4.1. Effect of the Mold Temperature on Residual Stresses

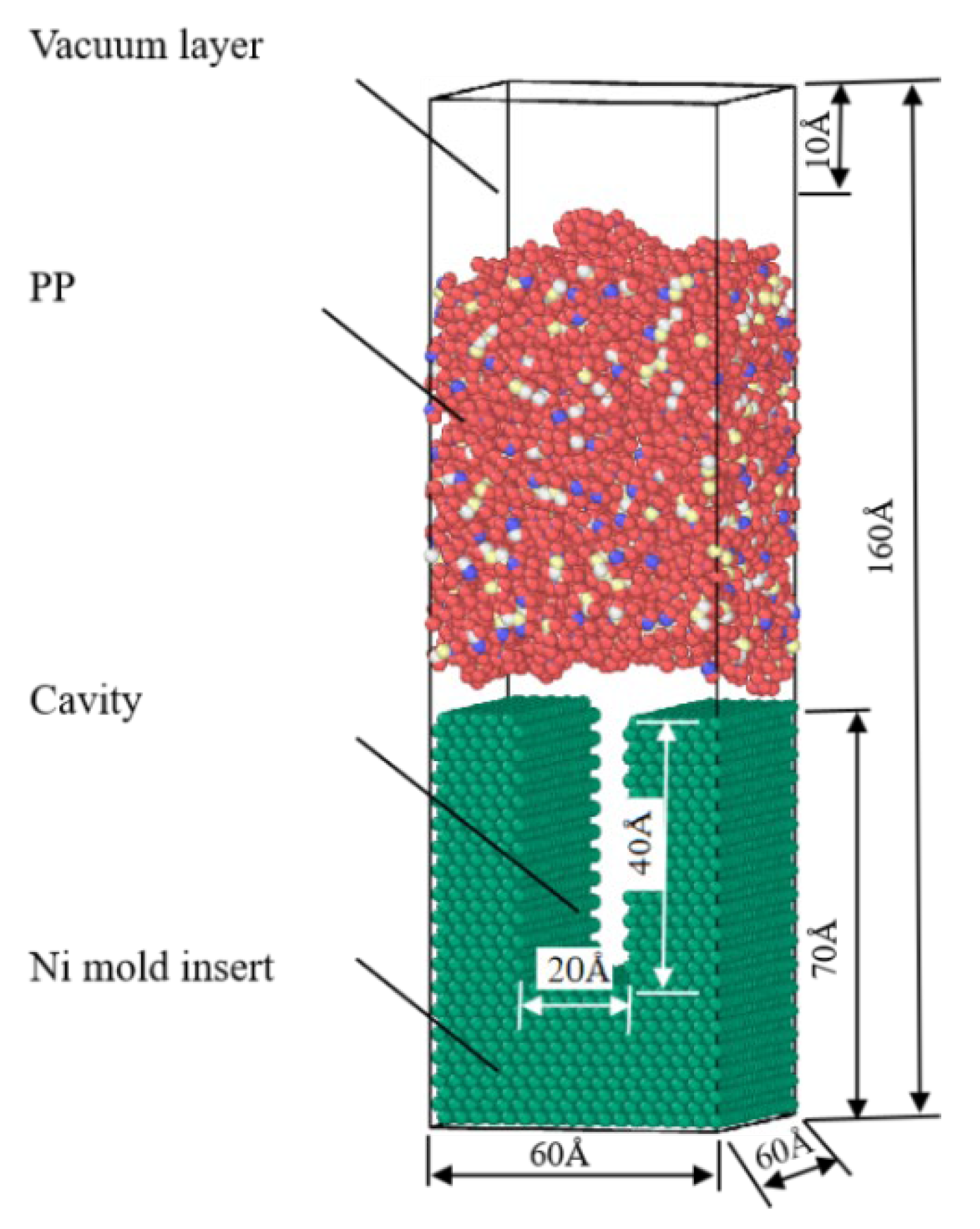

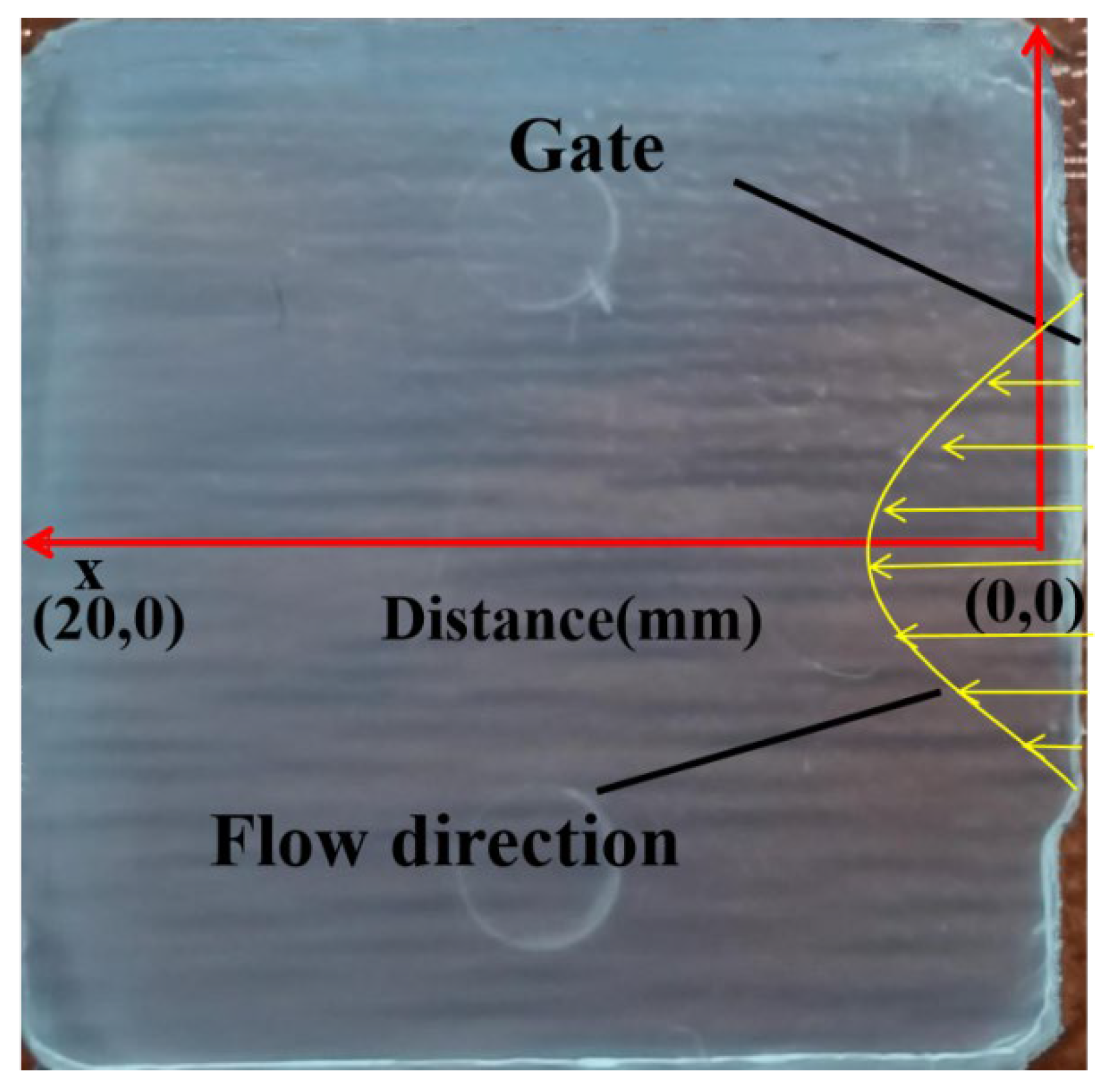

The horizontal and vertical midpoint position on the molded part is the origin, and the centerline is the horizontal axis as shown in

Figure 3. Additionally, the position of the gate and flow direction is marked on the part.

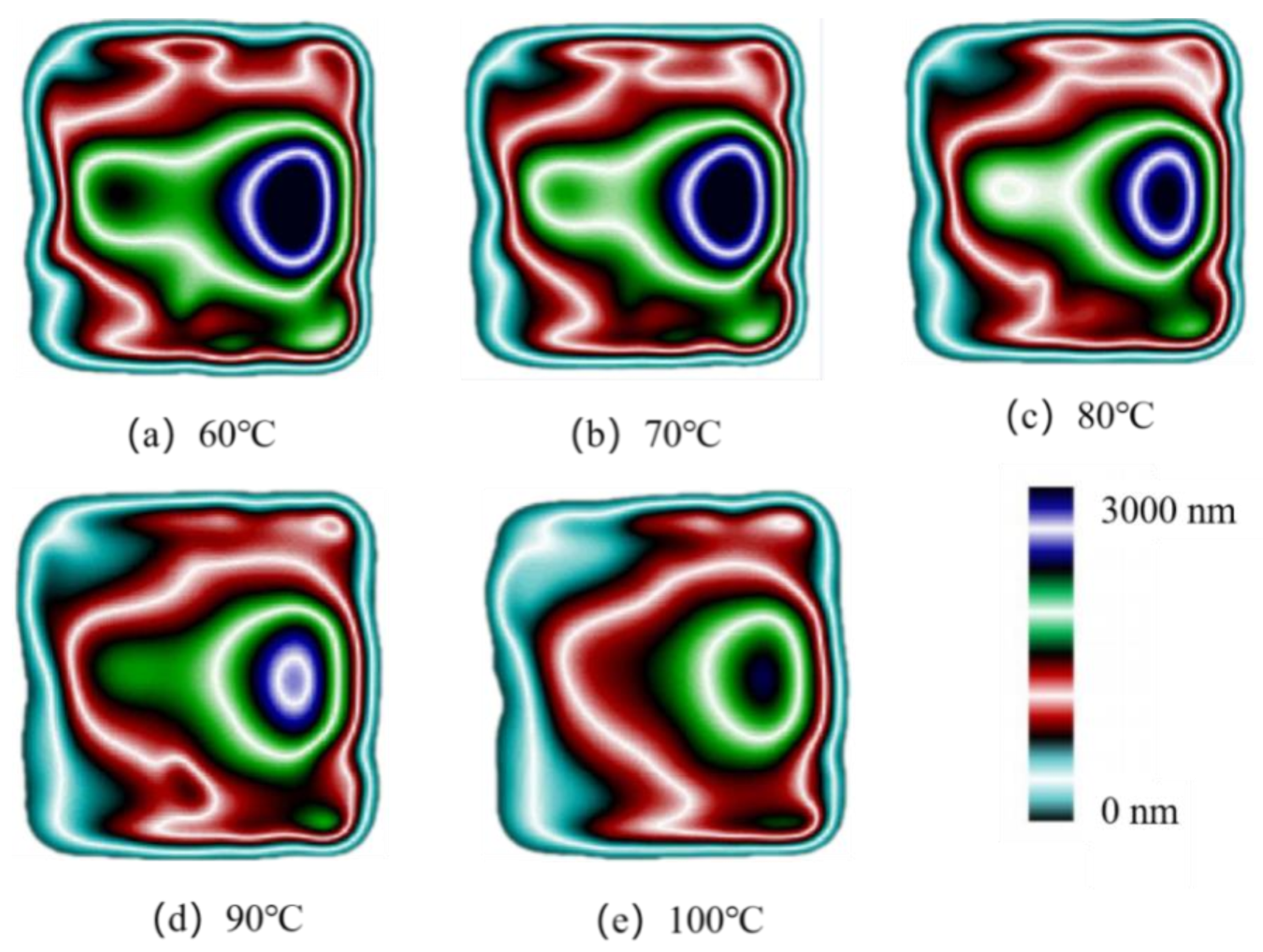

Figure 4 shows the birefringence distribution of residual stresses in the molded parts at different mold temperatures after injection molding in the experimental study. It can be seen that the overall distribution of residual stresses is axisymmetric along the centerline of the transverse axis and the further away from the gate, the smaller the stress value. Four different color stress zones are shown in the figure, corresponding to the stresses from high to low: dark blue, green, red, and light blue. The dark blue layer area has the highest stress value and forms an ellipse. By comparison, it can be clearly seen that the area of the dark blue layer and the green layer near the gate reduces with the increase in the mold temperature. When the mold temperature increases to 100 °C, the area of the dark blue layer basically disappears, while the area of the green layer on the left also disappears. Meanwhile, the outermost blue layer and the red layer keep expanding. It can be seen that the uniformity of residual stress distribution is effectively improved when the mold temperature increases.

Based on the optical path difference output in

Figure 4, the residual stresses of molded parts can be calculated according to the optical stress theorem, as shown in Equation (1):

where

represents residual stress value, (MPa);

represents optical path difference, (nm); K represents the pressure optical coefficient, h represents the thickness of the part being measured, (mm). According to the literature, the strain optical coefficient of PP is 1.30 × 10

−10 Pa

−1 [

21], residual stresses then can be calculated.

Figure 5 shows the stress variation curves along the centerline of the parts by calculation at various mold temperatures. As the mold temperature grows, the stress values of the parts decrease significantly. It can also be seen that the curves become smoother as the temperature increases and the stress concentration zone disappears at 5 mm from the origin, indicating that the uniformity of residual stresses is improved.

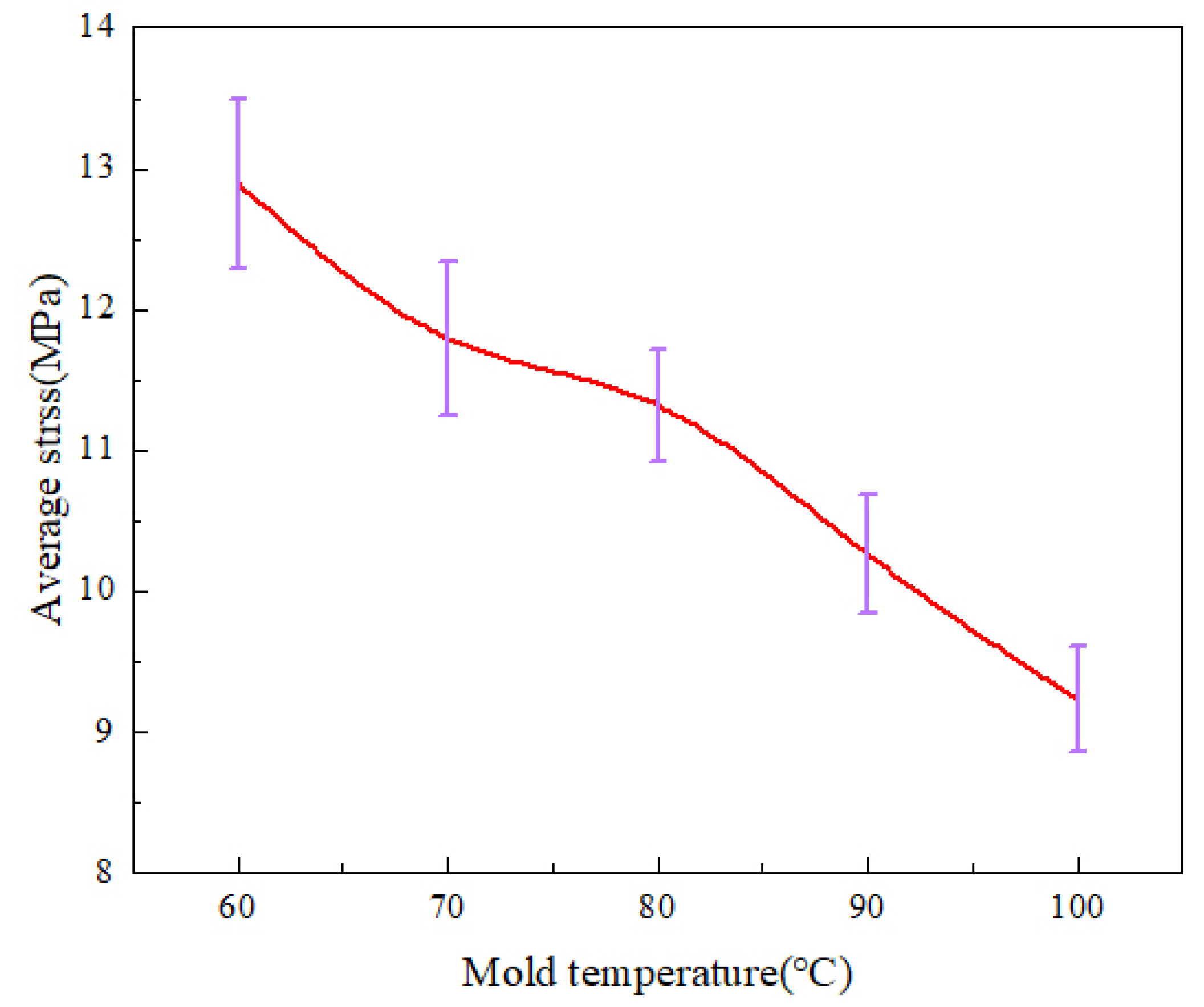

Figure 6 shows the average stress variations at different mold temperatures. When the mold temperature increases from 60 °C to 100 °C, the average stress decreases from 12.9 MPa to 9.2 Mpa, a decrease of 28.4%. The average stresses decrease significantly when the mold temperature increases.

The molding morphologies of the micro-pillar arrays at different mold temperatures in the experimental study are shown in

Figure 7. When the mold temperatures are 60 °C and 70 °C, respectively, the microstructures are presented only in the middle part with poor molding quality. When the temperature increases to 90 °C, it can be seen that the microstructures are filled completely without obvious defects. This phenomenon indicates that the higher the mold temperature, the smaller the shear effect and the lower the stress in the cavity before demolding, thus ensuring a smooth demolding stage. In addition, a higher mold temperature allows for slower melt cooling and sufficient time for filling. Therefore, increasing the mold temperature not only improves the residual stresses in the part after demolding, but also improves the quality of the microstructures.

The stress distributions of nanostructures at different mold temperatures in the MD simulation are illustrated in

Figure 8. It is found that the stress concentration phenomenon is particularly severe at the mold temperature of 60 °C, especially in the middle of the cavity. As the mold temperature keeps increasing, the stress concentration phenomenon begins to weaken, and the stress concentration region in the middle of the cavity gradually disappears. When the mold temperatures are 80 °C and 90 °C, respectively, the stress concentration areas are mainly distributed at the edges of the cavity. This may be the critical temperature for the formation of the condensation layer. As the temperature difference between the melt and the mold becomes larger, the thickness of the condensation layer becomes larger. When the mold temperature increases to 100 °C, the stress distribution in the cavity is relatively uniform, which is consistent with the experimentally observed phenomenon. It can be noticed that in the simulation, the stress is at the GPa level, while in the experiment it is at the MPa level. This is because the fact that microstructures are used in experiments, but nanostructures are used in the simulations. Additionally, stress is the ratio of pressure to the area, so the difference in stress values is several orders of magnitude.

The density distributions in the cavity at different mold temperatures in MD simulation are presented in

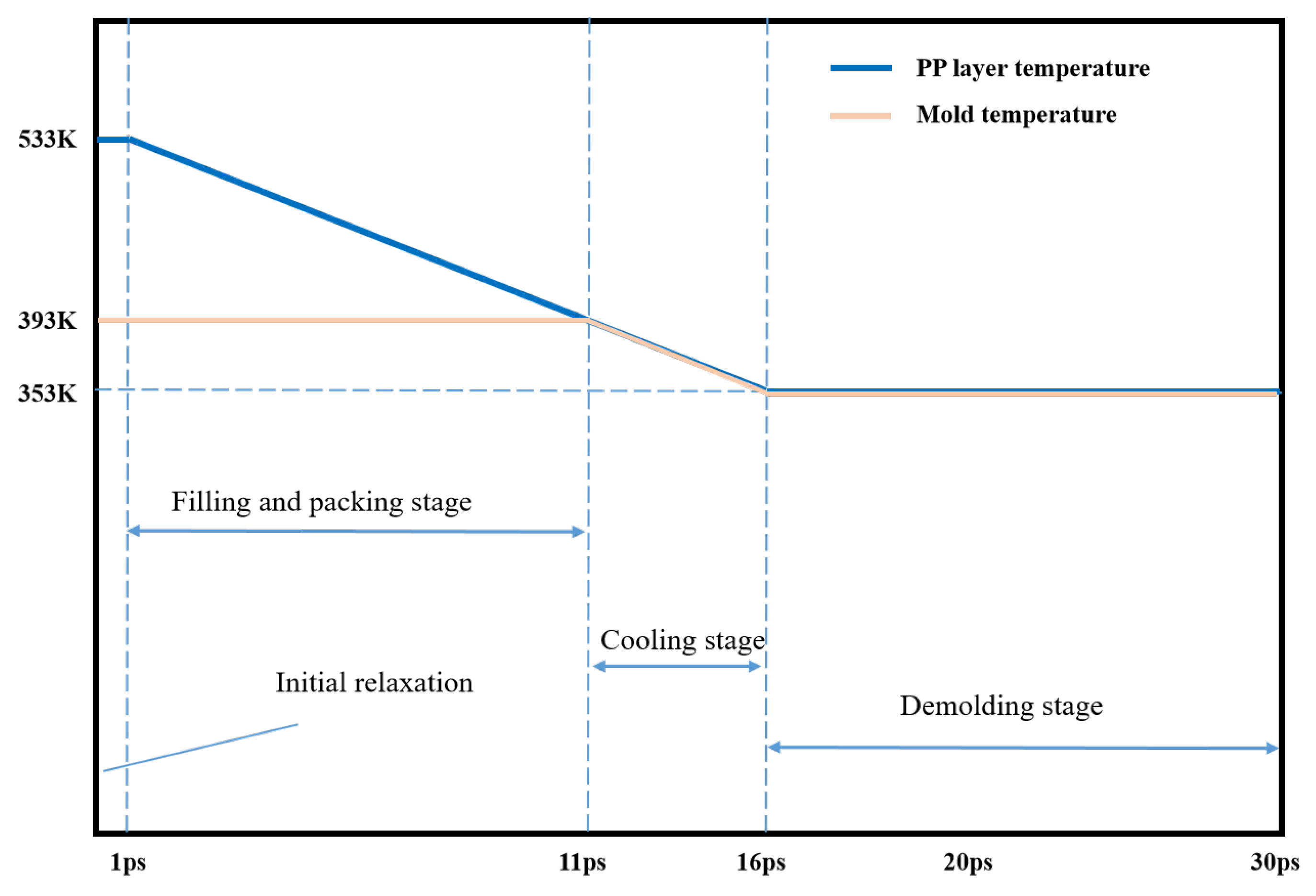

Figure 9. The stable values of density in the cavity, the density values, and the thicknesses of the condensation layer are increasing with the decrease in the mold temperature. The melt cooling rate is defined as Equation (2).

where T

1 is the initial melt temperature, 533 K, and T

2 is the melt temperature during filling and cooling process, which is affected by the mold temperature, (K); t is melt cooling time, (ps) which is set to a constant value in the simulation. This phenomenon indicates that the larger the temperature difference between the polymer and the mold, the faster the melt cooling rate and the greater the shrinkage of the polymer. The magnitude of thermal residual stress is related to the melt cooling rate. As the melt cooling rate increases, the value of thermal residual stress increases. So, when the mold temperature is lower, the polymer needs a longer cooling time, which leads to an increase in the thickness of the condensation layer. When the mold temperature is 60 °C, the thickness of the condensation layer is about 10 Å, while at a mold temperature of 100 °C is only 2 Å. In the experiments, the higher mold temperature results in slower cooling of the melt and lower thermal stresses to allow enough time for filling, thus improving the replication of microstructures and reducing residual stresses in the parts, as shown in

Figure 5 and

Figure 7.

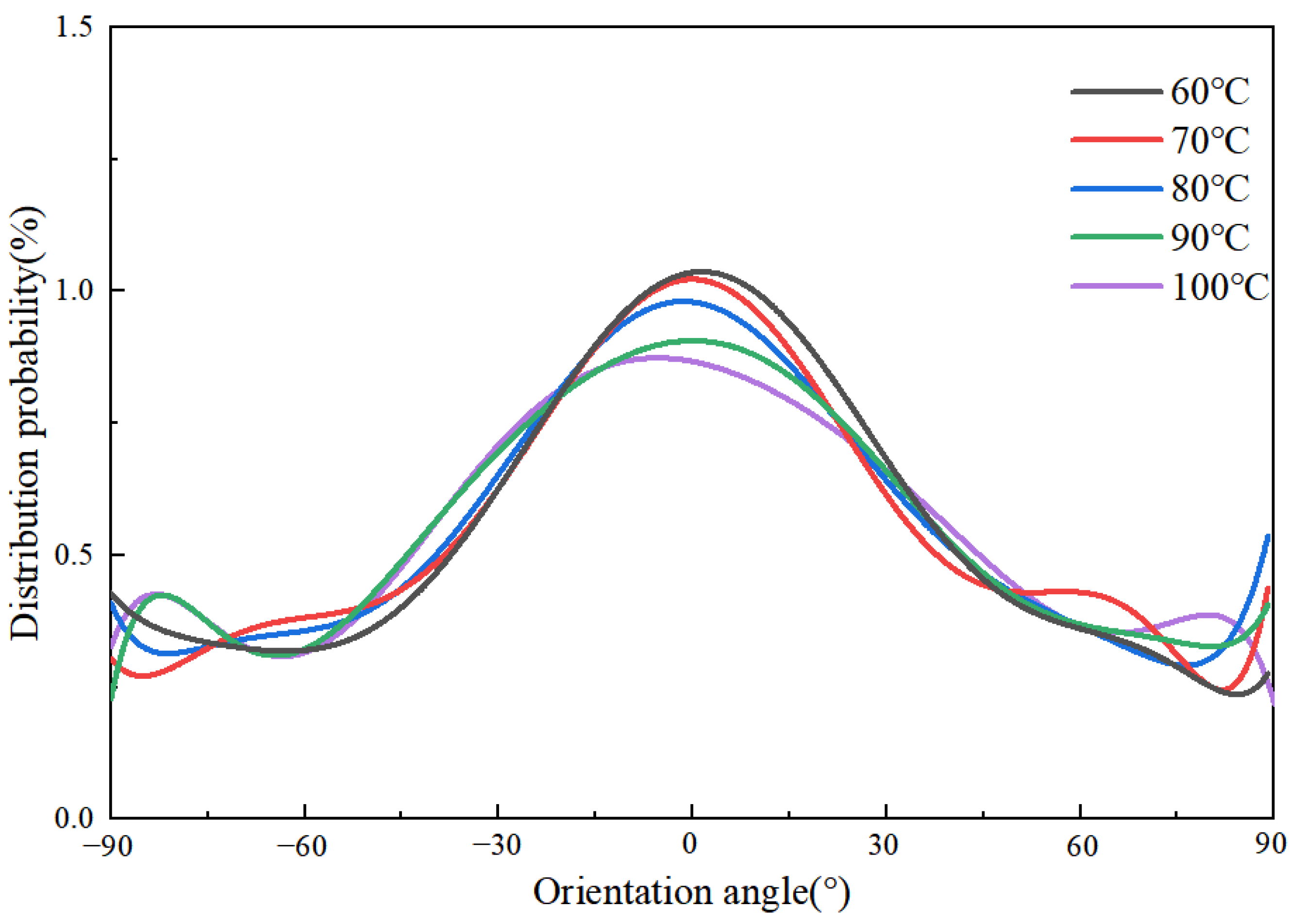

Figure 10 shows the variations in the orientation angle of PP for different mold temperatures in the MD simulation. As the mold temperature increases, the orientation angle along the flow direction decreases, and its peak values near 0° also decreases. This is because the viscosity of the filled polymer increases as it gradually cools to the mold temperature. Therefore, when the mold temperature is lower, the flow resistance of the PP melt is higher, and the orientation stress is correspondingly larger. This phenomenon indicates that the mold temperature will affect the orientation stress. The weaker the shear effect, and the lower the stresses in the cavity before demolding, thus ensuring a smooth demolding stage and improving the residual stresses in the parts and the replication quality of microstructures. By increasing the mold temperature, not only the residual stresses will be reduced, but also the uniformity of distribution also will be improved.

4.2. Effect of Packing Pressure on Residual Stresses

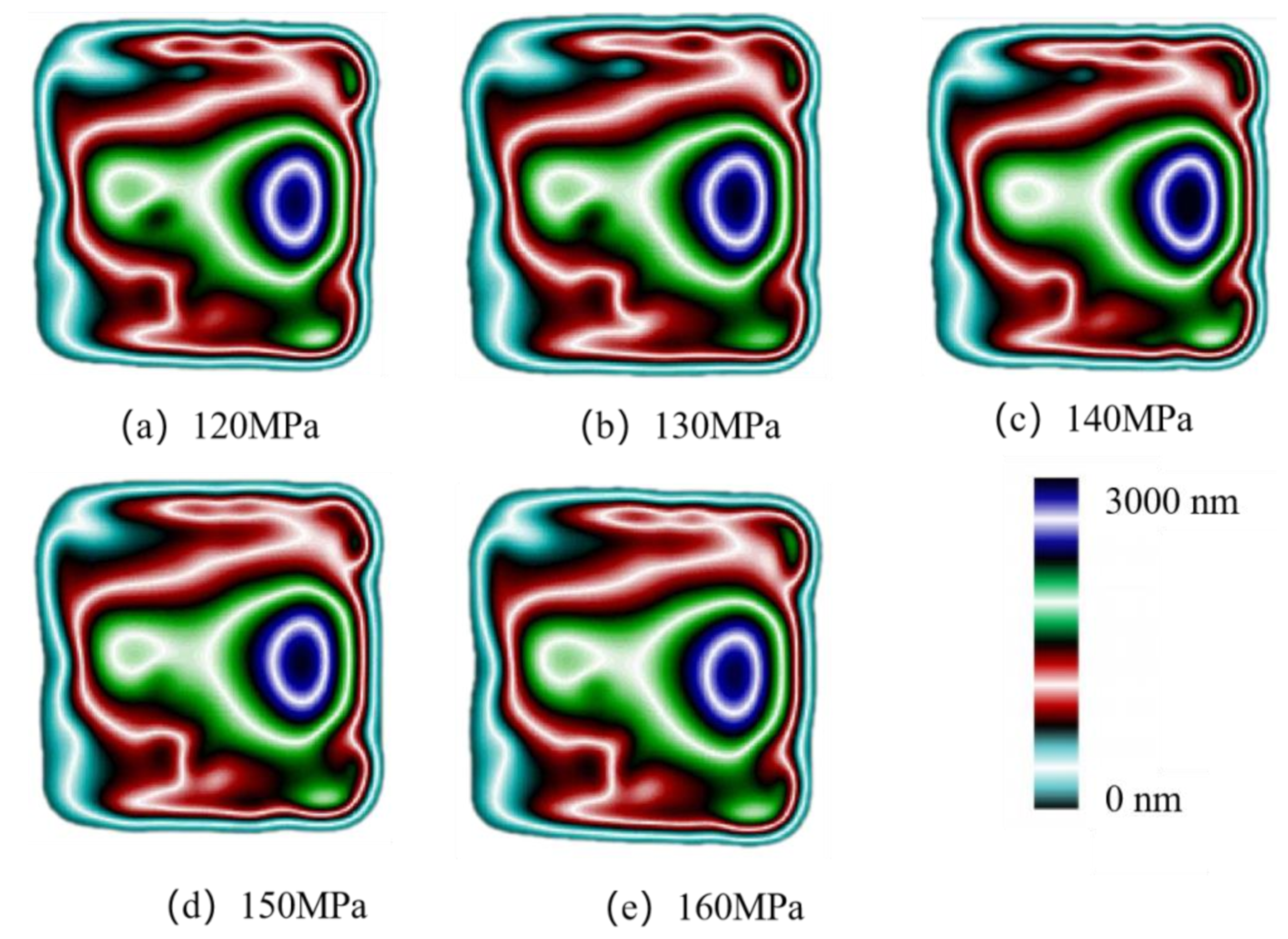

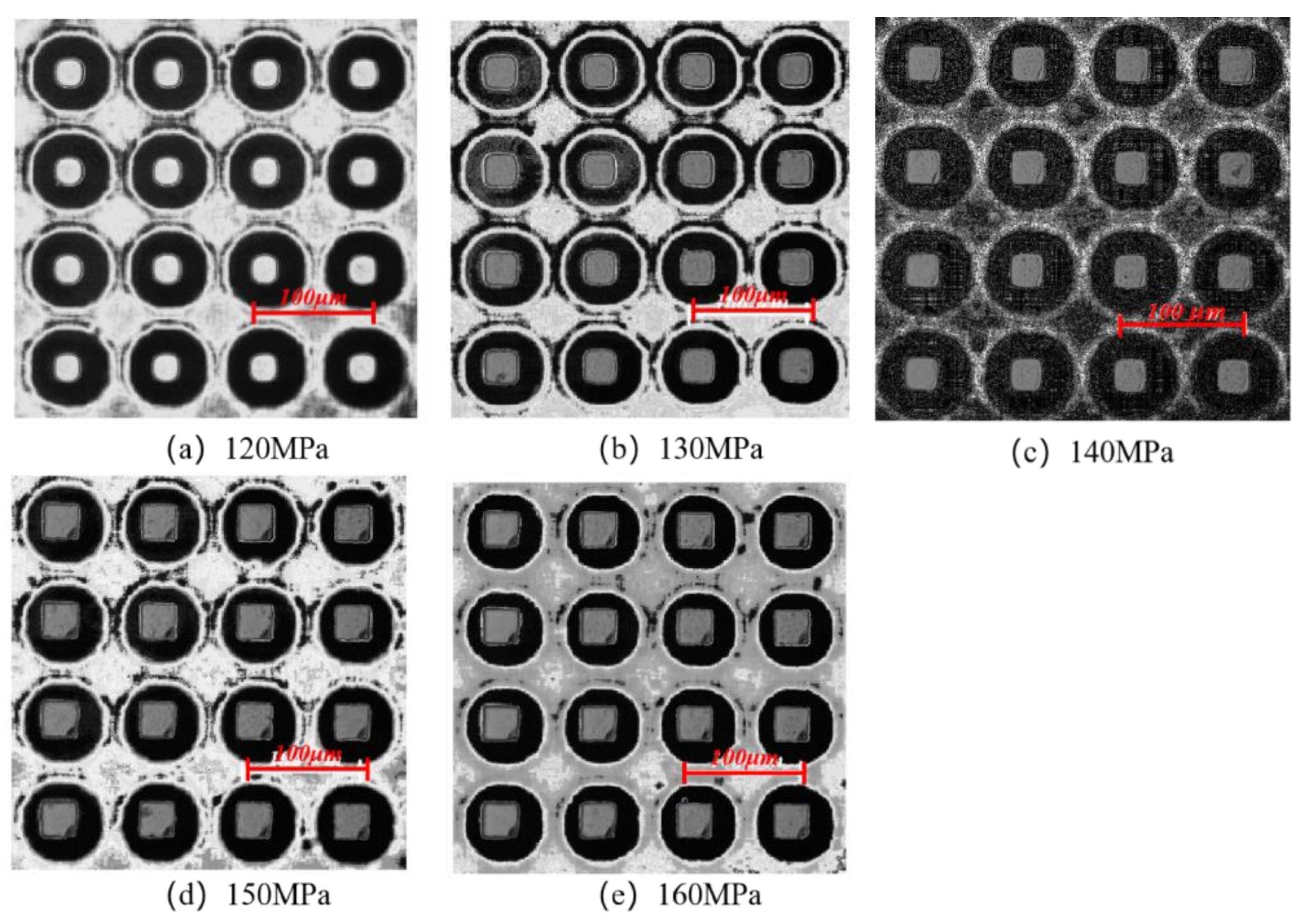

In injection molding, the packing pressure mainly plays a role in making the melt completely fill the cavity, and it has the most direct effect on the flow shear field. In the experimental study, the birefringence distribution of residual stresses in the molded parts with different packing pressures in the experimental study is shown in

Figure 11. It can be found that the distribution of residual stresses remains basically constant with the increase in the packing pressure. The stresses are calculated according to Equation (1) as shown in

Figure 12. The peak stress increases from 28.1 MPa to 29.3 MPa when the packing pressure increases from 120 MPa to 140 MPa, an increase of 4.2% can be seen. As the packing pressure continues to increase, the stress peak begins to decrease continuously until it drops to 29.1 MPa at a packing pressure of 160 MPa.

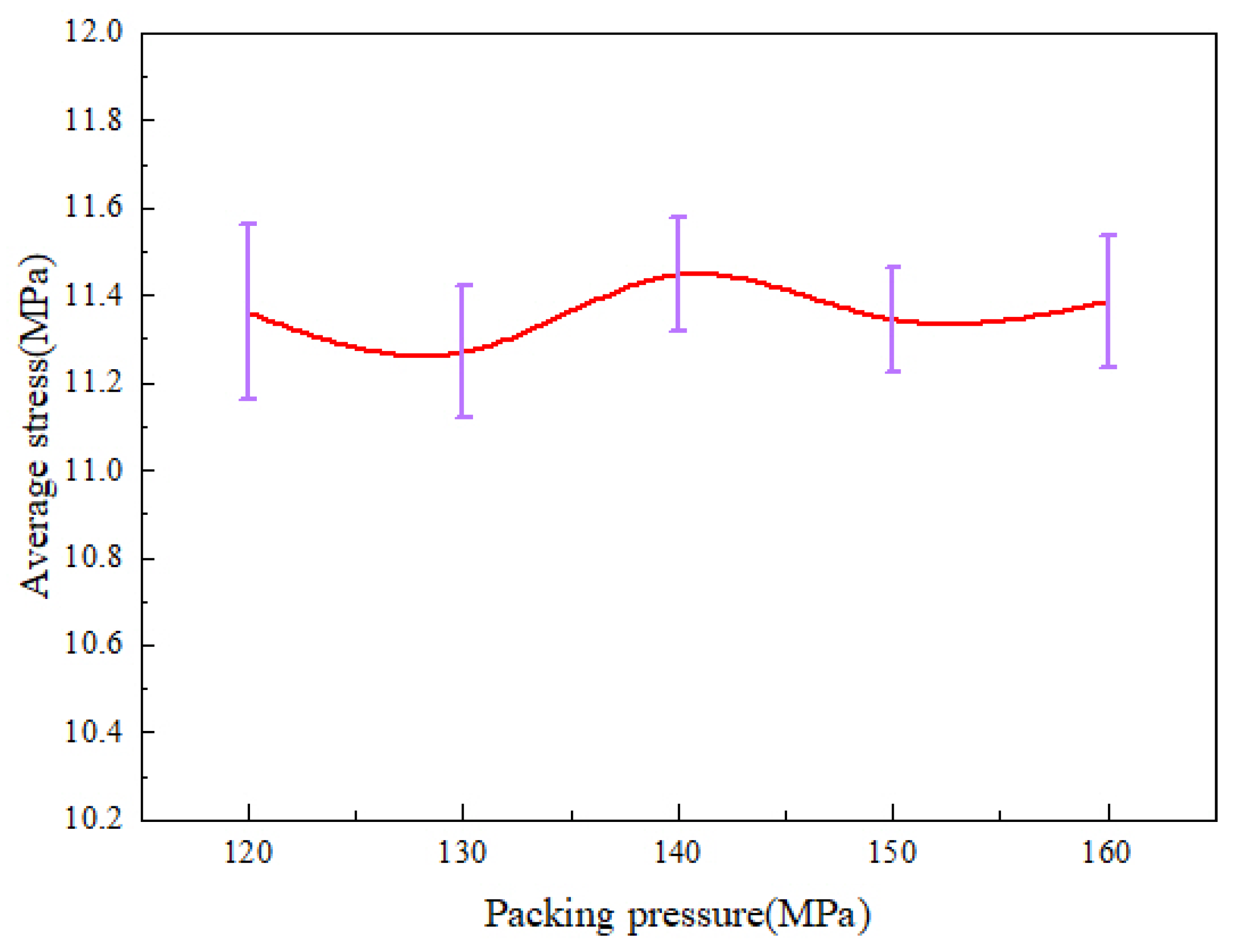

As shown in

Figure 13, it can be found that the average stress changes in much are basically the same as the above. The average stress reaches the maximum at the packing pressure of 140 MPa, which is 11.45 MPa. In general, the effect of packing pressure on the residual stresses is not obvious.

Figure 14 shows the morphologies of the micro-pillar arrays at different packing pressures in the experimental study. As the melt fills the cavity more completely with increasing packing pressure, the microstructures are also denser. In general, the degree of replication of microstructures improves with the increase in packing pressure. It can be found that the microstructures are uniform in size at a packing pressure of 130 MPa. When the packing pressure increases to 140 MPa, the microstructures become more complete, but the defects are more obvious. At the packing pressure of 150 MPa, the lower right corner of the fabricated part is warped. This is due to the fact that when the packing pressure is too high, the adhesion between the PP polymer and the Ni mold insert will be stronger, and the resistance caused by demolding will be higher. Therefore, increasing the packing pressure increases the possibility of defects.

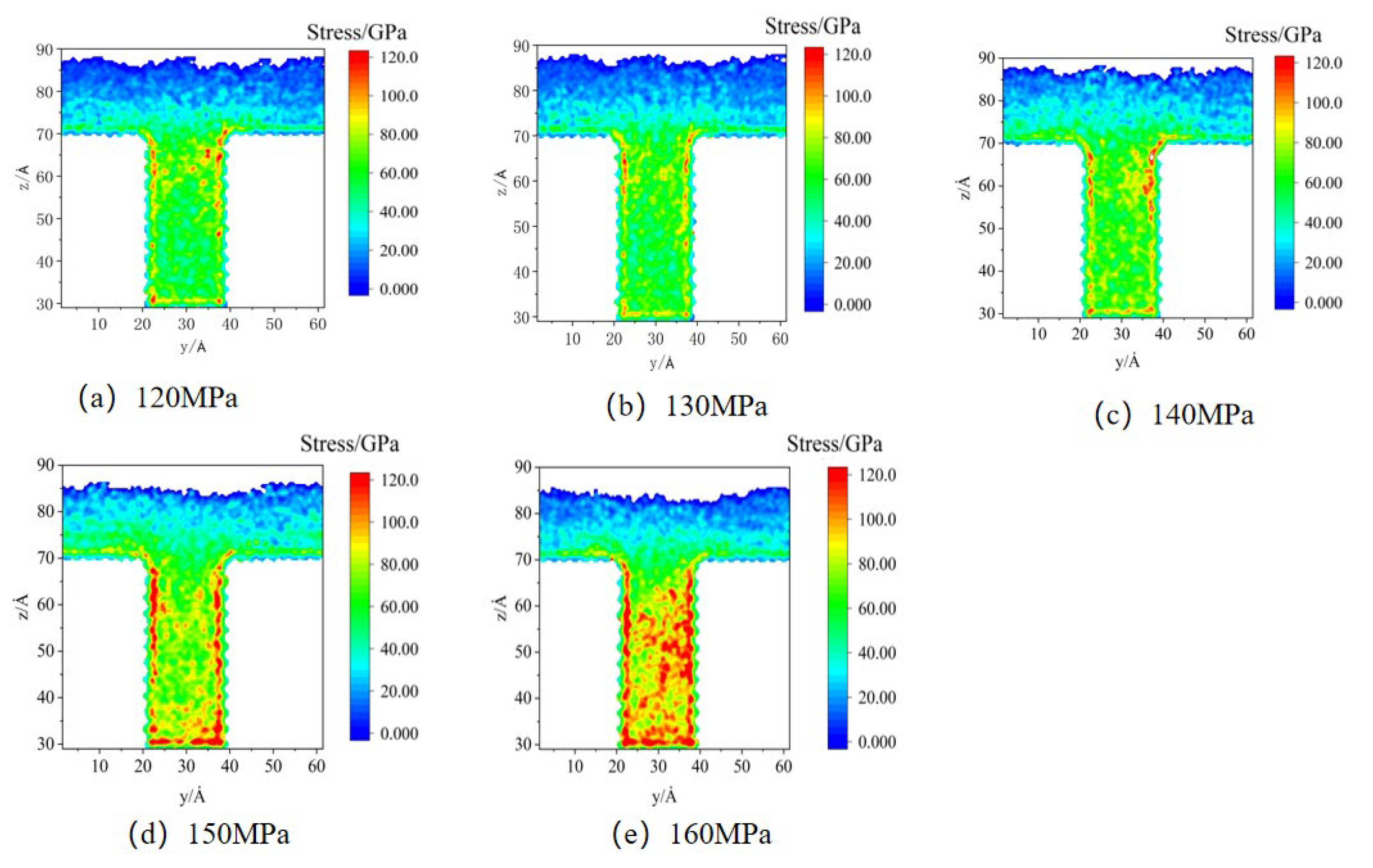

In the simulations, different pressures (1.2–1.6 kcal/mol Å) were applied to all atoms to represent the packing pressure in order to investigate the effect on residual stress formation. The stress distributions in the cavity in the MD are shown in

Figure 15. The results show that the residual stresses appear first in the side walls of the cavity. As the packing pressure increases, the stress concentration zone gradually expands to the center of the cavity and fills the whole cavity at a pressure of 160 MPa.

The density distributions of the cavity under different packing pressures in the MD simulation are shown in

Figure 16. It can be found that the packing pressure has a significant effect on the density of nanostructures. At a packing pressure of 160 MPa, the density of the condensation layer reaches about 2.8 g/cm

3. This is mainly due to the effect of the packing pressure, which makes the free volume of PP polymer continuously compressed, resulting in a gradual reduction of the intermolecular distance and a denser polymer, so the density is increasing. However, changing the packing pressure has almost no effect on the condensation layer’s thickness, which depends mainly on the cooling rate of the melt, so the effect of packing pressure on the thermal stresses is small. In the experiment, an increase in packing pressure will cause the melt to fill the cavity more completely, thereby improving the replication quality of microstructures. However, when the packing pressure is too high, the possibility of local defects increases.

The variation of the packing pressure brings different shear effects on the polymer in the cavity, which will also affect the flow state of the molecular chains. Therefore, the molecular orientation distribution curves at different packing pressure are output in the MD simulation, as shown in

Figure 17. It can be seen that when the packing pressure is 120 MPa, the fluctuation range of the probability curve of the orientation angle distribution is not large. When the packing pressure exceeds 140 MPa, the distribution probability of orientation angles at −30° and 30° drastically increases continuously. On the contrary, the distribution probability of the orientation angle in the range of −30° to −90° and 30° to 90° decreases continuously with the increase in the packing pressure. When the packing pressure increases to 160 MPa, its distribution in this range is almost zero. This indicates that the increase in packing pressure forces the molecules to be more mobile, and the molecular chains are continuously oriented along the flow direction, leading to an increase in the orientation stress in the PP polymer. This is an important reason for the greater and more concentrated stresses in the cavity during the packing stage. This phenomenon indicates that the packing pressure increases the orientation stress, and therefore the adhesion between the PP polymer and the Ni mold insert will be stronger and the resistance during demolding will be higher. As a result, warpage occurs at the edges and corners during demolding, and the residual stresses in the molded parts after demolding increase significantly.

However, as the packing pressure increases, there is very little increase in residual stresses in the cavity in the experiments, while there is a large increase in residual stresses in the simulation. This is due to the fact that the cavity is not in an ideal sealing condition in the experiments, which is different from the simulation and leads to a difference in the results.

4.3. Effect of Melt Temperature on Residual Stresses

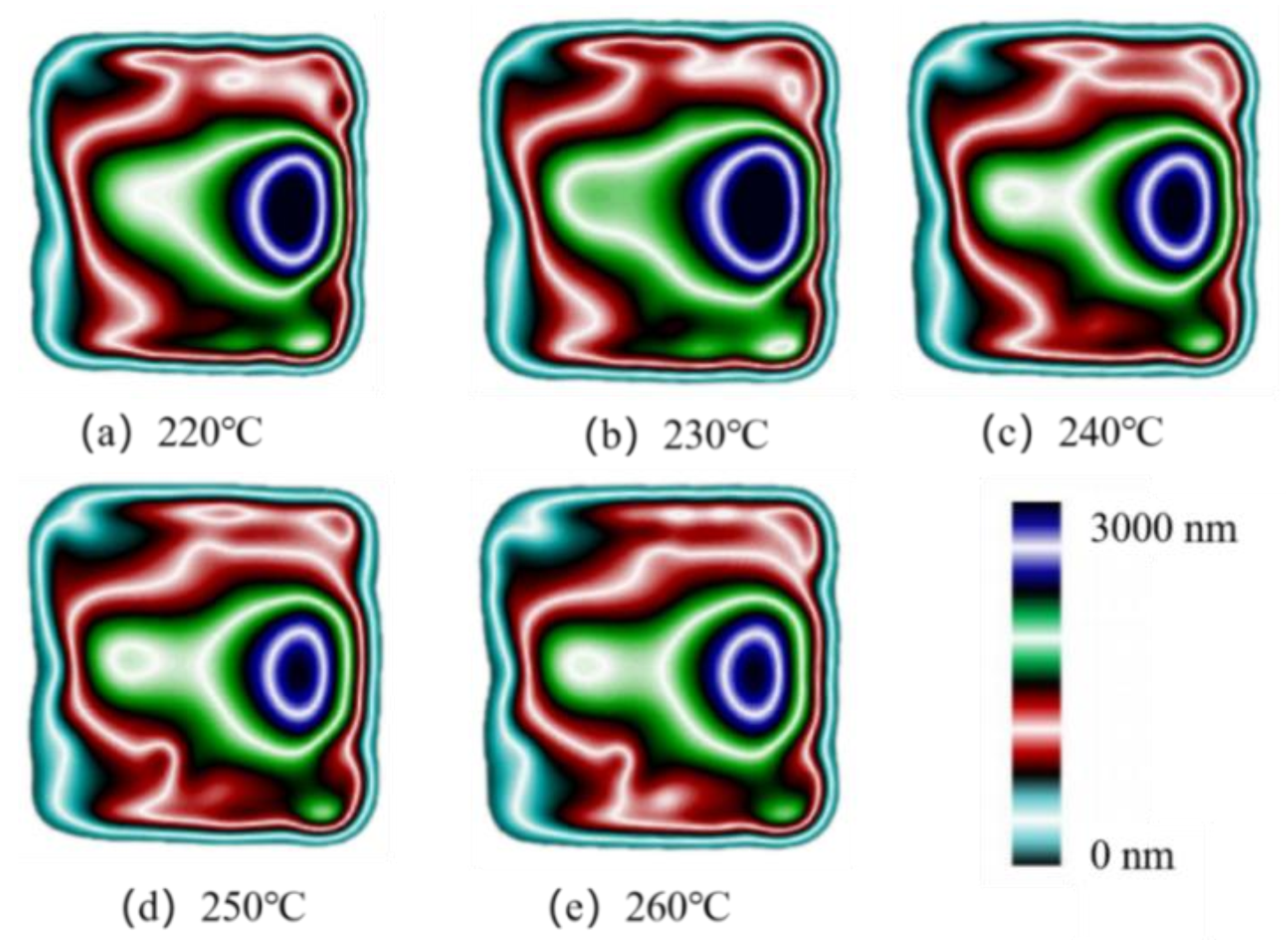

Micro-injection molding experiments were carried out at different melt temperatures. The birefringence distributions of residual stresses in PP micro-pillar arrays are shown in

Figure 18. As the melt temperature increases, the ellipse of the innermost dark blue layer, which is the maximum stress layer, keeps shrinking and the area keeps decreasing. While the green layer in the lower right corner is replaced by a red layer, the outermost light blue layer is also disappearing. Intuitively, the overall residual stresses in the parts continuously decrease as the melt temperature increases. The stress variation curves are shown in

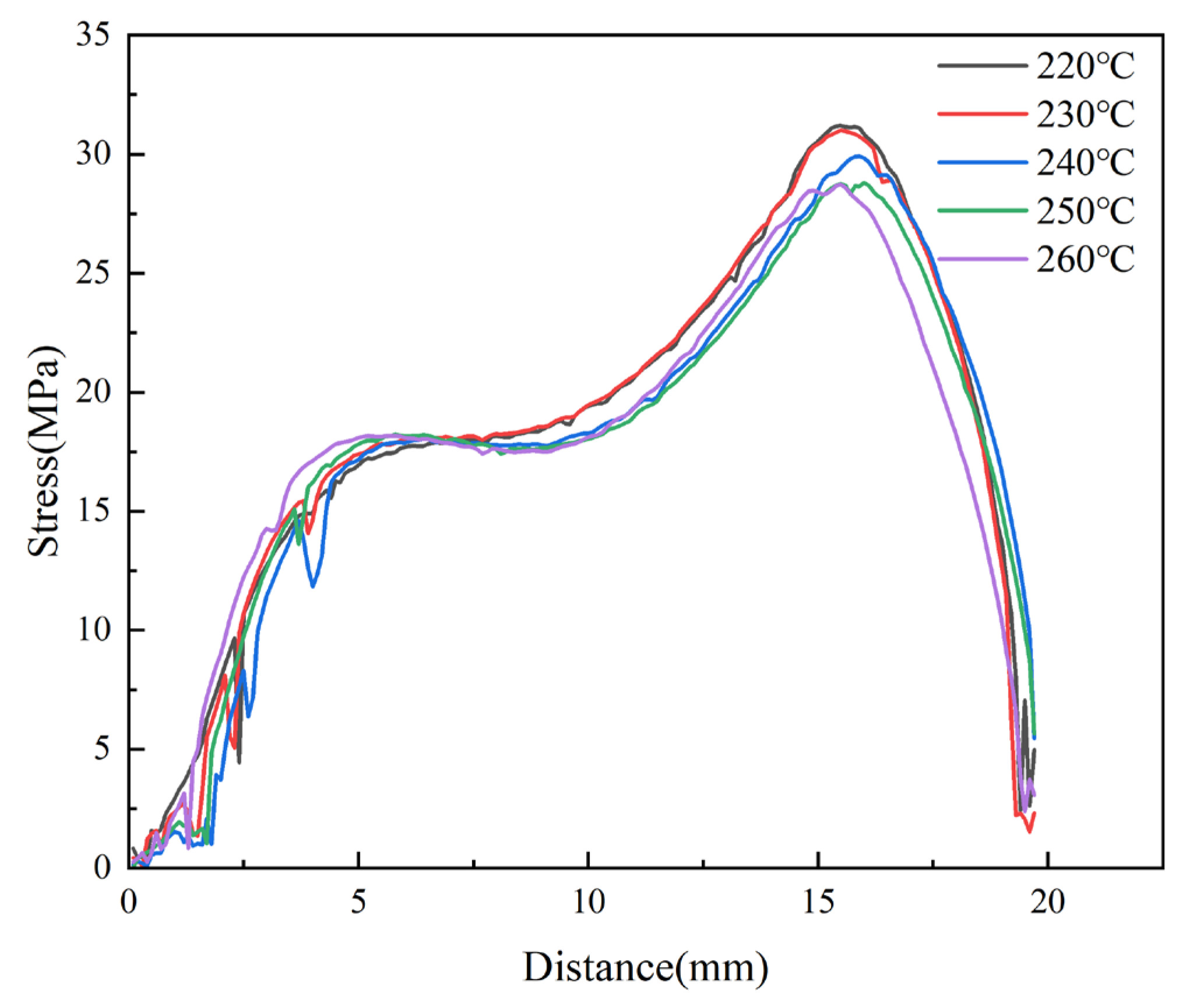

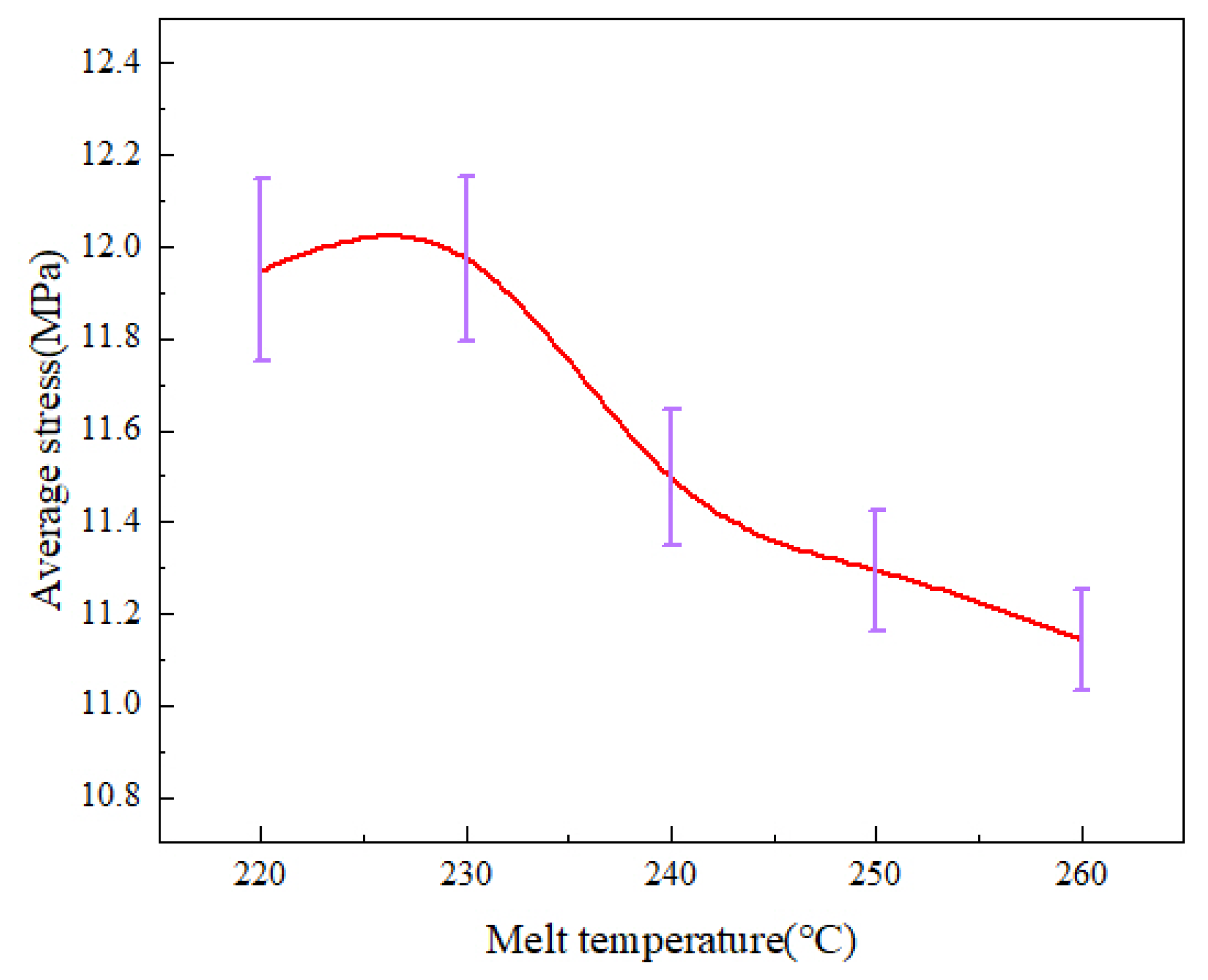

Figure 19. It can be seen that as the melt temperature increases from 220 °C to 260 °C, the stress curves essentially overlap until a distance of 5 mm from the origin, where the stress peak is obtained. However, the peak stress at a distance of 15.5 mm obviously decreases from 31.2 MPa to 28.7 MPa.

Figure 20 presents the graph of the average stress lines at different melt temperatures. The average stress tends to increase slightly when the melt temperature rises from 220 °C to 230 °C, while it decreases from 11.97MPa to 11.14MPa continuously when the melt temperature increases from 230 °C to 260 °C by almost 6.9%. Therefore, within a certain range, the residual stresses inside the part can be properly reduced by increasing the melt temperature.

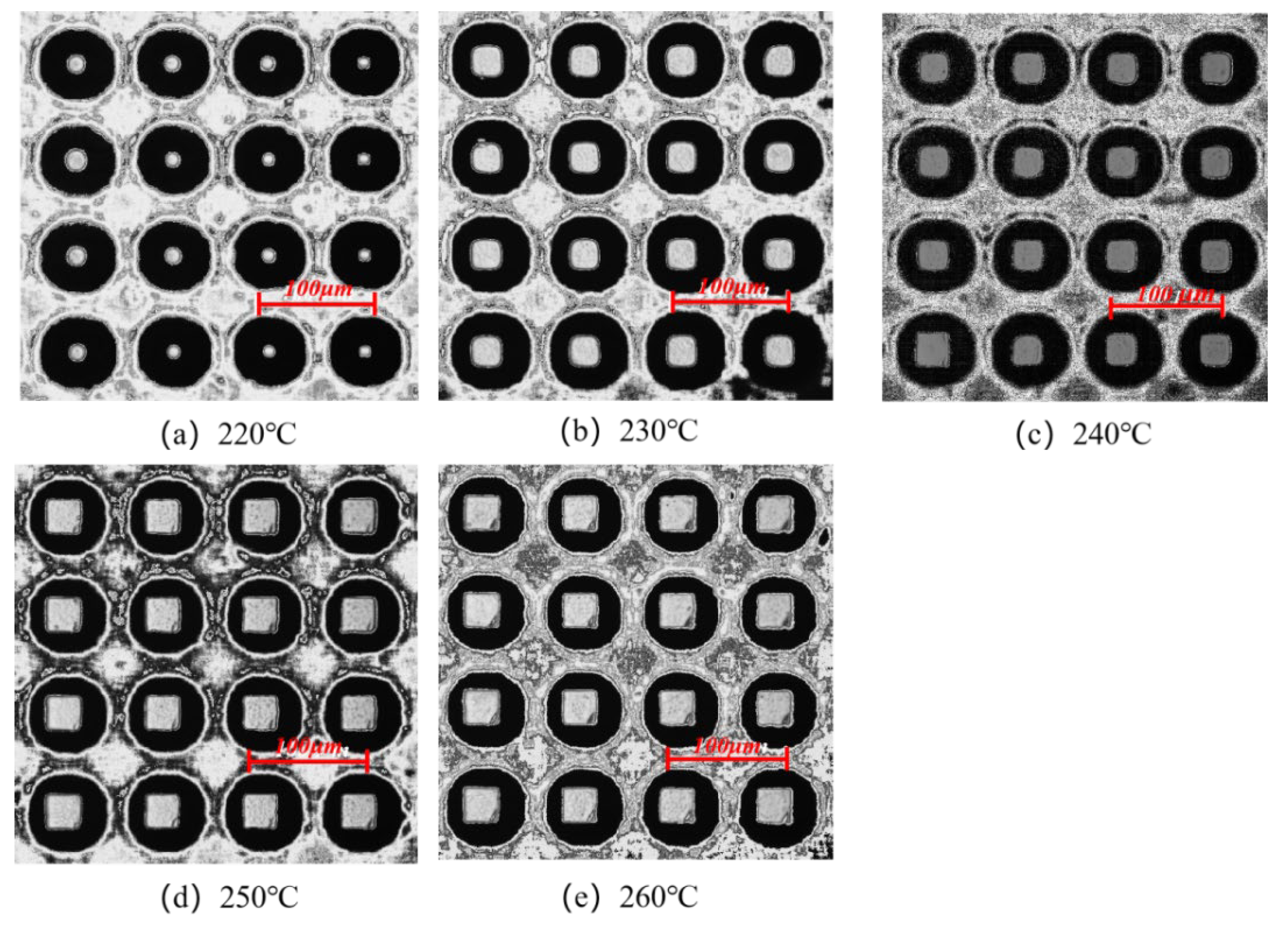

The morphologies of the micro-pillar arrays at different melt temperatures were examined in the experimental study, as shown in

Figure 21. With the increase in the melt temperature, the microstructure morphology changes from a dotted profile at 220 °C to a complete profile at 260 °C. As the melt temperature increases, the molecular chain orientation ability decreases, and the stress in the microstructure before demolding is less, which will be beneficial for the demolding stage and the replication quality will be improved. Therefore, increasing the melt temperature can not only reduce the residual stresses in the micro-pillar array after demolding to some extent but also significantly improve the molding quality of micro-pillars.

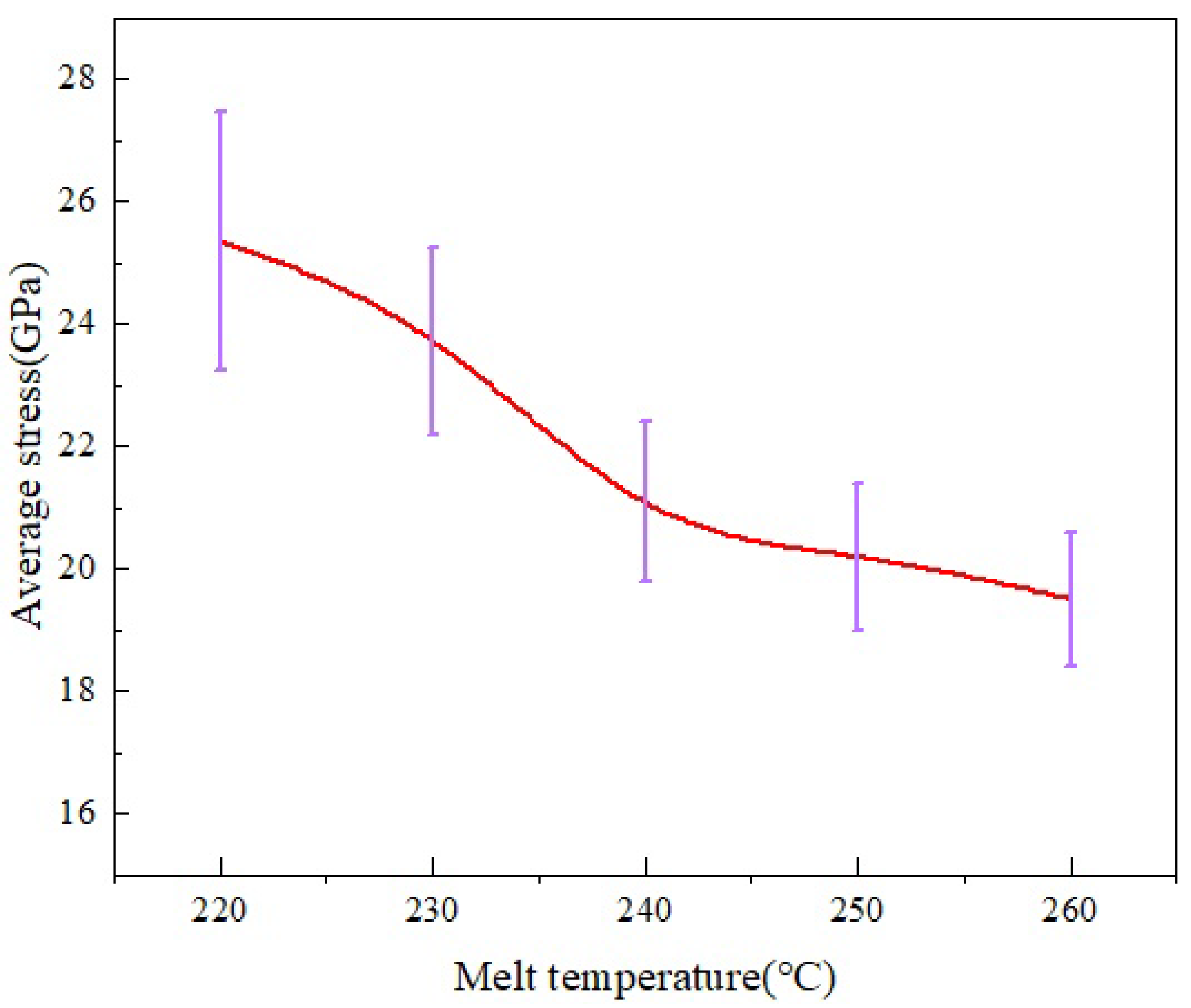

The distributions of average stress and uniformity at different melt temperatures in the MD simulation are shown in

Figure 22. It can be seen that as the melt temperature increases, the overall average stress of PP shows a decreasing trend. When the melt temperature is increased from 220 °C to 260 °C, the average stress decreases by 23% and the standard deviation also decreases, indicating that the uniformity of stress distribution also improves.

Figure 23 shows the density distributions of the melt at different melt temperatures in the MD simulation. It can be seen that the density rises sharply and reaches a peak near the cavity wall, and the peak value increases with the increase in the melt temperature. This is because as the melt temperature increases, the temperature difference with the mold is greater, the polymer shrinks more when it contacts the wall cavity, and the density increases. Additionally, the melt temperature increases the thermal motion of the molecules, which makes the flow resistance decrease. In other words, it is good for transferring the pressure to cool and solidify more of the melt, so that the maximum density can reach 2.1 g/cm

3 at the melt temperature of 260 °C.

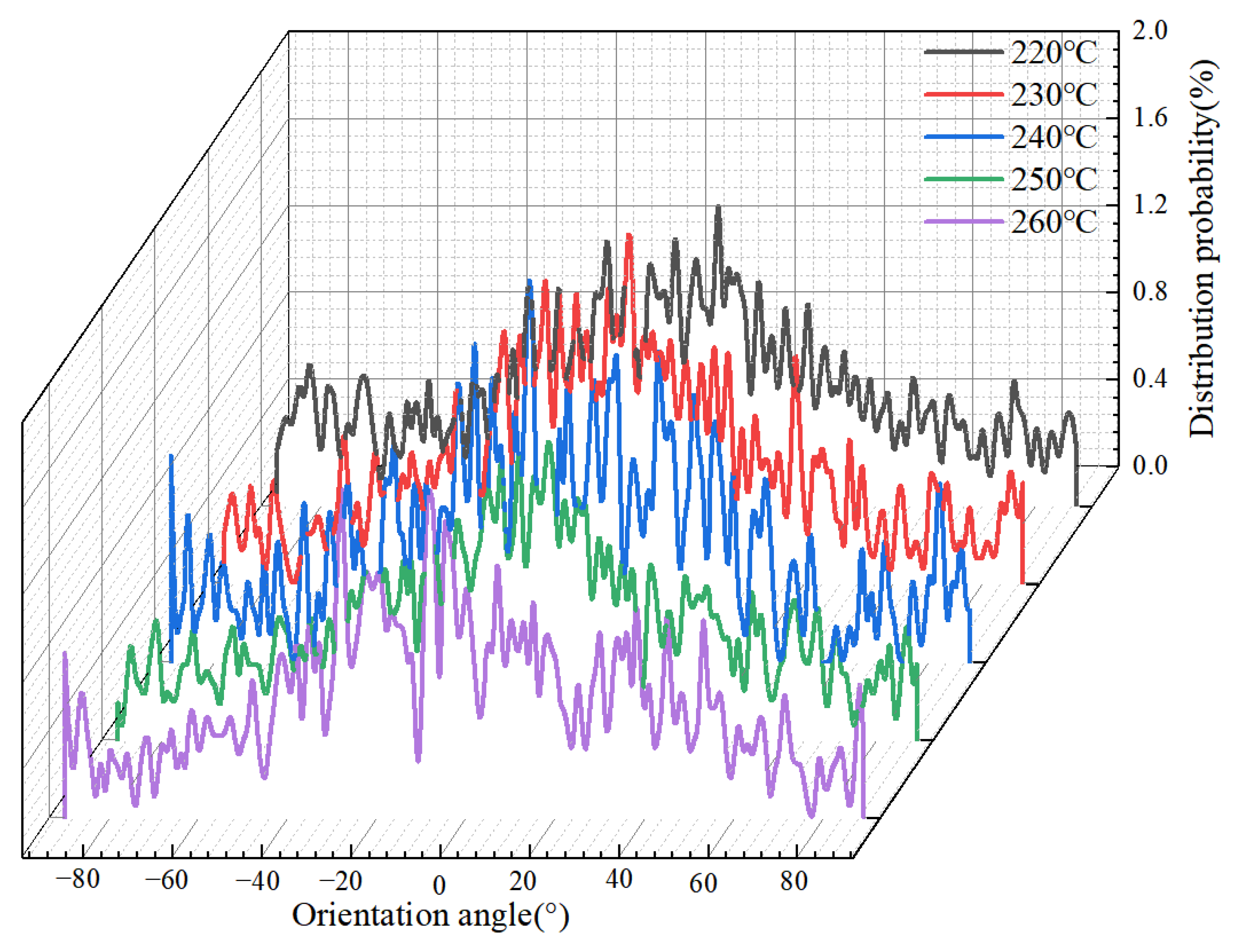

The simulation results of the orientation degree at different melt temperatures are shown in

Figure 24. It can be seen that the effect of the melt temperature on the orientation degree is not obvious. When the polymer filling is completed, the overall orientation peaks around 0°, indicating that both the flow of polymer and the restriction of the cavity walls cause the orientation of the molecular chains. At the melt temperature of 220 °C, a single peak appears on the probability distribution curve of the orientation angle with a value of about 1.2%. The probability density peak of the orientation angle near 0° decreases slightly with increasing melt temperature, indicating that increasing the melt temperature to a certain extent could reduce the orientation of molecular chains along the flow direction and improve the uniformity of residual stresses distribution. This is consistent with the experimental results. In the experiments, the decrease in orientation stress leads to less stress in the microstructure before demolding, and the replication quality is accordingly improved.