Carbon Fiber/PLA Recycled Composite

Abstract

:1. Introduction

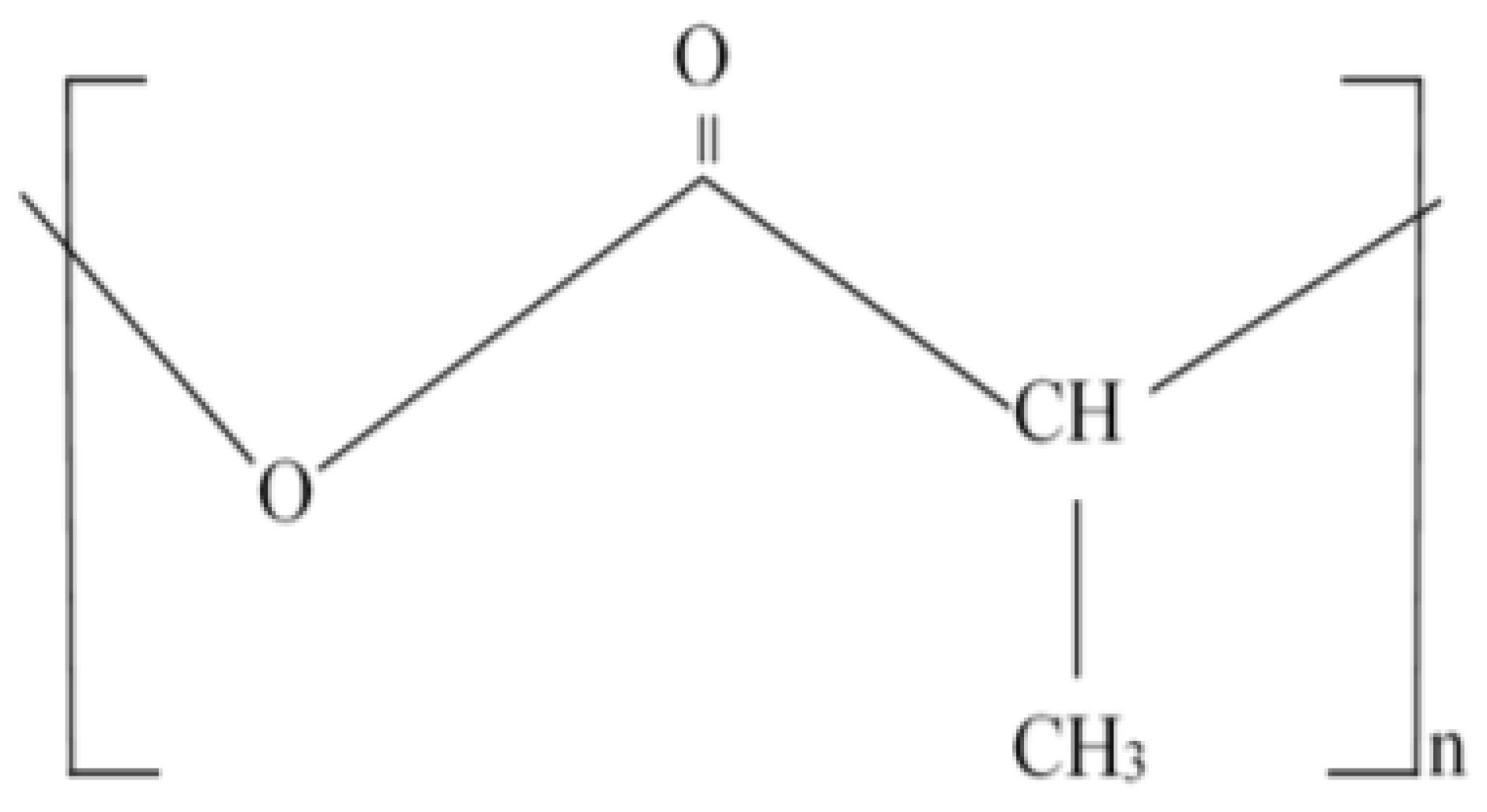

1.1. Polylactide (PLA)

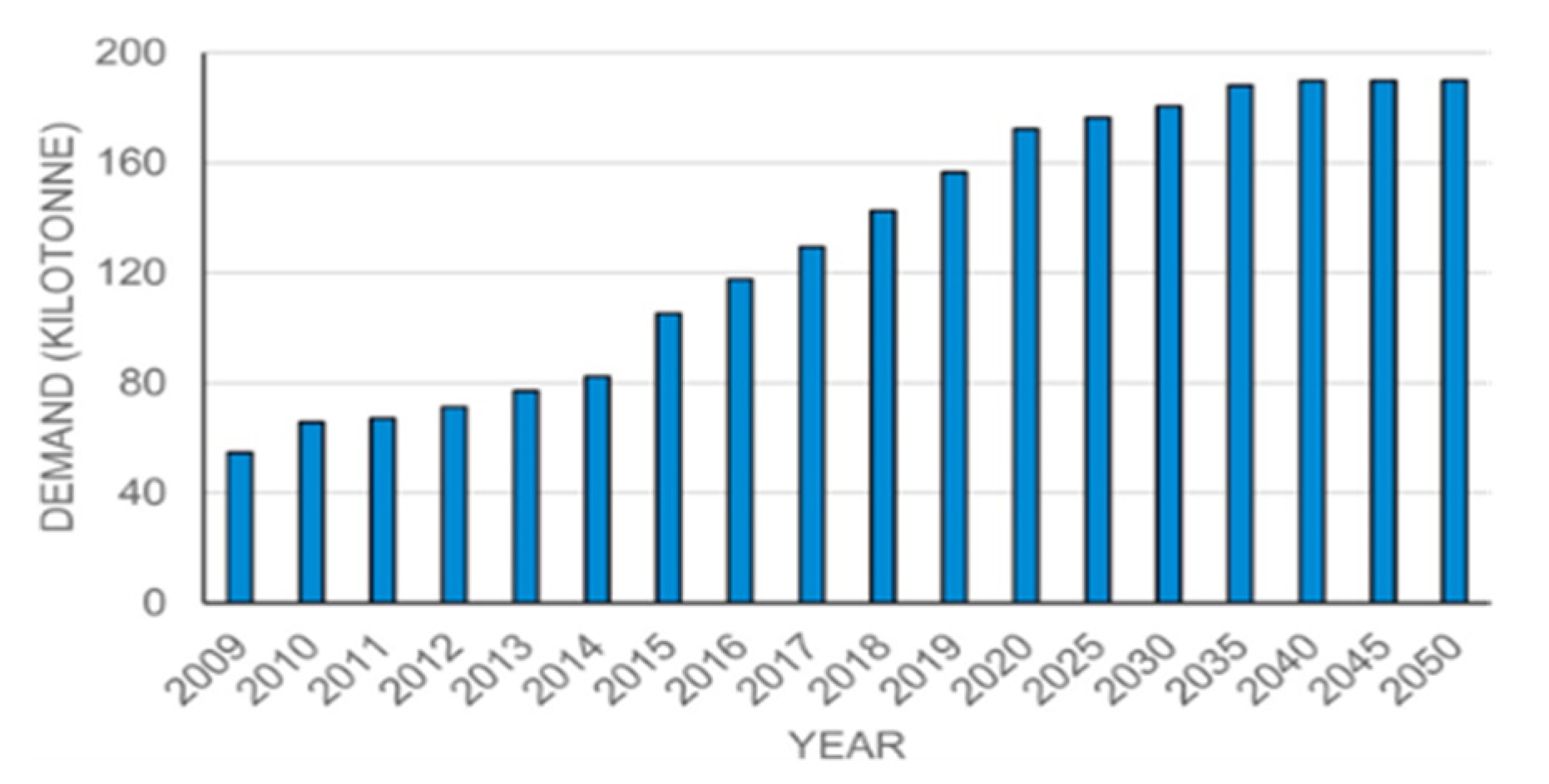

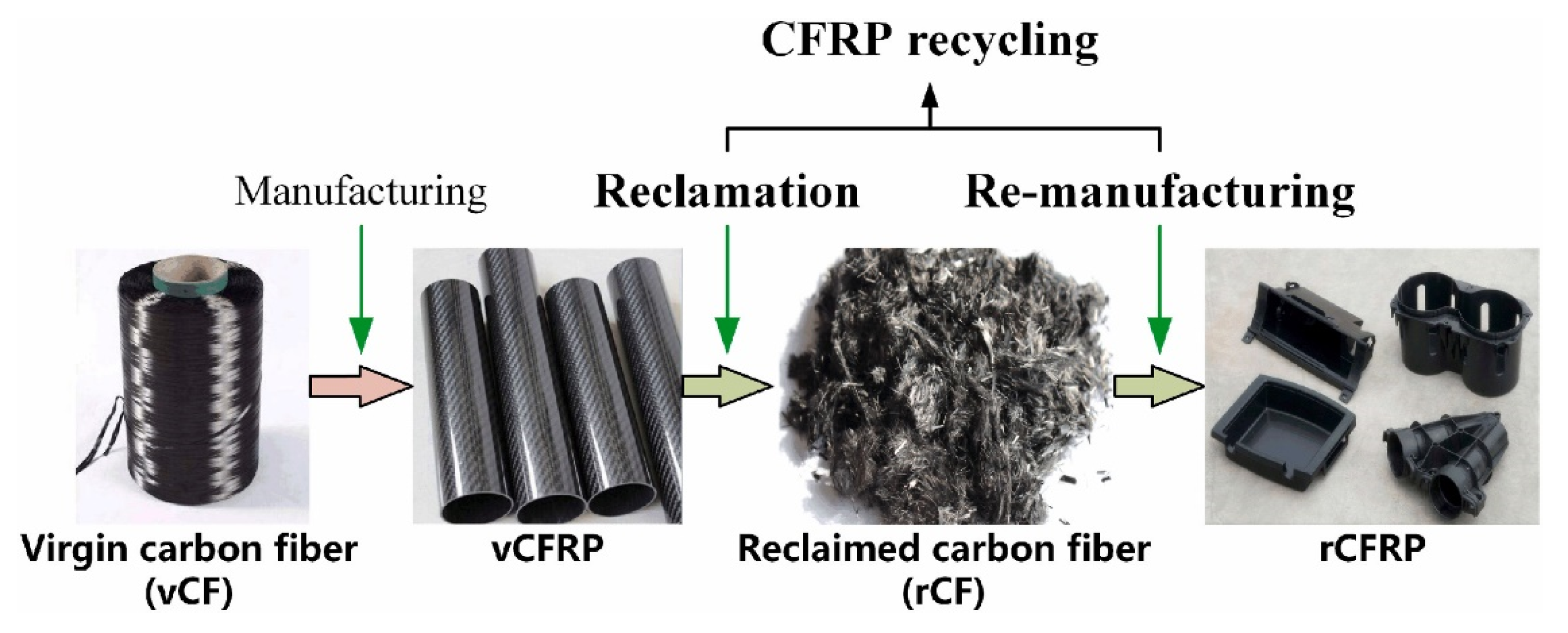

1.2. Carbon Fiber Reinforced Polymers (CFRP)

1.2.1. Recycling Techniques

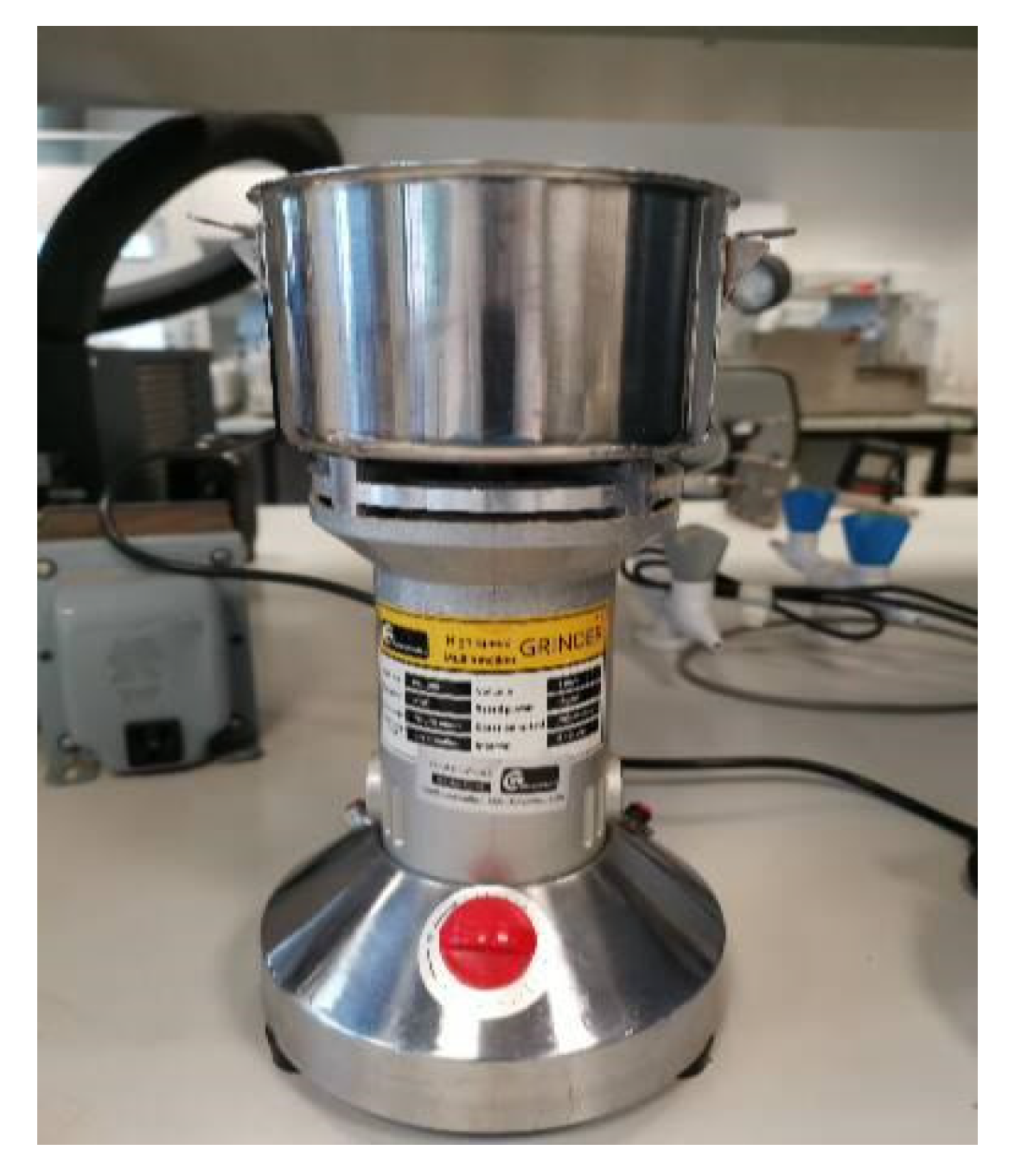

1.2.2. Mechanical Method

1.2.3. Pyrolysis

1.2.4. Chemical Method

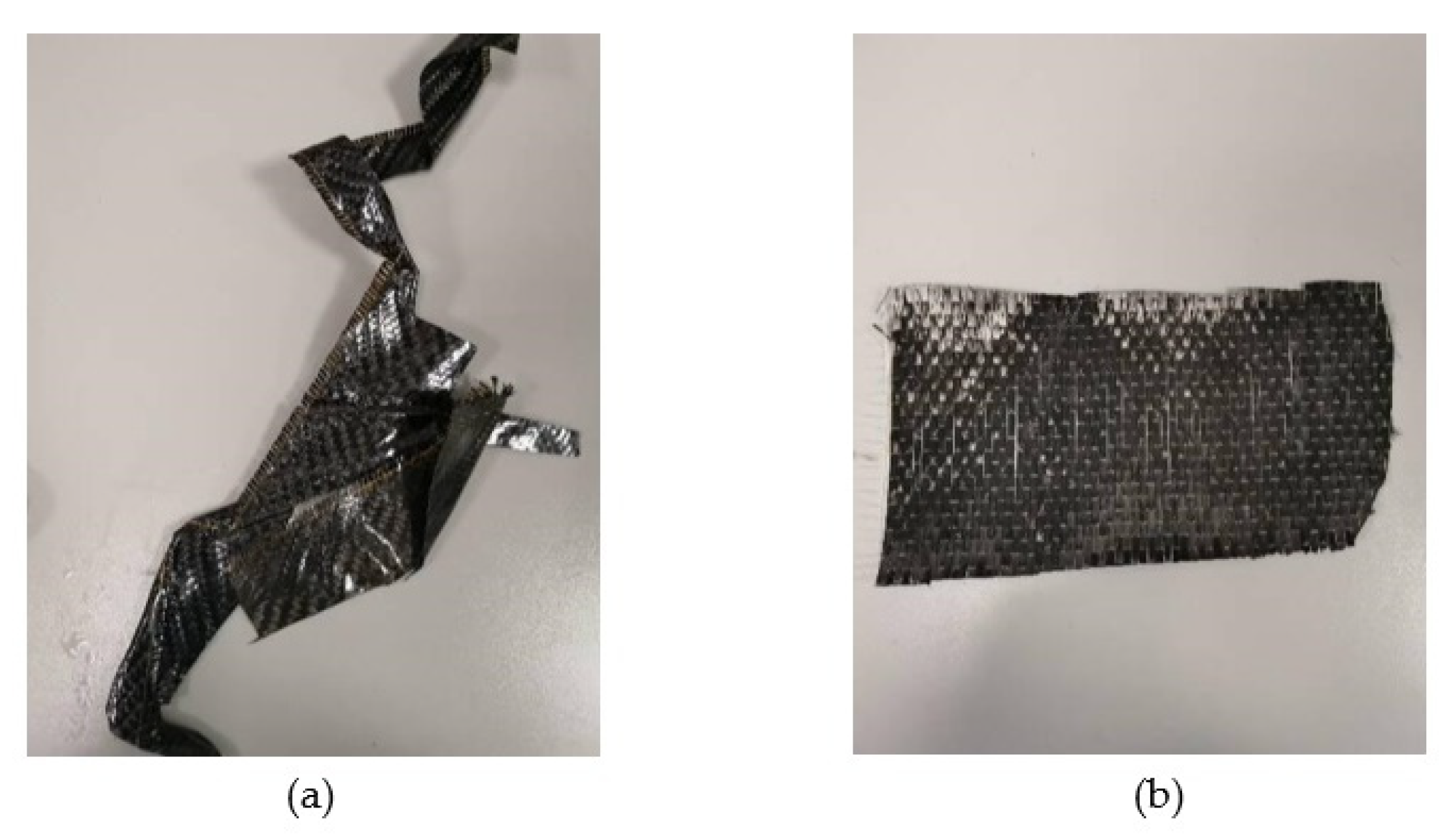

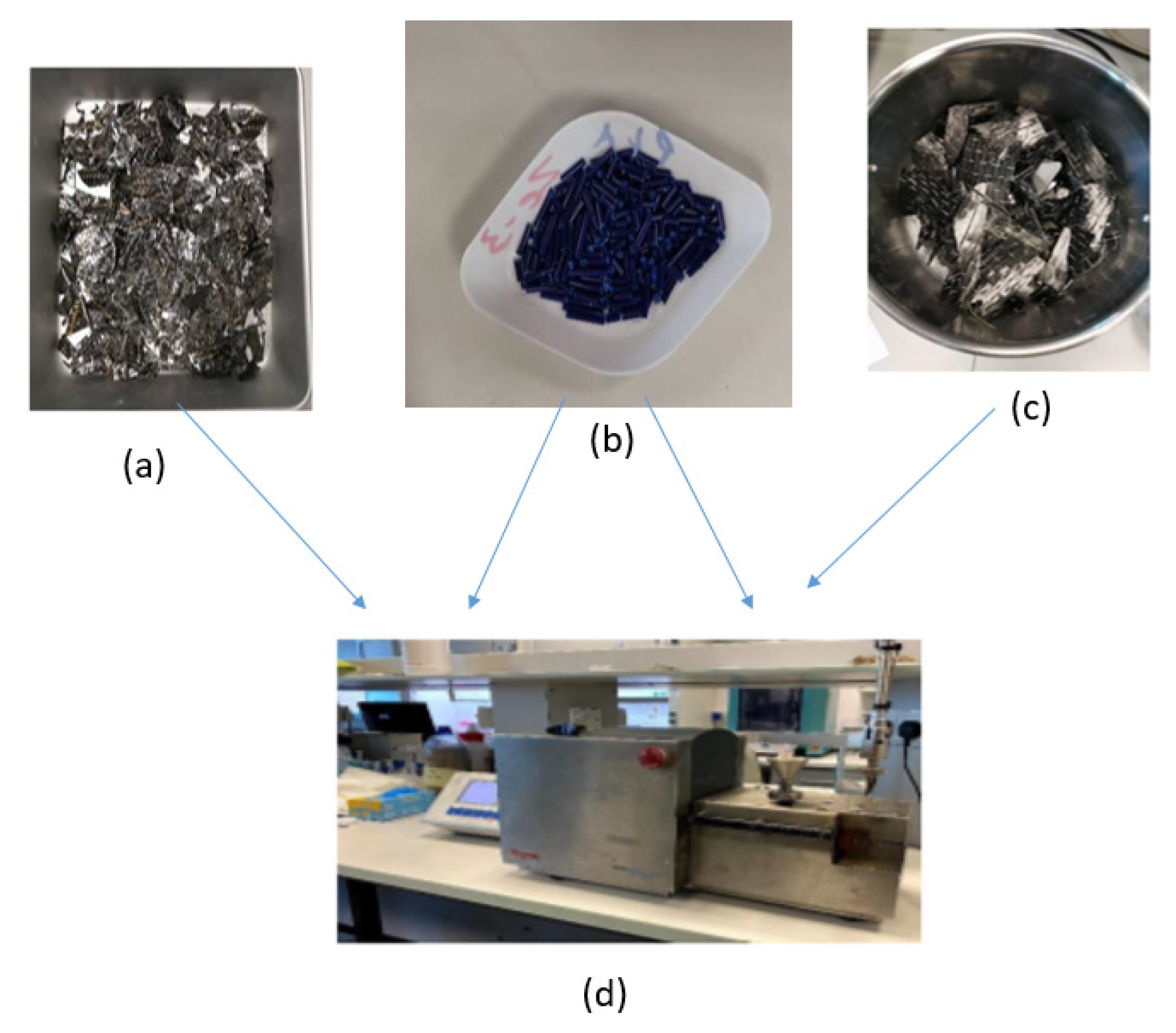

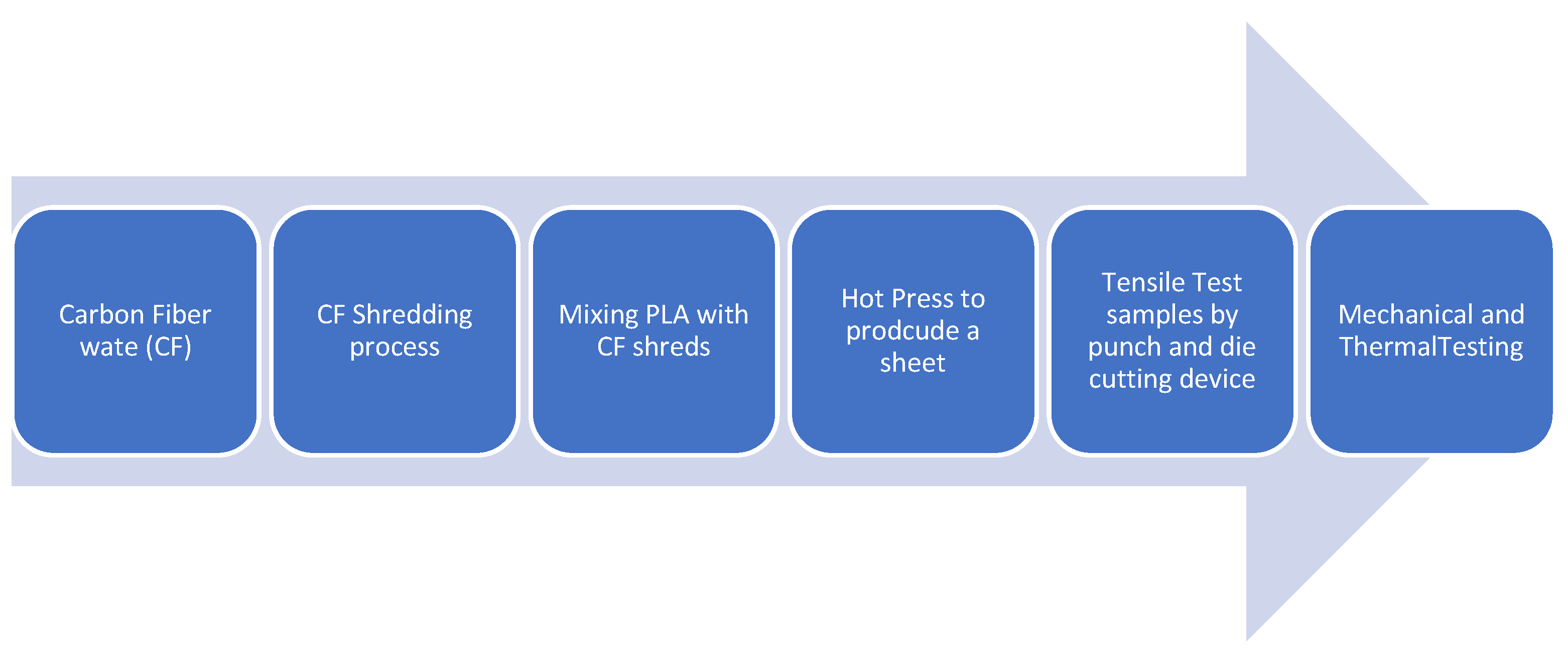

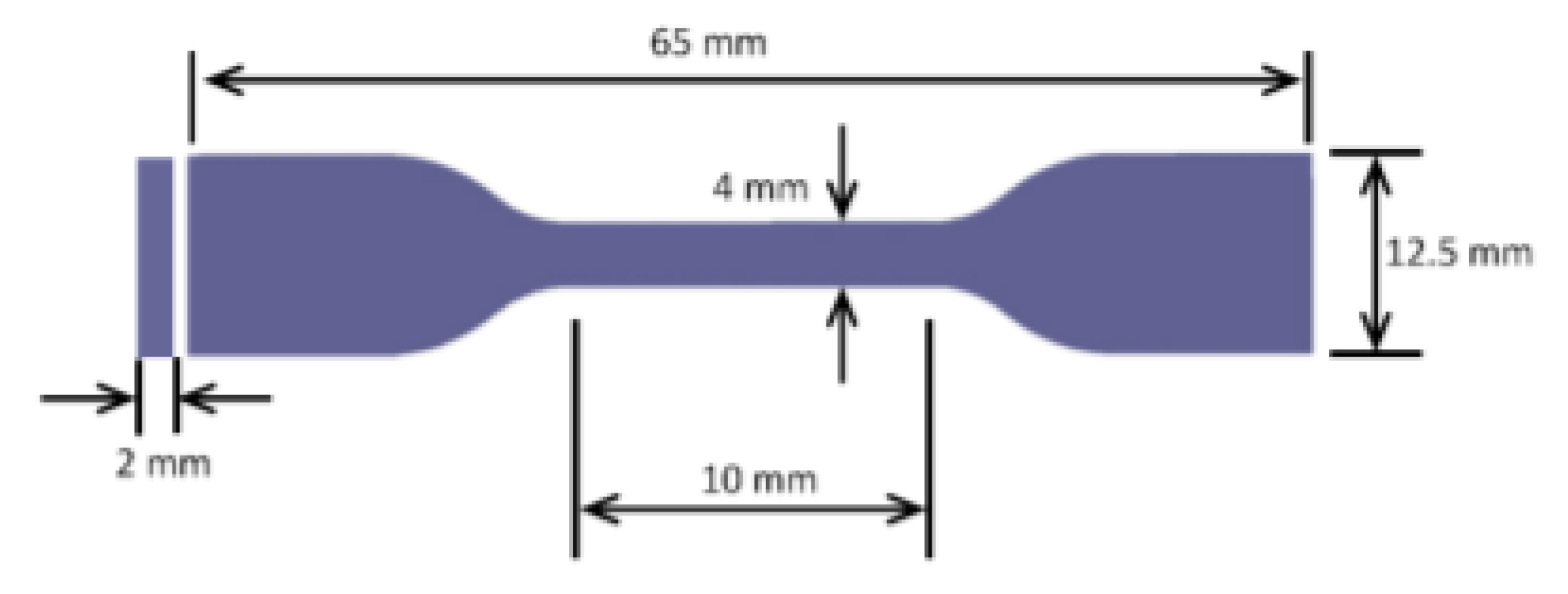

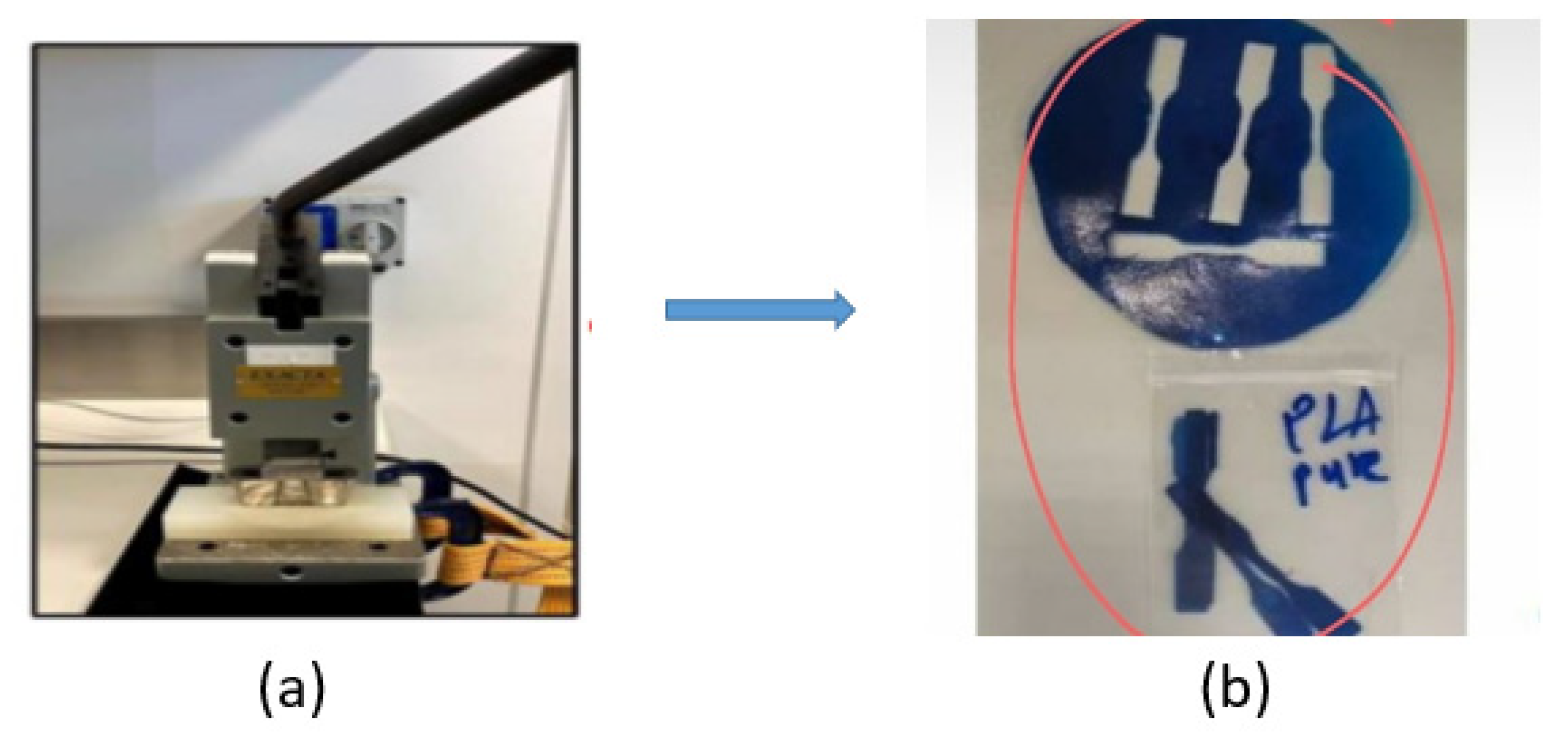

2. Materials and Methods

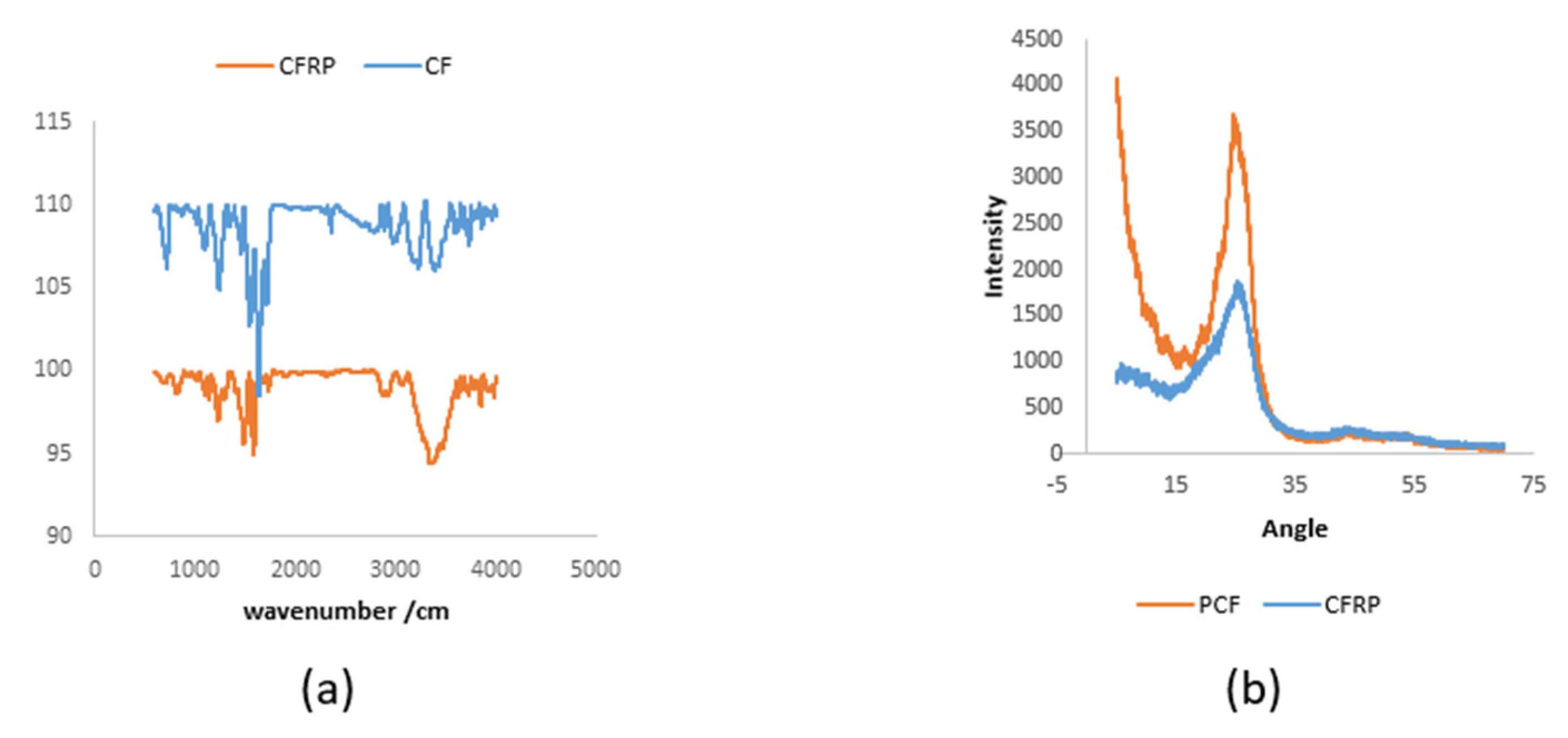

2.1. Fourier Transform (FTIR)

2.2. XRD

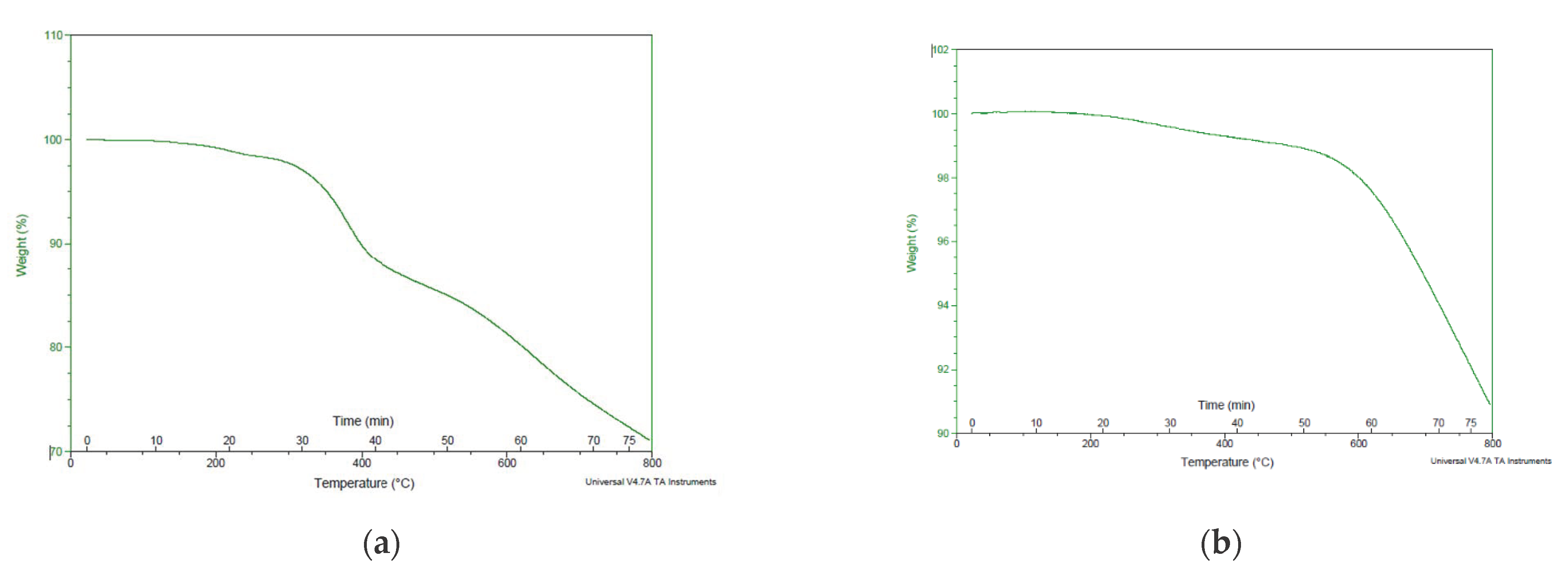

2.3. TGA

3. Results and Discussion

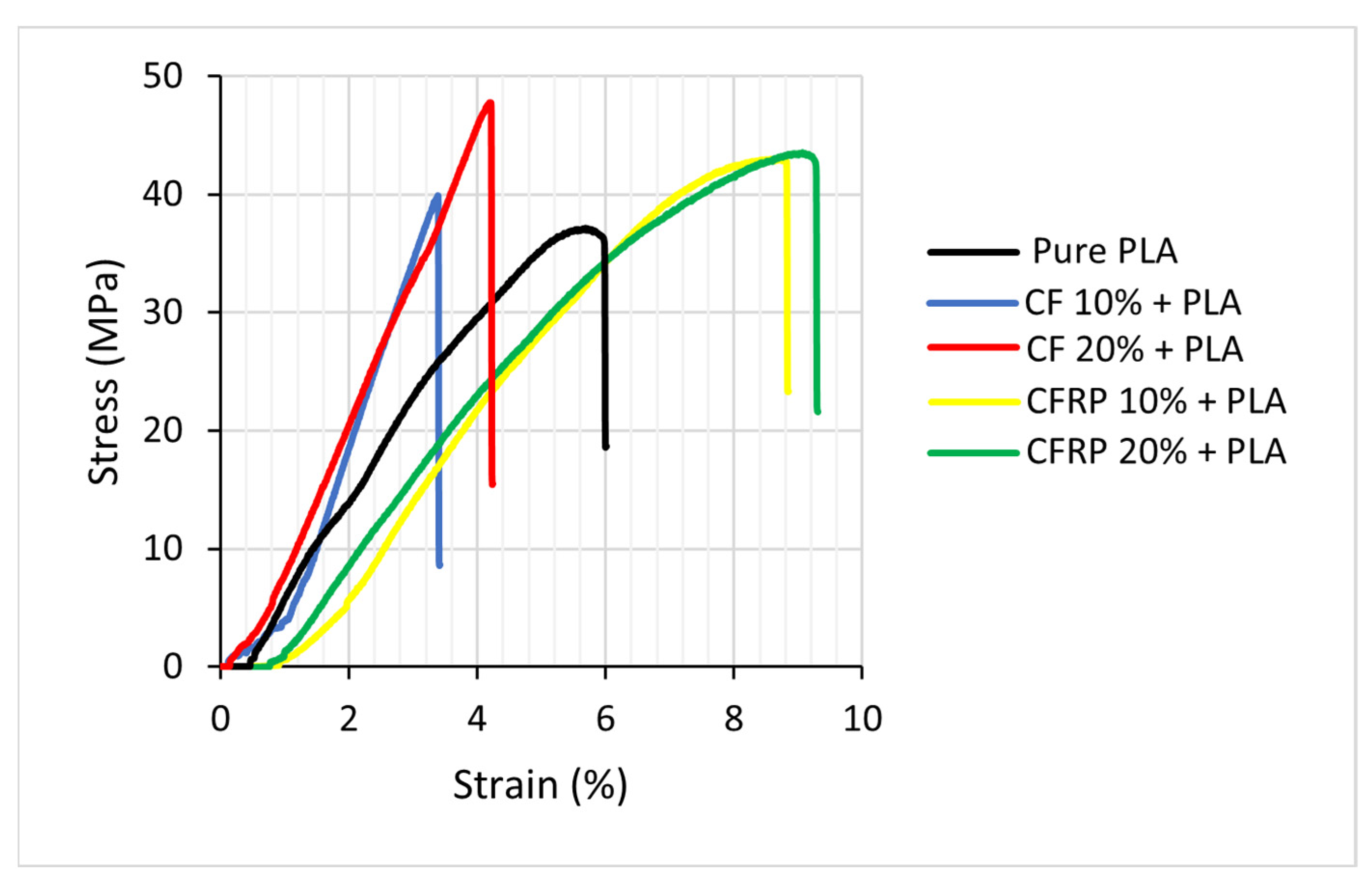

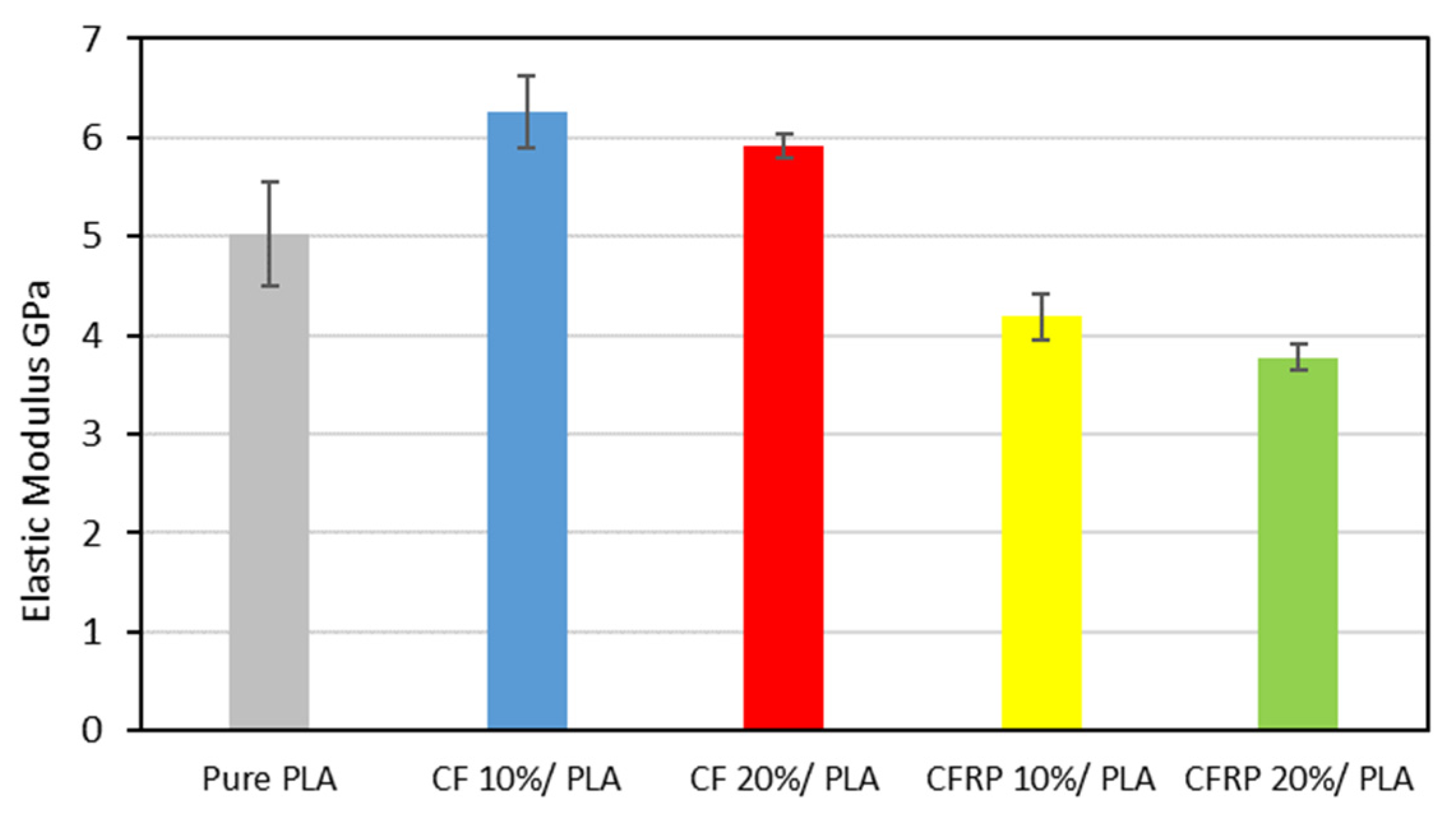

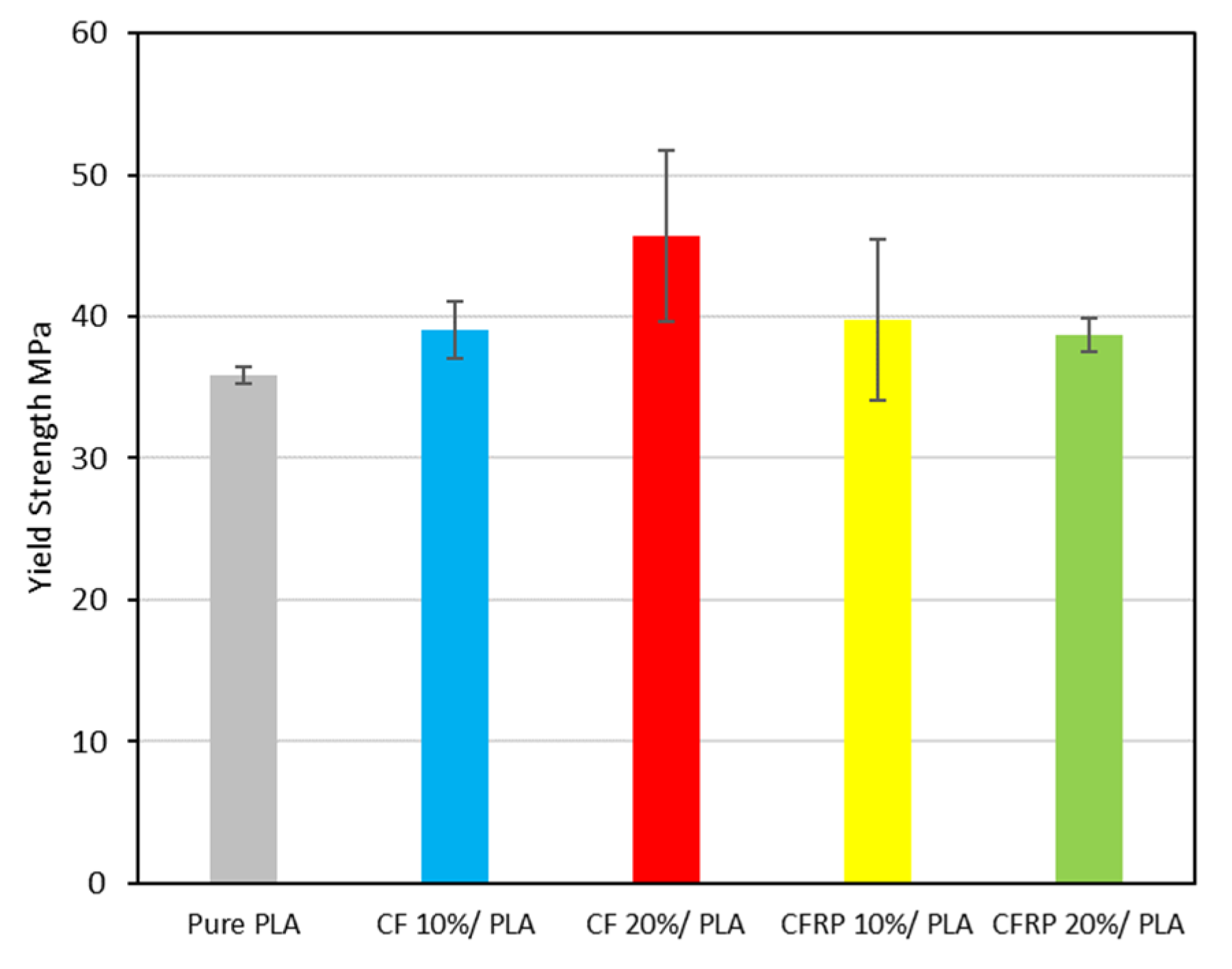

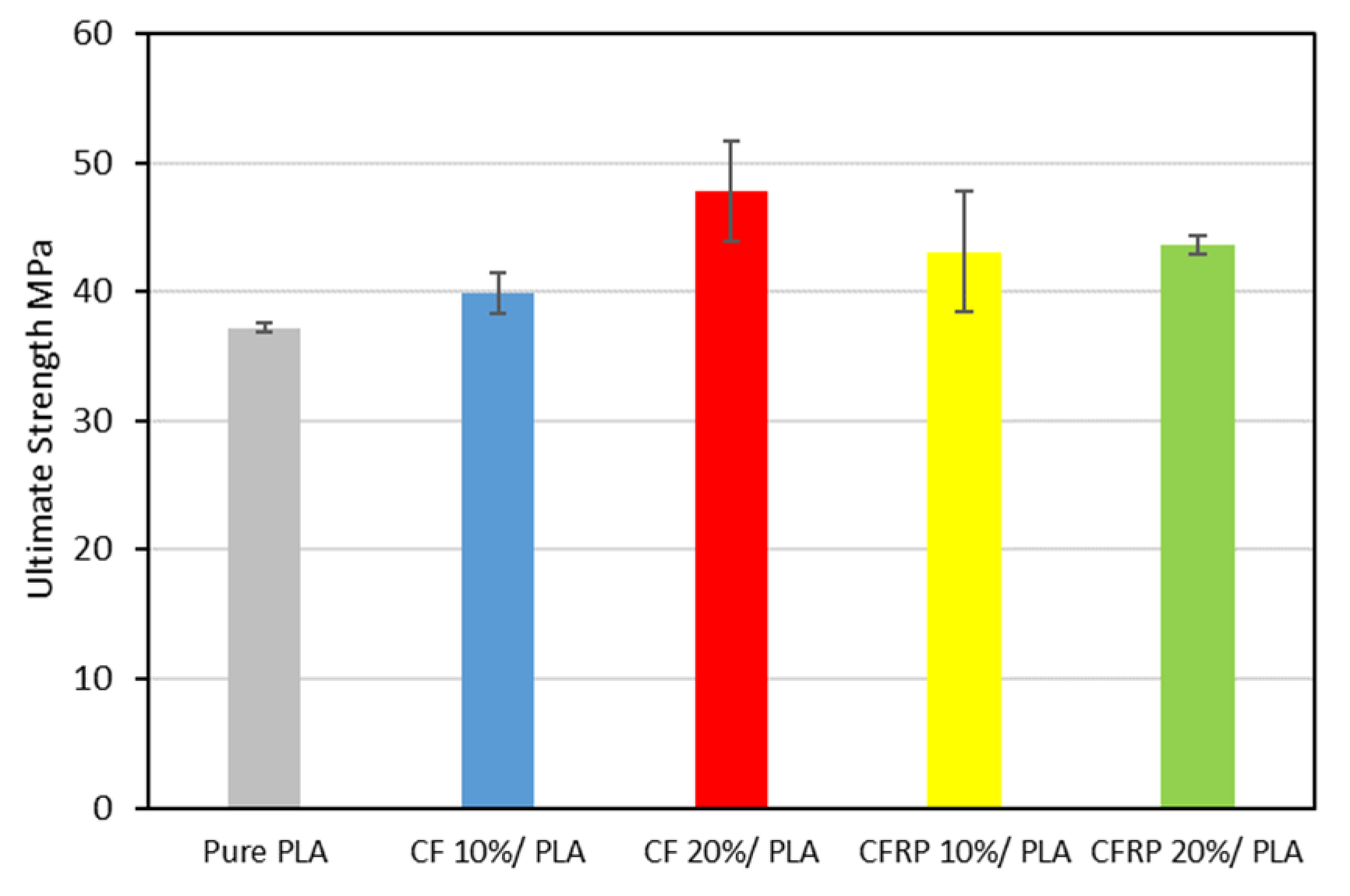

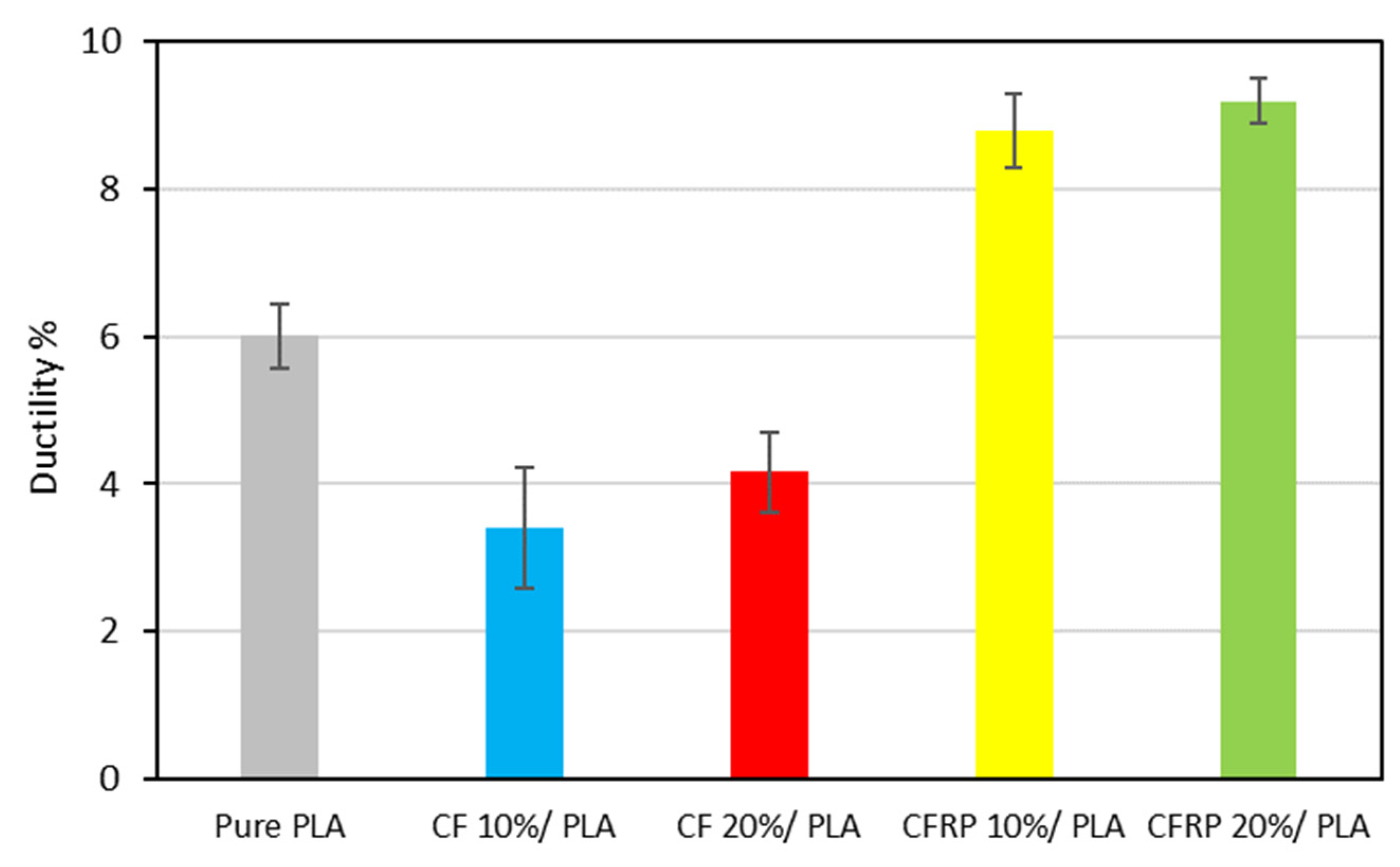

3.1. Mechanical Characterization

3.2. XRD, FTIR, and TGA Analysis

4. Conclusions

- The experimental investigation revealed the negative impact of the expired impregnated epoxy of the CFRP prepreg leftover scrape that may affect the mechanical properties of the produced composite, even though the properties of the CFRP/PLA composites in general showed better properties than the recycled PLA.

- For the modulus of elasticity, the CF/PLA composite at 20% has higher properties than the CFRP at 20%—specifically, the elastic modulus is 65% and 56% higher for the CF and the CFRP, respectively, in comparison to the PLA reference value.

- The yield strength of the 20% CF is the highest, whereas the 20% CFRP is the lowest.

- Carbon fiber in general enhanced the ultimate strength of the carbon/PLA blends, starting from 7% at 10% CF to 28% at 20% CF, and 15% at 10% CFRP to 17% at 20%.

- For the ductility, the recycled PLA showed a higher level of 15% compared to the commercial PLA filament. For the CF/PLA, the CF has an opposite impact on the ductility: it decreased the strain at the failure from 43% to 30% for 10% and 20% CF, respectively. In contrast, CFRP has been attributed to uplifting the strain at failure from 46% to 53% at the 10% and the 20% CFRP, respectively.

Author Contributions

Funding

Conflicts of Interest

References

- Hernandez, M.M.; Gupta, N.S.; Lee, K.-S.; Pital, A.C.; Marrone, B.L.; Iverson, C.N.; Dumont, J.H. Characterization of Polyhydroxybutyrate-Based Composites Prepared by Injection Molding. Polymers 2021, 13, 4444. [Google Scholar] [CrossRef] [PubMed]

- Naser, A.Z.; Deiab, I.; Defersha, F.; Yang, S. Expanding Poly(lactic acid) (PLA) and Polyhydroxyalkanoates (PHAs) Applications: A Review on Modifications and Effects. Polymers 2021, 13, 4271. [Google Scholar] [CrossRef] [PubMed]

- Merzah, Z.F.; Fakhry, S.; Allami, T.G.; Yuhana, N.Y.; Alamiery, A. Enhancement of the Properties of Hybridizing Epoxy and Nanoclay for Mechanical, Industrial, and Biomedical Applications. Polymers 2022, 14, 526. [Google Scholar] [CrossRef] [PubMed]

- Quecholac-Piña, X.; Hernández-Berriel, M.D.C.; Mañón-Salas, M.D.C.; Espinosa-Valdemar, R.M.; Vázquez-Morillas, A. Degradation of Plastics under Anaerobic Conditions: A Short Review. Polymers 2020, 12, 109. [Google Scholar] [CrossRef] [Green Version]

- Vu, T.H.N.; Morozkina, S.N.; Uspenskaya, M.V. Study of the Nanofibers Fabrication Conditions from the Mixture of Poly(vinyl alcohol) and Chitosan by Electrospinning Method. Polymers 2022, 14, 811. [Google Scholar] [CrossRef]

- Das, S. Life cycle assessment of carbon fiber-reinforced polymer composites. Int. J. Life Cycle Assess. 2011, 16, 268–282. [Google Scholar] [CrossRef]

- Cheng, H.; Guo, L.; Qian, Z.; Sun, R.; Zhang, J. Remanufacturing of recycled carbon fiber-reinforced composites based on fused deposition modeling processes. Int. J. Adv. Manuf. Technol. 2021, 116, 1609–1619. [Google Scholar] [CrossRef]

- Pakdel, E.; Wang, J.; Varley, R.; Wang, X. Recycled carbon fiber nonwoven functionalized with fluorine-free superhydrophobic PDMS/ZIF-8 coating for efficient oil-water separation. J. Environ. Chem. Eng. 2021, 9, 106329. [Google Scholar] [CrossRef]

- Tian, X.; Liu, T.; Wang, Q.; Dilmurat, A.; Li, D.; Ziegmann, G. Recycling and remanufacturing of 3D printed continuous carbon fiber reinforced PLA composites. J. Clean. Prod. 2017, 142, 1609–1618. [Google Scholar] [CrossRef]

- Maqsood, N.; Rimašauskas, M. Characterization of carbon fiber reinforced pla composites manufactured by fused deposition modeling. Compos. Part C Open Access 2021, 4, 100112. [Google Scholar] [CrossRef]

- Siakeng, R.; Jawaid, M.; Asim, M.; Fouad, H.; Awad, S.; Saba, N.; Siengchin, S. Flexural and dynamic mechanical properties of alkali-treated coir/pineapple leaf fibres reinforced polylactic acid hybrid biocomposites. J. Bionic Eng. 2021, 18, 1430–1438. [Google Scholar] [CrossRef]

- Bayart, M.; Foruzanmehr, M.R.; Vuillaume, P.Y.; Ovlaque, P.; Robert, M.; Elkoun, S. Poly(lactic acid)/flax composites: Effect of surface modification and thermal treatment on interfacial adhesion, crystallization, microstructure, and mechanical properties. Compos. Interfaces 2022, 29, 17–36. [Google Scholar] [CrossRef]

- Bonadies, I.; Capuano, R.; Avolio, R.; Castaldo, R.; Cocca, M.; Gentile, G.; Errico, M.E. Sustainable Cellulose-Aluminum-Plastic Composites from Beverage Cartons Scraps and Recycled Polyethylene. Polymers 2022, 14, 807. [Google Scholar] [CrossRef] [PubMed]

- Fong, K.; Mariatti, M.; Takagi, H. Effect of Matrix and Staking Sequence of Recycled Jute/Carbon Fiber Hybrid Laminated Composites. J. Polym. Mater. 2012, 29, 437–449. [Google Scholar]

- Rihayat, T.; Hadi, A.E.; Aidy, N.; Safitri, A.; Siregar, J.P.; Cionita, T.; Irawan, A.P.; Hamdan, M.H.M.; Fitriyana, D.F. Biodegradation of Polylactic Acid-Based Bio Composites Reinforced with Chitosan and Essential Oils as Anti-Microbial Material for Food Packaging. Polymers 2021, 13, 4019. [Google Scholar]

- Ramos, M.; Fortunati, E.; Beltrán, A.; Peltzer, M.; Cristofaro, F.; Visai, L.; Valente, A.J.M.; Jiménez, A.; Kenny, J.M.; Garrigós, M.C. Controlled Release, Disintegration, Antioxidant, and Antimicrobial Properties of Poly (Lactic Acid)/Thymol/Nanoclay Composites. Polymers 2020, 12, 1878. [Google Scholar] [CrossRef]

- Liu, W.; Huang, H.; Zhu, L.; Liu, Z. Integrating carbon fiber reclamation and additive manufacturing for recycling CFRP waste. Compos. Part B Eng. 2021, 215, 108808. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Zuhri, M.Y.M.; Aisyah, H.A.; Asyraf, M.R.M.; Hassan, S.A.; Zainudin, E.S.; Sapuan, S.M.; Sharma, S.; Bangar, S.P.; Jumaidin, R.; et al. Natural Fiber-Reinforced Polylactic Acid, Polylactic Acid Blends and Their Composites for Advanced Applications. Polymers 2022, 14, 202. [Google Scholar] [CrossRef]

- Han, H.; Wang, X.; Wu, D. Preparation, crystallization behaviors, and mechanical properties of biodegradable composites based on poly (L-lactic acid) and recycled carbon fiber. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1947–1958. [Google Scholar] [CrossRef]

- Puscaselu, G.R.; Besliu, I.; Gutt, G. Edible Biopolymers-Based Materials for Food Applications—The Eco Alternative to Conventional Synthetic Packaging. Polymers 2021, 13, 3779. [Google Scholar] [CrossRef]

- Tian, X.; Liu, T.; Wang, Q. Manufacturing and recycling of 3d printed continuous carbon fiber reinforced PLA composites. In Proceedings of the International Conference on Composite Materials 2017, Xi’an, China, 20 August 2017. [Google Scholar]

- Meng, F.; McKechnie, J.; Turner, T.; Wong, K.H.; Stephen, J. PickeringEnvironmental aspects of use of recycled carbon fiber composites in automotive applications. Environ. Sci. Technol. 2017, 51, 12727–12736. [Google Scholar] [CrossRef] [PubMed]

- Song, C.; Wang, F.; Liu, Y.; Wang, X.; Yang, B. Recycling carbon fiber from composite waste and its reinforcing effect on polyvinylidene fluoride composite: Mechanical, morphology, and interface properties. Polym. Compos. 2017, 38, 2544–2552. [Google Scholar] [CrossRef]

- Shehab, E.; Meiirbekov, A.; Amantayeva, A.; Suleimen, A.; Tokbolat, S.; Sarfraz, S. A Cost Modelling System for Recycling Carbon Fiber-Reinforced Composites. Polymers 2021, 13, 4208. [Google Scholar] [CrossRef] [PubMed]

- Rahimizadeh, A.; Kalman, J.; Henri, R.; Fayazbakhsh, K.; Lessard, L. Recycled glass fiber composites from wind turbine waste for 3D printing feedstock: Effects of fiber content and interface on mechanical performance. Materials 2019, 12, 3929. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rani, M.; Choudhary, P.; Krishnan, V.; Zafar, S. A review on recycling and reuse methods for carbon fiber/glass fiber composites waste from wind turbine blades. Compos. Part B Eng. 2021, 215, 108768. [Google Scholar] [CrossRef]

- Pakdel, E.; Kashi, S.; Varley, R.; Wang, X. Recent progress in recycling carbon fibre reinforced composites and dry carbon fibre wastes. Resour. Conserv. Recycl. 2021, 166, 105340. [Google Scholar] [CrossRef]

- Nie, W.; Liu, J.; Liu, W.; Wang, J.; Tang, T. Decomposition of waste carbon fiber reinforced epoxy resin composites in molten potassium hydroxide. Polym. Degrad. Stab. 2015, 111, 247–256. [Google Scholar] [CrossRef]

- Castéran, F.; Delage, K.; Hascoët, N.; Ammar, A.; Chinesta, F.; Cassagnau, P. Data-Driven Modelling of Polyethylene Recycling under High-Temperature Extrusion. Polymers 2022, 14, 800. [Google Scholar] [CrossRef]

- Takagi, H.; Kako, S.; Kusano, K.; Ousaka, A. Thermal conductivity of PLA-bamboo fiber composites. Adv. Compos. Mater. 2007, 16, 377–384. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Nakamura, T.; Sugiyama, K.; Ueda, M.; Todoroki, A.; Hirano, Y.; Yamagata, Y. Effects of set curvature and fiber bundle size on the printed radius of curvature by a continuous carbon fiber composite 3D printer. Addit. Manuf. 2018, 24, 93–102. [Google Scholar] [CrossRef]

- Wang, W. Preparation and Study on Mechanical Properties of Waste Blended Fibers/PLA Composites. China Plast. Ind. 2011, 11, 95–96. [Google Scholar]

- Wang, P.; Sterkenburg, R.; Kim, G.; He, Y. Investigating the Fiber Content, Fiber Length, and Curing Characteristics of 3D Printed Recycled Carbon Fiber. Int. J. Mater. Metall. Eng. 2019, 13, 161–164. [Google Scholar]

- Mohanty, A.K.; Vivekanandhan, S.; Pin, J.M.; Misra, M. Composites from renewable and sustainable resources: Challenges and innovations. Science 2018, 362, 536–542. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Starkova, O.; Platnieks, O.; Sabalina, A.; Gaidukovs, S. Hydrothermal Ageing Effect on Reinforcement Efficiency of Nanofibrillated Cellulose/Biobased Poly(butylene succinate) Composites. Polymers 2022, 14, 221. [Google Scholar] [CrossRef] [PubMed]

- Sadef, Y.A.; Nizami, S.; Batool, S.A.; Chaudary, M.N.O.; Ouda, K.M.Z.; Asam, Z.K.; Habib, M.; Rehan, A. Waste-to-energy and recycling value for developing integrated solid waste management plan in Lahore. Energy Sources Part B Econ. Plan. Policy 2016, 11, 569–579. [Google Scholar] [CrossRef]

- Di Mauro, C.; Genua, A.; Mija, A. Kinetical Study, Thermo-Mechanical Characteristics and Recyclability of Epoxidized Camelina Oil Cured with Antagonist Structure (Aliphatic/Aromatic) or Functionality (Acid/Amine) Hardeners. Polymers 2021, 13, 2503. [Google Scholar] [CrossRef]

- Feng, N.; Wang, X.; Wu, D. Surface modification of recycled carbon fiber and its reinforcement effect on nylon 6 composites: Mechanical properties, morphology and crystallization behaviors. Curr. Appl. Phys. 2013, 13, 2038–2050. [Google Scholar] [CrossRef]

- Math, R.K.; Goutham, R.; Prasad, K.S. Study of Effects on Mechanical Properties of PLA Filament which is blended with Recycled PLA Materials. In IOP Conference Series: Materials Science and Engineering 2018; IOP Publishing: Bristol, UK, 2018. [Google Scholar]

- Karuppannan Gopalraj, S.; Deviatkin, I.; Horttanainen, M.; Kärki, T. Life Cycle Assessment of a Thermal Recycling Process as an Alternative to Existing CFRP and GFRP Composite Wastes Management Options. Polymers 2021, 13, 4430. [Google Scholar] [CrossRef]

- Alshammari, B.A.; Alsuhybani, M.S.; Almushaikeh, A.M.; Alotaibi, B.M.; Alenad, A.M.; Alqahtani, N.B.; Alharbi, A.G. Comprehensive Review of the Properties and Modifications of Carbon Fiber-Reinforced Thermoplastic Composites. Polymers 2021, 13, 2474. [Google Scholar] [CrossRef]

- Awadallah, M.; Tawadros, P.; Walker, P.; Zhang, N. Comparative fuel economy, cost and emissions analysis of a novel mild hybrid and conventional vehicles. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2018, 232, 1846–1862. [Google Scholar] [CrossRef] [Green Version]

- Bank, T.; Klamor, S.; Sauer, D.U. Lithium ion cell requirements in a real-world 48 v system and implications for an extensive aging analysis. J. Energy Storage 2020, 30, 101465. [Google Scholar] [CrossRef]

- Capuano, R.; Bonadies, I.; Castaldo, R.; Cocca, M.; Gentile, G.; Protopapa, A.; Avolio, R.; Errico, M.E. Valorization and Mechanical Recycling of Heterogeneous Post-Consumer Polymer Waste through a Mechano-Chemical Process. Polymers 2021, 13, 2783. [Google Scholar] [CrossRef] [PubMed]

- Benajes, J.; García, A.; Monsalve-Serrano, J.; Martínez-Boggio, S. Optimization of the parallel and mild hybrid vehicle platforms operating under conventional and advanced combustion modes. Energy Convers. Manag. 2019, 190, 73–90. [Google Scholar] [CrossRef]

- Bitsche, O.; Gutmann, G. Systems for hybrid cars. J. Power Sources 2004, 127, 8–15. [Google Scholar] [CrossRef]

- Bubeck, S.; Tomaschek, J.; Fahl, U. Perspectives of electric mobility: Total cost of ownership of electric vehicles in Germany. Transp. Policy 2016, 50, 63–77. [Google Scholar] [CrossRef]

- Fico, D.; Rizzo, D.; Casciaro, R.; Esposito Corcione, C. A Review of Polymer-Based Materials for Fused Filament Fabrication (FFF): Focus on Sustainability and Recycled Materials. Polymers 2022, 14, 465. [Google Scholar] [CrossRef]

- Burke, A.; Liu, Z.; Zhao, H. Present and future applications of supercapacitors in electric and hybrid vehicles. In Proceedings of the 2014 IEEE International Electric Vehicle Conference (IEVC), Florence, Italy, 17–19 December 2014. [Google Scholar]

- Burke, A.F. Batteries and ultracapacitors for electric, hybrid, and fuel cell vehicles. Proc. IEEE 2007, 95, 806–820. [Google Scholar] [CrossRef]

- Capata, R. Experimental Fitting of Redesign Electrified Turbocompressor of a Novel Mild Hybrid Power Train for a City Car. Energies 2021, 14, 6516. [Google Scholar] [CrossRef]

- Giuliani, C.; Pascucci, M.; Riccucci, C.; Messina, E.; Salzano de Luna, M.; Lavorgna, M.; Maria Ingo, G.; Di Carlo, G. Functionalized chitosan-based coatings for active corrosion protection. Surf. Coat. Technol. 2013, 226, 51–59. [Google Scholar]

- Carneiro, J.; Tedim, J.; Ferreira, M. Chitosan as a smart coating for corrosion protection of aluminum alloy 2024: A review. Prog. Org. Coat. 2015, 89, 348–356. [Google Scholar] [CrossRef]

- Chauhan, D.S.; Srivastava, V.; Joshi, P.G.; Quraishi, M.A. PEG cross-linked chitosan: A biomacromolecule as corrosion inhibitor for sugar industry. Int. J. Ind. Chem. 2018, 9, 363–377. [Google Scholar] [CrossRef] [Green Version]

- Chauhan, D.S.; Mazumder, J.; Quraishi, M.A.; Ansari, K.R. Chitosan-cinnamaldehyde Schiff base: A bioinspired macromolecule as corrosion inhibitor for oil and gas industry. Int. J. Biol. Macromol. 2020, 158, 127–138. [Google Scholar] [CrossRef] [PubMed]

- Chauhan, D.S.; Mazumder, J.; Quraishi, M.A.; Ansari, K.R.; Suleiman, M.A. Microwave-assisted synthesis of a new Piperonal-Chitosan Schiff base as a bio-inspired corrosion inhibitor for oil-well acidizing. Int. J. Biol. Macromol. 2020, 158, 231–243. [Google Scholar] [CrossRef] [PubMed]

- Chauhan, D.S.; Mazumder, J.; Quraishi, M.A.; Bazzi, L. Aminotriazolethiol-functionalized chitosan as a macromolecule-based bioinspired corrosion inhibitor for surface protection of stainless steel in 3.5% NaCl. Int. J. Biol. Macromol. 2020, 152, 234–241. [Google Scholar] [CrossRef]

- Chein, R.; Huang, G. Thermoelectric cooler application in electronic cooling. Appl. Therm. Eng. 2004, 24, 2207–2217. [Google Scholar] [CrossRef]

- Pintus, V.; Baragona, A.J.; Cappa, F.; Haiml, C.; Hierl, C.; Sterflinger, K.; Schreiner, M. Multi-Analytical Investigations of Andy Warhol’s “Orange Car Crash”: Polymeric Materials in Modern Paints. Polymers 2022, 14, 633. [Google Scholar] [CrossRef]

- Chen, W.-H.; Liao, C.-Y.; Hung, C.-I. A numerical study on the performance of miniature thermoelectric cooler affected by Thomson effect. Appl. Energy 2012, 89, 464–473. [Google Scholar] [CrossRef]

- Cho, B. Control of a Hybrid Electric Vehicle with Predicitive Journey Estimation. Ph.D. Thesis, Cranfield University, Cranfield, UK, 2008. [Google Scholar]

- Da Silva, L.W.; Kaviany, M. Micro-thermoelectric cooler: Interfacial effects on thermal and electrical transport. Int. J. Heat Mass Transf. 2004, 47, 2417–2435. [Google Scholar] [CrossRef]

- Dahmani, L.; Khennane, A.; Kaci, S. Crack identification in reinforced concrete beams using ANSYS software. Strength Mater. 2010, 42, 232–240. [Google Scholar] [CrossRef]

- Macedo, R.G.M.d.A.; Marques, N.d.N.; Tonholo, J.; Balaban, R.d.C. Water-soluble carboxymethylchitosan used as corrosion inhibitor for carbon steel in saline medium. Carbohydr. Polym. 2019, 205, 371–376. [Google Scholar] [CrossRef]

- Eduok, U.; Ohaeri, E.; Szpunar, J.; Akpan, I. Synthesis, characterization and application of glucosyloxyethyl acrylate graft chitosan against pipeline steel corrosion. J. Mol. Liq. 2020, 315, 113772. [Google Scholar] [CrossRef]

- El Mouaden, K.; El Ibrahimi, B.; Oukhrib, R.; Bazzi, L.; Hammouti, B.; Jbara, O.; Tara, A.; Chauhan, D.S.; Quraishi, M.A. Chitosan polymer as a green corrosion inhibitor for copper in sulfide-containing synthetic seawater. Int. J. Biol. Macromol. 2018, 119, 1311–1323. [Google Scholar] [CrossRef] [PubMed]

- El-Haddad, M.N. Chitosan as a green inhibitor for copper corrosion in acidic medium. Int. J. Biol. Macromol. 2013, 55, 142–149. [Google Scholar] [CrossRef] [PubMed]

- Gamal, A.; El-Mahdy, A.; Hamad, A.; Al-Lohedan, A.A.; Ezzat, O. Influence of green corrosion inhibitor based on chitosan ionic liquid on the steel corrodibility in chloride solution. Int. J. Electrochem. Sci. 2015, 10, 5812–5826. [Google Scholar]

- Farhadian, A.; Varfolomeev, M.A.; Shaabani, A.; Nasiri, S.; Vakhitov, I.; Zaripova, Y.F.; Yarkovoi, V.V.; Sukhov, A.V. Sulfonated chitosan as green and high cloud point kinetic methane hydrate and corrosion inhibitor: Experimental and theoretical studies. Carbohydr. Polym. 2020, 236, 116035. [Google Scholar] [CrossRef]

- Waleed, F.F.; Hesham, A.; Raed, R.; Kafafy, I.; Idres, M.; Elmoselhy, S. Vehicle fuel consumption and emission modelling: An in-depth literature review. Int. J. Veh. Syst. Model. Test. 2011, 6, 318–395. [Google Scholar]

- Fayomi, O.S.I.; Akande, I.G.; Oluwole, O.O.; Daramola, D. Effect of water-soluble chitosan on the electrochemical corrosion behaviour of mild steel. Chem. Data Collect. 2018, 17, 321–326. [Google Scholar] [CrossRef]

- Fayomi, O.; Akande, I.; Popoola, A. Corrosion protection effect of chitosan on the performance characteristics of A6063 alloy. J. Bio- Tribo-Corros. 2018, 4, 73. [Google Scholar] [CrossRef]

- Fekry, A.; Mohamed, R.R. Acetyl thiourea chitosan as an eco-friendly inhibitor for mild steel in sulphuric acid medium. Electrochim. Acta 2010, 55, 1933–1939. [Google Scholar] [CrossRef]

- Gallina, P. Vibration in screw jack mechanisms: Experimental results. J. Sound Vib. 2005, 282, 1025–1041. [Google Scholar] [CrossRef]

- Gallina, P.; Giovagnoni, M. Design of a screw jack mechanism to avoid self-excited vibrations. J. Dyn. Sys. Meas. Control 2002, 124, 477–480. [Google Scholar] [CrossRef]

- Gordon, R.; Fussey, P. Mild hybrid operation with a downsized diesel engine: A practical approach to outstanding fuel economy. J. Automot. Res. 2002, 14, 84. [Google Scholar]

- Gupta, N.L.; Joshi, P.G.; Srivastava, V.; Quraishi, M.A. Chitosan: A macromolecule as green corrosion inhibitor for mild steel in sulfamic acid useful for sugar industry. Int. J. Biol. Macromol. 2018, 106, 704–711. [Google Scholar] [CrossRef] [PubMed]

- Genena, F.A.; Jamal, D.A.; Ahmed, W.; Almarzooqi, L.A.; Almazrouei, A.S.; Al-Naqbi, A.H. Implementing green solutions to recycle UAE domestic waste: Aircraft composite materials. In Proceedings of the 2018 5th International Conference on Renewable Energy: Generation and Applications (ICREGA), Abu Dhabi, United Arab Emirates, 26–28 February 2018; pp. 30–33. [Google Scholar]

- Mansour, A.; Alabdouli, H.; Almehairi, A.R.; Alhammadi, M.; Alqaidy, H.; Ahmed, W.; Hilal-Alnaqbi, A. Investigating the compressive strength of CFRP Pre-Preg Scrap from aerospace industries: Compression molding. In Proceedings of the 2019 Advances in Science and Engineering Technology International Conferences (ASET), Institute of Electrical and Electronics Engineers (IEEE), Dubai, United Arab Emirates, 26 March–11 April 2019; pp. 1–6. [Google Scholar]

- Ahmed, W.K.; Hilal-Alnaqbi, A.; Almazrouei, A.S.S.; Almarzooqi, L.A.A.M.; Al Jamal, D.; Genena, F.A.A. Method of Recycling Carbon Fiber Prepreg Waste. U.S. Patent US10328610B2, 25 June 2019. [Google Scholar]

- Ahmed, W.K. Method of Recycling Carbon Fiber Prepreg Waste and Transparent Thermoplastic Waste. U.S. Patent US10507598B2, 17 December 2019. [Google Scholar]

- D20 Committee. Guide for Determination of Thickness of Plastic Film Test Specimens; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Hoffman, J.M. New life for shredded plastic waste. Mach. Des. 2008, 80, 55–58. [Google Scholar]

- Maraveas, C. Production of Sustainable and Biodegradable Polymers from Agricultural Waste. Polymers 2020, 12, 1127. [Google Scholar] [CrossRef]

- Akyürek, F.; Yaman, K.; Tekiner, Z. An Experimental Work on Tool Wear Affected by Die Clearance and Punch Hardness. Arab. J. Sci. Eng. 2017, 42, 4683–4692. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modling Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Ahmed, W.; Zaneldin, E.; Al Hassan, A. Undergraduate Research Program to Recycle Composite Waste. Educ. Sci. 2021, 11, 354. [Google Scholar] [CrossRef]

- Wu, W.; Wang, Q.; Li, W. Comparison of Tensile and Compressive Properties of Carbon/Glass Interlayer and Intralayer Hybrid Composites. Materials 2018, 11, 1105. [Google Scholar] [CrossRef] [Green Version]

- Almazrouei, N.; Siraj, S.; Al-Marzouqi, A.-H.; Ahmed, W. Producing Particulate Composite Using 3D Printing Plastics Waste. In Proceedings of the 2022 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 21–24 February 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Ahmed, W.; Siraj, S.; Al-Marzouqi, A.H. 3D Printing PLA Waste to Produce Ceramic Based Particulate Reinforced Composite Using Abundant Silica-Sand: Mechanical Properties Characterization. Polymers 2020, 12, 2579. [Google Scholar] [CrossRef]

- Gvali, V.; Kubade, P.; Kulkarni, H. Mechanical and Thermo-mechanical Properties of Carbon fiber Reinforced Thermoplastic Composite Fabricated Using Fused Deposition Modeling Method. Mater. Today Proc. 2020, 22, 1786–1795. [Google Scholar] [CrossRef]

- Ferretti, E.; Moretti, M.; Chiusoli, A.; Naldoni, L.; de Fabritiis, F.; Visonà, M. Rice-Husk Shredding as a Means of Increasing the Long-Term Mechanical Properties of Earthen Mixtures for 3D Printing. Materials 2022, 15, 743. [Google Scholar] [CrossRef] [PubMed]

- Grigore, M.E. Methods of Recycling, Properties and Applications of Recycled Thermoplastic Polymers. Recycling 2017, 2, 24. [Google Scholar] [CrossRef] [Green Version]

- Omar, N.W.Y.; Shuaib, N.A.; Hadi, M.H.J.A.; Azmi, A.I.; Misbah, M.N. Mechanical and Physical Properties of Recycled-Carbon-Fiber-Reinforced Polylactide Fused Deposition Modelling Filament. Materials 2022, 15, 190. [Google Scholar] [CrossRef]

- Al-Mazrouei, N.; Ismail, A.; Ahmed, W.; Al-Marzouqi, A.H. ABS/Silicon Dioxide Micro Particulate Composite from 3D Printing Polymeric Waste. Polymers 2022, 14, 509. [Google Scholar] [CrossRef]

- Yamanaka, A.; Terada, M.; Ichiki, M.; Kimoto, Y.; Shiraki, K.; Nagata, M.; Shimamoto, D.; Hotta, Y. Evaluation of Fiber Orientation by X-ray Diffraction on Carbon Fiber Reinforced Polyamide 6. J. Fiber Sci. Technol. 2020, 76, 199–207. [Google Scholar] [CrossRef]

- Stănescu, M.M.; Bolcu, A. A Study of the Mechanical Properties in Composite Materials with a Dammar Based Hybrid Matrix and Reinforcement from Crushed Shells of Sunflower Seeds. Polymers 2022, 14, 392. [Google Scholar] [CrossRef]

- Nassar, M.M.A.; Tarboush, B.J.A.; Alzebdeh, K.I.; Al-Hinai, N.; Pervez, T. New Synthesis Routes toward Improvement of Natural Filler/Synthetic Polymer Interfacial Crosslinking. Polymers 2022, 14, 629. [Google Scholar] [CrossRef]

- Dong, Y.; Arvinder, G.; Hitoshi, T.; Hazim Haroosh, A.; Nakagaito, N.; Kin-Tak, L. Polylactic acid (PLA) biocomposites reinforced with coir fibres: Evaluation of mechanical performance and multifunctional properties. Compos. Part A 2014, 63, 76–84. [Google Scholar]

- Chumaevskii, A.; Yu, S.; Filippov, T.; Kolubaev, K.; Rubtsov, V.; Eliseev, A. Mechanical strength of additive manufactured carbon fiber reinforced Polyetheretherketone. Am. Inst. Phys. 2016, 17, 233–239. [Google Scholar]

- Ahmed, W. High Flexible Sandwich Panel Made of Glass Fibre Reinforced Nylon with Super Elastic Rubber Core Using Fused Filament Fabrication (FFF). U.S. Patent US11235514B1, 1 February 2022. [Google Scholar]

- Ning, F.; Cong, W.; Hu, Y.; Wang, H. Additive manufacturing of carbon fiber-reinforced plastic composites using fused deposition modelling: Effects of process parameters on tensile properties. J. Compos. Mater. 2016, 51, 451–462. [Google Scholar] [CrossRef]

- Tian, X.; Liu, T.; Yang, C.; Wang, Q.; Li, D. Interface and performance of 3D printed continuous carbon fiber reinforced PLA composites. Compos. Part A 2016, 88, 198–205. [Google Scholar]

- Mahajan, C.; Cormier, D. 3D Printing of Carbon Fiber Composites with Preferentially Aligned Fibers. In Proceedings of the 2015 Industrial and Systems Engineering Research Conference, Seville, Spain, 21–23 October 2015; pp. 1–12. [Google Scholar]

- Hull, E.; Weston, G.; Meng, Z.; Xiaoxu, S.; Weilong, J. Effects of process variables on extrusion of carbon fiber reinforced ABS filament for additive manufacturing. In Proceedings of the International Manufacturing Science and Engineering Conference, San Francisco, CA, USA, 8–12 June 2015; pp. 1–9. [Google Scholar]

| Samples | Length mm | Width mm | Thickness mm |

|---|---|---|---|

| CF-Prepreg 10% + PLA | 17.02 | 2.69 | 0.28 |

| CF 10% + PLA | 0.20 | ||

| CF-Prepreg 20% + PLA | 0.24 | ||

| CF 20% + PLA | 0.26 | ||

| Pure-PLA | 0.27 |

| Material ID | Elastic Modulus | Yield Strength | Ultimate Strength | Ductility | ||||

|---|---|---|---|---|---|---|---|---|

| GPa | MPa | MPa | % | |||||

| Value | SD | Value | SD | Value | SD | Value | SD | |

| Pure PLA | 5.02 | ±0.53 | 35.83 | ±0.60 | 37.20 | ±0.40 | 6.01 | ±0.44 |

| CF 10%/PLA | 6.26 | ±0.36 | 39.07 | ±1.97 | 39.90 | ±1.60 | 3.40 | ±0.82 |

| CF 20%/PLA | 5.91 | ±0.12 | 45.68 | ±6.00 | 47.81 | ±3.90 | 4.16 | ±0.55 |

| CFRP 10%/PLA | 4.19 | ±0.23 | 39.77 | ±5.70 | 43.07 | ±4.70 | 8.80 | ±0.50 |

| CFRP 20%/PLA | 3.78 | ±0.13 | 38.73 | ±1.21 | 43.58 | ±0.70 | 9.20 | ±0.31 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al Zahmi, S.; Alhammadi, S.; ElHassan, A.; Ahmed, W. Carbon Fiber/PLA Recycled Composite. Polymers 2022, 14, 2194. https://doi.org/10.3390/polym14112194

Al Zahmi S, Alhammadi S, ElHassan A, Ahmed W. Carbon Fiber/PLA Recycled Composite. Polymers. 2022; 14(11):2194. https://doi.org/10.3390/polym14112194

Chicago/Turabian StyleAl Zahmi, Salem, Saif Alhammadi, Amged ElHassan, and Waleed Ahmed. 2022. "Carbon Fiber/PLA Recycled Composite" Polymers 14, no. 11: 2194. https://doi.org/10.3390/polym14112194

APA StyleAl Zahmi, S., Alhammadi, S., ElHassan, A., & Ahmed, W. (2022). Carbon Fiber/PLA Recycled Composite. Polymers, 14(11), 2194. https://doi.org/10.3390/polym14112194