Corn Cob Char as Catalyst Support for Developing Carbon Nanotubes from Waste Polypropylene Plastics: Comparison of Activation Techniques

Abstract

:1. Introduction

2. Materials and Methods

2.1. Carbonization of Biomass

2.2. Char Activation

2.3. Preparation of Catalysts

2.4. Catalyst Testing (Synthesis of CNTs)

2.5. Characterization of Catalyst and CNTs

2.6. Ultimate and Proximate Analysis of Corn Cob, Char, and Waste PP

3. Results and Discussion

3.1. Characterization of Biomass (Corn Cob) and Biochar

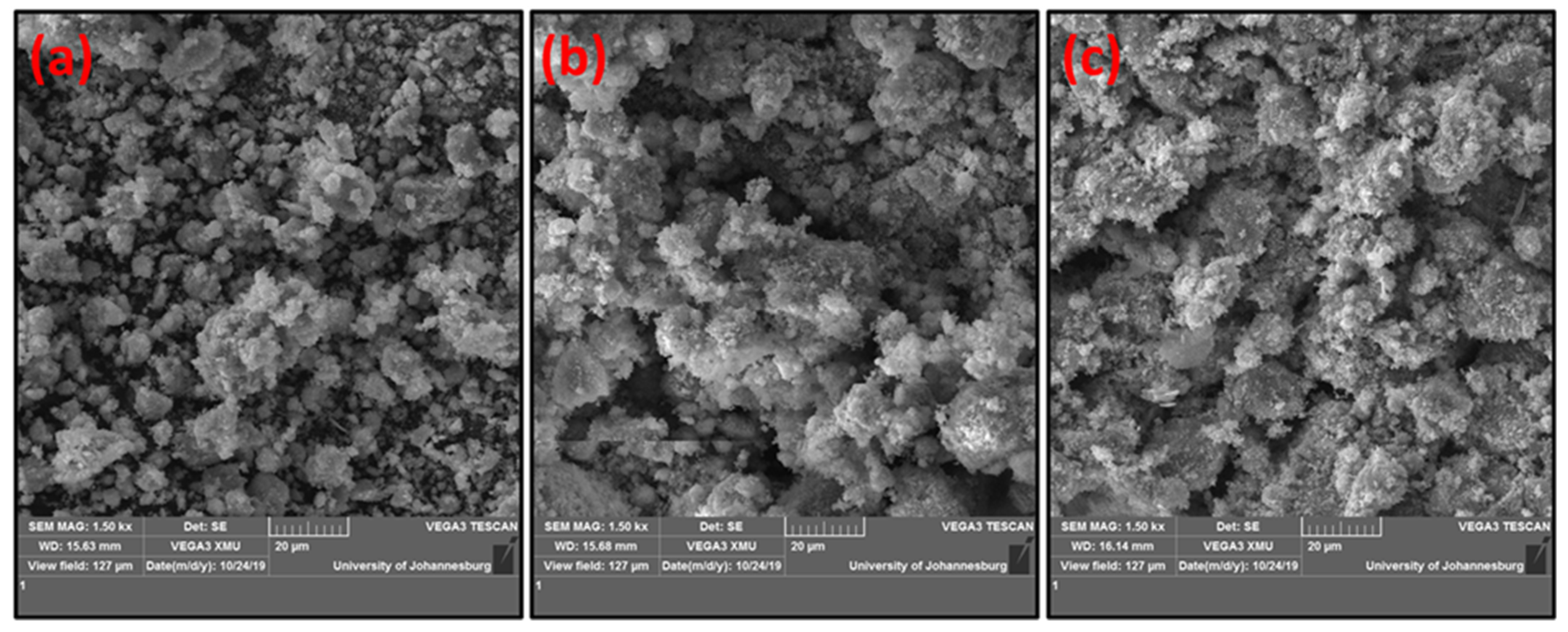

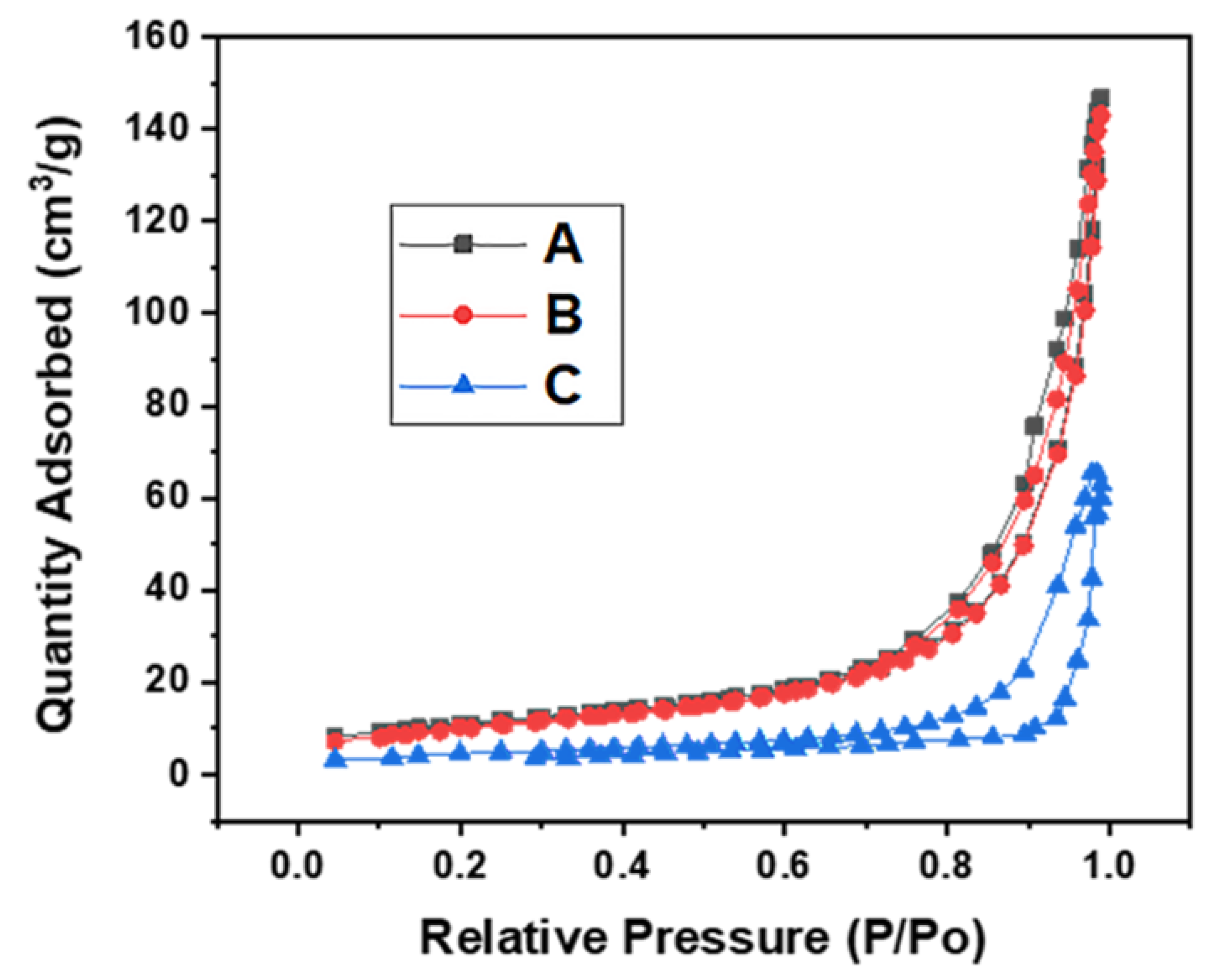

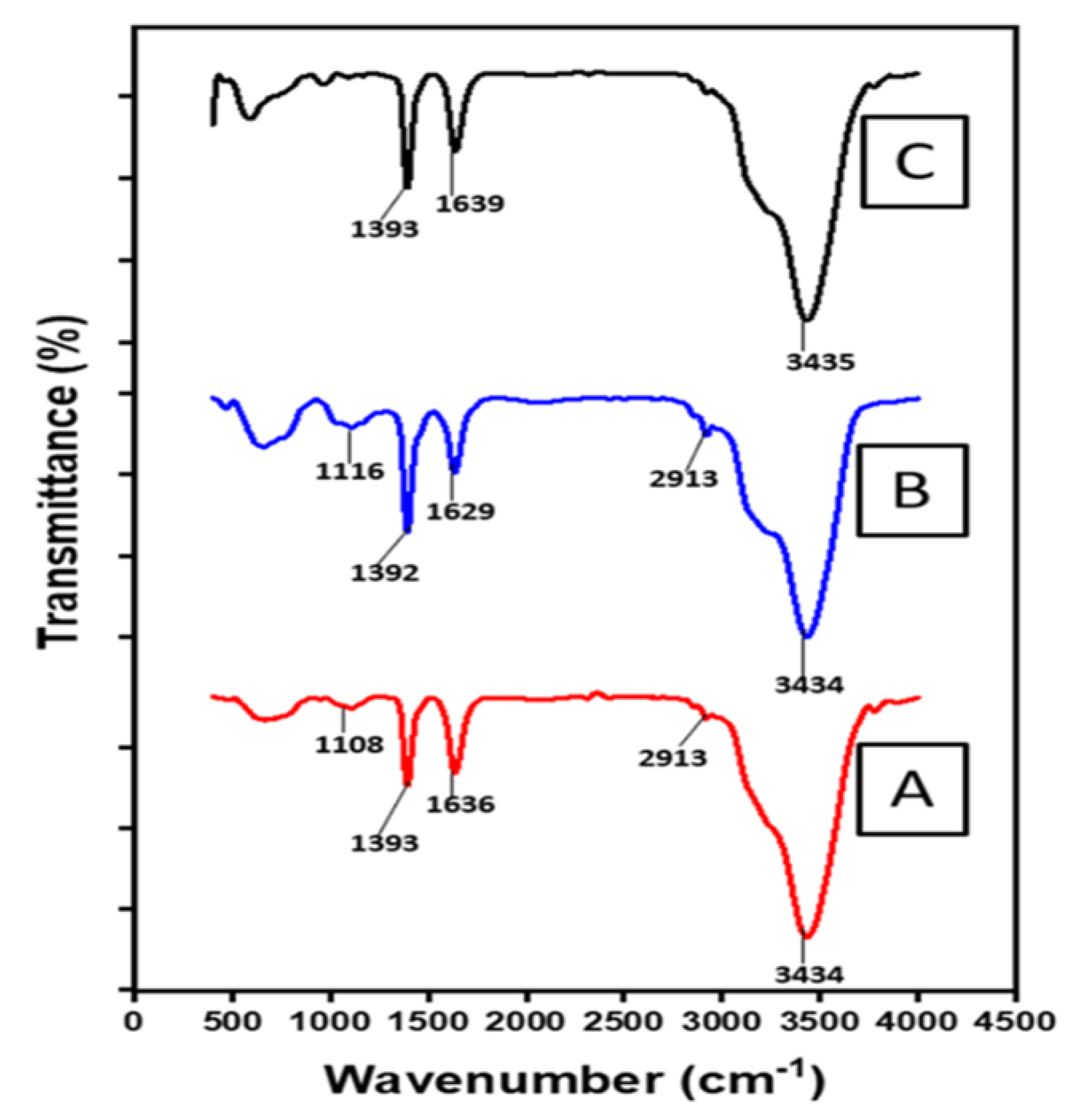

3.2. Characterization of Catalysts and Biochar

3.3. Effect of Activation Methods on the Microstructure and Morphology of Synthesized Carbon Nanomaterial

3.4. Influence of Activation Methods on the Quality and Yield of Deposited CNTs

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Paradise, M.; Goswami, T. Carbon nanotubes—Production and industrial applications. Mater. Des. 2007, 28, 1477–1489. [Google Scholar] [CrossRef]

- Ajayan, P.M.; Zhou, O.Z. Applications of carbon nanotubes. Carbon Nanotub. Top. Appl. Phys. 2001, 80, 391–425. [Google Scholar] [CrossRef]

- De Volder, M.F.L.; Tawfick, S.H.; Baughman, R.H.; Hart, A.J. Carbon nanotubes: Present and future commercial applications. Science 2013, 339, 535–539. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Han, T.; Nag, A.; Mukhopadhyay, S.C.; Xu, Y. Carbon nanotubes and its gas-sensing applications: A review. Sens. Actuators A Phys. 2019, 291, 107–143. [Google Scholar] [CrossRef]

- Peng, H.; Li, Q.; Chen, T. (Eds.) Industrial Applications of Carbon Nanotubes; Elsevier Inc.: Amsterdam, The Netherlands, 2017; ISBN 978-0-323-41481-4. [Google Scholar]

- Jia, X.; Wei, F. Advances in production and applications of carbon nanotubes. Top. Curr. Chem. 2017, 375, 18. [Google Scholar] [CrossRef] [PubMed]

- Moothi, K.; Iyuke, S.E.; Meyyappan, M.; Falcon, R. Coal as a carbon source for carbon nanotube synthesis. Carbon 2012, 50, 2679–2690. [Google Scholar] [CrossRef]

- Omoriyekomwan, J.E.; Tahmasebi, A.; Zhang, J.; Yu, J. Mechanistic study on direct synthesis of carbon nanotubes from cellulose by means of microwave pyrolysis. Energy Convers. Manag. 2019, 192, 88–99. [Google Scholar] [CrossRef]

- Li, W.; Wei, M.; Liu, Y.; Ye, Y.; Li, S.; Yuan, W.; Wang, M.; Wang, D. Catalysts evaluation for production of hydrogen gas and carbon nanotubes from the pyrolysis-catalysis of waste tyres. Int. J. Hydrog. Energy 2019, 44, 19563–19572. [Google Scholar] [CrossRef]

- Jiang, Z.; Song, R.; Bi, W.; Lu, J.; Tang, T.; Lu, J.; Tang, T. Polypropylene as a carbon source for the synthesis of multi-walled carbon nanotubes via catalytic combustion. Carbon 2007, 45, 449–458. [Google Scholar] [CrossRef]

- Chung, Y.; Jou, S. Carbon nanotubes from catalytic pyrolysis of polypropylene. Mater. Chem. Phys. 2005, 92, 256–259. [Google Scholar] [CrossRef]

- Acomb, J.C.; Wu, C.; Williams, P.T. Control of steam input to the pyrolysis-gasification of waste plastics for improved production of hydrogen or carbon nanotubes. Appl. Catal. B Environ. 2014, 147, 571–584. [Google Scholar] [CrossRef]

- Altalhi, T.; Kumeria, T.; Santos, A.; Losic, D. Synthesis of well-organised carbon nanotube membranes from non-degradable plastic bags with tuneable molecular transport: Towards nanotechnological recycling. Carbon 2013, 63, 423–433. [Google Scholar] [CrossRef]

- Liu, X.; Sun, H.; Wu, C.; Patel, D.; Huang, J. Thermal chemical conversion of high-density polyethylene for the production of valuable carbon nanotubes using Ni/AAO membrane catalyst. Energy Fuels 2018, 32, 4511–4520. [Google Scholar] [CrossRef]

- Modekwe, H.U.; Mamo, M.A.; Daramola, M.O.; Moothi, K. Catalytic performance of calcium titanate for catalytic decomposition of waste polypropylene to carbon nanotubes in a single-stage CVD reactor. Catalysts 2020, 10, 1030. [Google Scholar] [CrossRef]

- El Doukkali, M.; Iriondo, A.; Arias, P.L.; Requies, J.; Gandarías, I.; Jalowiecki-Duhamel, L.; Dumeignil, F. A comparison of sol-gel and impregnated Pt or/and Ni based γ-alumina catalysts for bioglycerol aqueous phase reforming. Appl. Catal. B Environ. 2012, 125, 516–529. [Google Scholar] [CrossRef]

- Gong, J.; Liu, J.; Wan, D.; Chen, X.; Wen, X.; Mijowska, E.; Jiang, Z.; Wang, Y.; Tang, T. Catalytic carbonization of polypropylene by the combined catalysis of activated carbon with Ni2O3 into carbon nanotubes and its mechanism. Appl. Catal. A Gen. 2012, 449, 112–120. [Google Scholar] [CrossRef]

- Ioannidou, O.; Zabaniotou, A.; Antonakou, E.V.; Papazisi, K.M.; Lappas, A.A.; Athanassiou, C. Investigating the potential for energy, fuel, materials and chemicals production from corn residues (cobs and stalks) by non-catalytic and catalytic pyrolysis in two reactor configurations. Renew. Sustain. Energy Rev. 2009, 13, 750–762. [Google Scholar] [CrossRef]

- Mohlala, L.M.; Bodunrin, M.O.; Awosusi, A.A.; Daramola, M.O.; Cele, N.P.; Olubambi, P.A. Beneficiation of corncob and sugarcane bagasse for energy generation and materials development in Nigeria and South Africa: A short overview. Alex. Eng. J. 2016, 55, 3025–3036. [Google Scholar] [CrossRef] [Green Version]

- Ayeni, A.O.; Daramola, M.O. Lignocellulosic biomass waste beneficiation: Evaluation of oxidative and non-oxidative pretreatment methodologies of South African corn cob. J. Environ. Chem. Eng. 2017, 5, 1771–1779. [Google Scholar] [CrossRef]

- Guizani, C.; Escudero Sanz, F.J.; Salvador, S. The nature of the deposited carbon at methane cracking over a nickel loaded wood-char. Comptes Rendus Chim. 2016, 19, 423–432. [Google Scholar] [CrossRef]

- Guo, F.; Liu, Y.; Liu, Y.; Guo, C. Catalytic reforming of tar using corncob char and char-supported potassium catalysts. J. Therm. Anal. Calorim. 2017, 130, 1297–1306. [Google Scholar] [CrossRef]

- Hu, X.; Xue, Y.; Long, L.; Zhang, K. Characteristics and batch experiments of acid- and alkali-modified corncob biomass for nitrate removal from aqueous solution. Environ. Sci. Pollut. Res. 2018, 25, 19932–19940. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Wang, S. Preparation, modification and environmental application of biochar: A review. J. Clean. Prod. 2019, 227, 1002–1022. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, S.; Ju, M.; Liu, L. Preparation and modification of biochar materials and their application in soil remediation. Appl. Sci. 2019, 9, 1365. [Google Scholar] [CrossRef] [Green Version]

- Song, M.; Jin, B.; Xiao, R.; Yang, L.; Wu, Y.; Zhong, Z.; Huang, Y. The comparison of two activation techniques to prepare activated carbon from corn cob. Biomass Bioenergy 2013, 48, 250–256. [Google Scholar] [CrossRef]

- Li, D.; Zhao, L.; Cao, X.; Xiao, Z.; Nan, H.; Qiu, H. Nickel-catalyzed formation of mesoporous carbon structure promoted capacitive performance of exhausted biochar. Chem. Eng. J. 2021, 406, 126856. [Google Scholar] [CrossRef]

- Wen, Y.; Kierzek, K.; Chen, X.; Gong, J.; Liu, J.; Niu, R.; Mijowska, E.; Tang, T. Mass production of hierarchically porous carbon nanosheets by carbonizing “real-world” mixed waste plastics toward excellent-performance supercapacitors. Waste Manag. 2019, 87, 691–700. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Tahmasebi, A.; Omoriyekomwan, J.E.; Yu, J. Direct synthesis of hollow carbon nanofibers on bio-char during microwave pyrolysis of pine nut shell. J. Anal. Appl. Pyrolysis 2018, 130, 142–148. [Google Scholar] [CrossRef]

- Fathy, N.A.; Lotfy, V.F.; Basta, A.H. Comparative study on the performance of carbon nanotubes prepared from agro- and xerogels as carbon supports. J. Anal. Appl. Pyrolysis 2017, 128, 114–120. [Google Scholar] [CrossRef]

- Bagheri, N.; Abedi, J. Preparation of high surface area activated carbon from corn by chemical activation using potassium hydroxide. Chem. Eng. Res. Des. 2009, 87, 1059–1064. [Google Scholar] [CrossRef]

- Modekwe, H.U.; Mamo, M.; Moothi, K.; Daramola, M.O. Synthesis of bimetallic NiMo/MgO catalyst for catalytic conversion of waste plastics (polypropylene) to carbon nanotubes (CNTs) via chemical vapour deposition method. Mater. Today Proc. 2021, 38, 549–552. [Google Scholar] [CrossRef]

- Zhuo, C.; Levendis, Y.A. Upcycling waste plastics into carbon nanomaterials: A review. J. Appl. Polym. Sci. 2014, 131, 1–14. [Google Scholar] [CrossRef]

- Aboul-Enein, A.A.; Awadallah, A.E. Impact of Co/Mo ratio on the activity of CoMo/MgO catalyst for production of high-quality multi-walled carbon nanotubes from polyethylene waste. Mater. Chem. Phys. 2019, 238, 121879. [Google Scholar] [CrossRef]

- Budai, A.; Wang, L.; Gronli, M.; Strand, L.T.; Antal, M.J.; Abiven, S.; Dieguez-Alonso, A.; Anca-couce, A.; Rasse, D.P. Surface properties and chemical composition of Corncob and miscanthus biochars: Effects of production temperature and method. J. Agric. Food Chem. 2014, 62, 3791–3799. [Google Scholar] [CrossRef]

- Awosusi, A.A.; Ayeni, A.O.; Adeleke, R.; Daramola, M.O. Biocompositional and thermodecompositional analysis of South African agro-waste corncob and husk towards production of biocommodities. Asia-Pac. J. Chem. Eng. 2017, 12, 960–968. [Google Scholar] [CrossRef]

- Ospina, V.; Buitrago-Sierra, R.; López, D. HDO of guaiacol over NiMo catalyst supported on activated carbon derived from castor de-oiled cake. Ing. Investig. 2015, 35, 49–55. [Google Scholar] [CrossRef]

- Anukam, A.I.; Goso, B.P.; Okoh, O.O.; Mamphweli, S.N. Studies on characterization of corn cob for application in a gasification process for energy production. J. Chem. 2017. [Google Scholar] [CrossRef] [Green Version]

- Srilek, N.; Aggarangsi, P. Key characteristics of carbonized corncob through hydrothermal and pyrolysis conversion techniques for further activation. Int. J. Eng. Adv. Technol. 2019, 8, 1089–1098. [Google Scholar] [CrossRef]

- Sing, K.S.W.; Williams, R.T. Physisorption hysteresis loops and the characterization of nanoporous materials. Adsorpt. Sci. Technol. 2004, 22, 773–782. [Google Scholar] [CrossRef]

- Nguyen, H.K.D.; Pham, V.V.; Do, H.T. Preparation of Ni/biochar Catalyst for Hydrotreating of Bio-Oil from Microalgae Biomass. Catal. Lett. 2016, 146, 2381–2391. [Google Scholar] [CrossRef]

- Hildago-Oporto, P.; Navia, R.; Hunter, R.; Coronado, G.; Gonzalez, M.E. Synthesis of carbon nanotubes using biochar as precursor material under microwave irradiation. J. Environ. Manage. 2019, 244, 83–91. [Google Scholar] [CrossRef] [PubMed]

- Hussain, Z.; Kumar, R. Synthesis and characterization of novel corncob-based solid acid catalyst for biodiesel production. Ind. Eng. Chem. Res. 2018, 57, 11645–11657. [Google Scholar] [CrossRef]

- Ma, H.; Li, J.; Liu, W.; Cheng, B.; Cao, X.; Mao, J.; Zhu, S. Hydrothermal preparation and characterization of novel corncob-derived solid acid catalysts. J. Agric. Food Chem. 2014, 62, 5345–5353. [Google Scholar] [CrossRef]

- Gomez-solís, C.; Ballesteros, J.C.; Torres-martínez, L.M.; Juárez-ramírez, I.; Torres, L.A.D.; Zarazua-morin, M.E.; Lee, S.W. Rapid synthesis of ZnO nano-corncobs from Nital solution and its application in the photodegradation of methyl orange. J. Photochem. Photobiol. A Chem. 2015, 298, 49–54. [Google Scholar] [CrossRef]

- Liakakou, E.T.; Heracleous, E.; Triantafyllidis, K.S.; Lemonidou, A.A. K-promoted NiMo catalysts supported on activated carbon for the hydrogenation reaction of CO to higher alcohols: Effect of support and active metal. Appl. Catal. B Environ. 2015, 165, 296–305. [Google Scholar] [CrossRef]

- Jia, Z.; Kou, K.; Qin, M.; Wu, H.; Puleo, F.; Liotta, L.F. Controllable and large-scale synthesis of carbon nanostructures: A review on bamboo-like Nanotubes. Catalysts 2017, 7, 256. [Google Scholar] [CrossRef] [Green Version]

- Oliveira, H.A.; Franceschini, D.F.; Passos, F.B. Support effect on carbon nanotube growth by methane chemical vapor deposition on cobalt catalysts. J. Braz. Chem. Soc. 2012, 23, 868–879. [Google Scholar] [CrossRef] [Green Version]

- Lefrant, S.; Baibarac, M.; Baltog, I. Raman and FTIR spectroscopy as valuable tools for the characterization of polymer and carbon nanotube based composites. J. Mater. Chem. 2009, 19, 5690–5704. [Google Scholar] [CrossRef]

- Yao, D.; Wu, C.; Yang, H.; Zhang, Y.; Nahil, M.A.; Chen, Y.; Williams, P.T.; Chen, H. Co-production of hydrogen and carbon nanotubes from catalytic pyrolysis of waste plastics on Ni-Fe bimetallic catalyst. Energy Convers. Manag. 2017, 148, 692–700. [Google Scholar] [CrossRef]

- Lobiak, E.V.; Shlyakhova, E.V.; Bulusheva, L.G.; Plyusnin, P.E.; Shubin, Y.V.; Okotrub, A.V. Ni–Mo and Co–Mo alloy nanoparticles for catalytic chemical vapor deposition synthesis of carbon nanotubes. J. Alloys Compd. 2015, 621, 351–356. [Google Scholar] [CrossRef]

- Yeoh, W.-M.; Lee, K.-Y.; Chai, S.-P.; Lee, K.-T.; Mohamed, A.R. Effective synthesis of carbon nanotubes via catalytic decomposition of methane: Influence of calcination temperature on metal-support interaction of Co-Mo/MgO catalyst. J. Phys. Chem. Solids 2013, 74, 1553–1559. [Google Scholar] [CrossRef]

- Shah, K.; Patel, S.; Halder, P.; Kundu, S.; Marzbali, M.H.; Hakeem, I.G.; Pramanik, B.K.; Chiang, K.; Patel, T. Conversion of pyrolytic non-condensable gases from polypropylene co-polymer into bamboo-type carbon nanotubes and high-quality oil using biochar as catalyst. J. Environ. Manage. 2022, 301, 113791. [Google Scholar] [CrossRef]

- Mohammed, I.A.; Bankole, M.T.; Abdulkareem, A.S.; Ochigbo, S.S.; Afolabi, A.S.; Abubakre, O.K. Full factorial design approach to carbon nanotubes synthesis by CVD method in argon environment. S. Afr. J. Chem. Eng. 2017, 24, 17–42. [Google Scholar] [CrossRef]

- Sahebian, S.; Zebarjad, S.M.; vahdati Khaki, J.; Lazzeri, A. A study on the dependence of structure of multi-walled carbon nanotubes on acid treatment. J. Nanostruct. Chem. 2015, 5, 287–293. [Google Scholar] [CrossRef] [Green Version]

- Scheibe, B.; Borowiak-Palen, E.; Kalenczuk, R.J. Oxidation and reduction of multiwalled carbon nanotubes—Preparation and characterization. Mater. Charact. 2010, 61, 185–191. [Google Scholar] [CrossRef]

- Zhao, Z.; Yang, Z.; Hu, Y.; Li, J.; Fan, X. Multiple functionalization of multi-walled carbon nanotubes with carboxyl and amino groups. Appl. Surf. Sci. 2013, 276, 476–481. [Google Scholar] [CrossRef]

- Yudianti, R.; Onggo, H.; Sudirman; Saito, Y.; Iwata, T.; Azuma, J. Analysis of functional group sited on multi-wall carbon nanotube surface. Open Mater. Sci. J. 2011, 5, 242–247. [Google Scholar] [CrossRef]

- Bajad, G.; Jain, R.; Harhare, W.; Vijayakumar, R.P.; Bose, S. Synthesis of fuel oil and carbon nanotubes in an autoclave using plastic waste as precursor. Mater. Manuf. Process. 2017, 32, 495–500. [Google Scholar] [CrossRef]

- Bajad, G.S.; Vijayakumar, R.P.; Gupta, A.G.; Jagtap, V.; Singh, Y. Production of liquid hydrocarbons, carbon nanotubes and hydrogen rich gases from waste plastic in a multi-core reactor. J. Anal. Appl. Pyrolysis 2017, 125, 83–90. [Google Scholar] [CrossRef]

- Aboul-Enein, A.A.; Adel-Rahman, H.; Haggar, A.M.; Awadallah, A.E. Simple method for synthesis of carbon nanotubes over Ni-Mo/Al2O3 catalyst via pyrolysis of polyethylene waste using a two-stage process. Fuller. Nanotub. Carbon Nanostruct. 2017, 25, 211–222. [Google Scholar] [CrossRef]

- Modekwe, H.U.; Mamo, M.A.; Moothi, K.; Daramola, M.O. Effect of different catalyst supports on the quality, yield and morphology of carbon nanotubes produced from waste polypropylene plastics. Catalysts 2021, 11, 692. [Google Scholar] [CrossRef]

| Proximate Analysis | Ultimate Analysis | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Moisture (%) | Ash * (%) | Fixed Carbon (%) | Volatile Matter (%) | Nitrogen (wt %) | Carbon (wt %) | Hydrogen (wt %) | Sulfur (wt %) | Oxygen * (wt %) | |

| Corn cob | 5.9 | 1.0 | 14.0 | 79.1 | 0.14 | 44.85 | 5.87 | ND | 49.14 |

| Biochar | 5.2 | 4.5 | 79.6 | 10.7 | 0.35 | 87.87 | 0.97 | 0.57 | 10.24 |

| Waste PP | 1.5 | 0.4 | 0.0 | 98.1 | 0.11 | 83.43 | 13.67 | ND | 2.78 |

| Composition | Corn Cob (wt %) | Biochar (wt %) |

|---|---|---|

| C | 57.68 | 88.43 |

| O | 41.07 | 8.41 |

| Si | 0.12 | 0.39 |

| Cl | 0.15 | 0.12 |

| K | 0.79 | 2.15 |

| Ni | 0.18 | 0.16 |

| Mg | - | 0.08 |

| P | - | 0.14 |

| S | - | 0.11 |

| Catalyst | BET Surface Area (m2 g−1) | Pore Volume (cm3 g−1) | Pore Size (nm) | NiO * Crystallite Size (nm) |

|---|---|---|---|---|

| Char | 0.78 ± 0.06 | 0.004 | 19.0 | - |

| AC0 | 38.13 ± 0.02 | 0.101 | 28.11 | |

| ACX | 48.15 ± 0.22 | 0.350 | 23.20 | - |

| ACT | 41.70 ± 0.14 | 0.281 | 24.19 | - |

| NiMo/ACX | 35.87 ± 0.06 | 0.227 | 25.82 | 12.3 |

| NiMo/ACT | 16.74 ± 0.16 | 0.349 | 19.72 | 16.0 @ |

| NiMo/AC0 | 21.02 ± 0.14 | 0.255 | 24.83 | 8.3 |

| Notation | Quality IG/ID | Defect ID/IG | Yield (mg CNTs/g Catalyst) |

|---|---|---|---|

| CNT0 | 1.09 | 0.92 | 430.0 |

| CNTX | 1.08 | 0.92 | 470.0 |

| CNTT | 1.44 | 0.69 | 70.0 |

| Catalyst | Feedstock | Synthesis Method/Condition | Peak Intensity Ratio | Yield | Refs. |

|---|---|---|---|---|---|

| Ni/Mo/MgO | PP | Autoclave, 800 °C | IG/ID = 0.75–0.93 | 3.2 g CNTs/6 g PP | [59] |

| Ni/Mo/MgO | HDPE | Multi-core reactor, 700–800 °C | IG/ID = 0.69–0.99 | 6.03 g CNTTs/30 g HDPE | [60] |

| NiMo/Al2O3 | LDPE | Two-stage CVD, 500–700 °C | ID/IG = 0.93–2.11 | 14.7–28.1% (% weight of polymer used) | [61] |

| NiMo/MgO | PP | One-stage CVD, 700 °C | IG/ID = 0.99 | 33.3% | [62] |

| NiMo/CaO | PP | One-stage CVD, 700 °C | IG/ID = 1.00 | 31.0% | [62] |

| NiMo/TiO2 | PP | One-stage CVD, 700 °C | IG/ID = 1.07 | 37.0% | [62] |

| NiMo/CaTiO3 | PP | One-stage CVD, 700 °C | IG/ID = 1.25 | 40.0% | [62] |

| NiMo | PP | One-stage CVD, 700 °C | IG/ID = 0.93 | 18.4% | [62] |

| NiMo/ AC0 | PP | One-stage CVD, 700 °C | IG/ID = 1.09; ID/IG = 0.92 | 430 mg CNTs/g catalyst | Present Study |

| NiMo/ ACX | PP | One-stage CVD, 700 °C | IG/ID = 1.08; ID/IG = 0.92 | 470 mg CNTs/g catalyst | Present Study |

| NiMo/ ACT | PP | One-stage CVD, 700 °C | IG/ID = 1.44; ID/IG = 0.69 | 70 mg CNTs/g catalyst | Present Study |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Modekwe, H.U.; Moothi, K.; Daramola, M.O.; Mamo, M.A. Corn Cob Char as Catalyst Support for Developing Carbon Nanotubes from Waste Polypropylene Plastics: Comparison of Activation Techniques. Polymers 2022, 14, 2898. https://doi.org/10.3390/polym14142898

Modekwe HU, Moothi K, Daramola MO, Mamo MA. Corn Cob Char as Catalyst Support for Developing Carbon Nanotubes from Waste Polypropylene Plastics: Comparison of Activation Techniques. Polymers. 2022; 14(14):2898. https://doi.org/10.3390/polym14142898

Chicago/Turabian StyleModekwe, Helen U., Kapil Moothi, Michael O. Daramola, and Messai A. Mamo. 2022. "Corn Cob Char as Catalyst Support for Developing Carbon Nanotubes from Waste Polypropylene Plastics: Comparison of Activation Techniques" Polymers 14, no. 14: 2898. https://doi.org/10.3390/polym14142898

APA StyleModekwe, H. U., Moothi, K., Daramola, M. O., & Mamo, M. A. (2022). Corn Cob Char as Catalyst Support for Developing Carbon Nanotubes from Waste Polypropylene Plastics: Comparison of Activation Techniques. Polymers, 14(14), 2898. https://doi.org/10.3390/polym14142898