Natural Hollow Fiber-Derived Carbon Microtube with Broadband Microwave Attenuation Capacity

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of KF-Derived Carbon Microtube

2.3. Characterizations

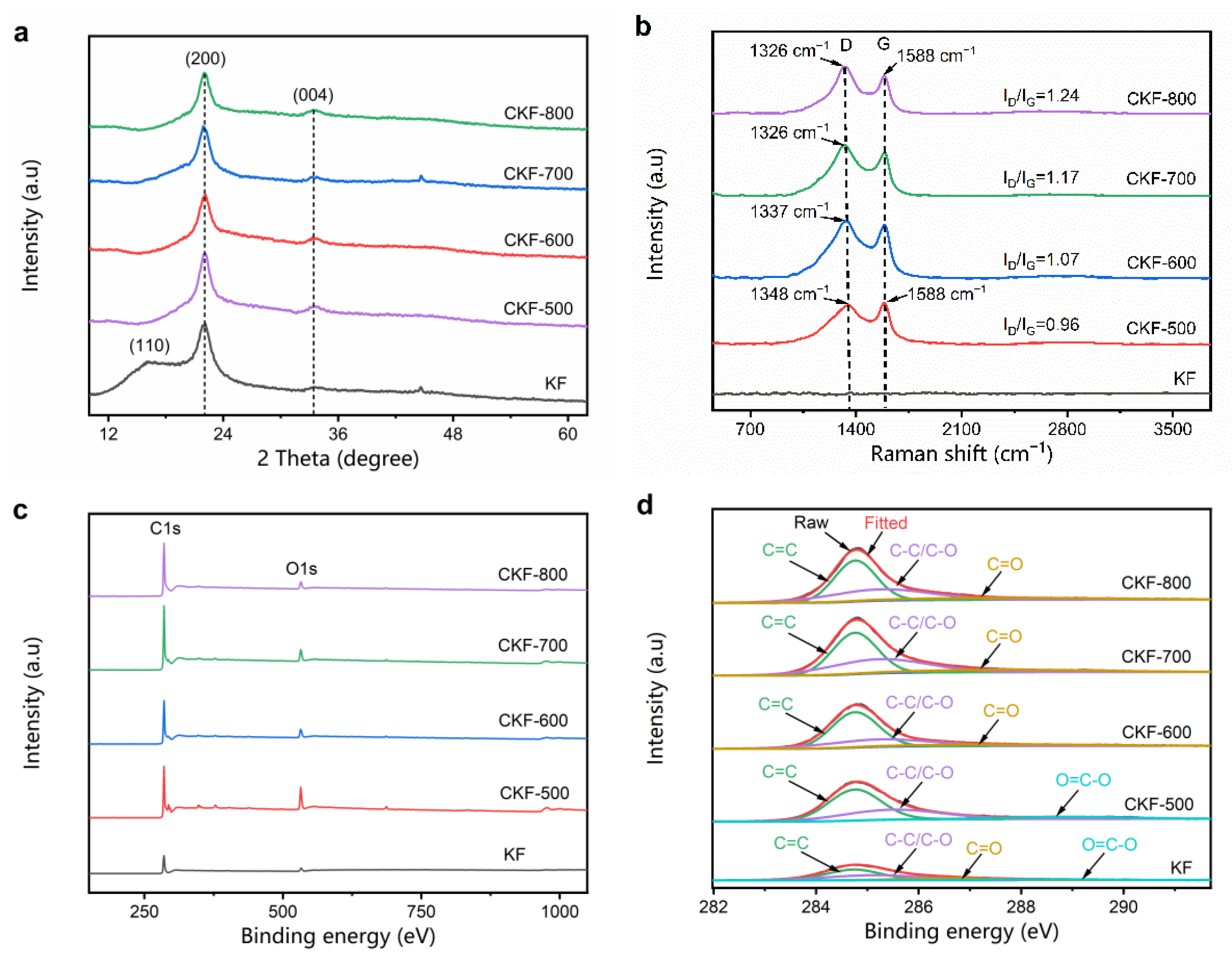

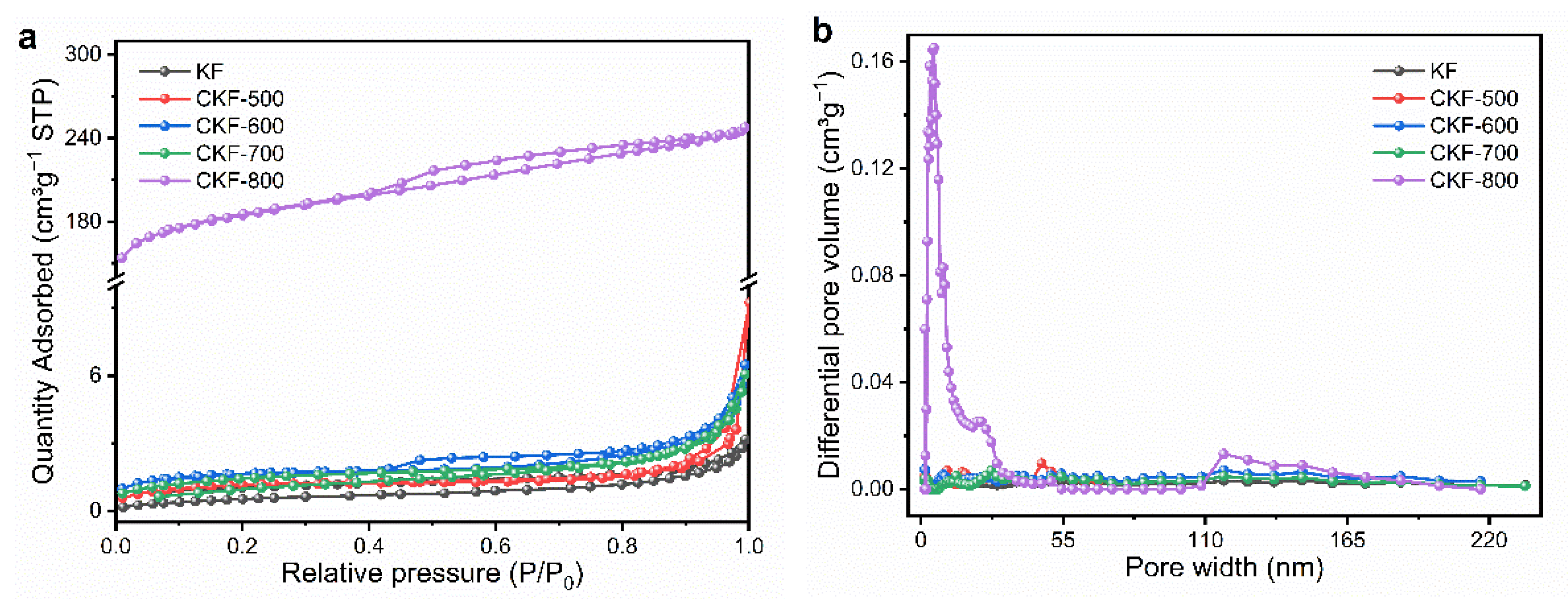

3. Results

3.1. Overview of KF-Derived Microtube as Microwave Absorber

3.2. Nanostructures and Morphology

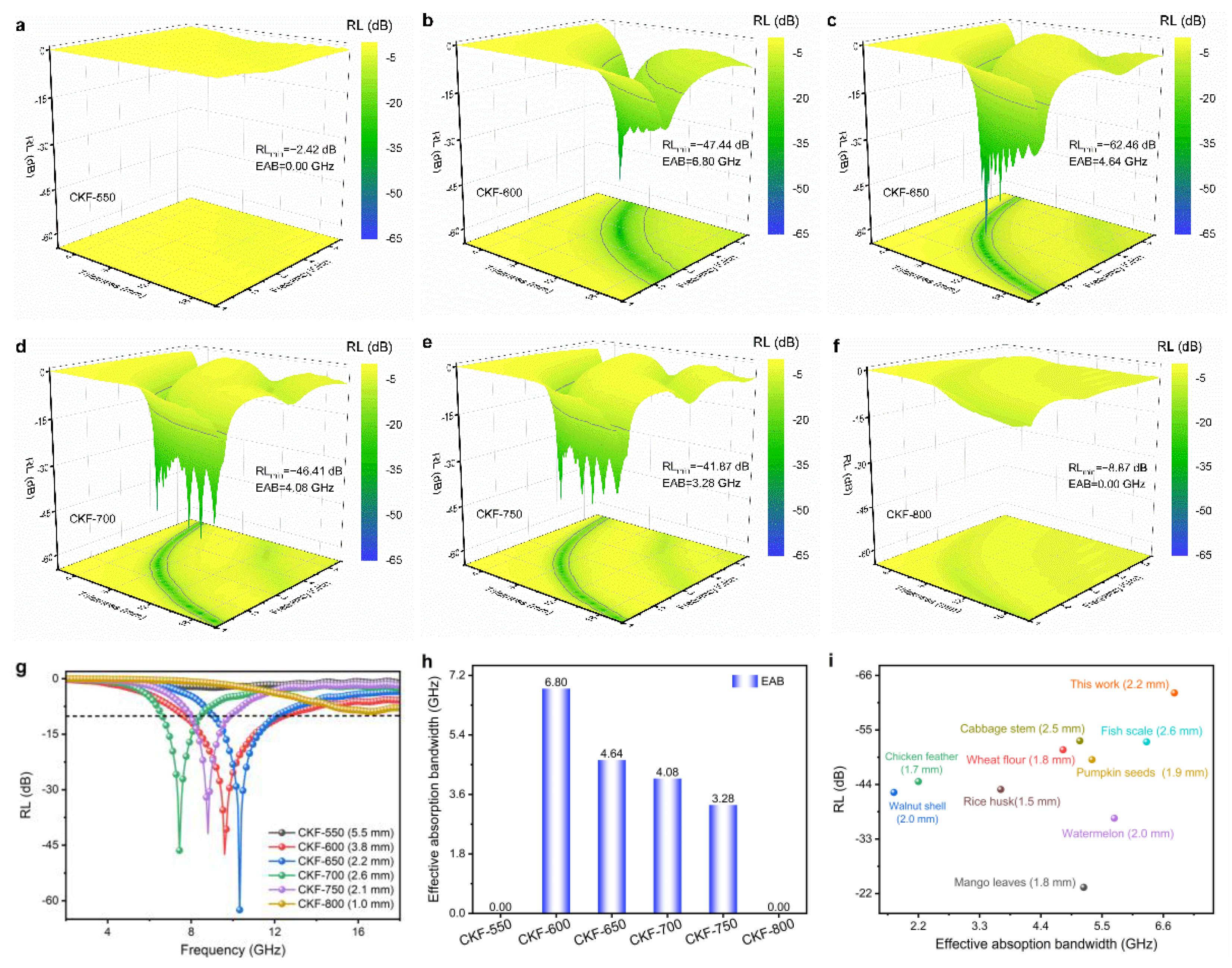

3.3. Microwave Absorbing Performance

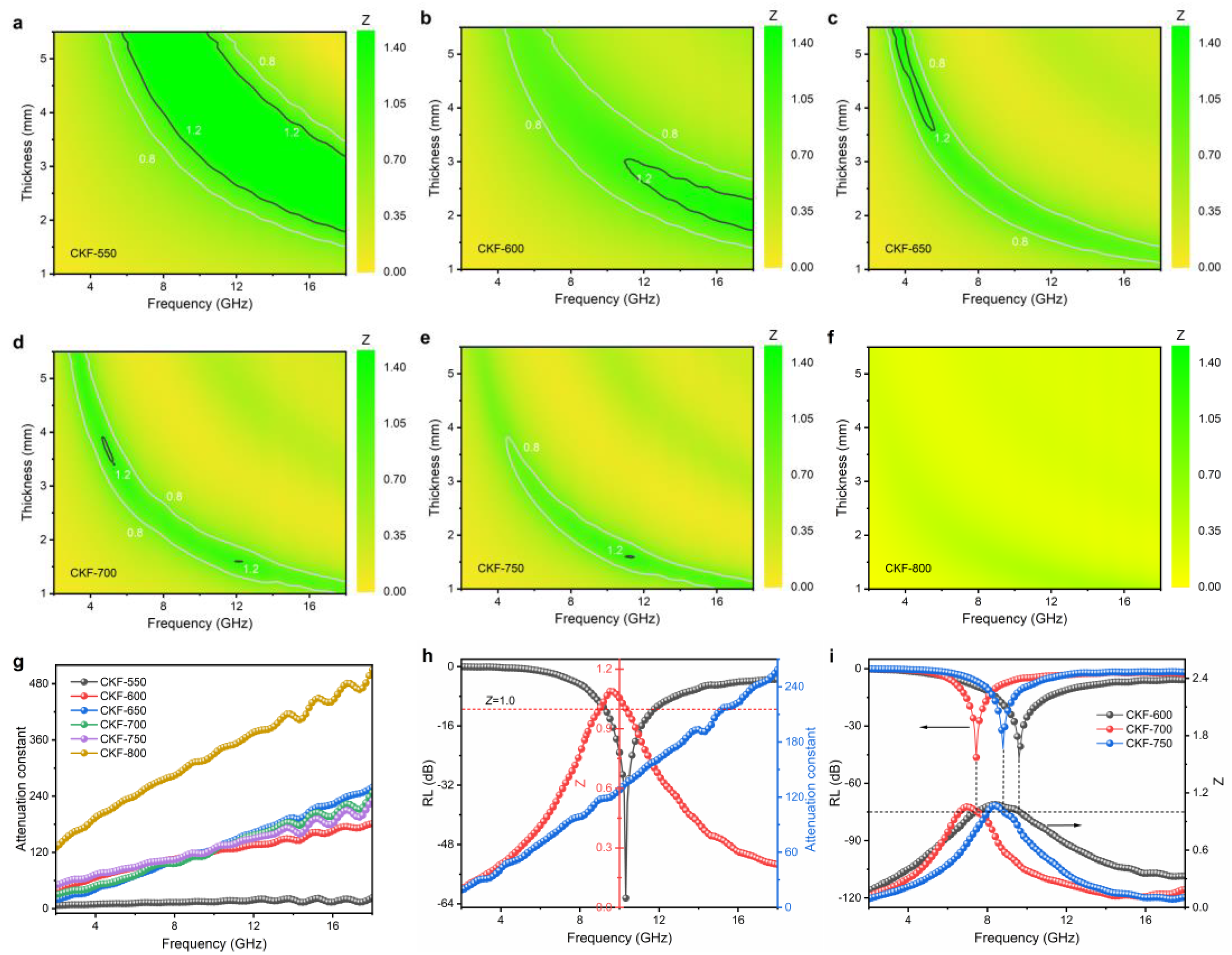

3.4. Attenuation Mechanism

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Thomassin, J.M.; Jérôme, C.; Pardoen, T.; Bailly, C.; Huynen, I.; Detrembleur, C. Polymer/carbon based composites as electromagnetic interference (EMI) shielding materials. Mater. Sci. Eng. R Rep. 2013, 74, 211–232. [Google Scholar] [CrossRef]

- Zeng, X.; Cheng, X.; Yu, R.; Stucky, G.D. Electromagnetic microwave absorption theory and recent achievements in microwave absorbers. Carbon 2020, 168, 606–623. [Google Scholar] [CrossRef]

- Ren, F.; Yu, H.; Wang, L.; Saleem, M.; Tian, Z.; Ren, P. Current progress on the modification of carbon nanotubes and their application in electromagnetic wave absorption. RSC Adv. 2014, 4, 14419–14431. [Google Scholar] [CrossRef]

- Xia, Y.; Gao, W.; Gao, C. A Review on Graphene-Based Electromagnetic Functional Materials: Electromagnetic Wave Shielding and Absorption. Adv. Funct. Mater. 2022, 32, 2204591. [Google Scholar] [CrossRef]

- El Assal, A.; Breiss, H.; Benzerga, R.; Sharaiha, A. Design and optimization of ultra-wideband planar multilayer absorber based on long-carbon fiber-loaded composites. J. Mater. Sci. 2021, 56, 19484–19500. [Google Scholar] [CrossRef]

- Zhang, X.; Qiao, J.; Jiang, Y.; Wang, F.; Tian, X.; Wang, Z.; Wu, L.; Liu, W.; Liu, J. Carbon-Based MOF Derivatives: Emerging Efficient Electromagnetic Wave Absorption Agents. Nano-Micro Lett. 2021, 13, 135. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, H.; Gu, W.; Yang, L.; Zhang, B. A biomass derived porous carbon for broadband and lightweight microwave absorption. Sci. Rep. 2019, 9, 18617. [Google Scholar] [CrossRef]

- Ma, X.; Li, Y.; Shen, B.; Zhang, L.; Chen, Z.; Liu, Y.; Zhai, W.; Zheng, W. Carbon Composite Networks with Ultrathin Skin Layers of Graphene Film for Exceptional Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2018, 10, 38255–38263. [Google Scholar] [CrossRef]

- Mondal, J.; Srivastava, S.K. δ-MnO2 Nanoflowers and Their Reduced Graphene Oxide Nanocomposites for Electromagnetic Interference Shielding. ACS Appl. Nano Mater. 2020, 3, 11048–11059. [Google Scholar] [CrossRef]

- González, M.; Baselga, J.; Pozuelo, J. High porosity scaffold composites of graphene and carbon nanotubes as microwave absorbing materials. J. Mater. Chem. C 2016, 4, 8575–8582. [Google Scholar] [CrossRef]

- Xu, H.; Yin, X.; Zhu, M.; Han, M.; Hou, Z.; Li, X.; Zhang, L.; Cheng, L. Carbon Hollow Microspheres with a Designable Mesoporous Shell for High-Performance Electromagnetic Wave Absorption. ACS Appl. Mater. Interfaces 2017, 9, 6332–6341. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Li, Y.; Huang, Y.; Cheng, Y.; Wang, S.; Yin, W. Achieving Super Broadband Electromagnetic Absorption by Optimizing Impedance Match of rGO Sponge Metamaterials. Adv. Funct. Mater. 2021, 32, 2107508. [Google Scholar] [CrossRef]

- Yang, D.P.; Li, Z.; Liu, M.; Zhang, X.; Chen, Y.; Xue, H.; Ye, E.; Luque, R. Biomass-Derived Carbonaceous Materials: Recent Progress in Synthetic Approaches, Advantages, and Applications. ACS Sustain. Chem. Eng. 2019, 7, 4564–4585. [Google Scholar] [CrossRef]

- Zhang, B.; Jiang, Y.; Balasubramanian, R. Synthesis, formation mechanisms and applications of biomass-derived carbonaceous materials: A critical review. J. Mater. Chem. A 2021, 9, 24759–24802. [Google Scholar] [CrossRef]

- Lyu, L.; Seong, K.-d.; Ko, D.; Choi, J.; Lee, C.; Hwang, T.; Cho, Y.; Jin, X.; Zhang, W.; Pang, H.; et al. Recent development of biomass-derived carbons and composites as electrode materials for supercapacitors. Mater. Chem. Front. 2019, 3, 2543–2570. [Google Scholar] [CrossRef]

- Lou, Z.; Wang, Q.; Kara, U.I.; Mamtani, R.S.; Zhou, X.; Bian, H.; Yang, Z.; Li, Y.; Lv, H.; Adera, S.; et al. Biomass-Derived Carbon Heterostructures Enable Environmentally Adaptive Wideband Electromagnetic Wave Absorbers. Nano-Micro Lett. 2021, 14, 11. [Google Scholar] [CrossRef]

- Guan, H.; Wang, Q.; Wu, X.; Pang, J.; Jiang, Z.; Chen, G.; Dong, C.; Wang, L.; Gong, C. Biomass derived porous carbon (BPC) and their composites as lightweight and efficient microwave absorption materials. Compos. Part B Eng. 2020, 207, 108562. [Google Scholar] [CrossRef]

- Liu, M.; Wang, S.; Jiang, L. Nature-inspired superwettability systems. Nat. Rev. Mater. 2017, 2, 17036. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, Z.; Chen, M.; Huang, Y.; Wang, C.; Song, W.L. From nanoscale to macroscale: Engineering biomass derivatives with nitrogen doping for tailoring dielectric properties and electromagnetic absorption. Appl. Surf. Sci. 2018, 439, 176–185. [Google Scholar] [CrossRef]

- Chen, X.; Zhou, M.; Zhao, Y.; Gu, W.; Wu, Y.; Tang, S.; Ji, G. Morphology control of eco-friendly chitosan-derived carbon aerogels for efficient microwave absorption at thin thickness and thermal stealth. Green Chem. 2022, 24, 5280–5290. [Google Scholar] [CrossRef]

- Qiu, X.; Wang, L.; Zhu, H.; Guan, Y.; Zhang, Q. Lightweight and efficient microwave absorbing materials based on walnut shell-derived nano-porous carbon. Nanoscale 2017, 9, 7408–7418. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Cheng, Y.; Lv, H.; Zhang, B.; Ji, G.; Du, Y. Achieving Sustainable Ultralight Electromagnetic Absorber from Flour by Turning Surface Morphology of Nanoporous Carbon. ACS Sustain. Chem. Eng. 2018, 6, 15850–15857. [Google Scholar] [CrossRef]

- Zheng, Y.; Song, Y.; Gao, T.; Yan, S.; Hu, H.; Cao, F.; Duan, Y.; Zhang, X. Lightweight and Hydrophobic Three-Dimensional Wood-Derived Anisotropic Magnetic Porous Carbon for Highly Efficient Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2020, 12, 40802–40814. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Lei, E.; Ma, C.; Wu, Z.; Xu, Z.; Liu, Y.; Li, W.; Liu, S. Fabrication of three-dimensional microtubular kapok fiber carbon aerogel/RuO2 composites for supercapacitors. Electrochim. Acta 2019, 300, 225–234. [Google Scholar] [CrossRef]

- Xi, J.; Zhou, E.; Liu, Y.; Gao, W.; Ying, J.; Chen, Z.; Gao, C. Wood-based straightway channel structure for high performance microwave absorption. Carbon 2017, 124, 492–498. [Google Scholar] [CrossRef]

- Xu, C.; Liu, P.; Wu, Z.; Zhang, H.; Zhang, R.; Zhang, C.; Wang, L.; Wang, L.; Yang, B.; Yang, Z.; et al. Customizing Heterointerfaces in Multilevel Hollow Architecture Constructed by Magnetic Spindle Arrays Using the Polymerizing-Etching Strategy for Boosting Microwave Absorption. Adv. Sci. 2022, 9, 2200804. [Google Scholar] [CrossRef]

- Huang, X.; Lu, M.; Zhang, X.; Wen, G.; Zhou, Y.; Fei, L. Carbon microtube/Fe3O4 nanocomposite with improved wave-absorbing performance. Scr. Mater. 2012, 67, 613–616. [Google Scholar] [CrossRef]

- Sun, J.; Wu, Z.; Ma, C.; Xu, M.; Luo, S.; Li, W.; Liu, S. Biomass-derived tubular carbon materials: Progress in synthesis and applications. J. Mater. Chem. A 2021, 9, 13822–13850. [Google Scholar] [CrossRef]

- Zhou, M.; Gu, W.; Wang, G.; Zheng, J.; Pei, C.; Fan, F.; Ji, G. Sustainable wood-based composites for microwave absorption and electromagnetic interference shielding. J. Mater. Chem. A 2020, 8, 24267–24283. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, J.; Wang, A. Recent advances in the potential applications of hollow kapok fiber-based functional materials. Cellulose 2021, 28, 5269–5292. [Google Scholar] [CrossRef]

- Long, A.; Zhao, P.; Liao, L.; Wang, R.; Tao, J.; Liao, J.; Liao, X.; Zhao, Y. Sustainable Kapok Fiber-Derived Carbon Microtube as Broadband Microwave Absorbing Material. Materials 2022, 15, 4845. [Google Scholar] [CrossRef] [PubMed]

- Rengasamy, R.; Das, D.; Karan, C.P. Study of oil sorption behavior of filled and structured fiber assemblies made from polypropylene, kapok and milkweed fibers. J. Hazard. Mater. 2011, 186, 526–532. [Google Scholar] [CrossRef] [PubMed]

- Song, P.; Cui, J.; Di, J.; Liu, D.; Xu, M.; Tang, B.; Zeng, Q.; Xiong, J.; Wang, C.; He, Q.; et al. Carbon Microtube Aerogel Derived from Kapok Fiber: An Efficient and Recyclable Sorbent for Oils and Organic Solvents. ACS Nano 2019, 14, 595–602. [Google Scholar] [CrossRef] [PubMed]

- Geng, H.; Zhang, X.; Xie, W.; Zhao, P.; Wang, G.; Liao, J.; Dong, L. Lightweight and broadband 2D MoS2 nanosheets/3D carbon nanofibers hybrid aerogel for high-efficiency microwave absorption. J. Colloid Interface Sci. 2021, 609, 33–42. [Google Scholar] [CrossRef] [PubMed]

- Ding, C.; Fu, H.; Wu, T.; Tang, Y.; Hu, X.; Wu, S.; Zhang, L.; Wen, G.; Huang, X. Heterogeneous network constructed by high aspect-ratio Kapok biomass microtube for lightweight and broadband microwave absorbent. Carbon 2022, 191, 424–432. [Google Scholar] [CrossRef]

- Yang, X.; Pang, X.; Cao, M.; Liu, X.; Li, X. Efficient microwave absorption induced by hierarchical pores of reed-derived ultralight carbon materials. Ind. Crops Prod. 2021, 171, 113814. [Google Scholar] [CrossRef]

- Zhao, H.; Cheng, Y.; Liu, W.; Yang, L.; Zhang, B.; Wang, L.P.; Ji, G.; Xu, Z.J. Biomass-Derived Porous Carbon-Based Nanostructures for Microwave Absorption. Nano-Micro Lett. 2019, 11, 24. [Google Scholar] [CrossRef]

- Negi, P.; Chhantyal, A.K.; Dixit, A.K.; Kumar, S.; Kumar, A. Activated carbon derived from mango leaves as an enhanced microwave absorbing material. Sustain. Mater. Technol. 2020, 27, e00244. [Google Scholar] [CrossRef]

- Singh, S.K.; Prakash, H.; Akhtar, M.J.; Kar, K.K. Lightweight and High-Performance Microwave Absorbing Heteroatom-Doped Carbon Derived from Chicken Feather Fibers. ACS Sustain. Chem. Eng. 2018, 6, 5381–5393. [Google Scholar] [CrossRef]

- Wang, N.; Wu, F.; Xie, A.M.; Dai, X.; Sun, M.; Qiu, Y.; Wang, Y.; Lv, X.; Wang, M. One-pot synthesis of biomass-derived carbonaceous spheres for excellent microwave absorption at the Ku band. RSC Adv. 2015, 5, 40531–40535. [Google Scholar] [CrossRef]

- Zhou, X.; Jia, Z.; Feng, A.; Wang, K.; Liu, X.; Chen, L.; Cao, H.; Wu, G. Dependency of tunable electromagnetic wave absorption performance on morphology-controlled 3D porous carbon fabricated by biomass. Compos. Commun. 2020, 21, 100404. [Google Scholar] [CrossRef]

- Zhou, X.; Jia, Z.; Feng, A.; Wang, X.; Liu, J.; Zhang, M.; Cao, H.; Wu, G. Synthesis of fish skin-derived 3D carbon foams with broadened bandwidth and excellent electromagnetic wave absorption performance. Carbon 2019, 152, 827–836. [Google Scholar] [CrossRef]

- Li, Q.; Zhu, J.; Wang, S.; Huang, F.; Liu, Q.; Kong, X. Microwave absorption on a bare biomass derived holey silica-hybridized carbon absorbent. Carbon 2020, 161, 639–646. [Google Scholar] [CrossRef]

- Lv, H.; Yang, Z.; Pan, H.; Wu, R. Electromagnetic absorption materials: Current progress and new frontiers. Prog. Mater. Sci. 2022, 127, 100946. [Google Scholar] [CrossRef]

- Liang, L.; Gu, W.; Wu, Y.; Zhang, B.; Wang, G.; Yang, Y.; Ji, G. Heterointerface Engineering in Electromagnetic Absorbers: New Insights and Opportunities. Adv. Mater. 2021, 34, 2106195. [Google Scholar] [CrossRef]

- Wu, Z.; Tian, K.; Huang, T.; Hu, W.; Xie, F.; Wang, J.; Su, M.; Li, L. Hierarchically Porous Carbons Derived from Biomasses with Excellent Microwave Absorption Performance. ACS Appl. Mater. Interfaces 2018, 10, 11108–11115. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Long, A.; Zhao, P.; Liao, L.; Wang, R.; Li, G.; Wang, B.; Liao, X.; Yu, R.; Liao, J. Natural Hollow Fiber-Derived Carbon Microtube with Broadband Microwave Attenuation Capacity. Polymers 2022, 14, 4501. https://doi.org/10.3390/polym14214501

Zhao Y, Long A, Zhao P, Liao L, Wang R, Li G, Wang B, Liao X, Yu R, Liao J. Natural Hollow Fiber-Derived Carbon Microtube with Broadband Microwave Attenuation Capacity. Polymers. 2022; 14(21):4501. https://doi.org/10.3390/polym14214501

Chicago/Turabian StyleZhao, Yanfang, Aichun Long, Pengfei Zhao, Lusheng Liao, Rui Wang, Gaorong Li, Bingbing Wang, Xiaoxue Liao, Rentong Yu, and Jianhe Liao. 2022. "Natural Hollow Fiber-Derived Carbon Microtube with Broadband Microwave Attenuation Capacity" Polymers 14, no. 21: 4501. https://doi.org/10.3390/polym14214501

APA StyleZhao, Y., Long, A., Zhao, P., Liao, L., Wang, R., Li, G., Wang, B., Liao, X., Yu, R., & Liao, J. (2022). Natural Hollow Fiber-Derived Carbon Microtube with Broadband Microwave Attenuation Capacity. Polymers, 14(21), 4501. https://doi.org/10.3390/polym14214501