Need for Sustainable Packaging: An Overview

Abstract

1. Introduction

2. Types of Packaging Materials

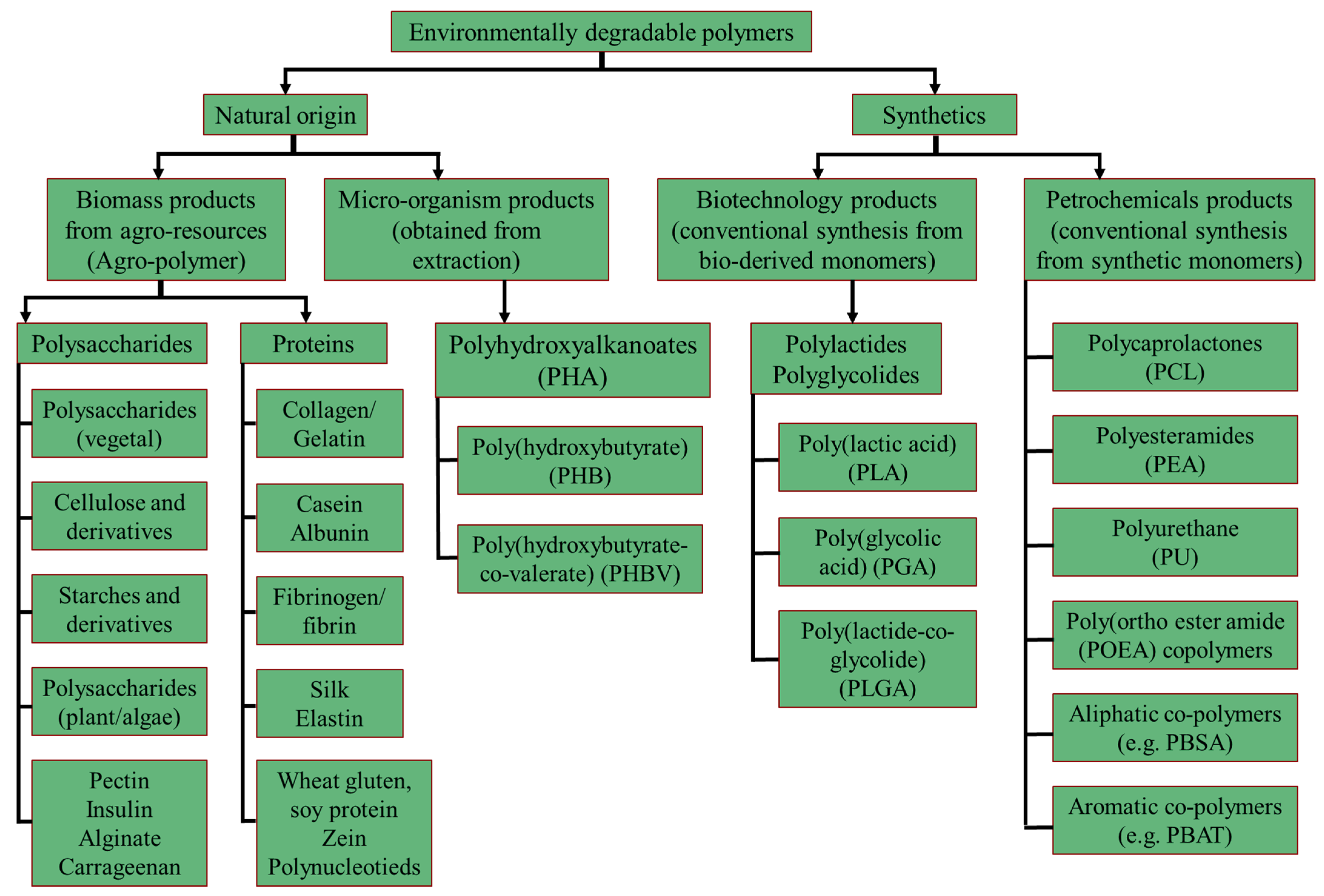

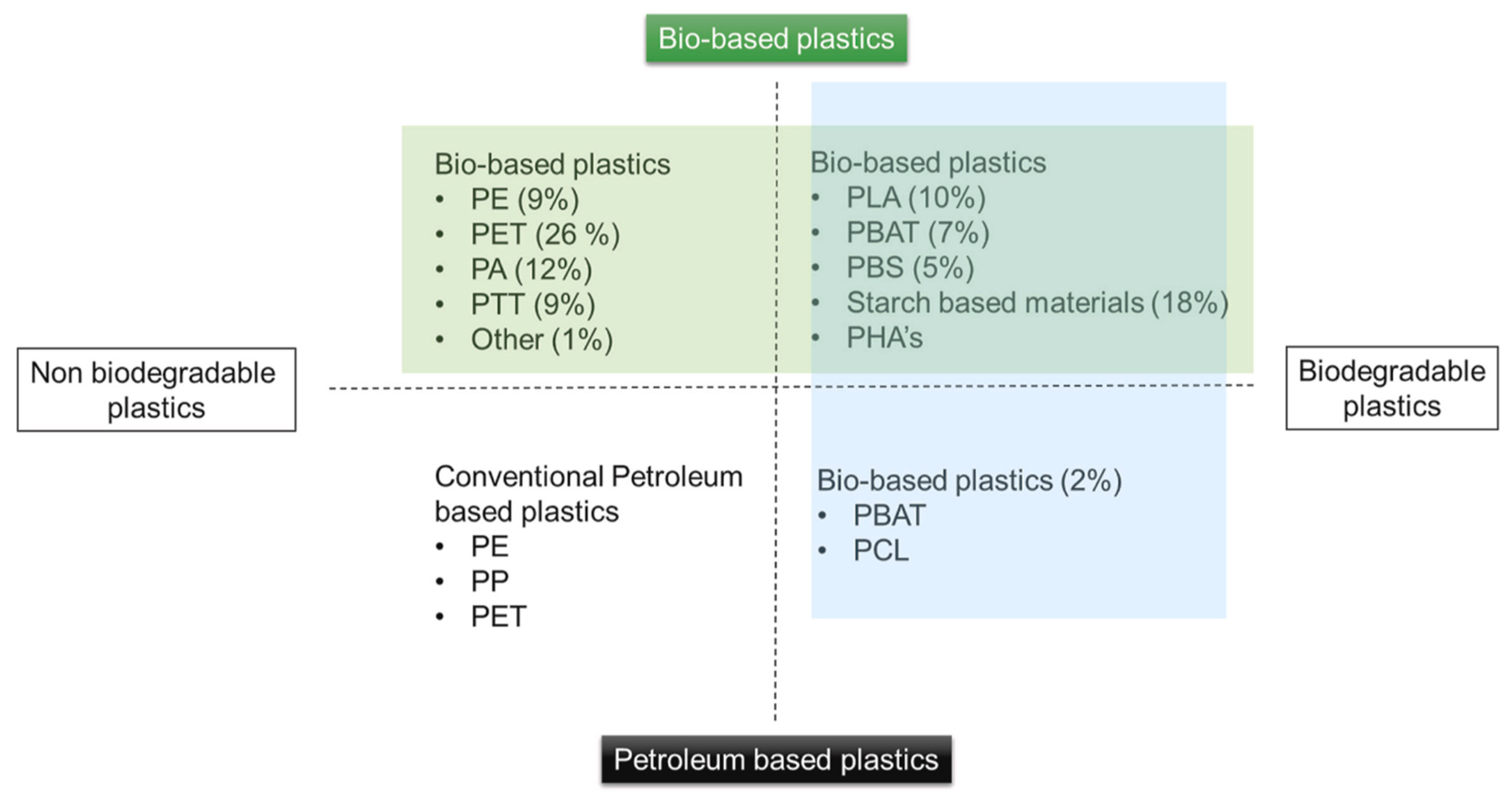

2.1. Plastics

- Biomass sources: the extraction of biopolymers directly from polysaccharides (e.g., cellulose, starch, galactomannans) and proteins (e.g., gluten and casein)

- Microorganism sources: the production of biopolymers by microorganisms. These polymers include polyhydroxyalkanoates (PHA) and polysaccharides.

- Chemical sources: the chemical synthesizing of bio-based monomers, such as polylactic-acid (PLA), and the lactic acid-based thermoplastic aliphatic polyester.

Drawbacks of Plastic Packaging Materials

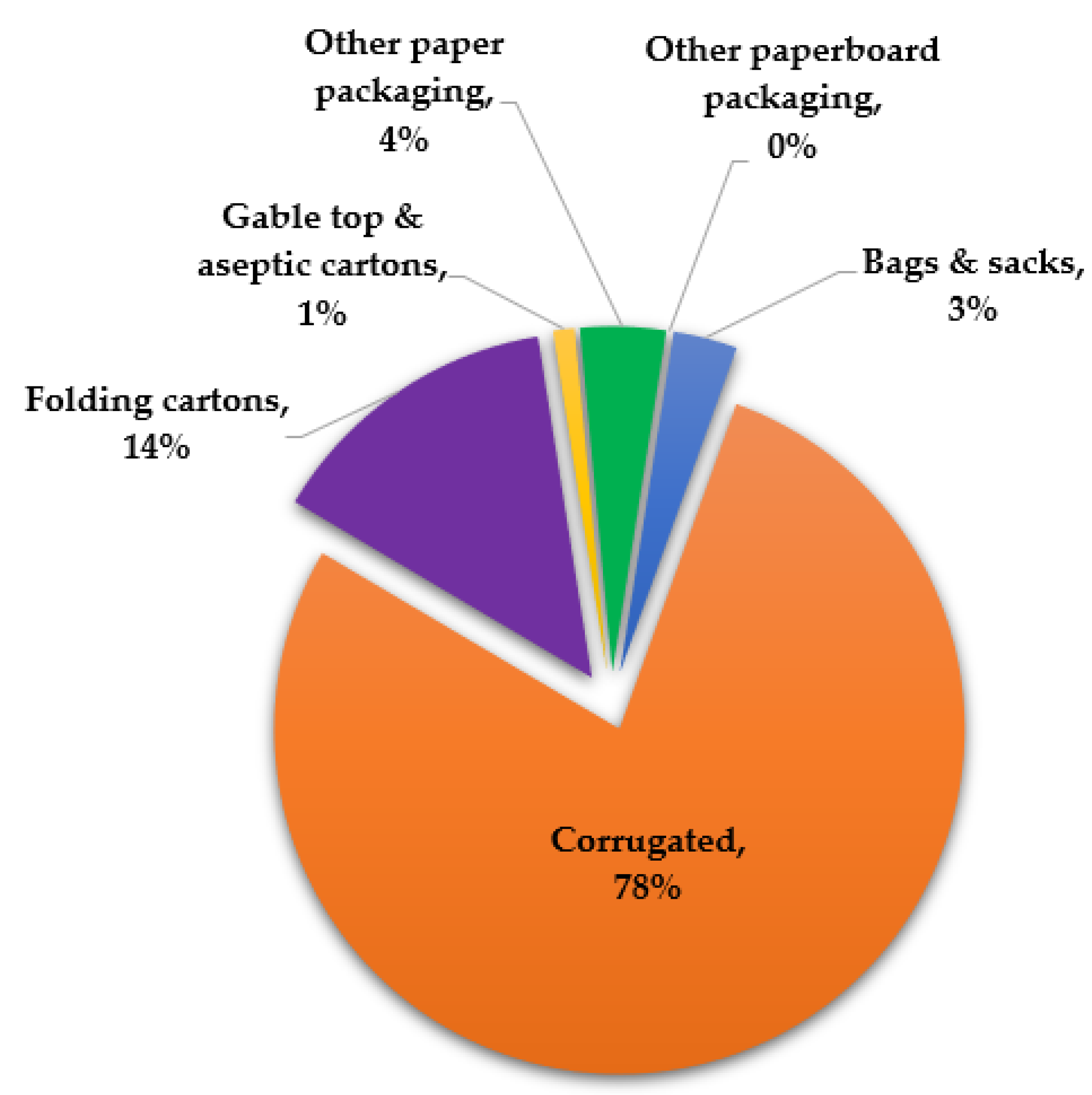

2.2. Paper and Paperboard

2.3. Glass

Drawbacks of Glass Packaging Materials

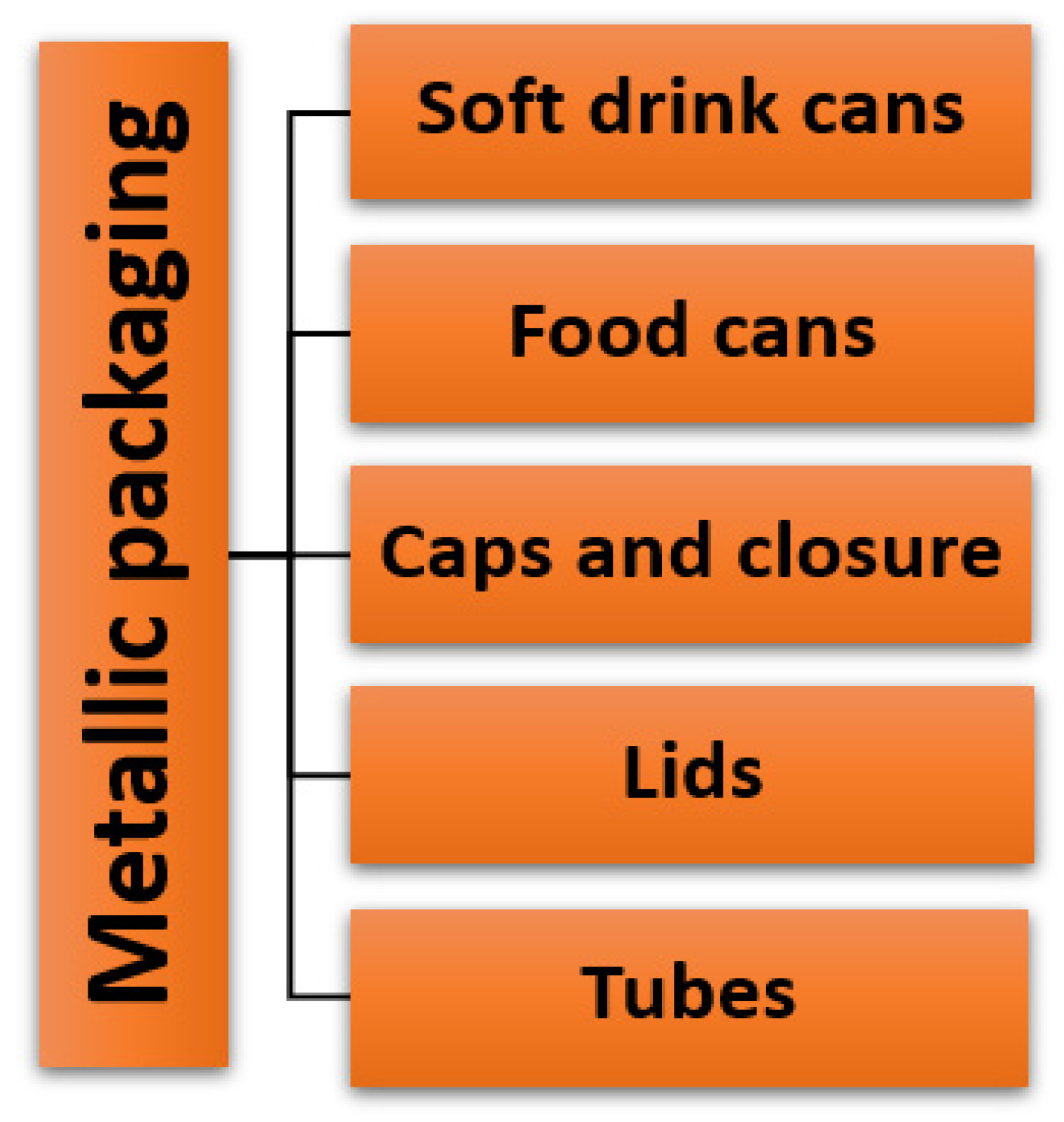

2.4. Metal

- Aluminum (Al)–It has excellent properties, such as recyclability, decorative potential, formability, physical protection, etc., making it the most used metal-based material for packaging [41]. Packaging materials are not made from pure aluminum; instead, alloys of aluminum are made by alloying it with other alloying metals, such as zinc, copper, silver, iron, and manganese. Traces of these metals can often be found in the content of the container when they corrode [52]. A high intake of Aℓ may lead to certain disorders in humans, and therefore, the content of corroded containers should not be consumed. Aluminum is used for canned drinks, and it can also be in the form of foil. The foil can either be thin or thick. Thin foils are often used to wrap food, while thick foils are used for trays, baking pans, etc. Foil provides a brilliant barrier to moisture, light temperatures, air odors and microorganisms. The use of aluminum-based packaging materials in microwave heating has been a major concern. Walsh and Kerry [41] reported in their study how the Fraunhofer Institute for Process Engineering and Packaging IVV in Freising, Germany, concluded that aluminum-based packaged food could be heated in a microwave. This was based on over 200 food samples that were heated in the microwave without any harmful outcomes recorded. Aluminum-based materials also give more uniformity in heating than other viable materials. The only drawback is that it takes about three times the normal time to heat in a microwave. Thus, this makes it an unpopular choice when it comes to the microwave heating of aluminum-based packaging materials [53].

- Tin (Sn)–This is often used to coat steel when used for packaging foodstuffs, and this is often achieved by the electrochemical deposition of tin onto the surface of the metal being coated. The area of application determines the level of coating, which ranges from 2.8 to 15.4 g/m2 [51]. Tin-coated containers should not be used directly for wet content due to the possibility of it dissolving in its content. This is why tin-coated metals used for wet food content are usually shielded with an organic protective coating. For dry foods, the tin-coated container may not be protected with an organic protective coating. To prevent any extra consumption of tin, or other metallic substances, there is a regulation on acceptable limits. The EU regulation limits the levels of tin in canned foods (excluding beverages) and beverages and foodstuffs for infants, respectively, to 200, 100 and 50 mg/kg. In most non-EU countries, the Codex Alimentarius advises limits of between 150 and 250 mg/kg for liquid and dry foods, respectively [51].

- Lead (Pb)–Lead-based containers are directly used for packaging, but they are also found in containers made from tin. This is possible due to Sn and Pb coexisting in the ore, and therefore, Pb contaminates the Sn and ultimately contaminates the food content if proper and due diligence is not followed in terms of the regulations surrounding the allowable lead limit in foodstuffs. According to EU regulation No 466/2001, the traces of lead content in foodstuffs should be within a range from 0.02 to 0.1 mg/kg. As explained in the European Standard EN 10333, the level of lead in tin-coated packaging containers has been reduced to a maximum of 100 mg/kg by industrial action in the USA and Europe [51]. Lead is toxic and could damage the organs in the human body, and the central nervous system could also be seriously damaged [54]. A high level of lead in children could cause convulsions, mental retardation, and encephalopathy (brain disease) [55].

- Chromium (Cr)–This is mostly used in tin-based containers, such as cans as a thin layer to improve their properties, including strength and stability against high oxidation levels [54]. High toxicity is associated with Cr and hexavalent forms, which could impact living organisms severely due to mutagenic and carcinogenic properties [56]. The level of Cr in tin-coated foodstuff containers is negligible and, thus, not of any health concern. There is no regulation for the Cr content in foodstuff, but for drinking water, the World Health Organization (WHO) has it limited to 0.025 mg/L.

3. Areas of Application of Packaging Materials

3.1. Food

3.2. Cosmetics

3.3. Pharmaceuticals

- Adaptable to high-speed packaging machines

- Approved by the Food and Drug Administration (FDA)

- Does not impart odor or taste to the product

- Non-reactive with the product

- Non-toxic

- Prevention and preparedness against environmental conditions

- Protects the dosage form against breakage or damage

- Tamper-resistant when necessary.

3.4. Meat, Poultry and Seafood

- Environment–The physical condition to which the food products are exposed (e.g., light, relative humidity, temperature, and customer handling).

- Product characteristics–These include physical, chemical, biological, etc.

- Packaging–The property/quality of the packaging material.

4. Measures for Improving Sustainability in Packaging

5. Conclusions

- Plastics—an inappropriate disposal and recycling mechanism can lead to the accumulation of plastics in landfills and water bodies (causing serious havoc on the aquatic organisms). The best practices should be encouraged and enforced. Manufacturers should be restricted to using plastic materials that are 100% recyclable, biodegradable, reusable, etc.

- Paper—is prone to chemical attacks and moisture absorption. The paper or paperboard can be coated with certain polymers, which provide the required barrier against chemical attacks and moisture absorption. Furthermore, the coating provides some form of improvement, such as strength and chemical resistance.

- Glass—has limitations, such as a high weight, breakage, fragility to thermal expansions or contractions and is not ideal for extreme temperatures. Similarly, when not properly handled during handling and transit, it could lead to physical injuries. Glass is highly recyclable and can be used for other purposes, including aggregates in concrete.

- Metal—is prone to corrosion due to moisture; thus, it can be coated with certain metals. Careful consideration is encouraged to minimize metal interaction with its contents and ensure that metal contamination is within the allowable limit according to various global regulations.

- Problematic and/or unnecessary plastic packaging materials should be eradicated through innovative and environmentally friendly approaches.

- The general goal behind packaging materials should be to ensure that no material ends up as waste.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Otto, S.; Strenger, M.; Maier-Nöth, A.; Schmid, M. Food packaging and sustainability–Consumer perception vs. correlated scientific facts: A review. J. Clean. Prod. 2021, 298, 126733. [Google Scholar] [CrossRef]

- Martin, J.; Henrichs, T.; Francis, C.; Hoogeveen, Y.; Kazmierczyk, P.; Pignatelli, R.; Speck, S. Environmental Indicator Report 2012: Ecosystem Resilience and Resource Efficiency in a Green Economy in Europe; European Environment Agency: Copenhagen, Denmark, 2012. [Google Scholar]

- Reichert, C.L.; Bugnicourt, E.; Coltelli, M.B.; Cinelli, P.; Lazzeri, A.; Canesi, I.; Braca, F.; Martínez, B.M.; Alonso, R.; Agosti-nis, L.; et al. Bio-based packaging: Materials, modifications, industrial applications and sustainability. Polymers 2020, 12, 1558. [Google Scholar] [CrossRef]

- Álvarez-Chávez, C.R.; Edwards, S.; Moure-Eraso, R.; Geiser, K. Sustainability of bio-based plastics: General comparative analysis and recommendations for improvement. J. Clean. Prod. 2012, 23, 47–56. [Google Scholar] [CrossRef]

- Hottle, T.A.; Bilec, M.M.; Landis, A.E. Sustainability assessments of bio-based polymers. Polym. Degrad. Stab. 2013, 98, 1898–1907. [Google Scholar] [CrossRef]

- De Feo, G.; Ferrara, C.; Minichini, F. Comparison between the perceived and actual environmental sustainability of bever-age packagings in glass, plastic, and aluminium. J. Clean. Prod. 2022, 333, 130158. [Google Scholar] [CrossRef]

- Walther, B.A.; Kusui, T.; Yen, N.; Hu, C.S.; Lee, H. Plastic pollution in East Asia: Macroplastics and microplastics in the aquatic environment and mitigation efforts by various actors. In Plastic Aquatic Environ—Part I; Springer Nature: Cham, Switzerland, 2020; pp. 353–403. [Google Scholar]

- Defruyt, S. Towards a new plastics economy. Field Actions Science Reports. J. Field Actions 2019, 78–81. [Google Scholar]

- Hamouda, T. Biopolymers and Biocomposites from Agro-Waste for Packaging Applications; Saba, N., Jawaid, M., Thariq, M., Eds.; Woodhead Publishing: Sawston, UK, 2021; pp. 113–126. [Google Scholar]

- Schmid, M.; Agulla, K. Both ecological and economical. Kunstst. Int. 2012, 102, 50–53. [Google Scholar]

- Han, J.H. New technologies in food packaging: Overiew. In Innovations in Food Packaging; Academic Press: Cambridge, MA, USA, 2005; pp. 3–11. [Google Scholar]

- Kirwan, M.J.; Plant, S.; Strawbridge, J.W. Food and Beverage Packaging Technology; John Wiley & Sons: Hoboken, NJ, USA, 2011; pp. 157–212. [Google Scholar]

- Ncube, L.K.; Ude, A.U.; Ogunmuyiwa, E.N.; Zulkifli, R.; Beas, I.N. An overview of plastic waste generation and management in food packaging industries. Recycling 2021, 6, 12. [Google Scholar] [CrossRef]

- Muranko, Ż.; Tassell, C.; Zeeuw van der Laan, A.; Aurisicchio, M. Characterisation and environmental value proposition of reuse models for fast-moving consumer goods: Reusable packaging and products. Sustainability 2021, 13, 2609. [Google Scholar] [CrossRef]

- Verma, M.K.; Shakya, S.; Kumar, P.; Madhavi, J.; Murugaiyan, J.; Rao, M.V.R. Trends in packaging material for food products: Historical background, current scenario, and future prospects. J. Food Sci. Technol. 2021, 58, 4069–4082. [Google Scholar] [CrossRef]

- Song, T.; Qian, S.; Lan, T.; Wu, Y.; Liu, J.; Zhang, H. Recent Advances in Bio-Based Smart Active Packaging Materials. Foods 2022, 11, 2228. [Google Scholar] [CrossRef]

- Cvek, M.; Paul, U.C.; Zia, J.; Mancini, G.; Sedlarik, V.; Athanassiou, A. Biodegradable films of PLA/PPC and curcumin as packaging materials and smart indicators of food spoilage. ACS Appl. Mater. Interfaces 2022, 14, 14654–14667. [Google Scholar] [CrossRef]

- Pal, M.; Devrani, M.; Hadush, A. Recent developments in food packaging technologies. Beverage Food World 2019, 46, 21–25. [Google Scholar]

- Mendes, A.C.; Pedersen, G.A. Perspectives on sustainable food packaging:–is bio-based plastics a solution? Trends in Food Sci. Technol. 2021, 112, 839–846. [Google Scholar] [CrossRef]

- MacArthur, E.; Waughray, D.; Stuchtey, M. Rethinking Plastics, Starting with Packaging; World Economic Forum: Cologny, Switzerland, 2016; pp. 1–206. [Google Scholar]

- Rutkowska, M.; Heimowska, A.; Krasowska, K.; Janik, H. Biodegradability of polyethylene starch blends in sea water. Polish J. Environ. Stud. 2002, 11, 267–272. [Google Scholar]

- Chatterjee, S.; Sharma, S. Microplastics in our oceans and marine health. Field Actions Science Reports. J. Field Actions 2019, 54–61. [Google Scholar]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Advan. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Plastic Europe. Plastics the Facts 2014/2015: An Analysis of European Plastics Production, Demand and Waste Data; Plastic Europe: Brussels, Belgium, 2015. [Google Scholar]

- Zhong, Y.; Godwin, P.; Jin, Y.; Xiao, H. Biodegradable polymers and green-based antimicrobial packaging materials: A mini-review. Adv. Ind. Eng. Polym. Res. 2020, 3, 27–35. [Google Scholar] [CrossRef]

- Singh, R.; Sharma, R.; Shaqib, M.; Sarkar, A.; Chauhan, K.D. Biopolymers and Their Industrial Applications; Thomas, S., Gopi, S., Amalraj, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 245–259. [Google Scholar] [CrossRef]

- Ferreira, A.R.; Alves, V.D.; Coelhoso, I.M. Polysaccharide-based membranes in food packaging applications. Membranes 2016, 6, 22. [Google Scholar] [CrossRef]

- Popa, M.; Mitelut, A.; Niculita, P.; Geicu, M.; Ghidurus, M.; Turtoi, M. Biodegradable materials for food packaging applications. J. Environ. Protec. Ecolo. 2011, 12, 1825–1834. [Google Scholar]

- Malathi, A.; Santhosh, K.; Nidoni, U. Recent trends of biodegradable polymer: Biodegradable films for food packaging and application of nanotechnology in biodegradable food packaging. Curr. Trends Technol. Sci. 2014, 3, 73–79. [Google Scholar]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compo. Part A Appl. Sci. Manufac. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Chinaglia, S.; Tosin, M.; Degli-Innocenti, F. Biodegradation rate of biodegradable plastics at molecular level. Polym. Degrad. Stab. 2018, 147, 237–244. [Google Scholar] [CrossRef]

- Cela, E.; Kaneko, S. Determining the effectiveness of the Danish packaging tax policy: The case of paper and paperboard packaging imports. Resour. Conserv. Recycl. 2011, 55, 836–841. [Google Scholar] [CrossRef]

- Chen, W.; Wang, X.; Tao, Q.; Wang, J.; Zheng, Z.; Wang, X. Lotus-like paper/paperboard packaging prepared with nano-modified overprint varnish. Appl. Sur. Sci. 2013, 266, 319–325. [Google Scholar] [CrossRef]

- Asgher, M.; Qamar, S.A.; Bilal, M.; Iqbal, H.M.N. Bio-based active food packaging materials: Sustainable alternative to conventional petrochemical-based packaging materials. Food Res. Int. 2020, 137, 109625. [Google Scholar] [CrossRef]

- Muller, J.; González-Martínez, C.; Chiralt, A. Combination of poly (lactic) acid and starch for biodegradable food packaging. Materials 2017, 10, 952. [Google Scholar] [CrossRef]

- Rhim, J.W.; Lee, J.H.; Hong, S.I. Increase in water resistance of paperboard by coating with poly (lactide). Pack. Technol. Sci. Int. J. 2007, 20, 393–402. [Google Scholar] [CrossRef]

- Lahtinen, K.; Maydannik, P.; Johansson, P.; Kääriäinen, T.; Cameron, D.C.; Kuusipalo, J. Utilisation of continuous atomic layer deposition process for barrier enhancement of extrusion-coated paper. J. Surf. Coat. Technol. 2011, 205, 3916–3922. [Google Scholar] [CrossRef]

- Coles, R. Paper and paperboard innovations and developments for the packaging of food, beverages and other fast-moving consumer goods. In Trends in Packaging of Food, Beverages and Other Fast-Moving Consumer Goods (FMCG); Farmer, N., Ed.; Woodhead Publishing: Sawston, UK, 2013; pp. 187–220. [Google Scholar] [CrossRef]

- Riley, A. Paper and paperboard packaging. In Packaging Technology; Emblem, A., Emblem, H., Eds.; Woodhead Publishing: Sawston, UK, 2012; pp. 178–239. [Google Scholar] [CrossRef]

- Selke, S.E.M. Packaging: Corrugated Paperboard. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2016; pp. 1–9. [Google Scholar] [CrossRef]

- Walsh, H.; Kerry, J.P. Packaging of ready-to-serve and retail-ready meat, poultry and seafood products. In Advances in Meat, Poultry and Seafood Packaging; Kerry, J.P., Ed.; Woodhead Publishing: Sawston, UK, 2012; pp. 406–436. [Google Scholar] [CrossRef]

- Schiffmann, R. Packaging for microwave foods. In The Microwave Processing of Foods, 2nd ed.; Regier, M., Knoerzer, K., Schubert, H., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 273–299. [Google Scholar] [CrossRef]

- Kobayashi, M.L. Glass Packaging Properties and Attributes. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Marsh, K.; Bugusu, B. Food packaging—Roles, materials, and environmental issues. J. Food Sci. 2007, 72, R39–R55. [Google Scholar] [CrossRef]

- Kobayashi, M.L.; Benassi, M.d.T. Impact of packaging characteristics on consumer purchase intention: Instant coffee in refill packs and glass jars. J. Sens. Stud. 2015, 30, 169–180. [Google Scholar] [CrossRef]

- Corso, M.P.; Benassi, M.D.T. Packaging attributes of antioxidant-rich instant coffee and their influence on the purchase intent. Beverages 2015, 1, 273–291. [Google Scholar] [CrossRef]

- Franco, I.; Falqué, E. Glass Packaging. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Grayhurst, P.; Girling, P.J. Packaging of food in glass containers. In Food and Beverage Packaging Technology; Blackwell Publishing Ltd.: Hoboken, NJ, USA, 2011; pp. 137–156. [Google Scholar]

- Vinci, G.; D’Ascenzo, F.; Esposito, A.; Musarra, M. Glass Beverages Packaging: Innovation by Sustainable Production. In Trends in Beverage Packaging; Grumezescu, A.M., Holban, A.M., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 105–133. [Google Scholar] [CrossRef]

- Girling, P. Food Packaging Technology; Blackwell Publishing: London, UK; CRC Press: Boca Raton, FL, USA, 2003; pp. 152–173. [Google Scholar]

- Whitaker, R. Metal packaging and chemical migration into food. In Chemical Migration and Food Contact Materials; Barnes, K.A., Sinclair, C.R., Watson, D.H., Eds.; Woodhead Publishing: Sawston, UK, 2007; pp. 251–270. [Google Scholar] [CrossRef]

- Rodushkin, I.; Magnusson, A. Aluminium migration to orange juice in laminated paperboard packages. J. Food Compos. Anal. 2005, 18, 365–374. [Google Scholar] [CrossRef]

- Annette, F. Future Food and Drinks Packaging; Simon Fraser University: Burnaby, BC, Canada, 2008. [Google Scholar]

- Alamri, M.S.; Qasem, A.A.A.; Mohamed, A.A.; Hussain, S.; Ibraheem, M.A.; Shamlan, G.; Alqah, H.A.; Qasha, A.S. Food packaging’s materials: A food safety perspective. Saudi J. Biol. Sci. 2021, 28, 4490–4499. [Google Scholar] [CrossRef] [PubMed]

- Skrzydlewska, E.; Balcerzak, M.; Vanhaecke, F. Determination of chromium, cadmium and lead in food-packaging materials by axial inductively coupled plasma time-of-flight mass spectrometry. Anal. Chim. Acta 2003, 479, 191–202. [Google Scholar] [CrossRef]

- Kim, K.-C.; Park, Y.-B.; Lee, M.-J.; Kim, J.-B.; Huh, J.-W.; Kim, D.-H.; Lee, J.-B.; Kim, J.-C. Levels of heavy metals in candy packages and candies likely to be consumed by small children. Food Res. Int. 2008, 41, 411–418. [Google Scholar] [CrossRef]

- Aguirre-Joya, J.A.; De Leon-Zapata, M.A.; Alvarez-Perez, O.B.; Torres-León, C.; Nieto-Oropeza, D.E.; Ventura-Sobrevilla, J.M.; Aguilar, M.A.; Ruelas-Chacón, X.; Rojas, R.; Ramos-Aguiñaga, M.E.; et al. Basic and Applied Concepts of Edible Packaging for Foods. In Food Packaging and Preservation; Grumezescu, A.M., Holban, A.M., Eds.; Academic Press: Cambridge, MA, USA, 2018; pp. 1–61. [Google Scholar] [CrossRef]

- Huntrakul, K.; Yoksan, R.; Sane, A.; Harnkarnsujarit, N. Effects of pea protein on properties of cassava starch edible films produced by blown-film extrusion for oil packaging. Food Packag. Shelf Life 2020, 24, 100480. [Google Scholar] [CrossRef]

- Moradi, M.; Guimarães, J.T.; Sahin, S. Current applications of exopolysaccharides from lactic acid bacteria in the development of food active edible packaging. Curr. Opin. Food Sci. 2020, 40, 33–39. [Google Scholar] [CrossRef]

- Sani, M.A.; Tavassoli, M.; Hamishehkar, H.; McClements, D.J. Carbohydrate-based films containing pH-sensitive red barberry anthocyanins: Application as biodegradable smart food packaging materials. Carbohyd. Polym. 2021, 255, 117488. [Google Scholar] [CrossRef]

- Jeya Jeevahan, J.; Chandrasekaran, M.; Venkatesan, S.P.; Sriram, V.; Britto Joseph, G.; Mageshwaran, G.; Durairaj, R.B. Scaling up difficulties and commercial aspects of edible films for food packaging: A review. Trends Food Sci. Technol. 2020, 100, 210–222. [Google Scholar] [CrossRef]

- Al-Tayyar, N.A.; Youssef, A.M.; Al-hindi, R. Antimicrobial food packaging based on sustainable Bio-based materials for reducing foodborne Pathogens: A review. Food Chem. 2020, 310, 125915. [Google Scholar] [CrossRef] [PubMed]

- Murat, P.; Ferret, P.-J.; Coslédan, S.; Simon, V. Assessment of targeted non-intentionally added substances in cosmetics in contact with plastic packagings. Analytical and toxicological aspects. Food Chem. Toxicol. 2019, 128, 106–118. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Song, M.; Liu, S.; Wu, S.; Thu, A.M. Analysis of phthalate plasticizer migration from PVDC packaging materials to food simulants using molecular dynamics simulations and artificial neural network. Food Chem. 2020, 317, 126465. [Google Scholar] [CrossRef]

- Murat, P.; Harohalli Puttaswamy, S.; Ferret, P.-J.; Coslédan, S.; Simon, V. Identification of Potential Extractables and Leachables in Cosmetic Plastic Packaging by Microchambers-Thermal Extraction and Pyrolysis-Gas Chromatography-Mass Spectrometry. Molecules 2020, 25, 2115. [Google Scholar] [CrossRef] [PubMed]

- Saha, T.; Hoque, M.E.; Mahbub, T. Biopolymers for Sustainable Packaging in Food, Cosmetics, and Pharmaceuticals. In Advanced Processing, Properties, and Applications of Starch and Other Bio-Based Polymers; Al-Oqla, F.M., Sapuan, S.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 197–214. [Google Scholar] [CrossRef]

- Shivsharan, U.; Raut, E.; Shaikh, Z. Packaging of cosmetics: A review. J. Pharm. Innov. 2014, 3, 286–293. [Google Scholar]

- Koparde, A.A.; Doijad, R.C.; Magdum, C.S. Natural products in drug discovery. Pharmacogn.-Med. Plant 2019, 1–20. [Google Scholar] [CrossRef]

- Wen, H.; Jung, H.; Li, X. Drug delivery approaches in addressing clinical pharmacology-related issues: Opportunities and challenges. AAPS J. 2015, 17, 1327–1340. [Google Scholar] [CrossRef]

- Sabee, M.M.S.M.; Uyen, N.T.T.; Ahmad, N.; Hamid, Z.A.A. Plastics Packaging for Pharmaceutical Products. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar] [CrossRef]

- Zadbuke, N.; Shahi, S.; Gulecha, B.; Padalkar, A.; Thube, M. Recent trends and future of pharmaceutical packaging technology. J. Pharm. Bioallied Sci. 2013, 5, 98. [Google Scholar] [CrossRef]

- Das, P.S.; Saha, P.; Das, R. Pharmaceutical Packaging Technology: A Brief Outline. Res. J. Pharm. Dos. Technol. 2018, 10, 23–28. [Google Scholar] [CrossRef]

- Available online: http://hvax.in/blog/types-of-pharmaceutical-packaging/ (accessed on 10 October 2022).

- Lyashenko, V.; Sotnik, S.; Baker, A.M. Features of Packaging from Polymers in Pharmaceutics. 2018. Available online: https://openarchive.nure.ua/handle/document/11644 (accessed on 20 December 2021).

- Harnkarnsujarit, N.; Wongphan, P.; Chatkitanan, T.; Laorenza, Y.; Srisa, A. Bioplastic for Sustainable Food Packaging. In Sustainable Food Processing and Engineering Challenges; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA, 2021; pp. 203–277. [Google Scholar] [CrossRef]

- Winotapun, C.; Phattarateera, S.; Aontee, A.; Junsook, N.; Daud, W.; Kerddonfag, N.; Chinsirikul, W. Development of multilayer films with improved aroma barrier properties for durian packaging application. Pack. Technol. Sci. 2019, 32, 405–418. [Google Scholar] [CrossRef]

- Totosaus, A. Packaging for frozen meat, seafood and poultry products. In Advances in Meat, Poultry and Seafood Packaging; Kerry, J.P., Ed.; Woodhead Publishing: Sawston, UK, 2012; pp. 363–376. [Google Scholar] [CrossRef]

- Campañone, L.A.; Salvadori, V.O.; Mascheroni, R.H. Weight loss during freezing and storage of unpackaged foods. J. Food Eng. 2001, 47, 69–79. [Google Scholar] [CrossRef]

- Robertson, G.L. Food Packaging and Shelf Life: A Practical Guide; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Janes, M.E.; Dai, Y. Edible films for meat, poultry and seafood. In Advances in Meat, Poultry and Seafood Packaging; Kerry, J.P., Ed.; Woodhead Publishing: Sawston, UK, 2012; pp. 504–521. [Google Scholar] [CrossRef]

- Nasrollahi, M.; Beynaghi, A.; Mohamady, F.M.; Mozafari, M. Plastic Packaging, Recycling, and Sustainable Development. In Responsible Consumption and Production; Encyclopedia of the UN Sustainable Development Goals; Leal Filho, W., Azul, A.M., Brandli, L., Özuyar, P.G., Wall, T., Eds.; Springer: Cham, Switzerland, 2020; pp. 544–551. [Google Scholar] [CrossRef]

- Salwa, H.; Sapuan, S.; Mastura, M.; Zuhri, M. Green bio composites for food packaging. Int. J. Recent Technol. Eng. 2019, 8, 450–459. [Google Scholar]

- Etxabide, A.; Uranga, J.; Guerrero, P.; De la Caba, K. Development of active gelatin films by means of valorisation of food processing waste: A review. Food Hydrocoll. 2017, 68, 192–198. [Google Scholar] [CrossRef]

- Romani, V.P.; Olsen, B.; Pinto Collares, M.; Meireles Oliveira, J.R.; Prentice, C.; Martins, V.G. Cold plasma and carnauba wax as strategies to produce improved bi-layer films for sustainable food packaging. Food Hydrocoll. 2020, 108, 106087. [Google Scholar] [CrossRef]

- Mohamed, S.A.; El-Sakhawy, M.; El-Sakhawy, M.A.-M. Polysaccharides, protein and lipid-based natural edible films in food packaging: A review. Carbohyd. Polym. 2020, 238, 116178. [Google Scholar] [CrossRef]

- Pasqualino, J.; Meneses, M.; Castells, F. The carbon footprint and energy consumption of beverage packaging selection and disposal. J. Food Eng. 2011, 103, 357–365. [Google Scholar] [CrossRef]

- Ghose, A.; Chinga-Carrasco, G. Environmental aspects of Norwegian production of pulp fibres and printing paper. J. Clean. Prod. 2013, 57, 293–301. [Google Scholar] [CrossRef]

- Harrison, E.; Berenjian, A.; Seifan, M. Recycling of waste glass as aggregate in cement-based materials. Environ. Sci. Ecotechnol. 2020, 4, 100064. [Google Scholar] [CrossRef]

- Alducin-Ochoa, J.; Martín-del-Río, J.; Torres-González, M.; Flores-Alés, V.; Hernández-Cruz, D. Performance of mortars based on recycled glass as aggregate by accelerated decay tests (ADT). Constr. Build. Mater. 2021, 300, 124057. [Google Scholar] [CrossRef]

- Adhikary, S.K.; Ashish, D.K.; Rudžionis, Ž. Expanded glass as light-weight aggregate in concrete—A review. J. Clean. Prod. 2021, 313, 127848. [Google Scholar] [CrossRef]

- Nodehi, M.; Mohamad Taghvaee, V. Sustainable concrete for circular economy: A review on use of waste glass. Glass Struct. Eng. 2021, 7, 3–22. [Google Scholar] [CrossRef]

- Ye, T.; Xiao, J.; Zhao, W.; Duan, Z.; Xu, Y. Combined use of recycled concrete aggregate and glass cullet in mortar: Strength, alkali expansion and chemical compositions. J. Build. Eng. 2022, 55, 104721. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ibrahim, I.D.; Hamam, Y.; Sadiku, E.R.; Ndambuki, J.M.; Kupolati, W.K.; Jamiru, T.; Eze, A.A.; Snyman, J. Need for Sustainable Packaging: An Overview. Polymers 2022, 14, 4430. https://doi.org/10.3390/polym14204430

Ibrahim ID, Hamam Y, Sadiku ER, Ndambuki JM, Kupolati WK, Jamiru T, Eze AA, Snyman J. Need for Sustainable Packaging: An Overview. Polymers. 2022; 14(20):4430. https://doi.org/10.3390/polym14204430

Chicago/Turabian StyleIbrahim, Idowu David, Yskandar Hamam, Emmanuel Rotimi Sadiku, Julius Musyoka Ndambuki, Williams Kehinde Kupolati, Tamba Jamiru, Azunna Agwo Eze, and Jacques Snyman. 2022. "Need for Sustainable Packaging: An Overview" Polymers 14, no. 20: 4430. https://doi.org/10.3390/polym14204430

APA StyleIbrahim, I. D., Hamam, Y., Sadiku, E. R., Ndambuki, J. M., Kupolati, W. K., Jamiru, T., Eze, A. A., & Snyman, J. (2022). Need for Sustainable Packaging: An Overview. Polymers, 14(20), 4430. https://doi.org/10.3390/polym14204430