y.D. A preliminary discussion of creep mechanism of fiber reinforced plastics. FRP/Compos 1985, 4, 29–33. [Google Scholar]

- Ghita, C.; Pop, N.; Popescu, I.N. Existence result of an effective stress for an isotropic visco-plastic composite. Comp. Mater. Sci. 2012, 64, 52–56. [Google Scholar] [CrossRef]

- Bai, X.Y. Experimental Study and Theoretical Analysis of Anchoring Mechanism of GFRP Anti-Floating Anchors; Qingdao University of Technology: Qingdao, China, 2015. [Google Scholar]

- Mu, X.Y. Creeping Mechanics; Xi’an Jiaotong University Press: Xi’an, China, 1990. [Google Scholar]

- Shen, S.Z. Creep properties of FRP. Q. J. Mech. 1982, 2, 71–78. [Google Scholar]

- Dutta, P.K.; Hui, D. Creep rupture of a GFRP composite at elevated temperatures. Comput. Struct. 2000, 76, 153–161. [Google Scholar] [CrossRef]

- Tannous, F.E.; Saadatmanesh, H. Durability of AR glass fiber reinforced plastic bars. J. Compos. Constr. 1999, 3, 12–19. [Google Scholar] [CrossRef]

- Uomoto, T.; Nishimura, T. Deterioration of aramid, glass, and carbon fibers due to alkali, acid, and water in different temperatures. ACI Spec. Publ. 1999, 188, 515–522. [Google Scholar]

- Li, G.W.; Gao, L.; Huang, Z.H.; Liu, C.Q.; Zhang, D. Experiments on the pull-out model of damage mechanism of full-length bonded glass fiber reinforced polymer anchors. J. Rock. Mech. Geotech. 2007, 26, 1653–1663. [Google Scholar]

- Li, G.W.; Liu, Z.Q.; Huang, Z.H.; Cai, Y.Q. Field test of applying glass fiber anchors to strengthen highway slopes. J. Rock. Mech. Eng. 2010, 29 (Suppl. 2), 4056–4062. [Google Scholar]

- Sun, Q. Experimental Study on the Mechanical Properties of GFRP Anchors under Freeze-Thaw Cycles and Long-Term Loading; Central South University: Changsha, China, 2012. [Google Scholar]

- Cui, Y.H.; Noruziaan, B.; Lee, S.; Chang, M.; Tao, J. Glass fiber/wood plastic hybrid composites and their synergistic reinforcing effects. Polym. Mater. Sci. Eng. 2006, 22, 231–234. [Google Scholar]

- Guo, D.; Lu, S.R.; Luo, C.X.; Liu, K.; Ling, R.H. Study on the structure and properties of glass fiber reinforced lignin/PP composites. Modern Plast. Process. Appl. 2012, 24, 23–26. [Google Scholar]

- Jeamtrakull, S.; Kositchaiyong, A.; Markpin, T.; Rosarpitak, V.; Sombatsompop, N. Effects of wood constituents and content, and glass fiber reinforcement on wear behavior of wood/PVC composites. Compos. Part B Eng. 2012, 43, 2721–2729. [Google Scholar] [CrossRef]

- Huang, R.; Xiong, W.; Xu, X.; Wu, Q. Thermal expansion behavior of co-extruded WPCs with glass-fiber reinforced shells. Bioresources 2012, 7, 5514–5526. [Google Scholar] [CrossRef]

- Kim, B.J.; Huang, R.; Han, J. Mechanical and morphological properties of coextruded wood plastic composites with glass fiber-filled shell. Polym. Compos. 2014, 37, 824–834. [Google Scholar] [CrossRef]

- Zolfaghari, A.; Behravesh, A.H.; Adli, A. Continuous glass fiber reinforced wood plastic composite in extrusion process: Mechanical properties. Mater. Des. 2013, 51, 701–708. [Google Scholar] [CrossRef]

- Pulngern, T.; Udtaranakron, T.; Chanto, K. Physical and Mechanical Behaviors of Thermally Modified Rubberwood Glulam Beam Under Sustained and Cyclic Loading. Wood Fiber Sci. 2020, 52, 1–15. [Google Scholar] [CrossRef]

- Pulngern, T.; Chitsamran, T.; Chucheepsakul, S.; Rosarpitak, V.; Patcharaphun, S.; Sombatsompop, N. Effect of temperature on mechanical properties and creep responses for wood/PVC composites. Constr. Build. Mater. 2016, 111, 191–198. [Google Scholar] [CrossRef]

- Sain, M.M.; Balatinecz, J.; Law, S. Creep fatigue in engineered wood fiber and plastic compositions. J. Appl. Polym. Sci. 2000, 77, 260–268. [Google Scholar] [CrossRef]

- Li, X.L.; Liu, W.Q.; Fang, H.; Huo, R.L.; Wu, P. Flexural creep behavior and life prediction of GFRP-balsa sandwich beams. Compos. Struct. 2019, 224, 111009. [Google Scholar] [CrossRef]

- Tian, X.L.; Li, Z.G.; Jiang, Y.T.; He, Q.; Wu, C.Y. Study of creep properties of WPCs under different loading methods. Plast. Ind. 2008, 36, 43–46. [Google Scholar]

- Cao, Y.; Xu, H.L.; Wang, W.H.; Wang, Q.W. Creep properties and creep modeling of molded poplar fiber/high density polyethylene composites. J. Compos. 2016, 33, 1174–1178. [Google Scholar]

- Du, H.H.; Wang, W.H.; Wang, H.G.; Wang, Q.W. Effect of wood fiber content on creep properties of WPCs. J. Constr. Mater. 2015, 18, 333–339. [Google Scholar]

- Xie, W.R. Design of Creep Testing Device and Creep Performance Study of WPCs; Northeast Forestry University: Harbin, China, 2017. [Google Scholar]

- Cao, J.Z. Wood Conservation and Modification; China Forestry Press: Beijing, China, 2018. [Google Scholar]

- Lu, X.C.; Fang, Q.H.; Lu, Q.Z.; Chen, F.Q.; Sun, X.M. Creep properties of PP/wood flour composites. Plastics 2009, 38, 81–84. [Google Scholar]

- Jiang, Y.T.; Li, Z.G.; Wu, Z.Y.; Ding, J.S. Creep and stress relaxation properties of WPCs. For. Mach. Woodwork. Equip. 2009, 37, 24–26. [Google Scholar]

- Shao, X.; He, C.X.; Jiang, C.Y. Creep and thermal stability of wood fiber/PVC composites. J. Mater. Sci. Eng. 2019, 37. [Google Scholar]

- Xu, H.L.; Cao, Y.; Wang, W.H.; Wang, Q.W.; Wang, H.G. Effect of poplar fiber size on mechanical and creep properties of hot compression molded poplar fiber/high density polyethylene composites. J. Compos. 2016, 33, 1168–1173. [Google Scholar]

- Zhang, X.L.; Deng, Z.C. Effects of Seawater Environment on the Degradation of GFRP Composites by Molecular Dynamics Method. Polymers 2022, 14, 2804. [Google Scholar] [CrossRef]

- Corigliano, A.; Rizzi, E.; Papa, E. Experimental characterization and numerical simulations of a syntactic-foam/glass-fibre composite sandwich. Compos. Sci. Technol. 2000, 60, 2169–2180. [Google Scholar] [CrossRef]

- Daniel, I.M.; Gdoutos, E.E. Failure Modes of Composite Sandwich Beams. Theor. Appl. Mech. 2009, 35, 197. [Google Scholar]

- George, J.; Sreekala, M.; Thomas, S. A review on interface modification and characterization of natural fiber reinforced plastic composites. Polym. Eng. Sci. 2001, 41, 1471–1485. [Google Scholar] [CrossRef]

- Sheng, G.Y.; Feng, M.B. Engineering Materials Testing Technology; China Metrology Press: Beijing, China, 2007. [Google Scholar]

- Hu, J.H.; Li, Y.P.; Chen, W.J.; Yang, D.Q. A combined loading-creep model of ETFE foils for flat-patterning structures. Thin. Wall. Struct. 2020, 157, 106976. [Google Scholar] [CrossRef]

- Chen, B.; Guo, L.P.; Zhang, W.X.; Bai, Y.; Wang, X.F. Compressive creep behavior of cellulose fiber reinforced concrete. IOP Conf. Ser. Earth Environ. Sci. 2021, 825, 012022. [Google Scholar]

- Song, Y.Q.; Li, X.L.; Ma, H.F.; Fu, H. Exploration of the full process of creep in generalized Kelvin model based on damaged body elements. Appl. Math. Mech. 2021, 42, 637–644. [Google Scholar]

- Shi, T.B.; Hu, J.H.; Chen, W.J.; Gao, C.J. A refined numerical model for determining inflation-burst behavior of composite membrane structures. Polym. Test. 2020, 81, 106123. [Google Scholar] [CrossRef]

- Ye, L.P.; Feng, P. Application and development of FRP in engineering structures. Chin. Civil. Eng. J. 2006, 39, 24–36. [Google Scholar]

- Li, C.G.; Guo, R.; Wang, J.Q.; Huang, H.X.; Xian, G.J. Performance evolution of CFRP@GFRP hybrid composite rods under water immersion environment. J. Compos. Mater. 2021, 38, 3290–3301. [Google Scholar]

- Feng, P. Development and application of composite materials in civil engineering. FRP/Compos. 2014, 9, 99–104. [Google Scholar]

- Cui, X.; Liu, J.; Xiao, J.Y.; Zhong, Y. Research progress of vacuum introduction molding process. Mater. Guide 2013, 27, 14–18. [Google Scholar]

- ASTM D6815−09; Standard Specification for Evaluation of Duration of Load and Creep Effects of Wood and Wood-Based Products. ASTM International: West Conshohocken, PA, USA, 2015.

| Specimen Types | Failure Mode | Specimen Number | Ultimate Load (N) | The Average (N) | Mean Mid-Span Displacement (mm) | The Average (mm) |

|---|---|---|---|---|---|---|

| Unreinforced | Shear failure | 1 | 1738 | 1720 | 27.62 | 28.63 |

| 2 | 1715 | 28.46 | ||||

| 3 | 1707 | 29.81 | ||||

| Reinforced with GFRP sheet | Bending shear failure | 1 | 6165 | 6150 | 43.24 | 44.30 |

| 2 | 6151 | 44.12 | ||||

| 3 | 6134 | 45.75 | ||||

| Reinforced with GFRP rebar | Exceed displacement limit | 1 | 4576 | 4560 | 65.22 | 66.70 |

| 2 | 4558 | 65.86 | ||||

| 3 | 4546 | 69.23 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, B.; Huo, R.; Wang, K.; Ma, Z.; Fang, H. Study on Bending Creep Performance of GFRP-Reinforced PVC-Based Wood-Plastic Composite Panels. Polymers 2022, 14, 4789. https://doi.org/10.3390/polym14224789

Dai B, Huo R, Wang K, Ma Z, Fang H. Study on Bending Creep Performance of GFRP-Reinforced PVC-Based Wood-Plastic Composite Panels. Polymers. 2022; 14(22):4789. https://doi.org/10.3390/polym14224789

Chicago/Turabian StyleDai, Bangbang, Ruili Huo, Kun Wang, Zhengqing Ma, and Hai Fang. 2022. "Study on Bending Creep Performance of GFRP-Reinforced PVC-Based Wood-Plastic Composite Panels" Polymers 14, no. 22: 4789. https://doi.org/10.3390/polym14224789

APA StyleDai, B., Huo, R., Wang, K., Ma, Z., & Fang, H. (2022). Study on Bending Creep Performance of GFRP-Reinforced PVC-Based Wood-Plastic Composite Panels. Polymers, 14(22), 4789. https://doi.org/10.3390/polym14224789