Accelerating the Layup Sequences Design of Composite Laminates via Theory-Guided Machine Learning Models

Abstract

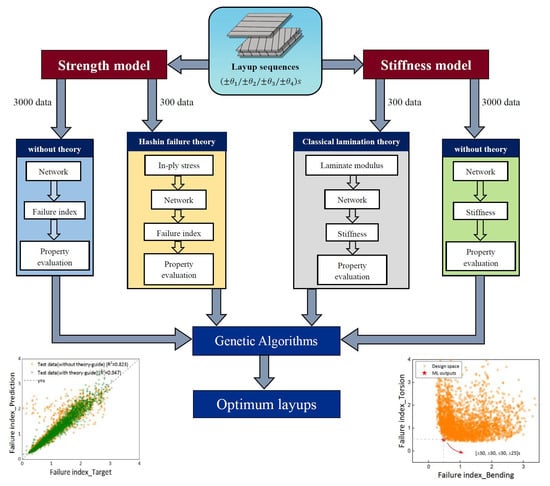

:1. Introduction

2. Materials and Methods

2.1. Problem Description

- (a)

- The strength model considers two load conditions on the composite tube: under a bending stress of 1300 N and a torsional stress of 300 N m. The corresponding layup sequences when the minimum failure indices are obtained are the optimal layup.

- (b)

- In designing the stiffness model evaluation threshold, two design objectives were set considering that the stiffness of the laminate should be designed to meet the stiffness requirements in practical engineering applications:

- Bending deformation stiffness greater than 250 N/mm

- Torsional deformation stiffness greater than 1500 N m/rad

2.2. Materials

2.2.1. Material and Fabrication

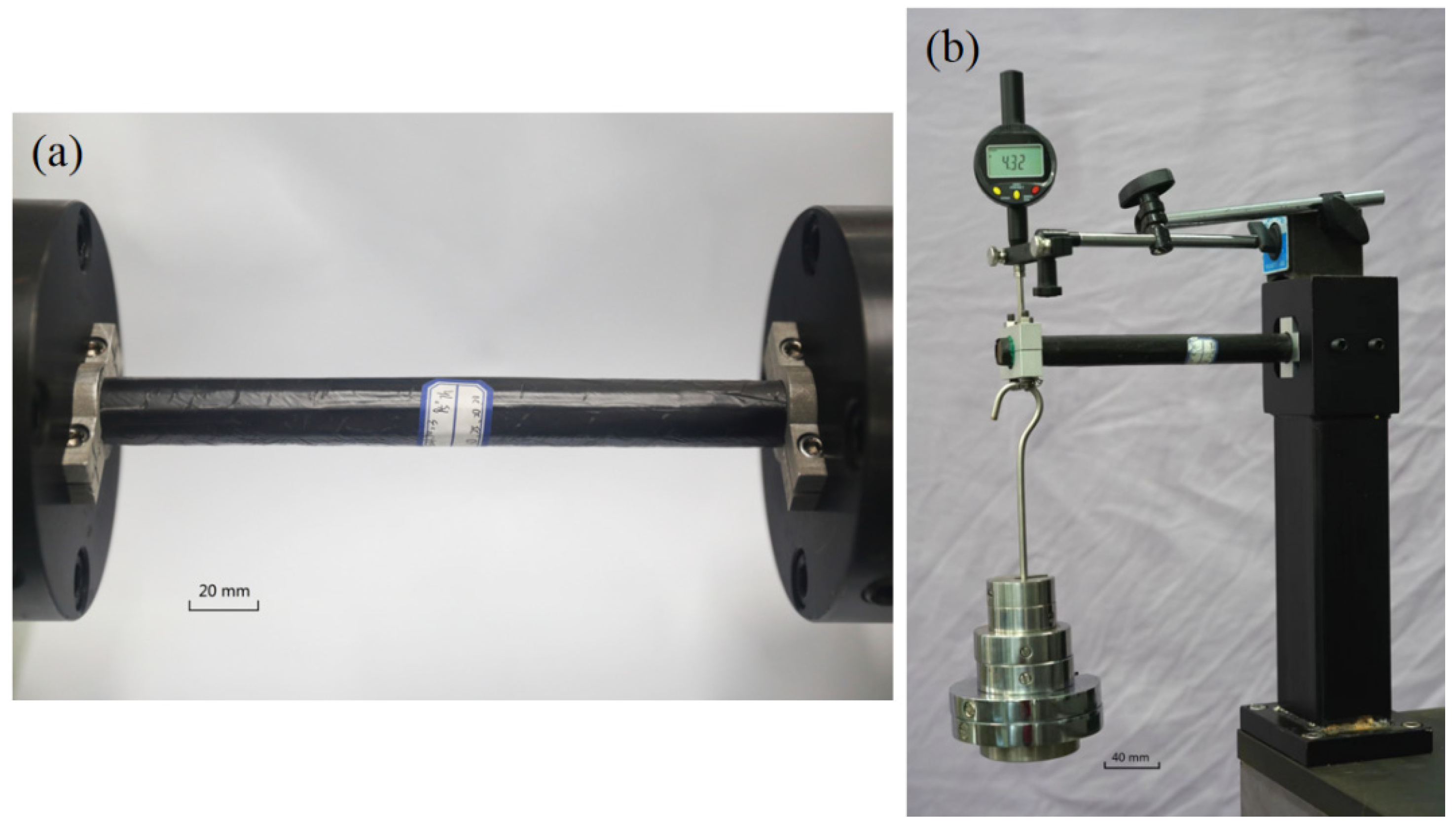

2.2.2. Experimental Preparation

2.3. Theory-Guided Machine Learning Layup Design Strategy

2.3.1. TGML Model for Design with Optimum Strength

2.3.2. TGML Model for Design with Optimum Stiffness

2.4. Model Main Parameter Settings

2.4.1. Configuration of NNs

2.4.2. Configuration of the GA Module

- (1)

- Group size: 20~100;

- (2)

- The terminal evolution algebra of genetic algorithm: 100~500;

- (3)

- Crossover probability: 0.4~0.99;

- (4)

- Variation probability: 0.0001~0.1.

3. Results and Discussion

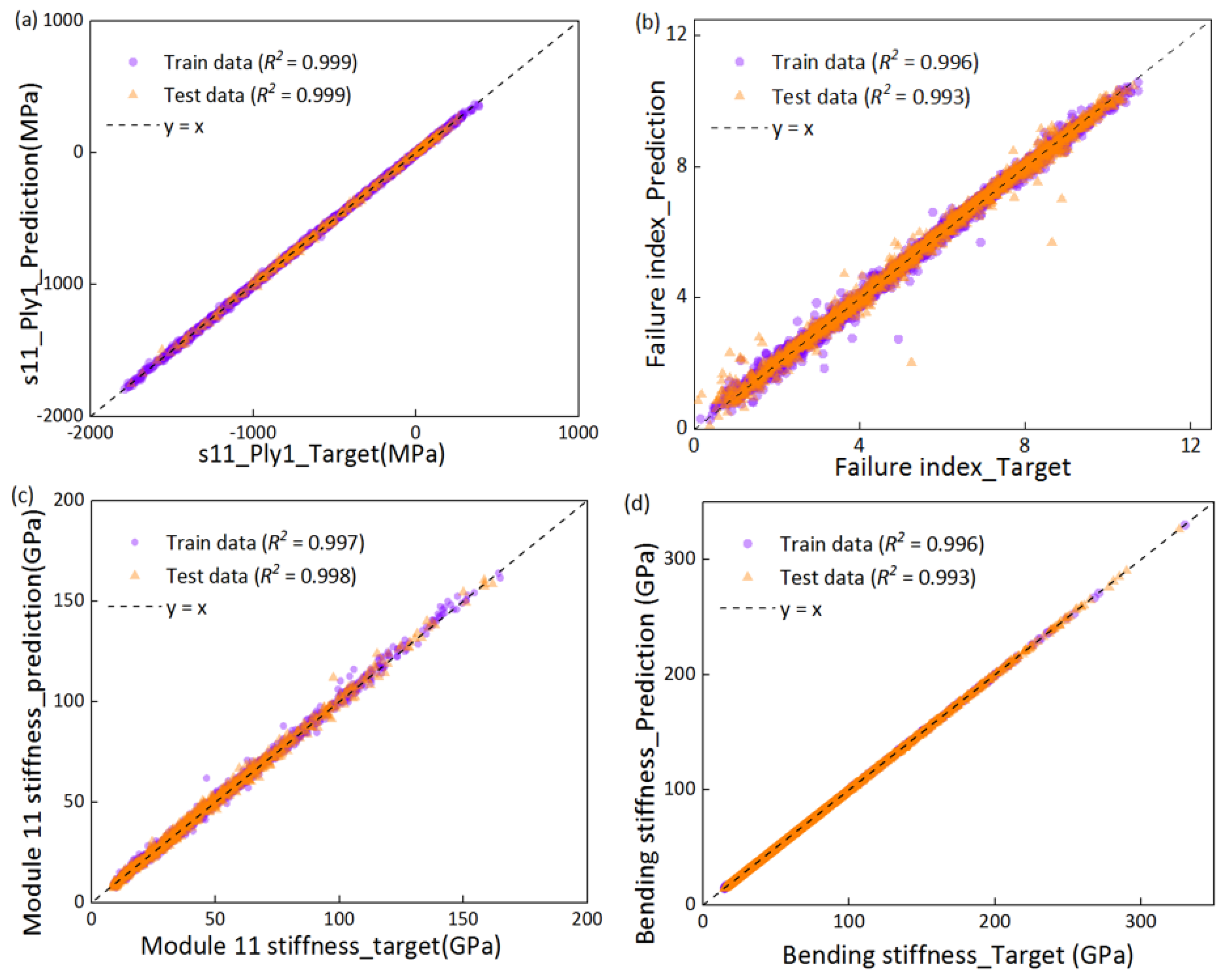

3.1. TGML Model Performances

3.2. Effect of the Theory-Guide

3.3. Calculation Efficiency

3.4. Solutions Provided by the TGML Models

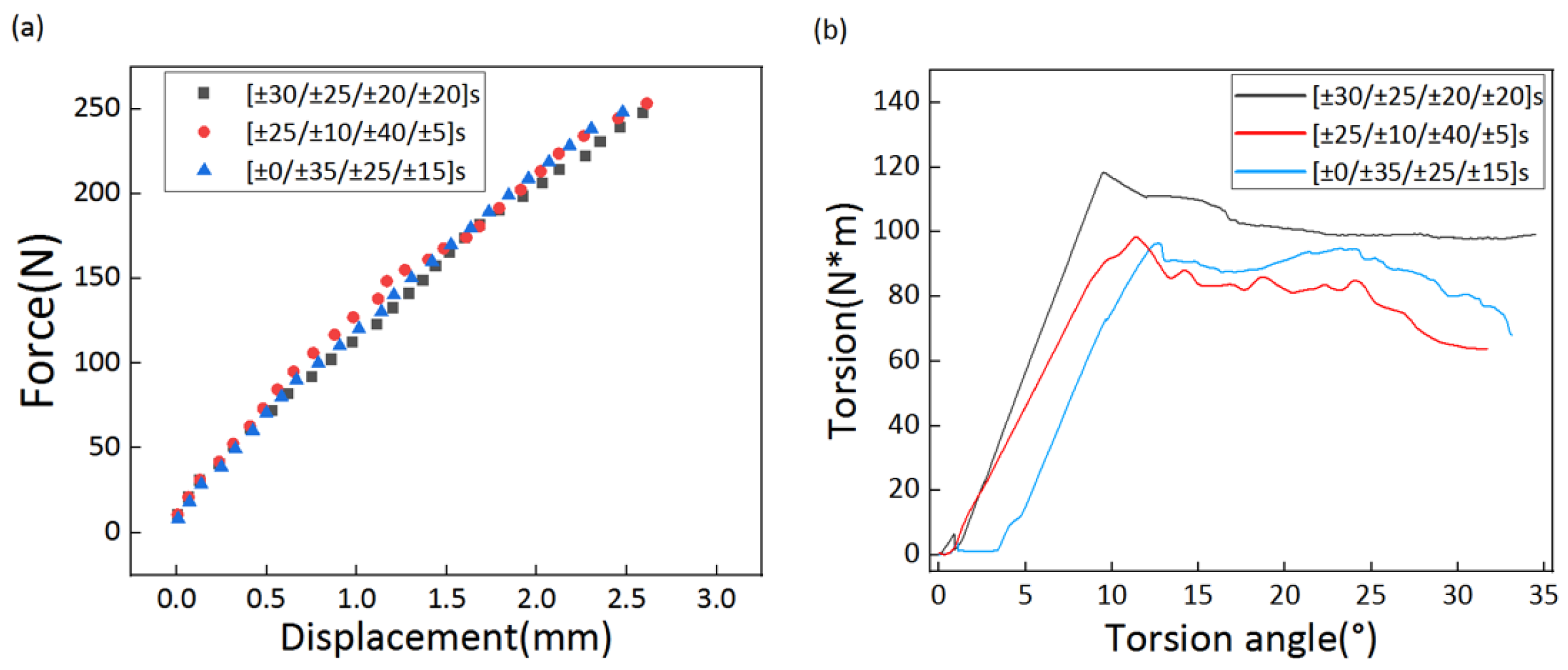

4. Experimental Validation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kazemi, M.E.; Shanmugam, L.; Yang, L.; Yang, J. A review on the hybrid titanium composite laminates (htcls) with focuses on surface treatments, fabrications, and mechanical properties. Compos. Part A Appl. Sci. Manuf. 2020, 128, 105679. [Google Scholar] [CrossRef]

- Sacco, C.; Radwan, A.B.; Anderson, A.; Harik, R.; Gregory, E. Machine Learning in Composites Manufacturing: A Case Study of Automated Fiber Placement Inspection. Compos. Struct. 2020, 250, 112514. [Google Scholar] [CrossRef]

- Zhu, W.; Yang, C.; Huang, B.; Guo, Y.; Xie, L.; Zhang, Y.; Wang, J. Predicting and Optimizing Coupling Effect in Magnetoelectric Multi-Phase Composites Based on Machine Learning Algorithm. Compos. Struct. 2021, 271, 114175. [Google Scholar] [CrossRef]

- Parandoush, P.; Lin, D. A review on additive manufacturing of polymer-fiber composites. Compos. Struct. 2017, 182, 36–53. [Google Scholar] [CrossRef]

- Yin, B.B.; Liew, K.M. Machine learning and materials informatics approaches for evaluating the interfacial properties of fiber-reinforced composites. Compos. Struct. 2021, 273, 114328. [Google Scholar] [CrossRef]

- Liu, X.; Tian, S.; Tao, F.; Yu, W. A review of artificial neural networks in the constitutive modeling of composite materials. Compos. Part B Eng. 2021, 224, 109152. [Google Scholar] [CrossRef]

- Kharghani, N.; Mittelstedt, C. Reduction of free-edge effects around a hole of a composite plate using a numerical layup optimization. Compos. Struct. 2022, 284, 115139. [Google Scholar] [CrossRef]

- Maung, P.T.; Prusty, B.G.; Phillips, A.W.; St. John, N.A. Curved fibre path optimisation for improved shape adaptive composite propeller blade design. Compos. Struct. 2021, 255, 112961. [Google Scholar] [CrossRef]

- Abdallah, M.H.; Braimah, A. Numerical design optimization of the fiber orientation of glass/phenolic composite tubes based on tensile and radial compression tests. Compos. Struct. 2022, 280, 114898. [Google Scholar] [CrossRef]

- Nebe, M.; Johman, A.; Braun, C.; van Campen, J.M.J.F. The effect of stacking sequence and circumferential ply drop locations on the mechanical response of type IV composite pressure vessels subjected to internal pressure: A numerical and experimental study. Compos. Struct. 2022, 294, 115585. [Google Scholar] [CrossRef]

- Singh, A.; Gu, Z.; Hou, X.; Liu, Y.; Hughes, D.J. Design optimisation of braided composite beams for lightweight rail structures using machine learning methods. Compos. Struct. 2022, 282, 115107. [Google Scholar] [CrossRef]

- Wanigasekara, C.; Oromiehie, E.; Swain, A.; Prusty, B.G.; Nguang, S.K. Machine learning based predictive model for AFP-based unidirectional composite laminates. J. Eng. 2020, 16, 2315–2324. [Google Scholar] [CrossRef]

- Mishra, B.B.; Kumar, A.; Samui, P.; Roshni, T. Buckling of laminated composite skew plate using FEM and machine learning methods. Eng. Comput. 2021, 38, 501–528. [Google Scholar] [CrossRef]

- Cheng, Q.; Han, Y.; Shanmugam, L.; Guan, Z.; Zhang, Z.; Du, S.; Yang, J. Machine learning-based prediction of the translaminar R-curve of composites from simple tensile test of pre-cracked samples. J. Micromechanics Mol. Phys. 2021, 6, 2050017. [Google Scholar]

- Şerban, A. Failure estimation of the composite laminates using machine learning techniques. Steel Compos. Struct. 2017, 25, 663–670. [Google Scholar]

- Veivers, H.; Bermingham, M.; Dunn, M.; Veidt, M. Layup optimisation of laminated composite tubular structures under thermomechanical loading conditions using PSO. Compos. Struct. 2021, 276, 114483. [Google Scholar] [CrossRef]

- Cai, R.; Wang, K.; Wen, W.; Peng, Y.; Baniassadi, M.; Ahzi, S. Application of machine learning methods on dynamic strength analysis for additive manufactured polypropylene-based composites. Polym. Test. 2022, 110, 107580. [Google Scholar] [CrossRef]

- Ouyang, T.; Bao, R.; Sun, W.; Guan, Z.; Tan, R. A fast and efficient numerical prediction of compression after impact (CAI) strength of composite laminates and structures. Thin-Walled Struct. 2020, 148, 106588. [Google Scholar] [CrossRef]

- Jiang, F.; Guan, Z.; Wang, X.; Li, Z.; Tan, R.; Qiu, C. Study on prediction of compression performance of composite laminates after impact based on convolutional neural networks. Appl. Compos. Mater. 2021, 28, 1153–1173. [Google Scholar] [CrossRef]

- Ramezankhani, M.; Crawford, B.; Narayan, A.; Voggenreiter, H.; Seethaler, R.; Milani, A.S. Making costly manufacturing smart with transfer learning under limited data: A case study on composites autoclave processing. J. Manuf. Syst. 2021, 59, 345–354. [Google Scholar] [CrossRef]

- Tan, R.K.; Qian, C.; Wang, M.; Ye, W. An efficient data generation method for ANN-based surrogate models. Struct. Multidiscip. Optim. 2022, 65, 90. [Google Scholar] [CrossRef]

- Pun, G.P.P.; Batra, R.; Ramprasad, R.; Mishin, Y. Physically informed artificial neural networks for atomistic modeling of materials. Nat. Commun. 2019, 10, 2339. [Google Scholar] [CrossRef] [PubMed]

- Zobeiry, N.; Reiner, J.; Vaziri, R. Theory-guided machine learning for damage characterization of composites. Compos. Struct. 2020, 246, 112407. [Google Scholar] [CrossRef]

- Qian, C.; Ye, W. Accelerating gradient-based topology optimization design with dual-model artificial neural networks. Struct. Multidiscip. Optim. 2021, 63, 1687–1707. [Google Scholar] [CrossRef]

- Ghatage, P.S.; Kar, V.R.; Sudhagar, P.E. On the numerical modelling and analysis of multi-directional functionally graded composite structures: A review. Compos. Struct. 2020, 236, 111837. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Z.; di Caprio, F.; Gu, G.X. Machine Learning for Accelerating the Design Process of Double-Double Composite Structures. Compos. Struct. 2022, 285, 115233. [Google Scholar] [CrossRef]

| Data | Process | Time (min) |

|---|---|---|

| 2700 data | FEM | 135 |

| Training—ML model | 2 | |

| 270 data | FEM | 13.5 |

| Training—ML model | 1.5 | |

| 3000 data | GA | 3 |

| Case No. | Load Conditions | Layups | Failure Index | ||

|---|---|---|---|---|---|

| Bending (N) | Torsion (N·m) | Bending (FEM) | Torsion (FEM) | ||

| 1 | 1000 | 300 | [±30/±30/±30/±25]s | 0.473 (0.505) | 0.493 (0.513) |

| 2 | 600 | 300 | [±35/±35/±50/±40]s | 0.393 (0.361) | 0.394 (0.392) |

| 3 | 1000 | 150 | [±20/±20/±20/±20]s | 0.315 (0.345) | 0.186 (0.178) |

| Case No. | Target Stiffness | Layups | E1M (GPa) | ML Output Stiffness | ||

|---|---|---|---|---|---|---|

| Bending (N/mm) | Torsion (N·m/rad) | Bending (FEM) (N/mm) | Torsion (FEM) (N·m/rad) | |||

| 1 | 250 | 1500 | [±0/±35/±25/±15]s | 266 | 250 (252) | 1500 (1442) |

| 2 | 300 | 1500 | [±25/±10/±40/±5]s | 312 | 300 (313) | 1500 (1448) |

| 3 | 200 | 2000 | [±30/±25/±20/±20]s | 281 | 200 (189) | 2000 (1802) |

| Case No. | Layups | Stiffness | Experiment | ML Output | Target Stiffness/E1T (ML Output/E1T) |

|---|---|---|---|---|---|

| 1 | [±0/±35/±25/±15]s | Bending (N/mm) | 99.3 ± 2.7 | 116 | 0.940 (1.087) |

| Torsional (N·/rad) | 628.7 ± 3.2 | 630.1 | 5.639 (5.530) | ||

| 2 | [±25/±10/±40/±5]s | Bending (N/mm) | 97.1 ± 2.1 | 114.2 | 0.962 (0.993) |

| Torsional (N·/rad) | 634.5 ± 2.9 | 651.5 | 5.517 (5.665) | ||

| 3 | [±30/±25/±20/±20]s | Bending (N/mm) | 98.7 ± 2.4 | 104.5 | 0.712 (0.909) |

| Torsional (N·/rad) | 788.6 ± 4.5 | 808.7 | 7.117 (7.032) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, Z.; Qiu, C.; Yang, J.; Yang, J.; Yang, L. Accelerating the Layup Sequences Design of Composite Laminates via Theory-Guided Machine Learning Models. Polymers 2022, 14, 3229. https://doi.org/10.3390/polym14153229

Liao Z, Qiu C, Yang J, Yang J, Yang L. Accelerating the Layup Sequences Design of Composite Laminates via Theory-Guided Machine Learning Models. Polymers. 2022; 14(15):3229. https://doi.org/10.3390/polym14153229

Chicago/Turabian StyleLiao, Zhenhao, Cheng Qiu, Jun Yang, Jinglei Yang, and Lei Yang. 2022. "Accelerating the Layup Sequences Design of Composite Laminates via Theory-Guided Machine Learning Models" Polymers 14, no. 15: 3229. https://doi.org/10.3390/polym14153229

APA StyleLiao, Z., Qiu, C., Yang, J., Yang, J., & Yang, L. (2022). Accelerating the Layup Sequences Design of Composite Laminates via Theory-Guided Machine Learning Models. Polymers, 14(15), 3229. https://doi.org/10.3390/polym14153229