Effect of Bleaching and Hot-Pressing Conditions on Mechanical Properties of Compressed Wood

Abstract

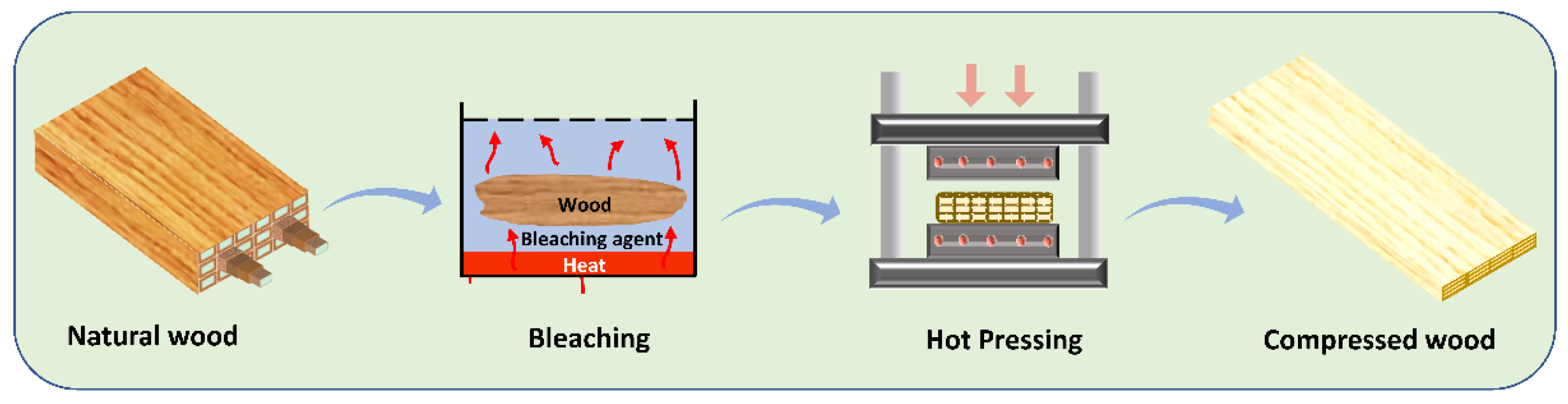

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Bleaching Process

- Step 1: 1% of NaClO2 was adjusted pH to 4–5 with acetic acid-sodium acetate buffer, then the sample was bleached at 80 °C for 12 h. The bleached wood was washed under running water for around 2 h and kept in a water bath for a day. After washing, the sample was kept in an oven drier at 40 °C for 1–2 days before proceeding to the next bleaching step.

- Step 2: In total, 2% of NaClO2 was adjusted to a pH of 4–5 with acetic acid-sodium acetate buffer, then the sample was bleached at 80 °C for 12 h. The bleached wood was washed under running water for 2 h and kept in a water bath for a day. After washing, the sample was kept in an oven drier at 40 °C for 1–2 days before proceeding to the next bleaching step.

- Step 3: Step 1 was repeated.

- Step 4: The sample was kept in 0.1% NaOH suspension for 1 day at room temperature, and then it was washed under running water for 2 h, followed by a water bath for 1 day. After washing, the sample was kept in an oven drier at 40 °C for 1–2 days before processing to the next step.

- Step 5: Step 1 was repeated.

2.2.2. Compressed Wood Preparation

2.3. Characterization

2.3.1. Morphology

2.3.2. Lignin and Alpha-Cellulose Contents

2.3.3. Mechanical Property

2.3.4. Swelling Ratio

3. Results and Discussion

3.1. Morphology

3.2. Lignin and Alpha-Cellulose Contents

3.3. The Compression Ratio

3.4. Three-Point Bending Test

3.5. Swelling

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Navi, P.; Heger, F. Combined densification and thermo-hydro-mechanical processing of wood. MRS Bull. 2004, 29, 332–336. [Google Scholar] [CrossRef]

- Kettunen, P.O. Wood: Structure and Properties; Trans Tech Publications, Ltd.: Uetikon am See, Switzerland, 2006. [Google Scholar]

- Laine, K.; Segerholm, K.; Wålinder, M.; Rautkari, L.; Hughes, M. Wood densification and thermal modification: Hardness, set-recovery and micromorphology. Wood Sci. Technol. 2016, 50, 883–894. [Google Scholar] [CrossRef]

- Pařil, P.; Brabec, M.; Maňák, O.; Rousek, R.; Rademacher, P.; Čermák, P.; Dejmal, A. Comparison of selected physical and mechanical properties of densified beech wood plasticized by ammonia and saturated steam. Eur. J. Wood Wood Prod. 2014, 72, 583–591. [Google Scholar] [CrossRef]

- Hill, C.A.; Ramsay, J.; Keating, B.; Laine, K.; Rautkari, L.; Hughes, M.; Constant, B. The water vapour sorption properties of thermally modified and densified wood. J. Mater. Sci. 2012, 47, 3191–3197. [Google Scholar] [CrossRef]

- Fang, C.-H.; Mariotti, N.; Cloutier, A.; Koubaa, A.; Blanchet, P. Densification of wood veneers by compression combined with heat and steam. Eur. J. Wood Wood Prod. 2012, 70, 155–163. [Google Scholar] [CrossRef]

- Laine, K.; Belt, T.; Rautkari, L.; Ramsay, J.; Hill, C.A.; Hughes, M. Measuring the thickness swelling and set-recovery of densified and thermally modified Scots pine solid wood. J. Mater. Sci. 2013, 48, 8530–8538. [Google Scholar] [CrossRef]

- Bekhta, P.; Proszyk, S.; Krystofiak, T. Colour in short-term thermo-mechanically densified veneer of various wood species. Eur. J. Wood Wood Prod. 2014, 72, 785–797. [Google Scholar] [CrossRef]

- Diouf, P.N.; Stevanovic, T.; Cloutier, A.; Fang, C.-H.; Blanchet, P.; Koubaa, A.; Mariotti, N. Effects of thermo-hygro-mechanical densification on the surface characteristics of trembling aspen and hybrid poplar wood veneers. Appl. Surf. Sci. 2011, 257, 3558–3564. [Google Scholar] [CrossRef]

- Cabral, J.P.; Kafle, B.; Subhani, M.; Reiner, J.; Ashraf, M. Densification of timber: A review on the process, material properties, and application. J. Wood Sci. 2022, 68, 20. [Google Scholar] [CrossRef]

- Luan, Y.; Fang, C.H.; Ma, Y.F.; Fei, B.H. Wood mechanical densification: A review on processing. Mater. Manuf. Process 2022, 37, 359–371. [Google Scholar] [CrossRef]

- Yano, H.; Hirose, A.; Collins, P.; Yazaki, Y. Effects of the removal of matrix substances as a pretreatment in the production of high strength resin impregnated wood based materials. J. Mater. Sci. Lett. 2001, 20, 1125–1126. [Google Scholar] [CrossRef]

- Song, J.; Chen, C.; Zhu, S.; Zhu, M.; Dai, J.; Ray, U.; Li, Y.; Kuang, Y.; Li, Y.; Quispe, N. Processing bulk natural wood into a high-performance structural material. Nature 2018, 554, 224–228. [Google Scholar] [CrossRef] [PubMed]

- Fang, Z.; Li, B.; Liu, Y.; Zhu, J.; Li, G.; Hou, G.; Zhou, J.; Qiu, X. Critical role of degree of polymerization of cellulose in super-strong nanocellulose films. Matter 2020, 2, 1000–1014. [Google Scholar] [CrossRef]

- Xia, Q.; Chen, C.; Li, T.; He, S.; Gao, J.; Wang, X.; Hu, L. Solar-assisted fabrication of large-scale, patternable transparent wood. Sci. Adv. 2021, 7, eabd7342. [Google Scholar] [CrossRef]

- Chen, H.; Baitenov, A.; Li, Y.; Vasileva, E.; Popov, S.; Sychugov, I.; Yan, M.; Berglund, L. Thickness Dependence of Optical Transmittance of Transparent Wood: Chemical Modification Effects. ACS Appl. Mater. Interfaces 2019, 11, 35451–35457. [Google Scholar] [CrossRef]

- Hai, L.V.; Muthoka, R.M.; Panicker, P.S.; Agumba, D.O.; Pham, H.D.; Kim, J. All-biobased transparent wood: A new approach and its environmental-friendly packaging applications. Carbohydr. Polym. 2021, 264, 139–150. [Google Scholar]

- TAPPI. Acid-Insoluble Lignin in Wood and Pulp, Test Method T 222 om-21; TAPPI: Atlanta, GA, USA, 2006. [Google Scholar]

- Hai, L.V.; Park, H.J.; Seo, Y.B. Effect of PFI mill and Valley beater refining on cellulose degree of polymerization, alpha cellulose contents, and crystallinity of wood and cotton fibers. J. Korea Tech. Assoc. Pulp Pap. Ind. 2013, 45, 27–33. [Google Scholar] [CrossRef] [Green Version]

- Gonultas, Z.; Candan, Z. Chemical characterization and FTIR spectroscopy of thermally compressed Eucalyptuswood panels. Maderas Cienc. Tecnol. 2018, 20, 431–442. [Google Scholar]

- Rabemanolontsoa, H.; Saka, H. Holocellulose Determination in Biomass. In Green Energy and Technology; Springer: Cham, Switzerland, 2011. [Google Scholar] [CrossRef]

- Sahin, H.T. Experimental determination of the anisotropic swelling and water sorption properties of chestnut wood. Wood Res. 2010, 55, 33–40. [Google Scholar]

- Morsing, N. Densification of Wood: The Influence of Hygrothermal Treatment on Compression of Beech Perpendicular to Gain. Ph.D. Thesis, Technical University of Denmark, Kongens Lyngby, Denmark, 1998. [Google Scholar]

- Candan, Z.; Gonultas, O.; Gorgun, H.V.; Unsal, O. Examining Parameters of Surface Quality Performance of Paulownia Wood Materials Modified by Thermal Compression Technique. Drv. Ind. 2021, 72, 231–236. [Google Scholar] [CrossRef]

- Candan, Z.; Gorgun, H.V.; Korkut, S.; Ünsal, O. Surface roughness and wettability performance of thermally modified rowan wood as a fast-growing species. Drewno 2021, 64, 208. [Google Scholar]

| Hot-Pressing Condition | Bleaching Condition | Bending Strength (MPa) | Young’s Modulus (GPa) | Elongation-at-Break (%) |

|---|---|---|---|---|

| Natural wood | 74.1 ± 2.9 | 3.7 ± 0.06 | 3.23± 0.05 | |

| HP-1 (13 MPa and 4 h) | NW±P | 78.7 ± 4.3 | 4.76 ± 0.11 | 2.10± 0.10 |

| B1 | 85.0 ± 3.9 | 5.60 ± 0.19 | 1.90± 0.24 | |

| B3 | 157.0 ± 17.6 | 10.60 ± 1.42 | 2.10 ± 0.24 | |

| B4 | 110.0 ± 16.8 | 9.88 ± 2.58 | 1.30± 0.27 | |

| B5 | 140.1± 16.9 | 11.50 ± 3.94 | 1.50± 0.16 | |

| HP-2 (26 MPa and 8 h) | NW±P | 133.7 ± 5.1 | 9.76 ± 0.02 | 1.60 ± 0.01 |

| B1 | 190.1 ± 27.0 | 17.27 ± 1.90 | 1.48 ± 0.16 | |

| B3 | 226.0 ± 23.9 | 24.49 ± 3.30 | 1.70 ± 0.17 | |

| B4 | 171.1 ± 26.7 | 22.64 ± 5.8 | 1.18 ± 0.60 | |

| B5 | 160.0 ± 38.4 | 18.90 ± 8.04 | 1.35 ± 0.05 | |

| HP-3 (52 MPa and 16 h) | NW±P | 142.0 ± 3.9 | 12.15 ± 2.54 | 1.54 ± 0.01 |

| B1 | 195.0 ± 52.2 | 16.22 ± 4.78 | 1.62 ± 0.16 | |

| B3 | 240.1 ± 35.7 | 23.08 ± 0.89 | 1.97 ± 0.17 | |

| B4 | 142.0± 10.5 | 17.14 ± 3.48 | 1.28 ± 0.60 | |

| B5 | 145.0 ± 21.0 | 17.20 ± 0.28 | 1.23 ± 0.05 | |

| Song et al. [13] | Partial lignin removal by NaOH, Na2SO3 | 549 | 42 | 1.3 |

| Fang et al. [14] | alkaline sulfite-anthraquinone-methanol cooking | 1000 | 60.2 | 3 |

| Paril et al. [4] | chemical modification of gaseous ammonia | 160 | 16 | - |

| Specimen | Weight (g) | Original Density (g/cm3) | Density after HP-1 (g/cm3) | Density after HP-2 (g/cm3) | Density after HP3 (g/cm3) |

|---|---|---|---|---|---|

| NW | 22.70 | 0.459 | 1.104 | 1.131 | 1.447 |

| B1 | 18.05 | 0.405 | 1.059 | 1.074 | 1.314 |

| B3 | 18.65 | 0.390 | 1.101 | 1.415 | 1.695 |

| B4 | 15.90 | 0.350 | 0.986 | 1.317 | 1.518 |

| B5 | 15.05 | 0.318 | 1.154 | 1.205 | 1.413 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Van Hai, L.; Pham, D.H.; Kim, J. Effect of Bleaching and Hot-Pressing Conditions on Mechanical Properties of Compressed Wood. Polymers 2022, 14, 2901. https://doi.org/10.3390/polym14142901

Van Hai L, Pham DH, Kim J. Effect of Bleaching and Hot-Pressing Conditions on Mechanical Properties of Compressed Wood. Polymers. 2022; 14(14):2901. https://doi.org/10.3390/polym14142901

Chicago/Turabian StyleVan Hai, Le, Duc Hoa Pham, and Jaehwan Kim. 2022. "Effect of Bleaching and Hot-Pressing Conditions on Mechanical Properties of Compressed Wood" Polymers 14, no. 14: 2901. https://doi.org/10.3390/polym14142901

APA StyleVan Hai, L., Pham, D. H., & Kim, J. (2022). Effect of Bleaching and Hot-Pressing Conditions on Mechanical Properties of Compressed Wood. Polymers, 14(14), 2901. https://doi.org/10.3390/polym14142901