Numerical and Experimental Analysis of Mechanical Properties of Natural-Fiber-Reinforced Hybrid Polymer Composites and the Effect on Matrix Material

Abstract

:1. Introduction

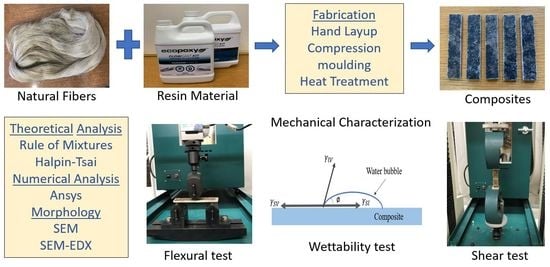

2. Materials and Methods

2.1. Materials

2.2. Preparation of Reinforcement and Matrix Materials

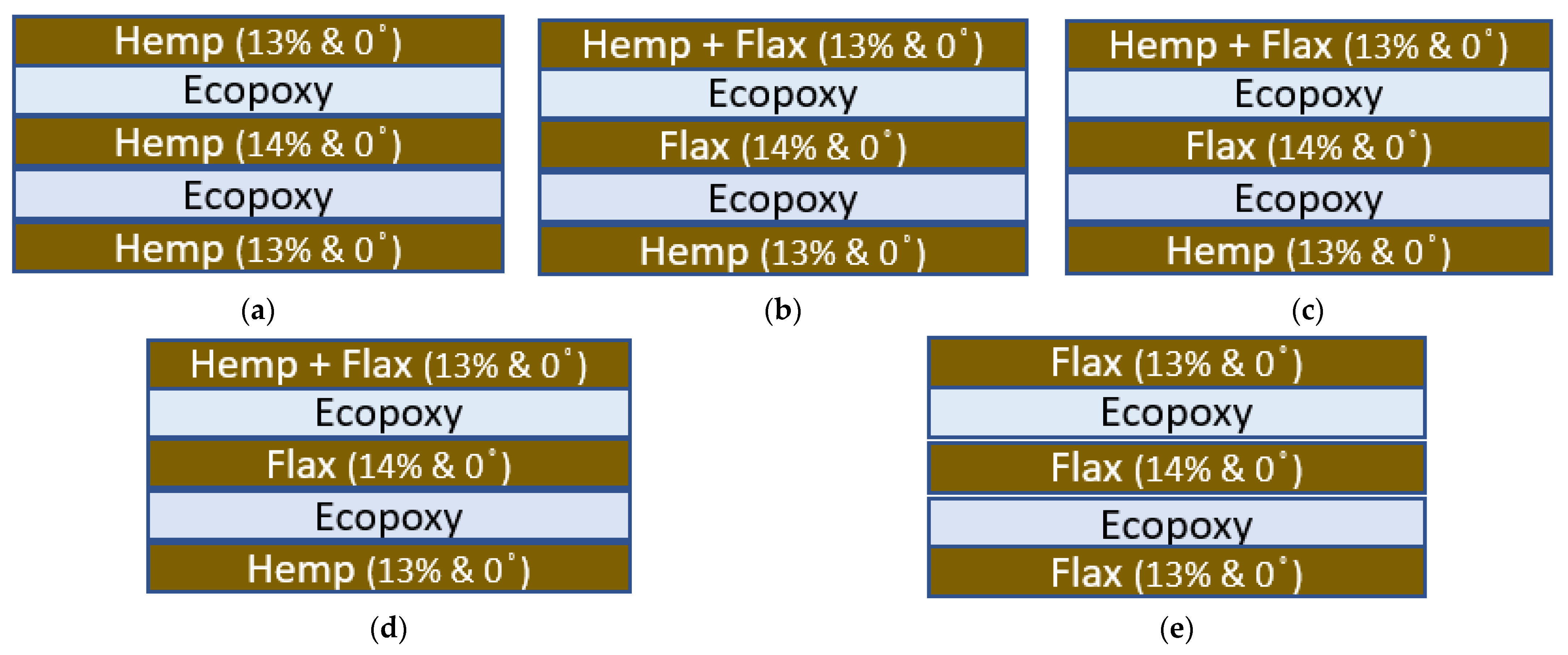

2.3. Composite Sample Preparation

2.4. Characterization Methods

2.4.1. Flexural Test

2.4.2. Interlaminar Shear Test

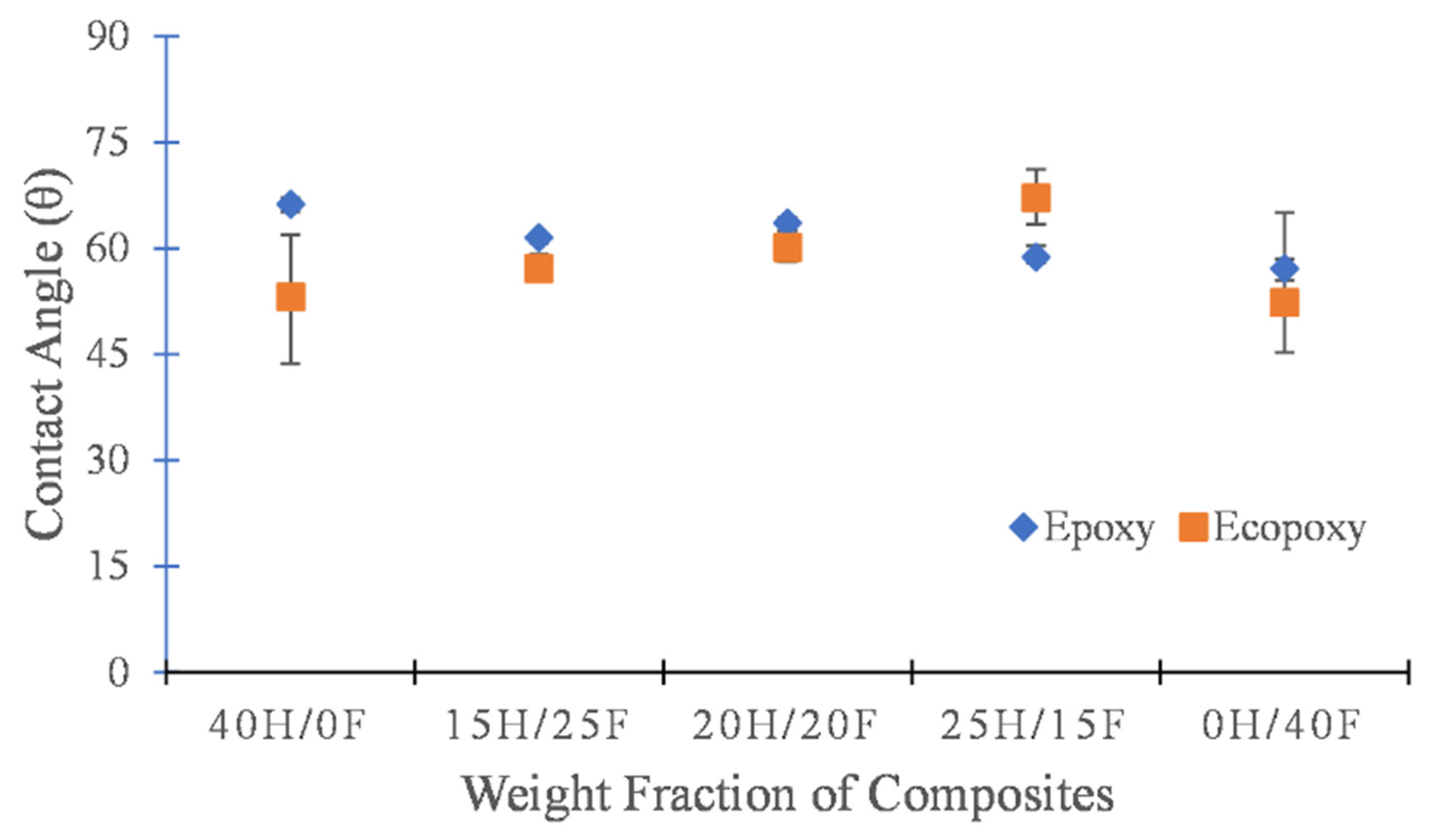

2.4.3. Wettability Test

2.4.4. SEM Energy Dispersive X-ray Spectrum Analysis

2.5. Numerical Analysis

3. Results

3.1. Flexural Properties

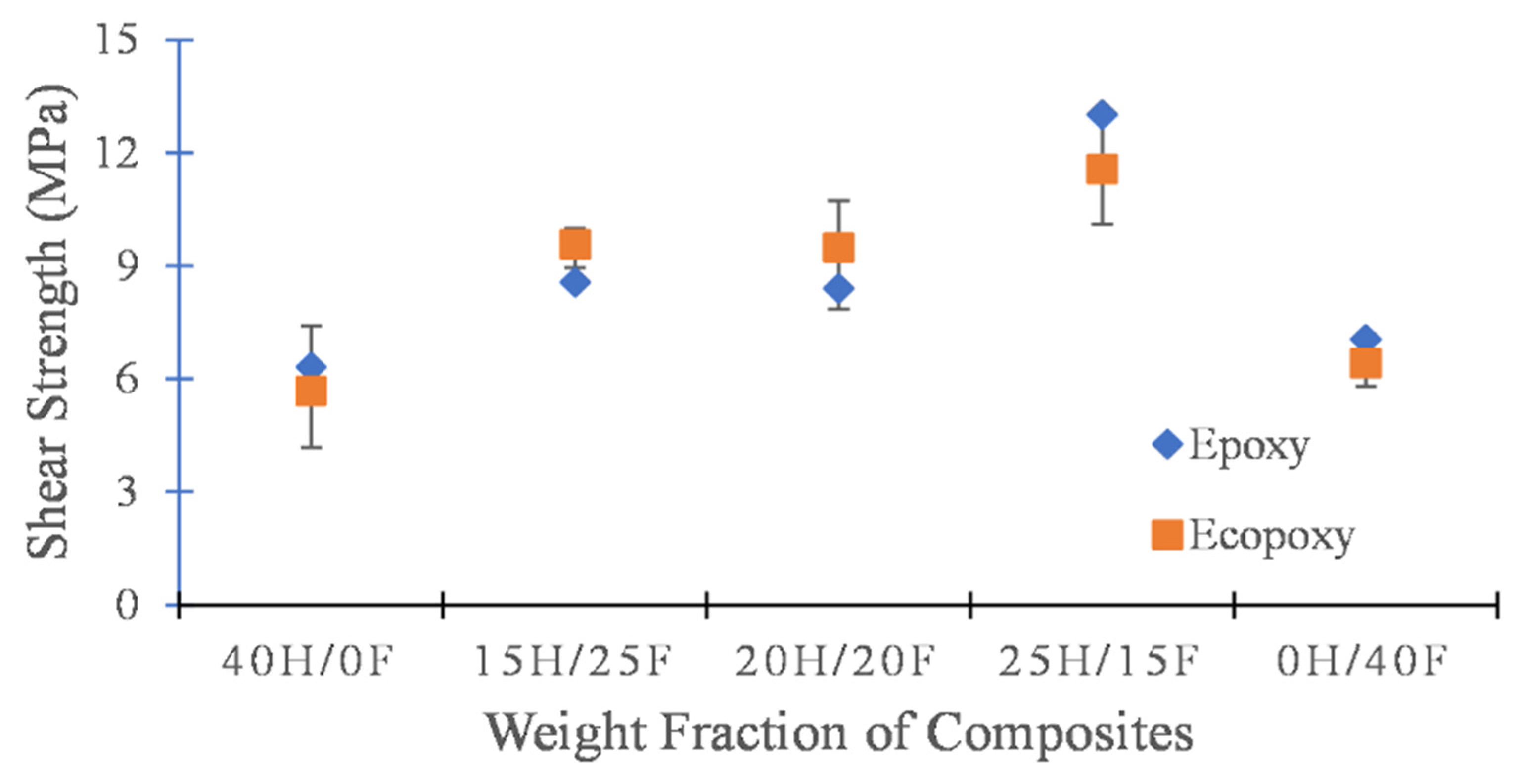

3.2. Interlaminar Shear Properties

3.3. Wettability Analysis

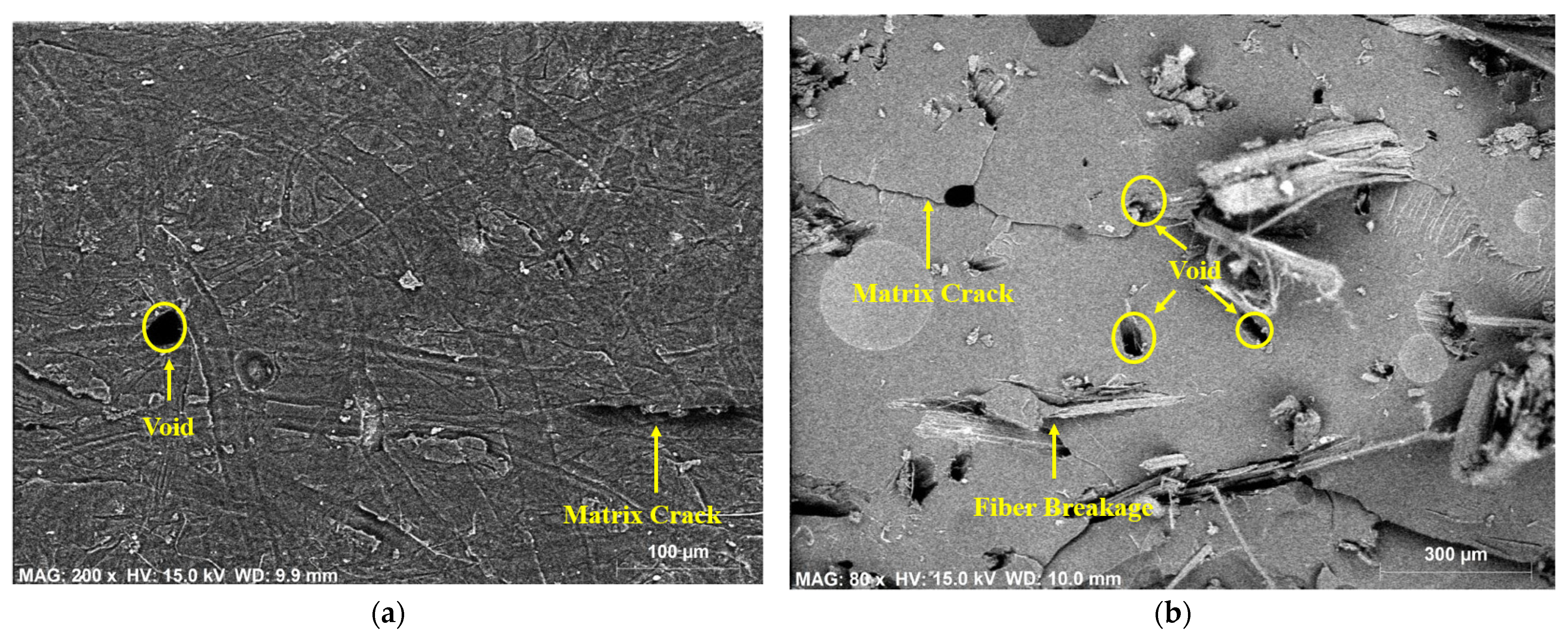

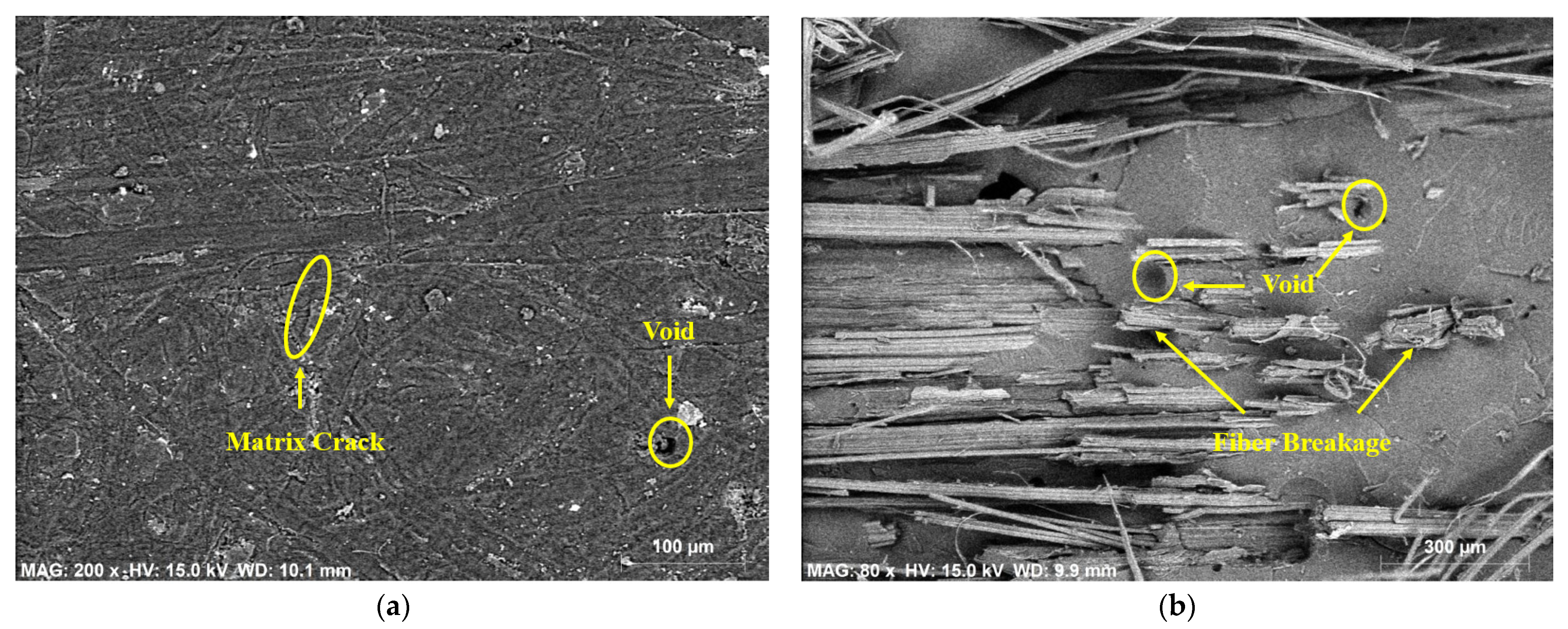

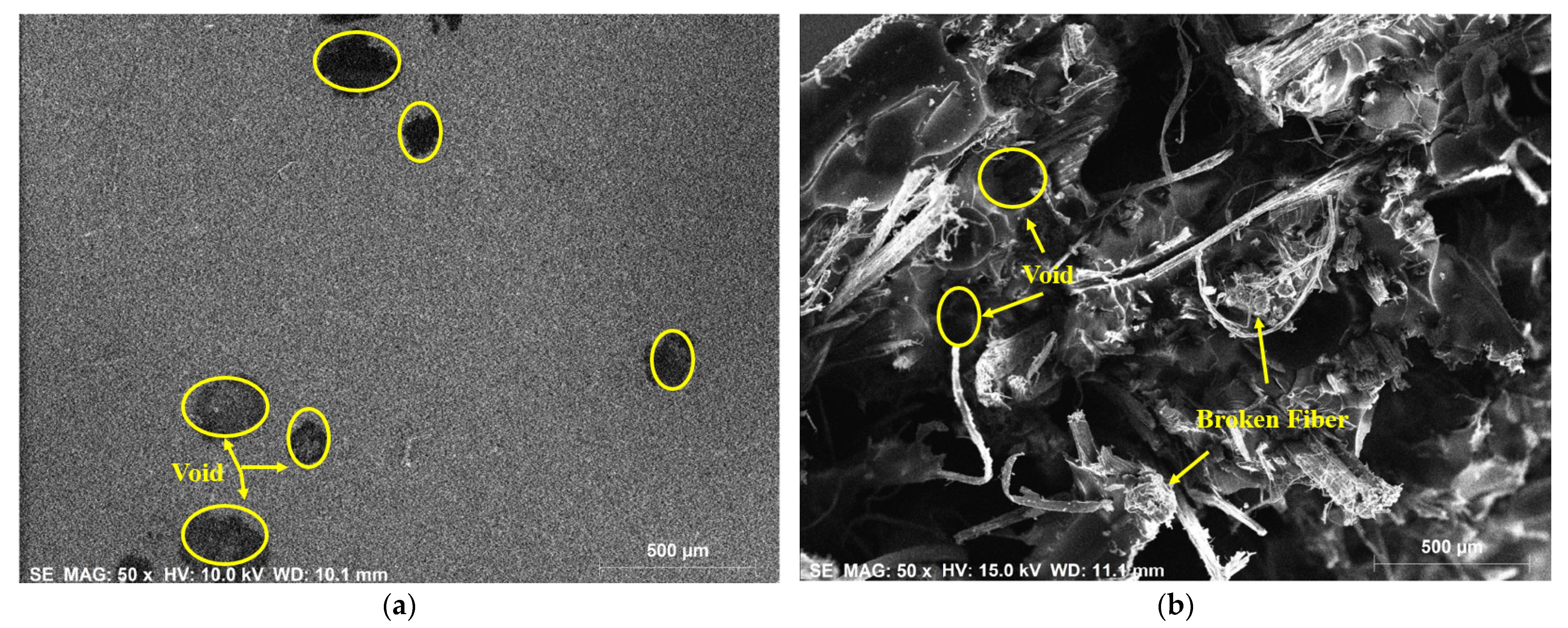

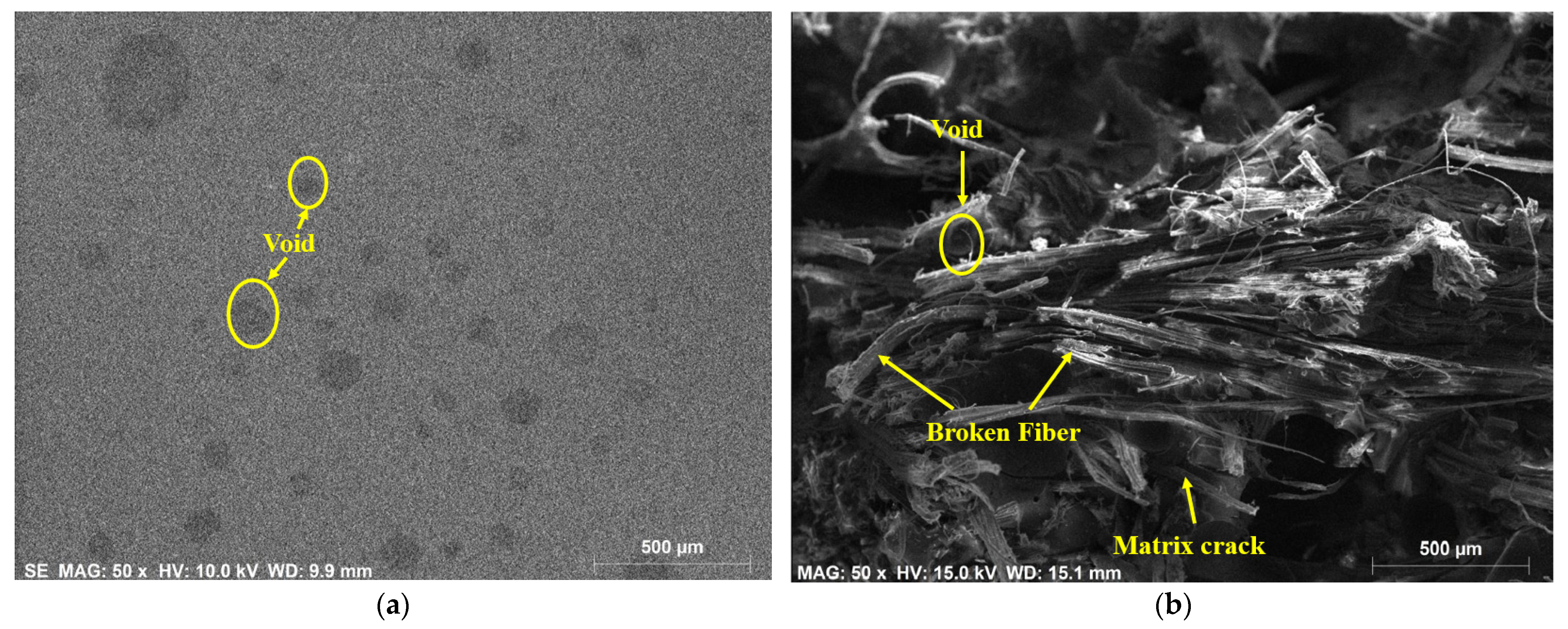

3.4. SEM-EDX Analysis

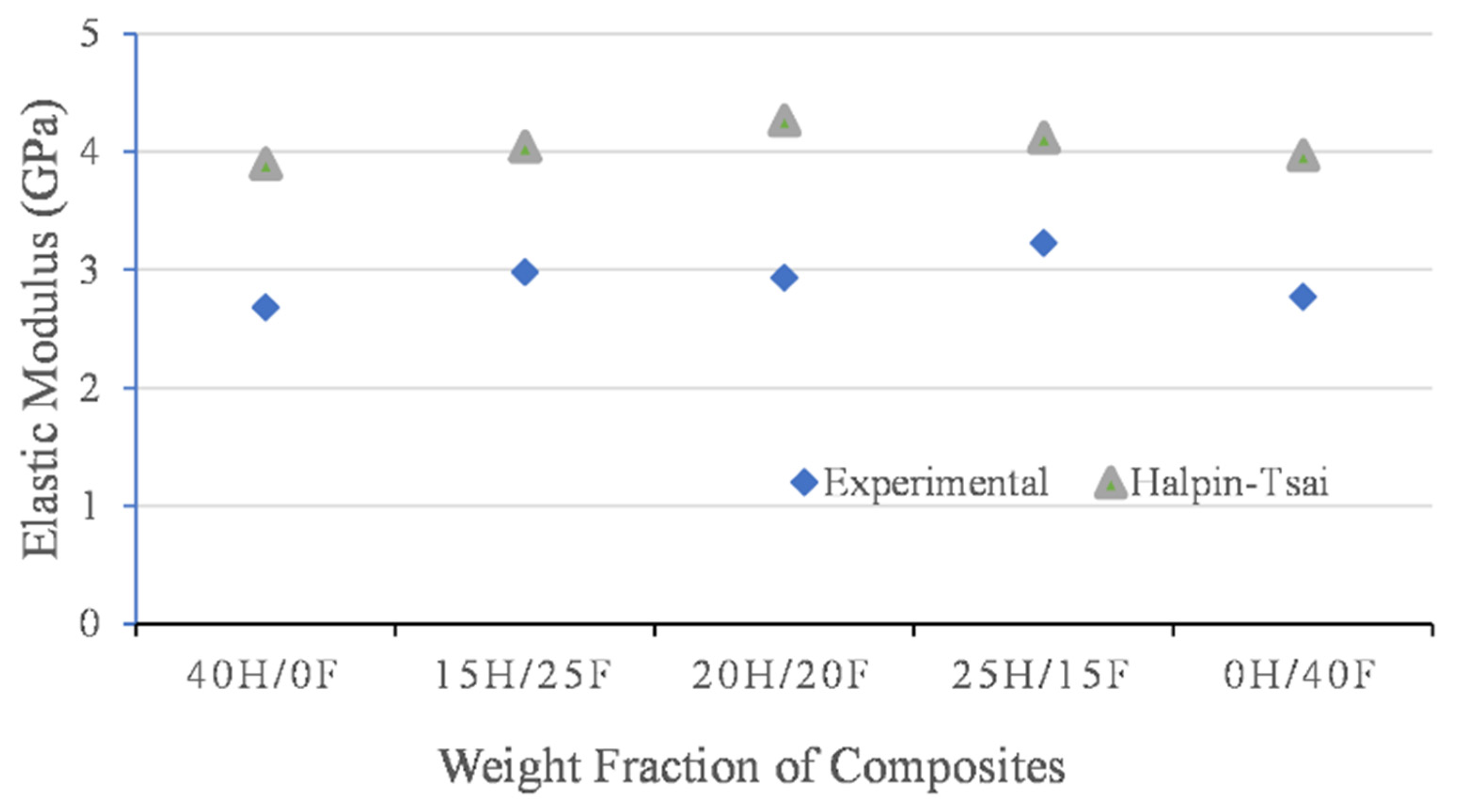

3.5. Numerical Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Terwadkar, A.A.; Walame, M.V. Mechanical Properties of Banana Fabric and Kenaf Fiber Reinforced Epoxy Composites: Effect of Treatment and Hybridization. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 1870–1874. [Google Scholar]

- Bhoopathi, R.; Deepa, C.; Sasikala, G.; Ramesh, M. Experimental Investigation on Mechanical Properties of Hemp-Banana-Glass Fiber Reinforced Composites. Appl. Mech. Mater. 2015, 766–767, 167–172. [Google Scholar]

- Gokuldass, R.; Ramesh, R. Mechanical Strength Behavior of Hybrid Composites Tailored by Glass/Kevlar Fibre-Reinforced in Nano-Silica and Micro-Rubber Blended Epoxy. Silicon 2019, 11, 2731–2739. [Google Scholar] [CrossRef]

- Ramakrishnan, G.; Ramnath, B.V.; Elanchezhian, C.; Kumar, A.A.; Gowtham, S. Investigation of Mechanical Behaviour of Basalt-Banana Hybrid Composites. Silicon 2019, 11, 1939–1948. [Google Scholar] [CrossRef]

- Sinha, A.K.; Narang, H.K.; Bhattacharya, S. Mechanical properties of natural fibre polymer composites. J. Polym. Eng. 2017, 37, 879–895. [Google Scholar] [CrossRef]

- Väisänen, T.; Batello, P.; Lappalainen, R.; Tomppo, L. Modification of hemp fibers (Cannabis sativa L.) for composite applications. Ind. Crops Prod. 2018, 111, 422–429. [Google Scholar] [CrossRef]

- Pandey, J.K.; Ahn, S.H.; Lee, C.S.; Mohanty, A.K.; Misra, M. Recent Advances in the Application of Natural Fiber Based Composites. Macromol. Mater. Eng. 2010, 295, 975–989. [Google Scholar] [CrossRef]

- Bodros, E.; Pillin, I.; Montrelay, N.; Baley, C. Could biopolymers reinforced by randomly scattered flax fibre be used in structural applications? Compos. Sci. Technol. 2007, 67, 462–470. [Google Scholar] [CrossRef]

- Agung, E.H.; Sapuan, S.M.; Megat Ahmad, M.M.H.; Zaman, D.K.M.; Mustofa, U. Investigation of Hardness of Short Abaca (Musa Textile Nee) Fibre-Reinforced High Impact Polystyrene (HIPS) Composites by Response Surface Methodology. Key Eng. Mater. 2011, 471–472, 821–826. [Google Scholar]

- Mochane, M.J.; Mokhena, T.C.; Mokhothu, T.H.; Mtibe, A.; Sadiku, E.R.; Ray, S.S.; Ibrahim, I.D.; Daramola, O.O. Recent progress on natural fiber hybrid composites for advanced applications: A review. Express Polym. Lett. 2019, 13, 159–198. [Google Scholar] [CrossRef]

- Li, Y.; Hu, C.; Yu, Y. Interfacial studies of sisal fiber reinforced high density polyethylene (HDPE) composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 570–578. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and properties of natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 2018, 172, 566–581. [Google Scholar] [CrossRef]

- Singha, A.S.; Thakur, V.K. Synthesis and Characterization of Pine Needles Reinforced RF Matrix Based Biocomposites. E-J. Chem. 2008, 5, 1055–1062. [Google Scholar] [CrossRef]

- Messana, A.; Airale, A.G.; Ferraris, A.; Sisca, L.; Carello, M. Correlation between thermo-mechanical properties and chemical composition of aged thermoplastic and thermosetting fiber reinforced plastic materials. Mater. Werkst. 2017, 48, 447–455. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Azwa, Z.N.; Yousif, B.F. Characteristics of kenaf fibre/epoxy composites subjected to thermal degradation. Polym. Degrad. Stab. 2013, 98, 2752–2759. [Google Scholar] [CrossRef]

- He, H.; Li, K.; Wang, J.; Sun, G.; Li, Y.; Wang, J. Study on thermal and mechanical properties of nano-calcium carbonate/epoxy composites. Mater. Des. 2011, 32, 4521–4527. [Google Scholar] [CrossRef]

- George, J.; Sreekala, M.S.; Thomas, S. A review on interface modification and characterization of natural fiber reinforced plastic composites. Polym. Eng. Sci. 2001, 41, 1471–1485. [Google Scholar] [CrossRef]

- Manteghi, S.; Mahboob, Z.; Fawaz, Z.; Bougherara, H. Investigation of the mechanical properties and failure modes of hybrid natural fiber composites for potential bone fracture fixation plates. J. Mech. Behav. Biomed. Mater. 2017, 65, 306–316. [Google Scholar] [CrossRef]

- Ramadan, N.; Taha, I.; Hammouda, R.; Abdellatif, M.H. Behaviour of Hybrid SiC/Jute Epoxy Composites Manufactured by Vacuum Assisted Resin Infusion. Polym. Polym. Compos. 2017, 25, 333–344. [Google Scholar] [CrossRef]

- Yusoff, R.B.; Takagi, H.; Nakagaito, A.N. Tensile and flexural properties of polylactic acid-based hybrid green composites reinforced by kenaf, bamboo and coir fibers. Ind. Crops Prod. 2016, 94, 562–573. [Google Scholar] [CrossRef]

- Nunna, S.; Chandra, P.R.; Shrivastava, S.; Jalan, A. A review on mechanical behavior of natural fiber based hybrid composites. J. Reinf. Plast. Compos. 2012, 31, 759–769. [Google Scholar] [CrossRef]

- Dong, C. Mechanical properties of natural fibre-reinforced hybrid composites. J. Reinf. Plast. Compos. 2019, 38, 910–922. [Google Scholar] [CrossRef]

- Tang, J.; Swolfs, Y.; Longana, M.L.; Yu, H.; Wisnom, M.R.; Lomov, S.V.; Gorbatikh, L. Hybrid composites of aligned discontinuous carbon fibers and self-reinforced polypropylene under tensile loading. Compos. Part A Appl. Sci. Manuf. 2019, 123, 97–107. [Google Scholar] [CrossRef]

- Kureemun, U.; Ravandi, M.; Tran, L.Q.N.; Teo, W.S.; Tay, T.E.; Lee, H.P. Effects of hybridization and hybrid fibre dispersion on the mechanical properties of woven flax-carbon epoxy at low carbon fibre volume fractions. Compos. Part B Eng. 2018, 134, 28–38. [Google Scholar] [CrossRef]

- Premkumar, T.; Siva, I.; Amico, S.C. Inter and intralayer basalt hybrid effects on the static and vibrational behaviors of Brazilian curauá/basalt hybrid composite. Mater. Today Proc. 2020, 33, 1212–1215. [Google Scholar] [CrossRef]

- Dong, C. Review of natural fibre-reinforced hybrid composites. J. Reinf. Plast. Compos. 2018, 37, 331–348. [Google Scholar] [CrossRef] [Green Version]

- Marques, G.; Rencoret, J.; Gutiérrez, A.; del Río, J.C. Evaluation of the Chemical Composition of Different Non-Woody Plant Fibers Used for Pulp and Paper Manufacturing. Open Agric. J. 2010, 4, 93–101. [Google Scholar] [CrossRef] [Green Version]

- Komuraiah, A.; Kumar, N.S.; Prasad, B.D. Chemical Composition of Natural Fibers and its Influence on their Mechanical Properties. Mech. Compos. Mater. 2014, 50, 359–376. [Google Scholar] [CrossRef]

- Wang, X.; Xie, J.; Zhang, H.; Zhang, W.; An, S.; Chen, S.; Luo, C. Determining the lignin distribution in plant fiber cell walls based on chemical and biological methods. Cellulose 2019, 26, 4241–4252. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Valenza, A. Characterization of a new natural fiber from Arundo donax L. as potential reinforcement of polymer composites. Carbohydr. Polym. 2014, 106, 77–83. [Google Scholar] [CrossRef] [PubMed]

- Chokshi, S.; Parmar, V.; Gohil, P.; Chaudhary, V. Chemical Composition and Mechanical Properties of Natural Fibers. J. Nat. Fibers 2020, 17, 1–12. [Google Scholar] [CrossRef]

- Riccio, A.; Raimondo, A.; Saputo, S.; Sellitto, A.; Battaglia, M.; Petrone, G. A numerical study on the impact behaviour of natural fibres made honeycomb cores. Compos. Struct. 2018, 202, 909–916. [Google Scholar] [CrossRef]

- Karimah, A.; Ridho, M.R.; Munawar, S.S.; Adi, D.S.; Ismadi; Damayanti, R.; Subiyanto, B.; Fatriasari, W.; Fudholi, A. A review on natural fibers for development of eco-friendly bio-composite: Characteristics, and utilizations. J. Mater. Res. Technol. 2021, 13, 2442–2458. [Google Scholar] [CrossRef]

- Pan, Y.; Zhong, Z. A micromechanical model for the mechanical degradation of natural fiber reinforced composites induced by moisture absorption. Mech. Mater. 2015, 85, 7–15. [Google Scholar] [CrossRef]

- Neves, A.C.C.; Rohen, L.A.; Mantovani, D.P.; Carvalho, J.P.R.G.; Vieira, C.M.F.; Lopes, F.P.D.; Simonassi, N.T.; da Luz, F.S.; Monteiro, S.N. Comparative mechanical properties between biocomposites of Epoxy and polyester matrices reinforced by hemp fiber. J. Mater. Res. Technol. 2020, 9, 1296–1304. [Google Scholar] [CrossRef]

- Sapuan, S.M.; Leenie, A.; Harimi, M.; Beng, Y.K. Mechanical properties of woven banana fibre reinforced epoxy composites. Mater. Des. 2006, 27, 689–693. [Google Scholar] [CrossRef]

- Sharavanan, R. A Review on Natural Fiber Hybrid Composites. Int. J. Mech. Prod. Eng. Res. Dev. 2018, 8, 943–948. [Google Scholar]

- Abedom, F.; Sakthivel, S.; Asfaw, D.; Melese, B.; Solomon, E.; Kumar, S.S. Development of Natural Fiber Hybrid Composites Using Sugarcane Bagasse and Bamboo Charcoal for Automotive Thermal Insulation Materials. Adv. Mater. Sci. Eng. 2021, 2021, 2508840. [Google Scholar] [CrossRef]

- Summerscales, J.; Virk, A.; Hall, W. A review of bast fibres and their composites: Part 3—Modelling. Compos. Part A Appl. Sci. Manuf. 2013, 44, 132–139. [Google Scholar] [CrossRef] [Green Version]

- Alhazmi, W.H.; Jazaa, Y.; Mousa, S.; Abd-Elhady, A.A.; Sallam, H.E.M. Tribological and Mechanical Properties of Epoxy Reinforced by Hybrid Nanoparticles. Lat. Am. J. Solids Struct. 2021, 18, e361. [Google Scholar] [CrossRef]

- Singh, S.; Deepak, D.; Aggarwal, L.; Gupta, V.K. Tensile and Flexural Behavior of Hemp Fiber Reinforced Virgin-recycled HDPE Matrix Composites. Procedia Mater. Sci. 2014, 6, 1696–1702. [Google Scholar] [CrossRef] [Green Version]

- Moudood, A.; Rahman, A.; Huq, N.M.L.; Öchsner, A.; Islam, M.M.; Francucci, G. Mechanical properties of flax fiber-reinforced composites at different relative humidities: Experimental, geometric, and displacement potential function approaches. Polym. Compos. 2020, 41, 4963–4973. [Google Scholar] [CrossRef]

- Zhong, Y.; Kureemun, U.; Tran, L.Q.N.; Lee, H.P. Natural Plant Fiber Composites-Constituent Properties and Challenges in Numerical Modeling and Simulations. Int. J. Appl. Mech. 2017, 9, 1750045. [Google Scholar] [CrossRef]

- BEHZAD, T.; SAIN, M. Finite element modeling of polymer curing in natural fiber reinforced composites. Compos. Sci. Technol. 2007, 67, 1666–1673. [Google Scholar] [CrossRef]

- José da Silva, L.; Hallak Panzera, T.; Luis Christoforo, A.; Miguel Pereira Dur, L.; Antonio Rocco Lahr, F. Numerical and Experimental Analyses of Biocomposites Reinforced with Natural Fibres. Int. J. Mater. Eng. 2012, 2, 43–49. [Google Scholar] [CrossRef] [Green Version]

- Sathishkumar, G.K.; Mohamed Akheel, M.; Ibrahim, M.; Rajkumar, G.; Karpagam, R.; Gopinath, B. Experimental and Finite Element Analysis of Lignite Fly Ash on the Mechanical Properties of Sisal-added Polymer Matrix Composite Using ANSYS Workbench. J. Nat. Fibers. 2021, 18, 1–25. [Google Scholar] [CrossRef]

- Prasanthi, P.P.; Babu, K.S.; Niranjan Kumar, M.S.R.; Kumar, A.E. Analysis of Sisal Fiber Waviness Effect on the Elastic Properties of Natural Composites Using Analytical and Experimental Methods. J. Nat. Fibers. 2021, 18, 1675–1688. [Google Scholar] [CrossRef]

- Balasubramanian, K.; Rajeswari, N.; Vaidheeswaran, K. Analysis of mechanical properties of natural fibre composites by experimental with FEA. Mater. Today Proc. 2019, 28, 1149–1153. [Google Scholar] [CrossRef]

- Gupta, M.K.; Ramesh, M.; Thomas, S. Effect of hybridization on properties of natural and synthetic fiber-reinforced polymer composites (2001–2020): A review. Polym. Compos. 2021, 42, 4981–5010. [Google Scholar] [CrossRef]

- Khan, M.Z.R.; Srivastava, S.K.; Gupta, M. Tensile and flexural properties of natural fiber reinforced polymer composites: A review. J. Reinf. Plast. Compos. 2018, 37, 1435–1455. [Google Scholar] [CrossRef]

- Aji, I.; Zainudin, E.; Abdan, K.; Sapuan, S.; Khairul, M. Mechanical properties and water absorption behavior of hybridized kenaf/pineapple leaf fibre-reinforced high-density polyethylene composite. J. Compos. Mater. 2013, 47, 979–990. [Google Scholar] [CrossRef]

- ASTM D-790; Standard Test Method for 3-Point Flexure Tests on Rigid and Semi-Rigid Plastics as Well as on Fiber Composites with Long-Fiber Reinforcements. ASTM International: West Conshohocken, PA, USA, 2003.

- ASTM D-3846-02; Standard Test Method for in Plane Shear Strength of Reinforced Plastics. ASTM International: West Conshohocken, PA, USA, 2005.

- Prakash, S.; Yeom, J. Interfaces in Microfluidic and Nanofluidic Systems. In Nano fluidics Microfluid; Elsevier: Amsterdam, The Netherlands, 2014; pp. 39–86. [Google Scholar]

- Esmonde-White, K.A.; Esmonde-White, F.W.L.; Morris, M.D.; Roessler, B.J. Characterization of biofluids prepared by sessile drop formation. Analyst 2014, 139, 2734–2741. [Google Scholar] [CrossRef] [Green Version]

- Skedros, J.G.; Knight, A.N.; Clark, G.C.; Crowder, C.M.; Dominguez, V.M.; Qiu, S.; Mulhern, D.M.; Donahue, S.W.; Busse, B.; Hulsey, B.I.; et al. Scaling of Haversian canal surface area to secondary osteon bone volume in ribs and limb bones. Am. J. Phys. Anthropol. 2013, 151, 230–244. [Google Scholar] [CrossRef]

- Tham, M.W.; Fazita, M.N.; Abdul Khalil, H.P.S.; Mahmud Zuhudi, N.Z.; Jaafar, M.; Rizal, S.; Haafiz, M.M. Tensile properties prediction of natural fibre composites using rule of mixtures: A review. J. Reinf. Plast. Compos. 2019, 38, 211–248. [Google Scholar] [CrossRef]

- Zhao, S.; Zhao, Z.; Yang, Z.; Ke, L.; Kitipornchai, S.; Yang, J. Functionally graded graphene reinforced composite structures: A review. Eng. Struct. 2020, 210, 110339. [Google Scholar] [CrossRef]

- Facca, A.G.; Kortschot, M.T.; Yan, N. Predicting the elastic modulus of natural fibre reinforced thermoplastics. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1660–1671. [Google Scholar] [CrossRef]

- Sathishkumar, T.P.; Navaneethakrishnan, P.; Shankar, S.; Rajasekar, R. Mechanical properties and water absorption of short snake grass fiber reinforced isophthallic polyester composites. Fibers Polym. 2014, 15, 1927–1934. [Google Scholar] [CrossRef]

- Nurihan, O.; Hisham, M.R.M.; Rasid, Z.A.; Hassan, M.Z.; Nor, A.F.M. The elastic properties of unidirectional bamboo fibre reinforced epoxy composites. Int. J. Recent Technol. Eng. 2019, 8, 7187–7193. [Google Scholar]

- Marmur, A. From Hygrophilic to Superhygrophobic: Theoretical Conditions for Making High-Contact-Angle Surfaces from Low-Contact-Angle Materials. Langmuir 2008, 24, 7573–7579. [Google Scholar] [CrossRef]

- Bazan, P.; Mierzwiński, D.; Bogucki, R.; Kuciel, S. Bio-based polyethylene composites with natural fiber: Mechanical, thermal, and ageing properties. Materials 2020, 13, 2595. [Google Scholar] [CrossRef] [PubMed]

- Pereira, A.L.; Banea, M.D.; Neto, J.S.S.; Cavalcanti, D.K.K. Mechanical and thermal characterization of natural intralaminar hybrid composites based on sisal. Polymers 2020, 12, 866. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vijay, C.; Pramendra Kumar, B.; Sachin, M. An Investigation on wear and dynamic mechanical behavior of Jute/Hemp/Flax Reinforced composites and its Hybrids for tribological applications. Fibers Polym. 2018, 19, 403–415. [Google Scholar]

| Composites | Hemp (%) | Flax (%) | Total Reinforcement Vol. (%) | Total Matrix Vol. (%) |

|---|---|---|---|---|

| 40H/0F | 40 | 0 | 40 | 60 |

| 25H/15F | 25 | 15 | 40 | 60 |

| 20H/20F | 20 | 20 | 40 | 60 |

| 15H/25F | 15 | 25 | 40 | 60 |

| 0H/40F | 0 | 40 | 40 | 60 |

| Material | Density (g/cm3) | Poisson’s Ratio | Young’s Modulus (GPa) | Shear Modulus (GPa) | Bulk Modulus (GPa) |

|---|---|---|---|---|---|

| Epoxy resin | 1.10 | 0.29 | 3.35 | 2.10 | 1.408 |

| Flax | 1.4–1.5 | 0.41 | 60 | 21.27 | 1.11 |

| Hemp | 1.48 | 0.39 | 70 | 25.18 | 1.06 |

| Ecopoxy | 1.13 | 0.23 | 2.28 | 0.98 | 1.26 |

| Element | Hemp Surface | Hemp Fracture | Flax Surface | Flax Fracture | ||||

|---|---|---|---|---|---|---|---|---|

| Atom. C (%) | Error (%) | Atom. C (%) | Error (%) | Atom. C (%) | Error (%) | Atom. C (%) | Error (%) | |

| Carbon | 73.74 | 21.6 | 69.97 | 20.3 | 74.66 | 21.9 | 59.98 | 21.8 |

| Oxygen | 26.15 | 10.4 | 29.76 | 11.4 | 25.09 | 10.0 | 39.57 | 14.7 |

| Chlorine | 0.11 | 0.0 | 0.10 | 0.0 | 0.15 | 0.0 | 0.18 | 0.0 |

| Calcium | -- | -- | 0.09 | 0.0 | -- | -- | 0.14 | 0.0 |

| Aluminum | -- | -- | 0.08 | 0.0 | -- | -- | -- | -- |

| Sodium | -- | -- | -- | -- | 0.10 | 0.0 | -- | -- |

| Potassium | -- | -- | -- | -- | -- | -- | 0.13 | 0.0 |

| Element | Hemp Surface | Hemp Fracture | Flax Surface | Flax Fracture | ||||

|---|---|---|---|---|---|---|---|---|

| Atom. C (%) | Error (%) | Atom. C (%) | Error (%) | Atom. C (%) | Error (%) | Atom. C (%) | Error (%) | |

| Carbon | 48.11 | 23.6 | 40.76 | 16.8 | 48.76 | 25.2 | 37.42 | 35.0 |

| Oxygen | 51.30 | 20.6 | 58.97 | 20.3 | 51.07 | 19.6 | 62.12 | 22.7 |

| Chlorine | 0.39 | 0.1 | 0.17 | 0.0 | 0.17 | 0.1 | 0.27 | 0.1 |

| Silicon | 0.20 | 0.1 | -- | -- | -- | -- | -- | -- |

| Calcium | -- | -- | 0.10 | 0.0 | -- | -- | 0.19 | 0.1 |

| Epoxy Composites | Experimental | Halpin–Tsai Method | Error (%) |

|---|---|---|---|

| 40H/0F | 2.683 | 3.896 | 45.21 |

| 15H/25F | 2.981 | 4.042 | 35.59 |

| 20H/20F | 2.934 | 4.264 | 45.33 |

| 25H/15F | 3.226 | 4.118 | 27.65 |

| 0H/40F | 2.772 | 3.968 | 43.15 |

| Ecopoxy Composites | Experimental | Halpin–Tsai Method | Error (%) |

|---|---|---|---|

| 40H/0F | 1.361 | 1.942 | 42.69 |

| 15H/25F | 1.683 | 2.248 | 33.57 |

| 20H/20F | 1.628 | 2.254 | 38.45 |

| 25H/15F | 1.737 | 2.324 | 33.79 |

| 0H/40F | 1.442 | 2.008 | 39.25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Atmakuri, A.; Palevicius, A.; Vilkauskas, A.; Janusas, G. Numerical and Experimental Analysis of Mechanical Properties of Natural-Fiber-Reinforced Hybrid Polymer Composites and the Effect on Matrix Material. Polymers 2022, 14, 2612. https://doi.org/10.3390/polym14132612

Atmakuri A, Palevicius A, Vilkauskas A, Janusas G. Numerical and Experimental Analysis of Mechanical Properties of Natural-Fiber-Reinforced Hybrid Polymer Composites and the Effect on Matrix Material. Polymers. 2022; 14(13):2612. https://doi.org/10.3390/polym14132612

Chicago/Turabian StyleAtmakuri, Ayyappa, Arvydas Palevicius, Andrius Vilkauskas, and Giedrius Janusas. 2022. "Numerical and Experimental Analysis of Mechanical Properties of Natural-Fiber-Reinforced Hybrid Polymer Composites and the Effect on Matrix Material" Polymers 14, no. 13: 2612. https://doi.org/10.3390/polym14132612

APA StyleAtmakuri, A., Palevicius, A., Vilkauskas, A., & Janusas, G. (2022). Numerical and Experimental Analysis of Mechanical Properties of Natural-Fiber-Reinforced Hybrid Polymer Composites and the Effect on Matrix Material. Polymers, 14(13), 2612. https://doi.org/10.3390/polym14132612