Modeling Solution Drying by Moving a Liquid-Vapor Interface: Method and Applications

Abstract

1. Introduction

2. Model and Simulation Methodology

2.1. Langevin Dynamics

2.2. Moving Interface Method

3. Applications of Moving Interface Method

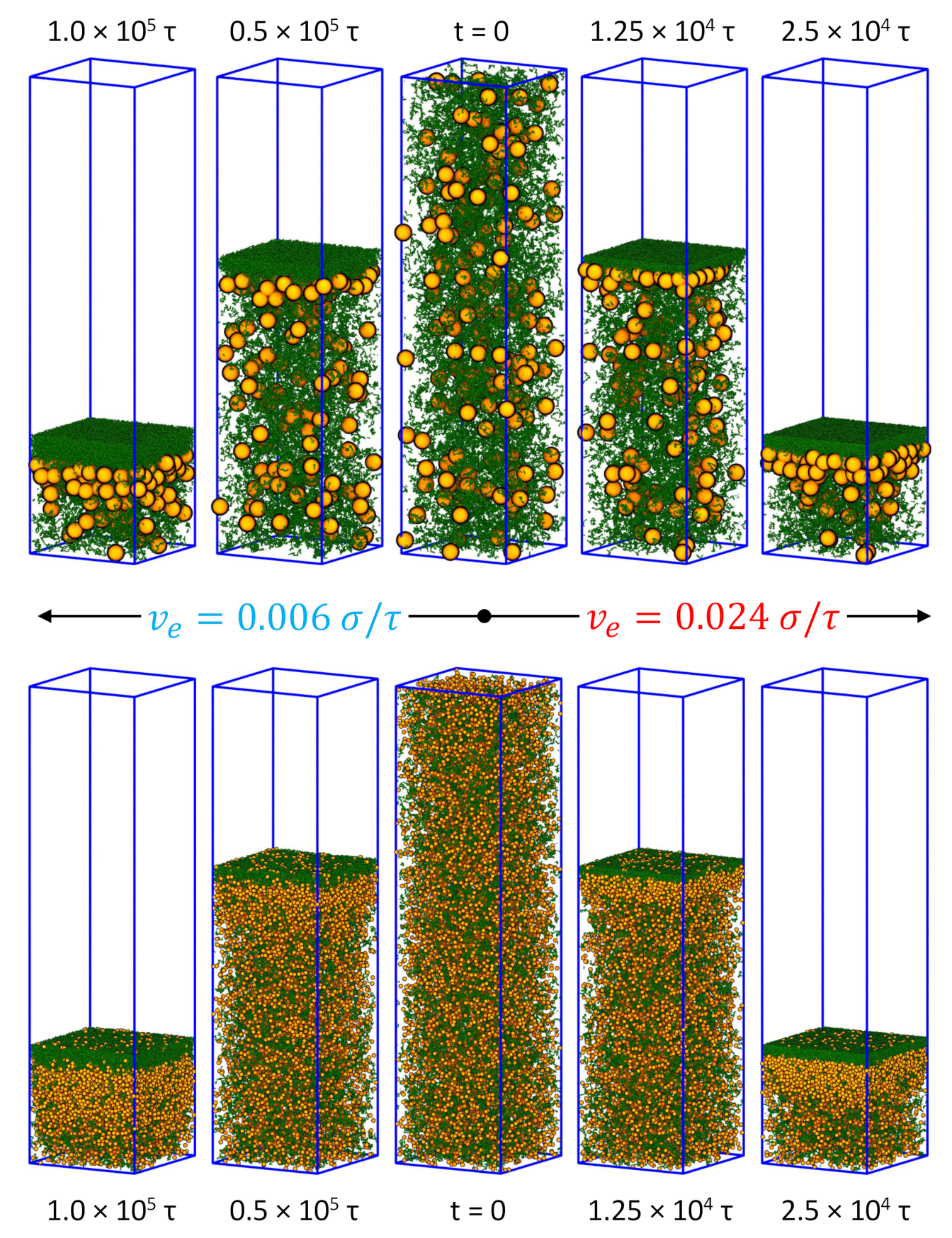

3.1. Drying of Solution Films of Polymer-Nanoparticle Mixtures

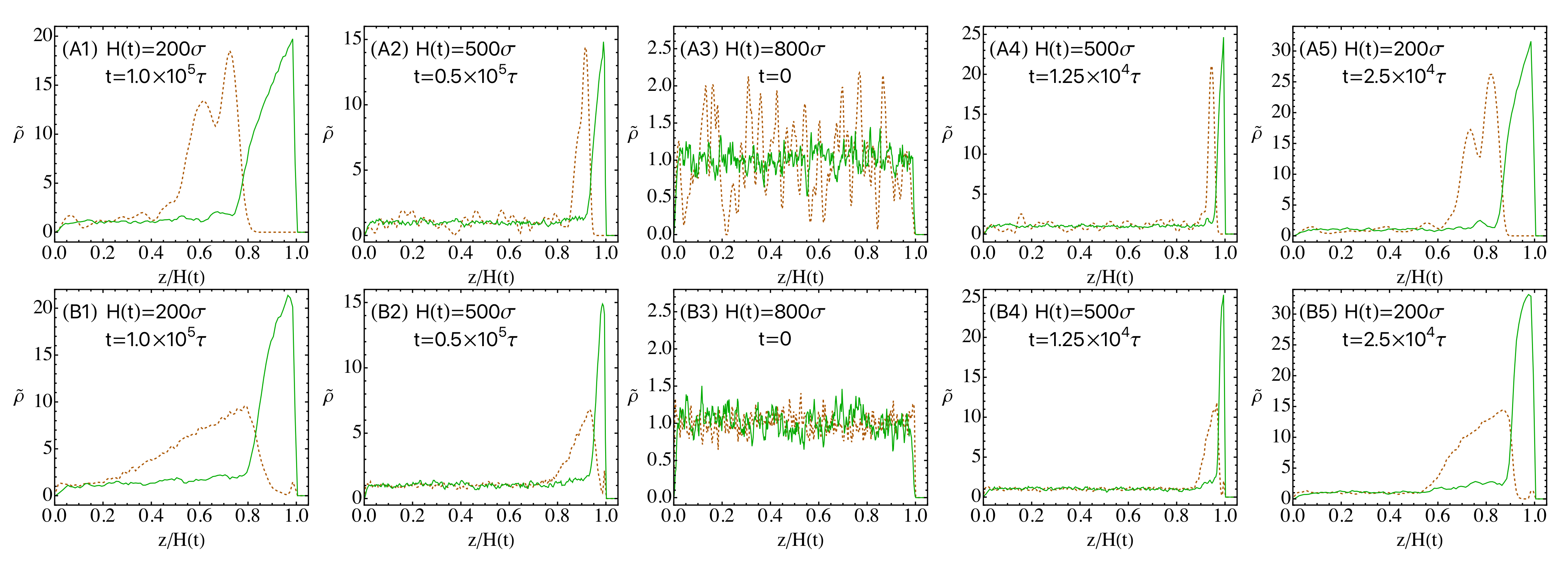

3.2. Drying of Suspension Droplets of Bidisperse Mixtures of Nanoparticles

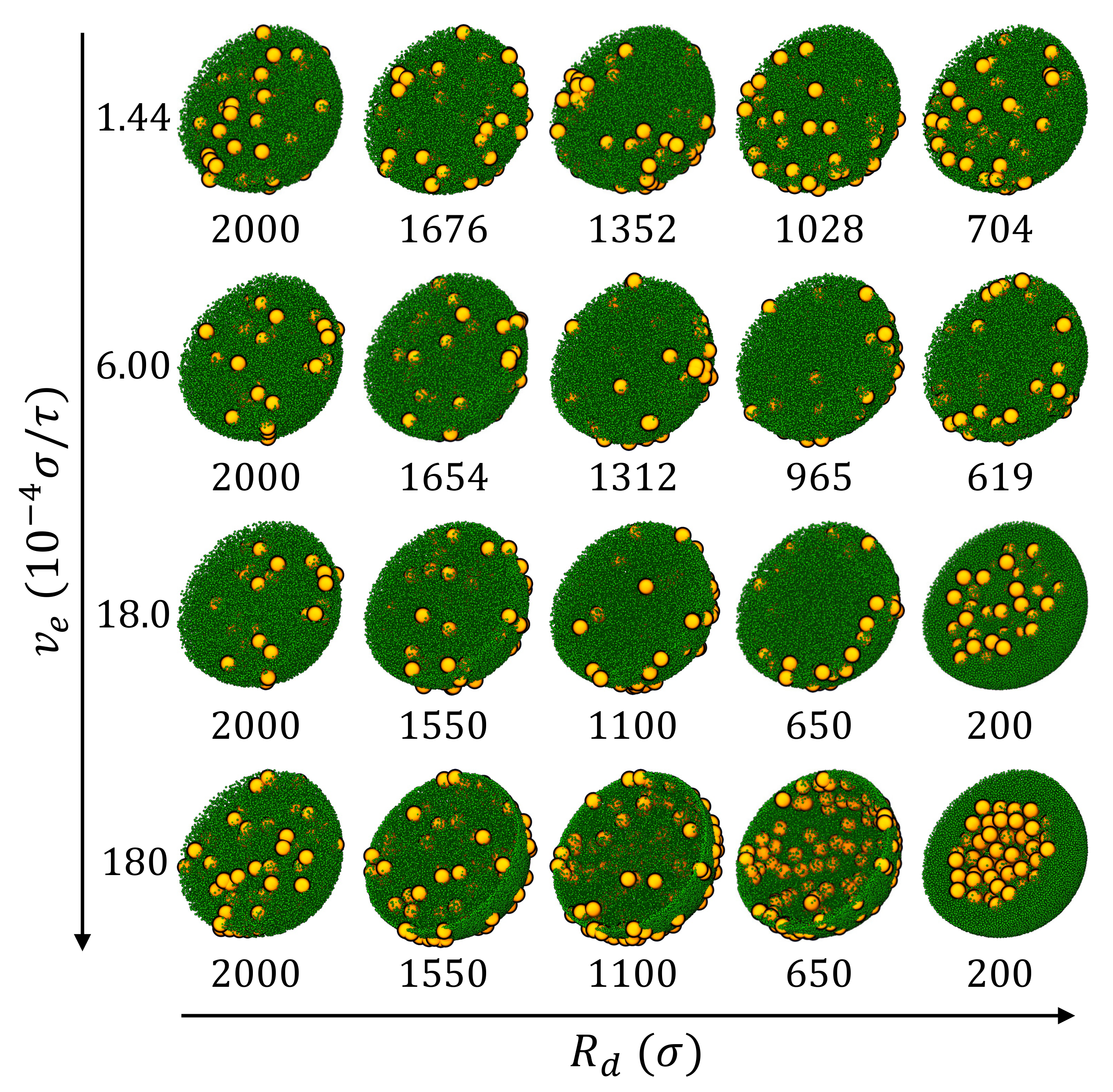

3.3. Drying of Solution Droplets of a Polymer Blend

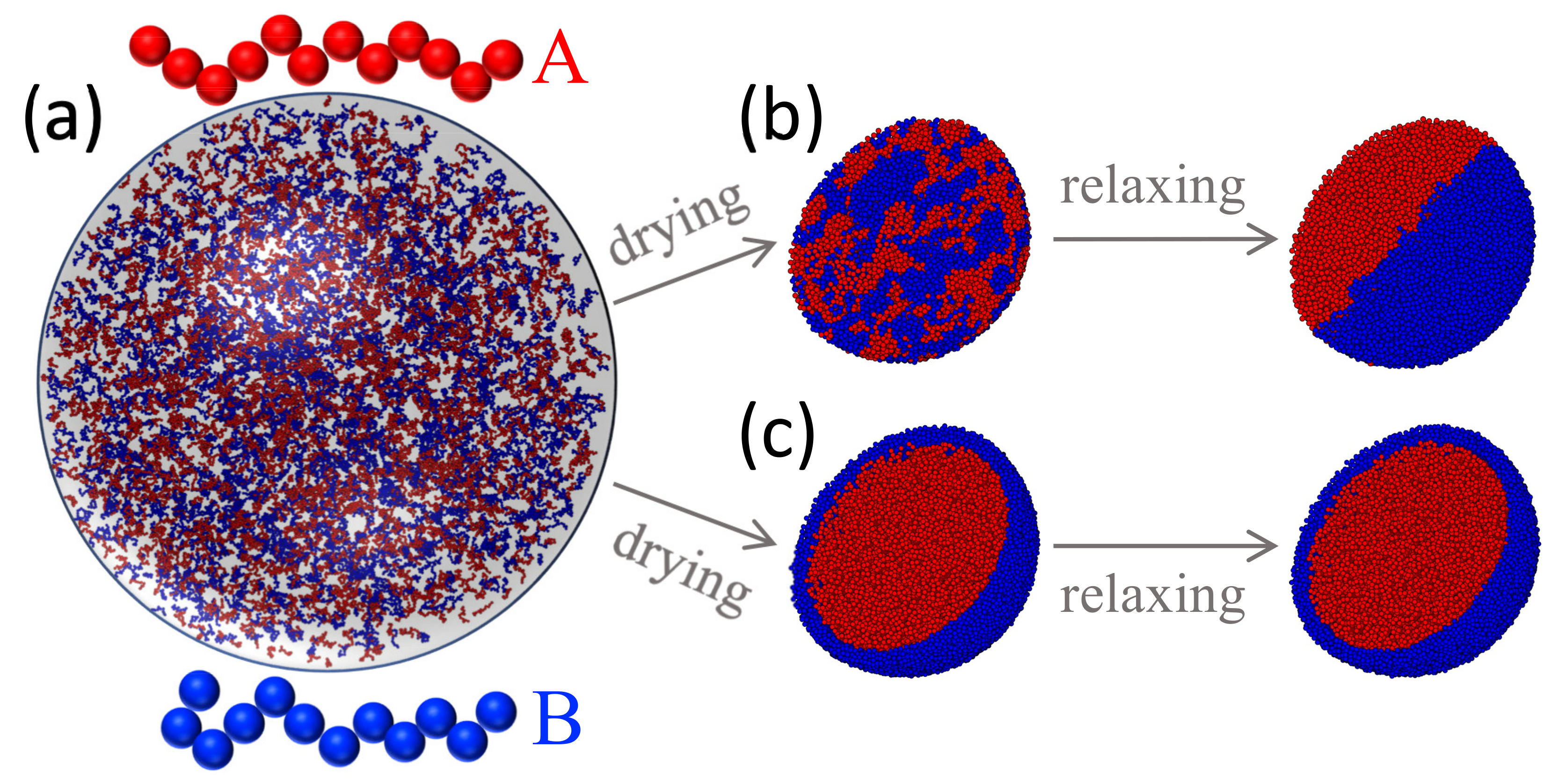

3.4. Drying of Solution Droplets of Diblock Copolymers

4. Summary and Discussion

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| COVID | Coronavirus disease |

| ODT | Oder-disorder transition |

| MD | Molecular dynamics |

| SNP | Small nanoparticle |

| MNP | Medium nanoparticle |

| LNP | Large nanoparticle |

| FENE | Finite extensible nonlinear elastic |

| LJ | Lennard-Jones |

| FNP | Flash nanoprecipitation |

References

- Dinçer, Í.; Zamfirescu, C. Drying Phenomena: Theory and Applications; Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2016. [Google Scholar]

- Brinker, C.J. Evaporation-induced self-assembly: Functional nanostructures made easy. MRS Bull. 2004, 29, 631–640. [Google Scholar] [CrossRef]

- Zhou, J.; Man, X.; Jiang, Y.; Doi, M. Structure formation in soft-matter solutions induced by solvent evaporation. Adv. Mater. 2017, 29, 1703769. [Google Scholar] [CrossRef]

- Keddie, J.L.; Routh, A.F. Fundamentals of Latex Film Formation: Processes and Properties; Springer: Dordrecht, The Netherlands, 2010. [Google Scholar]

- Keddie, J.L. Film formation of latex. Mater. Sci. Eng. R Rep. 1997, 21, 101–170. [Google Scholar] [CrossRef]

- Luo, H.; Cardinal, C.M.; Scriven, L.E.; Francis, L.F. Ceramic nanoparticle/monodisperse latex coatings. Langmuir 2008, 24, 5552–5561. [Google Scholar] [CrossRef]

- Van der Kooij, H.M.; Sprakel, J. Watching paint dry: More exciting than it seems. Soft Matter 2015, 11, 6353–6359. [Google Scholar] [CrossRef]

- Strawhecker, K.E.; Kumar, S.K.; Douglas, J.F.; Karim, A. The critical role of solvent evaporation on the roughness of spin-cast polymer films. Macromolecules 2001, 34, 4669–4672. [Google Scholar] [CrossRef]

- Luo, S.C.; Craciun, V.; Douglas, E.P. Instabilities during the formation of electroactive polymer thin films. Langmuir 2005, 21, 2881–2886. [Google Scholar] [CrossRef]

- Sousa, S.; Costa, A.; Silva, A.; Simões, R. Poly(lactic acid)/cellulose films produced from composite spheres prepared by emulsion-solvent evaporation method. Polymers 2019, 11, 66. [Google Scholar] [CrossRef]

- Shin, J.M.; Kim, Y.; Yun, H.; Yi, G.R.; Kim, B.J. Morphological evolution of block copolymer particles: Effect of solvent evaporation rate on particle shape and morphology. ACS Nano 2017, 11, 2133–2142. [Google Scholar] [CrossRef]

- Zhu, P.; Zhang, H.; Lu, H. Preparation of polyetherimide nanoparticles by a droplet evaporation-assisted thermally induced phase-separation method. Polymers 2021, 13, 1548. [Google Scholar] [CrossRef]

- Jouault, N.; Zhao, D.; Kumar, S.K. Role of casting solvent on nanoparticle dispersion in polymer nanocomposites. Macromolecules 2014, 47, 5246–5255. [Google Scholar] [CrossRef]

- Imel, A.E.; Dadmun, M.D. The impact of fullerenes on the ordering of polyacrylonitrile during nanocomposites formation. Polymer 2015, 75, 134–140. [Google Scholar] [CrossRef]

- Cheng, S.; Grest, G.S. Dispersing nanoparticles in a polymer film via solvent evaporation. ACS Macro Lett. 2016, 5, 694–698. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.K.; Ganesan, V.; Riggleman, R.A. Perspective: Outstanding theoretical questions in polymer-nanoparticle hybrids. J. Chem. Phys. 2017, 147, 020901. [Google Scholar] [CrossRef]

- Ge, T.; Cheng, S. Physicochemical properties of respiratory droplets and their role in COVID-19 pandemics: A critical review. Biomater. Transl. 2021, 2, 10–18. [Google Scholar] [CrossRef]

- Leung, N.H.L. Transmissibility and transmission of respiratory viruses. Nat. Rev. Microbiol. 2021, 19, 528–545. [Google Scholar] [CrossRef] [PubMed]

- Routh, A.F. Drying of thin colloidal films. Rep. Prog. Phys. 2013, 76, 046603. [Google Scholar] [CrossRef]

- Schulz, M.; Keddie, J.L. A critical and quantitative review of the stratification of particles during the drying of colloidal films. Soft Matter 2018, 14, 6181–6197. [Google Scholar] [CrossRef]

- Tsige, M.; Grest, G.S. Molecular dynamics study of the evaporation process in polymer films. Macromolecules 2004, 37, 4333–4335. [Google Scholar] [CrossRef]

- Tsige, M.; Mattsson, T.R.; Grest, G.S. Morphology of evaporated multiblock copolymer membranes studied by molecular dynamics simulations. Macromolecules 2004, 37, 9132–9138. [Google Scholar] [CrossRef]

- Tsige, M.; Grest, G.S. Solvent evaporation and interdiffusion in polymer films. J. Phys. Conden. Matt. 2005, 17, S4119. [Google Scholar] [CrossRef]

- Cheng, S.; Grest, G.S. Molecular dynamics simulations of evaporation-induced nanoparticle assembly. J. Chem. Phys. 2013, 138, 064701. [Google Scholar] [CrossRef] [PubMed]

- Cheng, S.; Stevens, M.J.; Grest, G.S. Ordering nanoparticles with polymer brushes. J. Chem. Phys. 2017, 147, 224901. [Google Scholar] [CrossRef] [PubMed]

- Fortini, A.; Martín-Fabiani, I.; De La Haye, J.L.; Dugas, P.Y.; Lansalot, M.; D’Agosto, F.; Bourgeat-Lami, E.; Keddie, J.L.; Sear, R.P. Dynamic stratification in drying films of colloidal mixtures. Phys. Rev. Lett. 2016, 116, 118301. [Google Scholar] [CrossRef] [PubMed]

- Fortini, A.; Sear, R.P. Stratification and size segregation of ternary and polydisperse colloidal suspensions during drying. Langmuir 2017, 33, 4796–4805. [Google Scholar] [CrossRef] [PubMed]

- Howard, M.P.; Nikoubashman, A.; Panagiotopoulos, A.Z. Stratification dynamics in drying colloidal mixtures. Langmuir 2017, 33, 3685–3693. [Google Scholar] [CrossRef]

- Howard, M.P.; Nikoubashman, A.; Panagiotopoulos, A.Z. Stratification in drying polymer-polymer and colloid-polymer mixtures. Langmuir 2017, 33, 11390–11398. [Google Scholar] [CrossRef] [PubMed]

- Howard, M.P.; Reinhart, W.F.; Sanyal, T.; Shell, M.S.; Nikoubashman, A.; Panagiotopoulos, A.Z. Evaporation-induced assembly of colloidal crystals. J. Chem. Phys. 2018, 149, 094901. [Google Scholar] [CrossRef]

- Reinhart, W.F.; Long, A.W.; Howard, M.P.; Ferguson, A.L.; Panagiotopoulos, A.Z. Machine learning for autonomous crystal structure identification. Soft Matter 2017, 13, 4733–4745. [Google Scholar] [CrossRef]

- Reinhart, W.F.; Panagiotopoulos, A.Z. Automated crystal characterization with a fast neighborhood graph analysis method. Soft Matter 2018, 14, 6083–6089. [Google Scholar] [CrossRef]

- Statt, A.; Howard, M.P.; Panagiotopoulos, A.Z. Solvent quality influences surface structure of glassy polymer thin films after evaporation. J. Chem. Phys. 2017, 147, 184901. [Google Scholar] [CrossRef]

- Statt, A.; Howard, M.P.; Panagiotopoulos, A.Z. Influence of hydrodynamic interactions on stratification in drying mixtures. J. Chem. Phys. 2018, 149, 024902. [Google Scholar] [CrossRef]

- Tatsumi, R.; Iwao, T.; Koike, O.; Yamaguchi, Y.; Tsuji, Y. Effects of the evaporation rate on the segregation in drying bimodal colloidal suspensions. Appl. Phys. Lett. 2018, 112, 053702. [Google Scholar] [CrossRef]

- Tang, Y.; Grest, G.S.; Cheng, S. Stratification in drying films containing bidisperse mixtures of nanoparticles. Langmuir 2018, 34, 7161–7170. [Google Scholar] [CrossRef]

- Tang, Y.; Grest, G.S.; Cheng, S. Control of stratification in drying particle suspensions via temperature gradients. Langmuir 2019, 35, 4296–4304. [Google Scholar] [CrossRef]

- Tang, Y.; Grest, G.S.; Cheng, S. Stratification of drying particle suspensions: Comparison of implicit and explicit solvent simulations. J. Chem. Phys. 2019, 150, 224901. [Google Scholar] [CrossRef]

- Deegan, R.D.; Bakajin, O.; Dupont, T.F.; Huber, G.; Nagel, S.R.; Witten, T.A. Capillary flow as the cause of ring stains from dried liquid drops. Nature 1997, 389, 827–829. [Google Scholar] [CrossRef]

- Mitov, Z.; Kumacheva, E. Convection-induced patterns in phase-separating polymeric fluids. Phys. Rev. Lett. 1998, 81, 3427–3430. [Google Scholar] [CrossRef]

- Bassou, N.; Rharbi, Y. Role of Bénard-Marangoni instabilities during solvent evaporation in polymer surface corrugations. Langmuir 2009, 25, 624–632. [Google Scholar] [CrossRef]

- Chapman, N.; Chapman, M.; Euler, W.B. Evolution of surface morphology of spin-coated poly(methyl methacrylate) thin films. Polymers 2021, 13, 2184. [Google Scholar] [CrossRef]

- Cheng, S.; Grest, G.S. Structure and diffusion of nanoparticle monolayers floating at liquid/vapor interfaces: A molecular dynamics study. J. Chem. Phys. 2012, 136, 214702. [Google Scholar] [CrossRef]

- Grest, G.S.; Wang, Q.; in ’t Veld, P.; Keffer, D.J. Effective potentials between nanoparticles in suspension. J. Chem. Phys. 2011, 134, 144902. [Google Scholar] [CrossRef]

- Tang, Y.; Cheng, S. Capillary forces on a small particle at a liquid-vapor interface: Theory and simulation. Phys. Rev. E 2018, 98, 032802. [Google Scholar] [CrossRef]

- Schneider, T.; Stoll, E. Molecular-dynamics study of a three-dimensional one-component model for distortive phase transitions. Phys. Rev. B 1978, 17, 1302–1322. [Google Scholar] [CrossRef]

- Grest, G.S.; Kremer, K. Molecular dynamics simulation for polymers in the presence of a heat bath. Phys. Rev. A 1986, 33, 3628–3631. [Google Scholar] [CrossRef]

- Pieranski, P. Two-dimensional interfacial colloidal crystals. Phys. Rev. Lett. 1980, 45, 569. [Google Scholar] [CrossRef]

- Joanny, J.F.; de Gennes, P.G. A model for contact angle hysteresis. J. Chem. Phys. 1984, 81, 552–562. [Google Scholar] [CrossRef]

- Bigioni, T.P.; Lin, X.M.; Nguyen, T.T.; Corwin, E.I.; Witten, T.A.; Jaeger, H.M. Kinetically driven self-assembly of highly ordered nanoparticle monolayers. Nat. Mater. 2006, 5, 265–270. [Google Scholar] [CrossRef]

- Kremer, K.; Grest, G.S. Dynamics of entangled linear polymer melts: A molecular-dynamics simulation. J. Chem. Phys. 1990, 92, 5057. [Google Scholar] [CrossRef]

- Everaers, R.; Ejtehadi, M.R. Interaction potentials for soft and hard ellipsoids. Phys. Rev. E 2003, 67, 041710. [Google Scholar] [CrossRef]

- In ’t Veld, P.J.; Plimpton, S.J.; Grest, G.S. Accurate and efficient methods for modeling colloidal mixtures in an explicit solvent using molecular dynamics. Comput. Phys. Commun. 2008, 179, 320–329. [Google Scholar] [CrossRef]

- Thompson, A.P.; Aktulga, H.M.; Berger, R.; Bolintineanu, D.S.; Brown, W.M.; Crozier, P.S.; in ’t Veld, P.J.; Kohlmeyer, A.; Moore, S.G.; Nguyen, T.D.; et al. LAMMPS-a flexible simulation tool for particle-based materials modeling at the atomic, meso, and continuum scales. Comp. Phys. Comm. 2022, 271, 108171. [Google Scholar] [CrossRef]

- Huang, Y.; Cheng, S. Chain conformations and phase separation in polymer solutions with varying solvent quality. J. Polym. Sci. 2021, 59, 2819–2831. [Google Scholar] [CrossRef]

- Rubinstein, M.; Colby, R.H. Polymer Physics; Oxford University Press: New York, NY, USA, 2003. [Google Scholar]

- Zhou, J.; Jiang, Y.; Doi, M. Cross interaction drives stratification in drying film of binary colloidal mixtures. Phys. Rev. Lett. 2017, 118, 108002. [Google Scholar] [CrossRef]

- Makepeace, D.K.; Fortini, A.; Markov, A.; Locatelli, P.; Lindsay, C.; Moorhouse, S.; Lind, R.; Sear, R.P.; Keddie, J.L. Stratification in binary colloidal polymer films: Experiment and simulations. Soft Matter 2017, 13, 6969–6980. [Google Scholar] [CrossRef]

- Liu, W.; Midya, J.; Kappl, M.; Butt, H.J.; Nikoubashman, A. Segregation in drying binary colloidal droplets. ACS Nano 2019, 13, 4972–4979. [Google Scholar] [CrossRef]

- Xiao, M.; Hu, Z.; Gartner, T.E.; Yang, X.; Li, W.; Jayaraman, A.; Gianneschi, N.C.; Shawkey, M.D.; Dhinojwala, A. Experimental and theoretical evidence for molecular forces driving surface segregation in photonic colloidal assemblies. Sci. Adv. 2019, 5, eaax1254. [Google Scholar] [CrossRef]

- Gartner, T.E.; Heil, C.M.; Jayaraman, A. Surface composition and ordering of binary nanoparticle mixtures in spherical confinement. Mol. Syst. Des. Eng. 2020, 5, 864–875. [Google Scholar] [CrossRef]

- Howard, M.P.; Nikoubashman, A. Stratification of polymer mixtures in drying droplets: Hydrodynamics and diffusion. J. Chem. Phys. 2020, 153, 054901. [Google Scholar] [CrossRef]

- Lintingre, E.; Lequeux, F.; Talini, L.; Tsapis, N. Control of particle morphology in the spray drying of colloidal suspensions. Soft Matter 2016, 12, 7435–7444. [Google Scholar] [CrossRef]

- Lintingre, E.; Ducouret, G.; Lequeux, F.; Olanier, L.; Périé, T.; Talini, L. Controlling the buckling instability of drying droplets of suspensions through colloidal interactions. Soft Matter 2015, 11, 3660–3665. [Google Scholar] [CrossRef]

- Lishchuk, S.V.; Ettelaie, R. Detachment force of particles with pinning of contact line from fluid bubbles/droplets. Langmuir 2016, 32, 13040–13045. [Google Scholar] [CrossRef]

- Van der Kooij, H.M.; van de Kerkhof, G.T.; Sprakel, J. A mechanistic view of drying suspension droplets. Soft Matter 2016, 12, 2858–2867. [Google Scholar] [CrossRef]

- Grest, G.S.; Lacasse, M.; Kremer, K.; Gupta, A.M. Efficient continuum model for simulating polymer blends and copolymers. J. Chem. Phys. 1996, 105, 10583–10594. [Google Scholar] [CrossRef]

- Higuchi, T.; Tajima, A.; Yabu, H.; Shimomura, M. Spontaneous formation of polymer nanoparticles with inner micro-phase separation structures. Soft Matter 2008, 4, 1302. [Google Scholar] [CrossRef]

- Bates, F.S.; Fredrickson, G.H. Block copolymer thermodynamics: Theory and experiment. Ann. Rev. Phys. Chem. 1990, 41, 525–557. [Google Scholar] [CrossRef]

- Johnson, B.K.; Prud’homme, R.K. Chemical processing and micromixing in confined impinging jets. AIChE J. 2003, 49, 2264–2282. [Google Scholar] [CrossRef]

- Johnson, B.K.; Prud’homme, R.K. Mechanism for rapid self-assembly of block copolymer nanoparticles. Phys. Rev. Lett. 2003, 91, 118302. [Google Scholar] [CrossRef]

- Grundy, L.S.; Lee, V.E.; Li, N.; Sosa, C.; Mulhearn, W.D.; Liu, R.; Register, R.A.; Nikoubashman, A.; Prud’homme, R.K.; Panagiotopoulos, A.Z.; et al. Rapid production of internally structured colloids by flash nanoprecipitation of block copolymer blends. ACS Nano 2018, 12, 4660–4668. [Google Scholar] [CrossRef]

- Javaid, S.; Mahmood, A.; Nasir, H.; Iqbal, M.; Ahmed, N.; Ahmad, N.M. Layer-by-layer self-assembled dip coating for antifouling functionalized finishing of cotton textile. Polymers 2022, 14, 2540. [Google Scholar] [CrossRef]

- Rodrigues, S.; da Costa, A.M.R.; Flórez-Fernández, N.; Torres, M.D.; Faleiro, M.L.; Buttini, F.; Grenha, A. Inhalable spray-dried chondroitin sulphate microparticles: Effect of different solvents on particle properties and drug activity. Polymers 2020, 12, 425. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, T.; Khan, A.U.; Liu, G. Block copolymer-based porous carbon fibers. Sci. Adv. 2019, 5, eaau6852. [Google Scholar] [CrossRef]

- Hu, H.; Larson, R.G. Marangoni effect reverses coffee-ring depositions. J. Phys. Chem. B 2006, 110, 7090–7094. [Google Scholar] [CrossRef]

- Joshi, A.S.; Sun, Y. Wetting dynamics and particle deposition for an evaporating colloidal drop: A lattice Boltzmann study. Phys. Rev. E 2010, 82, 041401. [Google Scholar] [CrossRef]

| System | Pe | Pe | |

|---|---|---|---|

| MNP-1 | 1391 | 2098 | |

| MNP-2 | 348 | 525 | |

| SNP-1 | 198 | 2023 | |

| SNP-2 | 49 | 506 |

| 7.0 | 0.76 | |

| 29 | 3.2 | |

| 87 | 9.5 | |

| 870 | 95 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, Y.; McLaughlan, J.E.; Grest, G.S.; Cheng, S. Modeling Solution Drying by Moving a Liquid-Vapor Interface: Method and Applications. Polymers 2022, 14, 3996. https://doi.org/10.3390/polym14193996

Tang Y, McLaughlan JE, Grest GS, Cheng S. Modeling Solution Drying by Moving a Liquid-Vapor Interface: Method and Applications. Polymers. 2022; 14(19):3996. https://doi.org/10.3390/polym14193996

Chicago/Turabian StyleTang, Yanfei, John E. McLaughlan, Gary S. Grest, and Shengfeng Cheng. 2022. "Modeling Solution Drying by Moving a Liquid-Vapor Interface: Method and Applications" Polymers 14, no. 19: 3996. https://doi.org/10.3390/polym14193996

APA StyleTang, Y., McLaughlan, J. E., Grest, G. S., & Cheng, S. (2022). Modeling Solution Drying by Moving a Liquid-Vapor Interface: Method and Applications. Polymers, 14(19), 3996. https://doi.org/10.3390/polym14193996