Mechanical Performance and Constitutive Model Analysis of Concrete Using PE Fiber-Strengthened Recycled Coarse Aggregate

Abstract

:1. Introduction

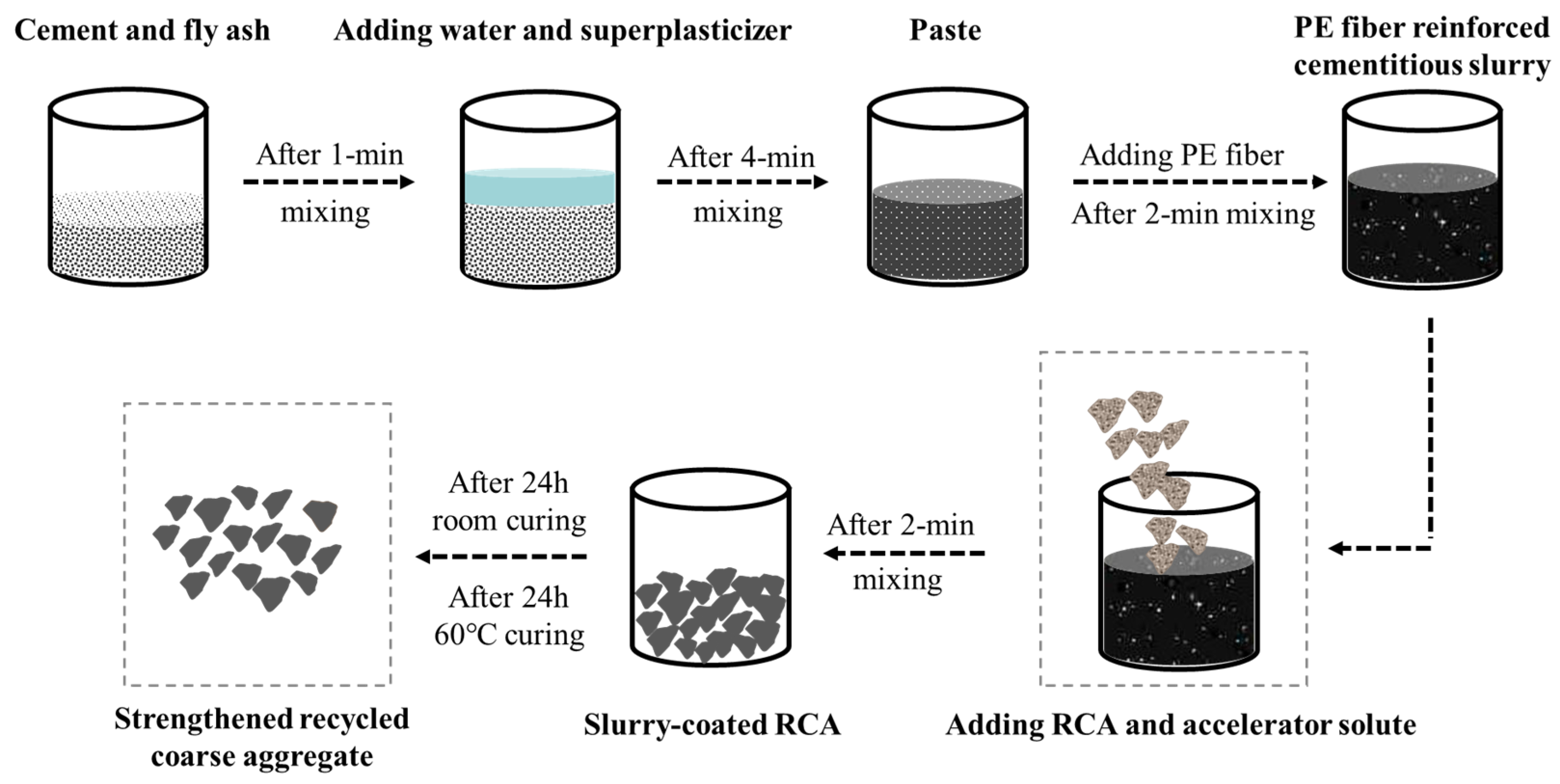

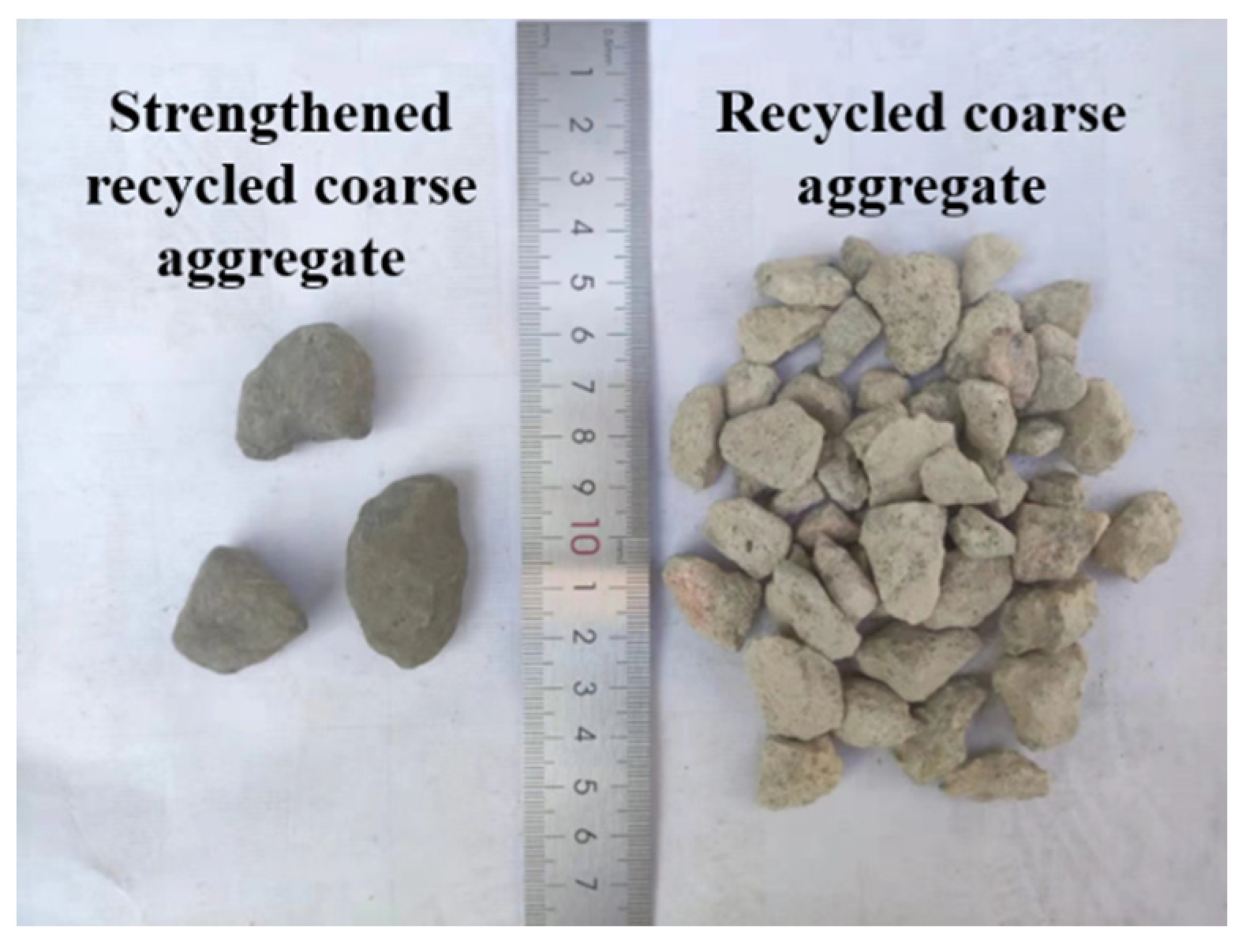

2. Preparation Process of Strengthened Recycled Coarse Aggregate

3. Experimental Program

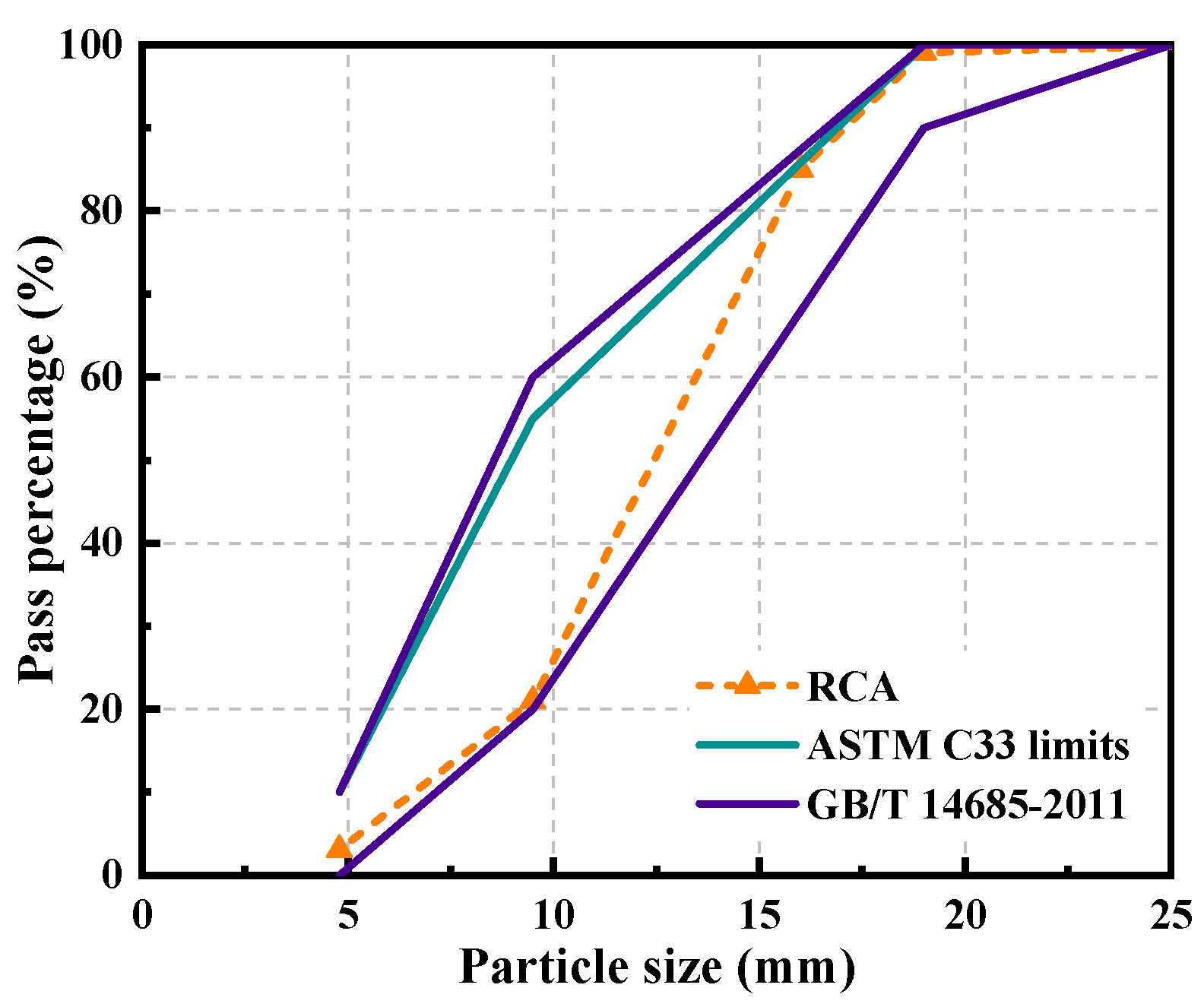

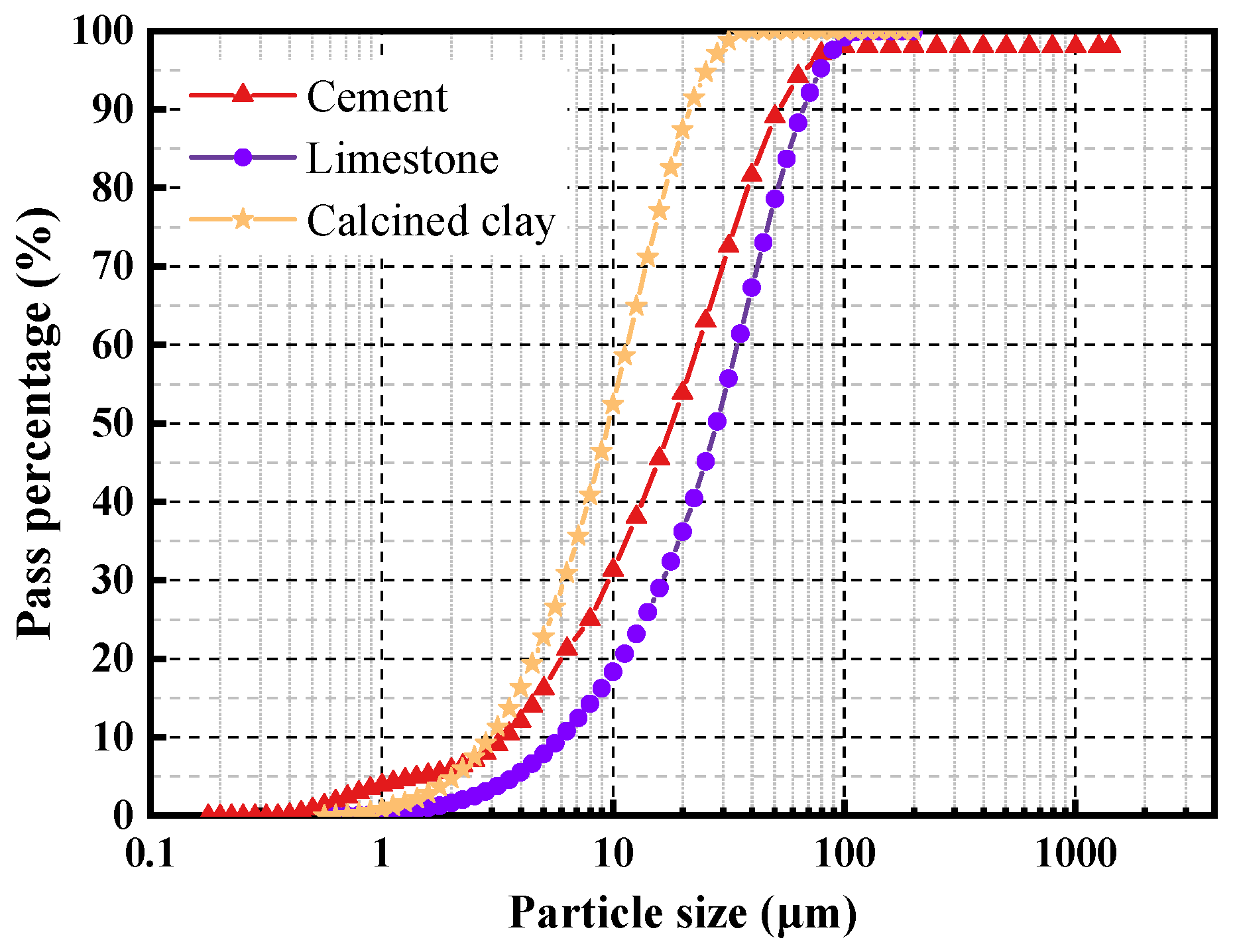

3.1. Materials

3.2. Mixture Proportions of Concrete

3.3. Compression Test

3.4. MIP Test

3.5. XRD Test

4. Mechanical Properties of Concrete

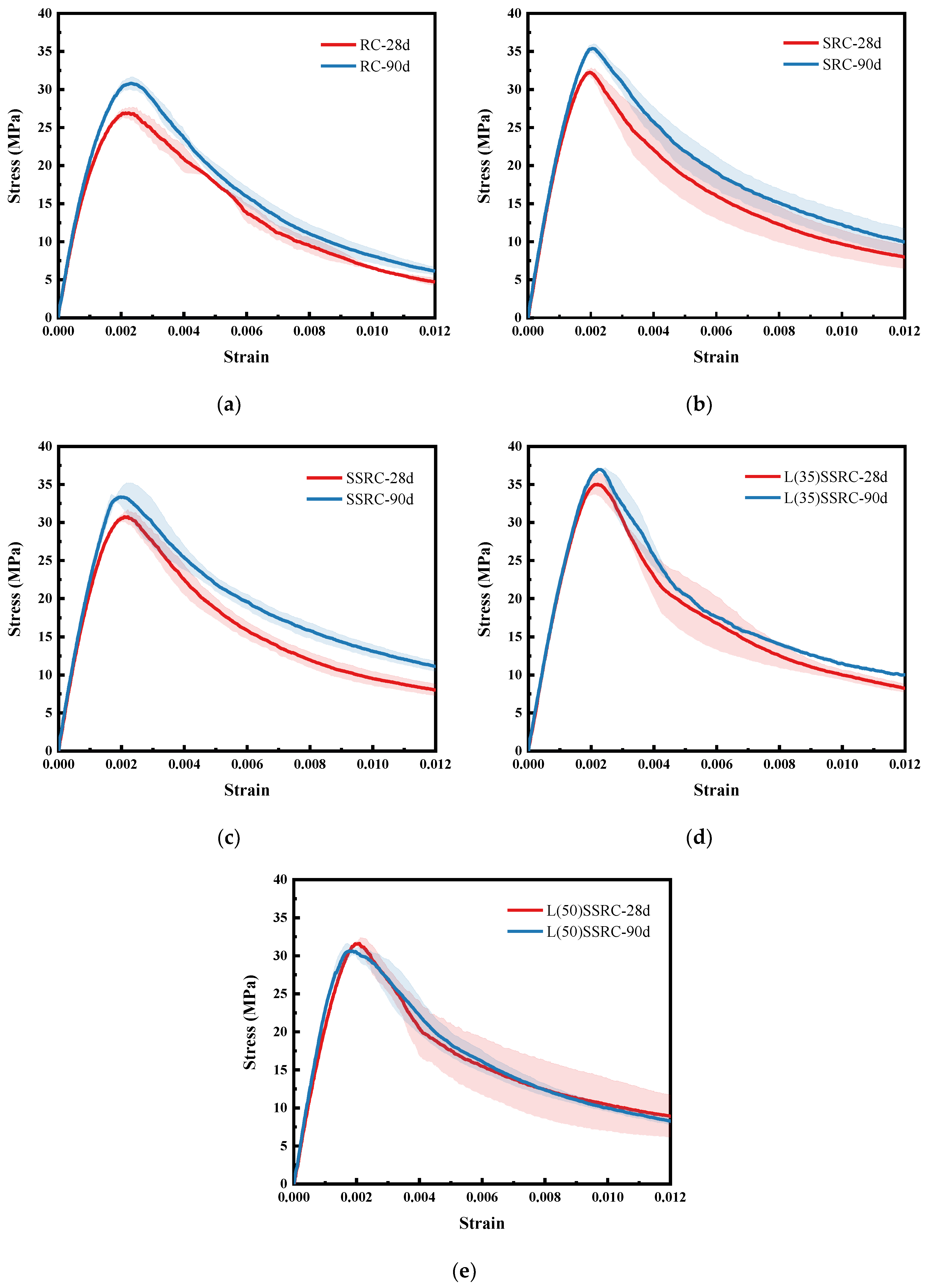

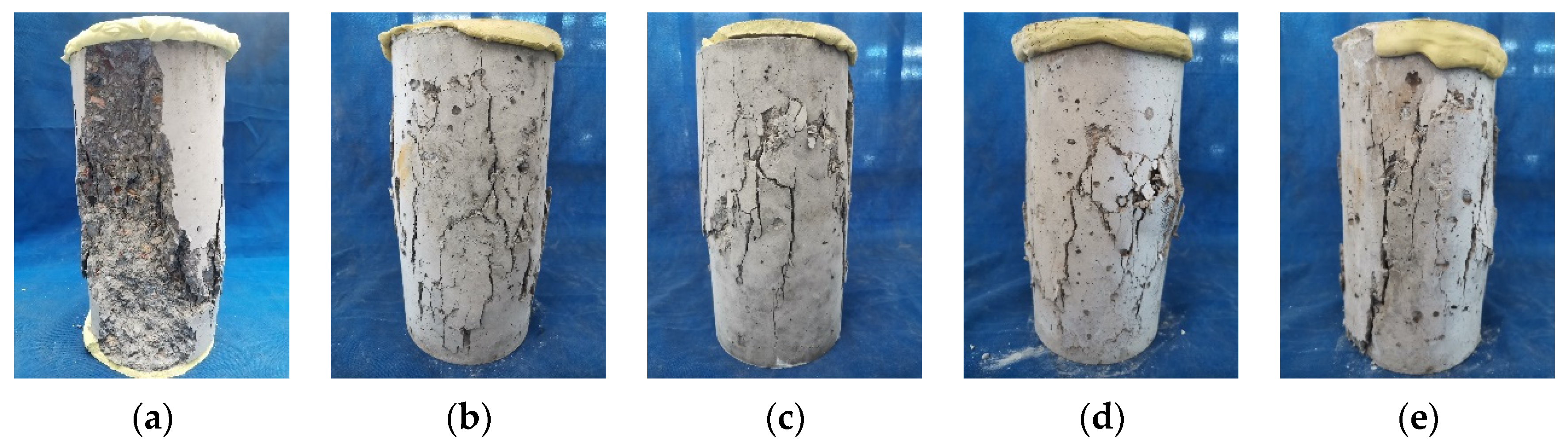

4.1. Stress-Strain Relationship

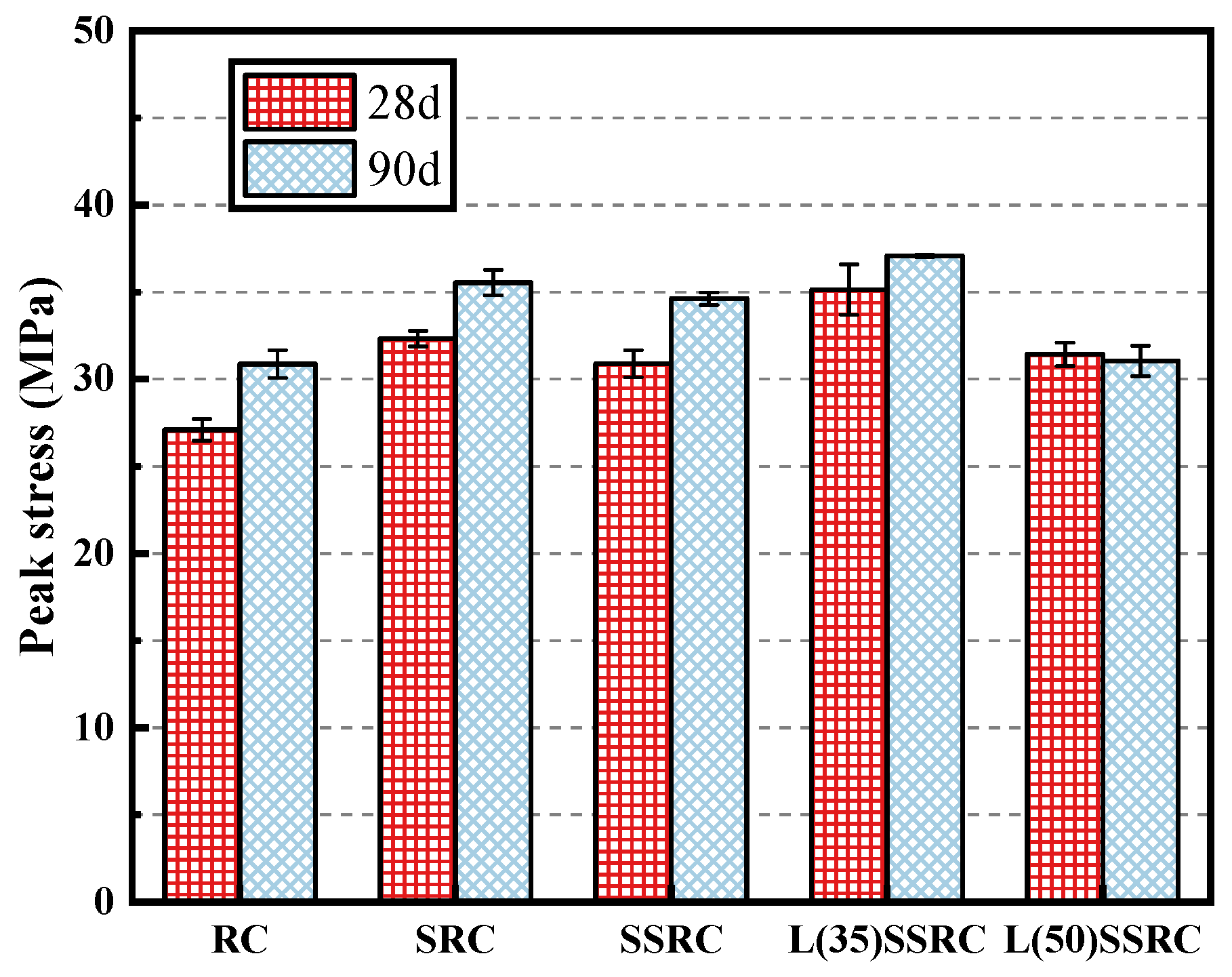

4.2. Peak Stress

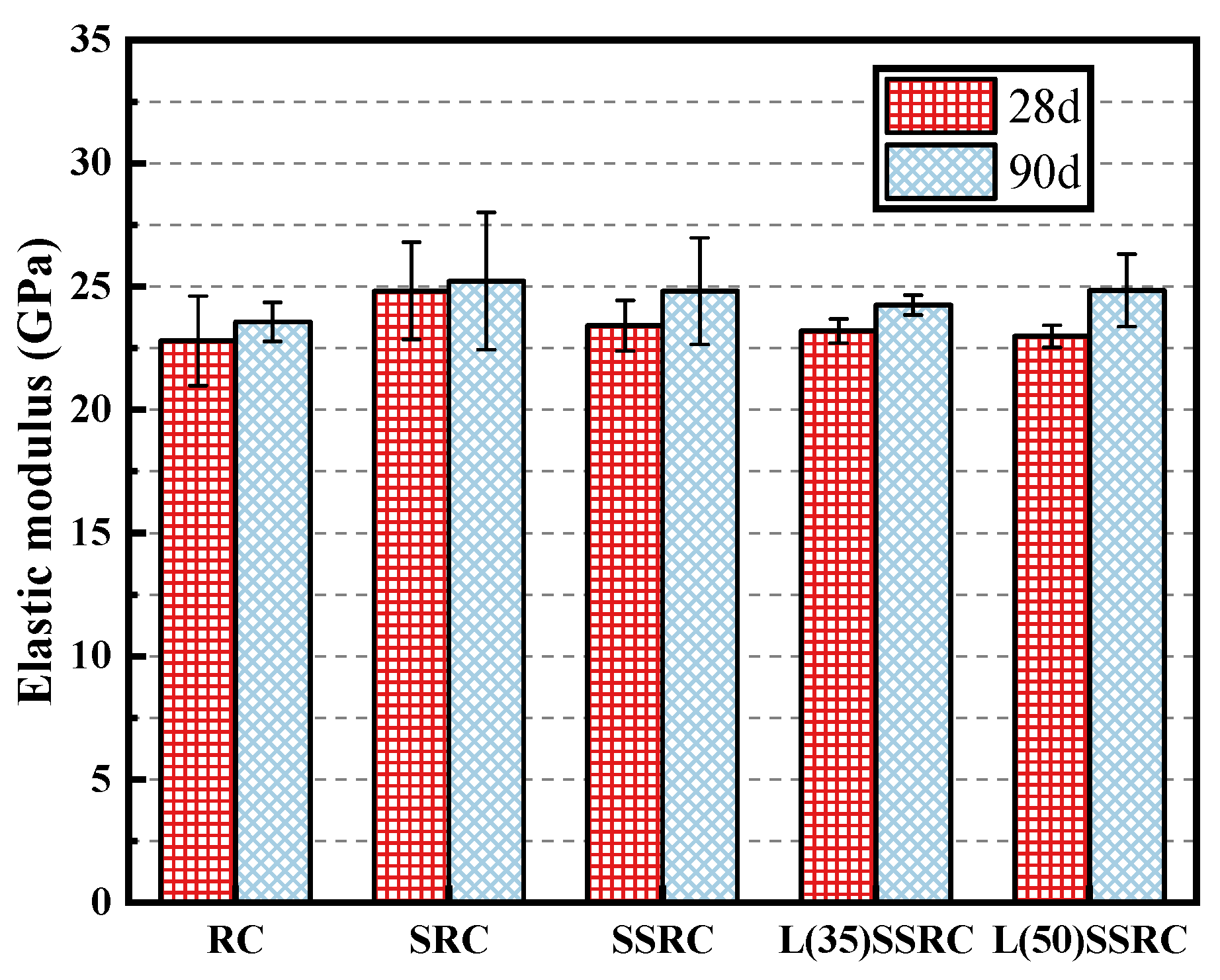

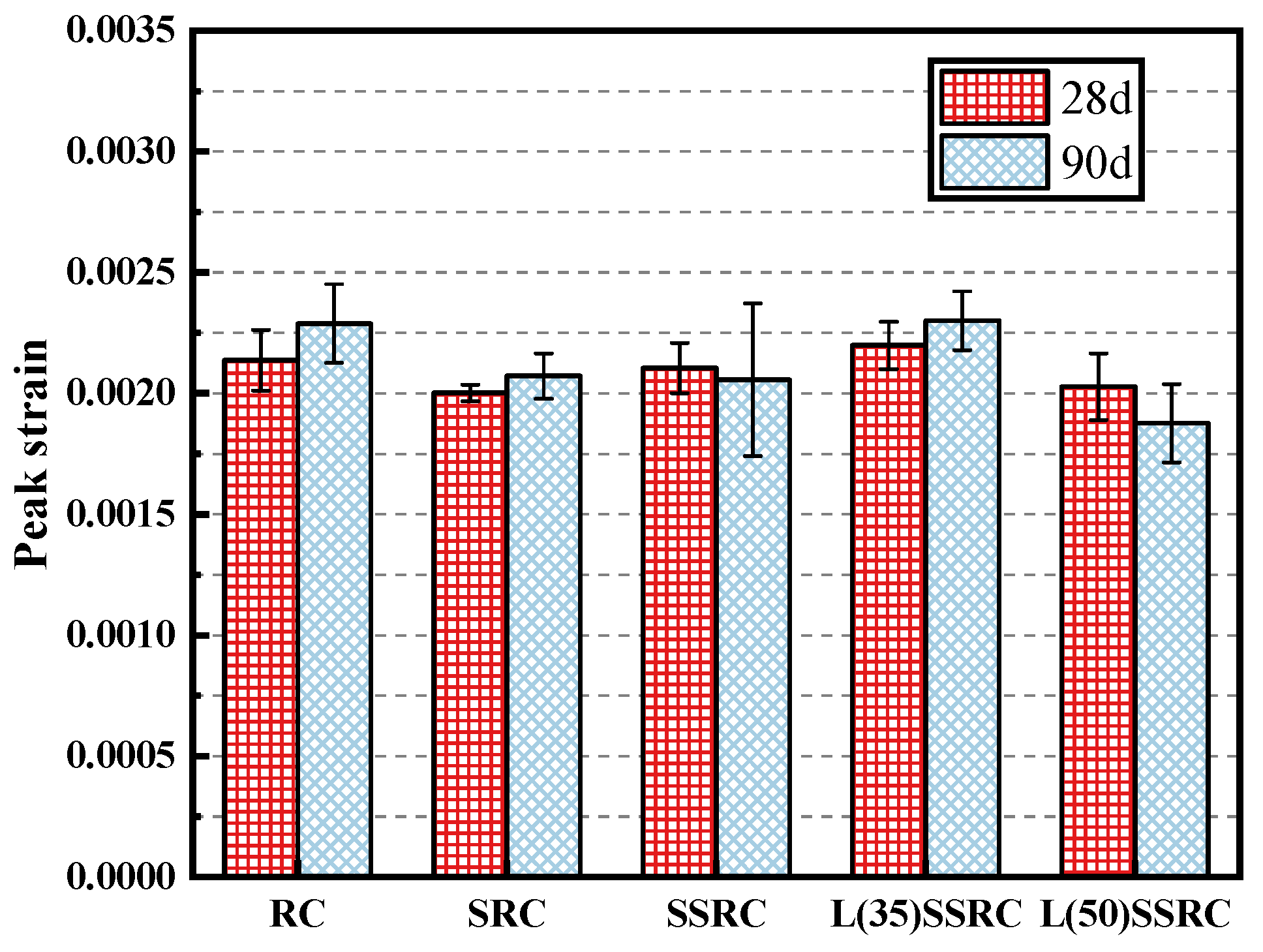

4.3. Elastic Modulus and Peak Strain

5. Microstructure of Concrete

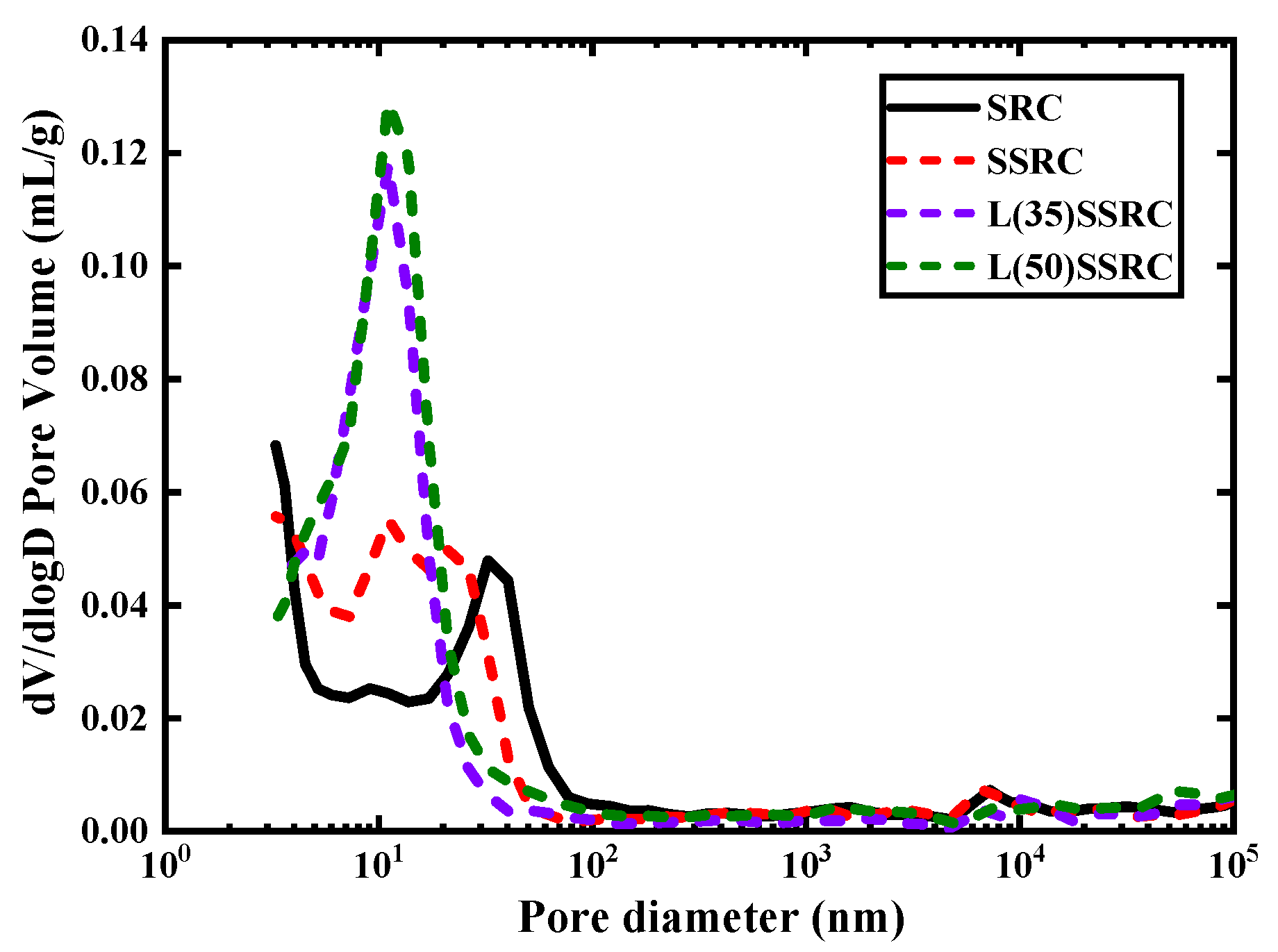

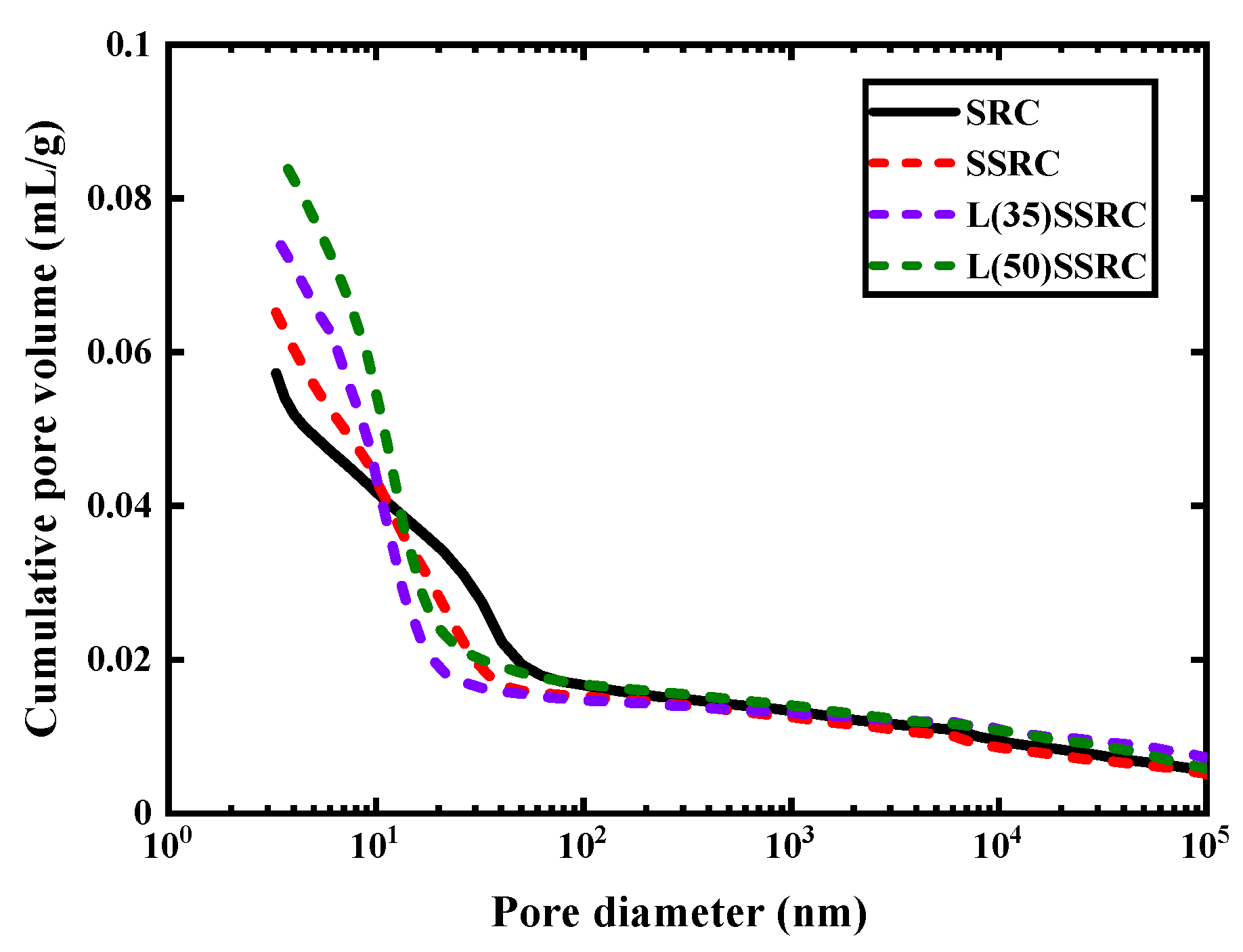

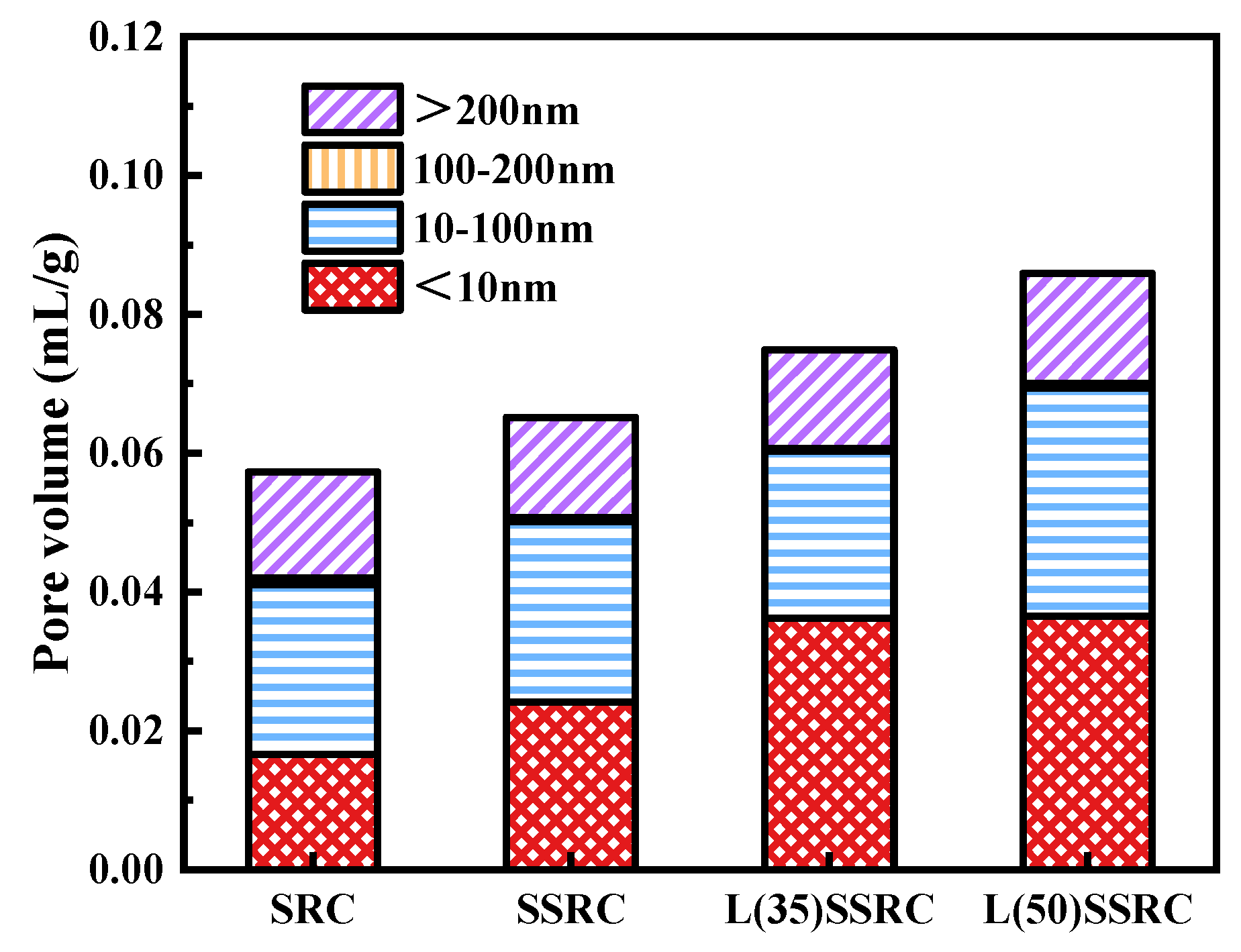

5.1. Pore Structure

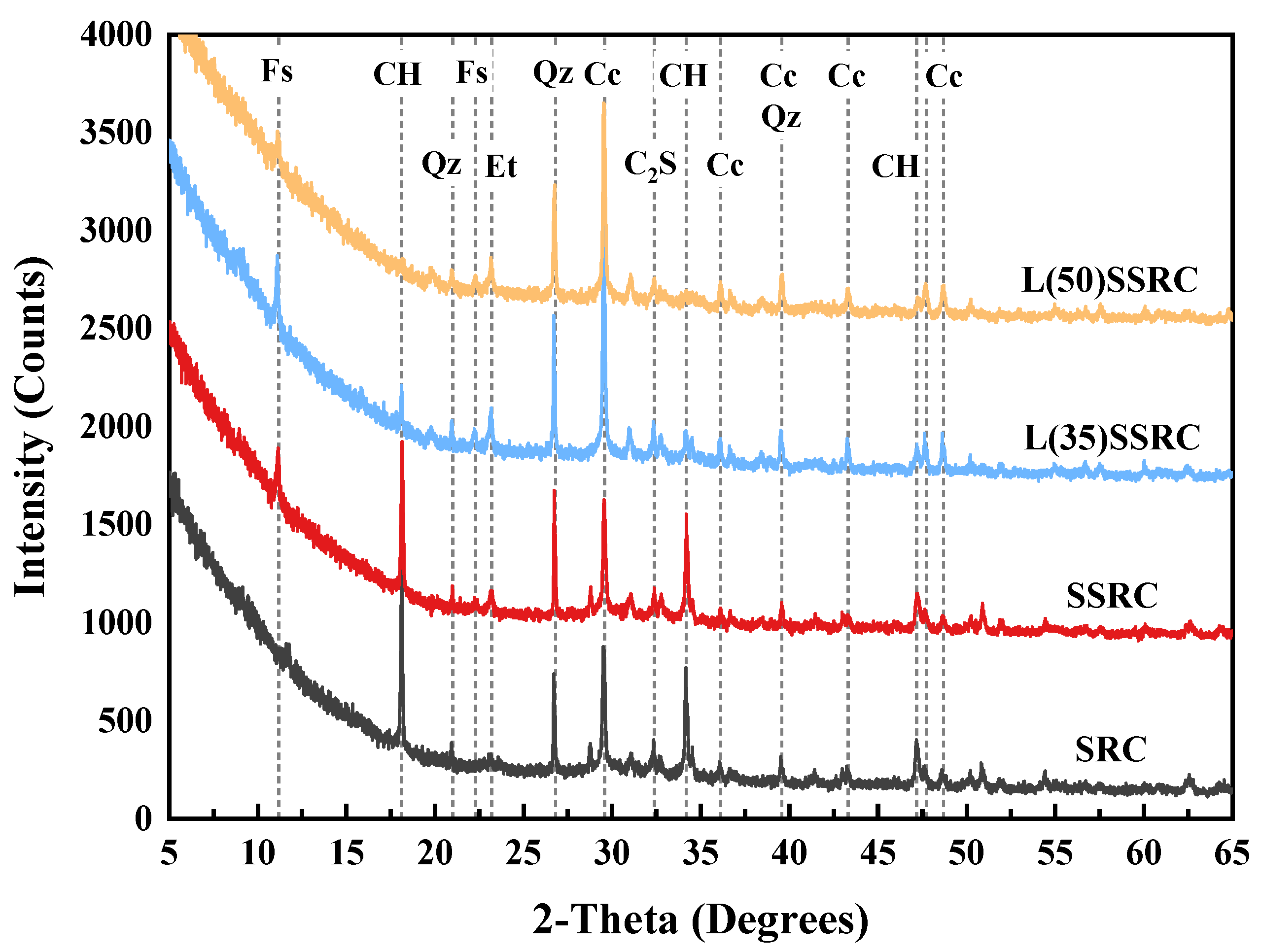

5.2. Hydration Products

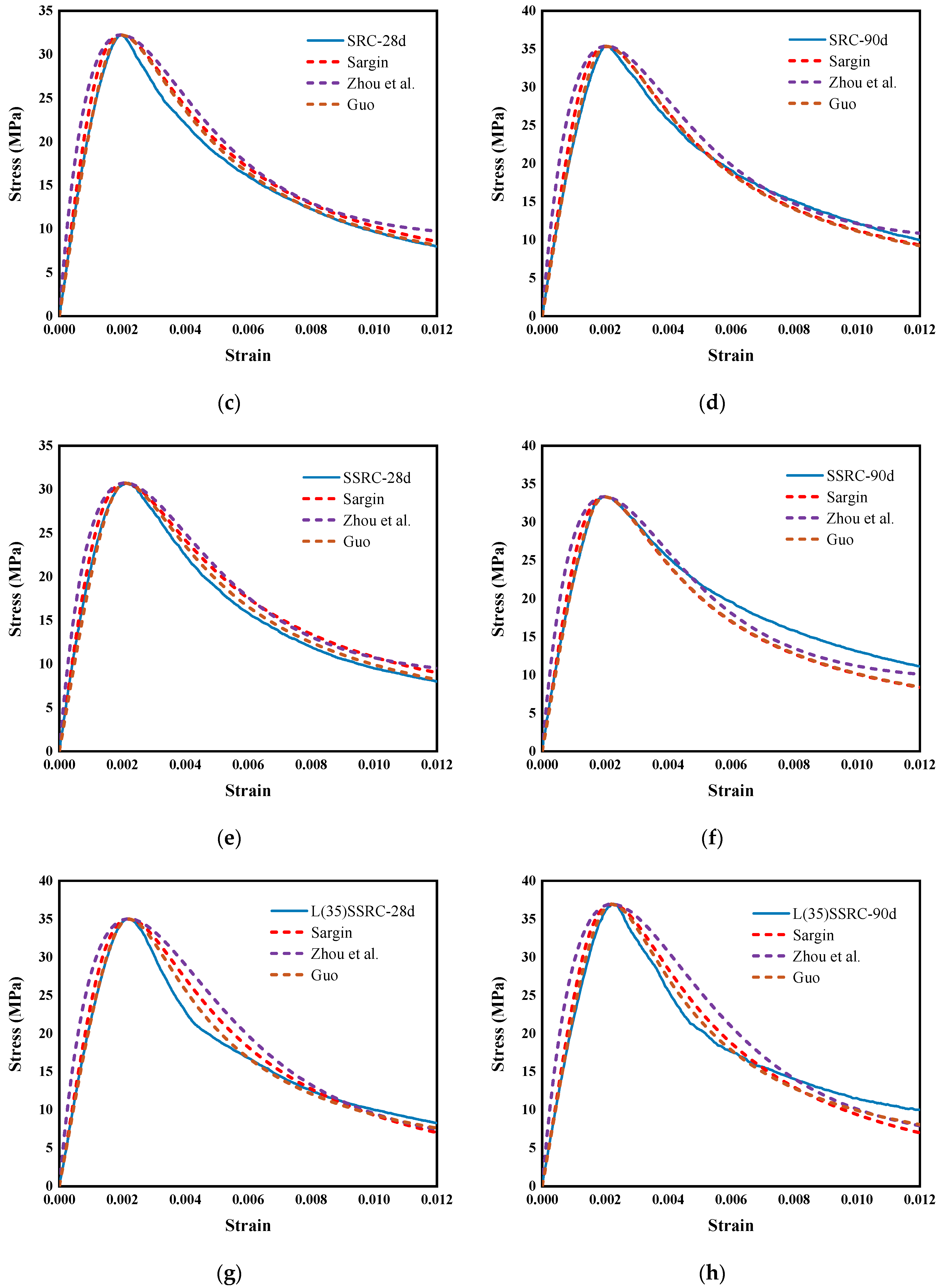

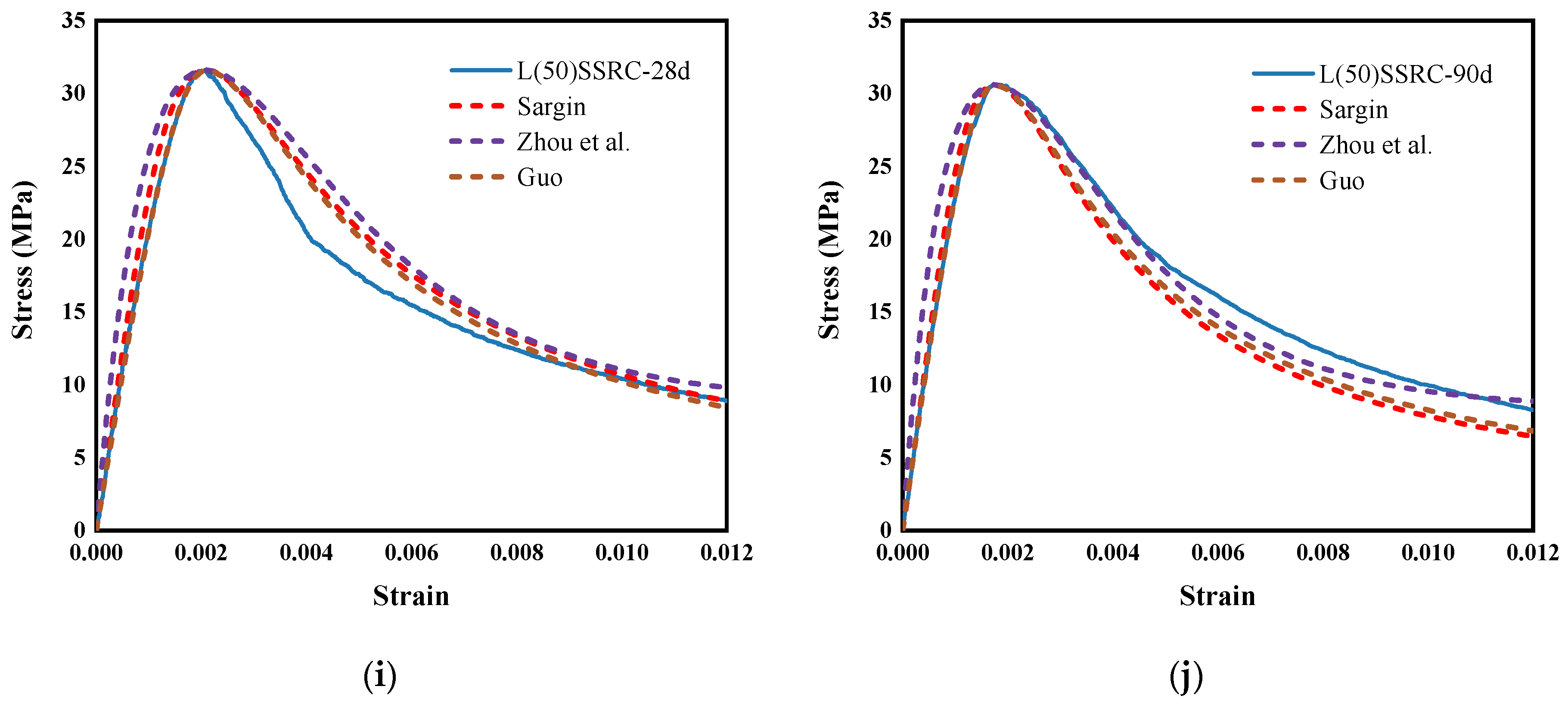

6. Constitutive Model Analysis

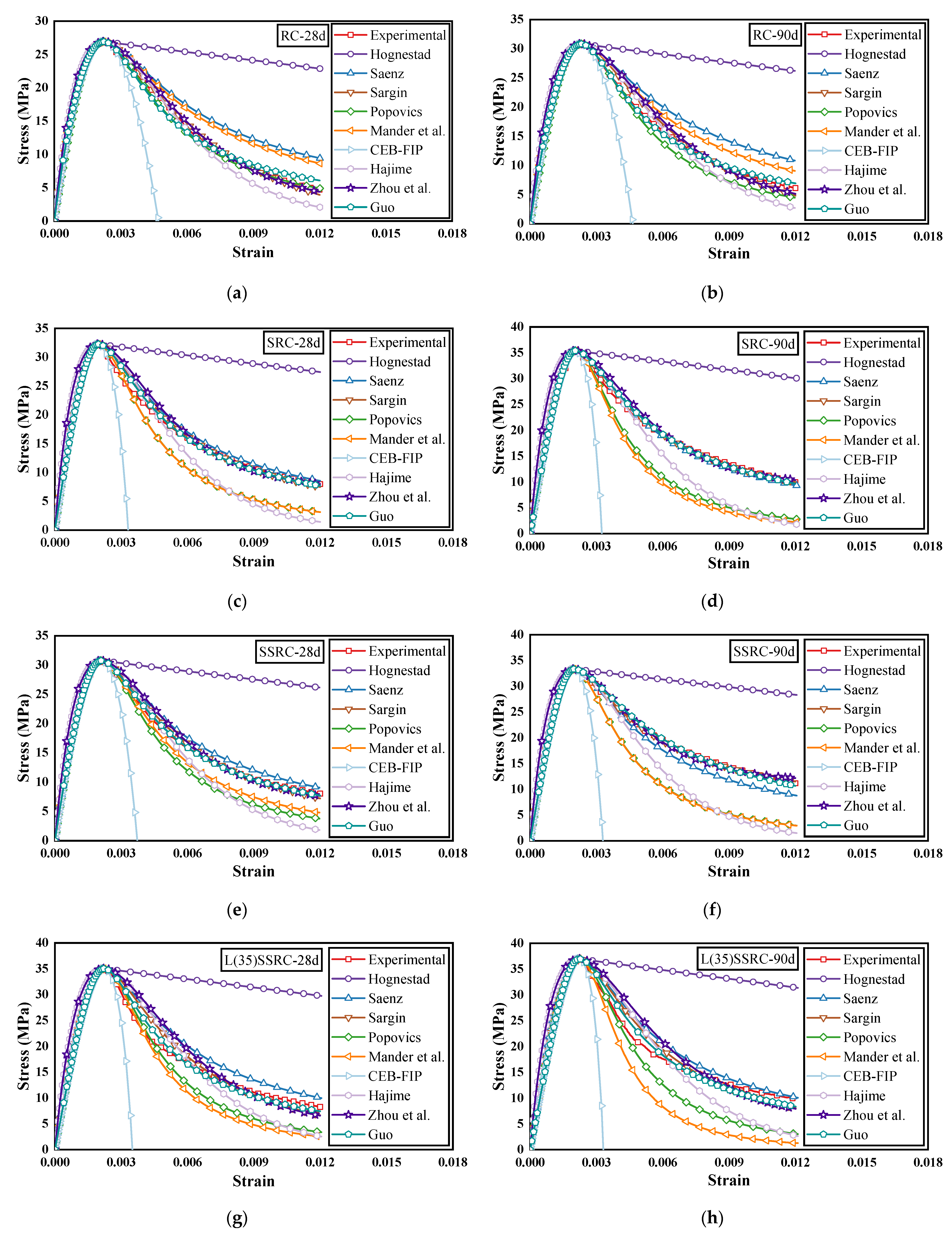

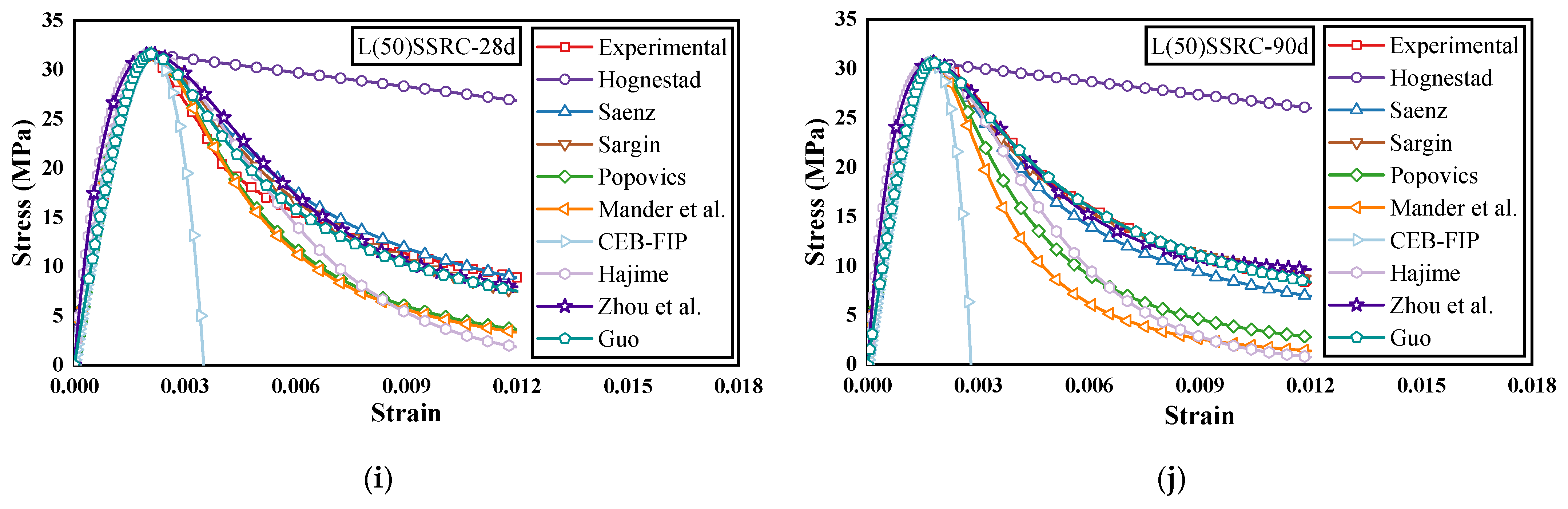

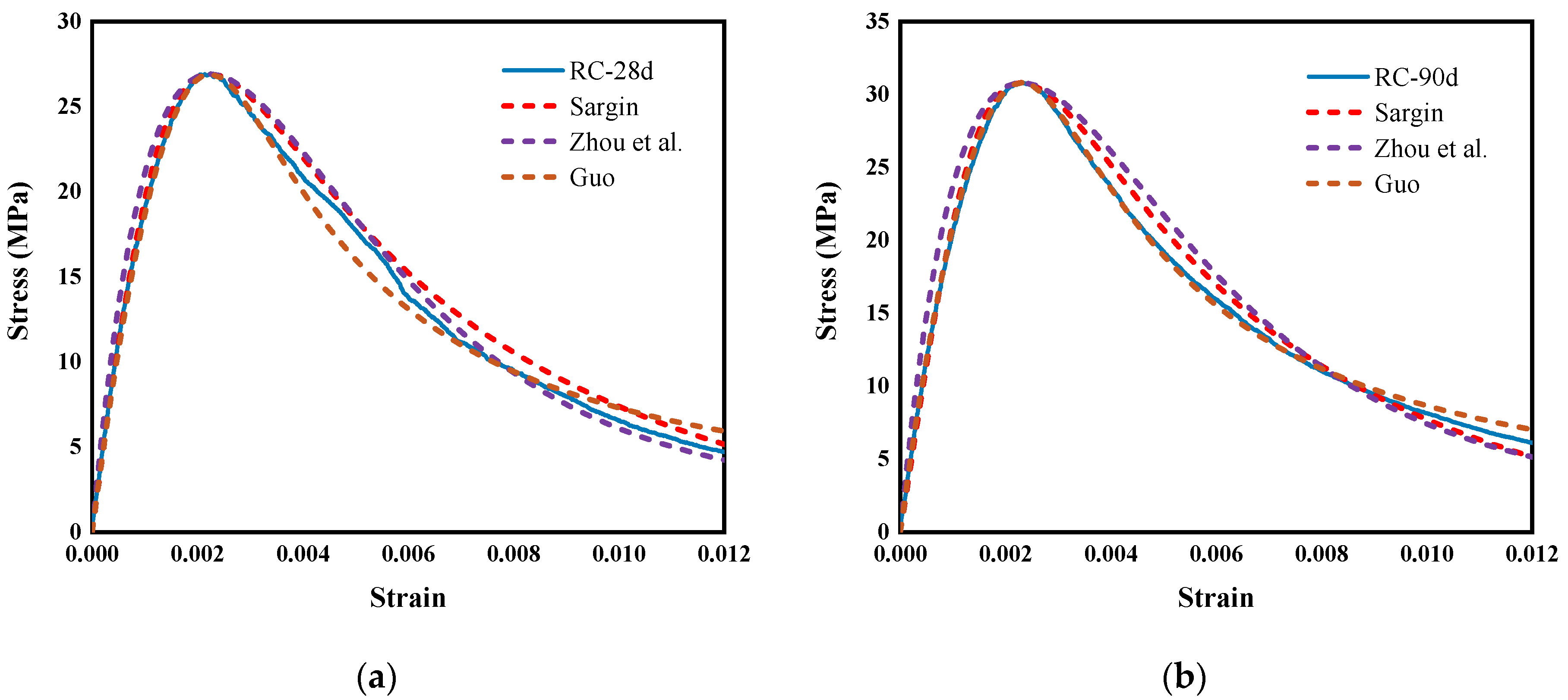

6.1. Existing Constitutive Models

6.2. Model Performance

6.3. Constitutive Model of Concrete

7. Conclusions

- (1)

- The mechanical performance of concrete using SRCA is remarkably improved, and the increasing ratio of 28-day compressive strength attains 19.34%. Slight reduction of compressive strength is observed when SWSS is incorporated, while, the situation is alleviated when 35% LC3 is added. The compressive strength of L(35)SSRC is the highest at both 28 and 90 days. Moreover, the failure mode of concrete cylinders is altered with the usage of SRCA. More cracks are generated, and the cylinders keep almost intact without concrete blocks peeling off from the cylinders.

- (2)

- The incorporation of both LC3 and SWSS refines the pore structure of concrete matrix. Although the total porosity is increased, the increment is mainly attributed to the rising of the volume of gel pores, which exhibit negligible influence on the strength of concrete.

- (3)

- SWSS leads to the formation of Friedel’s salt and additional ettringite, and the combination of LC3 and SWSS further promotes the formation of Friedel’s salt owing to the high content of aluminate phases in calcined clay. The content of Ca(OH)2 is reduced due to the pozzolanic reaction with the reactive components in calcined clay, while the content of CaCO3 is increased with the incorporation of limestone.

- (4)

- Based on the comparison analyses between the commonly used stress-strain models and the experimental results, the predictive constitutive models of the sustainable concretes are proposed by considering the influence of concrete age.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Meddah, M.S.; Al-Harthy, A.; Ismail, M.A. Recycled Concrete Aggregates and Their Influences on Performances of Low and Normal Strength Concretes. Buildings 2020, 10, 167. [Google Scholar] [CrossRef]

- Pacheco, J.; de Brito, J.; Chastre, C.; Evangelista, L. Experimental investigation on the variability of the main mechanical properties of concrete produced with coarse recycled concrete aggregates. Constr. Build. Mater. 2019, 201, 110–120. [Google Scholar] [CrossRef]

- Limbachiya, M.C.; Meddah, M.S.; Ouchagour, Y. Performance of Portland/Silica Fume Cement Concrete Produced with Recycled Concrete Aggregate. ACI Mater. J. 2012, 109, 91–100. [Google Scholar]

- Zheng, C.; Lou, C.; Du, G.; Li, X.; Liu, Z.; Li, L. Mechanical properties of recycled concrete with demolished waste concrete aggregate and clay brick aggregate. Results Phys. 2018, 9, 1317–1322. [Google Scholar] [CrossRef]

- Zhou, Y.; Hu, J.; Li, M.; Sui, L.; Xing, F. FRP-Confined Recycled Coarse Aggregate Concrete: Experimental Investigation and Model Comparison. Polymers 2016, 8, 375. [Google Scholar] [CrossRef]

- Peng, J.; Du, T.; Zhao, T.; Song, X.; Tang, J. Stress–Strain Relationship Model of Recycled Concrete Based on Strength and Replacement Rate of Recycled Coarse Aggregate. J. Mater. Civ. Eng. 2019, 31, 04019189. [Google Scholar] [CrossRef]

- Tang, W.; Khavarian, M.; Yousefi, A.; Chan, R.W.K.; Cui, H. Influence of Surface Treatment of Recycled Aggregates on Mechanical Properties and Bond Strength of Self-Compacting Concrete. Sustainability 2019, 11, 4182. [Google Scholar] [CrossRef]

- Limbachiya, M.C.; Meddah, M.S.; Ouchagour, Y. Use of Recycled Concrete Aggregate in Fly-Ash Concrete. Constr. Build. Mater. 2012, 27, 439–449. [Google Scholar] [CrossRef]

- Pedro, D.; de Brito, J.; Evangelista, L. Structural concrete with simultaneous incorporation of fine and coarse recycled concrete aggregates: Mechanical, durability and long-term properties. Constr. Build. Mater. 2017, 154, 294–309. [Google Scholar] [CrossRef]

- Bhasya, V.; Bharatkumar, B.H. Mechanical and Durability Properties of Concrete Produced with Treated Recycled Concrete Aggregate. ACI Mater. J. 2018, 115, 209–217. [Google Scholar] [CrossRef]

- Forero, J.A.; de Brito, J.; Evangelista, L.; Pereira, C. Improvement of the Quality of Recycled Concrete Aggregate Subjected to Chemical Treatments: A Review. Materials 2022, 15, 2740. [Google Scholar] [CrossRef] [PubMed]

- Revilla-Cuesta, V.; Evangelista, L.; de Brito, J.; Skaf, M.; Manso, J.M. Shrinkage prediction of recycled aggregate structural concrete with alternative binders through partial correction coefficients. Cem. Concr. Compos. 2022, 129, 104506. [Google Scholar] [CrossRef]

- Revilla-Cuesta, V.; Evangelista, L.; de Brito, J.; Ortega-López, V.; Manso, J.M. Effect of the maturity of recycled aggregates on the mechanical properties and autogenous and drying shrinkage of high-performance concrete. Constr. Build. Mater. 2021, 299, 124001. [Google Scholar] [CrossRef]

- Xiao, J.; Zhang, Q.; Zhang, P.; Shen, L.; Qiang, C. Mechanical behavior of concrete using seawater and sea-sand with recycled coarse aggregates. Struct. Concr. 2019, 20, 1631–1643. [Google Scholar] [CrossRef]

- Shi, C.; Li, Y.; Zhang, J.; Li, W.; Chong, L.; Xie, Z. Performance enhancement of recycled concrete aggregate—A review. J. Clean. Prod. 2016, 112, 466–472. [Google Scholar] [CrossRef]

- Kou, S.; Zhan, B.; Poon, C. Use of a CO2 curing step to improve the properties of concrete prepared with recycled aggregates. Cem. Concr. Compos. 2014, 45, 22–28. [Google Scholar] [CrossRef]

- Zhan, B.; Poon, C.; Liu, Q.; Kou, S.; Shi, C. Experimental study on CO2 curing for enhancement of recycled aggregate properties. Constr. Build. Mater. 2014, 67, 3–7. [Google Scholar] [CrossRef]

- Mukharjee, B.B.; Barai, S.V. Influence of incorporation of nano-silica and recycled aggregates on compressive strength and microstructure of concrete. Constr. Build. Mater. 2014, 71, 570–578. [Google Scholar] [CrossRef]

- Erdem, S.; Hanbay, S.; Guler, Z. Micromechanical damage analysis and engineering performance of concrete with colloidal nano-silica and demolished concrete aggregates. Constr. Build. Mater. 2018, 171, 634–642. [Google Scholar] [CrossRef]

- Ying, J.; Zhou, B.; Xiao, J. Pore structure structure and chloride diffusivity of recycled aggregate concrete with nano-SiO2 and nano-TiO2. Constr. Build. Mater. 2017, 150, 49–55. [Google Scholar] [CrossRef]

- Yue, Y.; Zhou, Y.; Xing, F.; Gong, G.; Hu, B.; Guo, M. An industrial applicable method to improve the properties of recycled aggregate concrete by incorporating nano-silica and micro-CaCO3. J. Clean. Prod. 2020, 259, 120920. [Google Scholar] [CrossRef]

- Qiu, J.; Tng, D.Q.S.; Yang, E. Surface treatment of recycled concrete aggregates through microbial carbonate precipitation. Constr. Build. Mater. 2014, 57, 144–150. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, S.; Lu, L.; Gong, C. Evaluation of pre-coated recycled aggregate for concrete and mortar. Constr. Build. Mater. 2013, 43, 191–196. [Google Scholar] [CrossRef]

- Kuylenstierna, J.; Najlis, P.; Bjorklund, G. The comprehensive assessment of the freshwater resources of the world—Policy options for an integrated sustainable water future. Water Int. 1998, 23, 17–20. [Google Scholar] [CrossRef]

- Global Cement and Concrete Association. Concrete Future. Available online: https://gccassociation.org/concretefuture/cement-concrete-around-the-world/ (accessed on 20 August 2022).

- Wei, W.; Liu, F.; Xiong, Z.; Yang, F.; Li, L.; Luo, H. Effect of loading rates on bond behaviour between basalt fibre-reinforced polymer bars and concrete. Constr. Build. Mater. 2020, 231, 117138. [Google Scholar] [CrossRef]

- Younis, A.; Ebead, U.; Suraneni, P.; Nanni, A. Fresh and hardened properties of seawater-mixed concrete. Constr. Build. Mater. 2018, 190, 276–286. [Google Scholar] [CrossRef]

- Guo, M.; Hu, B.; Xing, F.; Zhou, X.; Sun, M.; Sui, L.; Zhou, Y. Characterization of the mechanical properties of eco-friendly concrete made with untreated sea sand and seawater based on statistical analysis. Constr. Build. Mater. 2020, 234. [Google Scholar] [CrossRef]

- Huang, Y.; He, X.; Wang, Q.; Sun, Y. Mechanical properties of sea sand recycled aggregate concrete under axial compression. Constr. Build. Mater. 2018, 175, 55–63. [Google Scholar] [CrossRef]

- Limeira, J.; Etxeberria, M.; Agullo, L.; Molina, D. Mechanical and durability properties of concrete made with dredged marine sand. Constr. Build. Mater. 2011, 25, 4165–4174. [Google Scholar] [CrossRef]

- Nishida, T.; Otsuki, N.; Ohara, H.; Garba-Say, Z.M.; Nagata, T. Some considerations for applicability of seawater as mixing water in concrete. J. Mater. Civ. Eng. 2015, 27, B4014004. [Google Scholar] [CrossRef]

- Montanari, L.; Suraneni, P.; Tsui-Chang, M.; Khatibmasjedi, M.; Ebead, U.; Weiss, J.; Nanni, A. Hydration, Pore Solution, and Porosity of Cementitious Pastes Made with Seawater. J. Mater. Civ. Eng. 2019, 31, 04019154. [Google Scholar] [CrossRef]

- Li, Q.; Geng, H.; Shui, Z.; Huang, Y. Effect of metakaolin addition and seawater mixing on the properties and hydration of concrete. Appl. Clay Sci. 2015, 115, 51–60. [Google Scholar] [CrossRef]

- Zhao, Y.; Hu, X.; Shi, C.; Zhang, Z.; Zhu, D. A review on seawater sea-sand concrete: Mixture proportion, hydration, microstructure and properties. Constr. Build. Mater. 2021, 295, 123602. [Google Scholar] [CrossRef]

- Li, S.; Jin, Z.; Yu, Y. Chloride binding by calcined layered double hydroxides and alumina-rich cementitious materials in mortar mixed with seawater and sea sand. Constr. Build. Mater. 2021, 293, 123493. [Google Scholar] [CrossRef]

- Shi, Z.; Shui, Z.; Li, Q.; Geng, H. Combined effect of metakaolin and sea water on performance and microstructures of concrete. Constr. Build. Mater. 2015, 74, 57–64. [Google Scholar] [CrossRef]

- Maraghechi, H.; Avet, F.; Wong, H.; Kamyab, H.; Scrivener, K. Performance of Limestone Calcined Clay Cement (LC3) with various kaolinite contents with respect to chloride transport. Mater. Struct. 2018, 51, 125. [Google Scholar] [CrossRef]

- Scrivener, K.; Martirena, F.; Bishnoi, S.; Maity, S. Calcined clay limestone cements (LC3). Cem. Concr. Res. 2018, 114, 49–56. [Google Scholar] [CrossRef]

- Dhandapani, Y.; Sakthivel, T.; Santhanam, M.; Gettu, R.; Pillai, R.G. Mechanical properties and durability performance of concretes with Limestone Calcined Clay Cement (LC3). Cem. Concr. Res. 2018, 107, 136–151. [Google Scholar] [CrossRef]

- Li, Q.; Geng, H.; Huang, Y.; Shui, Z. Chloride resistance of concrete with metakaolin addition and seawater mixing: A comparative study. Constr. Build. Mater. 2015, 101, 184–192. [Google Scholar] [CrossRef]

- Dhandapani, Y.; Santhanam, M. Assessment of pore structure evolution in the limestone calcined clay cementitious system and its implications for performance. Cem. Concr. Compos. 2017, 84, 36–47. [Google Scholar] [CrossRef]

- Wang, Y.; Shui, Z.; Gao, X.; Yu, R.; Huang, Y.; Cheng, S. Understanding the chloride binding and diffusion behaviors of marine concrete based on Portland limestone cement-alumina enriched pozzolans. Constr. Build. Mater. 2019, 198, 207–217. [Google Scholar] [CrossRef]

- Antoni, M.; Rossen, J.; Martirena, F.; Scrivener, K. Cement substitution by a combination of metakaolin and limestone. Cem. Concr. Res. 2012, 42, 1579–1589. [Google Scholar] [CrossRef]

- De Weerdt, K.; Justnes, H. The effect of sea water on the phase assemblage of hydrated cement paste. Cem. Concr. Compos. 2015, 55, 215–222. [Google Scholar] [CrossRef]

- Xiao, J.; Zhang, P.; Zhang, Q.; Shen, J.; Li, Y.; Zhou, Y. Basic mechanical properties of recycled concrete with seawater and sea sand. J. Build. Sci. Eng. 2018, 35, 16–22. [Google Scholar]

- Guo, M.; Gong, G.; Yue, Y.; Xing, F.; Zhou, Y.; Hu, B. Performance evaluation of recycled aggregate concrete incorporating limestone calcined clay cement (LC3). J. Clean. Prod. 2022, 366, 132820. [Google Scholar] [CrossRef]

- Qu, F.; Li, W.; Wang, K.; Tam, V.W.Y.; Zhang, S. Effects of seawater and undesalted sea sand on the hydration products, mechanical properties and microstructures of cement mortar. Constr. Build. Mater. 2021, 310, 125229. [Google Scholar] [CrossRef]

- Krishnan, S.; Bishnoi, S. A numerical approach for designing composite cements with calcined clay and limestone. Cem. Concr. Res. 2020, 138, 106232. [Google Scholar] [CrossRef]

- GB/T 50081-2002; Standards for Testing Methods of Mechanical Properties of Ordinary Concrete. China Architecture and Building Press: Beijing, China, 2002.

- Etxeberria, M.; Fernandez, J.M.; Limeira, J. Secondary aggregates and seawater employment for sustainable concrete dyke blocks production: Case study. Constr. Build. Mater. 2016, 113, 586–595. [Google Scholar] [CrossRef]

- Etxeberria, M.; Gonzalez-Corominas, A. Properties of Plain Concrete Produced Employing Recycled Aggregates and Sea Water. Int. J. Civ. Eng. 2018, 16, 993–1003. [Google Scholar] [CrossRef]

- Bao, J.; Li, Y.; Xie, B.; Zhou, X.; Wang, M. Research progress on cement concrete pore structure. China Concr. Prog. 2010, 2010, 94–99. [Google Scholar]

- Wu, Z.; Zhang, H. Expanded Concrete; China Railway Press: Beijing, China, 1990. [Google Scholar]

- Cheng, S.; Shui, Z.; Sun, T.; Huang, Y.; Liu, K. Effects of seawater and supplementary cementitious materials on the durability and microstructure of lightweight aggregate concrete. Constr. Build. Mater. 2018, 190, 1081–1090. [Google Scholar] [CrossRef]

- Li, P.; Li, W.; Yu, T.; Qu, F.; Tam, V.W.Y. Investigation on early-age hydration, mechanical properties and microstructure of seawater sea sand cement mortar. Constr. Build. Mater. 2020, 249, 118776. [Google Scholar] [CrossRef]

- Lothenbach, B.; Le Saout, G.; Gallucci, E.; Scrivener, K. Influence of limestone on the hydration of Portland cements. Cem. Concr. Res. 2008, 38, 848–860. [Google Scholar] [CrossRef]

- Matschei, T.; Lothenbach, B.; Glasser, F.P. The role of calcium carbonate in cement hydration. Cem. Concr. Res. 2007, 37, 551–558. [Google Scholar] [CrossRef]

- Zajac, M.; Rossberg, A.; Le Saout, G.; Lothenbach, B. Influence of limestone and anhydrite on the hydration of Portland cements. Cem. Concr. Compos. 2014, 46, 99–108. [Google Scholar] [CrossRef]

- Gong, G.; Guo, M.; Zhou, Y.; Zheng, S.; Hu, B.; Zhu, Z.; Huang, Z. Multiscale Investigation on the Performance of Engineered Cementitious Composites Incorporating PE Fiber and Limstone Calcined Clay Cement (LC3). Polymers 2022, 14, 1291. [Google Scholar] [CrossRef]

- Wang, Y.; Shui, Z.; Huang, Y.; Sun, T.; Duan, P. Properties of coral waste-based mortar incorporating metakaolin: Part II. Chloride migration and binding behaviors. Constr. Build. Mater. 2018, 174, 433–442. [Google Scholar] [CrossRef]

- Hognestad, E. A Study of Combined Bending and Axial Load in Reinforced Concrete Members; Bulletin Series No. 399, Engineering Experiment Station; University of Illinois Urbana: Champaign, IL, USA, 1951. [Google Scholar]

- Hognestad, E.; Hanson, N.W.; Mchenry, D. Concrete stress distribution in ultimate strength design. ACI J. Proc. 1955, 27, 455–479. [Google Scholar]

- Saenz, L.P. Discussion of equation for the stress–strain curve of concrete by Desai and Krishnan. ACI J. 1964, 61, 1229–1235. [Google Scholar]

- Sargin, M. Stress–Strain Relationship for Concrete and the Analysis of Structural Concrete Section, Study, 4; Solid Mechanics Division, University of Waterloo: Waterloo, ON, Canada, 1971. [Google Scholar]

- Popovics, S. Numerical approach to the complete stress–strain relation for concrete. Cem. Concr. Res. 1973, 3, 583–599. [Google Scholar] [CrossRef]

- Mander, J.B.; Priestley, M.J.N.; Park, R. Theoretical stress–strain model for confined concrete. J. Struct. Eng. 1988, 114, 1804–1826. [Google Scholar] [CrossRef]

- Comite Euro-International du Beton. CEB-FIP Model Code 1990 (Concrete Structures); Bulletin D’information No. 213/214; Comite Euro-International du Beton: Lausanne, Switzerland, 1993. [Google Scholar]

- Jiang, J.; Lu, X.; Ye, L. Finite Element Analysis of Concrete Structures; Tsinghua University Press: Beijing, China, 2005. [Google Scholar]

- Zhou, Y.; Wu, Y. General model for constitutive relationships of concrete and its composite structures. Compos. Struct. 2012, 94, 580–592. [Google Scholar] [CrossRef]

- Guo, Z. Strength and Deformation of Concrete: The Relationship between Experimental Foundation and Constitutive; Tsinghua University Press: Beijing, China, 1997. [Google Scholar]

| Bulk Density (kg/m3) | Crushing Index (%) | Water Absorption Ratio (%) | |

|---|---|---|---|

| RCA | 2617 | 19.49 | 6.11 |

| SRCA | 2653 | 12.21 | 6.02 |

| Cement | Fly Ash | Water | PE Fiber | Quick-Setting Accelerator | Superplasticizer |

|---|---|---|---|---|---|

| 1130 | 380 | 580 | 14 | 30 | 21 |

| Length (mm) | Diameter (μm) | Aspect Ratio | Strength (GPa) | Elastic Modulus (GPa) | Elongation at Break (%) | Density (kg/m3) |

|---|---|---|---|---|---|---|

| 12 | 25 | 480 | 2.9 | 116 | 2.42 | 970 |

| Compounds | OPC | Calcined Clay | Limestone |

|---|---|---|---|

| SiO2 | 20.271 | 53.732 | 0.309 |

| Al2O3 | 5.184 | 39.405 | 0.130 |

| K2O | 0.809 | 4.229 | 0.040 |

| Fe2O3 | 4.087 | 2.056 | - |

| MgO | 0.086 | 0.307 | 0.769 |

| TiO2 | 0.349 | 0.18 | - |

| SO3 | 2.684 | 0.087 | - |

| CaO | 63.913 | 0.102 | 98.715 |

| Rb2O | - | 0.037 | - |

| SrO | 0.030 | - | 0.037 |

| MnO | 0.098 | - | - |

| ZnO | 0.079 | - | - |

| P2O5 | 0.044 | 0.037 | - |

| Na2O | 0.086 | - | - |

| Specific surface area (m2/g) | 0.96 | 11.53 | 0.25 |

| Specific gravity | 3.07 | 2.48 | 2.70 |

| Types | Sea Sand | Desalted Sea Sand |

|---|---|---|

| Fineness modulus | 2.3 | 2.2 |

| Sludge content (%) | 2.4 | 0.4 |

| Mud mass content (%) | 0.6 | 0.4 |

| Apparent density (kg/m3) | 2620 | 2620 |

| Bulk density (kg/m3) | 1480 | 1450 |

| Tight density (kg/m3) | 1670 | 1680 |

| Shell content (%) | 0.4 | 3.6 |

| Chloride ion content (%) | 0.159 | 0.007 |

| Sulfates and sulfides (%) | 0.90 | 0.81 |

| Organic matter | Qualified | Qualified |

| Types | Na+ | K+ | Ca2+ | Mg2+ | F− | Cl− | ||

|---|---|---|---|---|---|---|---|---|

| Seawater | 4.24 × 103 | 380 | 390 | 1.25 × 103 | <0.10 | 1.97 × 103 | 5.24 × 103 | 11.78 |

| Tap water | 2.69 | 11.20 | 6.65 | 1.76 | 0.17 | 10.90 | 7.19 | <0.10 |

| Concrete | OPC | Calcined Clay | Limestone | Tap Water | Desalted Sea Sand | Seawater | Sea Sand | RCA | SRCA | Effective w/b |

|---|---|---|---|---|---|---|---|---|---|---|

| RC | 538 | - | - | 274 | 576 | 1070 | 0.39 | |||

| SRC | 538 | - | - | 274 | 576 | - | 1070 | 0.39 | ||

| SSRC | 538 | - | - | - | - | 274 | 576 | - | 1070 | 0.39 |

| L(35)SSRC | 360 | 119 | 59 | - | - | 274 | 576 | - | 1070 | 0.39 |

| L(50)SSRC | 296 | 161 | 81 | - | - | 274 | 576 | - | 1070 | 0.39 |

| Model | Stress-Strain Model |

|---|---|

| Hognestad [61,62] | |

| Saenz [63] | |

| Sargin [64] | |

| Popovics [65] | |

| is in psi (1 MPa = 145 psi) | |

| Mander et al. [66] | |

| CEB-FIP [67] | |

| Hajime [68] | |

| Zhou et al. [69] | |

| Guo [70] | |

| Model | RC-28d | SRC-28d | SSRC-28d | L(35)SSRC-28d | L(50)SSRC-28d | |

|---|---|---|---|---|---|---|

| Sargin | D | 0.76 | 0.96 | 0.93 | 0.89 | 0.94 |

| R2 | 0.99 | 0.98 | 0.99 | 0.95 | 0.94 | |

| Zhou et al. | C | 0.02 | 0.06 | 0.06 | 0.03 | 0.06 |

| R2 | 0.98 | 0.92 | 0.95 | 0.85 | 0.86 | |

| Guo | a | 2.11 | 1.45 | 1.68 | 1.42 | 1.45 |

| R2 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | |

| b | 0.97 | 0.75 | 0.77 | 1.03 | 0.82 | |

| R2 | 0.98 | 0.99 | 0.99 | 0.97 | 0.95 |

| Model | RC-90d | SRC-90d | SSRC-90d | L(35)SSRC-90d | L(50)SSRC-90d | |

|---|---|---|---|---|---|---|

| Sargin | D | 0.77 | 1.04 | 1.12 | 0.93 | 1.09 |

| R2 | 0.98 | 0.98 | 0.99 | 0.95 | 0.99 | |

| Zhou et al. | C | 0.02 | 0.08 | 0.10 | 0.04 | 0.09 |

| R2 | 0.96 | 0.92 | 0.94 | 0.84 | 0.95 | |

| Guo | a | 1.93 | 1.33 | 1.44 | 1.27 | 1.38 |

| R2 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | |

| b | 1.02 | 0.66 | 0.50 | 0.95 | 0.54 | |

| R2 | 0.99 | 0.99 | 0.99 | 0.97 | 0.99 |

| Model | RC | SRC | SSRC | L(35)SSRC | L(50)SSRC | |

|---|---|---|---|---|---|---|

| Sargin | D | 0.8 | 1.0 | 1.0 | 0.9 | 1.0 |

| Zhou et al. | C | 0.02 | 0.08 | 0.08 | 0.04 | 0.08 |

| Guo | a | 2.0 | 1.4 | 1.4 | 1.4 | 1.4 |

| b | 1.0 | 0.7 | 0.7 | 1.0 | 0.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Q.; Zhou, Y.; Guan, Z.; Xing, F.; Guo, M.; Hu, B. Mechanical Performance and Constitutive Model Analysis of Concrete Using PE Fiber-Strengthened Recycled Coarse Aggregate. Polymers 2022, 14, 3964. https://doi.org/10.3390/polym14193964

Zhou Q, Zhou Y, Guan Z, Xing F, Guo M, Hu B. Mechanical Performance and Constitutive Model Analysis of Concrete Using PE Fiber-Strengthened Recycled Coarse Aggregate. Polymers. 2022; 14(19):3964. https://doi.org/10.3390/polym14193964

Chicago/Turabian StyleZhou, Qimi, Yingwu Zhou, Zhipei Guan, Feng Xing, Menghuan Guo, and Biao Hu. 2022. "Mechanical Performance and Constitutive Model Analysis of Concrete Using PE Fiber-Strengthened Recycled Coarse Aggregate" Polymers 14, no. 19: 3964. https://doi.org/10.3390/polym14193964

APA StyleZhou, Q., Zhou, Y., Guan, Z., Xing, F., Guo, M., & Hu, B. (2022). Mechanical Performance and Constitutive Model Analysis of Concrete Using PE Fiber-Strengthened Recycled Coarse Aggregate. Polymers, 14(19), 3964. https://doi.org/10.3390/polym14193964