The Use of Carbon Fibers Recovered by Pyrolysis from End-of-Life Wind Turbine Blades in Epoxy-Based Composite Panels

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Samples

2.3. Testing Procedure

3. Results and Discussion

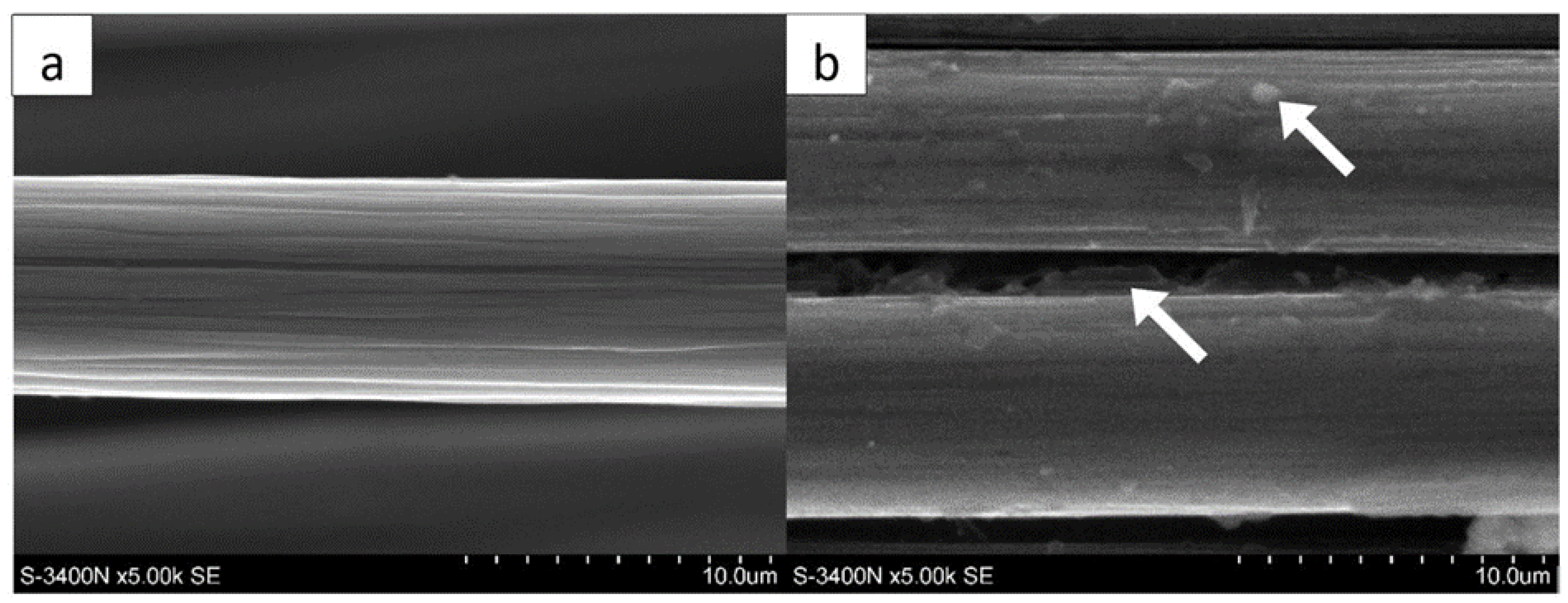

3.1. Surface of Fibers

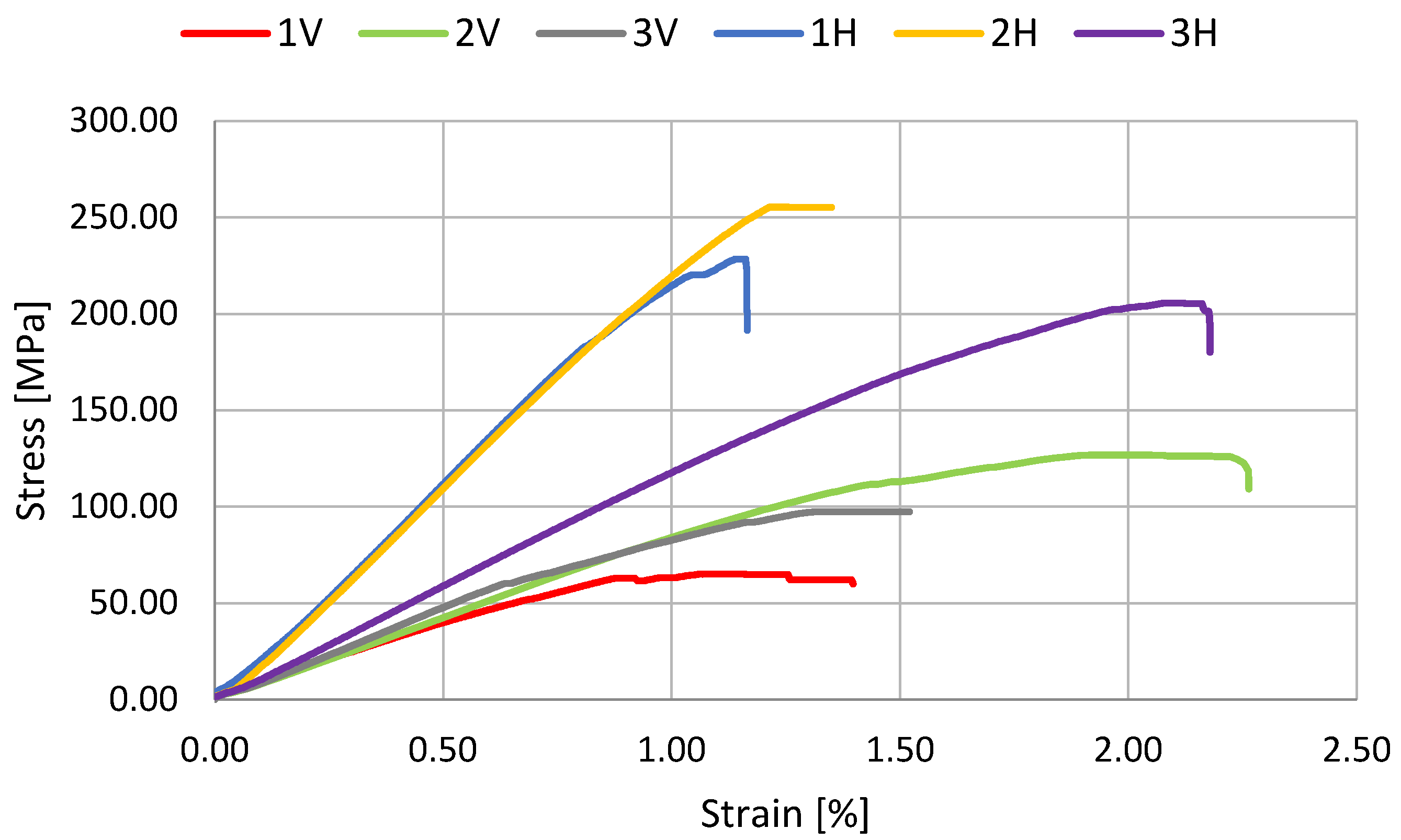

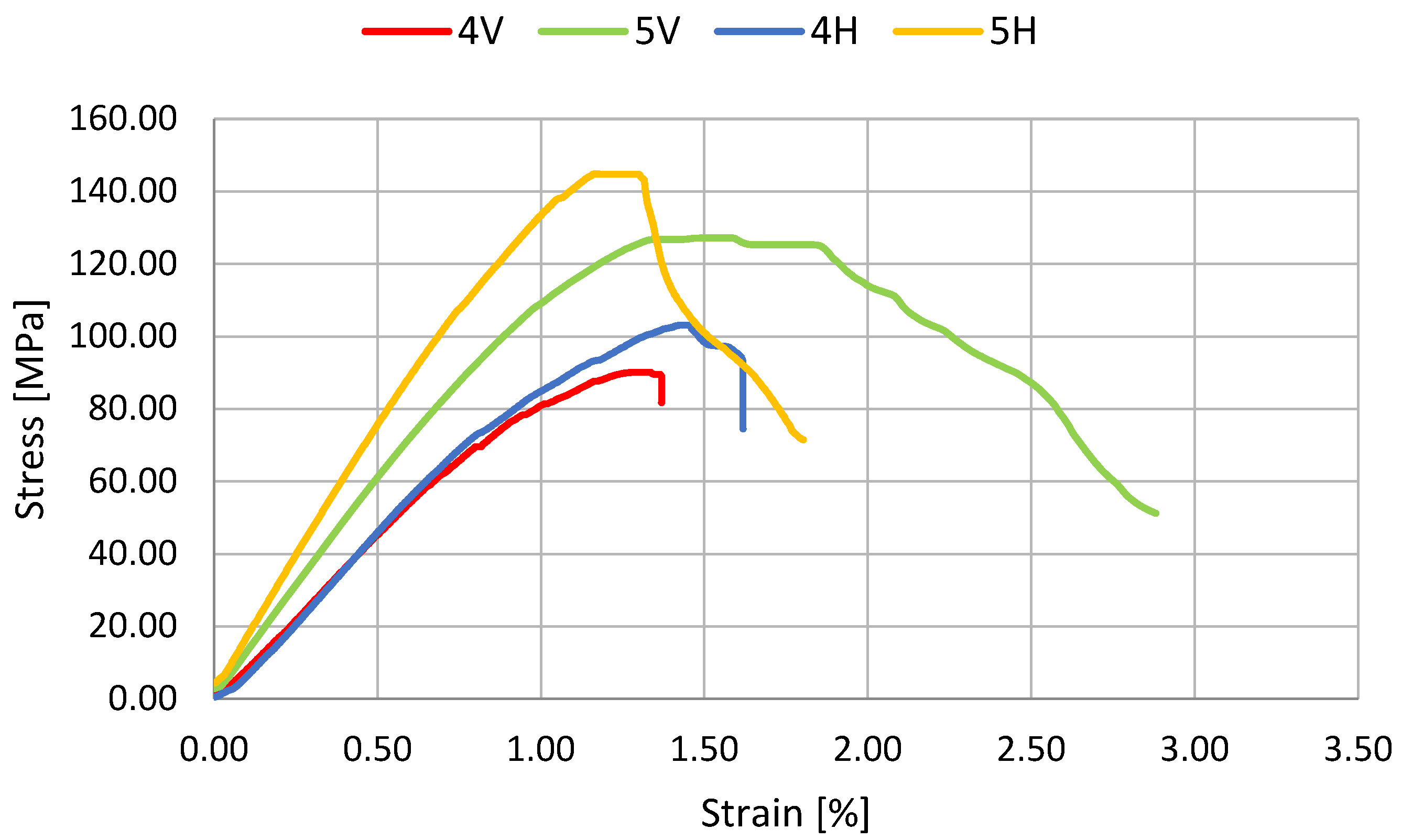

3.2. Three-Point Bending Tests

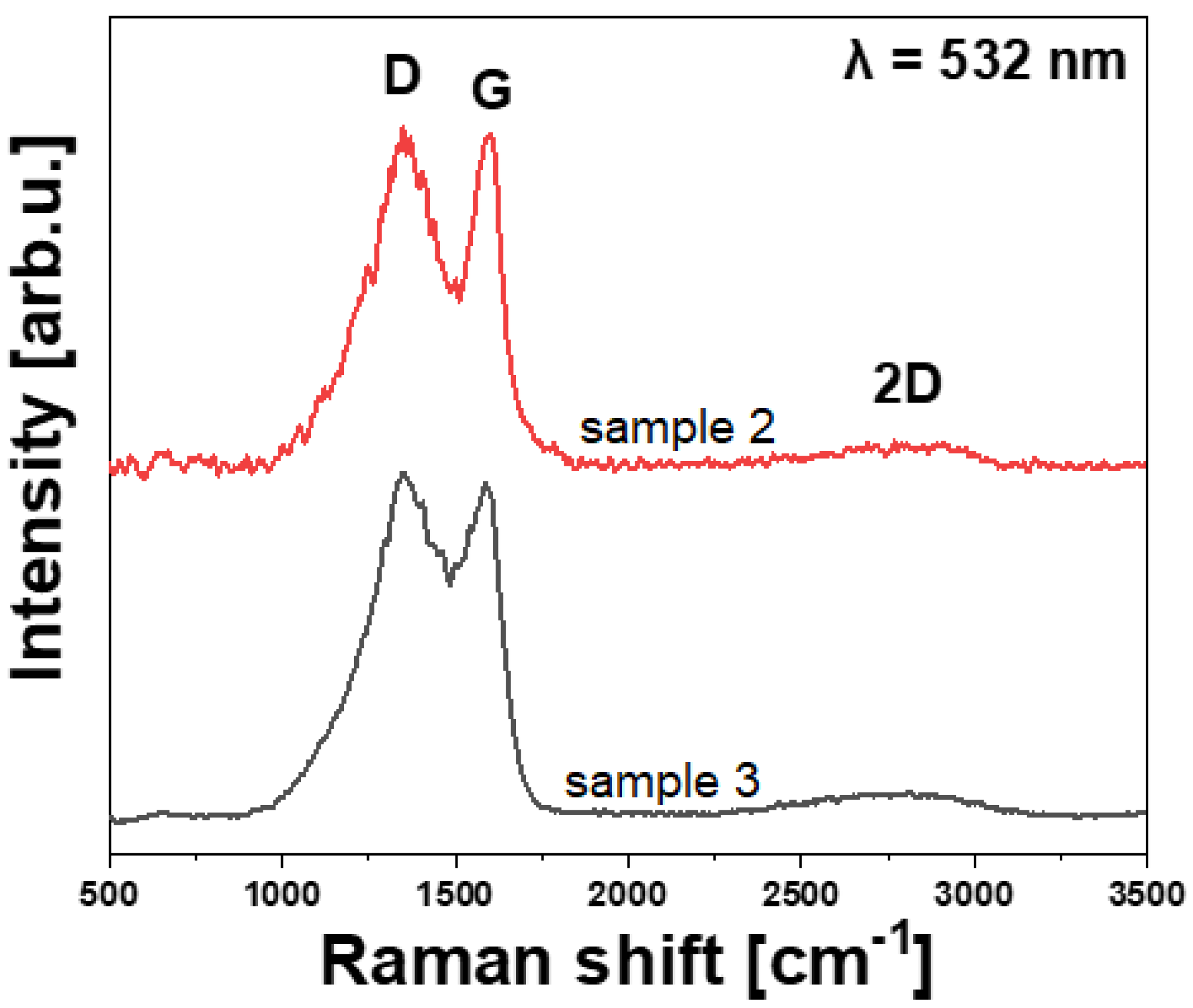

3.3. FT-IR and Raman Investigation

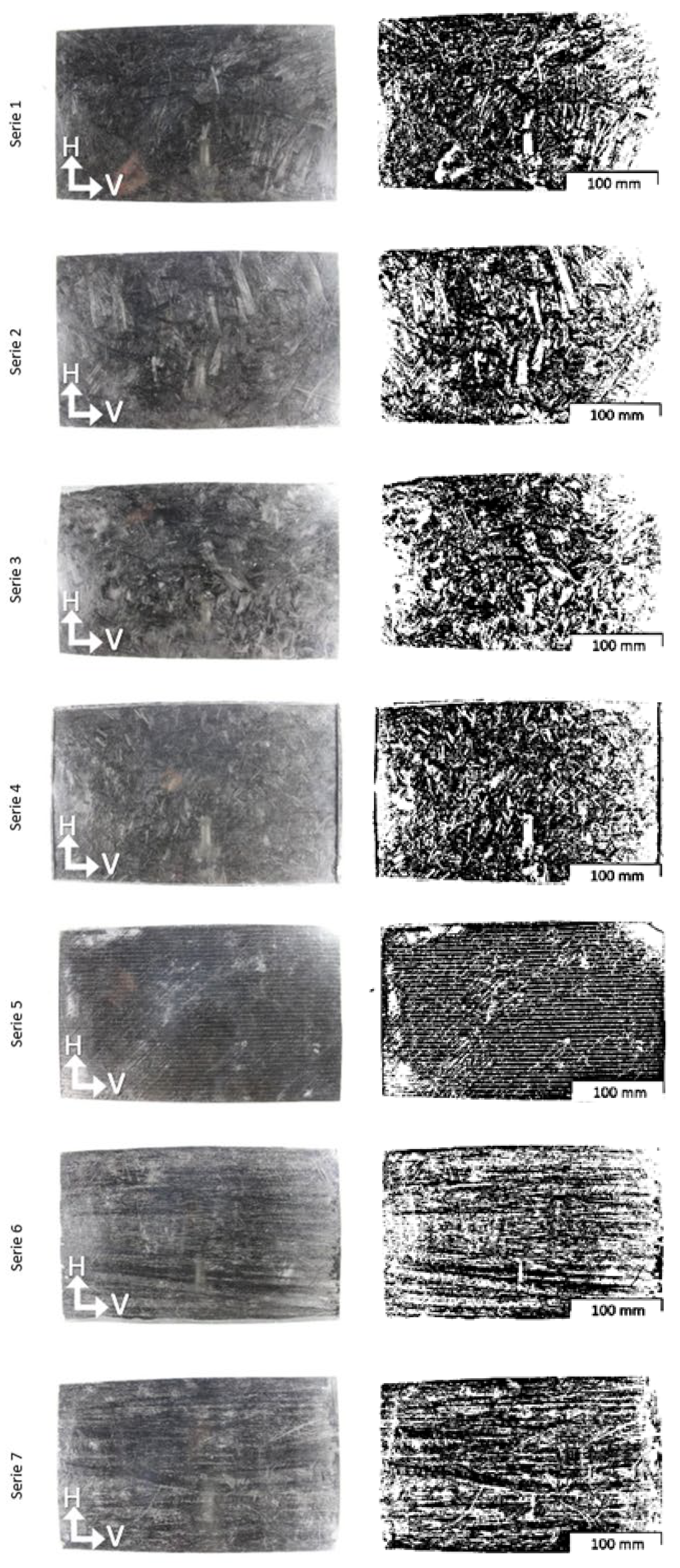

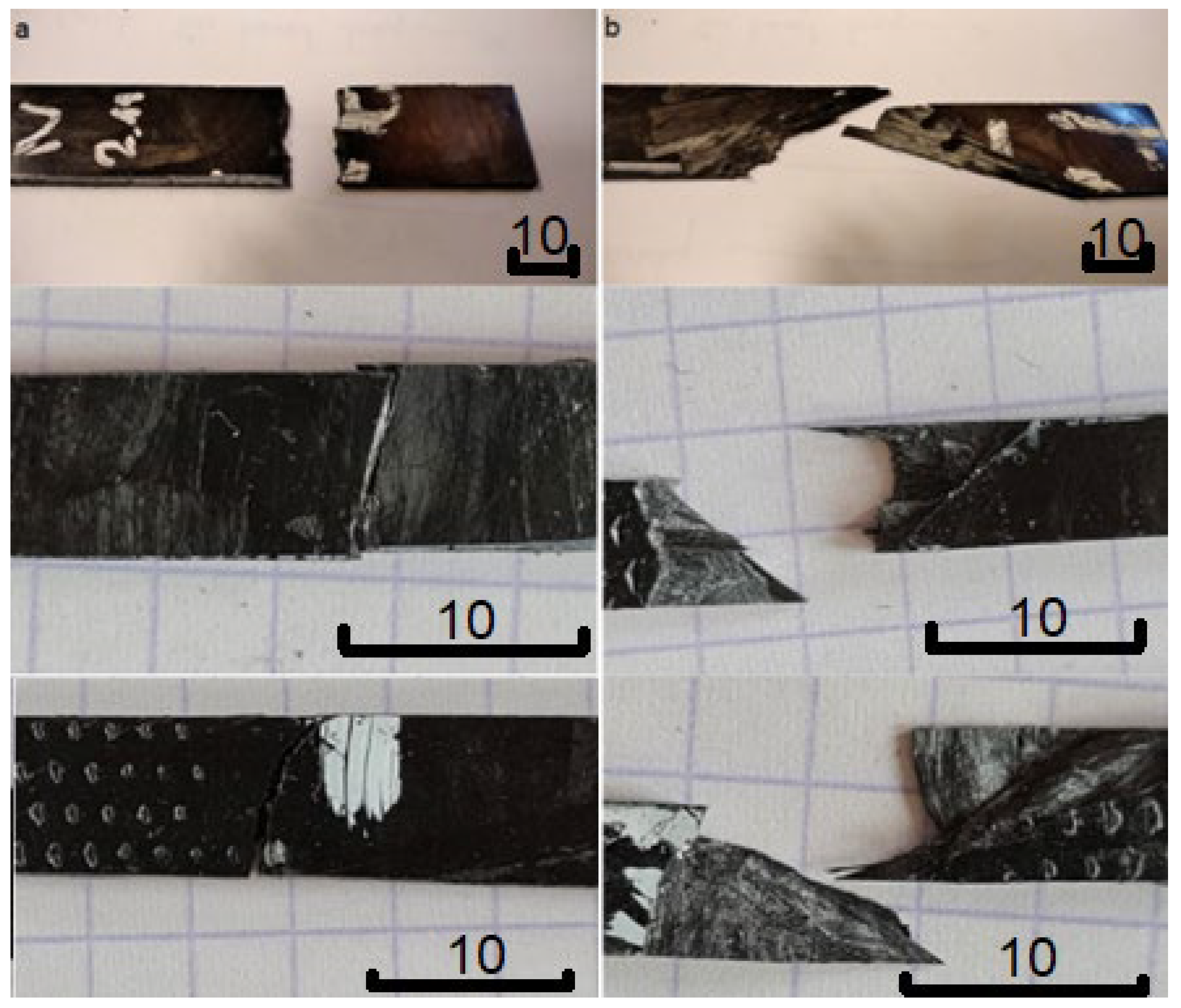

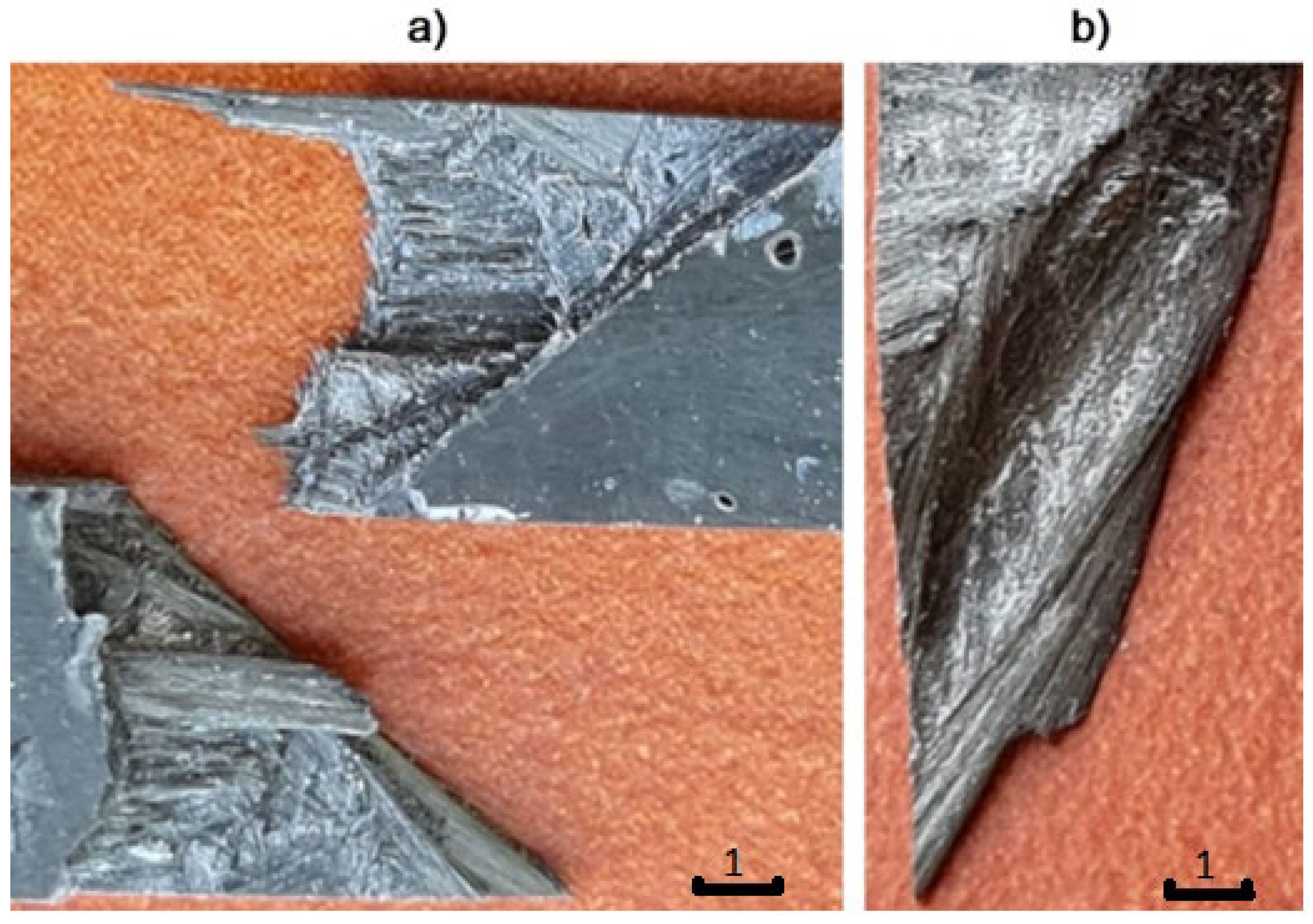

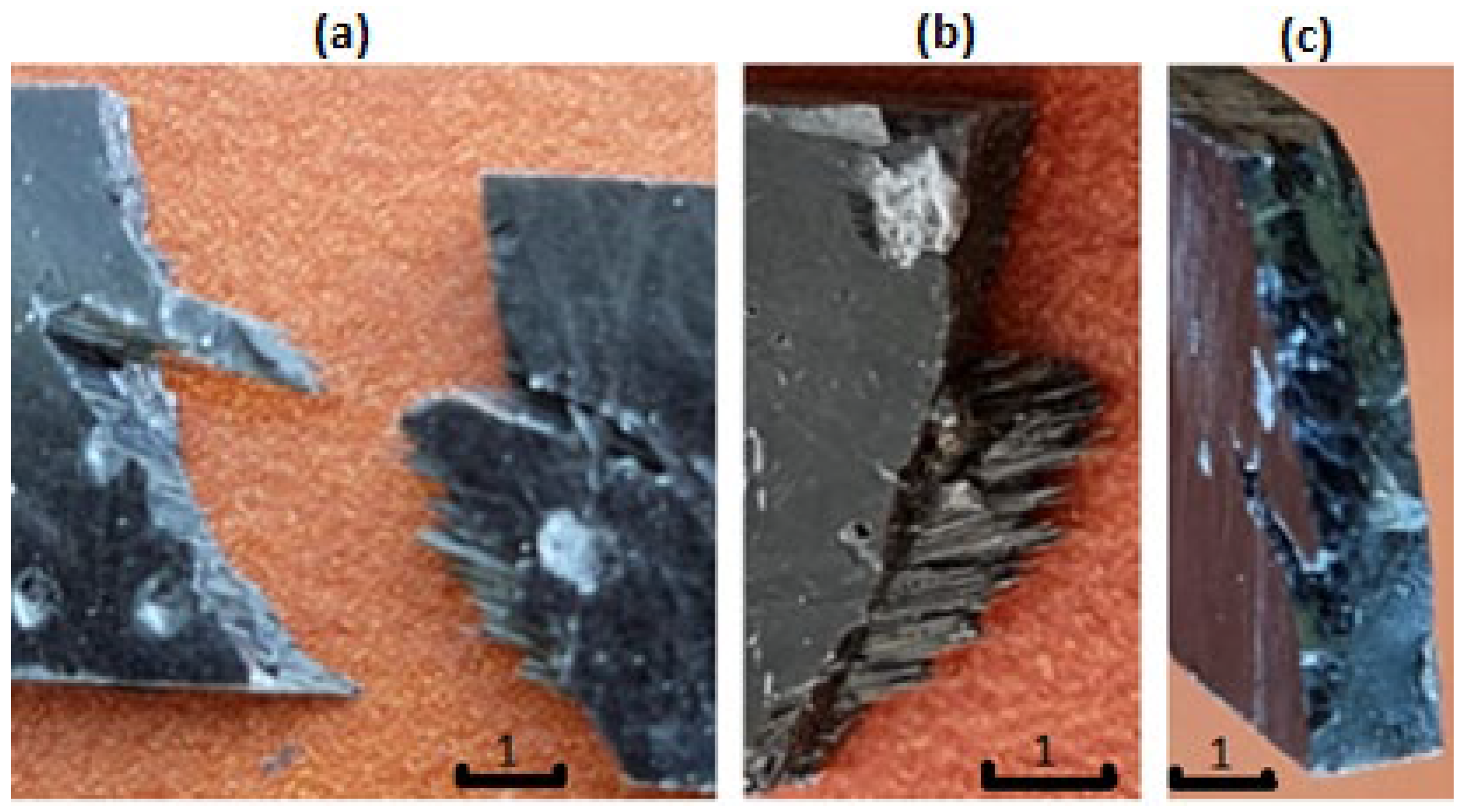

3.4. Failure Behavior of Tested Laminates

4. Conclusions

- The pyrolysis process decreases the strength of carbon fiber by about 20%;

- After the pyrolysis process, there are resin residues on the fiber surface;

- The Raman and FT-IR spectra show that after pyrolysis, the carbon fiber structure is slightly degraded, but the surface is more oxidized;

- The laminates with recycled carbon show a 35% higher flexural strength than the laminates with the original carbon fibers;

- The increase in strength is a result of a larger contact area between the fibers and the matrix.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

List of Nomenclature

| Rg | Flexural strength: MPa |

| Eflex | Young’s modulus |

| εflex | Bending strain corresponding with Rg point |

| λ | Wavelength |

References

- Chatys, R.; Piernik, K. Influence of speed of resin injection under pressure into mould on strength properties of polymer composite. Compos. Theory Pract. 2021, 21, 40–45. [Google Scholar]

- Nakada, M.; Miyano, Y. Accelerated testing for long-term fatigue strength of various FRP laminates for marine use. Compos. Sci. Technol. 2009, 69, 805–813. [Google Scholar] [CrossRef]

- Rahamathullah, I.; Shunmugam, M.S. Analyses of forces and hole quality in micro-drilling of carbon fabric laminate composites. J. Compos. Mater. 2013, 47, 1129–1140. [Google Scholar] [CrossRef]

- Kadlec, M.; Nováková, L.; Mlch, I.; Guadagno, L. Fatigue delamination of a carbon fabric/epoxy laminate with carbon nanotubes. Compos. Sci. Technol. 2016, 131, 32–39. [Google Scholar] [CrossRef]

- Kim, B.C.; Park, D.C.; Kim, B.J.; Lee, D.G. Through-thickness compressive strength of a carbon/epoxy composite laminate. Compos. Struct. 2010, 92, 480–487. [Google Scholar] [CrossRef]

- Zhu, J.-H.; Chen, P.; Su, M.; Pei, C.; Xing, F. Recycling of carbon fibre reinforced plastics by electrically driven heterogeneous catalytic degradation of epoxy resin. Green Chem. 2019, 21, 1635–1647. [Google Scholar] [CrossRef] [Green Version]

- Ma, C.; Sánchez-Rodríguez, D.; Kamo, T. Influence of thermal treatment on the properties of carbon fiber reinforced plastics under various conditions. Polym. Degrad. Stab. 2020, 178, 109199. [Google Scholar] [CrossRef]

- Overcash, M.; Twomey, J.; Asmatulu, E.; Vozzola, E.; Griffing, E. Thermoset composite recycling—Driving forces, development, and evolution of new opportunities. J. Compos. Mater. 2018, 52, 1033–1043. [Google Scholar] [CrossRef]

- Dauguet, M.; Mantaux, O.; Perry, N.; Zhao, Y.F. Recycling of CFRP for High Value Applications: Effect of Sizing Removal and Environmental Analysis of the SuperCritical Fluid Solvolysis. Procedia CIRP 2015, 29, 734–739. [Google Scholar] [CrossRef]

- Khalil, Y.F. Sustainability assessment of solvolysis using supercritical fluids for carbon fiber reinforced polymers waste management. Sustain. Prod. Consum. 2019, 17, 74–84. [Google Scholar] [CrossRef]

- Sun, H.; Guo, G.; Memon, S.A.; Xu, W.; Zhang, Q.; Zhu, J.-H.; Xing, F. Recycling of carbon fibers from carbon fiber reinforced polymer using electrochemical method. Compos. Part A Appl. Sci. Manuf. 2015, 78, 10–17. [Google Scholar] [CrossRef]

- Yamaguchi, A.; Hashimoto, T.; Kakichi, Y.; Urushisaki, M.; Sakaguchi, T.; Kawabe, K.; Kondo, K.; Iyo, H. Recyclable carbon fiber-reinforced plastics (CFRP) containing degradable acetal linkages: Synthesis, properties, and chemical recycling. J. Polym. Sci. Part A Polym. Chem. 2015, 53, 1052–1059. [Google Scholar] [CrossRef]

- Pickering, S.J. Recycling Technologies for Thermoset Composite Materials—Current Status. Compos. Part A 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Ramírez-Herrera, C.A.; Cruz-Cruz, I.; Jiménez-Cedeño, I.H.; Martínez-Romero, O.; Elías-Zúñiga, A. Influence of the Epoxy Resin Process Parameters on the Mechanical Properties of Produced Bidirectional ±45° Carbon/Epoxy Woven Composites. Polymers 2021, 13, 1273. [Google Scholar] [CrossRef]

- Krauklis, A.E.; Echtermeyer, A.T. Mechanism of Yellowing: Carbonyl Formation during Hygrothermal Aging in a Common Amine Epoxy. Polymers 2018, 10, 1017. [Google Scholar] [CrossRef] [Green Version]

- Qian, X.; Wang, X.; Zhong, J.; Zhi, J.; Heng, F.; Zhang, Y.; Song, S. Effect of fiber microstructure studied by Raman spectroscopy upon the mechanical properties of carbon fibers. J. Raman Spectrosc. 2019, 50, 665–673. [Google Scholar] [CrossRef]

- Roh, J.-S. Structural Study of the Activated Carbon Fiber using Laser Raman Spectroscopy. Carbon Lett. 2008, 9, 127–130. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Zhao, J.; Rabczuk, T. The interface strength and delamination of fiber-reinforced composites using a continuum modeling approach. Compos. Part B Eng. 2018, 137, 225–234. [Google Scholar] [CrossRef]

- Montes-Moràn, M.; Young, R. Raman Spectroscopy Study of HM Carbon Fibers: Effect of Plasma Treatment on the Interfacial Properties of Single Fiber/Epoxy Composites, Part I: Fiber characterization. Carbon 2022, 40, 845–855. [Google Scholar] [CrossRef]

- Meyer, L.O.; Schulte, K.; Grove-Nielsen, E. CFRP-Recycling following a Pyrolysis Route: Process Optimization and Potentials. J. Compos. Mater. 2009, 43, 1121–1132. [Google Scholar] [CrossRef] [Green Version]

- Giorgini, L.; Benelli, T.; Brancolini, G.; Mazzocchetti, L. Recycling of carbon fiber reinforced composite waste to close their life cycle in a cradle-to-cradle approach. Curr. Opin. Green Sustain. Chem. 2020, 26, 100368. [Google Scholar] [CrossRef]

| Sample Series | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| Length of carbon fibers, mm | 75 | 75 | 75 * | 15 | 15 + biaxial fabric ** | >300 | >300 * |

| Conditions of pressing | 10 min: 2 MPa 10 min: 7 MPa | 10 min: 2 MPa 120 min: 7 MPa | |||||

| Sample | Flexural Strength, Rg [MPa] | Young’s Modulus, Eflex [GPa] | Bending Strain Corresponding with Rg Point (εflex), [%] |

|---|---|---|---|

| 1H | 227 ± 100 | 19.4 ± 5.8 | 1.11 ± 0.33 |

| 1V | 71.5 ± 12.6 | 7.73 ± 1.51 | 1.38 ± 0.43 |

| 2H | 274 ± 75 | 21.7 ± 11.3 | 1.58 ± 0.27 |

| 2V | 156 ± 80 | 10.11 ± 5.77 | 1.53 ± 0.46 |

| 3H | 203 ± 56 | 14.9 ± 6 | 1.94 ± 0.54 |

| 3V | 148 ± 99 | 9.54 ± 2.84 | 1.91 ± 0.78 |

| 4H | 110 ± 21 | 9.55 ± 2.23 | 1.23 ± 0.2 |

| 4V | 89 ± 16 | 10.1 ± 3.3 | 1.21 ± 0.33 |

| 5H | 154 ± 40 | 14.9 ± 3.1 | 1.35 ± 0.29 |

| 5V | 135 ± 24 | 13.8 ± 2.3 | 1.35 ± 0.21 |

| 6H | 644 ± 96 | 37.8 ± 5.9 | 0.91 ± 0.07 |

| 6V | 239 ± 69 | 8.37 ± 1.91 | 2.99 ± 0.42 |

| 7H | 560 ± 76 | 29.6 ± 8 | 0.92 ± 0.07 |

| 7V | 143 ± 10 | 6.89 ± 0.58 | 3.42 ± 0.61 |

| Wavenumber (cm−1) | Band Assignment |

|---|---|

| ~550 | −−C−H/−N−H, bending |

| ~750 | =C−H/C−H, aromatic ring |

| 820 | −C−O−C, oxirane, stretching |

| 1030 | −C−O−C, ethers, stretching |

| 1080–1100 | −O−C−C, stretching |

| 1180–1240 | −C−C−O−C, stretching |

| 1360–1460 | −CH2−, −CH3−, bending |

| 1508–1608 | −C=C−H, aromatic, stretching |

| 1740 | −C=O, carbonyl group |

| 2850 | −CH2−, −CH3−, symmetric, stretching |

| 2920–2960 | −CH2−, −CH3−, asymmetric, stretching |

| 3030–3050 | =C−H, aromatic, stretching |

| 3340 | −OH, stretching |

| Band Position (cm−1) | Assignments |

|---|---|

| 641–668 | Aromatic ring vibrations (p−substituted benzene); aromatic C−H out of plane deformation |

| 735–762 | C−C skeletal |

| 819 | Out of plane bending of aromatic C−H |

| 916–933 | Epoxy group |

| 1002 | Epoxy group |

| 1114 | Aromatic C−H stretching and in plane deformation |

| 1186 | C−O stretching vibration |

| 1237–1300 | C−O stretching vibration ether bridge |

| 1456 | Stretching vibration of benzene rings |

| 1610 | C−C stretching vibration of aromatic; C−O stretching vibration of amide; skeletal vibrations of C=C double bonds in aromatic ring |

| Original carbon fiber | 2274 | 2317 | 2069 | 2088 | 2391 | 2353 | 2357 | 2147 | 2419 | 2268 |

| Pyrolyzed carbon fiber | 2039 | 2044 | 2164 | 1898 | 1711 | 1829 | 1090 | 1881 | 1924 | 1842 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Smoleń, J.; Olesik, P.; Jała, J.; Adamcio, A.; Kurtyka, K.; Godzierz, M.; Kozera, R.; Kozioł, M.; Boczkowska, A. The Use of Carbon Fibers Recovered by Pyrolysis from End-of-Life Wind Turbine Blades in Epoxy-Based Composite Panels. Polymers 2022, 14, 2925. https://doi.org/10.3390/polym14142925

Smoleń J, Olesik P, Jała J, Adamcio A, Kurtyka K, Godzierz M, Kozera R, Kozioł M, Boczkowska A. The Use of Carbon Fibers Recovered by Pyrolysis from End-of-Life Wind Turbine Blades in Epoxy-Based Composite Panels. Polymers. 2022; 14(14):2925. https://doi.org/10.3390/polym14142925

Chicago/Turabian StyleSmoleń, Jakub, Piotr Olesik, Jakub Jała, Andrzej Adamcio, Klaudia Kurtyka, Marcin Godzierz, Rafał Kozera, Mateusz Kozioł, and Anna Boczkowska. 2022. "The Use of Carbon Fibers Recovered by Pyrolysis from End-of-Life Wind Turbine Blades in Epoxy-Based Composite Panels" Polymers 14, no. 14: 2925. https://doi.org/10.3390/polym14142925

APA StyleSmoleń, J., Olesik, P., Jała, J., Adamcio, A., Kurtyka, K., Godzierz, M., Kozera, R., Kozioł, M., & Boczkowska, A. (2022). The Use of Carbon Fibers Recovered by Pyrolysis from End-of-Life Wind Turbine Blades in Epoxy-Based Composite Panels. Polymers, 14(14), 2925. https://doi.org/10.3390/polym14142925