Electron Transport Layer Optimization for Efficient PTB7:PC70BM Bulk-Heterojunction Solar Cells

Abstract

:1. Introduction

2. Device Modeling and Simulation Methods

2.1. Simulation Methodology

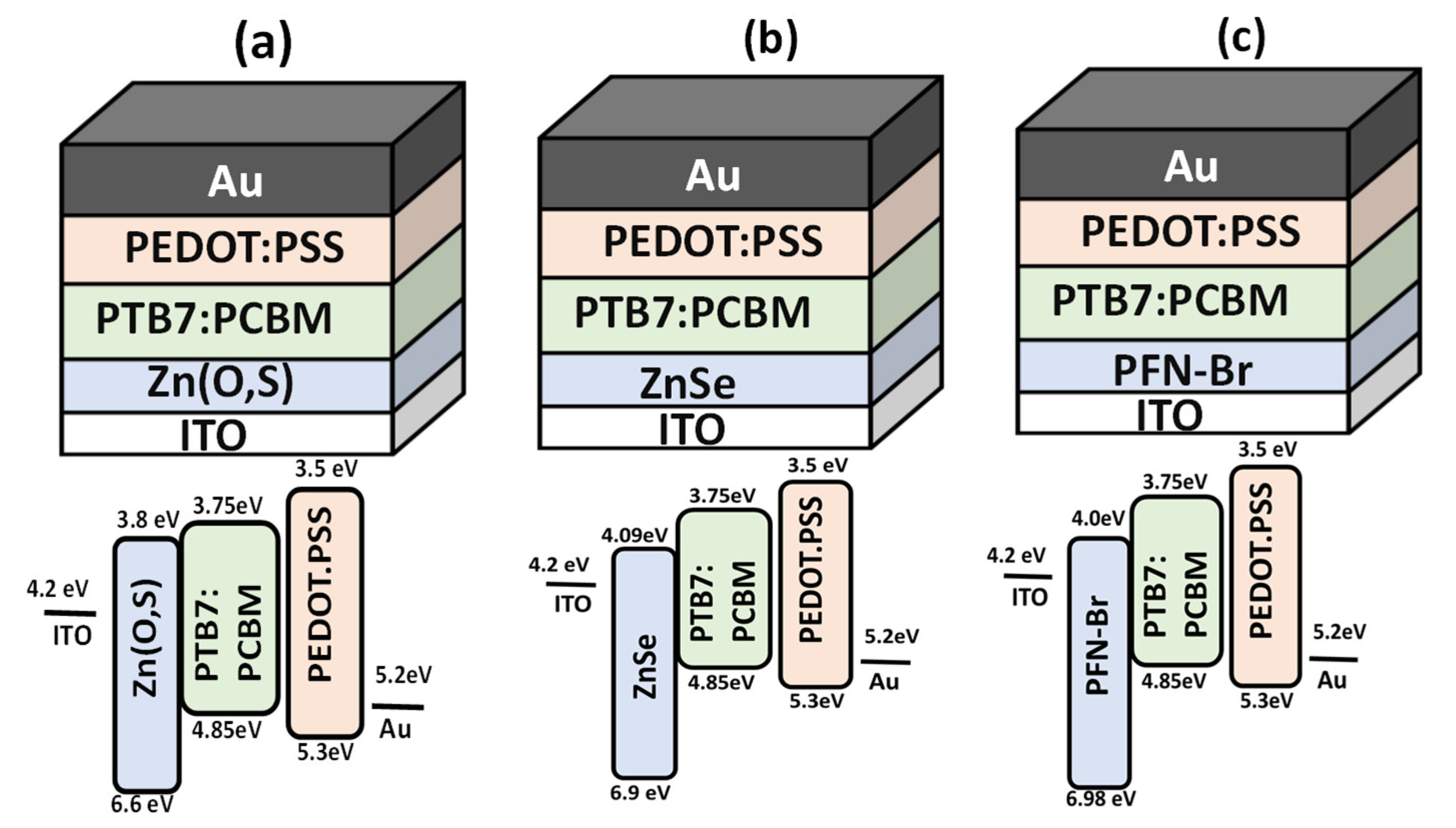

2.2. Device Structure:

- ITO/Zn(O,S)/PTB7:PC70BM/PEDOT:PSS/Ag (Zn(O,S) device);

- ITO/ZnSe/PTB7:PC70BM/PEDOT:PSS/Ag (ZnSe device);

- ITO/PFN-Br/PTB7:PC70BM/PEDOT:PSS/Ag (PFN-Br device).

2.3. Simulation Parameters

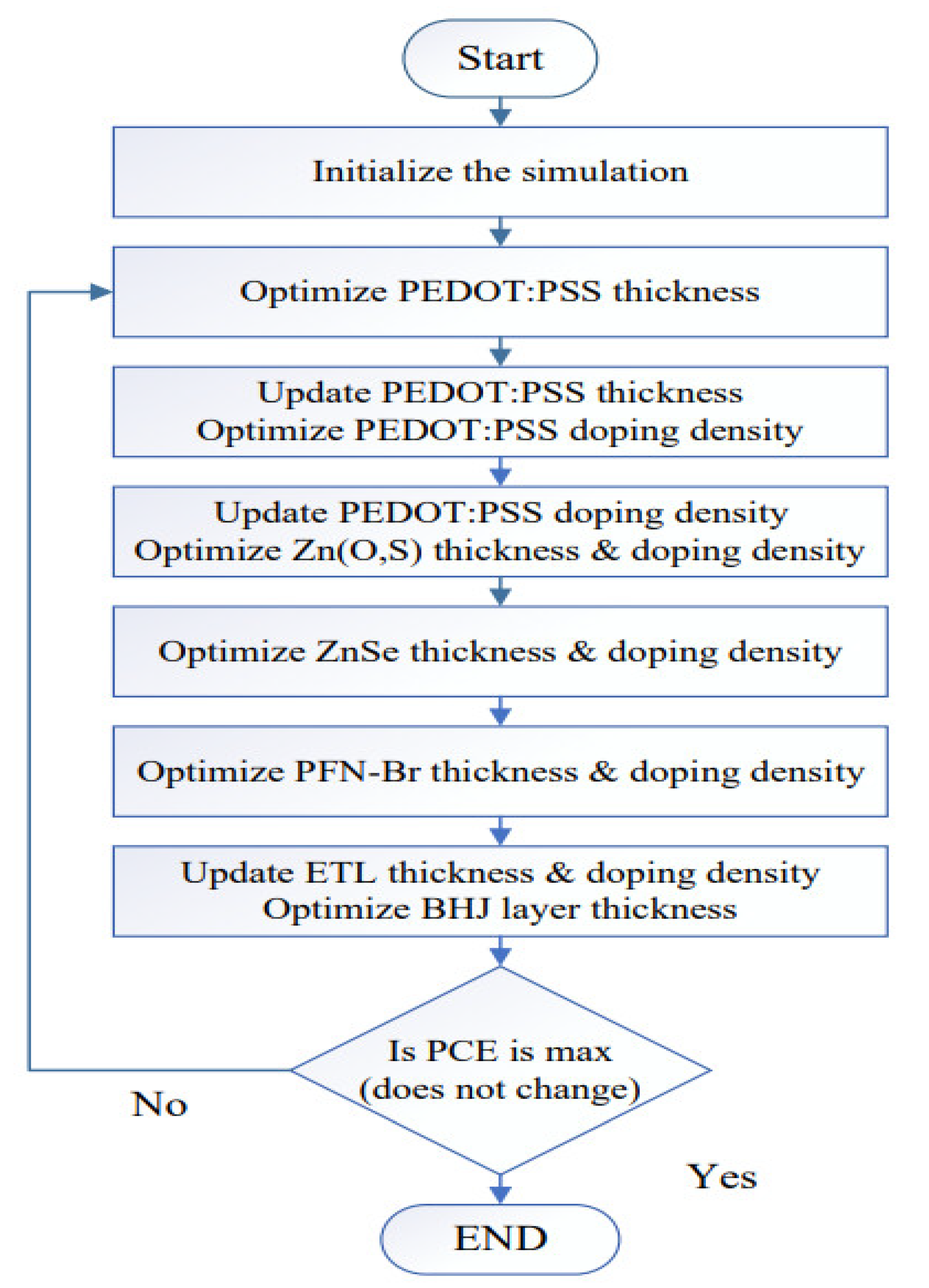

2.4. Simulation Flowchart

3. Results and Discussion

3.1. Optimization of PEDOT:PSS Layer Thickness

3.2. Optimization PEDOT:PSS Doping Density

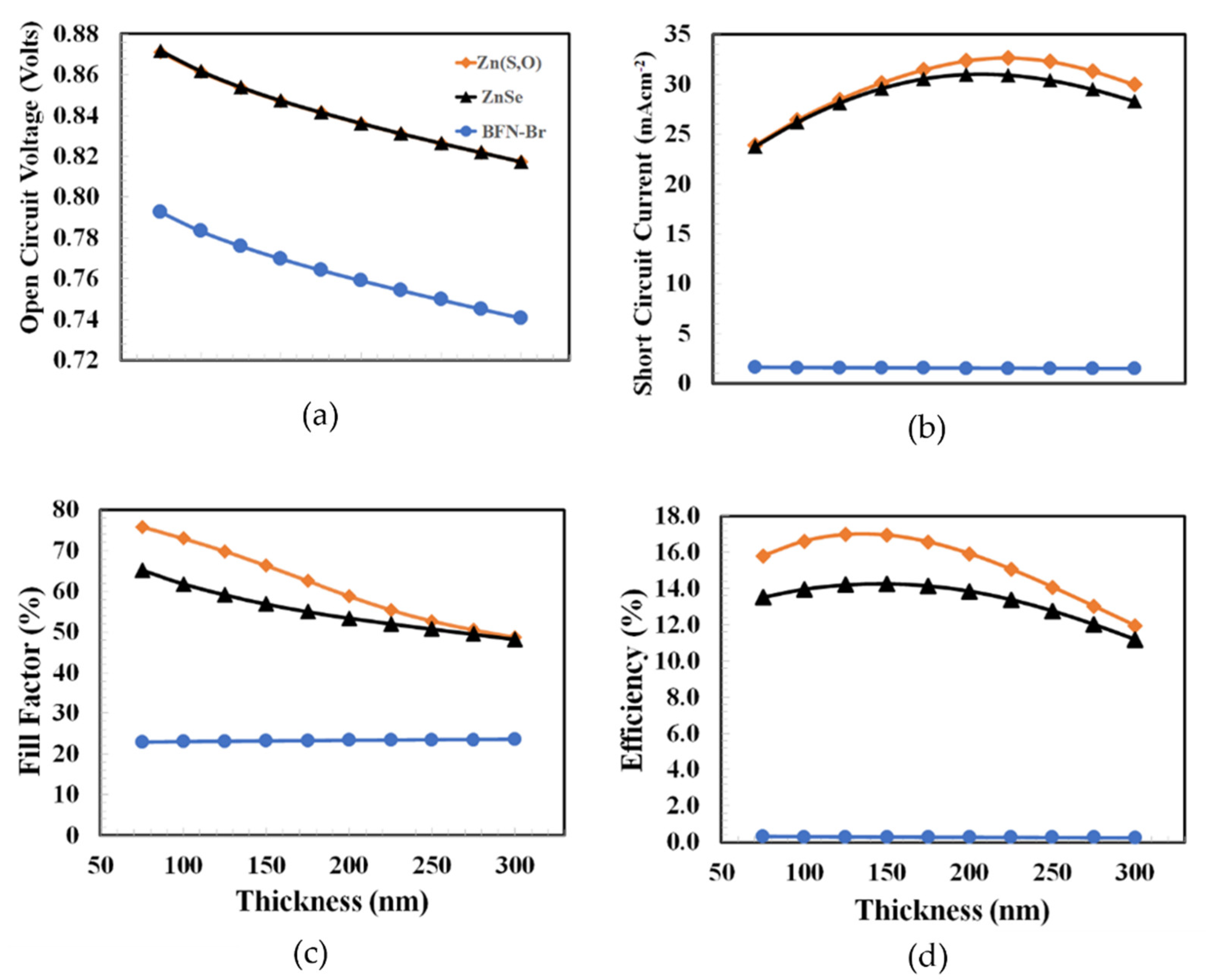

3.3. Optimization of Electron Transport Layer Thickness

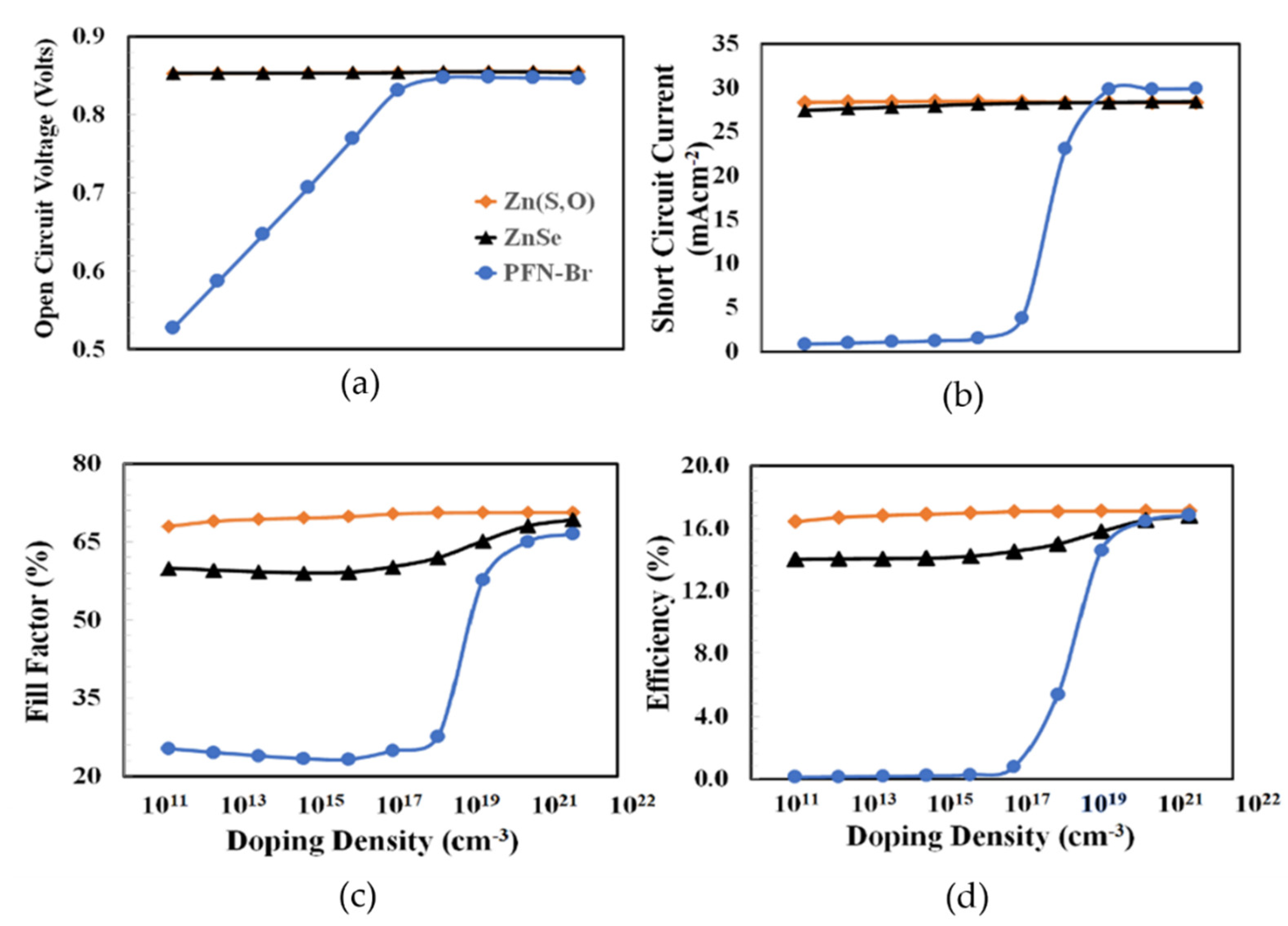

3.4. Optimization of Electron Transport Layer Doping

3.5. Optimization of BHJ Active Layer Thickness

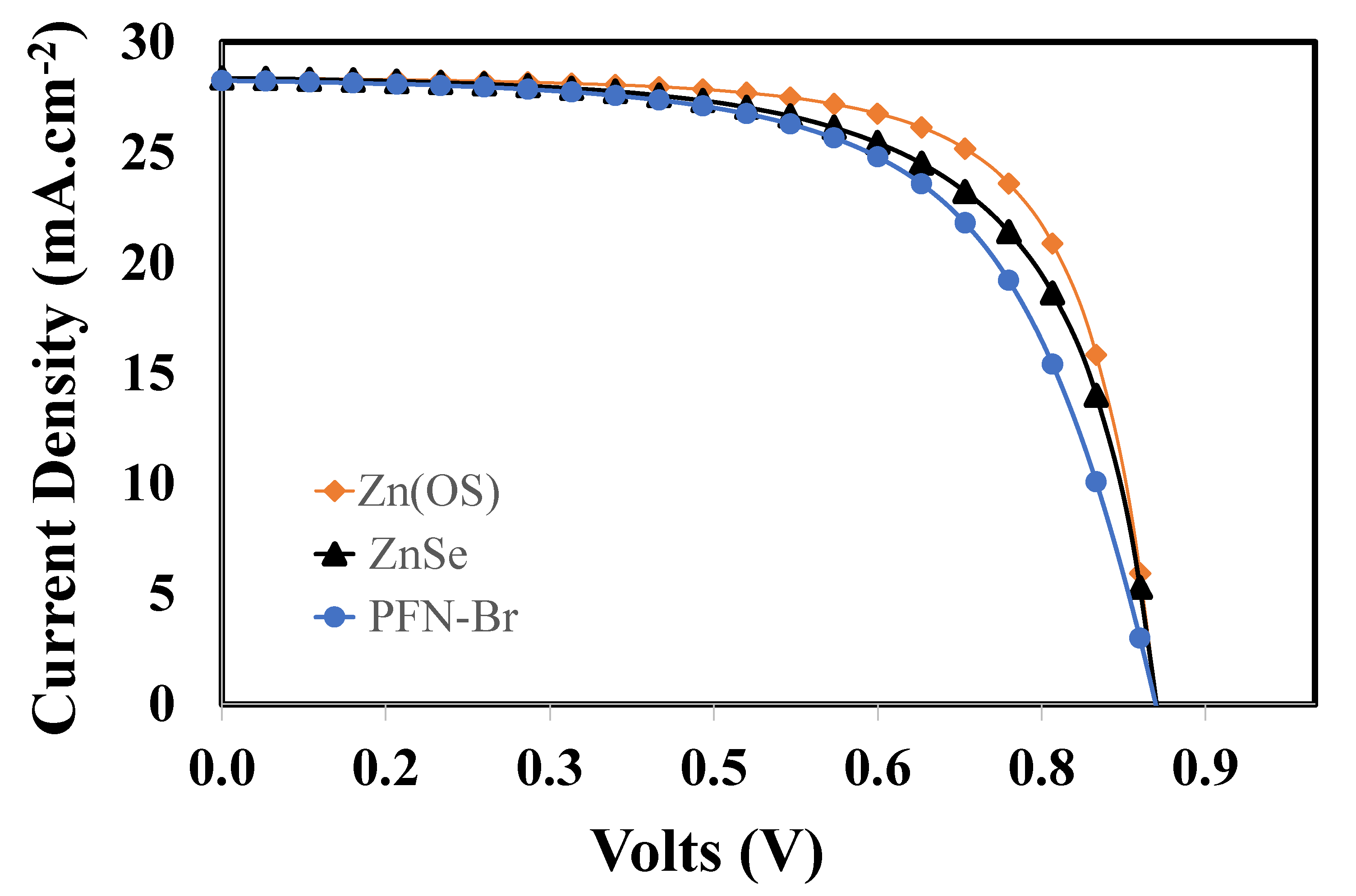

3.6. Overall Photovoltaic Response of the Proposed Devices

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Perez, M.; Perez, R. Update 2022—A Fundamental Look at Supply Side Energy Reserves for the Planet. Sol. Energy Adv. 2022, 2, 100014. [Google Scholar] [CrossRef]

- Shafiee, S.; Topal, E. When Will Fossil Fuel Reserves Be Diminished? Energy Policy 2009, 37, 181–189. [Google Scholar] [CrossRef]

- Kabir, E.; Kumar, P.; Kumar, S.; Adelodun, A.A.; Kim, K.H. Solar Energy: Potential and Future Prospects. Renew. Sustain. Energy Rev. 2018, 82, 894–900. [Google Scholar] [CrossRef]

- Gross, R.; Leach, M.; Bauen, A. Progress in Renewable Energy. Environ. Int. 2003, 29, 105–122. [Google Scholar] [CrossRef]

- Dincer, I. Renewable Energy and Sustainable Development: A Crucial Review. Renew. Sustain. Energy Rev. 2000, 4, 105–122. [Google Scholar] [CrossRef]

- Colasante, A.; D’Adamo, I.; Morone, P. What Drives the Solar Energy Transition? The Effect of Policies, Incentives and Behavior in a Cross-Country Comparison. Energy Res. Soc. Sci. 2022, 85, 102405. [Google Scholar] [CrossRef]

- Liang, C.; Gu, H.; Xia, J.; Mei, S.; Pang, P.; Zhang, N.; Guo, J.; Guo, R.; Shen, Y.; Yang, S.; et al. Recent Progress in Perovskite-Based Reversible Photon–Electricity Conversion Devices. Adv. Funct. Mater. 2022, 32, 2108926. [Google Scholar] [CrossRef]

- Liang, C.; Xing, G. Doping Electron Transporting Layer: An Effective Method to Enhance J SC of All-Inorganic Perovskite Solar Cells. Energy Environ. Mater. 2021, 4, 500–501. [Google Scholar] [CrossRef]

- Saga, T. Advances in Crystalline Silicon Solar Cell Technology for Industrial Mass Production. NPG Asia Mater. 2010, 2, 96–102. [Google Scholar] [CrossRef]

- Ballif, C.; Haug, F.J.; Boccard, M.; Verlinden, P.J.; Hahn, G. Status and Perspectives of Crystalline Silicon Photovoltaics in Research and Industry. Nat. Rev. Mater. 2022, 7, 597–616. [Google Scholar] [CrossRef]

- Li, Y.; Huang, W.; Zhao, D.; Wang, L.; Jiao, Z.; Huang, Q.; Wang, P.; Sun, M.; Yuan, G. Recent Progress in Organic Solar Cells: A Review on Materials from Acceptor to Donor. Molecules 2022, 27, 1800. [Google Scholar] [CrossRef] [PubMed]

- Moiz, S.A.; Alahmadi, A.N.M.; Karimov, K.S. Improved Organic Solar Cell by Incorporating Silver Nanoparticles Embedded Polyaniline as Buffer Layer. Solid-State Electron. 2020, 163, 107658. [Google Scholar] [CrossRef]

- Helgesen, M.; Søndergaard, R.; Krebs, F.C. Advanced Materials and Processes for Polymer Solar Cell Devices. J. Mater. Chem. 2010, 20, 36–60. [Google Scholar] [CrossRef]

- Kuik, M.; Wetzelaer, G.J.A.H.; Nicolai, H.T.; Craciun, N.I.; de Leeuw, D.M.; Blom, P.W.M. 25th Anniversary Article: Charge Transport and Recombination in Polymer Light-Emitting Diodes. Adv. Mater. 2014, 26, 512–531. [Google Scholar] [CrossRef]

- Garnier, F.; Hajlaoui, R.; Yassar, A.; Srivastava, P. All-Polymer Field-Effect Transistor Realized by Printing Techniques. Science 1994, 265, 1684–1686. [Google Scholar] [CrossRef] [PubMed]

- Harsányi, G. Polymer films in sensor applications: A review of present uses and future possibilities. Sens. Rev. 2000, 20, 98–105. [Google Scholar] [CrossRef]

- Cichosz, S.; Masek, A.; Zaborski, M. Polymer-based sensors: A review. Polym. Test. 2018, 67, 342–348. [Google Scholar] [CrossRef]

- Yin, H.; Yan, C.; Hu, H.; Ho, J.K.W.; Zhan, X.; Li, G.; So, S.K. Recent Progress of All-Polymer Solar Cells—From Chemical Structure and Device Physics to Photovoltaic Performance. Mater. Sci. Eng. R Rep. 2020, 140, 100542. [Google Scholar] [CrossRef]

- Brédas, J.L.; Norton, J.E.; Cornil, J.; Coropceanu, V. Molecular Understanding of Organic Solar Cells: The Challenges. ACC Chem. Res. 2009, 42, 1691–1699. [Google Scholar] [CrossRef]

- Hendry, E.; Schins, J.M.; Candeias, L.P.; Siebbeles, L.D.A.; Bonn, M. Efficiency of Exciton and Charge Carrier Photogeneration in a Semiconducting Polymer. Phys. Rev. Lett. 2004, 92, 196601. [Google Scholar] [CrossRef] [Green Version]

- Moiz, S.A.; Nahhas, A.M.; Um, H.-D.; Jee, S.-W.; Cho, H.K.; Kim, S.-W.; Lee, J.-H. A Stamped PEDOT:PSS–Silicon Nanowire Hybrid Solar Cell. Nanotechnology 2012, 23, 145401. [Google Scholar] [CrossRef] [PubMed]

- Heeger, A.J. 25th Anniversary Article: Bulk Heterojunction Solar Cells: Understanding the Mechanism of Operation. Adv. Mater. 2014, 26, 10–28. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Li, S.; Yao, H.; Zhang, S.; Zhang, Y.; Yang, B.; Hou, J. Molecular Optimization Enables over 13% Efficiency in Organic Solar Cells. J. Am. Chem. Soc. 2017, 139, 7148–7151. [Google Scholar] [CrossRef] [PubMed]

- Kang, H.; Kim, G.; Kim, J.; Kwon, S.; Kim, H.; Lee, K. Bulk-Heterojunction Organic Solar Cells: Five Core Technologies for Their Commercialization. Adv. Mater. 2016, 28, 7821–7861. [Google Scholar] [CrossRef]

- He, Z.; Zhong, C.; Su, S.; Xu, M.; Wu, H.; Cao, Y. Enhanced Power-Conversion Efficiency in Polymer Solar Cells Using an Inverted Device Structure. Nat. Photonics 2012, 6, 591–595. [Google Scholar] [CrossRef]

- Kwiatkowska, E.; Mech, W.; Wincukiewicz, A.; Korona, K.P.; Zarębska, K.; Kamińska, M.; Skompska, M. Investigation of Polyaniline Doped with Camphorsulfonic Acid in Chloroform Solution as a Hole Transporting Layer in PTB7: PCBM and Perovskite-Based Solar Cells. Electrochim. Acta 2021, 380, 138264. [Google Scholar] [CrossRef]

- Alahmadi, A.N.M. Design of an Efficient PTB7:PC70BM-Based Polymer Solar Cell for 8% Efficiency. Polymers 2022, 14, 889. [Google Scholar] [CrossRef]

- Ratcliff, E.L.; Zacher, B.; Armstrong, N.R. Selective Interlayers and Contacts in Organic Photovoltaic Cells. J. Phys. Chem. Lett. 2011, 2, 1337–1350. [Google Scholar] [CrossRef] [PubMed]

- Girtan, M.; Rusu, M. Role of ITO and PEDOT: PSS in Stability/Degradation of Polymer: Fullerene Bulk Heterojunctions Solar Cells. Sol. Energy Mater. Sol. Cells 2010, 94, 446–450. [Google Scholar] [CrossRef]

- Moiz, S.A.; Alahmadi, A.N.M.; Aljohani, A.J. Design of Silicon Nanowire Array for PEDOT: PSS-Silicon Nanowire-Based Hybrid Solar Cell. Energies 2020, 13, 3797. [Google Scholar] [CrossRef]

- Moiz, S.A.; Alahmadi, A.N.M.; Aljohani, A.J. Design of a Novel Lead-Free Perovskite Solar Cell for 17.83% Efficiency. IEEE Access 2021, 9, 54254–54263. [Google Scholar] [CrossRef]

- van Dijken, A.; Perro, A.; Meulenkamp, E.A.; Brunner, K. The Influence of a PEDOT:PSS Layer on the Efficiency of a Polymer Light-Emitting Diode. Org. Electron. 2003, 4, 131–141. [Google Scholar] [CrossRef]

- Nguyen, T.P.; le Rendu, P.; Long, P.D.; de Vos, S.A. Chemical and Thermal Treatment of PEDOT:PSS Thin Films for Use in Organic Light Emitting Diodes. Surf. Coat. Technol. 2004, 180–181, 646–649. [Google Scholar] [CrossRef]

- Zhao, X.; Zhan, X. Electron Transporting Semiconducting Polymers in Organic Electronics. Chem. Soc. Rev. 2011, 40, 3728–3743. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Paine, D.C.; Gleason, K.K. Heavily Doped poly (3,4-ethylenedioxythiophene) Thin Films with High Carrier Mobility Deposited Using Oxidative CVD: Conductivity Stability and Carrier Transport. Adv. Funct. Mater. 2014, 24, 7187–7196. [Google Scholar] [CrossRef]

- Shao, G. Work function and electron affinity of semiconductors: Doping effect and complication due to fermi level pinning. Energy Environ. Mater. 2021, 4, 273–276. [Google Scholar] [CrossRef]

- Burgelman, M.; Nollet, P.; Degrave, S. Modelling Polycrystalline Semiconductor Solar Cells. Thin Solid Film. 2000, 361, 527–532. [Google Scholar] [CrossRef]

- Minbashi, M.; Omrani, M.K.; Memarian, N.; Kim, D.H. Comparison of Theoretical and Experimental Results for Band-Gap-Graded CZTSSe Solar Cell. Curr. Appl. Phys. 2017, 17, 1238–1243. [Google Scholar] [CrossRef]

- Verschraegen, J.; Burgelman, M. Numerical Modeling of Intra-Band Tunneling for Heterojunction Solar Cells in Scaps. Thin Solid Film. 2007, 515, 6276–6279. [Google Scholar] [CrossRef]

- Dridi, C.; Touafek, N.; Mahamdi, R. Inverted PTB7: PC70BM Bulk Heterojunction Solar Cell Device Simulations for Various Inorganic Hole Transport Materials. Optik 2022, 252, 168447. [Google Scholar] [CrossRef]

- Chiew, E.K.; Yahaya, M.; Othman, A.P. Electrical Characterization of P3HT/PCBM Bulk Heterojunction Organic Solar Cell. Int. J. Comput. Mater. Sci. Eng. 2012, 01, 1250004. [Google Scholar] [CrossRef]

- Moiz, S.A.; Alahmadi, A.N.M. Design of Dopant and Lead-Free Novel Perovskite Solar Cell for 16.85% Efficiency. Polymers 2021, 13, 2110. [Google Scholar] [CrossRef] [PubMed]

- Aguirre, J.C.; Hawks, S.A.; Ferreira, A.S.; Yee, P.; Subramaniyan, S.; Jenekhe, S.A.; Tolbert, S.H.; Schwartz, B.J. Sequential Processing for Organic Photovoltaics: Design Rules for Morphology Control by Tailored Semi-Orthogonal Solvent Blends. Adv. Energy Mater. 2015, 5, 1402020. [Google Scholar] [CrossRef]

- Groves, C.; Blakesley, J.C.; Greenham, N.C. Effect of charge trapping on geminate recombination and polymer solar cell performance. Nano Lett. 2010, 10, 1063–1069. [Google Scholar] [CrossRef] [PubMed]

- Hu, Z.; Zhang, J.; Hao, Z.; Zhao, Y. Influence of Doped PEDOT: PSS on the Performance of Polymer Solar Cells. Sol. Energy Mater. Sol. Cells 2011, 95, 2763–2767. [Google Scholar] [CrossRef]

- Chi, D.; Huang, S.; Yue, S.; Liu, K.; Lu, S.; Wang, Z.; Qu, S.; Wang, Z. Ultra-Thin ZnO Film as an Electron Transport Layer for Realizing the High Efficiency of Organic Solar Cells. RSC Adv. 2017, 7, 14694–14700. [Google Scholar] [CrossRef]

- Swami, S.K.; Chaturvedi, N.; Kumar, A.; Kumar, V.; Garg, A.; Dutta, V. Spray Deposited Gallium Doped Zinc Oxide (GZO) Thin Film as the Electron Transport Layer in Inverted Organic Solar Cells. Sol. Energy 2022, 231, 458–463. [Google Scholar] [CrossRef]

- Lee, S.; Lee, J.H.; Lee, J.H.; Kim, J.J. The Mechanism of Charge Generation in Charge-Generation Units Composed of p-Doped Hole-Transporting Layer/HATCN/n-Doped Electron-Transporting Layers. Adv. Funct. Mater. 2012, 22, 855–860. [Google Scholar] [CrossRef]

- Yap, C.C.; Yahaya, M.; Salleh, M.M. Influence of Thickness of Functional Layer on Performance of Organic Salt-Doped OLED with ITO/PVK:PBD:TBAPF6/Al Structure. Curr. Appl. Phys. 2008, 8, 637–644. [Google Scholar] [CrossRef]

- Ratcliff, E.L.; Lee, P.A.; Armstrong, N.R. Work Function Control of Hole-Selective Polymer/ITO Anode Contacts: An Electrochemical Doping Study. J. Mater. Chem. 2010, 20, 2672–2679. [Google Scholar] [CrossRef]

- Kirchartz, T.; Agostinelli, T.; Campoy-Quiles, M.; Gong, W.; Nelson, J. Understanding the Thickness-Dependent Performance of Organic Bulk Heterojunction Solar Cells: The Influence of Mobility, Lifetime, and Space Charge. J. Phys. Chem. Lett. 2012, 3, 3470–3475. [Google Scholar] [CrossRef] [PubMed]

- Moiz, S.A. Optimization of Hole and Electron Transport Layer for Highly Efficient Lead-Free Cs2TiBr6-Based Perovskite Solar Cell. Photonics 2022, 9, 23. [Google Scholar] [CrossRef]

- Blom, P.W.M.; Mihailetchi, V.D.; Koster, L.J.A.; Markov, D.E. Device Physics of Polymer: Fullerene Bulk Heterojunction Solar Cells. Adv. Mater. 2007, 19, 1551–1566. [Google Scholar] [CrossRef]

- Waldauf, C.; Scharber, M.C.; Schilinsky, P.; Hauch, J.A.; Brabec, C.J. Physics of Organic Bulk Heterojunction Devices for Photovoltaic Applications. J. Appl. Phys. 2006, 99, 104503. [Google Scholar] [CrossRef]

- Gasparini, N.; Wadsworth, A.; Moser, M.; Baran, D.; McCulloch, I.; Brabec, C.J. The Physics of Small Molecule Acceptors for Efficient and Stable Bulk Heterojunction Solar Cells. Adv. Energy Mater. 2018, 8, 1703298. [Google Scholar] [CrossRef]

- Nam, S.; Seo, J.; Woo, S.; Kim, W.H.; Kim, H.; Bradley, D.D.C.; Kim, Y. Inverted Polymer Fullerene Solar Cells Exceeding 10% Efficiency with Poly(2-Ethyl-2-Oxazoline) Nanodots on Electron-Collecting Buffer Layers. Nat. Commun. 2015, 6, 8929. [Google Scholar] [CrossRef]

- Yao, H.; Zhao, W.; Zheng, Z.; Cui, Y.; Zhang, J.; Wei, Z.; Hou, J. PBDT-TSR: A Highly Efficient Conjugated Polymer for Polymer Solar Cells with a Regioregular Structure. J. Mater. Chem. A 2016, 4, 1708–1713. [Google Scholar] [CrossRef]

- Ye, L.; Zhang, S.; Zhao, W.; Yao, H.; Hou, J. Highly Efficient 2D-Conjugated Benzodithiophene-Based Photovoltaic Polymer with Linear Alkylthio Side Chain. Chem. Mater. 2014, 26, 3603–3605. [Google Scholar] [CrossRef]

- Jao, M.H.; Liao, H.C.; Su, W.F. Achieving a High Fill Factor for Organic Solar Cells. J. Mater. Chem. A 2016, 4, 5784–5801. [Google Scholar] [CrossRef]

- Qi, B.; Wang, J. Fill Factor in Organic Solar Cells. Phys. Chem. Chem. Phys. 2013, 15, 8972–8982. [Google Scholar] [CrossRef]

- Korir, B.K.; Kibet, J.K.; Ngari, S.M. Computational Simulation of a Highly Efficient Hole Transport-Free Dye-Sensitized Solar Cell Based on Titanium Oxide (TiO2) and Zinc Oxysulfide (ZnOS) Electron Transport Layers. J. Electron. Mater. 2021, 50, 7259–7274. [Google Scholar] [CrossRef]

| Parameters | Symbol | Unit | PEDOT:PSS | BHJ | ETL | ||

|---|---|---|---|---|---|---|---|

| Zn(O,S) | ZnSe | PFN-Br | |||||

| Thickness | T | nm | 300 | 300 | 75 | 75 | 75 |

| Energy Band Gap | Eg | eV | 1.80 | 1.10 | 2.8 | 2.81 | 2.98 |

| Electron Affinity | Χ | eV | 3.50 | 3.75 | 3.80 | 4.09 | 4.00 |

| Dielectric Permittivity | εr | - | 3.00 | 3.90 | 9.00 | 8.60 | 5.00 |

| Effective Density of States at Conduction Band | NC | cm−3 | 2.2 × 1018 | 6 × 1019 | 2.2 × 1018 | 2.2 × 1018 | 1.0 × 1019 |

| Effective Density of States at Valance Band | NV | cm−3 | 1.8 × 1019 | 2.0 × 1019 | 1.8 × 1019 | 1.8 × 1018 | 1.0 × 1019 |

| Electron Thermal Velocity | Ve | cm/s | 1.0 × 107 | 1.0 × 107 | 1.0 × 107 | 1.0 × 107 | 1.0 × 107 |

| Hole Thermal Velocity | Vh | cm/s | 1.0 × 107 | 1.0 × 107 | 1.0 × 107 | 1.0 × 107 | 1.0 × 107 |

| Electron Mobility | µe | cm2/V·s | 1 | 4.4 × 10−4 | 1.0 × 102 | 4.0 × 102 | 2.0 × 10−6 |

| Hole Mobility | µh | cm2/V·s | 2.0 × 101 | 2.5 × 10−4 | 2.5 × 101 | 1.1 × 102 | 1.0 × 10−4 |

| Donor Density | ND | cm−3 | - | 1.0 × 1019 | 1.0 × 1019 | 1.0 × 1019 | 1.0 × 1019 |

| Hole Density | NA | cm−3 | 1.0 × 1018 | 1.0 × 1019 | - | - | - |

| Defect Density | Nt | cm−3 | 1.0 × 1014 | 1.0 × 1014 | 1.0 × 1014 | 1.0 × 1014 | 1.0 × 1014 |

| ETL | Voc (Volt) | Jsc (mA/cm2) | FF (%) | PCE (%) |

|---|---|---|---|---|

| Zn(O,S) | 0.8549 | 28.376 | 70.69 | 17.15 |

| ZnSe | 0.8551 | 28.370 | 65.15 | 15.81 |

| PFN-Br | 0.8546 | 28.255 | 62.49 | 15.09 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moiz, S.A.; Alzahrani, M.S.; Alahmadi, A.N.M. Electron Transport Layer Optimization for Efficient PTB7:PC70BM Bulk-Heterojunction Solar Cells. Polymers 2022, 14, 3610. https://doi.org/10.3390/polym14173610

Moiz SA, Alzahrani MS, Alahmadi ANM. Electron Transport Layer Optimization for Efficient PTB7:PC70BM Bulk-Heterojunction Solar Cells. Polymers. 2022; 14(17):3610. https://doi.org/10.3390/polym14173610

Chicago/Turabian StyleMoiz, Syed Abdul, Mohammed Saleh Alzahrani, and Ahmed N. M. Alahmadi. 2022. "Electron Transport Layer Optimization for Efficient PTB7:PC70BM Bulk-Heterojunction Solar Cells" Polymers 14, no. 17: 3610. https://doi.org/10.3390/polym14173610

APA StyleMoiz, S. A., Alzahrani, M. S., & Alahmadi, A. N. M. (2022). Electron Transport Layer Optimization for Efficient PTB7:PC70BM Bulk-Heterojunction Solar Cells. Polymers, 14(17), 3610. https://doi.org/10.3390/polym14173610