Properties Enhancement of Oil Palm Trunk Plywood against Decay and Termite for Marine Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Treatability of Oil Palm Veneers

2.2. Production of Marine Grade Equivalent (MGE) Plywood

2.3. Dimensional Stability of MGE Plywood

2.4. Mechanical Performance of MGE Plywood

2.5. Decay Resistance Test

2.6. Termite Resistance Test

3. Results and Discussion

3.1. Weight Percent Gain (WPG) and Polymer Retention (PR) of OPT Veneers

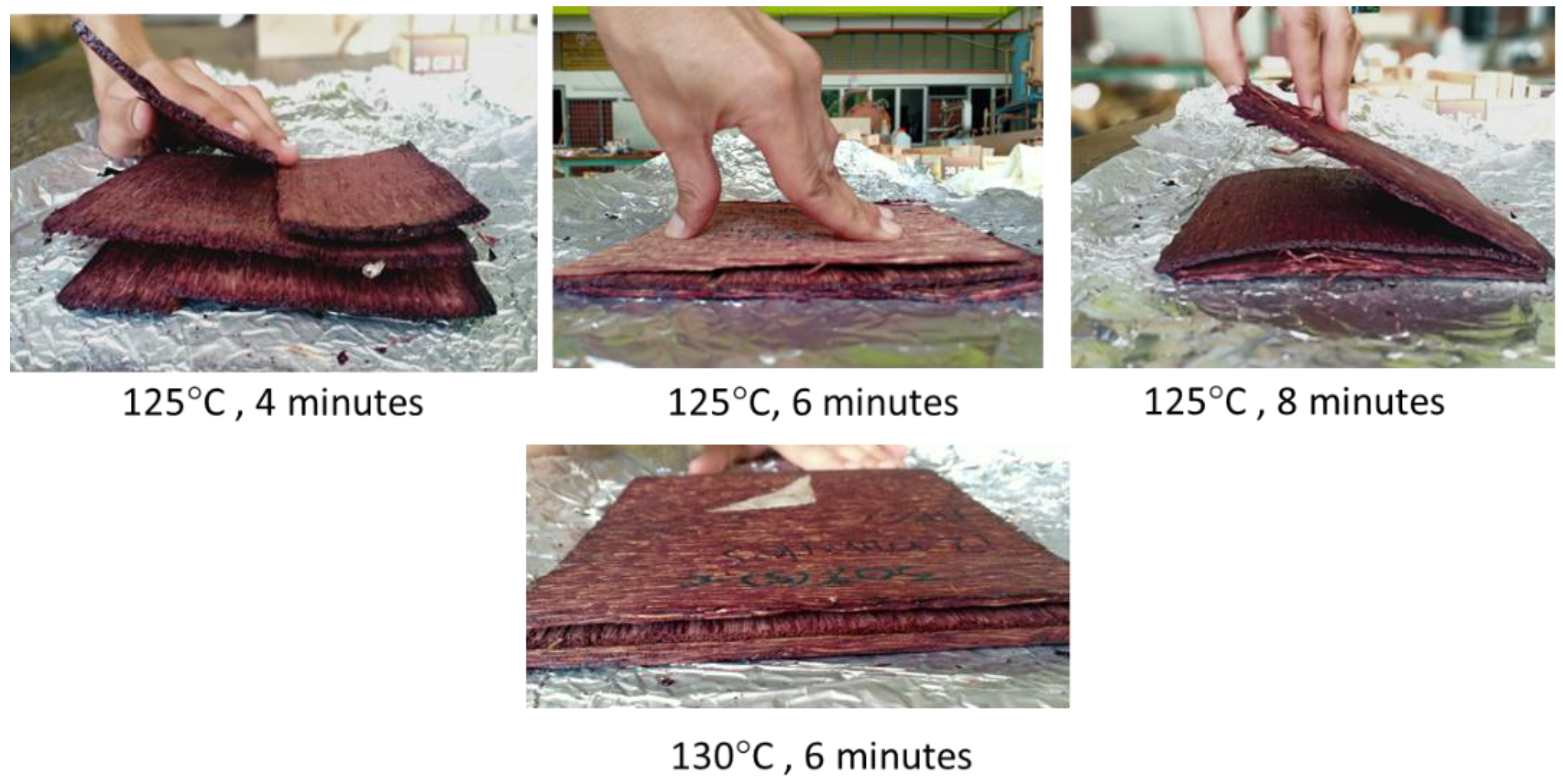

3.2. Optimized Pressing Temperature and Time for MGE Plywood

3.3. Dimensional Stability and Mechanical Performance of MGE Plywood

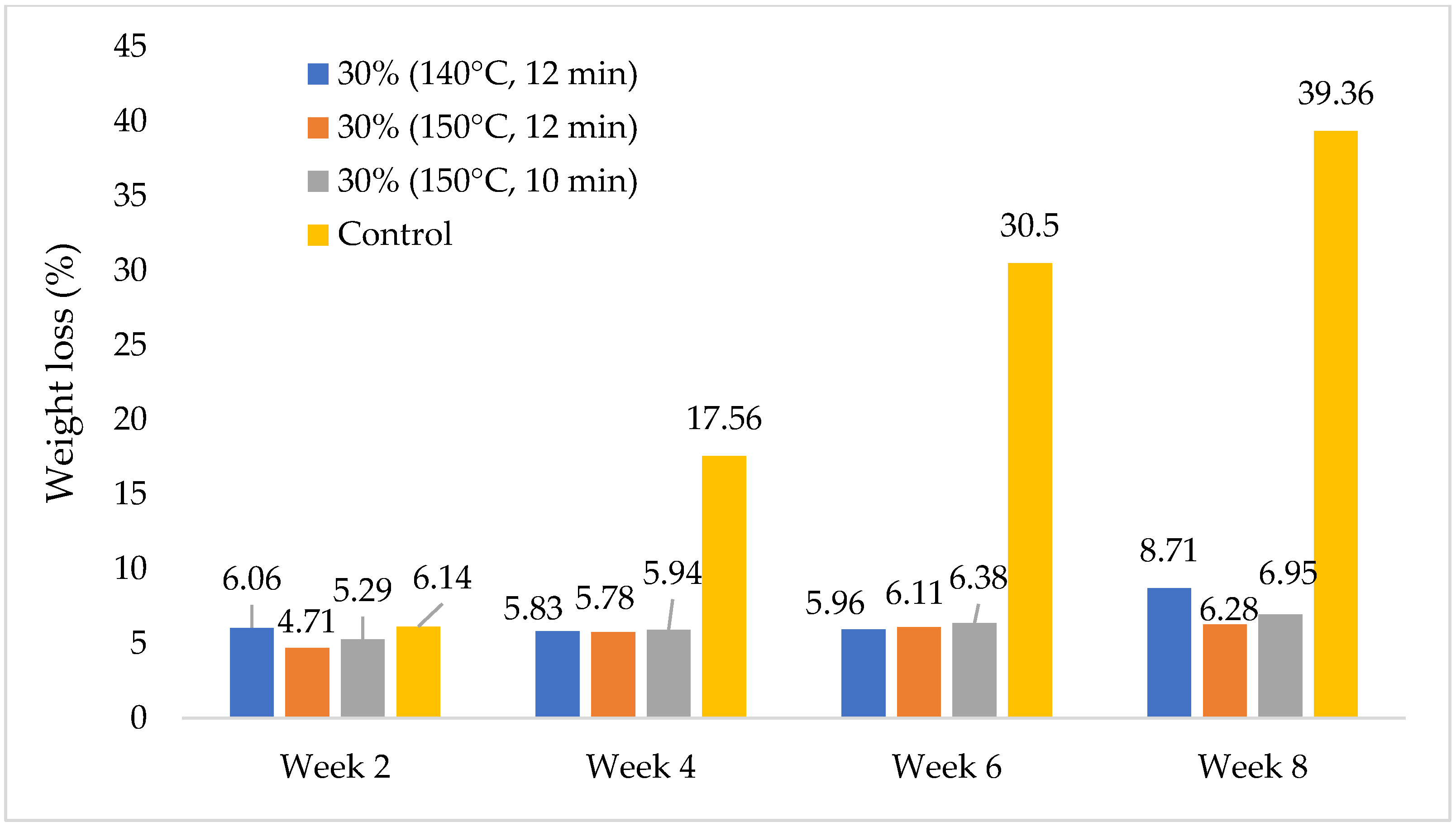

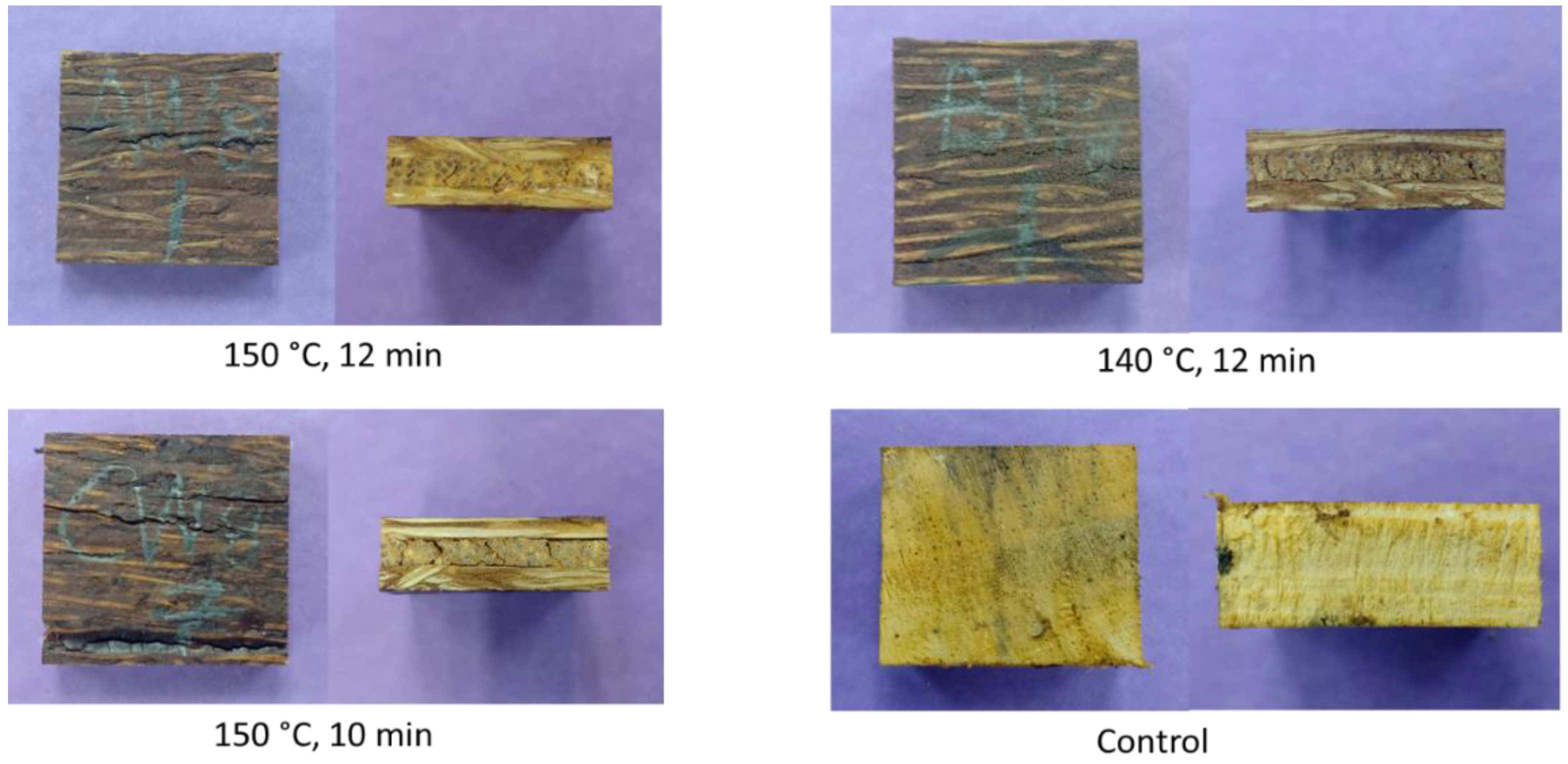

3.4. Decay Resistance of MGE Plywood

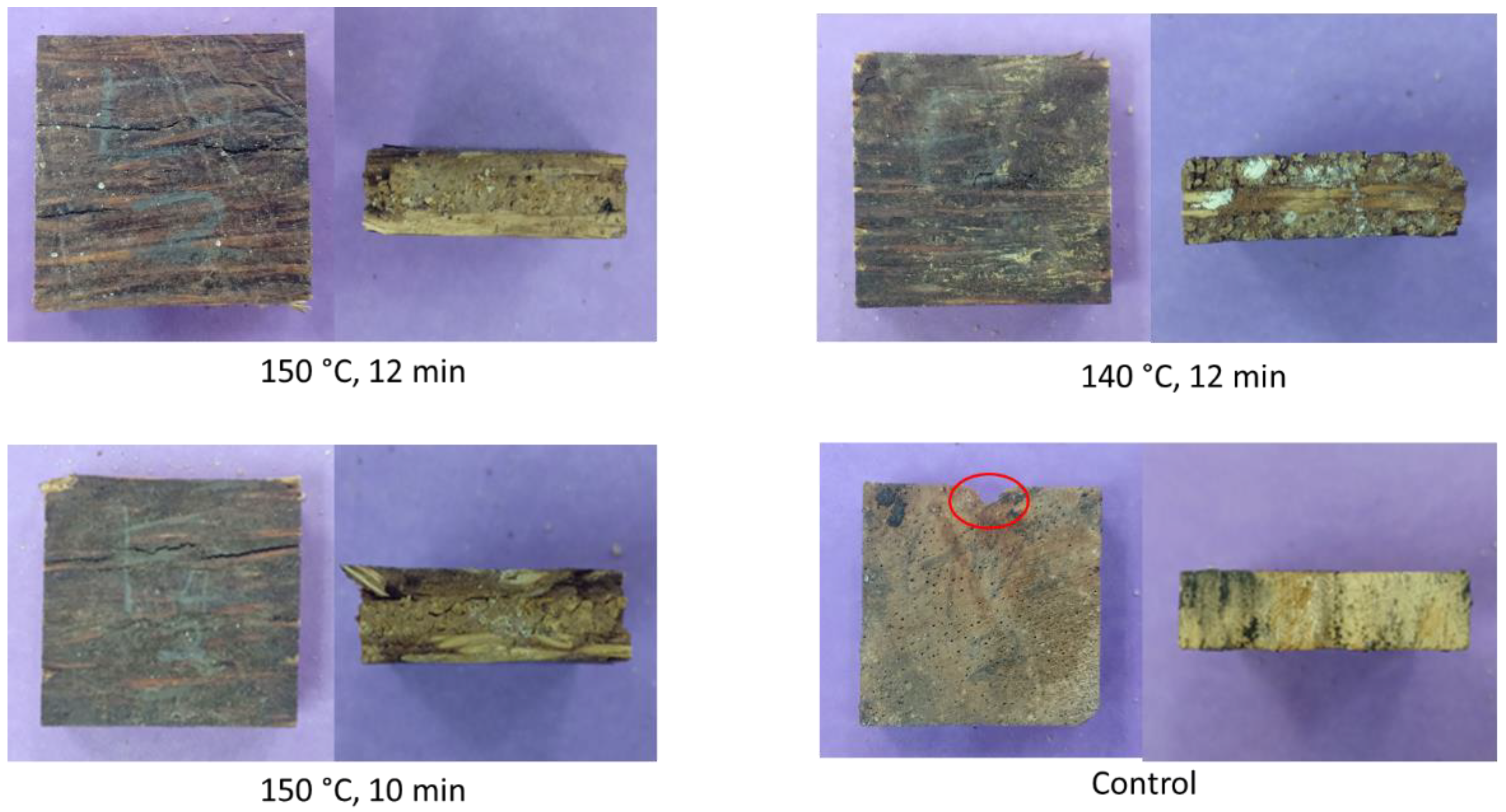

3.5. Termite Resistance of MGE Plywood

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- BS 1088-1; Marine Plywood—Part 1: Requirements. The British Standards Institution: London, UK, 2003.

- Reh, R.; Kristak, L.; Sedliacik, J.; Bekhta, P.; Bozikova, M.; Kunecova, D.; Vozarova, V.; Tudor, E.M.; Antov, P.; Savov, V. Utilization of Birch Bark as an Eco-Friendly Filler in Urea-Formaldehyde Adhesives for Plywood Manufacturing. Polymers 2021, 13, 511. [Google Scholar] [CrossRef] [PubMed]

- Mirski, R.; Dziurka, D.; Łęcka, J. Potential of shortening pressing time or reducing pressing temperature for plywood resinated with PF resin modified using alcohols and esters. Eur. J. Wood Wood Prod. 2011, 69, 317–323. [Google Scholar] [CrossRef]

- Lubis, M.A.R.; Jeong, B.; Park, B.D.; Lee, S.M.; Kang, E.C. Effect of synthesis method and melamine content of melamine-urea-formaldehyde resins on bond-line features in plywood. J. Korean Wood Sci. Technol. 2019, 47, 579–586. [Google Scholar] [CrossRef]

- Zhou, X.; Pizzi, A. Pine tannin based adhesive mixes for plywood. Int. Wood Prod. J. 2014, 5, 27–32. [Google Scholar] [CrossRef]

- Lubis, M.A.R.; Labib, A.; Sudarmanto; Akbar, F.; Nuryawan, A.; Antov, P.; Kristak, L.; Papadopoulos, A.N.; Pizzi, A. Influence of Lignin Content and Pressing Time on Plywood Properties Bonded with Cold-Setting Adhesive Based on Poly (Vinyl Alcohol), Lignin, and Hexamine. Polymers 2022, 14, 2111. [Google Scholar] [CrossRef] [PubMed]

- Lubis, M.A.R.; Yadav, S.M.; Park, B.D. Modification of oxidized starch polymer with nanoclay for enhanced adhesion and free formaldehyde emission of plywood. J. Polym. Environ. 2021, 29, 2993–3003. [Google Scholar] [CrossRef]

- Kristak, L.; Antov, P.; Bekhta, P.; Lubis, M.A.R.; Iswanto, A.H.; Reh, R.; Sedliacik, J.; Savov, V.; Taghiyari, H.R.; Papadopoulos, A.N.; et al. Recent progress in ultra-low formaldehyde emitting adhesive systems and formaldehyde scavengers in wood-based panels: A review. Wood Mater. Sci. Eng. 2022; published online. [Google Scholar] [CrossRef]

- Ghani, A.; Bawon, P.; Ashaari, Z.; Wahab, M.W.; Hua, L.S.; Chen, L.W. Addition of propylamine as formaldehyde scavenger for urea formaldehyde-bonded particleboard. Wood Res. 2017, 62, 329–334. [Google Scholar]

- Ghani, A.; Ashaari, Z.; Bawon, P.; Lee, S.H. Reducing formaldehyde emission of urea formaldehyde-bonded particleboard by addition of amines as formaldehyde scavenger. Build. Environ. 2018, 142, 188–194. [Google Scholar] [CrossRef]

- Ahmed, S.; Mohamed, M.; Mansour, N.; El-Komy, D.; Sadek, E. Modified resol type phenolic resin nanocomposites as surface metal coatings. SPE Polym. 2021, 2, 28–37. [Google Scholar] [CrossRef]

- EN 350; Durability of Wood and Wood-Based Products—Testing and Classification of the Durability to Biological Agents of Wood and Wood-Based Materials. European Committee for Standardization: Brussels, Belgium, 2016.

- Bakar, E.S.; Lee, S.H.; Lum, W.C.; SaifulAzry, S.O.A.; Lee, C.H. Processing of oil palm trunk and lumber. In Oil Palm Biomass for Composite Panels; Sapuan, S.M., Paridah, M.T., Syeed, S.O.A., Lee, S.H., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 113–130. [Google Scholar]

- Mokhtar, A.; Hassan, K.; Aziz, A.A.; Wahid, M. Plywood from oil palm trunks. J. Oil. Palm. Res. 2011, 23, 1159–1165. [Google Scholar]

- Hamzah, N.N.; Bakar, E.S.; Ashaari, Z.; Hua, L.S. Assessment of oil palm wood quality improvement through integrated treatment process as function of sawing pattern and slab thickness. J. Oil. Palm. Res. 2017, 29, 366–372. [Google Scholar] [CrossRef][Green Version]

- Loh, Y.F.; Paridah, M.; Hoong, Y. Density distribution of oil palm stem veneer and its influence on plywood mechanical properties. J. Appl. Sci. 2011, 11, 824–831. [Google Scholar]

- Lamaming, J.; Sulaiman, O.; Sugimoto, T.; Hashim, R.; Said, N.; Sato, M. Influence of chemical components of oil palm on properties of binderless particleboard. Bioresources 2013, 8, 3358–3371. [Google Scholar] [CrossRef]

- Schmidt, O.; Magel, E.; Frühwald, A.; Glukhykh, L.; Erdt, K.; Kaschuro, S. Influence of sugar and starch content of palm wood on fungal development and prevention of fungal colonization by acid treatment. Holzforschung 2016, 70, 783–791. [Google Scholar] [CrossRef]

- Schmidt, O.; Bahmani, M.; Koch, G.; Potsch, T.; Brandt, K. Study of the fungal decay of oil palm wood using TEM and UV techniques. Int. Biodeter. Biodegr. 2016, 111, 37–44. [Google Scholar] [CrossRef]

- Bakar, E.S.; Hao, J.; Ashaari, Z.; Yong, A.C.C. Durability of phenolic-resin-treated oil palm wood against subterranean termites a white-rot fungus. Int. Biodeter. Biodegr. 2013, 85, 126–130. [Google Scholar] [CrossRef]

- Ashaari, Z.; Lee, S.H.; Lum, W.C.; SaifulAzry, S.O.A. Biological durability and deterioration of oil palm biomass. In Oil Palm Biomass for Composite Panels; Sapuan, S.M., Paridah, M.T., Syeed, S.O.A., Lee, S.H., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 57–67. [Google Scholar]

- Loh, Y.F.; Hoong, Y.B.; Norjihan, A.B.; Radzi, B.M.; Fazli, M.M.; Azuar, H.M. Enhancement of manufacturing process and quality for oil palm trunk plywood. In Oil Palm Biomass for Composite Panels; Sapuan, S.M., Paridah, M.T., Syeed, S.O.A., Lee, S.H., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 253–266. [Google Scholar]

- BS 373; Methods of Testing Small Clear Specimens of Timber. The British Standards Institution: London, UK, 1957.

- ISO 12466-1; Plywood—Bonding Quality—Part 1: Test Methods. International Organization for Standardization: London, UK, 2007.

- AWPA E10-16; Laboratory Method for Evaluating the Decay Resistance of Wood-Based Materials against Pure Basidiomycete Cultures: Soil/Block Test. American Wood Protection Association: Hoover, AL, USA, 2022.

- AWPA E1-17; Laboratroy Methods for Evaluating the Termite Resistance of Wood-Based Materials: Choice and No-choice Tests. American Wood Protection Association: Hoover, AL, USA, 2017.

- Purba, T.P.; Zaidon, A.; Bakar, E.S.; Paridah, M.T. Effects of Processing Factors and Polymer Retention on the Performance of Phenolic treated Wood. J. Trop. For. Sci. 2014, 26, 320–330. [Google Scholar]

- Wang, H.; Zhao, Y. Studies on pre-treatment by compression for wood impregnation III: Effects of the solid content of low-molecular-weight phenol formaldehyde resin on the impregnation. J. Wood Sci. 2022, 68, 28. [Google Scholar] [CrossRef]

- Li, H.; Li, C.; Chen, H.; Zhang, D.; Zhang, S.; Li, J. Effects of hot-pressing parameters on shear strength of plywood bonded with modified soy protein adhesives. BioResources 2014, 9, 5858–5870. [Google Scholar] [CrossRef]

- ISO 12466-2; Plywood—Bonding Quality—Part 2: Requirements. International Organization for Standardization: London, UK, 2007.

- Lee, S.H.; Ashaari, Z. Durability of phenolic-resin-treated sesenduk (Endospermum diadenum) and jelutong (Dyera costulata) wood against white rot fungus. Eur. J. Wood Wood Prod. 2015, 73, 553–555. [Google Scholar] [CrossRef]

- Mourant, D.; Yang, D.Q.; Roy, C. Decay resistance of pf-pyrolytic oil resin-treated wood. For. Prod. J. 2007, 57, 30–35. [Google Scholar]

- Nabil, F.L.; Zaidon, A.; Anwar, U.M.K.; Bakar, E.S.; Lee, S.H.; Paridah, M.T. Impregnation of sesenduk (Endospermum diadenum) wood with phenol formaldehyde and nanoclay admixture: Effect on fungal decay and termites attack. Sains Malays. 2016, 45, 255–262. [Google Scholar]

- Trisatya, D.R.; Satiti, E.R.; Indrawan, D.A.; Tampubolon, R.M. Durability of fiber boards made of jabon and andong bamboo with additional activated carbon additives against dry wood termites and subterranean termites. IOP Conf. Ser. Earth Environ. Sci. 2020, 415, 012004. [Google Scholar] [CrossRef]

- Kajita, H.; Imamura, Y. Improvement of physical and biological properties of particleboards by impregnation with phenolic resin. Wood Sci. Technol. 1991, 26, 63–70. [Google Scholar] [CrossRef]

- Deka, M.; Saikia, C.N.; Baruah, K.K. Treatment of wood with thermosetting resins: Effects on dimensional stability, strength and termite resistance. Indian J. Chem. Technol. 2000, 7, 312–317. [Google Scholar]

- Delaplane, K.S.; La Fage, J.P. Foraging tenacity of Reticulitermes flavipes and Coptotermes formosanus (Isoptera: Rhinotermitidae). Sociobiology 1989, 16, 183–189. [Google Scholar]

- Kulis, J.; Sajap, A.S.; Loong, C.Y. Effect of moisture and relative humidity on survival and feeding activity of the Asian subterranean termite Coptotermes gestroi (Isoptera: Rhinotermitidae). Sociobiology 2008, 52, 579–587. [Google Scholar]

- Bari, E.; Taghiyari, H.R.; Schmidt, O.; Ghorbani, A.; Aghababaei, H. Effects of nano-clay on biological resistance of wood plastic composite against five wood-deteriorating fungi. Maderas Cienc. Tecnol. 2015, 17, 205–212. [Google Scholar] [CrossRef]

| Parameters | Solid Content (%) | Soaking Time under Pressure (min) | Pressing Temperature (°C) | Pressing Time (min) |

|---|---|---|---|---|

| A | 30 | 15 | 140 | 12 |

| B | 30 | 15 | 150 | 12 |

| C | 30 | 15 | 150 | 10 |

| Solid Content (%) | Soaking Time (min) | Pressing Temp. (°C) | Pressing Time (min) | Density (kg/m3) | Thickness Swelling (%) | Water Absorption (%) |

|---|---|---|---|---|---|---|

| 30 | 15 | 140 | 12 | 651 | 6.1 | 57 |

| 30 | 15 | 150 | 12 | 474 | 4.04 | 101 |

| 30 | 15 | 150 | 10 | 628 | 5.04 | 67 |

| Solid Content (%) | Soaking Time (min) | Pressing Temp. (°C) | Pressing Time (min) | Dry Shear (MPa) | 24 h Cold Soak Shear (MPa) | 6 h Boil Shear (MPa) | BDB Shear (MPa) |

|---|---|---|---|---|---|---|---|

| 30 | 15 | 140 | 12 | 3.71 | 2.98 | 2.63 | 1.55 |

| 30 | 15 | 150 | 12 | 0.52 | Sample Failed | - | - |

| 30 | 15 | 150 | 10 | 2.13 | 2.34 | 1.93 | 0.95 |

| Solid Content (%) | Soaking Time (min) | Pressing Temp. (°C) | Pressing Time (min) | MOR (MPa) | MOE (MPa) |

|---|---|---|---|---|---|

| 30 | 15 | 140 | 12 | 38.85 | 5120 |

| 30 | 15 | 150 | 12 | 32.19 | 4110 |

| 30 | 15 | 150 | 10 | 31.03 | 4400 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Che Ismail, A.; Salim, S.; Md Tahir, P.; Lee, S.H.; Abd Ghani, M.A.; Al Edrus, S.S.; Ahmad Faisal, F.Q. Properties Enhancement of Oil Palm Trunk Plywood against Decay and Termite for Marine Applications. Polymers 2022, 14, 2680. https://doi.org/10.3390/polym14132680

Che Ismail A, Salim S, Md Tahir P, Lee SH, Abd Ghani MA, Al Edrus SS, Ahmad Faisal FQ. Properties Enhancement of Oil Palm Trunk Plywood against Decay and Termite for Marine Applications. Polymers. 2022; 14(13):2680. https://doi.org/10.3390/polym14132680

Chicago/Turabian StyleChe Ismail, Atikah, Sabiha Salim, Paridah Md Tahir, Seng Hua Lee, Muhammad Aizat Abd Ghani, Syeed SaifulAzry Al Edrus, and Fadhlin Qayyum Ahmad Faisal. 2022. "Properties Enhancement of Oil Palm Trunk Plywood against Decay and Termite for Marine Applications" Polymers 14, no. 13: 2680. https://doi.org/10.3390/polym14132680

APA StyleChe Ismail, A., Salim, S., Md Tahir, P., Lee, S. H., Abd Ghani, M. A., Al Edrus, S. S., & Ahmad Faisal, F. Q. (2022). Properties Enhancement of Oil Palm Trunk Plywood against Decay and Termite for Marine Applications. Polymers, 14(13), 2680. https://doi.org/10.3390/polym14132680