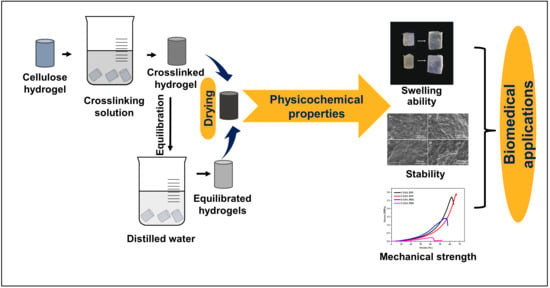

Physicochemical Properties of Cellulose-Based Hydrogel for Biomedical Applications

Abstract

1. Introduction

2. Materials and Methods

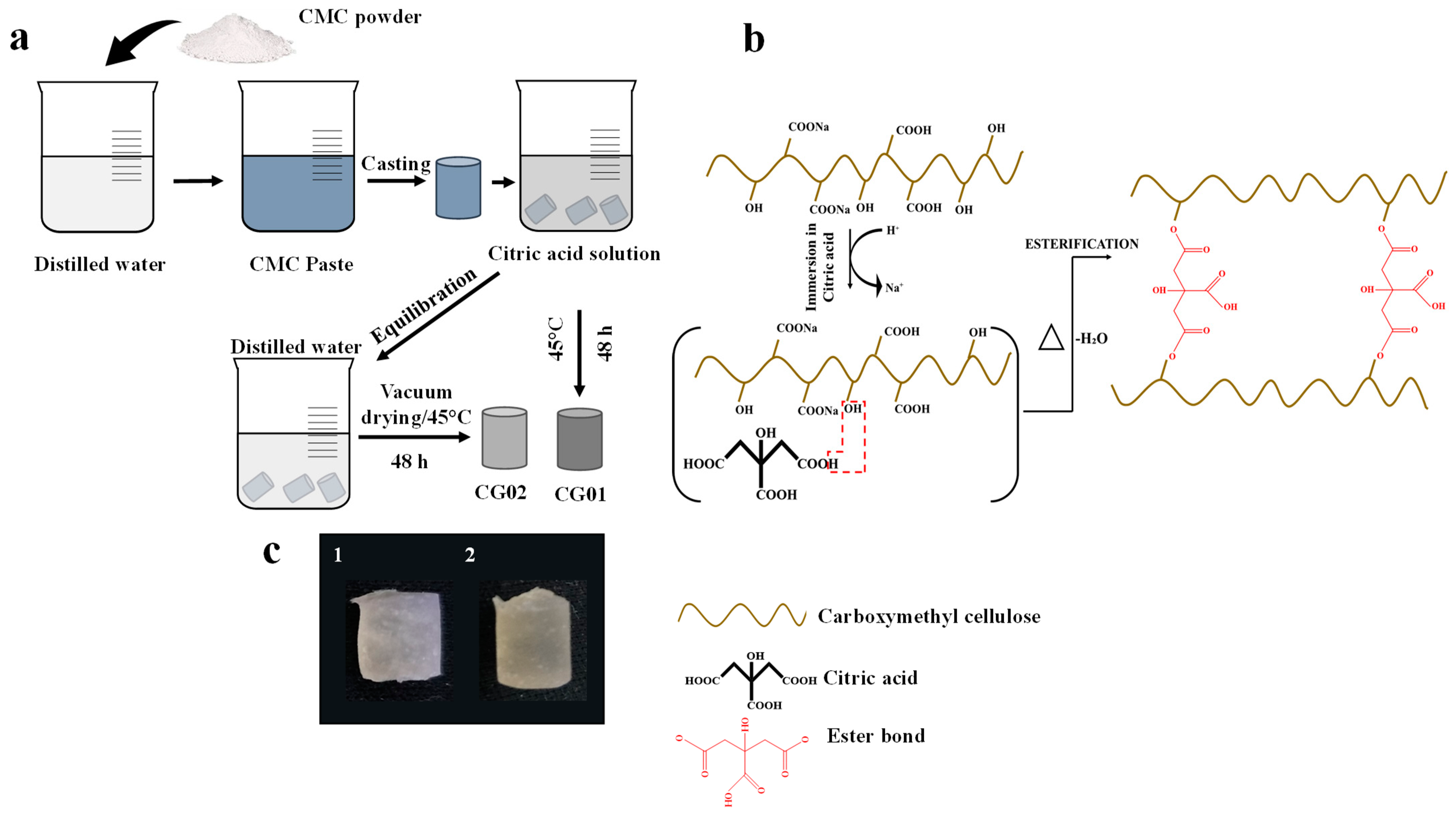

2.1. Fabrication of Cellulose Hydrogel

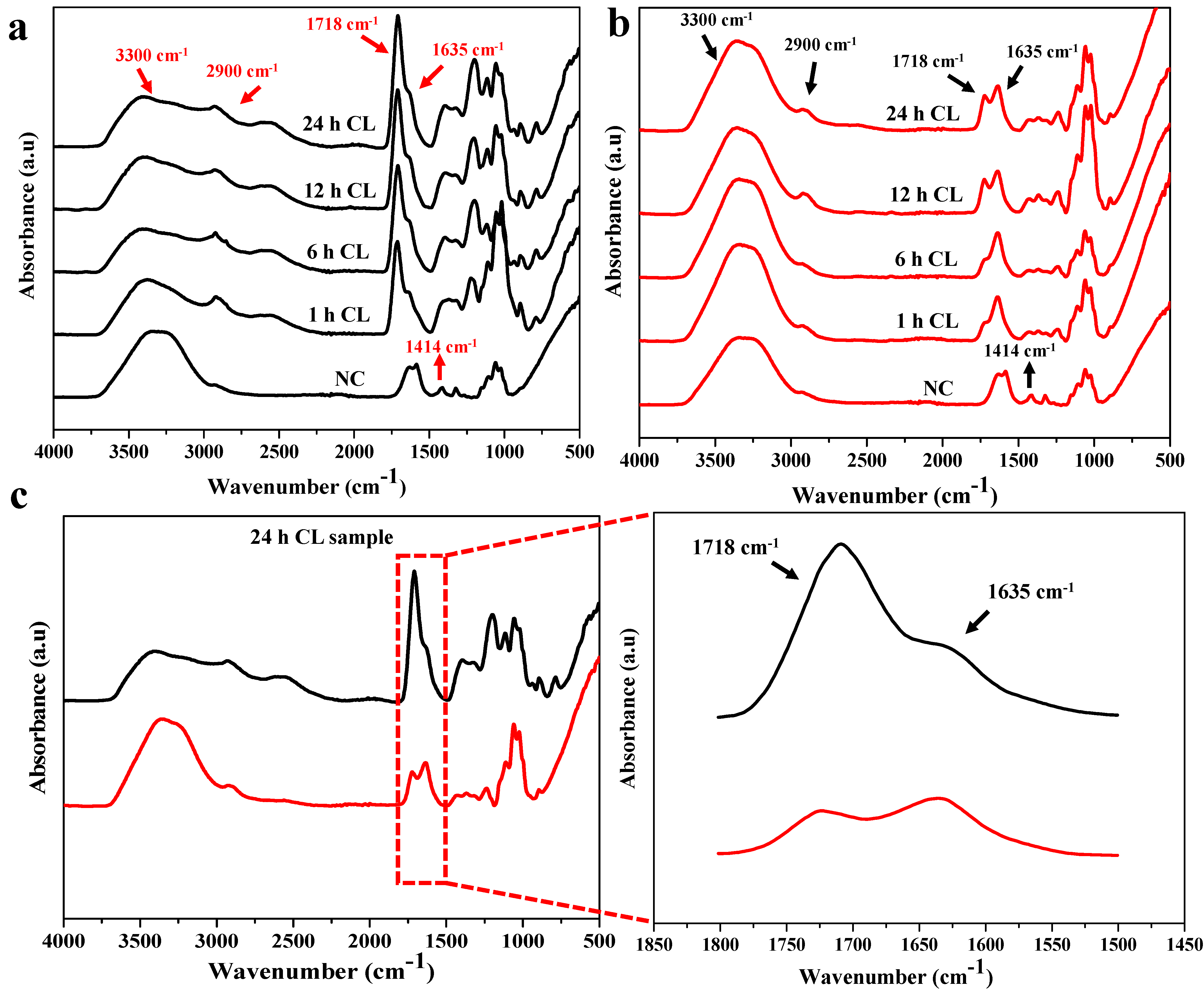

2.2. Fourier Transform Infrared Spectroscopy (FTIR)

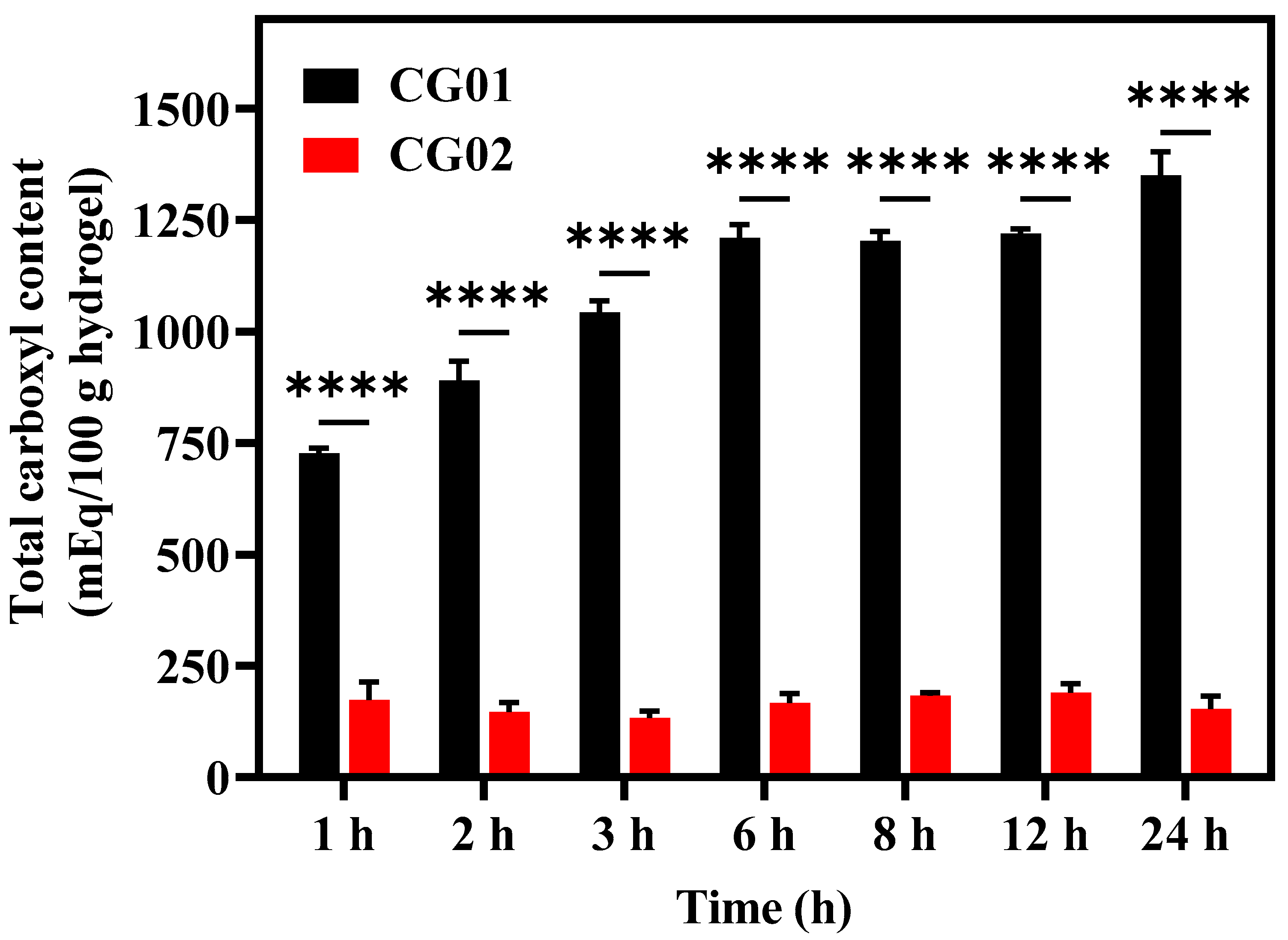

2.3. Carboxyl Content

2.4. Swelling Study

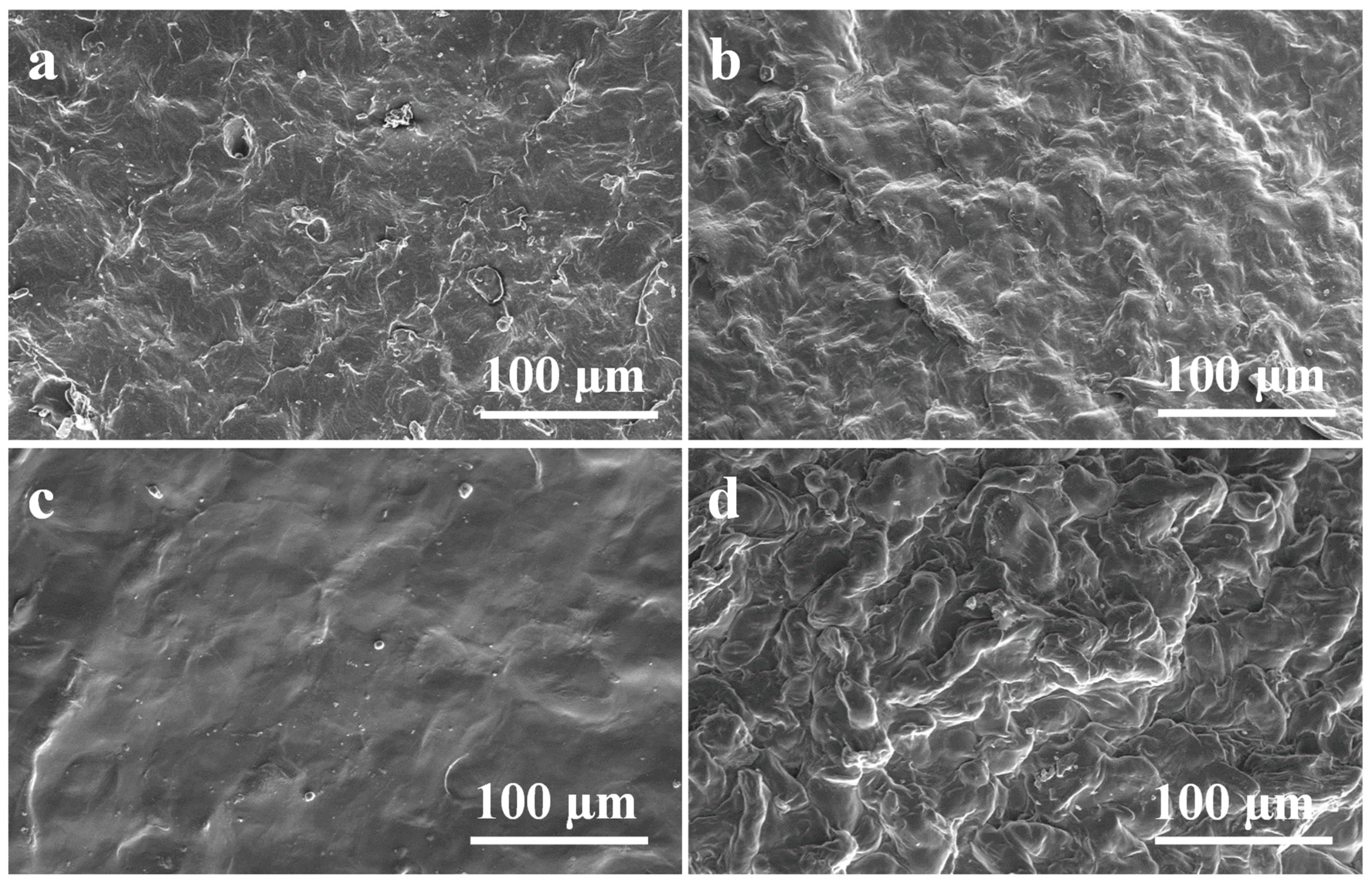

2.5. Morphology of Hydrogel

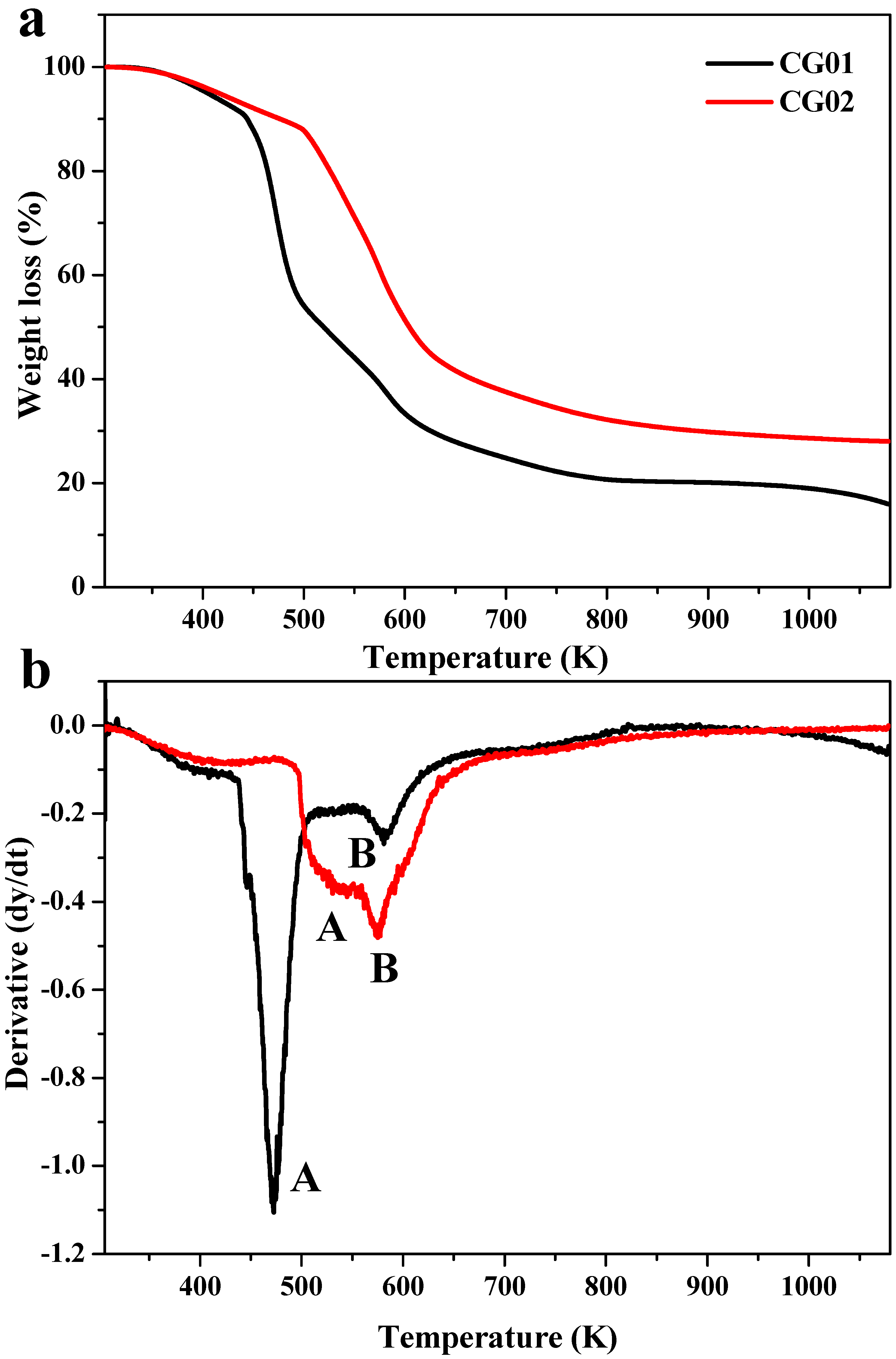

2.6. Thermal Analysis

2.7. Mechanical Study

2.8. Statistical Analysis

3. Results and Discussion

3.1. Fabrication of Cellulose Hydrogel

3.2. Fourier Transform Infrared Spectroscopy

3.3. Total Carboxyl Content

3.4. Swelling Study

3.5. Morphology of Hydrogel

3.6. Thermal Analysis

3.7. Mechanical Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aswathy, S.H.; Narendrakumar, U.; Manjubala, I. Heliyon Commercial Hydrogels for Biomedical Applications. Heliyon 2020, 6, e03719. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.U.A.; Iqbal, I.; Ansari, M.N.M.; Razak, S.I.A.; Raza, M.A.; Sajjad, A.; Jabeen, F.; Mohamad, M.R.; Jusoh, N. Development of Antibacterial, Degradable and Ph-Responsive Chitosan/Guar Gum/Polyvinyl Alcohol Blended Hydrogels for Wound Dressing. Molecules 2021, 26, 5937. [Google Scholar] [CrossRef] [PubMed]

- Chai, Q.; Jiao, Y.; Yu, X. Hydrogels for Biomedical Applications: Their Characteristics and the Mechanisms behind Them. Gels 2017, 3, 6. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.Y.; Mooney, D.J. Hydrogels for Tissue Engineering. Chem. Rev. 2001, 101, 1869–1880. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.U.A.; Haider, S.; Raza, M.A.; Shah, S.A.; Razak, S.I.A.; Kadir, M.R.A.; Subhan, F.; Haider, A. Smart and PH-Sensitive RGO/Arabinoxylan/Chitosan Composite for Wound Dressing: In-Vitro Drug Delivery, Antibacterial Activity, and Biological Activities. Int. J. Biol. Macromol. 2021, 192, 820–831. [Google Scholar] [CrossRef] [PubMed]

- Feksa, L.R.; Troian, E.A.; Muller, C.D.; Viegas, F.; Machado, A.B.; Rech, V.C. Hydrogels for Biomedical Applications. In Nanostructures for the Engineering of Cells, Tissues and Organs: From Design to Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 403–438. ISBN 9780128136669. [Google Scholar]

- Khan, M.U.A.; Razak, S.I.A.; Hassan, A.; Qureshi, S.; Stojanović, G.M. Ihsan-Ul-Haq Multifunctional Arabinoxylan-Functionalized-Graphene Oxide Based Composite Hydrogel for Skin Tissue Engineering. Front. Bioeng. Biotechnol. 2022, 10, 1–12. [Google Scholar] [CrossRef]

- Zabed, H.; Sahu, J.N.; Boyce, A.N.; Faruq, G. Fuel Ethanol Production from Lignocellulosic Biomass: An Overview on Feedstocks and Technological Approaches. Renew. Sustain. Energy Rev. 2016, 66, 751–774. [Google Scholar] [CrossRef]

- Aarstad, O.; Heggset, E.B.; Pedersen, I.S.; Bjørnøy, S.H.; Syverud, K.; Strand, B.L. Mechanical Properties of Composite Hydrogels of Alginate and Cellulose Nanofibrils. Polymers 2017, 9, 378. [Google Scholar] [CrossRef]

- Seddiqi, H.; Oliaei, E.; Honarkar, H.; Jin, J. Cellulose and Its Derivatives: Towards Biomedical Applications; Springer: Amsterdam, The Netherlands, 2021; Volume 28, ISBN 1057002003. [Google Scholar]

- Sannino, A.; Demitri, C.; Madaghiele, M. Biodegradable Cellulose-Based Hydrogels: Design and Applications. Materials 2009, 2, 353–373. [Google Scholar] [CrossRef]

- Jeong, D.; Joo, S.; Hu, Y.; Vilas, V.; Cho, E.; Jung, S. Carboxymethyl Cellulose-Based Superabsorbent Hydrogels Containing Carboxymehtyl β -Cyclodextrin for Enhanced Mechanical Strength and e Ff Ective Drug Delivery. Eur. Polym. J. 2018, 105, 17–25. [Google Scholar] [CrossRef]

- Barbucci, R.; Magnani, A.; Consumi, M. Swelling Behavior of Carboxymethylcellulose Hydrogels in Relation to Cross-Linking, PH, and Charge Density. Macromolecules 2000, 33, 7475–7480. [Google Scholar] [CrossRef]

- Zainal, S.H.; Mohd, N.H.; Suhaili, N.; Anuar, F.H.; Lazim, A.M.; Othaman, R. Preparation of Cellulose-Based Hydrogel: A Review. J. Mater. Res. Technol. 2021, 10, 935–952. [Google Scholar] [CrossRef]

- Ciolacu, D.E.; Suflet, D.M. 11—Cellulose-Based Hydrogels for Medical/Pharmaceutical Applications; Elsevier B.V.: Amsterdam, The Netherlands, 2019; ISBN 9780444637741. [Google Scholar]

- Basu, P.; Narendrakumar, U.; Arunachalam, R.; Devi, S.; Manjubala, I. Characterization and Evaluation of Carboxymethyl Cellulose-Based Films for Healing of Full-Thickness Wounds in Normal and Diabetic Rats. ACS Omega 2018, 3, 12622–12632. [Google Scholar] [CrossRef] [PubMed]

- Priya, G.; Madhan, B.; Narendrakumar, U.; Suresh Kumar, R.V.; Manjubala, I. In Vitro and in Vivo Evaluation of Carboxymethyl Cellulose Scaffolds for Bone Tissue Engineering Applications. ACS Omega 2021, 6, 1246–1253. [Google Scholar] [CrossRef] [PubMed]

- Capanema, N.S.V.; Mansur, A.A.P.; de Jesus, A.C.; Carvalho, S.M.; de Oliveira, L.C.; Mansur, H.S. Superabsorbent Crosslinked Carboxymethyl Cellulose-PEG Hydrogels for Potential Wound Dressing Applications. Int. J. Biol. Macromol. 2018, 106, 1218–1234. [Google Scholar] [CrossRef] [PubMed]

- Salam, A.; Pawlak, J.J.; Venditti, R.A.; El-tahlawy, K. Incorporation of Carboxyl Groups into Xylan for Improved Absorbency. Cellulose 2011, 18, 1033–1041. [Google Scholar] [CrossRef]

- Zheng, W.J.; Gao, J.; Wei, Z.; Zhou, J.; Chen, Y.M. Facile Fabrication of Self-Healing Carboxymethyl Cellulose Hydrogels. Eur. Polym. J. 2015, 72, 514–522. [Google Scholar] [CrossRef]

- Mali, K.K.; Dhawale, S.C.; Dias, R.J.; Dhane, N.S.; Ghorpade, V.S. Citric Acid Crosslinked Carboxymethyl Cellulose-Based Composite Hydrogel Films for Drug Delivery. Indian J. Pharm. Sci. 2018, 80, 657–667. [Google Scholar] [CrossRef]

- Priya, G.; Narendrakumar, U.; Manjubala, I. Thermal Behavior of Carboxymethyl Cellulose in the Presence of Polycarboxylic Acid Crosslinkers. J. Therm. Anal. Calorim. 2019, 138, 89–95. [Google Scholar] [CrossRef]

- Lima, G.F.; Souza, A.G.; Rosa, D. dos S. Nanocellulose as Reinforcement in Carboxymethylcellulose Superabsorbent Nanocomposite Hydrogels. Macromol. Symp. 2020, 394, 2000126. [Google Scholar] [CrossRef]

- Raucci, M.G.; Alvarez-Perez, M.A.; Demitri, C.; Giugliano, D.; De Benedictis, V.; Sannino, A.; Ambrosio, L. Effect of Citric Acid Crosslinking Cellulose-Based Hydrogels on Osteogenic Differentiation. J. Biomed. Mater. Res. Part A 2015, 103, 2045–2056. [Google Scholar] [CrossRef] [PubMed]

- Sampatrao, V.; Vyankatrao, A.; Jacky, R. Citric Acid Crosslinked—Cyclodextrin/Carboxymethylcellulose Hydrogel Films for Controlled Delivery of Poorly Soluble Drugs. Carbohydr. Polym. 2017, 164, 339–348. [Google Scholar] [CrossRef]

- Vishal Gupta, N.; Shivakumar, H.G. Investigation of Swelling Behavior and Mechanical Properties of a PH-Sensitive Superporous Hydrogel Composite. Iran. J. Pharm. Res. 2012, 11, 481–493. [Google Scholar] [CrossRef]

- Fijul Kabir, S.M.; Sikdar, P.P.; Haque, B.; Bhuiyan, M.A.R.; Ali, A.; Islam, M.N. Cellulose-based Hydrogel Materials Chemistry, Properties and Their Prospective Applications. Prog. Biomater. 2018, 7, 153–174. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Marchant, R.E. Design Properties of Hydrogel Tissue-Engineering Scaffolds. Expert Rev. Med. Devices 2011, 8, 607–626. [Google Scholar] [CrossRef]

- Liu, X.; Steiger, C.; Lin, S.; Parada, G.A.; Liu, J.; Chan, H.F.; Yuk, H.; Phan, N.V.; Collins, J.; Tamang, S.; et al. Ingestible Hydrogel Device. Nat. Commun. 2019, 10, 493. [Google Scholar] [CrossRef]

- Trattnig, S.; Ohel, K.; Mlynarik, V.; Juras, V.; Zbyn, S.; Korner, A. Morphological and Compositional Monitoring of a New Cell-Free Cartilage Repair Hydrogel Technology—GelrinC by MR Using Semi-Quantitative MOCART Scoring and Quantitative T2 Index and New Zonal T2 Index Calculation. Osteoarthr. Cartil. 2015, 23, 2224–2232. [Google Scholar] [CrossRef]

- Ghorpade, V.S.; Yadav, A.V.; Dias, R.J.; Mali, K.K.; Pargaonkar, S.S.; Shinde, P.V.; Dhane, N.S. Citric Acid Crosslinked Carboxymethylcellulose-Poly(Ethylene Glycol) Hydrogel Films for Delivery of Poorly Soluble Drugs. Int. J. Biol. Macromol. 2018, 118, 783–791. [Google Scholar] [CrossRef]

| Samples | Total Carboxyl Content (mEq/100 g Hydrogel) | ||||||

|---|---|---|---|---|---|---|---|

| 1 h | 2 h | 3 h | 6 h | 8 h | 12 h | 24 h | |

| CG01 | 726 | 890 | 1043 | 1210 | 1203 | 1200 | 1350 |

| CG02 | 173 | 146 | 133 | 166 | 183 | 190 | 153 |

| Samples | Stages of Decomposition | T (Max) K | % Weight Loss | Residue (%) at 1073 K |

|---|---|---|---|---|

| CG01 | A | 472.14 | 84.48 | 15.52 |

| B | 581.73 | |||

| CG02 | A | 532.51 | 71.89 | 28.11 |

| B | 576.91 |

| Samples | DRY | WET | ||||

|---|---|---|---|---|---|---|

| Distilled Water | PBS | |||||

| Maximum Stress (MPa) | Strain at Max Stress (%) | Maximum Stress (MPa) | Strain at Max Stress (%) | Maximum Stress (MPa) | Strain at Max Stress (%) | |

| CG01 | 3.55 ± 0.84 | 70 | 2.57 ± 0.20 | 61 | 1.3 ± 0.09 | 55 |

| CG02 | 2.48 ± 0.63 | 70 | 2.27 ± 0.98 | 66 | 0.25 ± 0.03 | 42 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aswathy, S.H.; NarendraKumar, U.; Manjubala, I. Physicochemical Properties of Cellulose-Based Hydrogel for Biomedical Applications. Polymers 2022, 14, 4669. https://doi.org/10.3390/polym14214669

Aswathy SH, NarendraKumar U, Manjubala I. Physicochemical Properties of Cellulose-Based Hydrogel for Biomedical Applications. Polymers. 2022; 14(21):4669. https://doi.org/10.3390/polym14214669

Chicago/Turabian StyleAswathy, Sreeja Harikumar, Uttamchand NarendraKumar, and Inderchand Manjubala. 2022. "Physicochemical Properties of Cellulose-Based Hydrogel for Biomedical Applications" Polymers 14, no. 21: 4669. https://doi.org/10.3390/polym14214669

APA StyleAswathy, S. H., NarendraKumar, U., & Manjubala, I. (2022). Physicochemical Properties of Cellulose-Based Hydrogel for Biomedical Applications. Polymers, 14(21), 4669. https://doi.org/10.3390/polym14214669