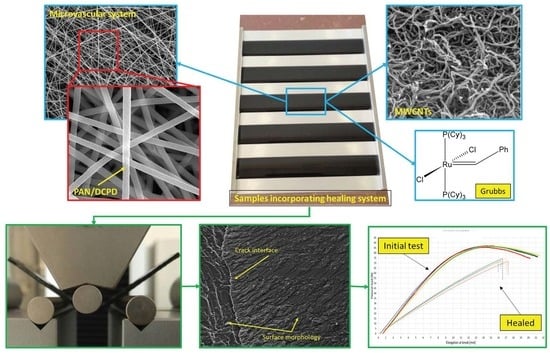

A Microvascular System Self-Healing Approach on Polymeric Composite Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

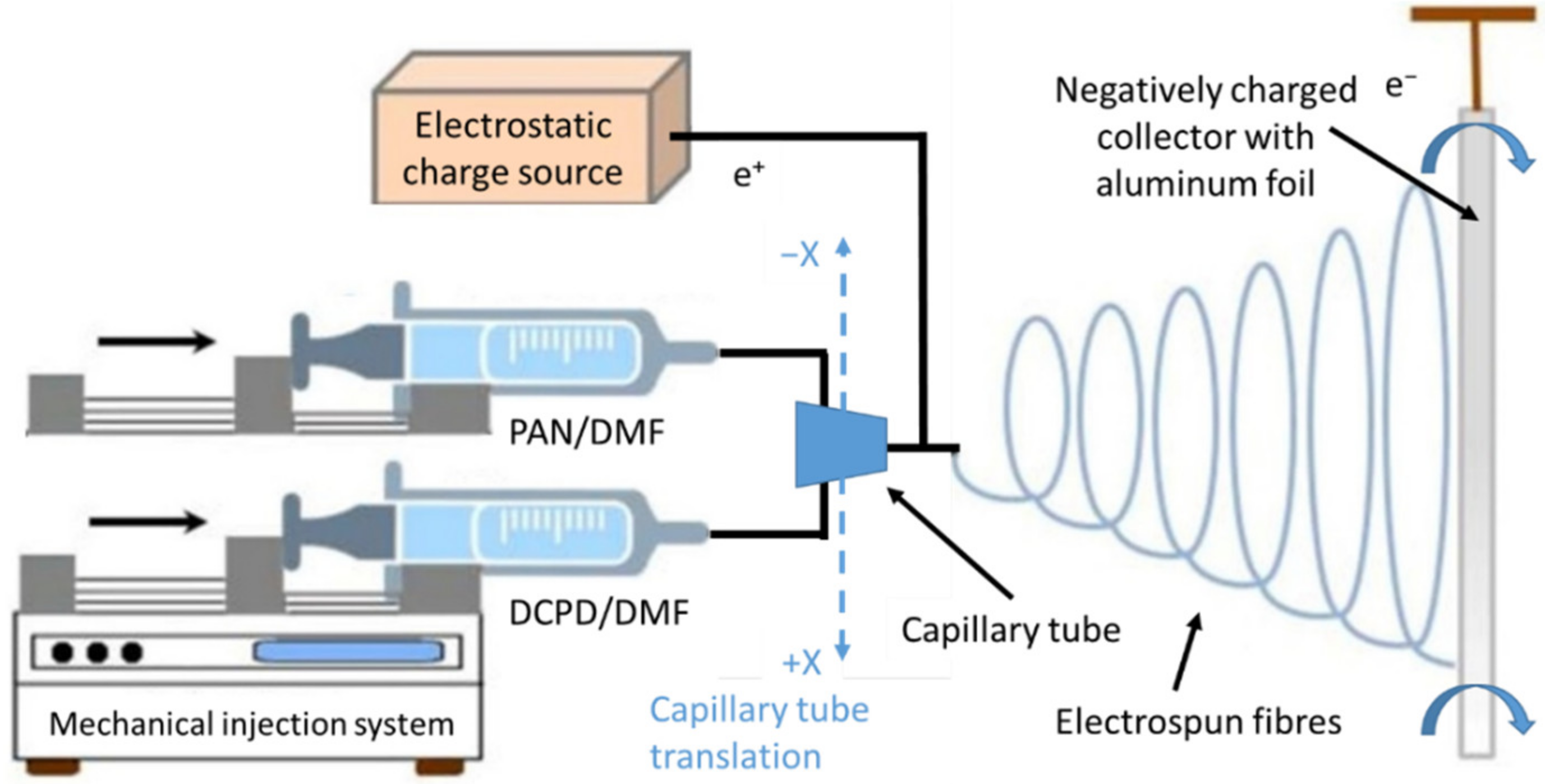

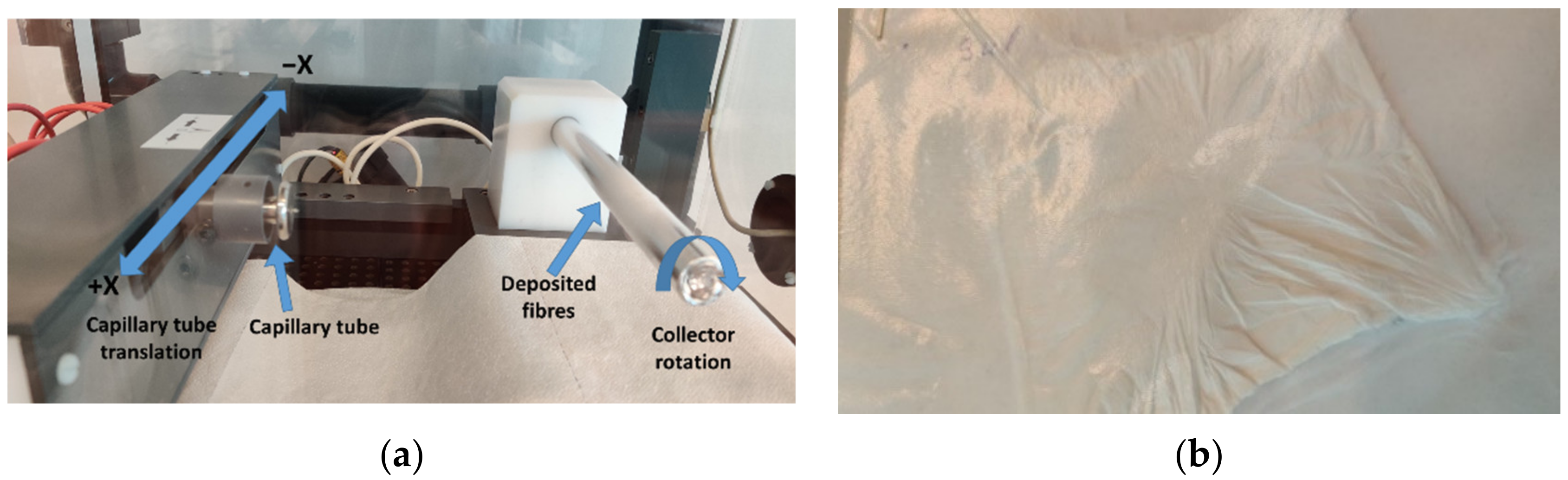

2.2. Electrospinning Process

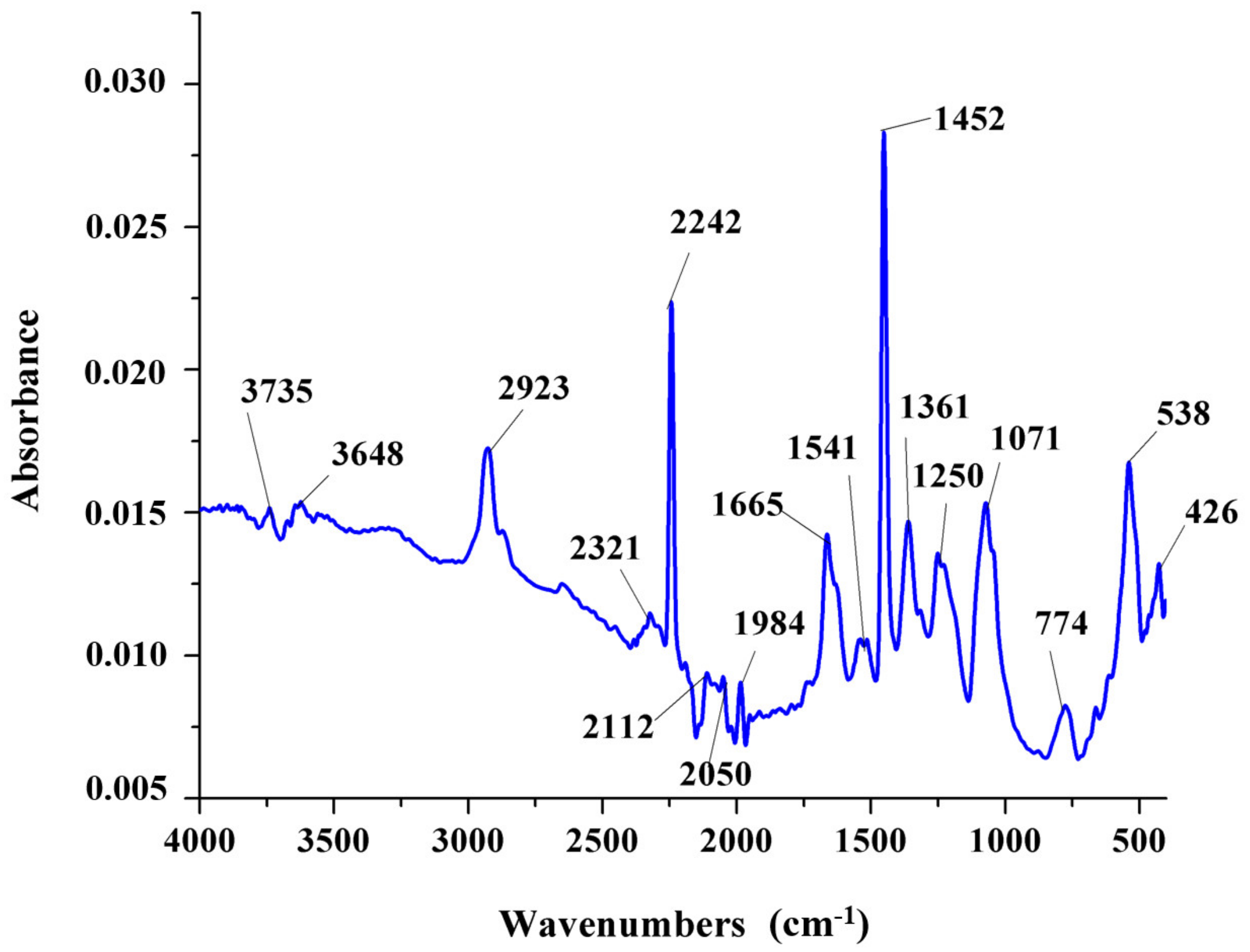

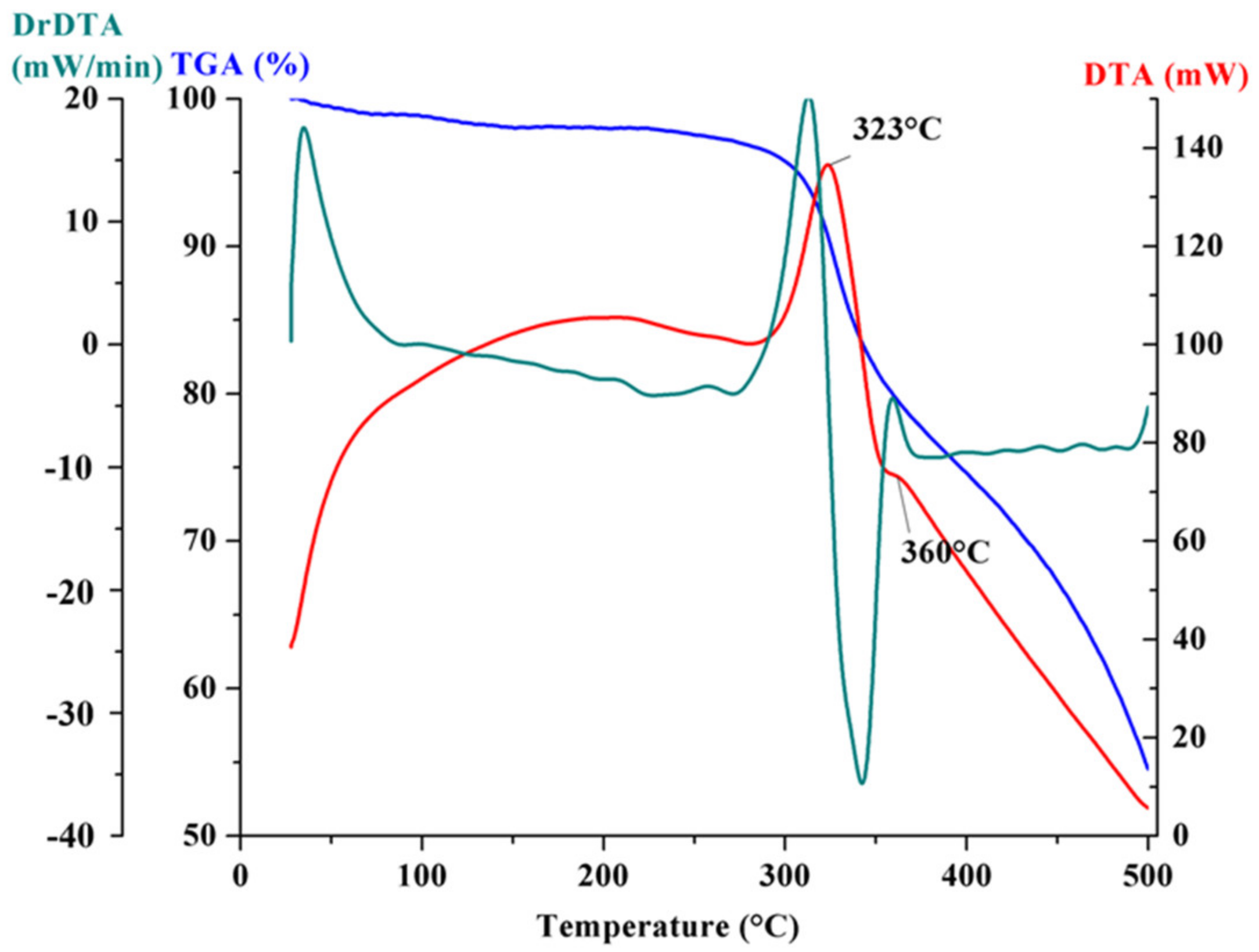

2.3. Chemical and Thermodynamic Analyses

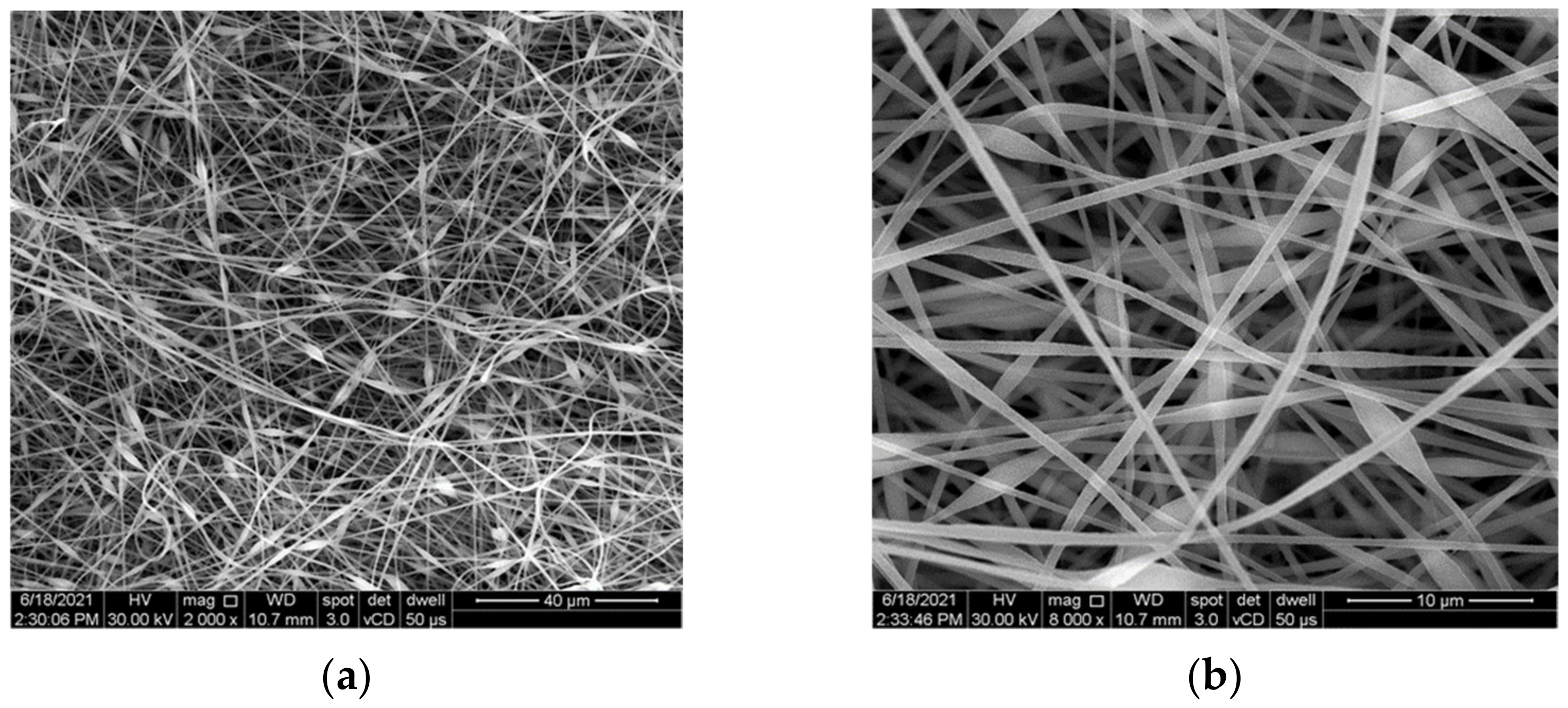

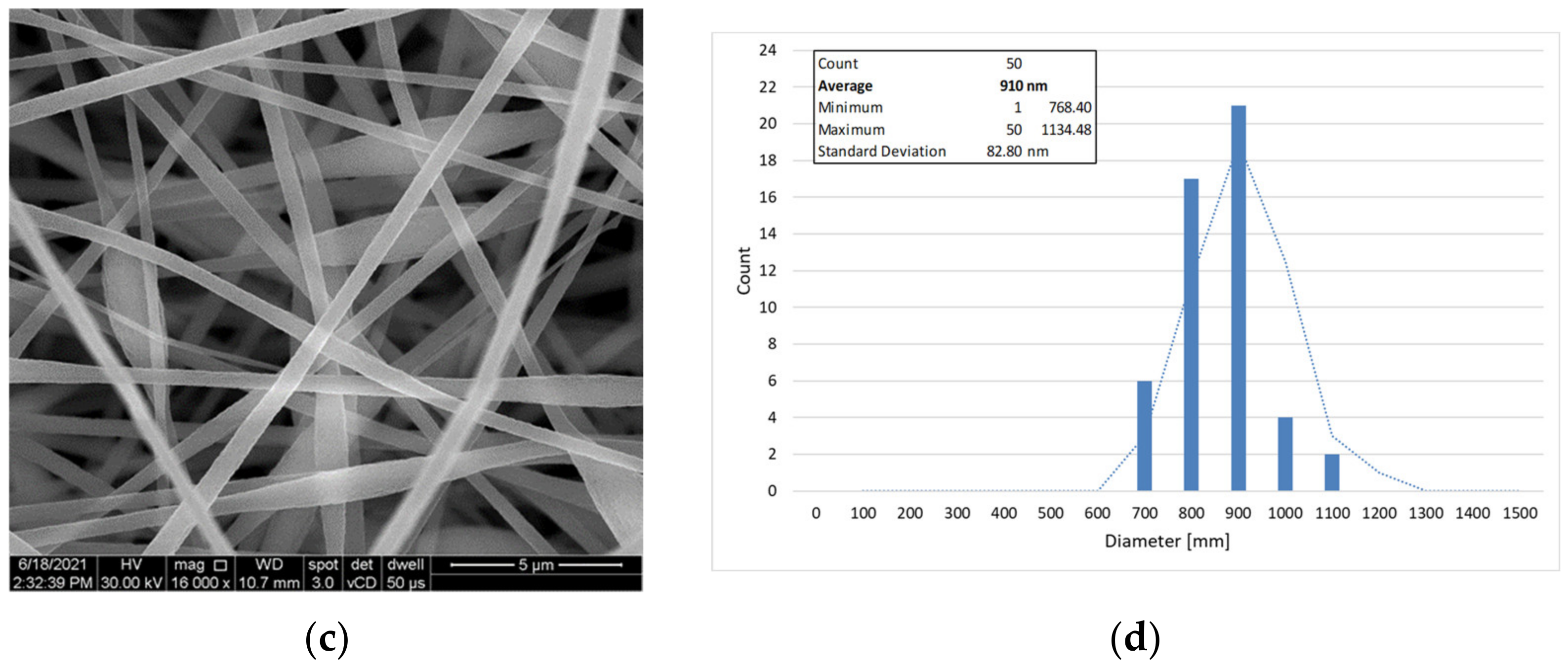

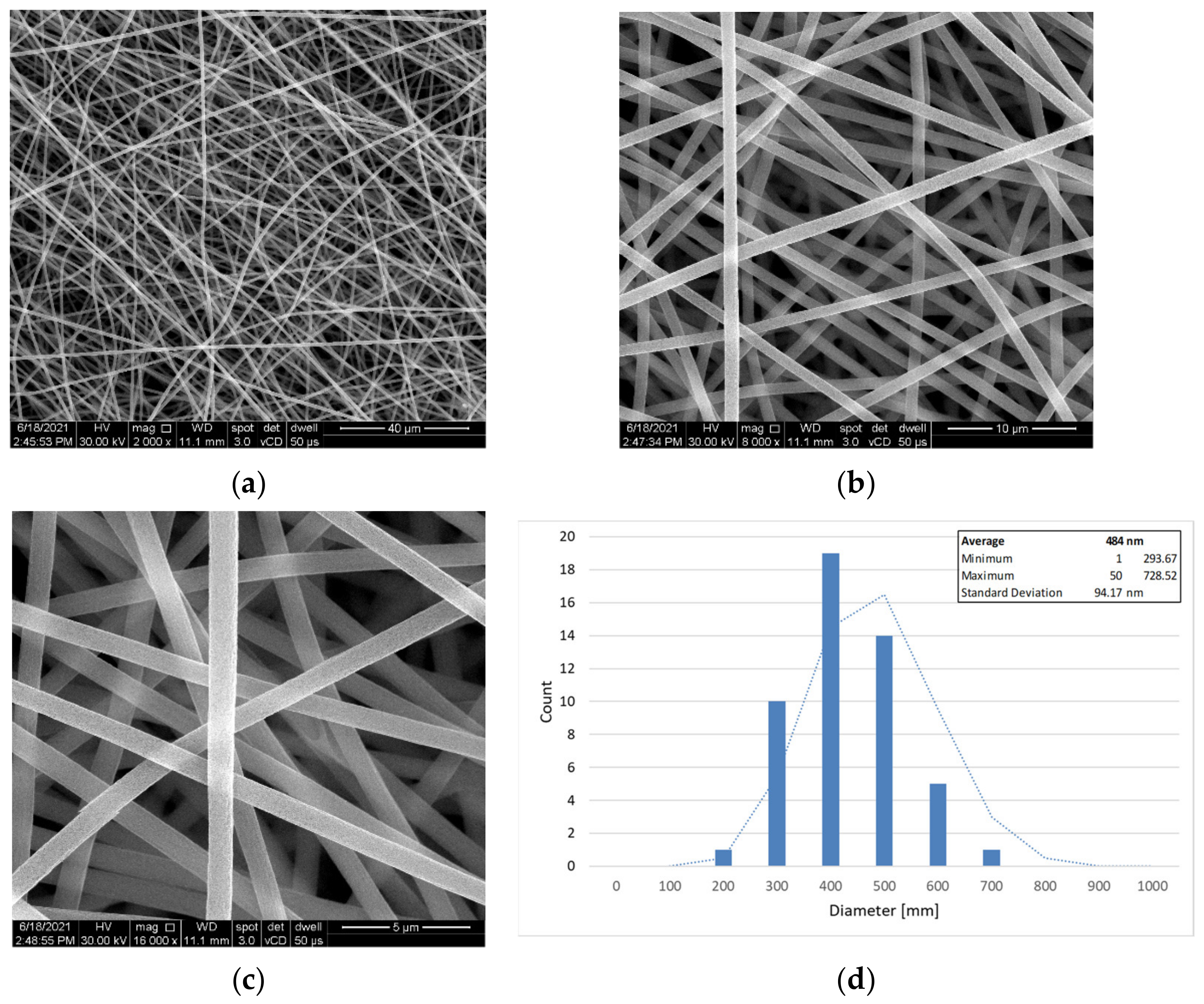

2.4. Microstructural Analysis

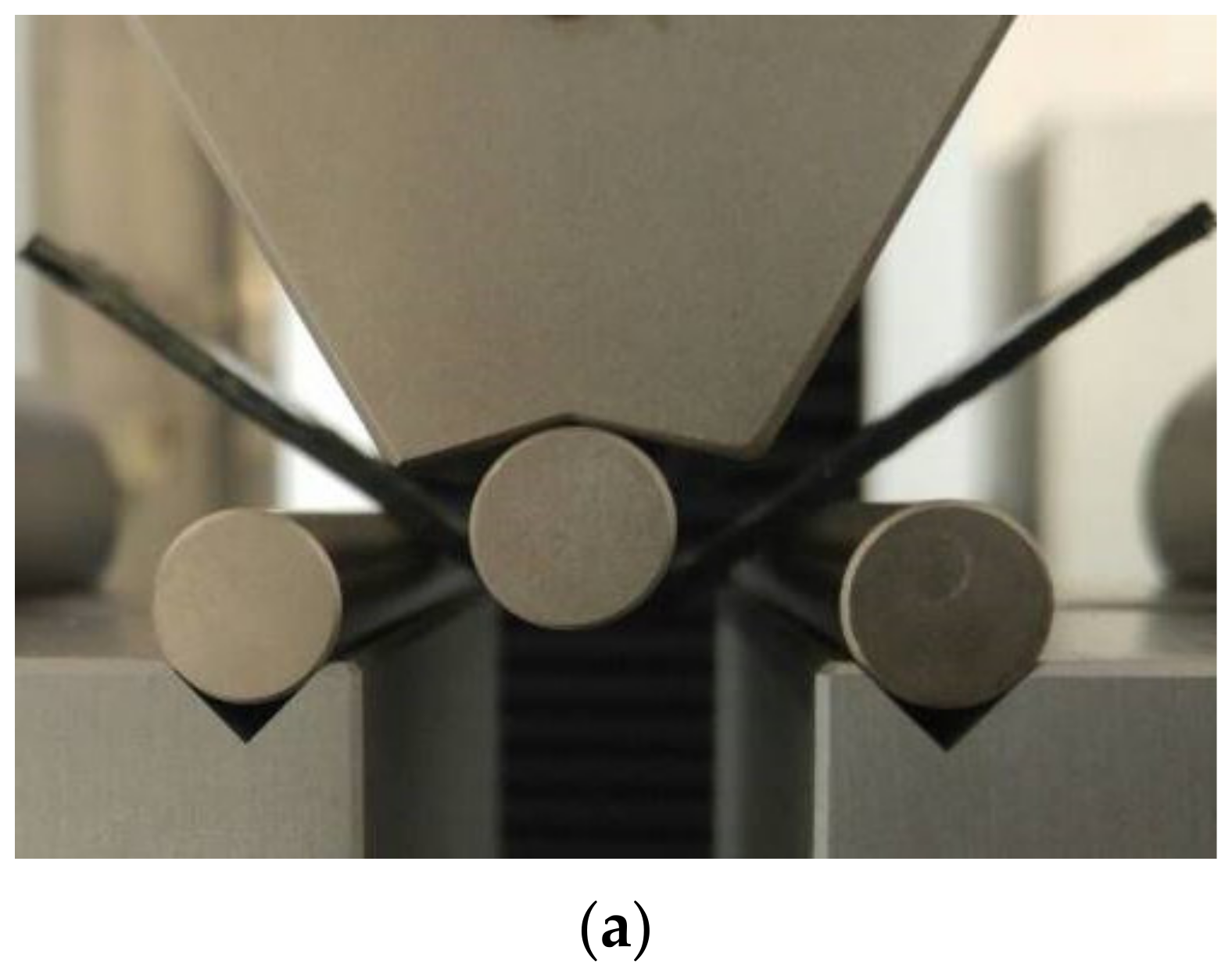

2.5. Mechanical Tests

3. Results

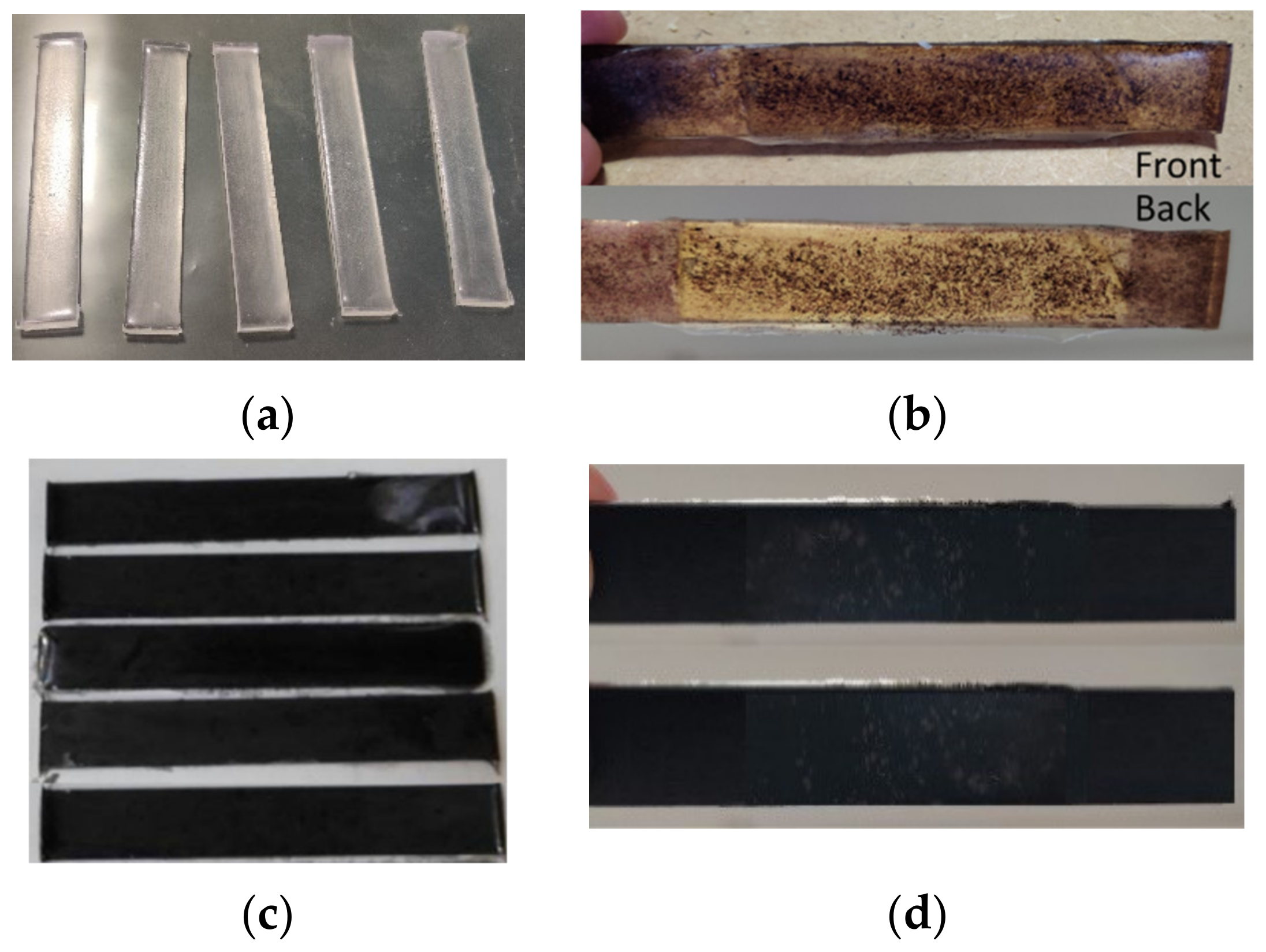

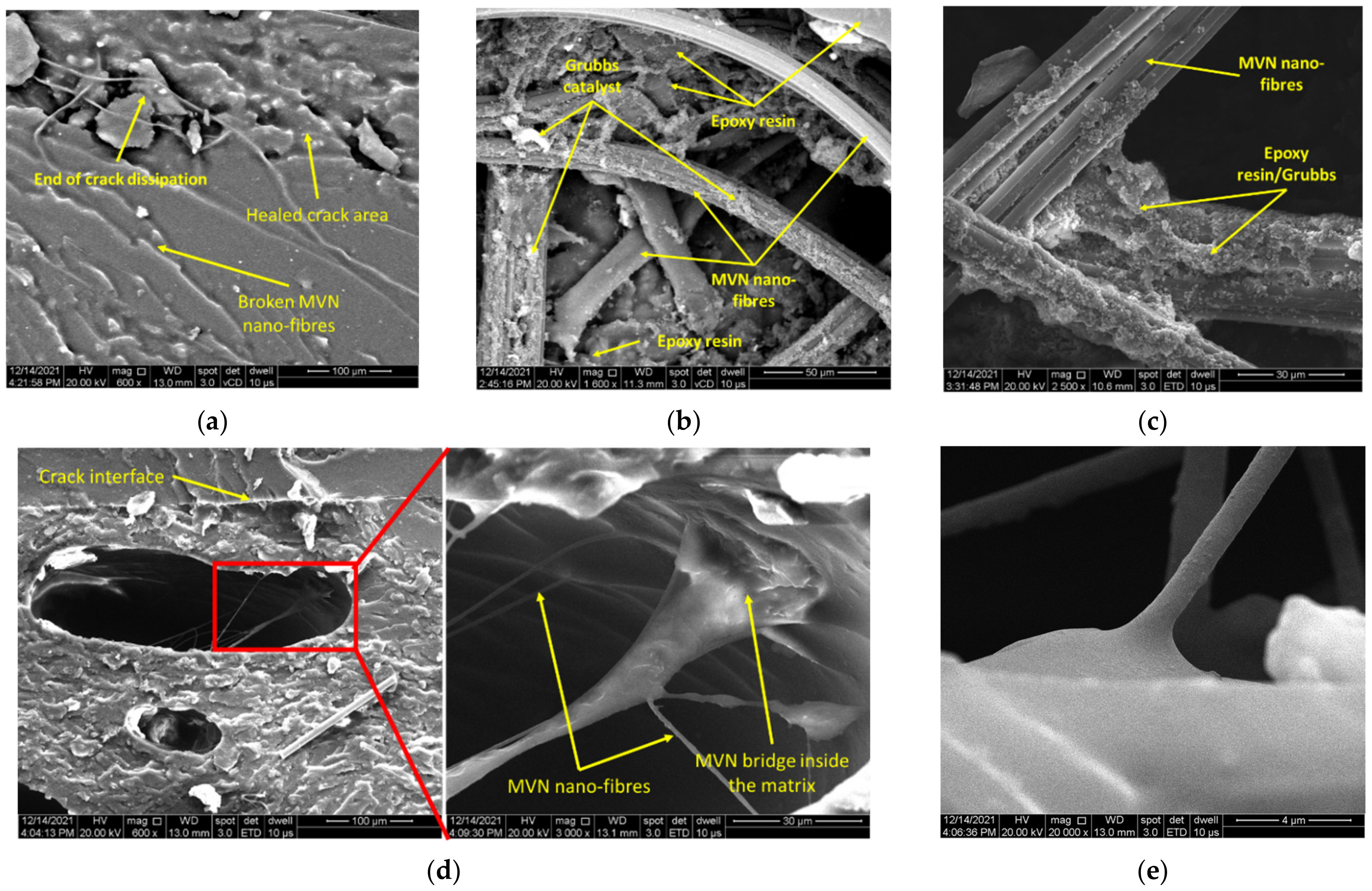

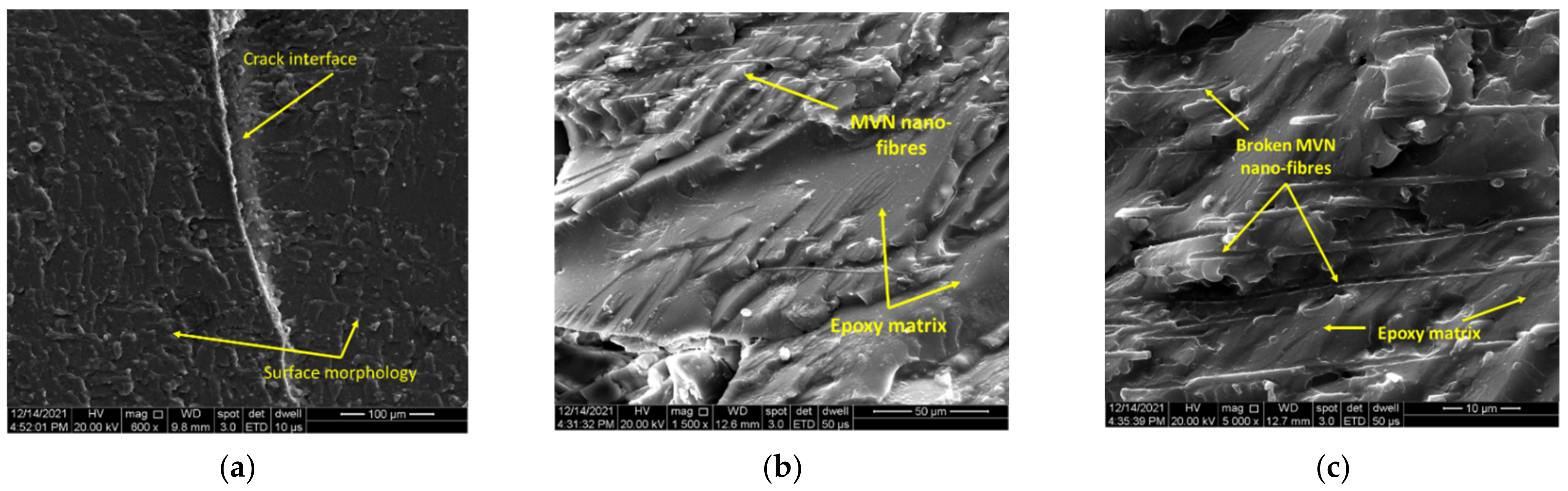

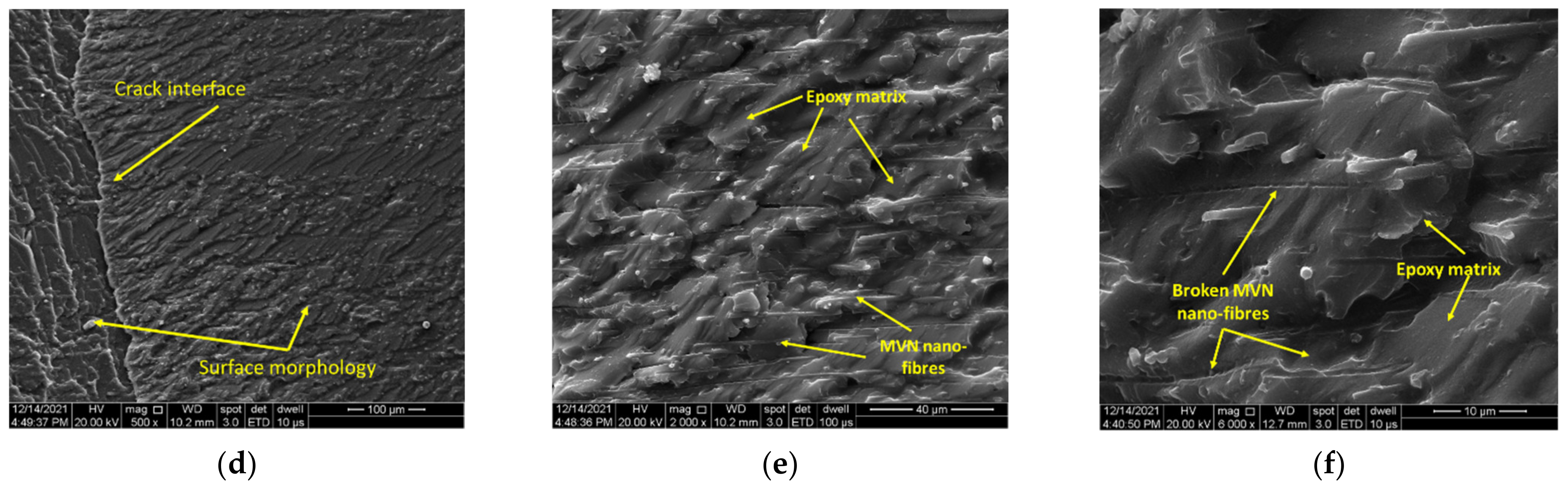

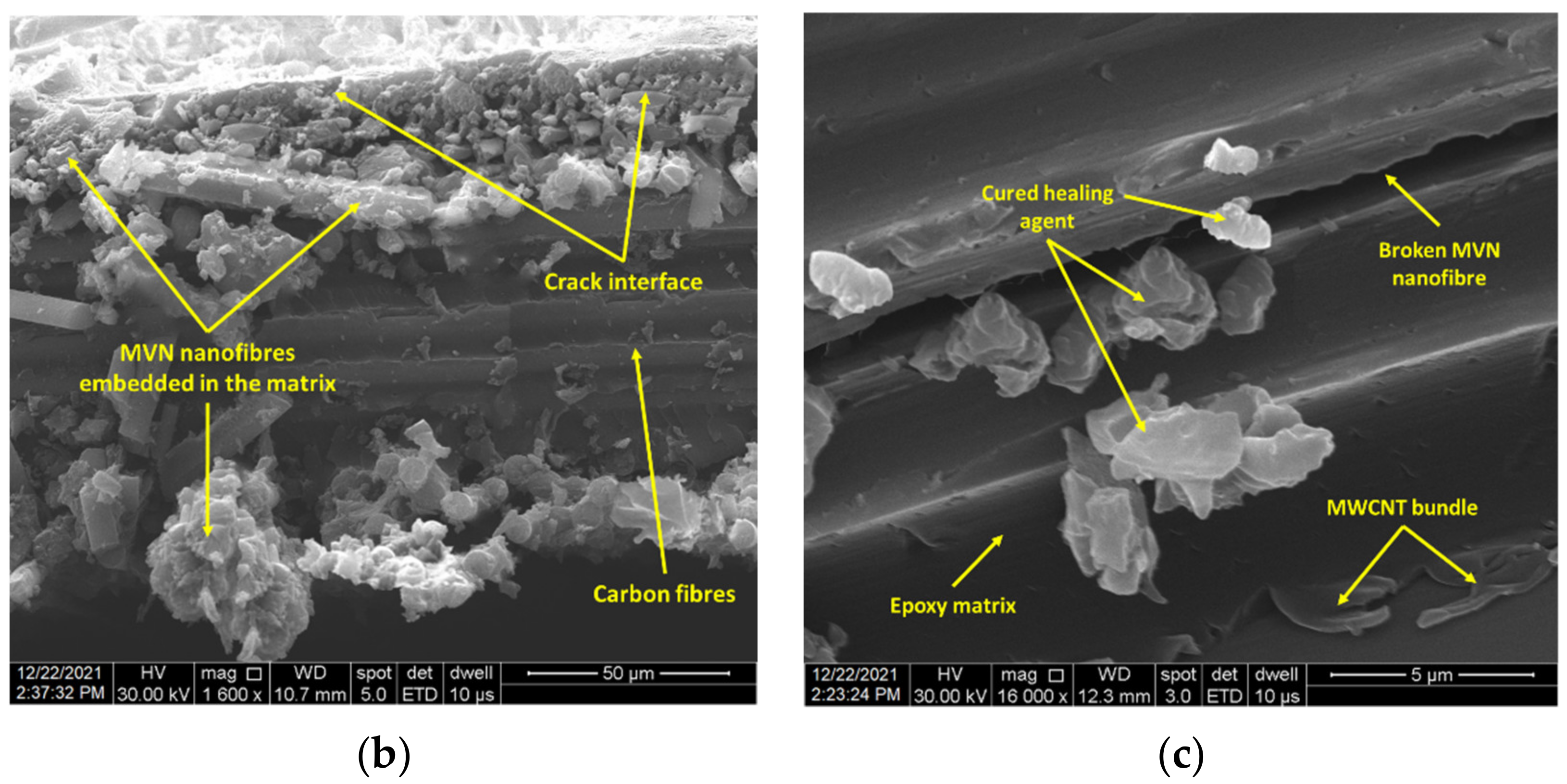

3.1. Microstructural Analysis

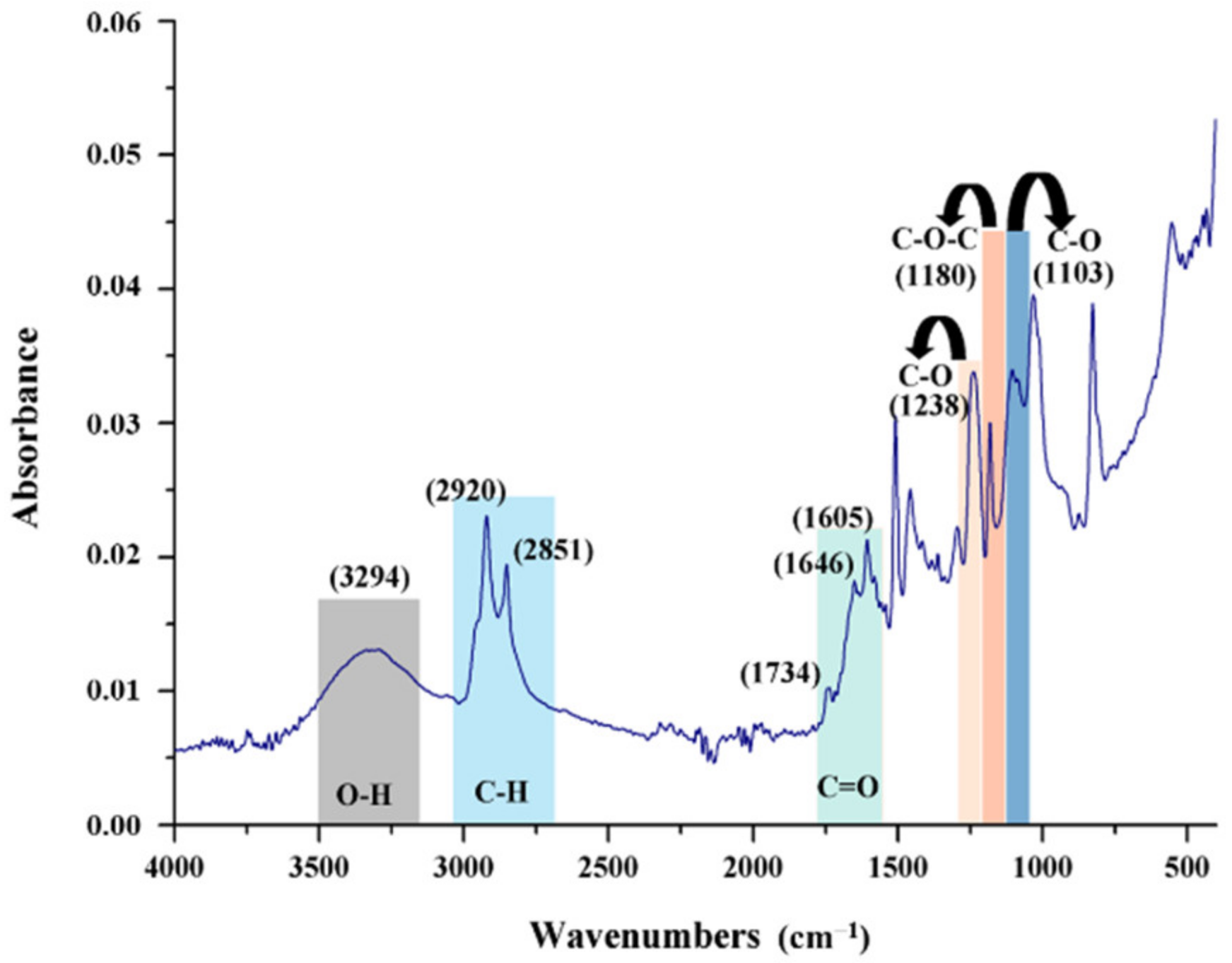

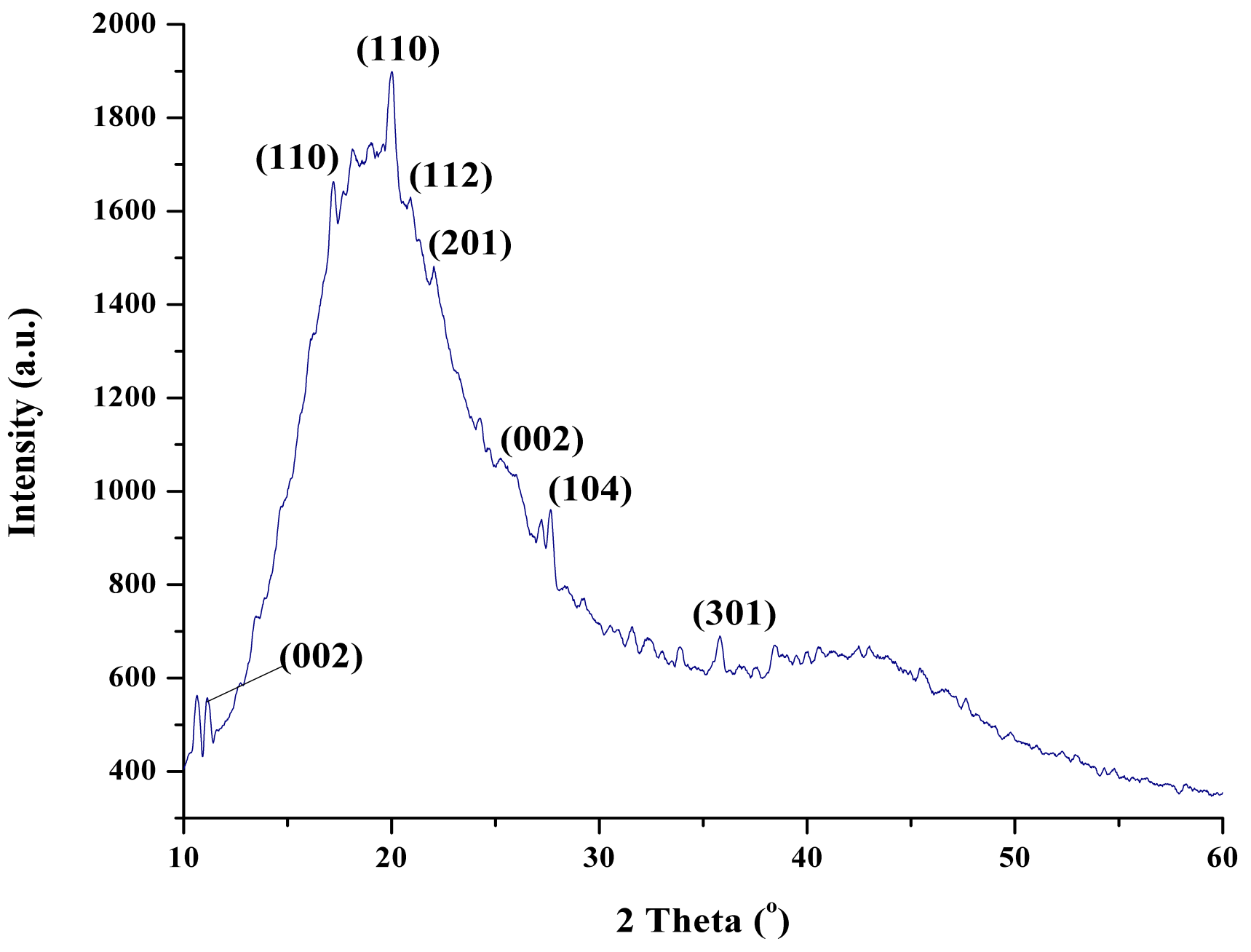

3.2. Chemical and Thermodynamic Analyses

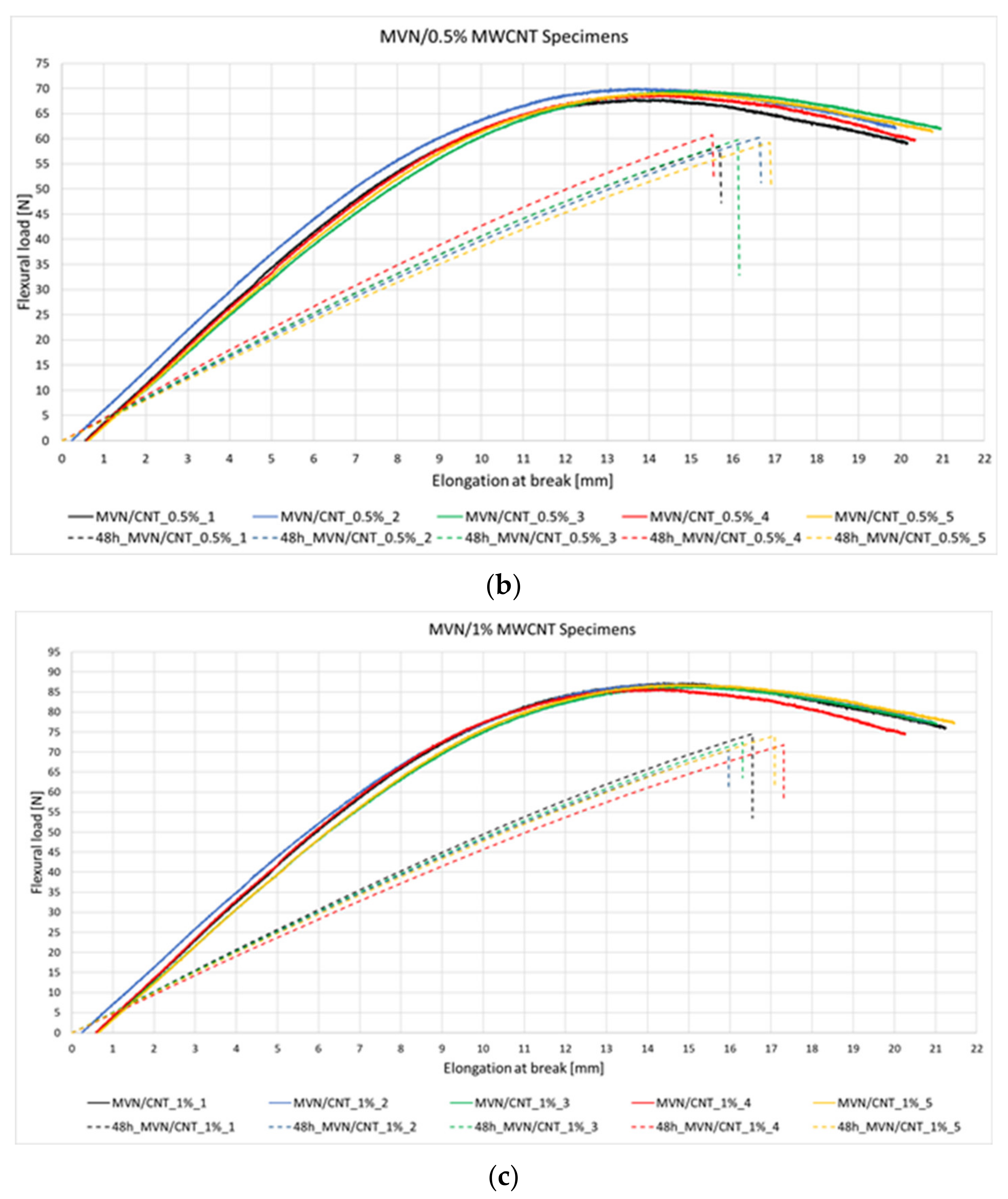

3.3. Mechanical Tests

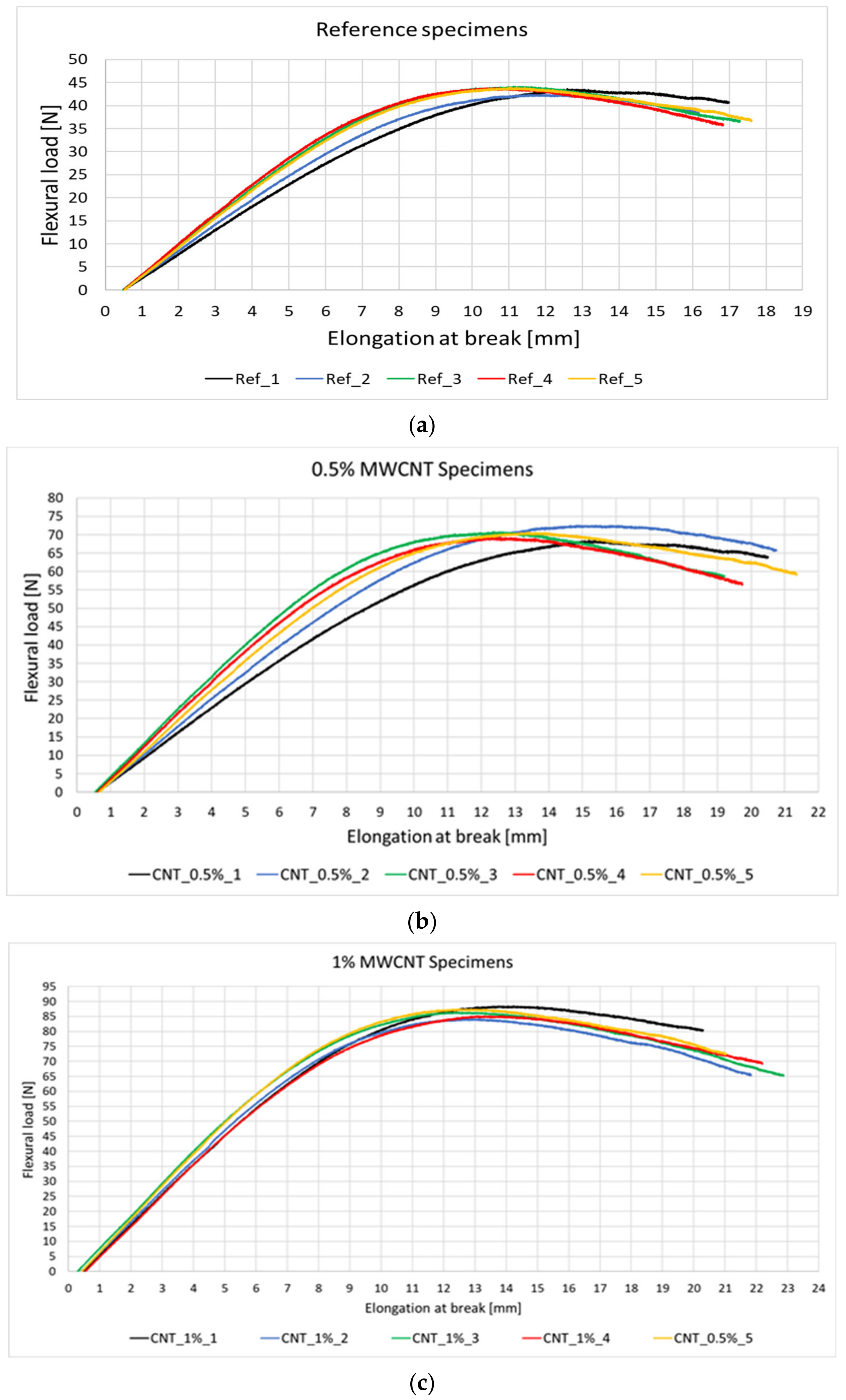

3.3.1. Epoxy System Specimens

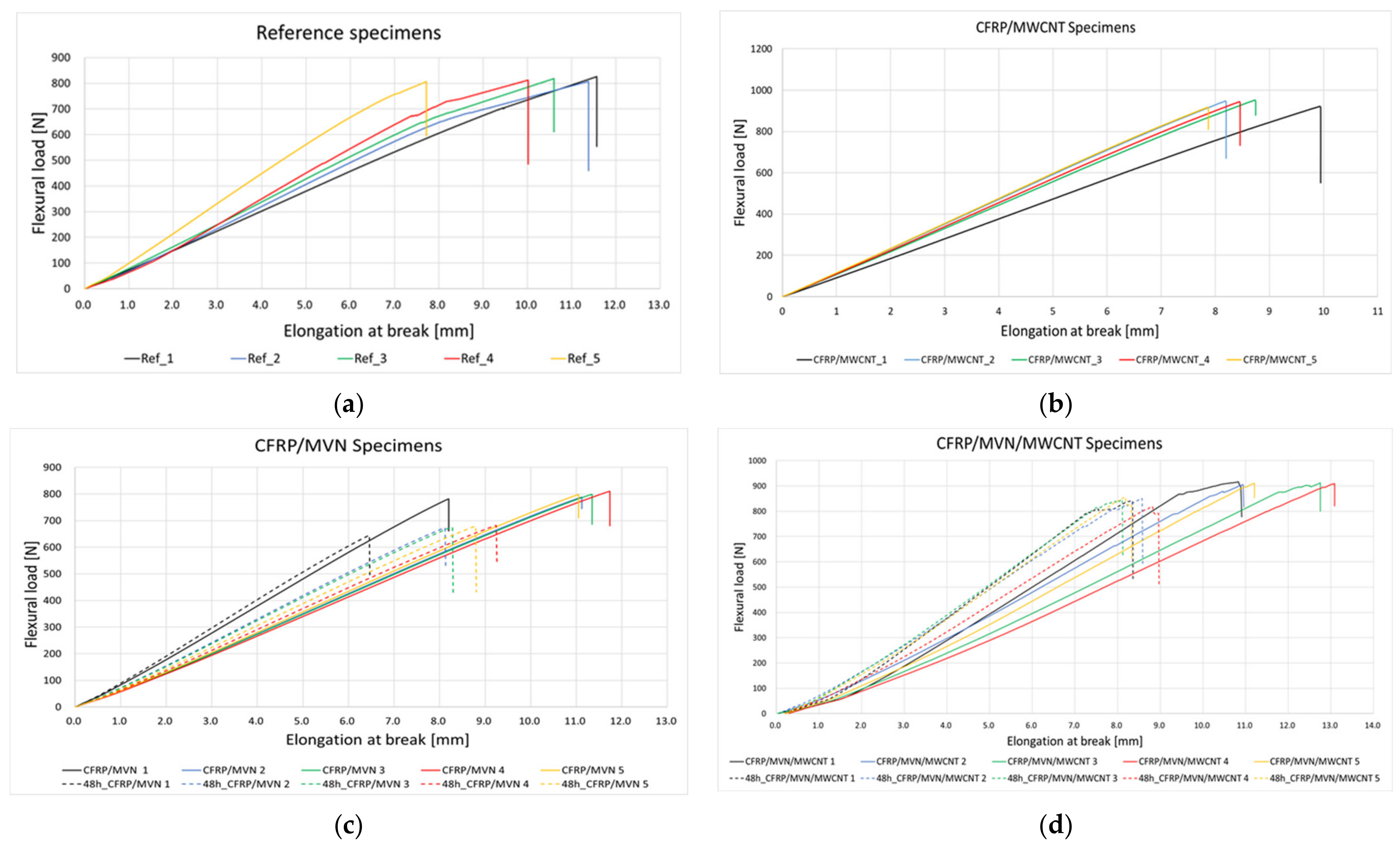

3.3.2. FRP Composite Specimens

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CFRP | Carbon Fibre Reinforced Polymers |

| CNT | Carbon Nanotubes |

| DCPD | Dicyclopentadiene |

| DMF | Dimethylformamide |

| DTA | Differential Thermal Analysis |

| FRP | Fibre Reinforced Polymer |

| FTIR | Fourier Transform Infrared |

| GFRP | Glass Fibre Reinforced Composite |

| MVN | Microvascular Network |

| MWCNT | Multi Walled Carbon Nanotubes |

| PAN | Polyacrylonitrile |

| PCM | Polymeric Composite Materials |

| PMMA | Poly(methyl Methacrylate |

| SAN | Styrene Acrylonitrile |

| SEM | Scanning Electron Microscopy |

| TGA | Thermogravimetric Analysis |

References

- Neisiany, R.E.; Lee, J.K.Y.; Khorasani, S.N.; Ramakrishna, S. Towards the development of self-healing carbon/epoxy composites with improved potential provided by efficient encapsulation of healing agents in core-shell nanofibers. Polym. Test. 2017, 62, 79–87. [Google Scholar] [CrossRef]

- Kotrotsos, A. An innovative synergy between solution electrospinning process technique and self-healing of materials. A critical review. Polym. Eng. Sci. 2020, 61, 5–21. [Google Scholar] [CrossRef]

- Kausar, A. Self-healing polymer/carbon nanotube nanocomposite: A review. J. Plast. Film. Sheeting 2021, 37, 160–181. [Google Scholar] [CrossRef]

- Kausar, A. Shape memory polyurethane/graphene nanocomposites: Structures, properties, and applications. J. Plast. Film. Sheeting 2019, 36, 151–166. [Google Scholar] [CrossRef]

- Raji, M.; El Achaby, M.; Bouhfid, R. Polymer nanocomposite-based smart materials, Chapter 3. In Self-Healing Based on Composites and Nanocomposites Materials: From Synthesis to Application and Modelling; Woodhead Publishing: Sawston, UK, 2020; pp. 41–60. [Google Scholar] [CrossRef]

- Nik Md Noordin Kahar, N.N.F.; Osman, A.F.; Alosime, E.; Arsat, N.; Mohammad Azman, N.A.; Syamsir, A.; Itam, Z.; Abdul Hamid, Z.A. The versatility of polymeric materials as self-healing agents for various types of applications: A review. Polymers 2021, 13, 1194. [Google Scholar] [CrossRef]

- Ullah, H.; Azizli, K.A.M.; Man, Z.B.; Ismail, M.B.C.; Khan, M.I. The potential of microencapsulated self-healing materials for microcracks recovery in self-healing composite systems: A review. Polym. Rev. 2016, 56, 429–485. [Google Scholar] [CrossRef]

- Thakur, V.K.; Kessler, M.R. Self-healing polymer nanocomposite materials: A review. Polymer 2015, 69, 369–383. [Google Scholar] [CrossRef] [Green Version]

- Kanu, N.J.; Gupta, E.; Vates, U.K.; Singh, G.K. Self-healing composites: A state-of-the-art review. Compos. Part A 2019, 121, 474–486. [Google Scholar] [CrossRef]

- Torre-Muruzabal, A.; Daelemans, L.; Assche, G.V.; de Clerck, K.; Rahier, H. Creation of a nanovascular network by electrospun sacrificial nanofibers for self-healing applications and its effect on the flexural properties of the bulk material. Polym. Test. 2016, 54, 78–83. [Google Scholar] [CrossRef] [Green Version]

- Vintila, I.S.; Iovu, H.; Alcea, A.; Cucuruz, A.; Mandoc, A.C.; Vasile, B.S. The synthetization and analysis of dicyclopentadiene and ethylidene-norbornene microcapsule systems. Polymers 2020, 12, 1052. [Google Scholar] [CrossRef]

- Vintila, I.S.; Draghici, S.; Petrescu, H.A.; Paraschiv, A.; Condruz, M.R.; Maier, L.R.; Bara, A.; Necolau, M. Evaluation of dispersion methods and mechanical behaviour of glass fibre composites with embedded self-healing systems. Polymers 2021, 13, 1642. [Google Scholar] [CrossRef] [PubMed]

- Park, J.H.; Braun, P.V. Coaxial electrospinning of self-healing coatings. Adv. Mater. 2010, 22, 496–499. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.; Chen, Y.; Duan, G.; Mei, C.; Greiner, A.; Agarwal, S. Electrospun nanofiber reinforced composites: A review. Polym. Chem. 2018, 9, 2685–2720. [Google Scholar] [CrossRef]

- Ahmadian, A.; Shafiee, A.; Aliahmad, N.; Agarwal, M. Overview of nano-fiber mats fabrication via electrospinning and morphology analysis. Textiles 2021, 1, 206–226. [Google Scholar] [CrossRef]

- Sinha-Ray, S.; Pelot, D.; Zhou, Z.; Rahman, A.; Wu, X.-F.; Yarin, A.L. Encapsulation of self-healing materials by coelectrospinning, emulsion electrospinning, solution blowing and intercalation. J. Mater. Chem. 2012, 22, 9138–9146. [Google Scholar] [CrossRef]

- Wu, X.F.; Rahman, A.; Zhou, Z.; Pelot, D.D.; Sinha-Ray, S.; Chen, B.; Payne, S.; Yarin, A.L. Electrospinning core-shell nanofibers for interfacial toughening and self-healing of carbon-fiber/epoxy composites. J. Appl. Polym. Sci. 2013, 129, 1383–1393. [Google Scholar] [CrossRef]

- Neisiany, R.E.; Lee, J.K.Y.; Khorasani, S.N.; Ramakrishna, S. Self-healing and interfacially toughened carbon fibre-epoxy composites based on electrospun core–shell nanofibres. J. Appl. Polym. Sci. 2017, 134, 44956. [Google Scholar] [CrossRef]

- Esmaeely Neisiany, R.; Lee, J.K.Y.; Nouri Khorasani, S.; Bagheri, R.; Ramakrishna, S. Facile strategy toward fabrication of highly responsive self-healing carbon/epoxy composites via incorporation of healing agents encapsulated in poly(methylmethacrylate) nanofiber shell. J. Ind. Eng. Chem. 2018, 59, 456–466. [Google Scholar] [CrossRef]

- Seyyed Monfared Zanjani, J.; Saner Okan, B.; Yilmaz, C.; Menceloglu, Y.; Yildiz, M. Monitoring the interface and bulk self-healing capability of tri-axial electrospun fibers in glass fiber reinforced epoxy composites. Compos. Part A Appl. Sci. Manuf. 2017, 99, 221–232. [Google Scholar] [CrossRef]

- Neisiany, R.E.; Khorasani, S.N.; Kong Yoong Lee, J.; Ramakrishna, S. Encapsulation of epoxy and amine curing agent in PAN nanofibers by coaxial electrospinning for self-healing purposes. RSC Adv. 2016, 6, 70056–70063. [Google Scholar] [CrossRef]

- Mohammadi, M.A.; Eslamin-Farsani, R.; Ebrahimnezhad-Khaljiri, H. Experimental investigation of the healing properties of the microvascular channels-based self-healing glass fibers/epoxy composites containing the three-part healant. Polym. Test. 2020, 91, 106862. [Google Scholar] [CrossRef]

- Wei, Q.F.; Gao, W.D.; Hou, D.Y.; Wang, X.Q. Surface modification of polymer nanofibers by plasma treatment. Appl. Surf. Sci. 2005, 245, 16–20. [Google Scholar] [CrossRef]

- Wilken, R.; Hollander, A.; Behnisch, J. Surface radical analysis on plasma-treated polymers. Surf. Coat. Technol. 1999, 116–119, 991–995. [Google Scholar] [CrossRef]

- Mozaffari, A.; Gashti, M.P. Air plasma functionalization of electrospun nanofibers for skin tissue engineering. Biomedicines 2022, 10, 617. [Google Scholar] [CrossRef] [PubMed]

- Mozaffari, A.; Gashti, M.P.; Mirjalili, M.; Parsania, M. Argon and argon–oxygen plasma surface modification of gelatin nanofibers for tissue engineering applications. Membranes 2021, 11, 31. [Google Scholar] [CrossRef]

- Begum, H.A.; Khan, K.R. Study on the various types of needle based and needleless electrospinning system for nanofiber production. Int. J. Text. Sci. 2017, 6, 110–117. [Google Scholar] [CrossRef]

- Kang, S.; Zhao, K.; Yu, D.G.; Zheng, X.; Huang, C. Advances in biosensing and environmental monitoring based on electrospun nanofibers. Adv. Fiber Mater. 2022, 4, 404–435. [Google Scholar] [CrossRef]

- Liu, H.; Jiang, W.; Yang, Z.; Chen, X.; Yu, D.-G.; Shao, J. Hybrid films prepared from a combination of electrospinning and casting for offering a dual-phase drug release. Polymers 2022, 14, 2132. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, F.; Wang, M.; Lv, H.; Yu, D.G.; Liu, X.; Shen, H. Electrospun hierarchical structural films for effective wound healing. Biomater. Adv. 2022, 136, 212795. [Google Scholar] [CrossRef]

- Liu, H.; Wang, H.; Lu, X.; Murugadoss, V.; Huang, M.; Yang, H.; Wan, F.; Yu, D.G.; Guo, Z. Electrospun structural nanohybrids combining three composites for fast helicide delivery. Adv. Compos. Hybrid Mater. 2022. [Google Scholar] [CrossRef]

- Jiang, X.; Xi, M.; Bai, L.; Wang, W.; Yang, L.; Chen, H.; Niu, Y.; Cui, Y.; Yang, H.; Wei, D. Surface-initiated PET-ATRP and mussel-inspired chemistry for surface engineering of MWCNTs and application in self-healing nanocomposite hydrogels. Mater. Sci. Eng. C Mater. Biol. Appl. 2020, 109, 110553. [Google Scholar] [CrossRef] [PubMed]

- Habib, S.; Khan, A.; Nawaz, M.; Sliem, M.H.R.; Shakoor, R.A.; Kahraman, R.; Abdullah, A.M.; Zekri, A. Self-Healing performance of multifunctional polymeric smart coatings. Polymers 2019, 11, 1519. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alharbi, A.R.; Alarifi, I.M.; Khan, W.S.; Asmatulu, R. Highly Hydrophilic electrospun polyacrylonitrile/polyvinypyrrolidone nanofibers incorporated with gentamicin as filter medium for dam water and wastewater treatment. J. Membr. Sep. Technol. 2016, 5, 38–56. [Google Scholar] [CrossRef]

- ISO 14125:1998; Fibre-Reinforced Plastic Composites—Determination of Flexural Properties. International Standardization Organization: Geneva, Switzerland, 1998. Available online: https://www.iso.org/standard/23637.html (accessed on 10 April 2022).

- Da Silva, V.A.; Rezende, M.C. Effect of the morphology and structure on the microwave absorbing properties of multiwalled carbon nanotube filled epoxy resin nanocomposites. Mater. Res. 2018, 21, 5. [Google Scholar] [CrossRef] [Green Version]

- Song, Y.S.; Youn, J.R. Influence of dispersion states of carbon nanotubes on physical properties of epoxy nanocomposites. Carbon 2005, 43, 1378–1385. [Google Scholar] [CrossRef]

- Farukh, M.; Singh, A.P.; Dhawan, S.K. Enhanced electromagnetic shielding behavior of multi-walled carbon nanotube entrenched poly (3,4-thylenedioxythiophene) nanocomposites. Compos. Sci. Technol. 2015, 114, 94–102. [Google Scholar] [CrossRef]

- Albuquerque de Oliveira, M.C.; de Souza Menezes, L.; Pincheira, P.I.R.; Rojhas-Ulloa, C.; Gomez, N.K.; Pequeno de Oliveira, H.; Gomes, A.S.L. A random laser based on electrospun polymeric composite nanofibers with dual-size distribution. Nanoscale Adv. 2019, 1, 728. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Liu, X.; Liu, P.; Chen, X.; Yu, D.-G. Electrospun multiple-chamber nanostructure and its potential self-healing applications. Polymers 2020, 12, 2413. [Google Scholar] [CrossRef]

- Sadeghi, S.A.M.; Borhani, S.; Zadhoush, A.; Dinari, M. Single nozzle electrospinning of encapsulated epoxy and mercaptan in PAN for self-healing application. Polymer 2020, 186, 122007. [Google Scholar] [CrossRef]

- Eren, O.; Ucar, N.; Onen, A.; Kizildag, N.; Karacan, I. Synergistic effect of polyaniline, nanosilver, and carbon nanotube mixtures on the structure and properties of polyacrylonitrile composite nanofiber. J. Compos. Mater. 2015, 50, 2073–2086. [Google Scholar] [CrossRef]

| Material | Molecular Formula | Physical Properties | Role in the Synthesis |

|---|---|---|---|

| PAN | (C3H3N)n | White crystalline powder. Melting point at 300 °C. | Formation of nano-fibres shell. |

| DCPD | C10H12 | Gel-like (room temperature). Melting point at 32.5 °C. | Nano-fibres core, microvascular self-healing agent. |

| DMF | C3H7NO | Colourless liquid solution, strong ammonia odour. Melting point at −61 °C. | Used as solvent for PAN and DCPD. |

| Grubb’s catalyst | C43H72Cl2P2Ru | Purple crystalline powder. Melting point at 153 °C. | Used for activation of self-healing agent. |

| Parameter | Value |

|---|---|

| Chamber humidity | 35% |

| Chamber temperature | 25 °C |

| Distance between capillary tube and collector | 160 mm |

| Capillary tube translation | 140 mm (−70 mm/+70 mm) |

| Capillary tube translation speed | 3 mm/s |

| PAN/DMF: DCPD/DMF flow | 9:4.5 µL/min |

| Collector rotation speed | 150 rot/min |

| Applied voltage | 17 kV |

| Specimen Sets | Specimen Type | Relevance of Test |

|---|---|---|

| 1 | Neat epoxy | Reference specimens |

| 2 | Epoxy system with 0.5% MWCNT | Evaluate the MWCNT influence over the mechanical properties of epoxydic matrix |

| 3 | Epoxy system with 1% MWCNT | |

| 4 | Epoxy system with MVN and Grubb’s catalyst | Evaluating the mechanical properties and self-healing ability of matrix with the introduction of new elements |

| 5 | Epoxy system with MVN, Grubb’s catalyst and 0.5% MWCNT | |

| 6 | Epoxy system with MVN, Grubb’s catalyst and 1% MWCNT |

| Specimen Type | Maximum Flexural Strength, σm (MPa) | Flexural Load at Break, F (N) | Elongation at Break, ε (mm) | Flexural Modulus, E [MPa] | Absorbed Energy, AE [J] |

|---|---|---|---|---|---|

| Epoxy Reference | 65.17 | 43.59 | 16.98 | 3812.35 | 4671.30 |

| Epoxy/0.5% MWCNT | 85.78 | 70.37 | 20.31 | 6333.83 | 7056.04 |

| Epoxy/1% MWCNT | 102.12 | 86.43 | 21.65 | 7717.50 | 7118.11 |

| Epoxy/MVN/Grubbs | 63.26 | 45.19 | 14.68 | 5476.00 | 3294.30 |

| Epoxy/MVN/Grubbs (48 h) | 41.76 | 33.28 | 10.29 | 3231.54 | 3263.02 |

| Epoxy/MVN/Grubbs/0.5% MWCNT | 89.12 | 69.15 | 20.43 | 6151.89 | 6502.78 |

| Epoxy/MVN/Grubbs/0.5% MWCNT (48 h) | 78.02 | 60.15 | 16.17 | 4456.31 | 4246.08 |

| Epoxy/MVN/Grubbs/1% MWCNT | 99.39 | 86.77 | 20.99 | 7714.41 | 8143.10 |

| Epoxy/MVN/Grubbs/1% MWCNT (48 h) | 82.70 | 72.66 | 16.65 | 4939.92 | 5129.15 |

| Laminate No. | No. of Specimens | Specimen Type |

|---|---|---|

| 1 | 5 | CFRP Reference |

| 2 | 5 | CFRP/0.5% MWCNT |

| 3 | 5 | CFRP/MVN |

| 4 | 5 | CFRP/MVN/0.5% MWCNT |

| Specimen Type | Maximum Flexural Strength, σm (MPa) | Flexural Load at Break, F (N) | Flexural Strain, ε (mm) | Flexural Modulus, E [MPa] | Absorbed Energy, AE [J] |

|---|---|---|---|---|---|

| CFRP Reference | 832.25 | 813.99 | 10.26 | 45,276.86 | 95,181.85 |

| CFRP/MWCNT | 947.18 | 936.56 | 8.64 | 48,238.86 | 101,408.67 |

| CFRP/MVN | 934.45 | 795.18 | 10.69 | 44,515.16 | 94,025.40 |

| CFRP/MVN/MWCNT | 942.96 | 910.48 | 11.78 | 47,392.57 | 99,629.57 |

| CFRP/MVN (48 h) | 730.24 | 671.01 | 9.02 | 49,635.25 | 99,540.61 |

| CFRP/MVN/MWCNT (48 h) | 878.86 | 843.09 | 8.48 | 51,073.96 | 107,368.65 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vintila, I.S.; Ghitman, J.; Iovu, H.; Paraschiv, A.; Cucuruz, A.; Mihai, D.; Popa, I.F. A Microvascular System Self-Healing Approach on Polymeric Composite Materials. Polymers 2022, 14, 2798. https://doi.org/10.3390/polym14142798

Vintila IS, Ghitman J, Iovu H, Paraschiv A, Cucuruz A, Mihai D, Popa IF. A Microvascular System Self-Healing Approach on Polymeric Composite Materials. Polymers. 2022; 14(14):2798. https://doi.org/10.3390/polym14142798

Chicago/Turabian StyleVintila, Ionut Sebastian, Jana Ghitman, Horia Iovu, Alexandru Paraschiv, Andreia Cucuruz, Dragos Mihai, and Ionut Florian Popa. 2022. "A Microvascular System Self-Healing Approach on Polymeric Composite Materials" Polymers 14, no. 14: 2798. https://doi.org/10.3390/polym14142798

APA StyleVintila, I. S., Ghitman, J., Iovu, H., Paraschiv, A., Cucuruz, A., Mihai, D., & Popa, I. F. (2022). A Microvascular System Self-Healing Approach on Polymeric Composite Materials. Polymers, 14(14), 2798. https://doi.org/10.3390/polym14142798