Optically Transparent Bamboo: Preparation, Properties, and Applications

Abstract

1. Introduction

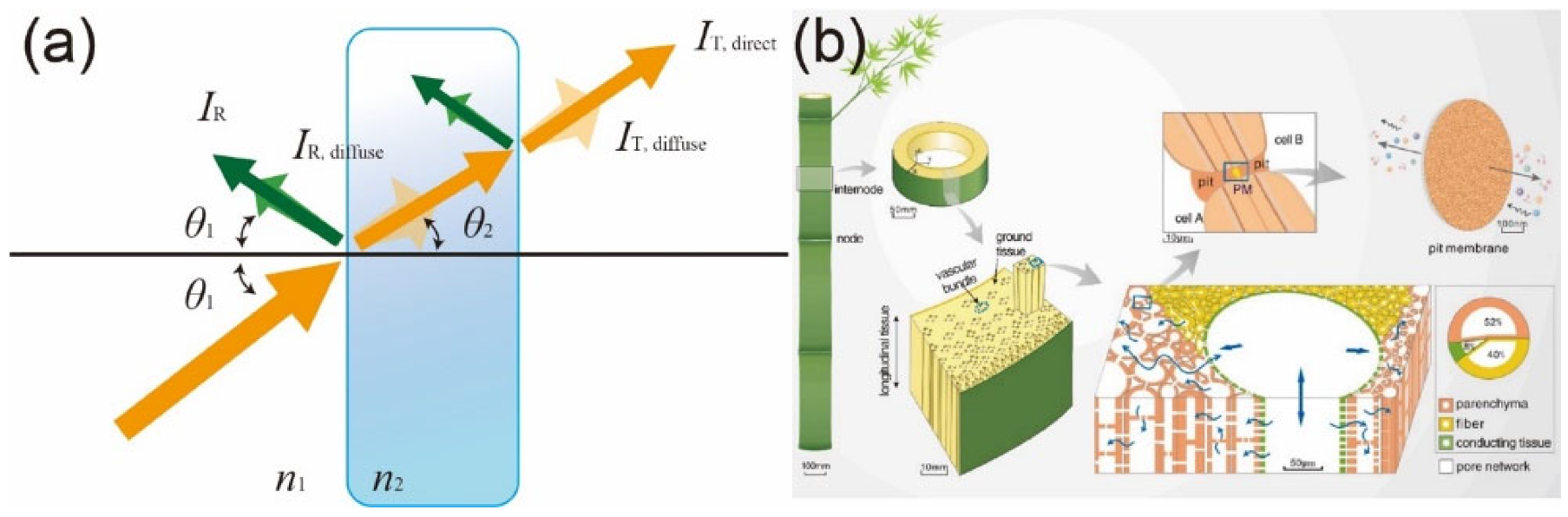

2. Basics of Light–Bamboo Interaction

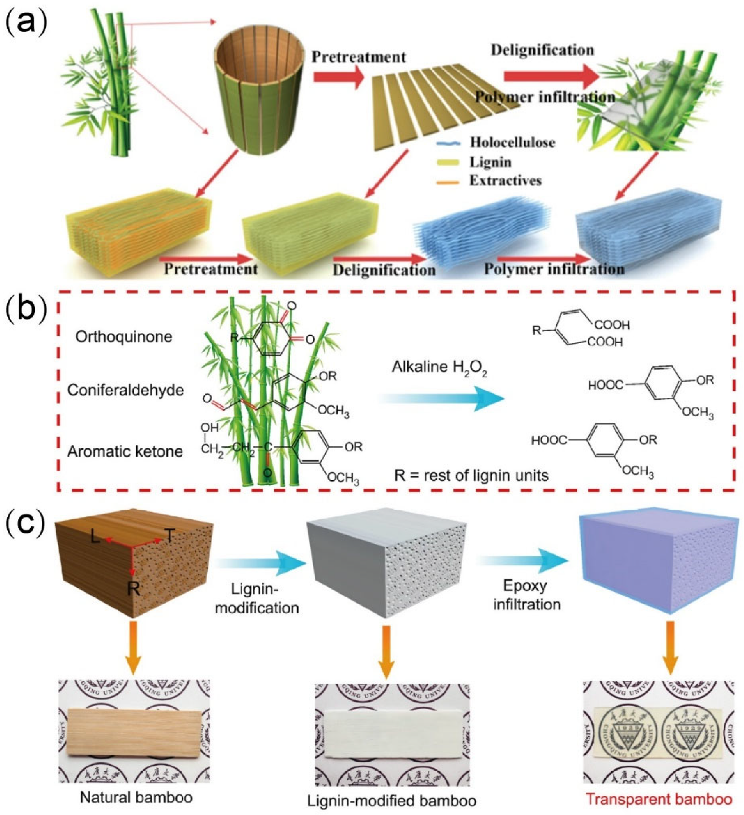

3. Preparation of TB

3.1. Preparation of the Bamboo Template

3.1.1. Acid Delignification Method

3.1.2. Alkali Delignification Method

3.1.3. Lignin Modification (Lignin Retaining) Method

3.1.4. Biological Enzyme Delignification

4. Properties of TB

4.1. Optical Properties

4.2. Mechanical Properties

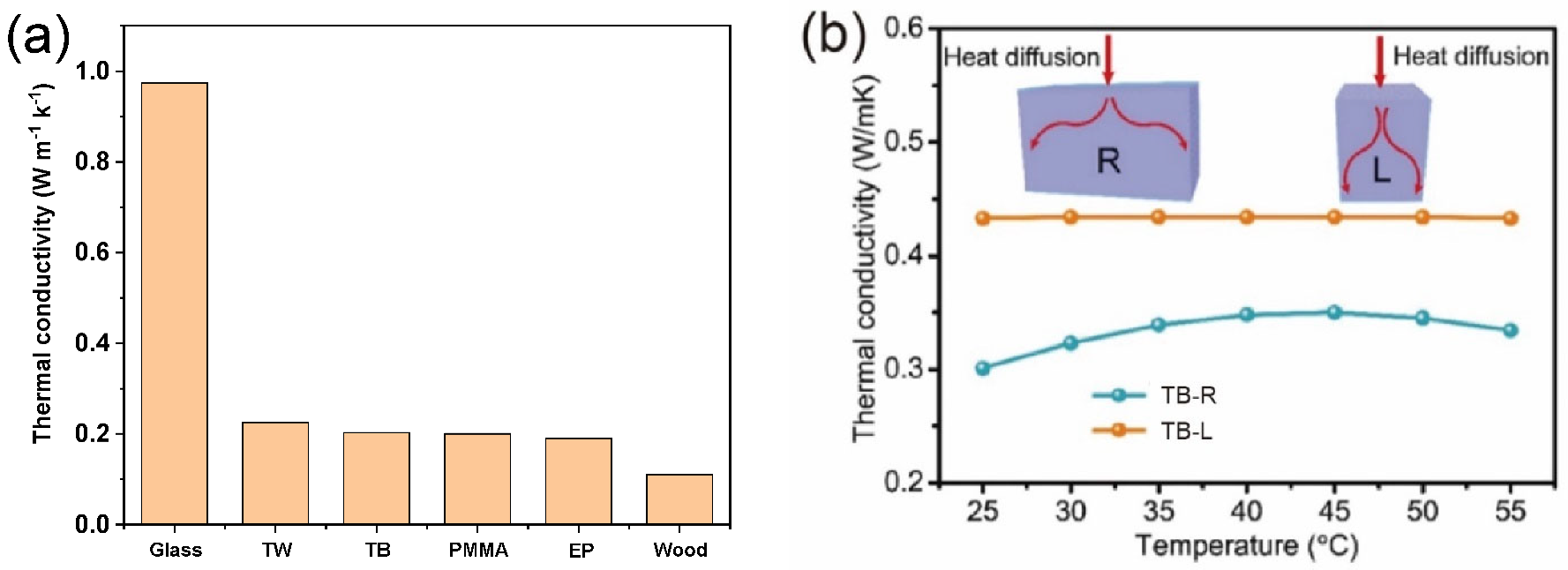

4.3. Thermal Conductivity

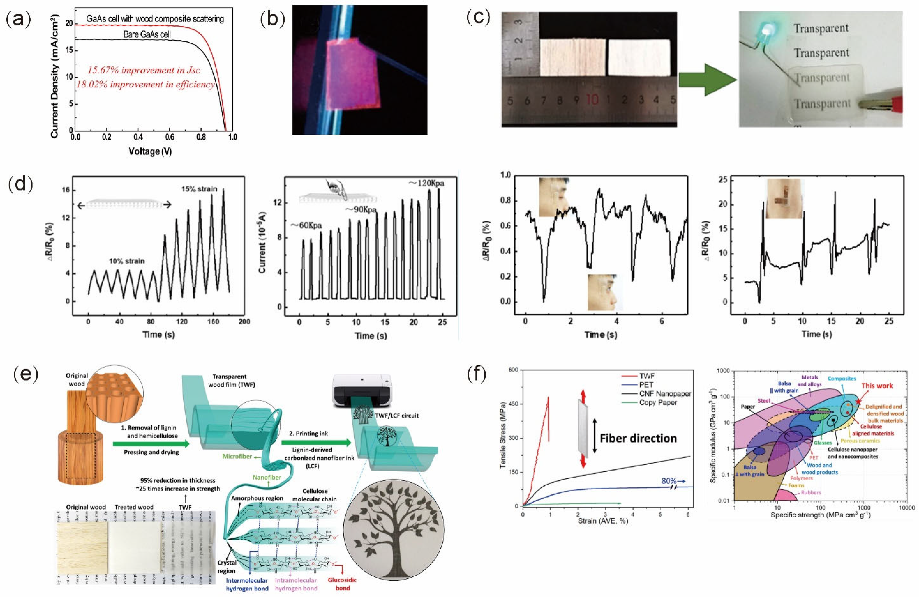

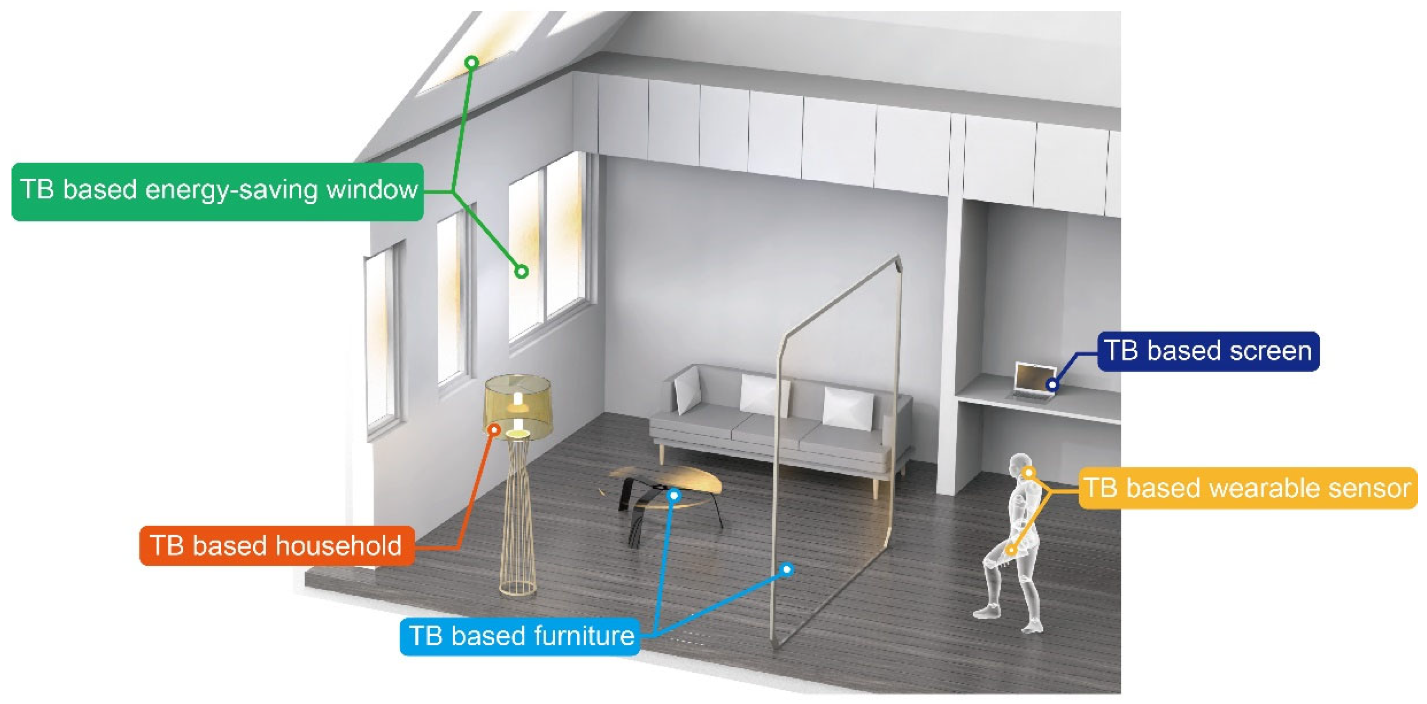

5. Functionalized TB and its Potential Applications

5.1. Energy-Saving Windows

5.2. Decorative Applications

5.3. Optoelectronic Devices

6. Conclusions and Outlook

- The delignification process used to prepare TB will affect its optical and mechanical properties. Previous experimental results indicate that TB prepared by lignin modification has better properties than the TB prepared using other methods. However, lignin modification requires more chemical solvents than most other methods. Thus, several sustainability issues related to delignification technology optimization should be addressed in future research. For example, environmentally friendly “green” chemistry approaches are necessary to minimize the use of solvents, reduce reaction time and waste streams in the preparation of TB, and develop TB-specific functionalization methodologies. Proper resin selection is also essential to realizing the desired TB properties. However, as there have been few attempts to prepare TB using different resin types, different resins and resin modifications should be studied to increase the functionality of TB.

- Scaling up the production of TB is expected to be challenging, although some strategies targeting TB have been explored with promising results. Furthermore, the results reported to date have focused on small and thin TB samples. As an increase in thickness causes the light to travel longer and decay inside the TB, increasing thickness while maintaining sufficient transparency represents a significant challenge to the successful implementation of this technology at the industrial scale. Various technical optimization approaches are therefore worthy of investigation, such as the effect of parallel lamination and cross lamination on TB performance.The potential functionalizations of TB include its development as a: (i) thermal insulation material, (ii) decorative material, (iii) conductive material, and (iv) or magnetic material. To date, TB has typically been singly functionalized for a specific scenario. The versatility of TB should therefore be further evaluated, such as the simultaneous combination of thermal insulation and magnetic functions to address a variety of situations using the same material. The functional utilization of bamboo is far less than that of wood at present, so there remains a wide range of strategies to be explored to develop novel functionalized bamboo materials.

- The functionalization of TB enables its application to diverse fields such as: (i) energy-saving windows, (ii) decorative applications, and (iii) optoelectronic devices. Several applications targeting TB have been explored with promising results. As the research community pays increasing attention to sustainable development, it is likely that functional TB technology will continue to develop over the next several years.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Scurlock, J.M.O.; Dayton, D.C.; Hames, B. Bamboo: An Overlooked Biomass Resource? Biomass Bioenergy 2000, 19, 229–244. [Google Scholar] [CrossRef]

- Yu, Y.; Jiang, Z.; Fei, B.; Wang, G.; Wang, H. An Improved Microtensile Technique for Mechanical Characterization of Short Plant Fibers: A Case Study on Bamboo Fibers. J. Mater. Sci. 2011, 46, 739–746. [Google Scholar] [CrossRef]

- Liu, D.; Song, J.; Anderson, D.P.; Chang, P.R.; Hua, Y. Bamboo Fiber and Its Reinforced Composites: Structure and Properties. Cellulose 2012, 19, 1449–1480. [Google Scholar] [CrossRef]

- Yu, Y.; Liu, R.; Huang, Y.; Meng, F.; Yu, W. Preparation, Physical, Mechanical, and Interfacial Morphological Properties of Engineered Bamboo Scrimber. Constr. Build. Mater. 2017, 157, 1032–1039. [Google Scholar] [CrossRef]

- Chung, M.J.; Wang, S.Y. Mechanical Properties of Oriented Bamboo Scrimber Boards Made of Phyllostachys Pubescens (Moso Bamboo) from Taiwan and China as a Function of Density. Holzforschung 2018, 72, 151–158. [Google Scholar] [CrossRef]

- Lin, Q.; Huang, Y.; Li, X.; Yu, W. Effects of Shape, Location and Quantity of the Joint on Bending Properties of Laminated Bamboo Lumber. Constr. Build. Mater. 2020, 230, 117023. [Google Scholar] [CrossRef]

- Chen, G.; Yu, Y.; Li, X.; He, B. Mechanical Behavior of Laminated Bamboo Lumber for Structural Application: An Experimental Investigation. Eur. J. Wood Wood Prod. 2020, 78, 53–63. [Google Scholar] [CrossRef]

- Huang, J.K.; Young, W.B. The Mechanical, Hygral, and Interfacial Strength of Continuous Bamboo Fiber Reinforced Epoxy Composites. Compos. Part. B Eng. 2019, 166, 272–283. [Google Scholar] [CrossRef]

- Wu, J.; Wu, Y.; Yang, F.; Tang, C.; Huang, Q.; Zhang, J. Impact of Delignification on Morphological, Optical and Mechanical Properties of Transparent Wood. Compos. Part. A Appl. Sci. Manuf. 2019, 117, 324–331. [Google Scholar] [CrossRef]

- Li, Y.; Vasileva, E.; Sychugov, I.; Popov, S.; Berglund, L. Optically Transparent Wood: Recent Progress, Opportunities, and Challenges. Adv. Opt. Mater. 2018, 6, 1–14. [Google Scholar] [CrossRef]

- Li, Y.; Fu, Q.; Yu, S.; Yan, M.; Berglund, L. Optically Transparent Wood from a Nanoporous Cellulosic Template: Combining Functional and Structural Performance. Biomacromolecules 2016, 17, 1358–1364. [Google Scholar] [CrossRef] [PubMed]

- Subba Rao, A.N.; Nagarajappa, G.B.; Nair, S.; Chathoth, A.M.; Pandey, K.K. Flexible Transparent Wood Prepared from Poplar Veneer and Polyvinyl Alcohol. Compos. Sci. Technol. 2019, 182, 107719. [Google Scholar] [CrossRef]

- Wu, Y.; Zhou, J.; Huang, Q.; Yang, F.; Wang, Y.; Liang, X.; Li, J. Study on the Colorimetry Properties of Transparent Wood Prepared from Six Wood Species. ACS Omega 2020, 5, 1782–1788. [Google Scholar] [CrossRef]

- Chen, L.; Xu, Z.; Wang, F.; Duan, G.; Xu, W.; Zhang, G.; Yang, H.; Liu, J.; Jiang, S. A Flame-Retardant and Transparent Wood / Polyimide Composite with Excellent Mechanical Strength. Compos. Commun. 2020, 20, 100355. [Google Scholar] [CrossRef]

- Wan, C.; Liu, X.; Huang, Q.; Cheng, W.; Su, J.; Wu, Y. A Brief Review of Transparent Wood: Synthetic Strategy, Functionalization and Applications. Curr. Org. Synth. 2021, 18, 615–623. [Google Scholar] [CrossRef]

- Chen, D.; Gao, A.; Cen, K.; Zhang, J.; Cao, X.; Ma, Z. Investigation of Biomass Torrefaction Based on Three Major Components: Hemicellulose, Cellulose, and Lignin. Energy Convers. Manag. 2018, 169, 228–237. [Google Scholar] [CrossRef]

- Cogulet, A.; Blanchet, P.; Landry, V. Wood Degradation under UV Irradiation: A Lignin Characterization. J. Photochem. Photobiol. B Biol. 2016, 158, 184–191. [Google Scholar] [CrossRef] [PubMed]

- Schwanninger, M.; Steiner, M.; Zobl, H. Yellowing and IR-Changes of Spruce Wood as Result of UV-Irradiation. J. Photochem. Photobiol. B Biol. 2003, 69, 97–105. [Google Scholar]

- Emaminasab, M.; Tarmian, A.; Oladi, R.; Pourtahmasi, K.; Avramidis, S. Fluid Permeability in Poplar Tension and Normal Wood in Relation to Ray and Vessel Properties. Wood Sci. Technol. 2016. [Google Scholar] [CrossRef]

- Zauer, M.; Hempel, S.; Pfriem, A. Investigations of the Pore-Size Distribution of Wood in the Dry and Wet State by Means of Mercury Intrusion Porosimetry. Wood Sci Technol 2014, 1229–1240. [Google Scholar] [CrossRef]

- Wang, L.; Liu, Y.; Zhan, X.; Luo, D.; Sun, X. Correction: Photochromic Transparent Wood for Photo-Switchable Smart Window Applications. J. Mater. Chem. C 2019, 518055. [Google Scholar] [CrossRef]

- Sun, Y.; Cheng, J. Hydrolysis of Lignocellulosic Materials for Ethanol Production: A Review. Bioresour. Technol. 2002, 83, 1–11. [Google Scholar] [CrossRef]

- Wang, X.; Shan, S.; Shi, S.Q.; Zhang, Y.; Cai, L.; Smith, L.M. Optically Transparent Bamboo with High Strength and Low Thermal Conductivity. ACS Appl. Mater. Interfaces 2021, 13, 1662–1669. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Wang, J.; Wang, Y.; Zhou, J. Properties of Multilayer Transparent Bamboo Materials. ACS Omega 2021, 6, 33747–33756. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Wang, Y.; Yang, F.; Wang, J.; Wang, X. Study on the Properties of Transparent Bamboo Prepared by Epoxy Resin Impregnation. Polymers 2020, 12, 863. [Google Scholar] [CrossRef]

- Zhu, H.; Parvinian, S.; Preston, C.; Vaaland, O.; Ruan, Z.; Hu, L. Transparent Nanopaper with Tailored Optical Properties. Nanoscale 2013, 5, 3787–3792. [Google Scholar] [CrossRef]

- Hsu, P.C.; Song, A.Y.; Catrysse, P.B.; Liu, C.; Peng, Y.; Xie, J.; Fan, S.; Cui, Y. Radiative Human Body Cooling by Nanoporous Polyethylene Textile. Science. 2016, 353, 1019–1023. [Google Scholar] [CrossRef]

- Larena, A.; Millán, F.; Pérez, G.; Pinto, G. Effect of Surface Roughness on the Optical Properties of Multilayer Polymer Films. Appl. Surf. Sci. 2002, 187, 339–346. [Google Scholar] [CrossRef]

- Nogi, M.; Yano, H. Optically Transparent Nanofiber Sheets by Deposition of Transparent Materials: A Concept for a Roll-to-Roll Processing. Appl. Phys. Lett. 2009, 94. [Google Scholar] [CrossRef]

- Fink, S. Transparent Wood—A New Approach in the Functional Study of Wood Structure. Holzforschung 1992, 46, 403–408. [Google Scholar] [CrossRef]

- Liu, R.; Zhang, S.; Semple, K.; Lian, C.; Chen, M.; Luo, J.; Yang, F.; Dai, C.; Fei, B. Precise Microcasting Revealing the Connectivity of Bamboo Pore Network. Ind. Crops Prod. 2021, 170, 113787. [Google Scholar] [CrossRef]

- Li, Y.; Fu, Q.; Yang, X.; Berglund, L. Transparent Wood for Functional and Structural Applications. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2018, 376. [Google Scholar] [CrossRef] [PubMed]

- Zou, W.; Sun, D.; Wang, Z.; Li, R.; Yu, W.; Zhang, P. Eco-Friendly Transparent Poplar-Based Composites That Are Stable and Flexible at High Temperature. RSC Adv. 2019, 9, 21566–21571. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Yang, X.; Fu, Q.; Rojas, R.; Yan, M.; Berglund, L. Towards Centimeter Thick Transparent Wood through Interface Manipulation. J. Mater. Chem. A 2018, 6, 1094–1101. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, F.; Li, Y.; Zhu, W.; Huang, P.; Hu, N.; Fu, S. High Overall Performance Transparent Bamboo Composite via a Lignin-Modification Strategy. Compos. Part. B Eng. 2022, 235, 109798. [Google Scholar] [CrossRef]

- Wu, Y.; Wu, J.; Yang, F.; Tang, C.; Huang, Q. Effect of H2O2 Bleaching Treatment on the Properties of Finished Transparent Wood. Polymers 2019, 11, 776. [Google Scholar] [CrossRef]

- Shi, J.; Peng, J.; Huang, Q.; Cai, L.; Shi, S.Q. Fabrication of Densified Wood via Synergy of Chemical Pretreatment, Hot-Pressing and Post Mechanical Fixation. J. Wood Sci. 2020, 66. [Google Scholar] [CrossRef]

- Yang, R.; Cao, Q.; Liang, Y.; Hong, S.; Xia, C.; Wu, Y.; Li, J.; Cai, L.; Sonne, C.; Van Le, Q.; et al. High Capacity Oil Absorbent Wood Prepared through Eco-Friendly Deep Eutectic Solvent Delignification. Chem. Eng. J. 2020, 401, 126150. [Google Scholar] [CrossRef]

- Zhou, J.; Wu, Y. Research Progress on Preparation and Application of Transparent Wood. China For. Prod. Ind. 2020, 57, 17–22. [Google Scholar] [CrossRef]

- Lasseuguette, E.; Roux, D.; Nishiyama, Y. Rheological Properties of Microfibrillar Suspension of TEMPO-Oxidized Pulp. Cellulose 2008, 15, 425–433. [Google Scholar] [CrossRef]

- Jacucci, G.; Schertel, L.; Zhang, Y.; Yang, H.; Vignolini, S. Light Management with Natural Materials: From Whiteness to Transparency. Adv. Mater. 2021, 33. [Google Scholar] [CrossRef] [PubMed]

- Abdul Khalil, H.P.S.; Bhat, I.U.H.; Jawaid, M.; Zaidon, A.; Hermawan, D.; Hadi, Y.S. Bamboo Fibre Reinforced Biocomposites: A Review. Mater. Des. 2012, 42, 353–368. [Google Scholar] [CrossRef]

- Cai, M.; Takagi, H.; Nakagaito, A.N.; Katoh, M.; Ueki, T.; Waterhouse, G.I.N.; Li, Y. Influence of Alkali Treatment on Internal Microstructure and Tensile Properties of Abaca Fibers. Ind. Crops Prod. 2015, 65, 27–35. [Google Scholar] [CrossRef]

- Vijaya Ramnath, B.; Manickavasagam, V.M.; Elanchezhian, C.; Vinodh Krishna, C.; Karthik, S.; Saravanan, K. Determination of Mechanical Properties of Intra-Layer Abaca-Jute-Glass Fiber Reinforced Composite. Mater. Des. 2014, 60, 643–652. [Google Scholar] [CrossRef]

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Mechanical Property Evaluation of Sisal-Jute-Glass Fiber Reinforced Polyester Composites. Compos. Part. B Eng. 2013, 48, 1–9. [Google Scholar] [CrossRef]

- Mohamad, M.; Ting, S.W.; Bakar, M.B.A.; Osman, W.H.W. The Effect of Alkaline Treatment on Mechanical Properties of Polylactic Acid Reinforced with Kenaf Fiber Mat Biocomposite. IOP Conf. Ser. Earth Environ. Sci. 2020, 596. [Google Scholar] [CrossRef]

- Asim, M.; Jawaid, M.; Abdan, K.; Ishak, M.R. Effect of Alkali and Silane Treatments on Mechanical and Fibre-Matrix Bond Strength of Kenaf and Pineapple Leaf Fibres. J. Bionic Eng. 2016, 13, 426–435. [Google Scholar] [CrossRef]

- Li, T.; Song, J.; Zhao, X.; Yang, Z.; Pastel, G.; Xu, S.; Jia, C.; Dai, J.; Dai, C.; Gong, A.; et al. Anisotropic, Lightweight, Strong, and Super Thermally Insulating Nanowood with Naturally Aligned Nanocellulose. Sci. Adv. 2018, 4, 1–10. [Google Scholar] [CrossRef]

- Simona, P.L.; Spiru, P.; Ion, I.V. Increasing the Energy Efficiency of Buildings by Thermal Insulation. Energy Procedia 2017, 128, 393–399. [Google Scholar] [CrossRef]

- Li, T.; Zhu, M.; Yang, Z.; Song, J.; Dai, J.; Yao, Y.; Luo, W.; Pastel, G.; Yang, B.; Hu, L. Wood Composite as an Energy Efficient Building Material: Guided Sunlight Transmittance and Effective Thermal Insulation. Adv. Energy Mater. 2016, 6. [Google Scholar] [CrossRef]

- Zhao, X.; Huang, C.; Liu, Q.; Smalyukh, I.I.; Yang, R. Thermal Conductivity Model for Nanofiber Networks. J. Appl. Phys. 2018, 123. [Google Scholar] [CrossRef]

- Qiu, Z.; Xiao, Z.; Gao, L.; Li, J.; Wang, H.; Wang, Y.; Xie, Y. Transparent Wood Bearing a Shielding Effect to Infrared Heat and Ultraviolet via Incorporation of Modified Antimony-Doped Tin Oxide Nanoparticles. Compos. Sci. Technol. 2019, 172, 43–48. [Google Scholar] [CrossRef]

- Huang, X.; Jiang, P.; Tanaka, T. A Review of Dielectric Polymer Composites with High Thermal Conductivity. IEEE Electr. Insul. Mag. 2011, 27, 8–16. [Google Scholar] [CrossRef]

- Gan, W.; Gao, L.; Sun, Q.; Jin, C.; Lu, Y.; Li, J. Multifunctional Wood Materials with Magnetic, Superhydrophobic and Anti-Ultraviolet Properties. Appl. Surf. Sci. 2015, 332, 565–572. [Google Scholar] [CrossRef]

- Guo, H.; Fuchs, P.; Cabane, E.; Michen, B.; Hagendorfer, H.; Romanyuk, Y.E.; Burgert, I. UV-Protection of Wood Surfaces by Controlled Morphology Fine-Tuning of ZnO Nanostructures. Holzforschung 2016, 70, 699–708. [Google Scholar] [CrossRef]

- Trey, S.; Olsson, R.T.; Ström, V.; Berglund, L.; Johansson, M. Controlled Deposition of Magnetic Particles within the 3-D Template of Wood: Making Use of the Natural Hierarchical Structure of Wood. RSC Adv. 2014, 4, 35678–35685. [Google Scholar] [CrossRef]

- Merk, V.; Chanana, M.; Keplinger, T.; Gaan, S.; Burgert, I. Hybrid Wood Materials with Improved Fire Retardance by Bio-Inspired Mineralisation on the Nano- and Submicron Level. Green Chem. 2015, 17, 1423–1428. [Google Scholar] [CrossRef]

- Zhang, Y.; Luo, W.; Wang, C.; Li, Y.; Chen, C.; Song, J.; Dai, J.; Hitz, E.M.; Xu, S.; Yang, C.; et al. High-Capacity, Low-Tortuosity, and Channel-Guided Lithium Metal Anode. Proc. Natl. Acad. Sci. USA 2017, 114, 3584–3589. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, Y.; Li, Y.; Dai, J.; Song, J.; Yao, Y.; Gong, Y.; Kierzewski, I.; Xie, J.; Hu, L. All-Wood, Low Tortuosity, Aqueous, Biodegradable Supercapacitors with Ultra-High Capacitance. Energy Environ. Sci. 2017, 10, 538–545. [Google Scholar] [CrossRef]

- Hassel, B.I.; Trey, S.; Leijonmarck, S.; Johansson, M. A Study on the Morphology, Mechanical, and Electrical Performance of Polyaniline-Modified Wood—A Semiconducting Composite Material. BioResources 2014, 9, 5007–5023. [Google Scholar] [CrossRef][Green Version]

- Li, Y.; Fu, Q.; Rojas, R.; Yan, M.; Lawoko, M.; Berglund, L. Lignin-Retaining Transparent Wood. ChemSusChem 2017, 10, 3445–3451. [Google Scholar] [CrossRef] [PubMed]

- Burgert, I.; Cabane, E.; Zollfrank, C.; Berglund, L. Bio-Inspired Functionalwood-Basedmaterials-Hybrids and Replicates. Int. Mater. Rev. 2015, 60, 431–450. [Google Scholar] [CrossRef]

- Torres-Pierna, H.; Ruiz-Molina, D.; Roscini, C. Highly Transparent Photochromic Films with Tunable and Fast Solution-like Response. Mater. Horizons 2020, 1–11. [Google Scholar] [CrossRef]

- Zhang, S.; Cao, S.; Zhang, T.; Lee, J.Y. Plasmonic Oxygen-Deficient TiO 2-x Nanocrystals for Dual-Band Electrochromic Smart Windows with Efficient Energy Recycling. Adv. Mater. 2020, 2004686, 2–9. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Wang, S.; Peng, J.; Tan, Y.; Li, C.; Yin, F.; Zhou, Y.; Wang, S.; Peng, J.; Tan, Y.; et al. Article Liquid Thermo-Responsive Smart Window Derived from Hydrogel Liquid Thermo-Responsive Smart Window Derived from Hydrogel. Joule 2020, 4, 1–17. [Google Scholar] [CrossRef]

- Ke, Y.; Zhang, Q.; Wang, T.; Wang, S.; Li, N.; Lin, G. Cephalopod-Inspired Versatile Design Based on Plasmonic VO 2 Nanoparticle for Energy-Efficient Mechano-Thermochromic Windows. Nano Energy 2020, 73. [Google Scholar] [CrossRef]

- Chen, R.; Das, S.R.; Jeong, C.; Khan, M.R.; Janes, D.B.; Alam, M.A. Co-Percolating Graphene-Wrapped Silver Nanowire Network for High Performance, Highly Stable, Transparent Conducting Electrodes. Adv. Funct. Mater. 2013, 1–9. [Google Scholar] [CrossRef]

- Lee, D.; Lee, H.; Ahn, Y.; Jeong, Y.; Lee, D.-Y.; Lee, Y. Highly Stable and Flexible Silver Nanowire—Graphene Hybrid Transparent Conducting Electrodes for Emerging Optoelectronic Devices. Nanoscale 2013, 5, 7750. [Google Scholar] [CrossRef]

- Yuan, Z.; Dryden, N.H.; Vittal, J.J.; Puddephatt, R.J. Chemical Vapor Deposition of Silver. Chem. Mater. 1995, 7, 1696–1702. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, A.; Zhu, T.; Chen, Z.; Wu, Y.; Gao, Y. Transparent Wood Composites Fabricated by Impregnation of Epoxy Resin and W-Doped VO2 Nanoparticles for Application in Energy-Saving Windows. ACS Appl. Mater. Interfaces 2020, 12, 34777–34783. [Google Scholar] [CrossRef]

- Ke, Y.; Chen, J.; Lin, G.; Wang, S.; Zhou, Y.; Yin, J.; Lee, P.S.; Long, Y. Smart Windows: Electro-, Thermo-, Mechano-, Photochromics, and Beyond. Adv. Energy Mater. 2019, 1902066, 1–38. [Google Scholar] [CrossRef]

- Heidarinejad, M.; Dalgo, D.; Mi, R.; Zhao, X.; Song, J. A Radiative Cooling Structural Material. Struct. Mater. 2019, 763, 760–763. [Google Scholar]

- Raman, A.P.; Anoma, M.A.; Zhu, L.; Rephaeli, E.; Fan, S. Passive Radiative Cooling below Ambient Air Temperature under Direct Sunlight. Nature 2014. [Google Scholar] [CrossRef] [PubMed]

- Zhao, B.; Hu, M.; Ao, X.; Chen, N.; Pei, G. Radiative Cooling: A Review of Fundamentals, Materials, Applications, and Prospects. Appl. Energy. 2019, 236, 489–513. [Google Scholar] [CrossRef]

- Zhou, C.; Julianri, I.; Wang, S.; Chan, S.H.; Li, M.; Long, Y. Transparent Bamboo with High Radiative Cooling Targeting Energy Savings. ACS Mater. Lett. 2021, 3, 883–888. [Google Scholar] [CrossRef]

- Wang, J.; Wu, Y.; Wang, Y.; Zheng, Y. Research Progress of Transparent Bamboo and Home Product Design. Furniture 2021, 42, 52–56. [Google Scholar] [CrossRef]

- Zhao, B.; Yu, L.; Li, H.; Fei, B. The Research Progress and Application of Bamboo Packaging Materials. CHINA For. Prod. Ind. 2018. [Google Scholar] [CrossRef]

- Zhu, M.; Li, T.; Davis, C.S.; Yao, Y.; Dai, J.; Wang, Y.; AlQatari, F.; Gilman, J.W.; Hu, L. Transparent and Haze Wood Composites for Highly Efficient Broadband Light Management in Solar Cells. Nano Energy. 2016, 26, 332–339. [Google Scholar] [CrossRef]

- Nogi, M.; Karakawa, M.; Komoda, N.; Yagyu, H.; Nge, T.T. Transparent Conductive Nanofiber Paper for Foldable Solar Cells. Sci. Rep. 2015, 5, 17254. [Google Scholar] [CrossRef]

- Li, Y.; Cheng, M.; Jungstedt, E.; Xu, B.; Sun, L.; Berglund, L. Optically Transparent Wood Substrate for Perovskite Solar Cells. ACS Sustain. Chem. Eng. 2019, 7, 6061–6067. [Google Scholar] [CrossRef]

- Gan, W.; Xiao, S.; Gao, L.; Gao, R.; Li, J.; Zhan, X. Luminescent and Transparent Wood Composites Fabricated by Poly(Methyl Methacrylate) and γ-Fe2O3@YVO4:Eu3+ Nanoparticle Impregnation. ACS Sustain. Chem. Eng. 2017, 5, 3855–3862. [Google Scholar] [CrossRef]

- Gan, W.; Gao, L.; Xiao, S.; Zhang, W.; Zhan, X.; Li, J. Transparent Magnetic Wood Composites Based on Immobilizing Fe3O4 Nanoparticles into a Delignified Wood Template. J. Mater. Sci. 2017, 52, 3321–3329. [Google Scholar] [CrossRef]

- Wang, M.; Li, R.; Chen, G.; Zhou, S.; Feng, X.; Chen, Y.; He, M.; Liu, D.; Song, T.; Qi, H. Highly Stretchable, Transparent, and Conductive Wood Fabricated by in Situ Photopolymerization with Polymerizable Deep Eutectic Solvents. ACS Appl. Mater. Interfaces 2019, 11, 14313–14321. [Google Scholar] [CrossRef] [PubMed]

- Fu, Q.; Chen, Y.; Sorieul, M. Wood-Based Flexible Electronics. ACS Appl. Mater. Interfaces 2020. [Google Scholar] [CrossRef]

| Ref. | Template Preparation Method; Temperature; Time | Polymer | Variable | Optical Property | Mechanical Property | |||

|---|---|---|---|---|---|---|---|---|

| t (mm) | Tr (%) | haze (%) | l × w × t (mm3) | TS (MPa) | ||||

| Wu et al. [25] | Delignification: NaClO2; 80–90 °C; 2–4 h | Epoxy (E51) (RI = approximately 1.5) | inner | 1.1 | approximately 12 | — | 3 × 4.4 × 1.1 | 35.31 |

| outer | 1.8 | approximately 2 | — | 3 × 7.8 × 1.8 | 82.18 | |||

| Wang et al. [23] | Delignification: preconditioned in NaOH + 10 h; NaClO2; 85 °C; 3 h | Two-part epoxy resin (Clearcast 7000) (RI = approximately 1.5) | — | 1 | approximately 80 | 80 | 165 × 13 × 1 | 92 |

| — | 1.5 | approximately 75 | 80 | 165 × 13 × 1.5 | — | |||

| Wu et al. [24] | Delignification: NaClO2; 80–90 °C; 2–3 h | Epoxy (E51) (RI = 1.52) | — | 0.3 | 92.4 | 43.5 | 40 × 20 × 0.3 | 47.1 |

| multi-layer (3 layers) | 1.2 | 78.6 | 70 | 40 × 20 × 1.2 | 61.89 | |||

| multi-layer (5 layers) | 2.3 | 67.1 | 70.55 | 40 × 20 × 2.3 | approximately 60 | |||

| multi-layer (7 layers) | 2.9 | 23.7 | 82.95 | 40 × 20 × 2.9 | approximately 60 | |||

| single layer | 1.2 | 10.4 | 97.02 | 40 × 20 × 1.2 | 61.15 | |||

| single layer | 2.3 | 5.5 | ~100 | 40 × 20 × 2.3 | approximately 30 | |||

| single layer | 2.9 | 1.7 | ~100 | 40 × 20 × 2.9 | approximately 10 | |||

| Wang et al. [35] | Lignin modification: lignin-modification solution; 70 °C; until become white | Epoxy (E51) (RI = approximately 1.5) | inner | 1.5 | 87 | — | — | — |

| middle | 1.5 | 74 | — | — | — | |||

| outer | 1.5 | 66 | — | — | — | |||

| radial | 1.5 | — | 90 | 20 × 8 × 1.5 | 30 | |||

| longitudinal | 1.5 | 80 | 70 | 50 × 10 × 1.5 | 118 | |||

| Ref. | Type of Fibre | Density (g/cm3) | Tensile Strength (MPa) | Young’s Modulus (MPa) |

|---|---|---|---|---|

| Abdul Khalil et al. [42] | Moso bamboo (Phyllostachys pubescens) | 1.2–1.5 | 500–575 | 27–40 |

| Liu et al. [3] | Oil palm | 0.7–1.6 | 248 | 3.2 |

| Liu et al. [3] | Pineapple | 0.8–1.6 | 1.44 | 34.5–82.5 |

| Cai et al. [43] | Abaca | 1.5 | 717 | 18.6 |

| Vijaya Ramnath et al. [44] | Jute | 1.3–1.49 | 393–800 | 13–26.5 |

| Ramesh et al. [45] | Sisal | 1.41 | 350–370 | 12.8 |

| Mohamad et al. [46] | Kenaf | 1.2 | 282.6 | 7.13 |

| Asim et al. [47] | Coconut | 1.2 | 140–225 | 3–5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Zhang, W.; Li, J.; Li, X.; Li, N.; Zhang, Z.; Zhang, D.; Rao, F.; Chen, Y. Optically Transparent Bamboo: Preparation, Properties, and Applications. Polymers 2022, 14, 3234. https://doi.org/10.3390/polym14163234

Li X, Zhang W, Li J, Li X, Li N, Zhang Z, Zhang D, Rao F, Chen Y. Optically Transparent Bamboo: Preparation, Properties, and Applications. Polymers. 2022; 14(16):3234. https://doi.org/10.3390/polym14163234

Chicago/Turabian StyleLi, Xuelian, Weizhong Zhang, Jingpeng Li, Xiaoyan Li, Neng Li, Zhenhua Zhang, Dapeng Zhang, Fei Rao, and Yuhe Chen. 2022. "Optically Transparent Bamboo: Preparation, Properties, and Applications" Polymers 14, no. 16: 3234. https://doi.org/10.3390/polym14163234

APA StyleLi, X., Zhang, W., Li, J., Li, X., Li, N., Zhang, Z., Zhang, D., Rao, F., & Chen, Y. (2022). Optically Transparent Bamboo: Preparation, Properties, and Applications. Polymers, 14(16), 3234. https://doi.org/10.3390/polym14163234