Dielectric and Mechanical Properties of CTAB-Modified Natural Rubber Latex–Cement Composites

Abstract

:1. Introduction

2. Experimental Details

2.1. Materials

2.2. Mixture Design

2.3. Mixing Process

2.4. Characterization and Test Methods

3. Results and Discussion

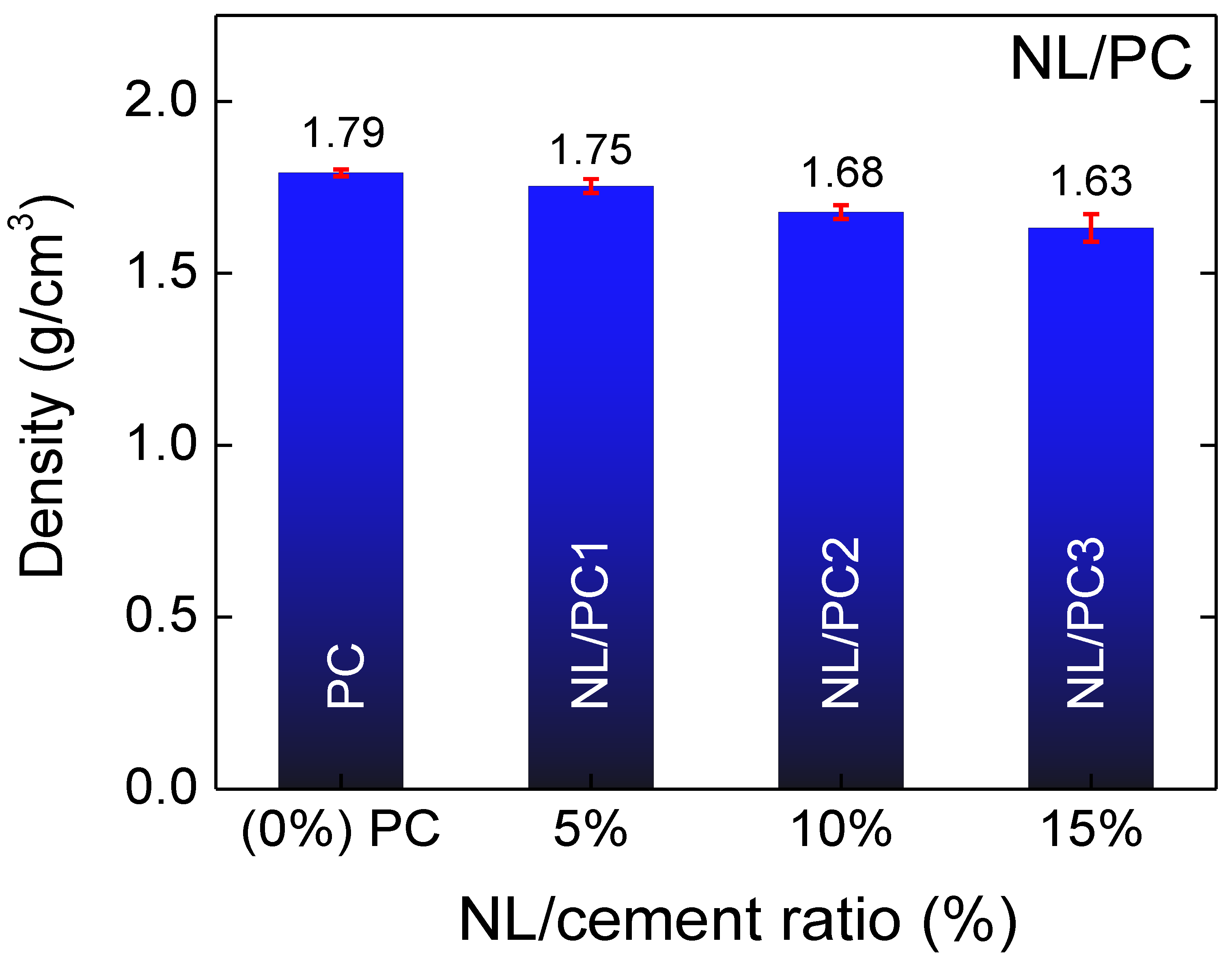

3.1. Density and Microstructure of NL/PC Composites

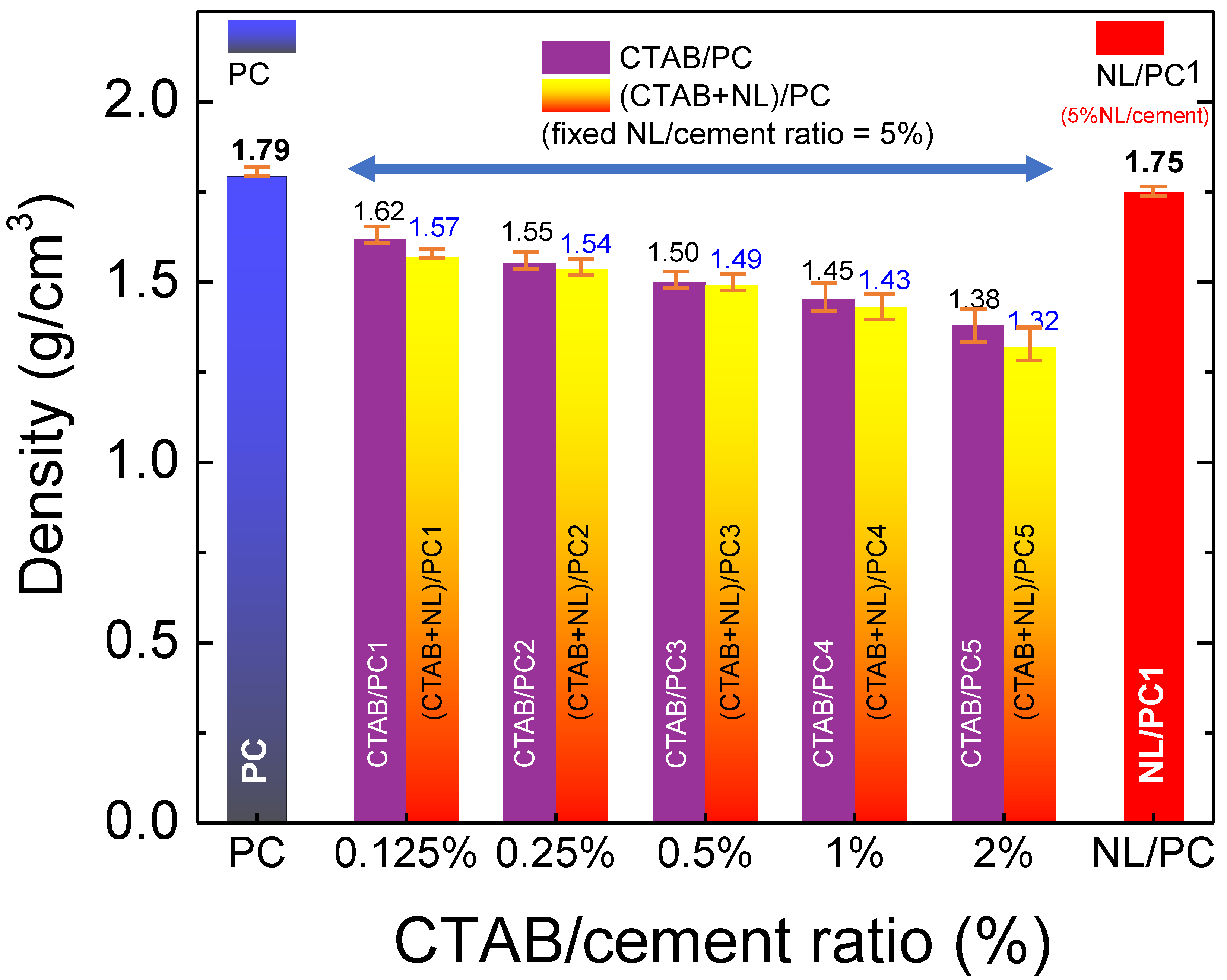

3.2. Density and Microstructure of CTAB/PC and (CTAB + NL)/PC Composites

3.3. Phase Formation of PC and (CTAB + NL)/PC Composites

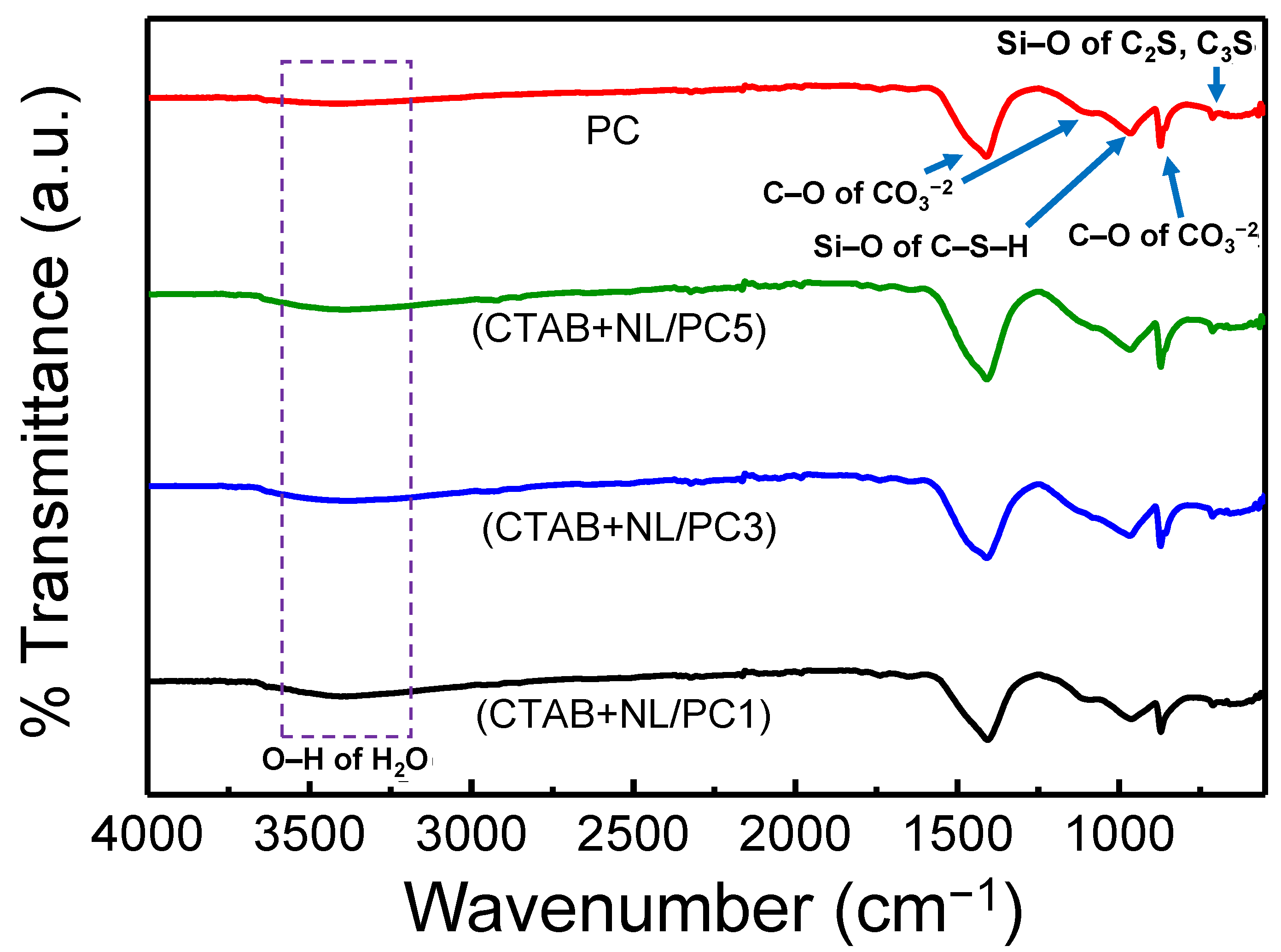

3.4. FTIR Spectroscopy

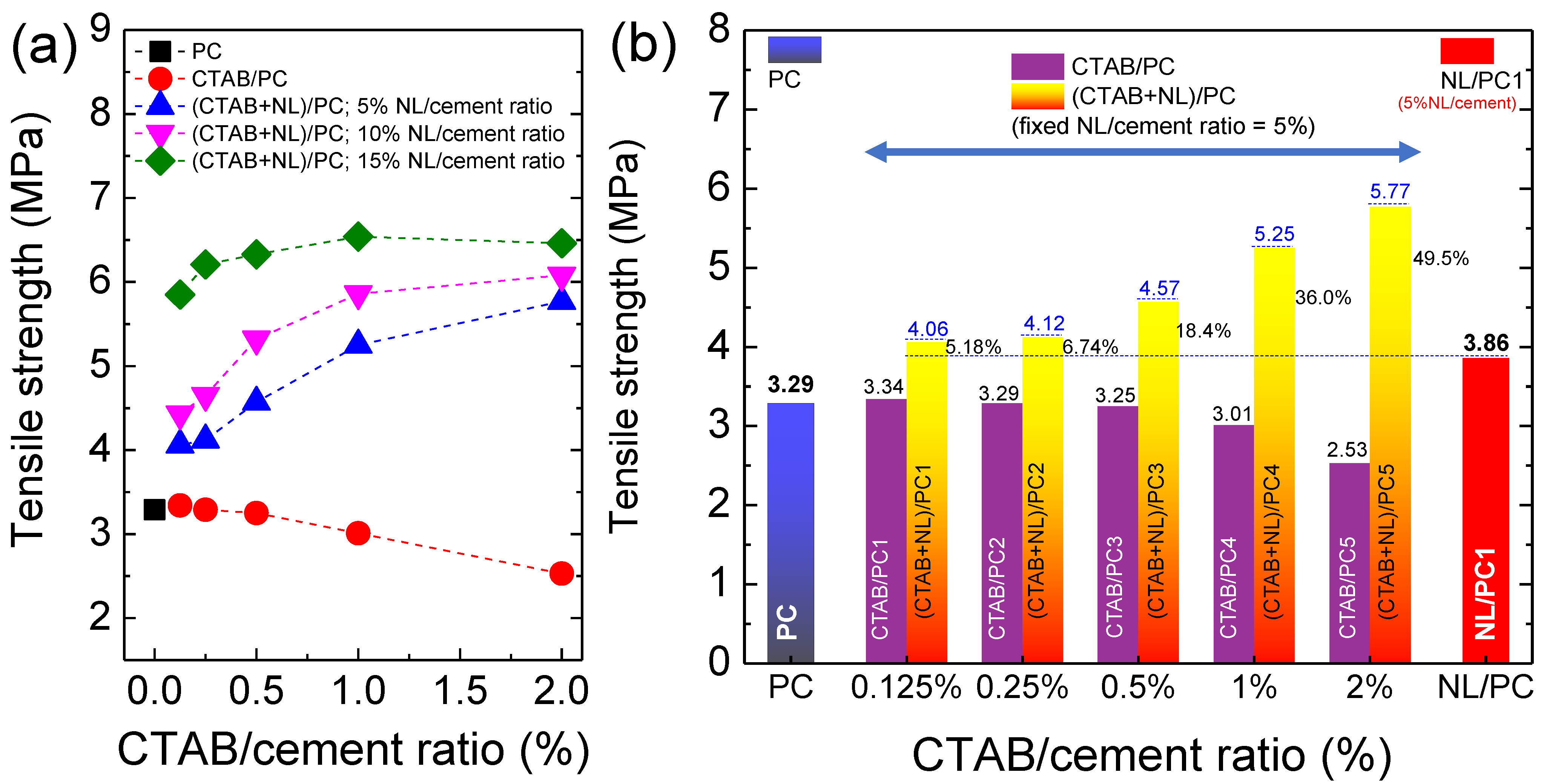

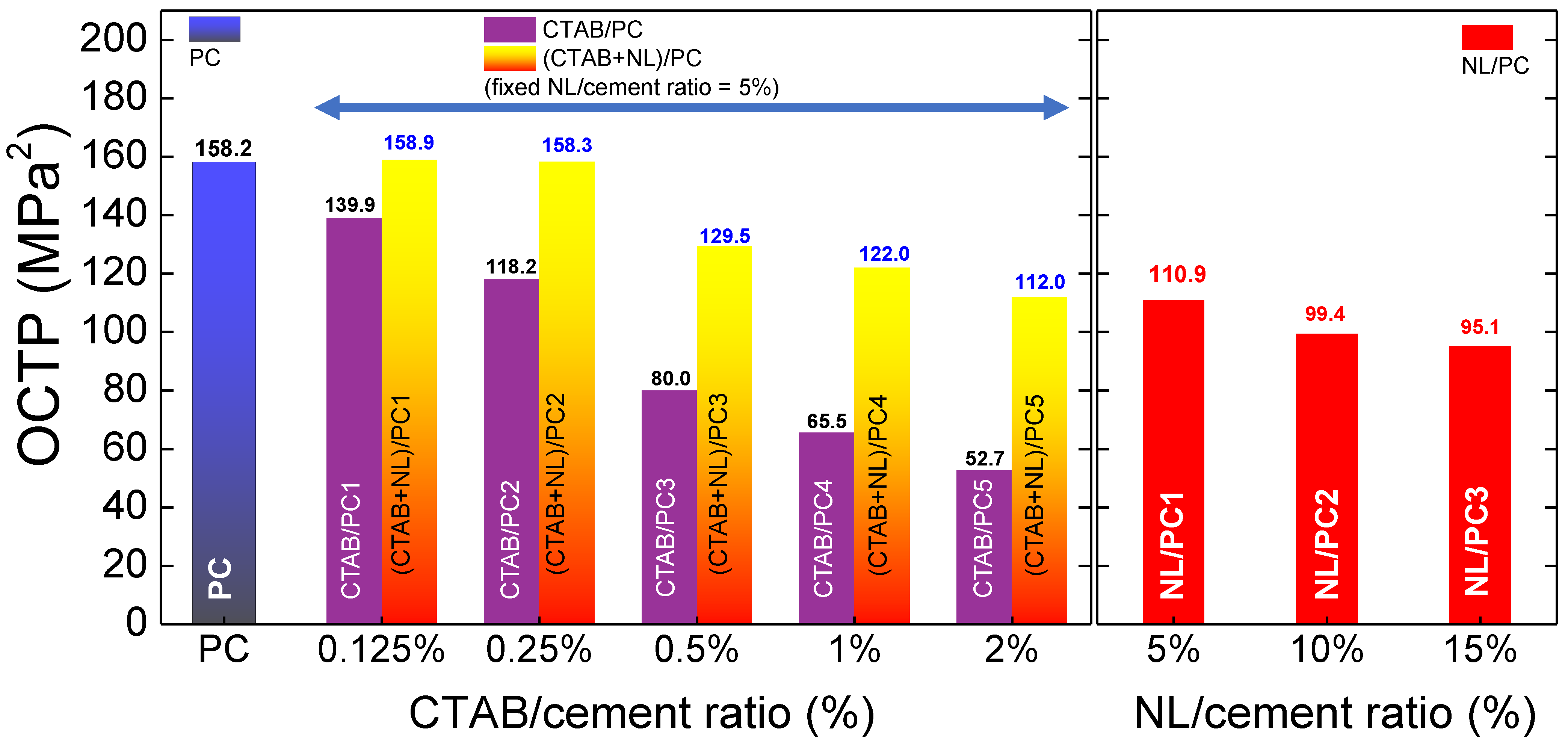

3.5. Compressive Strength, Tensile Strength, and Optimized Mechanical Performance

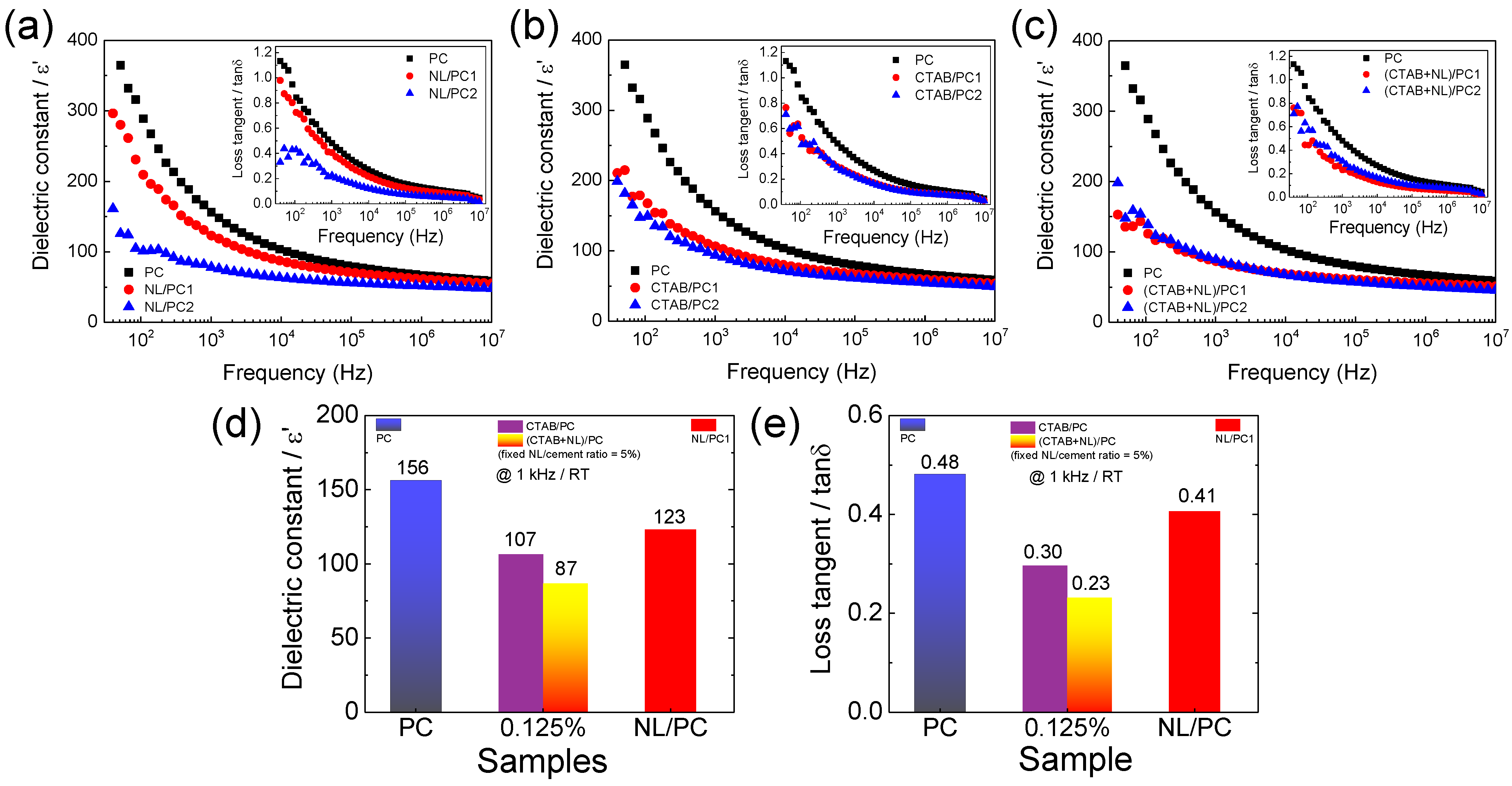

3.6. Dielectric Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- de Andrade Silva, F.; Toledo Filho, R.D.; de Almeida Melo Filho, J.; Fairbairn, E.d.M.R. Physical and mechanical properties of durable sisal fiber–cement composites. Constr. Build. Mater. 2010, 24, 777–785. [Google Scholar] [CrossRef]

- Yaowarat, T.; Horpibulsuk, S.; Arulrajah, A.; Mirzababaei, M.; Rashid, A.S.A. Compressive and flexural strength of polyvinyl alcohol-modified pavement concrete using recycled concrete aggregates. J. Mater. Civ. Eng. 2018, 30, 04018046. [Google Scholar] [CrossRef]

- Afridi, M.U.K.; Ohama, Y.; Demura, K.; Iqbal, M.Z. Development of polymer films by the coalescence of polymer particles in powdered and aqueous polymer-modified mortars. Cem. Concr. Res. 2003, 33, 1715–1721. [Google Scholar] [CrossRef]

- Bhogayata, A.; Arora, N.K. Workability, strength, and durability of concrete containing recycled plastic fibers and styrene-butadiene rubber latex. Constr. Build. Mater. 2018, 180, 382–395. [Google Scholar] [CrossRef]

- Doğan, M.; Bideci, A. Effect of Styrene Butadiene Copolymer (SBR) admixture on high strength concrete. Constr. Build. Mater. 2016, 112, 378–385. [Google Scholar] [CrossRef]

- De Andrade Silva, F.; Mobasher, B.; Soranakom, C.; Toledo Filho, R.D. Effect of fiber shape and morphology on interfacial bond and cracking behaviors of sisal fiber cement based composites. Cem. Concr. Compos. 2011, 33, 814–823. [Google Scholar] [CrossRef]

- Rocha Ferreira, S.; Rodrigues Sena Neto, A.; de Andrade Silva, F.; Gomes de Souza, F.; Toledo Filho, R.D. The influence of carboxylated styrene butadiene rubber coating on the mechanical performance of vegetable fibers and on their interface with a cement matrix. Constr. Build. Mater. 2020, 262, 120770. [Google Scholar] [CrossRef]

- Kumar, R.; Goel, P.; Mathur, R.; Bhattacharjee, B. Suitability of synthetic fiber for the construction of concrete pavements. J. Sci. Ind. Res. 2014, 73, 448–452. [Google Scholar]

- Ferreira, S.R.; de Andrade Silva, F.; Lima, P.R.L.; Toledo Filho, R.D. Effect of fiber treatments on the sisal fiber properties and fiber–matrix bond in cement based systems. Constr. Build. Mater. 2015, 101, 730–740. [Google Scholar] [CrossRef]

- Ferreira, S.R.; de Andrade Silva, F.; Lima, P.R.L.; Toledo Filho, R.D. Effect of hornification on the structure, tensile behavior and fiber matrix bond of sisal, jute and curauá fiber cement based composite systems. Constr. Build. Mater. 2017, 139, 551–561. [Google Scholar] [CrossRef]

- Buritatun, A.; Takaikaew, T.; Udomchai, A.; Hoy, M.; Vichitcholchai, N.; Arulrajah, A. Mechanical strength improvement of cement-stabilized soil using natural rubber latex for pavement base applications. J. Mater. Civ. Eng. 2020, 32, 04020372. [Google Scholar] [CrossRef]

- Muhammad, B.; Ismail, M.; Haron, Z.; Yussuf, A. Elastomeric effect of natural rubber latex on compressive strength of concrete at high temperatures. J. Mater. Civ. Eng. 2011, 23, 1697–1702. [Google Scholar] [CrossRef]

- Ismail, M.; Muhammad, B.; Yussuf, A.; Ismail, Z. Mechanical capabilities and fire endurance of natural rubber latex modified concrete. Can. J. Civ. Eng. 2011, 38, 661–668. [Google Scholar] [CrossRef]

- Wang, R.; Li, X.-G.; Wang, P.-M. Influence of polymer on cement hydration in SBR-modified cement pastes. Cem. Concr. Res. 2006, 36, 1744–1751. [Google Scholar] [CrossRef]

- Eren, F.; Gödek, E.; Keskinateş, M.; Tosun-Felekoğlu, K.; Felekoğlu, B. Effects of latex modification on fresh state consistency, short term strength and long term transport properties of cement mortars. Constr. Build. Mater. 2017, 133, 226–233. [Google Scholar] [CrossRef]

- Huang, Z.; Liang, T.; Huang, B.; Zhou, Y.; Ye, J. Ultra-lightweight high ductility cement composite incorporated with low PE fiber and rubber powder. Constr. Build. Mater. 2021, 312, 125430. [Google Scholar] [CrossRef]

- Loykaew, A.; Utara, S. Effect of acidic and sulfated environments on phase transformation, compressive strength and microstructure of natural rubber latex-modified cement pastes. J. Mater. Res. Technol. 2020, 9, 15496–15512. [Google Scholar] [CrossRef]

- Yaowarat, T.; Suddeepong, A.; Hoy, M.; Takaikaew, T.; Vichitcholchai, N.; Arulrajah, A.; Chinkulkijniwat, A. Improvement of flexural strength of concrete pavements using natural rubber latex. Constr. Build. Mater. 2021, 282, 122704. [Google Scholar] [CrossRef]

- Machado, P.J.C.; dos Reis Ferreira, R.A.; de Castro Motta, L.A. Study of the effect of silica fume and latex dosages in cementitious composites reinforced with cellulose fibers. J. Build. Eng. 2020, 31, 101442. [Google Scholar] [CrossRef]

- Machado, P.J.C.; dos Reis Ferreira, R.A.; de Castro Motta, L.A.; Pasquini, D. Characterization and properties of cementitious composites with cellulose fiber, silica fume and latex. Constr. Build. Mater. 2020, 257, 119602. [Google Scholar] [CrossRef]

- Jebadurai, S.V.S.; Tensing, D.; Pradhan, P.M.; Hemalatha, G. Enhancing performance of infill masonry with latex modified mortar subjected to cyclic load. Structures 2020, 23, 551–557. [Google Scholar] [CrossRef]

- Xiong, Z.; Tang, Z.; He, S.; Fang, Z.; Chen, Z.; Liu, F.; Li, L. Analysis of mechanical properties of rubberised mortar and influence of styrene-butadiene latex on interfacial behaviour of rubber-cement matrix. Constr. Build. Mater. 2021, 300, 124027. [Google Scholar] [CrossRef]

- Li, G.; Morlor, C.S.; Leung, C.; Wang, H. Mechanical properties and fractal analysis of cement mortar incorporating styrene-butadiene rubber latex and carboxylated MWCNTs. Constr. Build. Mater. 2021, 309, 125175. [Google Scholar] [CrossRef]

- Sukmak, G.; Sukmak, P.; Horpibulsuk, S.; Yaowarat, T.; Kunchariyakun, K.; Patarapaiboolchai, O.; Arulrajah, A. Physical and mechanical properties of natural rubber modified cement paste. Constr. Build. Mater. 2020, 244, 118319. [Google Scholar] [CrossRef]

- Vo, M.; Plank, J. Evaluation of natural rubber latex as film forming additive in cementitious mortar. Constr. Build. Mater. 2018, 169, 93–99. [Google Scholar] [CrossRef]

- Buritatum, A.; Horpibulsuk, S.; Udomchai, A.; Suddeepong, A.; Takaikaew, T.; Vichitcholchai, N.; Horpibulsuk, J.; Arulrajah, A. Durability improvement of cement stabilized pavement base using natural rubber latex. Transp. Geotech. 2021, 28, 100518. [Google Scholar] [CrossRef]

- Peaklin, S.; Magaraphan, R. Core–shell natural rubber and its effect on toughening and mechanical properties of poly(methyl methacrylate). Polym. Bull. 2019, 76, 3329–3354. [Google Scholar]

- Long, W.-J.; Wei, J.; Xing, F.; Khayat, K. Enhanced dynamic mechanical properties of cement paste modified with graphene oxide nanosheets and its reinforcing mechanism. Cem. Concr. Compos. 2018, 93, 127–139. [Google Scholar] [CrossRef]

- Kim, H.; Son, H.M.; Park, S.; Lee, H.K. Effects of biological admixtures on hydration and mechanical properties of Portland cement paste. Constr. Build. Mater. 2020, 235, 117461. [Google Scholar] [CrossRef]

- Muhammad, B.; Ismail, M.; Yussuf, A.; Muhammad, A.R.B. Elastomeric influence of natural rubber latex on cement mortar at high temperatures using thermal degradation analysis. Constr. Build. Mater. 2011, 25, 2223–2227. [Google Scholar] [CrossRef]

- Nicoletti, G.; Boghossian, V.; Gurevitch, F.; Borland, R.; Morgenroth, P. The antimicrobial activity in vitro of chlorhexidine, a mixture of isothiazolinones (‘Kathon’ CG) and Cetyl Trimethyl Ammonium Bromide (CTAB). J. Hosp. Infect. 1993, 23, 87–111. [Google Scholar] [CrossRef]

- Cross, J.; Singer, E.J. Cationic Surfactants: Analytical and Biological Evaluation; Marcel Dekker, Inc.: New York, NY, USA, 1994. [Google Scholar]

- Pandey, N.; Ghosh, S.; Dasgupta, S. Effect of surfactants on preformed fibrils of human serum albumin. Int. J. Biol. Macromol. 2013, 59, 39–45. [Google Scholar] [CrossRef]

- Peter, R.; Sreelekshmi, R.V.; Menon, A.R.R. Cetyltrimethyl ammonium bromide modified kaolin as a reinforcing filler for natural rubber. J. Polym. Environ. 2018, 26, 39–47. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, S.; Yu, X.; Zhang, H.; Yan, S. Study on the Use of CTAB-Treated Illite as an Alternative Filler for Natural Rubber. ACS Omega 2021, 6, 19017–19025. [Google Scholar] [CrossRef] [PubMed]

- Kum-onsa, P.; Phromviyo, N.; Thongbai, P. Na1/3Ca1/3Bi1/3Cu3Ti4O12–Ni@NiO/poly(vinylidene fluoride): Three–phase polymer composites with high dielectric permittivity and low loss tangent. Results Phys. 2020, 18, 103312. [Google Scholar] [CrossRef]

- Kum−onsa, P.; Thongbai, P. Na1/3Ca1/3Bi1/3Cu3Ti4O12/poly(vinylidene fluoride) composites with high dielectric permittivity and low dielectric loss. Mater. Chem. Phys. 2020, 256, 123664. [Google Scholar] [CrossRef]

- Kum-onsa, P.; Thongbai, P. Improved dielectric properties of poly(vinylidene fluoride) composites incorporating Na1/2Y1/2Cu3Ti4O12 particles. Mater. Today Commun. 2020, 25, 101654. [Google Scholar] [CrossRef]

- Wu, J.; Nan, C.-W.; Lin, Y.; Deng, Y. Giant dielectric permittivity observed in Li and Ti doped NiO. Phys. Rev. Lett. 2002, 89, 217601. [Google Scholar] [CrossRef]

- Kao, K.-C. Dielectric Phenomena in Solids: With Emphasis on Physical Concepts of Electronic Processes; Academic Press: Amsterdam, The Netherlands; Boston, MA, USA, 2004; 581p. [Google Scholar]

- Boonlakhorn, J.; Chanlek, N.; Manyam, J.; Srepusharawoot, P.; Krongsuk, S.; Thongbai, P. Enhanced giant dielectric properties and improved nonlinear electrical response in acceptor-donor (Al3+, Ta5+)-substituted CaCu3Ti4O12 ceramics. J. Adv. Ceram. 2021, 10, 1243–1255. [Google Scholar] [CrossRef]

- ASTM-C192; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory; American Society of Testing Materials: West Conshohocken, PA, USA, 2016.

- ASTM C109; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. Or [50-mm] Cube Specimens); American Society of Testing Materials: West Conshohocken, PA, USA, 2016.

- ASTM C496. Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. Available online: https://www.astm.org/c0496-96.html (accessed on 15 December 2021).

- Choudhary, H.K.; Anupama, A.V.; Kumar, R.; Panzi, M.E.; Matteppanavar, S.; Sherikar, B.N.; Sahoo, B. Observation of phase transformations in cement during hydration. Constr. Build. Mater. 2015, 101, 122–129. [Google Scholar] [CrossRef]

- Govindarajan, D.; Gopalakrishnan, R. Spectroscopic studies on Indian Portland cement hydrated with distilled water and sea water. Front. Sci. 2012, 1, 21–27. [Google Scholar] [CrossRef] [Green Version]

- Kong, X.; Pakusch, J.; Jansen, D.; Emmerling, S.; Neubauer, J.; Goetz-Neuhoeffer, F. Effect of polymer latexes with cleaned serum on the phase development of hydrating cement pastes. Cem. Concr. Res. 2016, 84, 30–40. [Google Scholar] [CrossRef]

- Liu, P.; Yao, Z.; Li, L.; Zhou, J. In situ synthesis and mechanical, thermal properties of polyimide nanocomposite film by addition of functionalized graphene oxide. Polym. Compos. 2016, 37, 907–914. [Google Scholar] [CrossRef]

- Klinger, D.; Wang, C.X.; Connal, L.A.; Audus, D.J.; Jang, S.G.; Kraemer, S.; Killops, K.L.; Fredrickson, G.H.; Kramer, E.J.; Hawker, C.J. A facile synthesis of dynamic, shape-changing polymer particles. Angew. Chem. Int. Ed. 2014, 53, 7018–7022. [Google Scholar] [CrossRef] [Green Version]

- Nawamawat, K.; Sakdapipanich, J.T.; Ho, C.C.; Ma, Y.; Song, J.; Vancso, J.G. Surface nanostructure of Hevea brasiliensis natural rubber latex particles. Colloids Surf. A Physicochem. Eng. Asp. 2011, 390, 157–166. [Google Scholar] [CrossRef]

- Tangboriboonrat, P.; Suchiva, K.; Riess, G. Surface characterization of a γ-radiation-crosslinked natural rubber latex by a phase transfer technique with cationic surfactants. Polymer 1995, 36, 781–785. [Google Scholar] [CrossRef]

- Kong, X.; Emmerling, S.; Pakusch, J.; Rückel, M.; Nieberle, J. Retardation effect of styrene-acrylate copolymer latexes on cement hydration. Cem. Concr. Res. 2015, 75, 23–41. [Google Scholar] [CrossRef]

- Chhetri, S.; Adak, N.C.; Samanta, P.; Mandal, N.; Kuila, T.; Murmu, N.C. Investigation of mechanical and thermal properties of the cetyltrimethylammonium bromide functionalized molybdenum disulfide (MoS2)/epoxy composites. Polym. Bull. 2018, 75, 327–343. [Google Scholar] [CrossRef]

- Liu, Q.; Luo, W.; Chen, Y.; Zou, H.; Liang, M. Enhanced mechanical and thermal properties of CTAB-functionalized graphene oxide–polyphenylene sulfide composites. High. Perform. Polym. 2017, 29, 889–898. [Google Scholar] [CrossRef]

- Moulson, A.J.; Herbert, J.M. Electroceramics: Materials, Properties, Applications, 2nd ed.; John Wiley & Sons: West Sussex, UK; New York, NY, USA, 2003; 557p. [Google Scholar]

- Thongbai, P.; Tangwancharoen, S.; Yamwong, T.; Maensiri, S. Dielectric relaxation and dielectric response mechanism in (Li, Ti)-doped NiO ceramics. J. Phys. Condens. Matter 2008, 20, 395227. [Google Scholar] [CrossRef]

- Liu, P.; Yao, Z.; Zhou, J. Mechanical, thermal and dielectric properties of graphene oxide/polyimide resin composite. High Perform. Polym. 2016, 28, 1033–1042. [Google Scholar] [CrossRef]

- Qian, M.; Zou, B.; Shi, Y.; Zhang, Y.; Wang, X.; Huang, W.; Zhu, Y. Enhanced mechanical and dielectric properties of natural rubber using sustainable natural hybrid filler. Appl. Surf. Sci. Adv. 2021, 6, 100171. [Google Scholar] [CrossRef]

- Yang, D.; Ni, Y.; Kong, X.; Gao, D.; Wang, Y.; Hu, T.; Zhang, L. Mussel-inspired modification of boron nitride for natural rubber composites with high thermal conductivity and low dielectric constant. Compos. Sci. Technol. 2019, 177, 18–25. [Google Scholar] [CrossRef]

- Drakopoulos, S.X.; Karger-Kocsis, J.; Kmetty, Á.; Lendvai, L.; Psarras, G.C. Thermoplastic starch modified with microfibrillated cellulose and natural rubber latex: A broadband dielectric spectroscopy study. Carbohydr. Polym. 2017, 157, 711–718. [Google Scholar] [CrossRef] [Green Version]

- Thakur, V.K.; Gupta, R.K. Recent progress on ferroelectric polymer-based nanocomposites for high energy density capacitors: Synthesis, dielectric properties, and future aspects. Chem. Rev. 2016, 116, 4260–4317. [Google Scholar]

- Mahapatra, S.D.; Mohapatra, P.C.; Aria, A.I.; Christie, G.; Mishra, Y.K.; Hofmann, S.; Thakur, V.K. Piezoelectric materials for energy harvesting and sensing applications: Roadmap for future smart materials. Adv. Sci. 2021, 8, 2100864. [Google Scholar] [CrossRef]

| Property | Test Results |

|---|---|

| Total solid content | 61.74% |

| Dry rubber content | 60.12% |

| Non-rubber content | 1.62% |

| Alkalinity (as ammonia by total weight) | 0.69% |

| Volatile fatty acids | 0.0282% |

| pH value at 25.6 | 10.49 |

| Mechanical stability time | 800 s |

| Specific gravity at 25 °C | 0.9456 |

| Samples | NL/Cement Ratio (%) | CTAB/Cement Ratio (%) |

|---|---|---|

| PC | - | - |

| NL/PC1 | 5 | - |

| NL/PC2 | 10 | - |

| NL/PC3 | 15 | - |

| CTAB/PC1 | - | 0.125 |

| CTAB/PC2 | - | 0.25 |

| CTAB/PC3 | - | 0.50 |

| CTAB/PC4 | - | 1.00 |

| CTAB/PC5 | - | 2.00 |

| (CTAB + NL)/PC1 | 5 | 0.125 |

| (CTAB + NL)/PC2 | 5 | 0.25 |

| (CTAB + NL)/PC3 | 5 | 0.50 |

| (CTAB + NL)/PC4 | 5 | 1.00 |

| (CTAB + NL)/PC5 | 5 | 2.00 |

| (CTAB + NL)/PC6 | 10 | 0.125 |

| (CTAB + NL)/PC7 | 10 | 0.25 |

| (CTAB + NL)/PC8 | 10 | 0.50 |

| (CTAB + NL)/PC9 | 10 | 1.00 |

| (CTAB + NL)/PC10 | 10 | 2.00 |

| (CTAB + NL)/PC11 | 15 | 0.125 |

| (CTAB + NL)/PC12 | 15 | 0.25 |

| (CTAB + NL)/PC13 | 15 | 0.50 |

| (CTAB + NL)/PC14 | 15 | 1.00 |

| (CTAB + NL)/PC15 | 15 | 2.00 |

| Samples | CTAB Powder (g) | Natural Rubber Latex | Addition Water II(g) | ||

|---|---|---|---|---|---|

| NL Content (g) | Water in NL (g) | Solid in NL (g) | |||

| PC | - | - | - | - | 450 |

| NL/PC1 | - | 50 | 19 | 31 | 431 |

| NL/PC2 | - | 100 | 37 | 62 | 412 |

| NL/PC3 | - | 150 | 58 | 93 | 393 |

| CTAB/PC1 | 1.25 | - | - | - | 450 |

| CTAB/PC2 | 2.50 | - | - | - | 450 |

| CTAB/PC3 | 5.0 | - | - | - | 450 |

| CTAB/PC4 | 10.0 | - | - | - | 450 |

| CTAB/PC5 | 20.0 | - | - | - | 450 |

| (CTAB + NL)/PC1 | 1.25 | 50 | 19 | 31 | 431 |

| (CTAB + NL)/PC2 | 2.50 | 50 | 19 | 31 | 431 |

| (CTAB + NL)/PC3 | 5.0 | 50 | 19 | 31 | 431 |

| (CTAB + NL)/PC4 | 10.0 | 50 | 19 | 31 | 431 |

| (CTAB + NL)/PC5 | 20.0 | 50 | 19 | 31 | 431 |

| (CTAB + NL)/PC6 | 1.25 | 100 | 38 | 62 | 412 |

| (CTAB + NL)/PC7 | 2.50 | 100 | 38 | 62 | 412 |

| (CTAB + NL)/PC8 | 5.0 | 100 | 38 | 62 | 412 |

| (CTAB + NL)/PC9 | 10.0 | 100 | 38 | 62 | 412 |

| (CTAB + NL)/PC10 | 20.0 | 100 | 38 | 62 | 412 |

| (CTAB + NL)/PC11 | 1.25 | 150 | 57 | 93 | 393 |

| (CTAB + NL)/PC12 | 2.50 | 150 | 57 | 93 | 393 |

| (CTAB + NL)/PC13 | 5.0 | 150 | 57 | 93 | 393 |

| (CTAB + NL)/PC14 | 10.0 | 150 | 57 | 93 | 393 |

| (CTAB + NL)/PC15 | 20.0 | 150 | 57 | 93 | 393 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Phromviyo, N.; Boonlakhorn, J.; Posi, P.; Thongbai, P.; Chindaprasirt, P. Dielectric and Mechanical Properties of CTAB-Modified Natural Rubber Latex–Cement Composites. Polymers 2022, 14, 320. https://doi.org/10.3390/polym14020320

Phromviyo N, Boonlakhorn J, Posi P, Thongbai P, Chindaprasirt P. Dielectric and Mechanical Properties of CTAB-Modified Natural Rubber Latex–Cement Composites. Polymers. 2022; 14(2):320. https://doi.org/10.3390/polym14020320

Chicago/Turabian StylePhromviyo, Nutthakritta, Jakkree Boonlakhorn, Patcharapol Posi, Prasit Thongbai, and Prinya Chindaprasirt. 2022. "Dielectric and Mechanical Properties of CTAB-Modified Natural Rubber Latex–Cement Composites" Polymers 14, no. 2: 320. https://doi.org/10.3390/polym14020320

APA StylePhromviyo, N., Boonlakhorn, J., Posi, P., Thongbai, P., & Chindaprasirt, P. (2022). Dielectric and Mechanical Properties of CTAB-Modified Natural Rubber Latex–Cement Composites. Polymers, 14(2), 320. https://doi.org/10.3390/polym14020320