Experimental Study on the Flexural Behavior of Lap-Spliced Ultra-High-Performance Fiber-Reinforced Concrete Beams

Abstract

1. Introduction

2. Design Recommendations for Lap Splice Length

2.1. Eurocode 2

2.2. AFGC Recommendation

2.3. KCI2012

2.4. KICT

3. Test Program

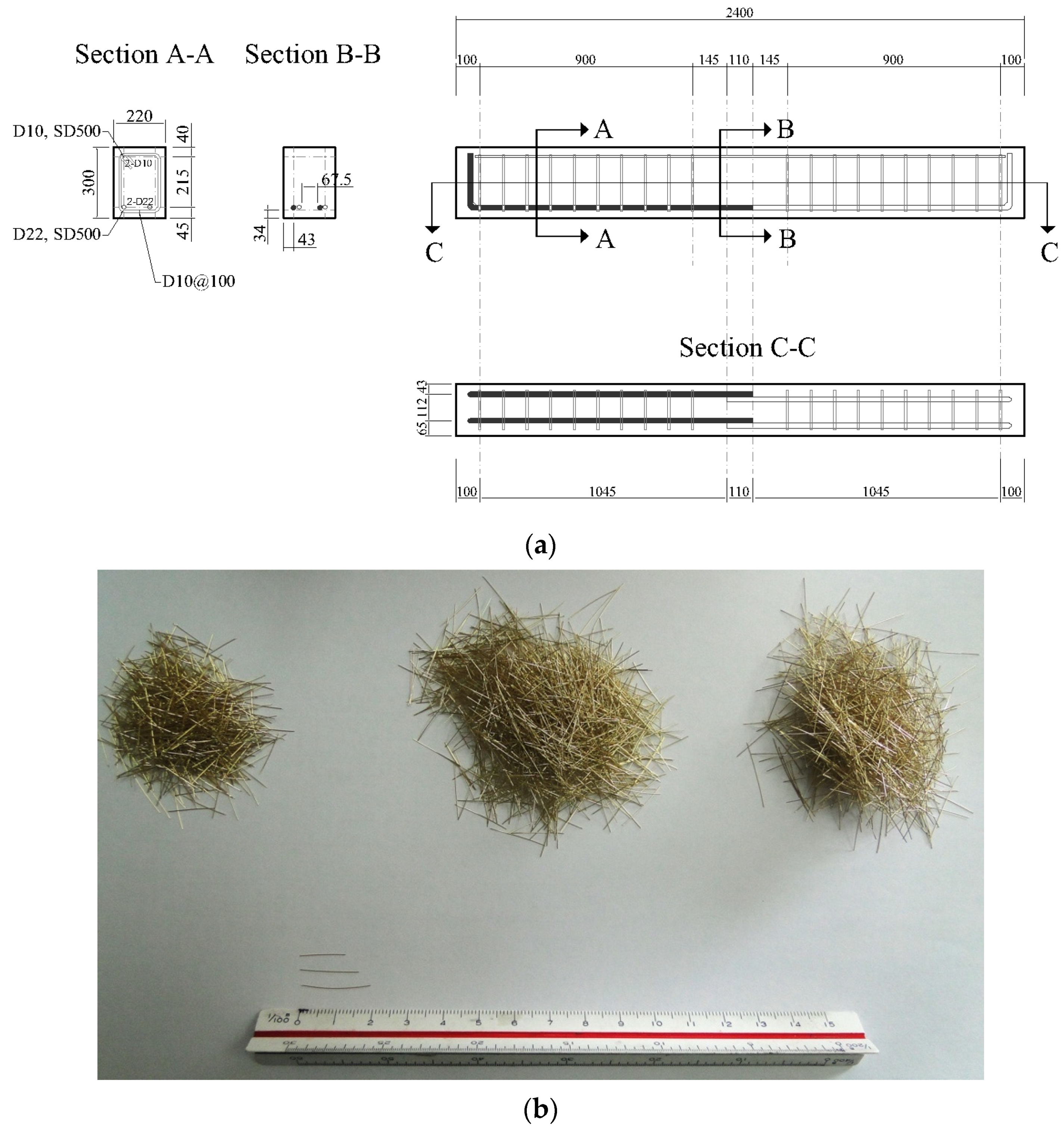

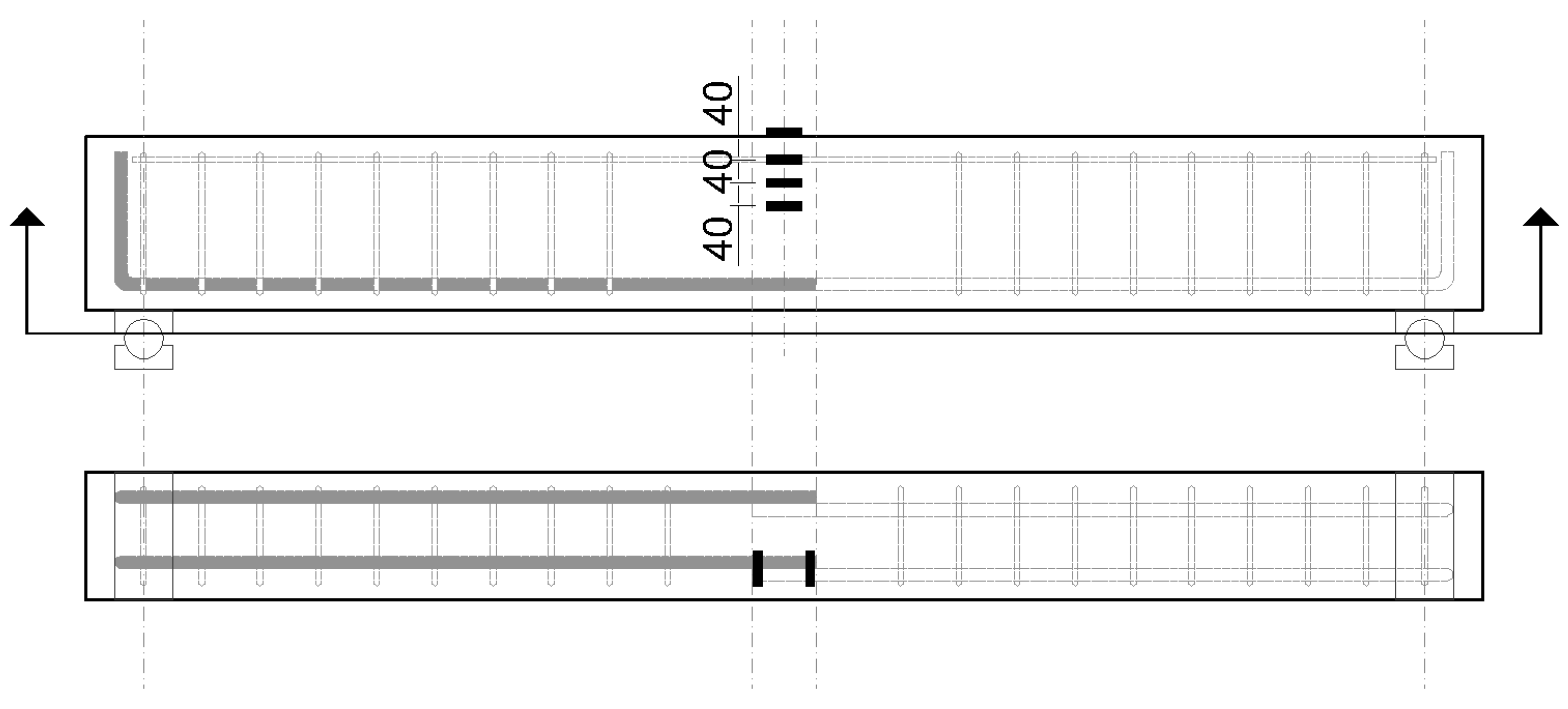

3.1. Subsection Variables and Specimen Detail

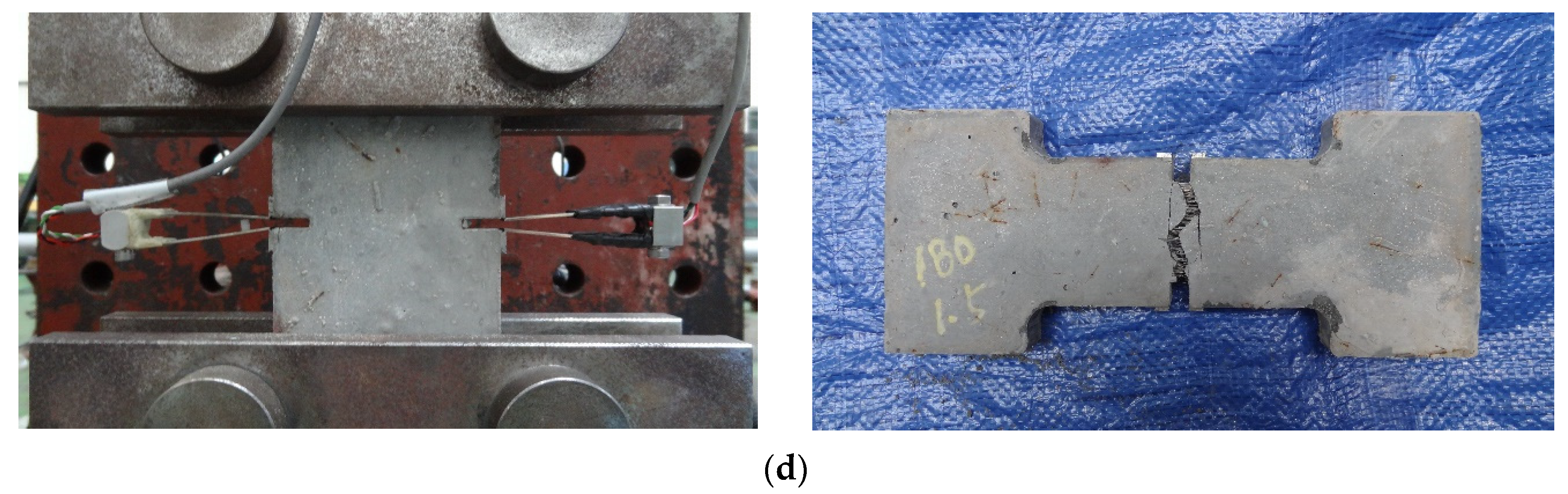

3.2. Material Properties

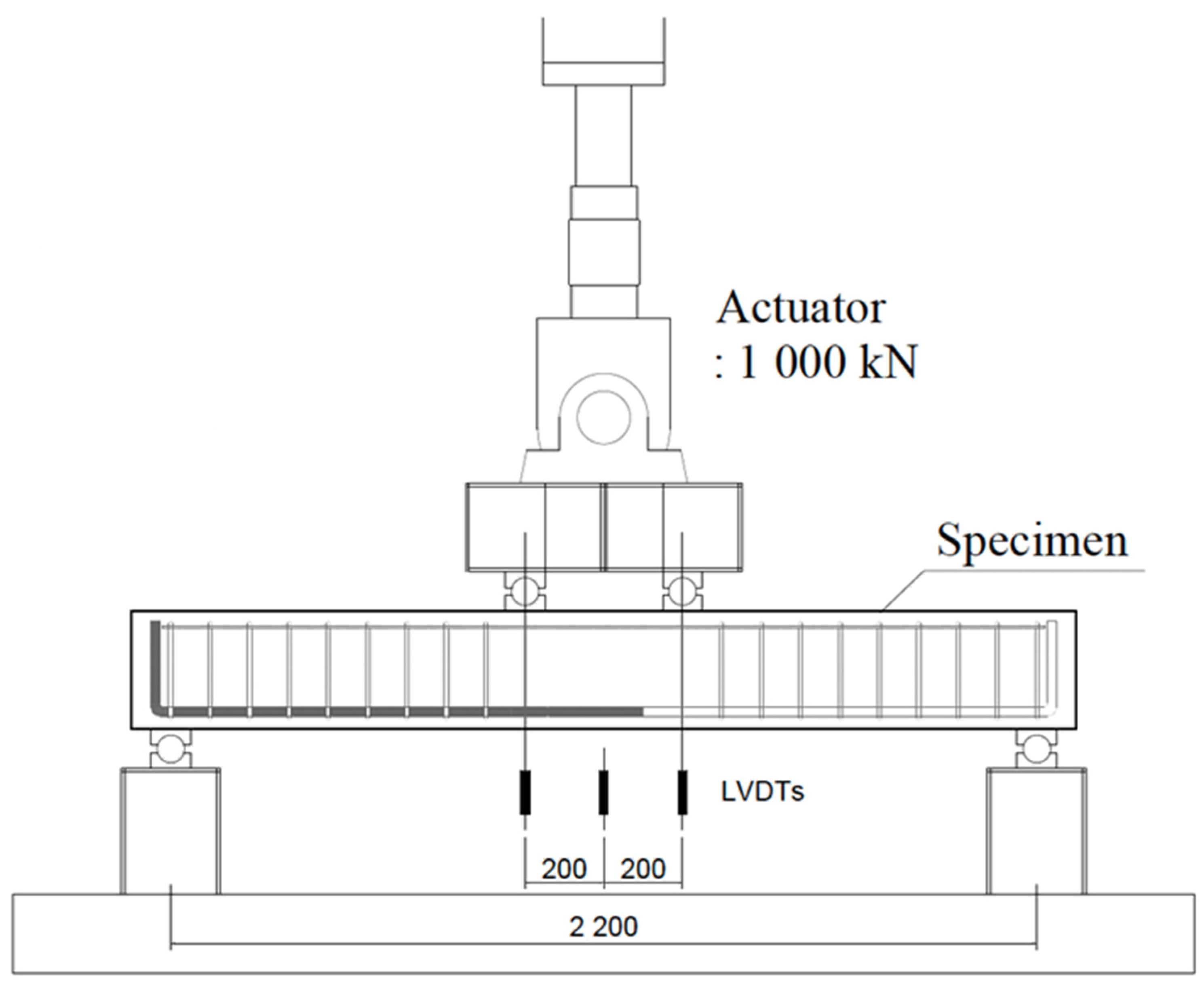

3.3. Measurement Plan

4. Test Results

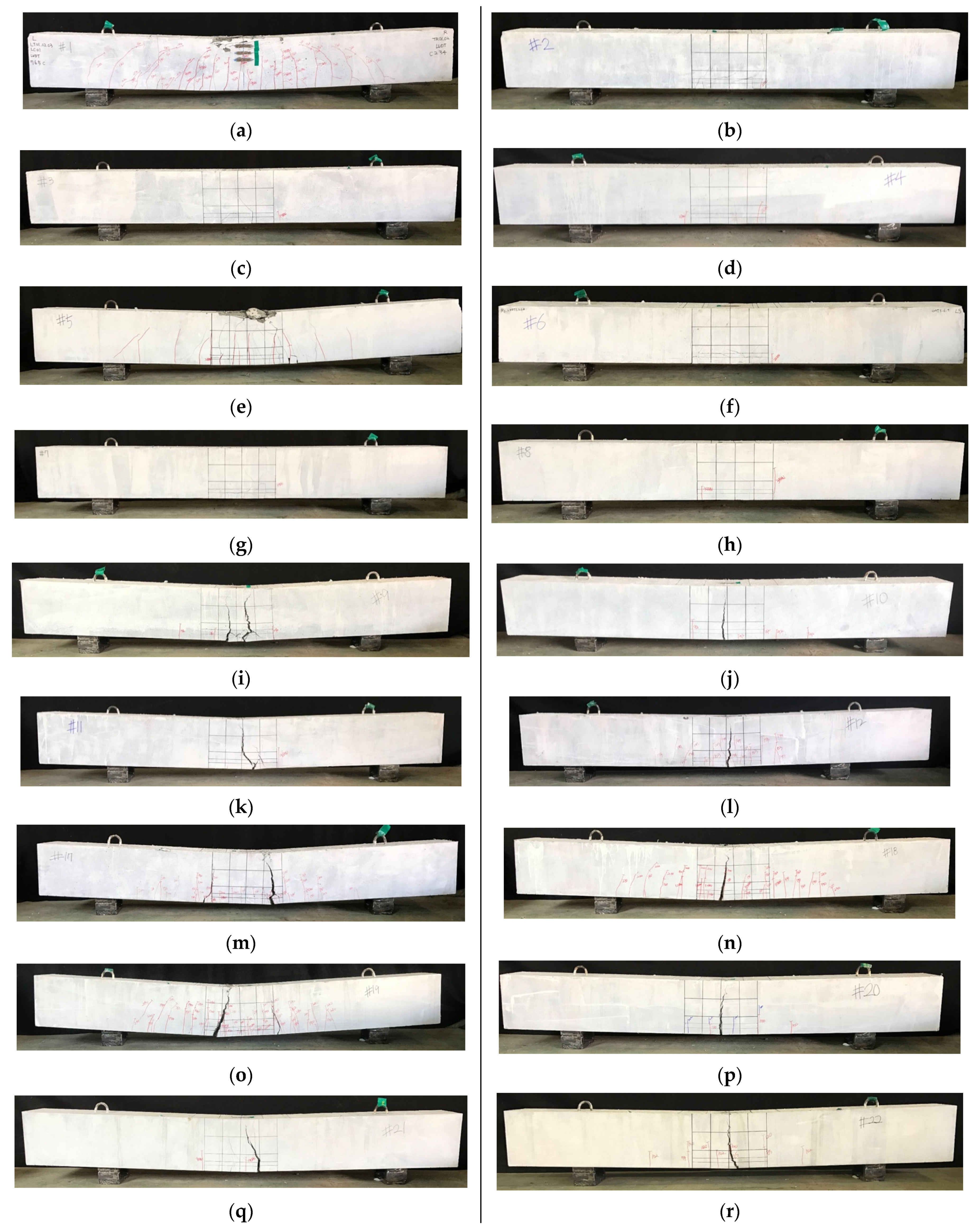

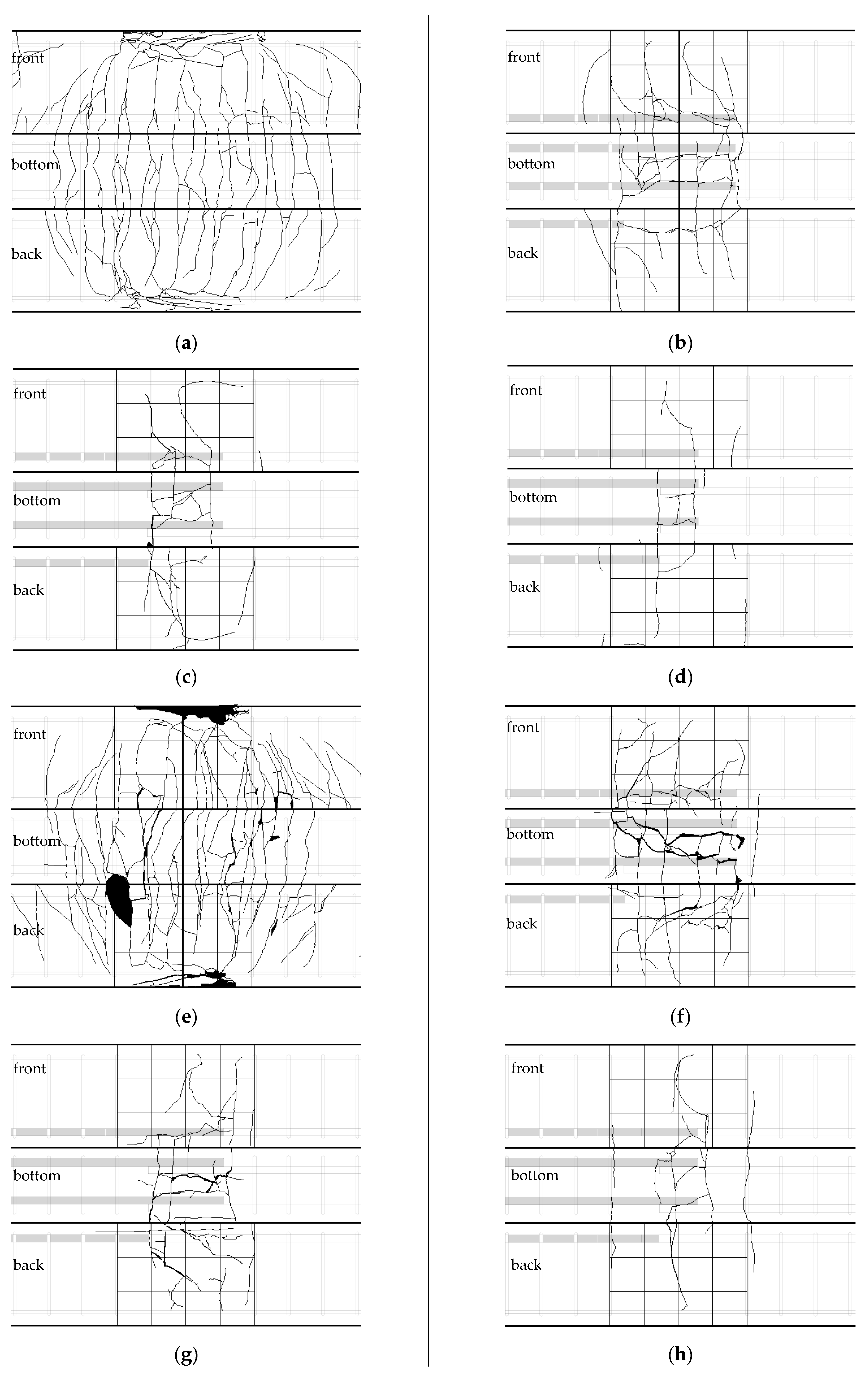

4.1. Mode of Failure

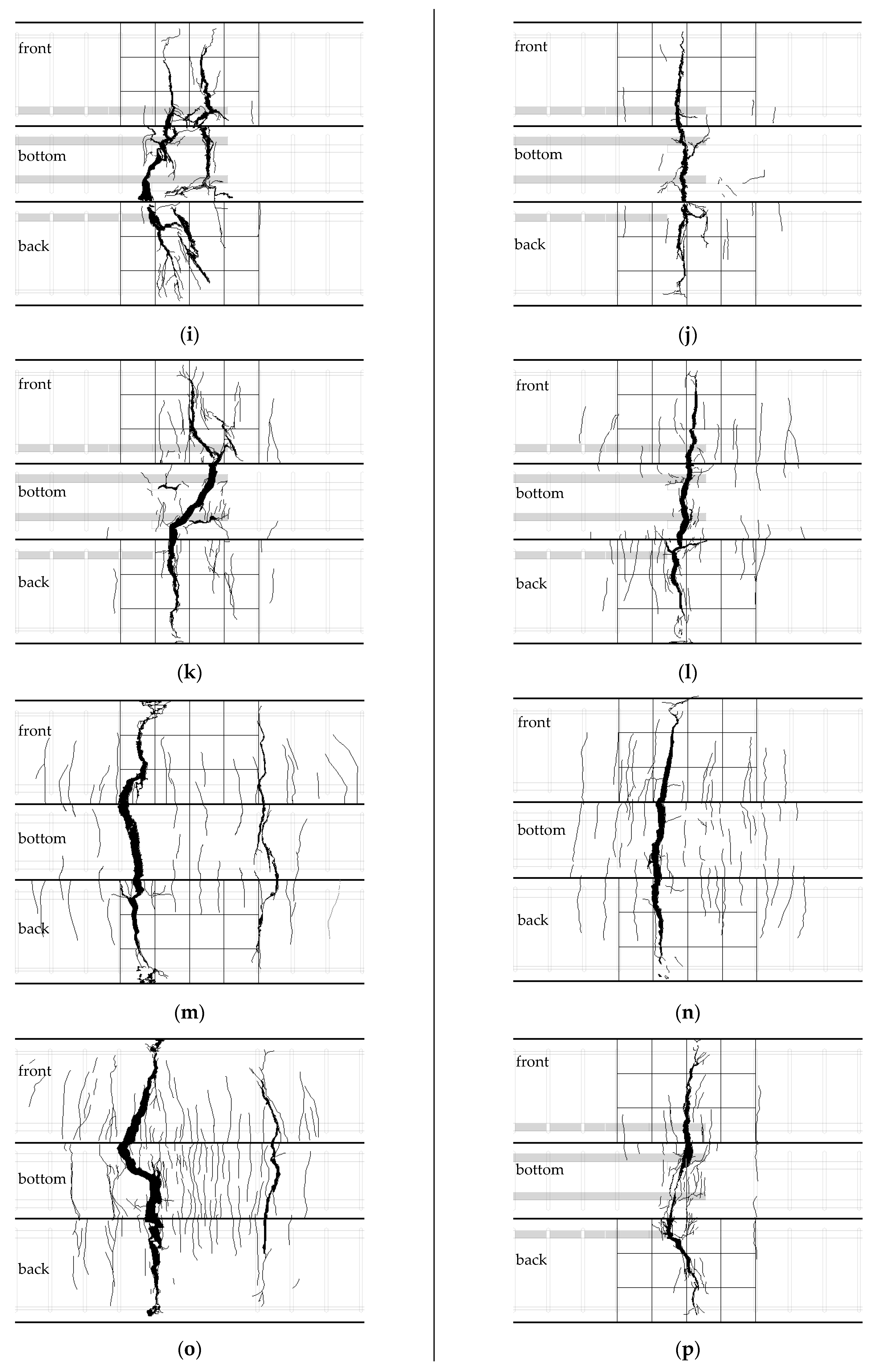

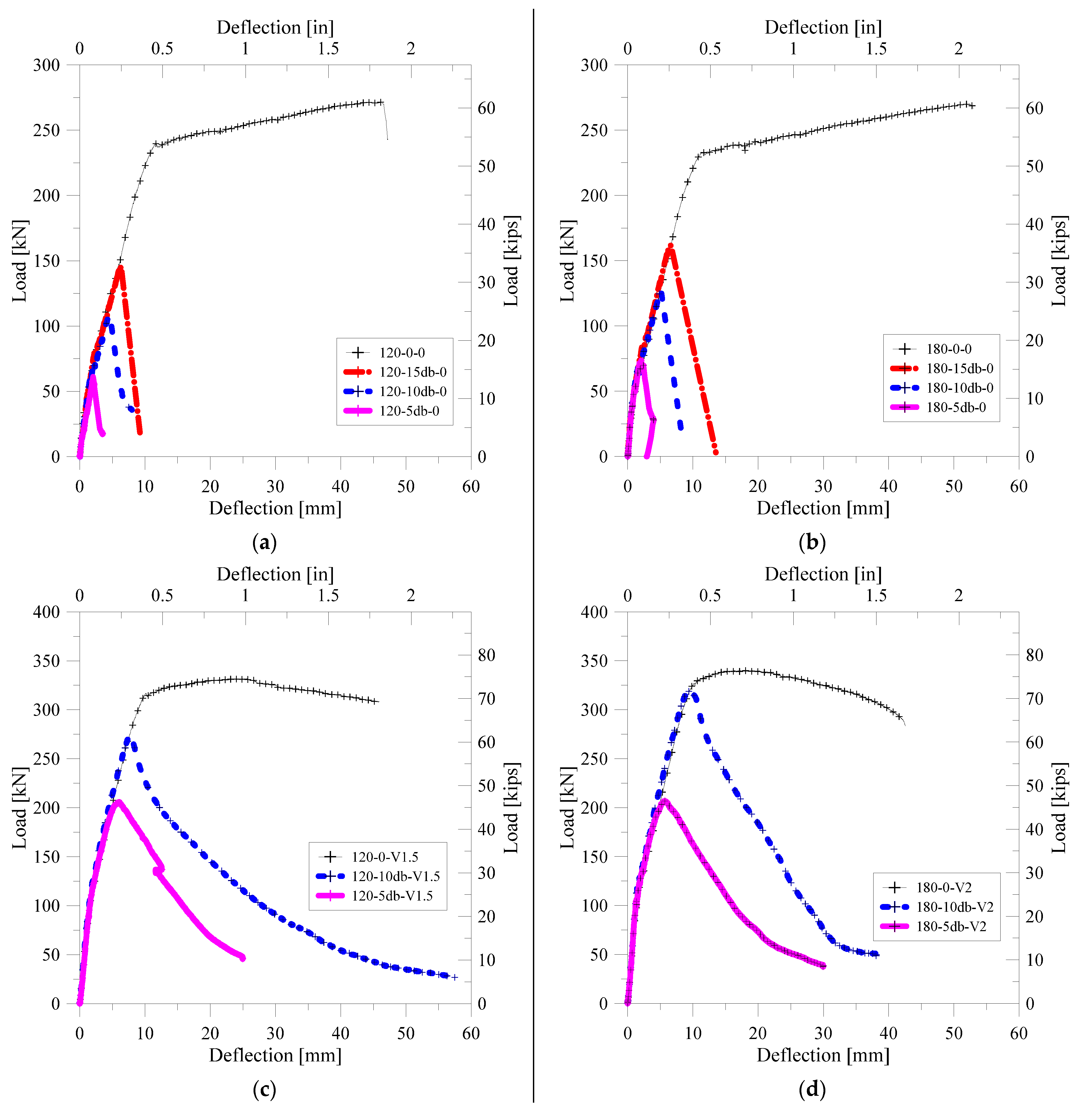

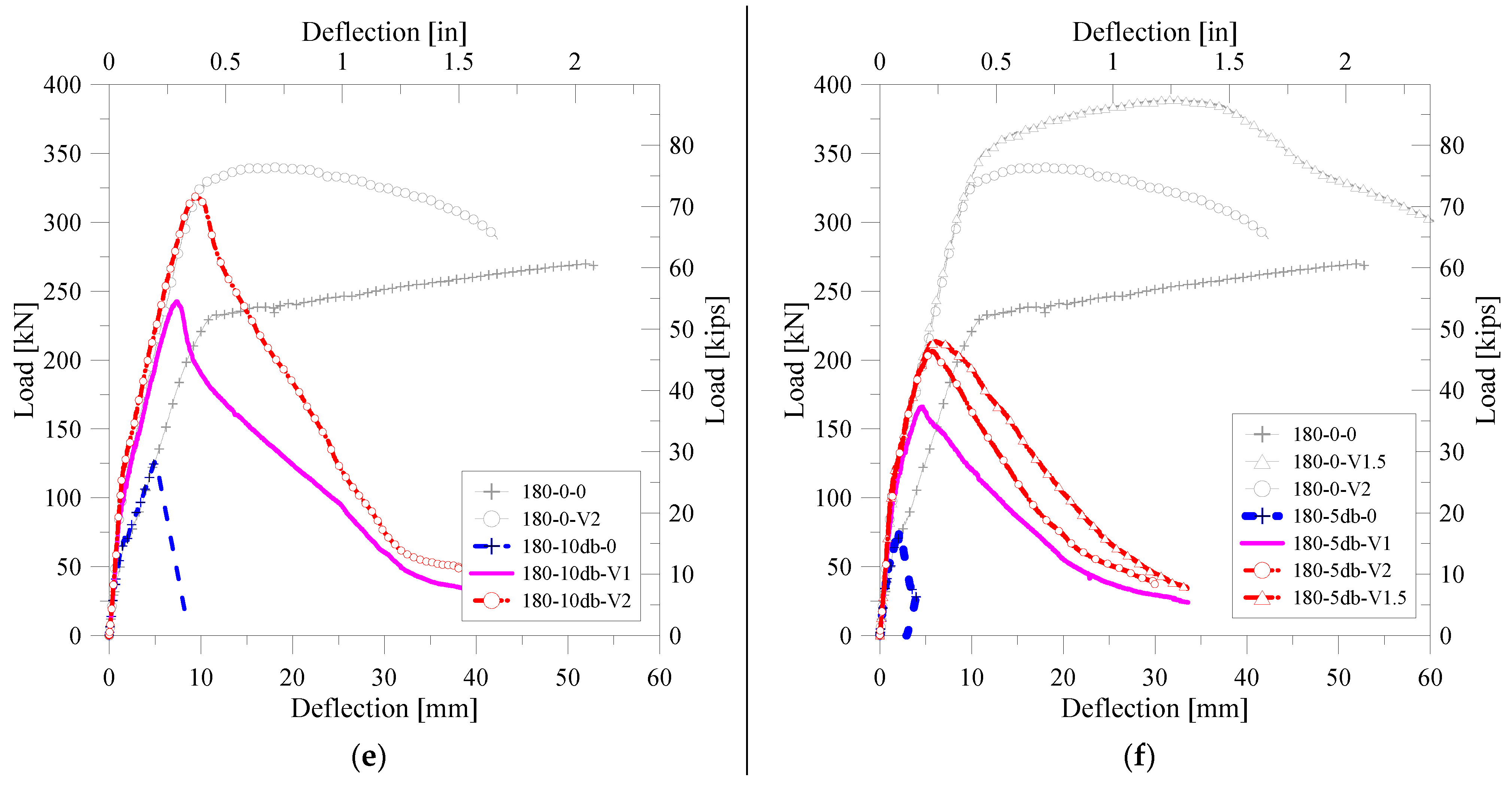

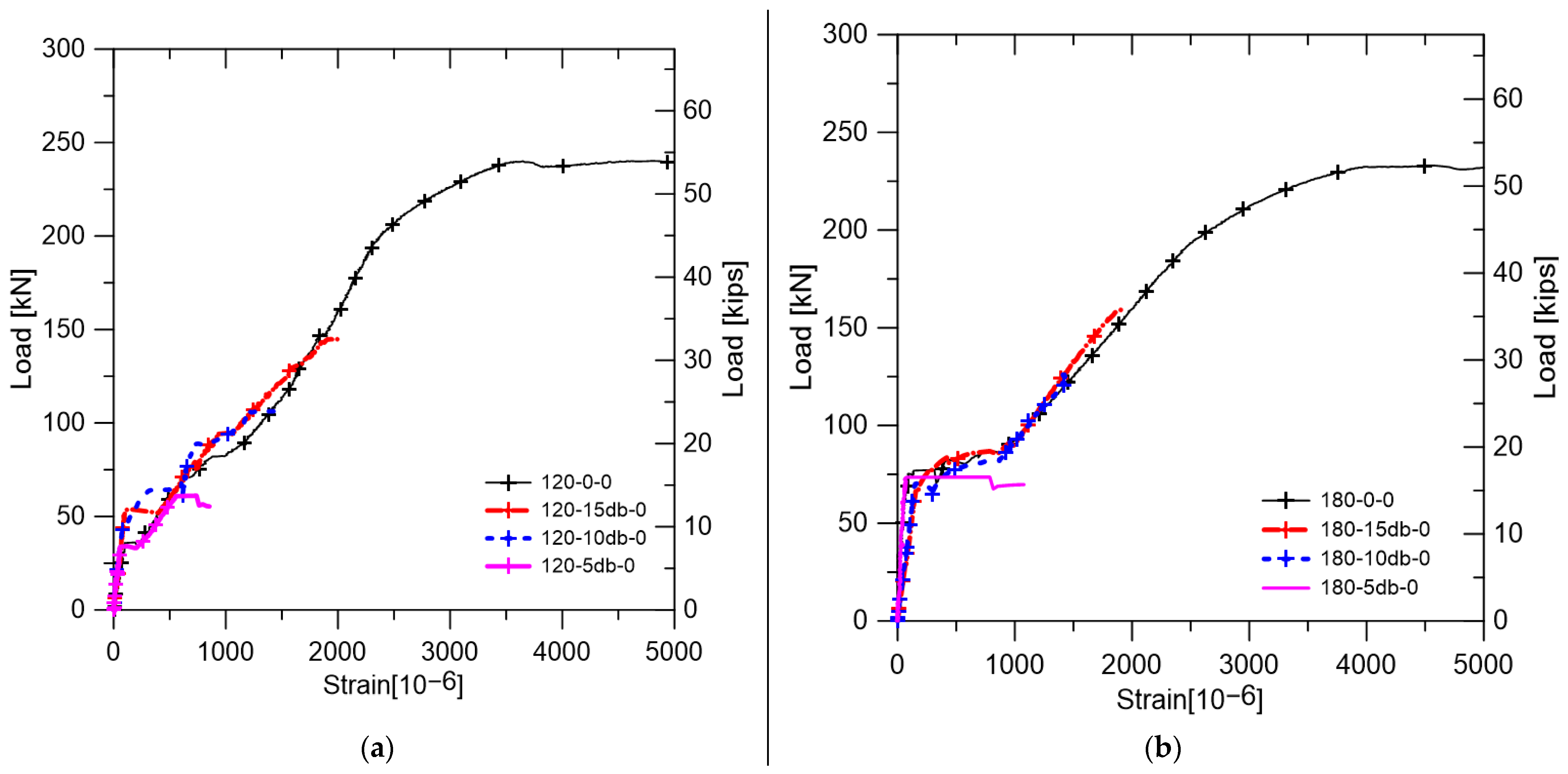

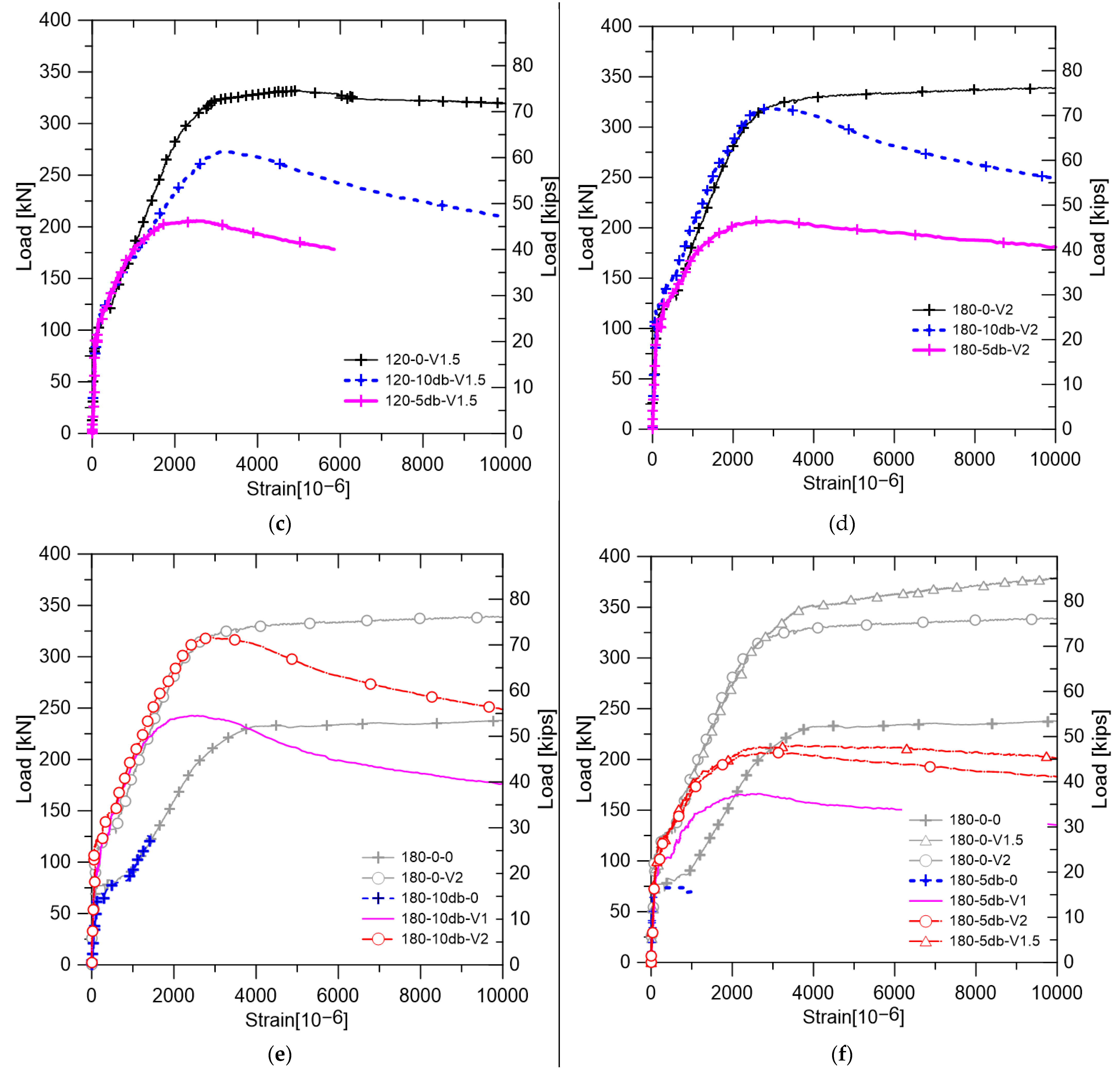

4.2. Load-Deflection Curves

5. Applied Stress to Tensile Reinforcements

5.1. Strain of Steel at Lap-Spliced Region

5.2. Strain Calculated by Sectional Analysis

- (1)

- plane sections before bending remain plane after bending;

- (2)

- steel rebar perfectly bonded to the concrete under compression and tension;

- (3)

- the tensile stress–strain relation should be considered for the UHPFRC matrix but the tensile stress–strain relation can be neglected when concrete is not reinforced with steel fiber.

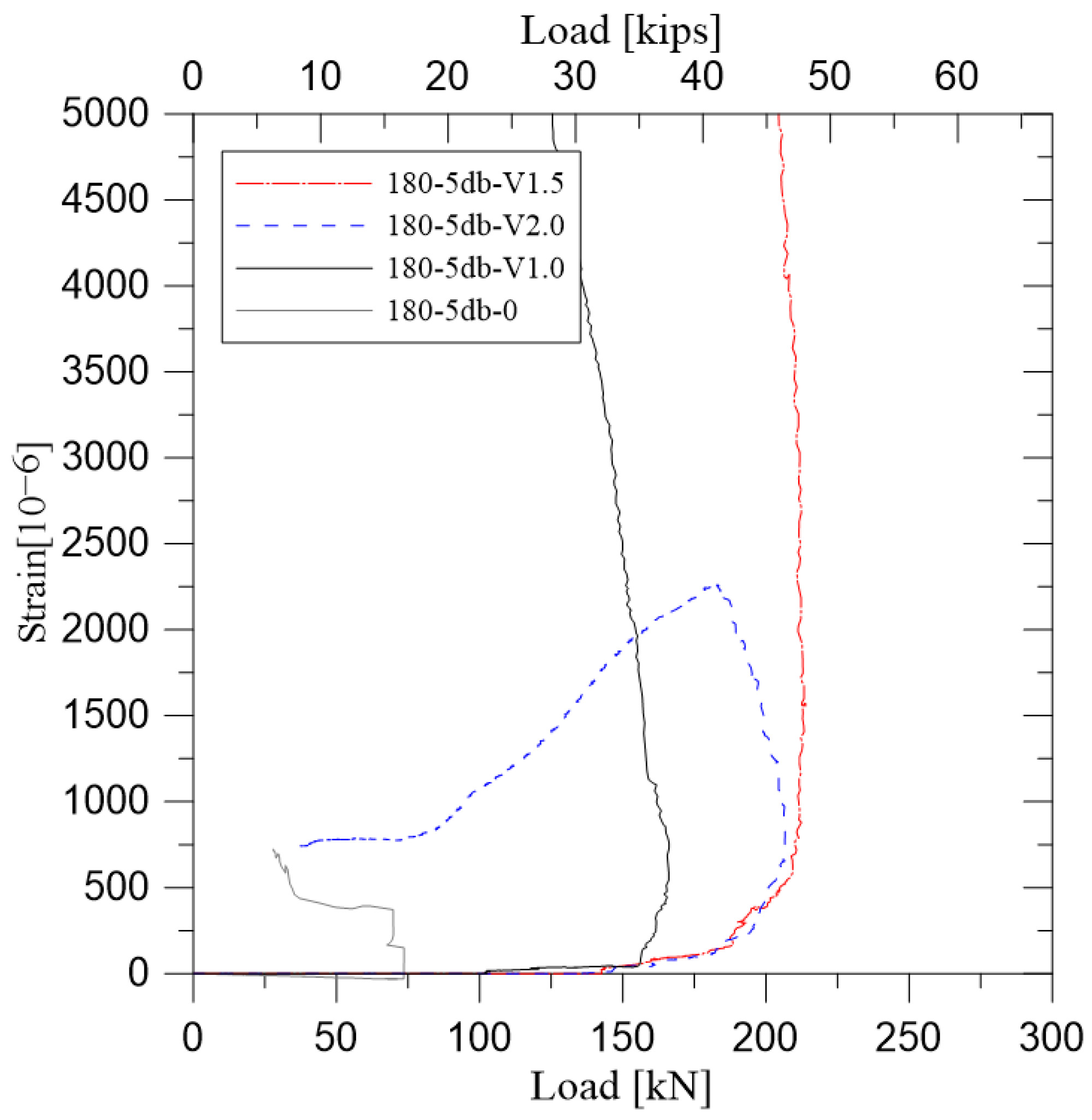

5.3. Expansion of Concrete Adjacent to Lap-Spliced Rebar

6. Discussion

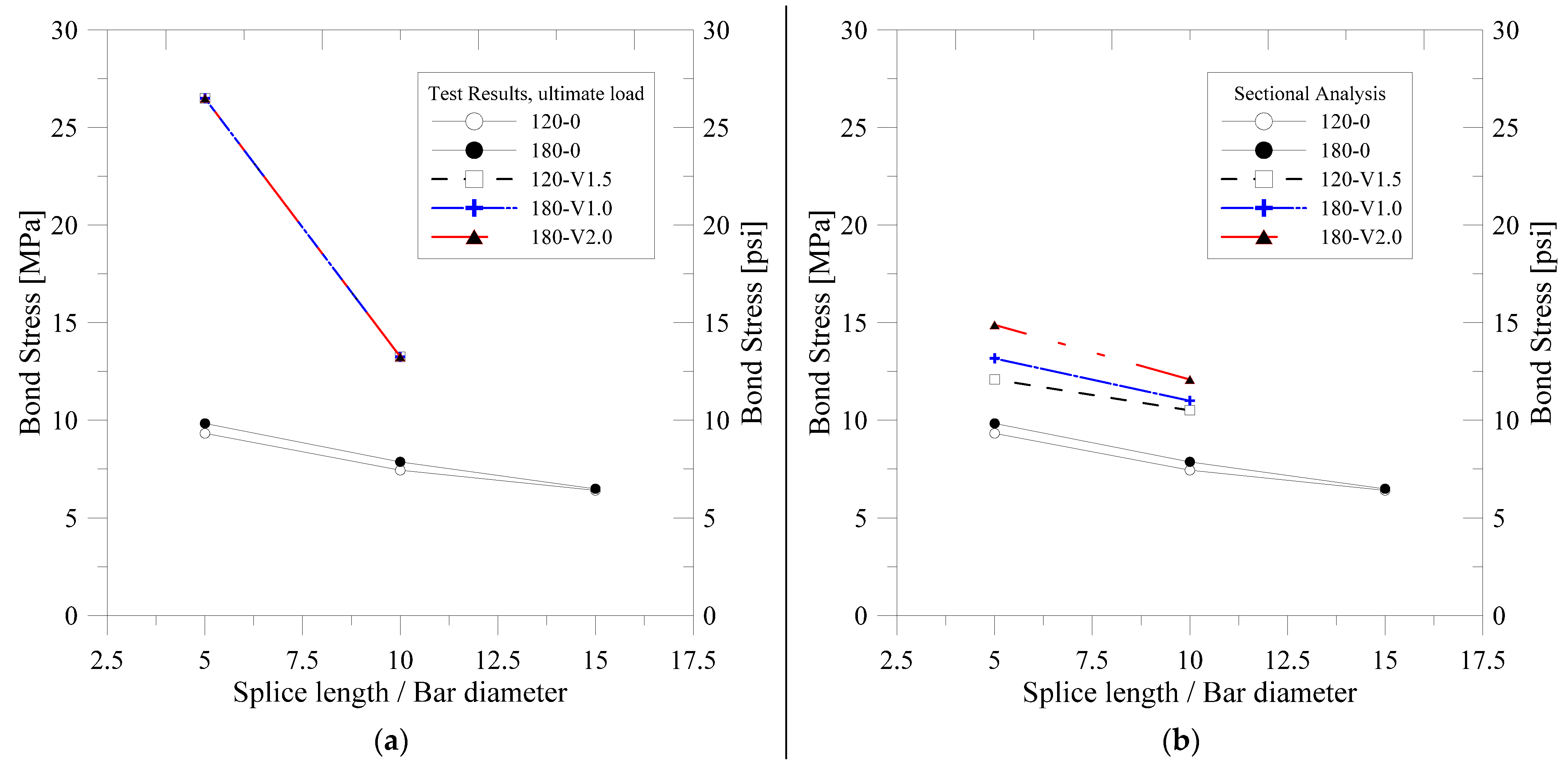

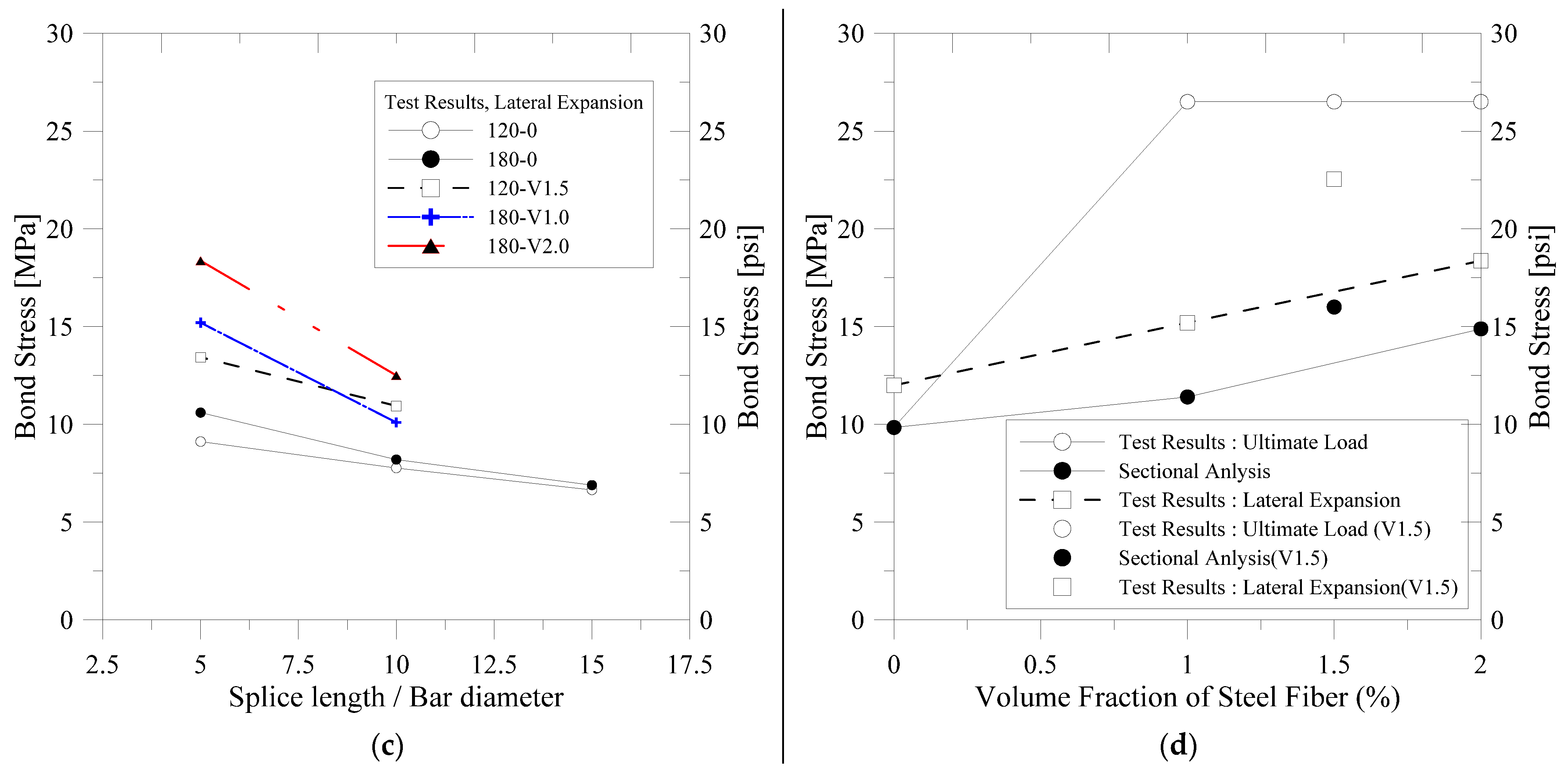

6.1. Ultimate Average Bond Stress

6.2. Required Lap Splice Length

7. Conclusions

- (1)

- As a result of evaluating the flexural performance of the ultra-high-performance concrete using the concrete matrix of 120 MPa and 180 MPa, it was confirmed that compressive strength does not have a great influence on flexural strength. However, the increase in flexural strength due to the inclusion of the steel fiber was confirmed, and the hybrid-type steel fiber with the two lengths of steel fiber had higher bending strength. Ductility decreased with the inclusion of steel fiber because of the increase in tensile force of the section and crack localization;

- (2)

- The lap-spliced beams, which were not reinforced with steel fiber, failed due to splitting failure similar to ordinary concrete lap-spliced beams. As a result of experiments at 5 times, 10 times, and 15 times of the diameter of tensile reinforcement, it was found that the fracture occurred due to the cracks at the bottom surface in the longitudinal direction of the reinforcing bars in both lap splice beams with the compressive strengths of 120 and 180 MPa;

- (3)

- In the case of UHPFRC lap spliced beams, initial cracking was delayed and did not experience abrupt loss of load carrying capacity after experiencing maximum load due to the dispersion of cracks. For all the lap-spliced test specimens, the maximum strength did not reach the flexural strength, but the rebar experienced yielding at maximum strength;

- (4)

- It could be confirmed that the strength of lap-spliced UHPFRC test specimens changed with the inclusion of steel fiber. The maximum strength of the specimen increased linearly with the increase in the steel fiber volume fraction. The hybrid-type UHPFRC with lower steel fiber volume fraction using two types of steel fiber was effective in improving the bond strength;

- (5)

- As a result of the measurement of the expansion strain of the concrete around the reinforced concrete, it was confirmed that when the steel fiber is not reinforced, the maximum strength and the strain increase at the same time. On the other hand, when reinforced with steel fiber, the maximum strength was not reached even when the rapid expansion strain started. It can be seen that the steel fiber prevents the pullout failure bridging the longitudinal cracks;

- (6)

- As a result of evaluating the lap splice performance with the average bond stress, it was found that the hybrid fiber reinforced test specimen had the highest strength. Although the matrix types are the same, the average bond stress varies depending on the lap splice length. Therefore, the bond stress concentration phenomenon and the nonlinear distribution phenomenon are also observed in UHPFRC;

- (7)

- As a result of the sectional analysis, it was confirmed that the magnitude of the average bond stress was smaller than that of the experimental results, and it was considered that the result of the sectional analysis through the stress–strain relation proposed by AFGC can be used in designing the lap splice length of UHPFRC flexural members;

- (8)

- It was confirmed that the splice length was required to be conservative when designing the UHPFRC member as the current design standard. The KICT design recommendation is conservative because it is a design recommendation derived from only one type of UHPFRC matrix. The AFGC design recommendation considered the tensile strength of UHPFRC in the determination of the bond stress, but it was found that the bond stress was overestimated as the bond stress calculation formula was derived by the direct pull-out test. Therefore, in order to construct a safe design formula, additional research based on the lap-spliced beam test, which is more disadvantageous in estimating the bond stress, should be performed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Graybeal, B.A. Flexural behavior of an ultra high-performance concrete I-girder. J. Bridge Eng. 2008, 13, 602–610. [Google Scholar] [CrossRef]

- Chen, L.; Graybeal, B.A. Modeling structural performance of second-generation ultrahigh-performance concrete pi-girders. J. Bridge Eng. 2011, 17, 634–643. [Google Scholar] [CrossRef]

- Bentur, A.; Mindess, S. Fibre Reinforced Cementitious Composites; Elsevier: London, UK; New York, NY, USA, 1990. [Google Scholar]

- Graybeal, B.A. Material Property Characterization of Ultra-High Performance Concrete; Rep. No. FHWA-HRT-06-103; Federal Highway Administration: Washington, DC, USA, 2006.

- Sucharda, O.; Lehner, P.; Konečný, P.; Ponikiewski, T. Investigation of Fracture Properties by Inverse Analysis on Selected SCC Concrete Beams with Different Amount of Fibres. Procedia Struct. Integr. 2018, 13, 1533–1538. [Google Scholar] [CrossRef]

- Brandt, A.M. Fiber reinforced cement-based (FRC) composites after over 40 years of development in building and civil engineering. Compos. Struct. 2008, 86, 3–9. [Google Scholar] [CrossRef]

- Pająk, M.; Ponikiewski, T. Flexural behavior of self-compacting concrete reinforced with different types of steel fibers. Constr. Build. Mater. 2013, 47, 397–408. [Google Scholar] [CrossRef]

- Richard, P.; Cheyrezy, M.H. Reactive powder concretes with high ductility and 200–800 MPa compressive strength. Spec. Publ. 1994, 144, 507–518. [Google Scholar]

- Collepardi, S.; Coppola, L.; Troli, R.; Collepardi, M. Mechanical properties of modified reactive powder concrete. Spec. Publ. 1997, 173, 1–22. [Google Scholar]

- Tepfers, R. Cracking of concrete cover along anchored deformed reinforcing bars. Mag. Concr. Res. 1979, 31, 3–12. [Google Scholar] [CrossRef]

- ACI Committee. Building Code Requirements for Structural Concrete (ACI 318-14) and Commentary; American Concrete Institute: Farmington Hills, MI, USA, 2014. [Google Scholar]

- Korean Concrete Institute. Concrete Design Code and Commentary; Korea Concrete Institute: Seoul, Korea, 2012. [Google Scholar]

- EN 1992-1 2004; Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings. European Committee for Standarization (CEN): Brussels, Belgium, 2004.

- AFGC/SETRA. Ultra High Performance Fibre-Reinforced Concretes; Interim Recommendations; SETRA: Bagneux, France, 2002. [Google Scholar]

- Holschemacher, K.; Weiße, D.; Klotz, S. Bond of Reinforcement in Ultra High-Strength Concrete. Spec. Publ. 2005, 228, 513–528. [Google Scholar]

- RILEM. Technical Recommendations for the Testing and Use of Construction Materials: RC 6, Bond Test for Reinforcement Steel. 2. Pull-Out Test; E & FN SPON: New York, NY, USA, 1970. [Google Scholar]

- Jungwirth, J. Zum Zugtragverhalten von zugbeanspruchten Bauteilen aus Ultra-Hochleistungs-Faserbeton. In Thèse No 3429, Faculté Environnement Naturel, Architectural et Construit; École Polytechnique Fédérale de Lausanne: Lausanne, Switzerland, 2006. [Google Scholar]

- Leutbecher, T. Rissbildung und Zugtragverhalten von mit Stabstahl und Fasern bewehrtem Ultrahochfesten Beton (UHPC); Kassel University: Kassel, Germany, 2007. [Google Scholar]

- Azhar Saleem, M.; Mirmiran, A.; Xia, J.; Mackie, K. Development Length of High-Strength Steel Rebar in Ultrahigh Performance Concrete. J. Mater. Civ. Eng. 2013, 25, 991–998. [Google Scholar] [CrossRef]

- Bae, B.-I.; Choi, H.-K.; Choi, C.-S. Bond stress between conventional reinforcement and steel fibre reinforced reactive powder concrete. Constr. Build. Mater. 2016, 112, 825–835. [Google Scholar] [CrossRef]

- ACI Committee 408. Splice and Development Length of High Relative Rib Area Reinforcing Bars in Tension (408.3-01); American Concrete Institute: Framington Hills, MI, USA, 2001. [Google Scholar]

- Lee, J.K. Bonding behavior of lap-spliced reinforcing bars embedded in Ultra-high Strength Concrete with steel fibers. KSCE J. Civ. Eng. 2016, 20, 273–281. [Google Scholar] [CrossRef]

- Kim, S.; Lee, J.; Joh, C.; Kwahk, I. Flexural Bond Behavior of Rebar in Ultra-High Performance Concrete Beams Considering Lap-Splice Length and Cover Depth. Engineering 2016, 8, 116–129. [Google Scholar] [CrossRef][Green Version]

- AFGC (Association Française de Génie Civil). Interim Recommendations. In Ultra High Performance Fibre Reinforced Concretes; Association Française de Génie Civil: Paris, France, 2013. [Google Scholar]

- KCI-M-12-003; Design Guidelines for K-UHPC. KCI (Korea Concrete Institute): Seoul, Korea, 2012.

- Goto, Y. Cracks formed in concrete around deformed tension bars. Spec. Publ. 1971, 68, 244–251. [Google Scholar]

- Markovic, I. High-Performance Hybrid-Fibre Concrete–Development and Utilization. Ph.D. Thesis, DUP Science, Delft University Press, Delft, The Netherlands, 2006. [Google Scholar]

- KS F 2405; Standard Test Method for Compressive Strength of Concrete. Korean Standard Information Center: Seoul, Korea, 2010.

- JCI-S-001; Method of Test for Fracture energy of Concrete by Use of Notched Beam. Japan Concrete Institute: Tokyo, Japan, 2003.

- KS F 2423; Method of Test for Splitting Tensile Strength of Concrete. Korean Standard Information Center: Seoul, Korea, 2011.

- KS B 0802; Method of Tensile Test for Metallic Materials. Korean Standard Information Center: Seoul, Korea, 2013.

- Park, R.; Paulay, T. Reinforced Concrete Structures; Wiley-Interscience Publication: New York, NY, USA, 1975. [Google Scholar]

- Azizinamini, A.; Pavel, R.; Hatfield, E.; Ghosh, S.K. Behavior of Lap-Spliced Reinforcing Bars Embedded in High-Strength Concrete. ACI Struct. J. 1999, 96, 826–835. [Google Scholar]

| ID | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (MPa) | (mm) | (%) | (mm) | ||||||||

| 120-0-0 | 220 | 255 | - | 22.2 (D22) | - | - | 120 | 500 | 400 | 9.5 (D10) | 0 | - | - |

| 120-15db-0 | 330 | 15 | 43 | ||||||||||

| 120-10db-0 | 220 | 10 | |||||||||||

| 120-5db-0 | 110 | 5 | |||||||||||

| 180-0-0 | - | - | - | 180 | |||||||||

| 180-15db-0 | 330 | 15 | 43 | ||||||||||

| 180-10db-0 | 220 | 10 | |||||||||||

| 180-5db-0 | 110 | 5 | |||||||||||

| 120-10db-V1.5 | 220 | 10 | 120 | 1.5 | 16/19 | 0.2 | |||||||

| 120-5db-V1.5 | 110 | 5 | |||||||||||

| 180-10db-V2.0 | 220 | 10 | 180 | 2 | 13 | 0.2 | |||||||

| 180-5db-V2.0 | 110 | 5 | |||||||||||

| 120-0-V1.5 | - - - | - | - | 120 | |||||||||

| 180-0-V2.0 | 180 | ||||||||||||

| 180-0-V1.5 | 1.5 | 16/19 | |||||||||||

| 180-5db-V1.5 | 110 | 5 | 43 | ||||||||||

| 180-10db-V1.0 | 220 | 10 | 1 | 13 | 0.2 | ||||||||

| 180-5db-V1.0 | 110 | 5 | |||||||||||

| ID | Water | Cement | Basalt Furnace | Silica Fume | Filler | Sand | Shrinkage Reducing Agent | Super Plasticizer | Steel Fiber (13/0.2) | Steel Fiber (19.5/0.2) | Steel Fiber (16.3/0.2) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Unit Weight (kg/m3) | |||||||||||

| 120-0 | 204 | 781.5 | 136.8 | 58.6 | 234.4 | 859.6 | 7.8 | 18 | |||

| 120-V1.5 | 204 | 781.5 | 136.8 | 58.6 | 234.4 | 859.6 | 7.8 | 18 | 78 | 39 | |

| 180-0 | 170 | 799.5 | 199.9 | 239.9 | 879.5 | 8 | 18.4 | ||||

| 180-V1.0 | 170 | 799.5 | 199.9 | 239.9 | 879.5 | 8 | 18.4 | 78 | |||

| 180-V2.0 | 170 | 799.5 | 199.9 | 239.9 | 879.5 | 8 | 18.4 | 156 | |||

| 180-V1.5 | 170 | 799.5 | 199.9 | 239.9 | 879.5 | 8 | 18.4 | 78 | 39 | ||

| ID | Vf | Ec | fc′ | fr | fsp | ft |

|---|---|---|---|---|---|---|

| (%) | (MPa) | |||||

| 120-0 | 0 | 44,302 | 140.8(1.90 *) | 5.2(2.27 *) | 2.4(0.25 *) | |

| 120-V1.5 | 2.0 | 44,767 | 142.2(4.26 *) | 12.6(3.47 *) | 15.9(1.60 *) | 10.6(1.25 *) |

| 180-0 | 0 | 52,046 | 173.3(5.59 *) | 9.5(1.40 *) | 3.0(0.13 *) | |

| 180-V1.0 | 1.0 | 51,253 | 174.0(4.37 *) | 9.8(2.38 *) | 12.43(1.22 *) | 7.6(1.30 *) |

| 180-V2.0 | 2.0 | 53,336 | 178.5(5.35 *) | 13.2(2.88 *) | 18.0(3.84 *) | 11.6(2.25 *) |

| 180-V1.5 | 1.5 | 52,333 | 175.9(5.56 *) | 14.3(2.970 *) | 20.1(3.77 *) | 12.4(1.47 *) |

| ID | Es | fy | fu | |

|---|---|---|---|---|

| [MPa] | ||||

| D10 | 200,000 | 541 | 653 | 0.00270 |

| D22 | 200,000 | 530 | 681 | 0.00265 |

| ID | fs,test,ult | fs,calc | fs,test,cr | us,test,ult | us,calc | us,test,cr |

|---|---|---|---|---|---|---|

| (MPa) | ||||||

| 120-15db-0 | 381 | 381 | 395 | 6.41 | 6.41 | 6.65 |

| 120-10db-0 | 295 | 295 | 308 | 7.44 | 7.44 | 7.77 |

| 120-5db-0 | 185 | 185 | 181 | 9.33 | 9.33 | 9.12 |

| 180-15db-0 | 386 | 386 | 409 | 6.49 | 6.49 | 6.89 |

| 180-10db-0 | 312 | 312 | 325 | 7.87 | 7.87 | 8.20 |

| 180-5db-0 | 195 | 195 | 210 | 9.84 | 9.84 | 10.60 |

| 120-10db-V1.5 | 530 | 417 | 434 | 13.25 | 10.51 | 10.94 |

| 120-5db-V1.5 | 530 | 240 | 266 | 26.50 | 12.09 | 13.43 |

| 180-10db-V2.0 | 530 | 479 | 495 | 13.25 | 12.09 | 12.50 |

| 180-5db-V2.0 | 530 | 295 | 364 | 26.50 | 14.89 | 18.37 |

| 180-5db-V1.5 | 530 | 317 | 447 | 26.50 | 16.00 | 22.54 |

| 180-10db-V1.0 | 530 | 358 | 400 | 13.25 | 9.03 | 10.10 |

| 180-5db-V1.0 | 530 | 226 | 301 | 26.50 | 11.4 | 15.20 |

| ID | ld,rqd | ld,ACI | ld,KICT | ld,EC2 | ld,AFGC | ld,specimen |

|---|---|---|---|---|---|---|

| (mm) | ||||||

| 120-15db-0 | 442 | 612 | 390 | 932 | 715 | 330 |

| 120-10db-0 | 379 | 220 | ||||

| 120-5db-0 | 322 | 110 | ||||

| 180-15db-0 | 427 | 500 | 318 | 870 | 572 | 330 |

| 180-10db-0 | 359 | 220 | ||||

| 180-5db-0 | 278 | 110 | ||||

| 120-10db-V1.5 | 269 | 612 | 390 | 932 | 200(116) | 220 |

| 120-5db-V1.5 | 219 | 110 | ||||

| 180-10db-V2.0 | 235 | 500 | 318 | 870 | 181(102) | 220 |

| 180-5db-V2.0 | 160 | 110 | ||||

| 180-5db-V1.5 | 130 | 181(95) | 110 | |||

| 180-10db-V1.0 | 291 | 196(160) | 110 | |||

| 180-5db-V1.0 | 194 | 110 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bae, B.-I.; Choi, H.-K. Experimental Study on the Flexural Behavior of Lap-Spliced Ultra-High-Performance Fiber-Reinforced Concrete Beams. Polymers 2022, 14, 2138. https://doi.org/10.3390/polym14112138

Bae B-I, Choi H-K. Experimental Study on the Flexural Behavior of Lap-Spliced Ultra-High-Performance Fiber-Reinforced Concrete Beams. Polymers. 2022; 14(11):2138. https://doi.org/10.3390/polym14112138

Chicago/Turabian StyleBae, Baek-Il, and Hyun-Ki Choi. 2022. "Experimental Study on the Flexural Behavior of Lap-Spliced Ultra-High-Performance Fiber-Reinforced Concrete Beams" Polymers 14, no. 11: 2138. https://doi.org/10.3390/polym14112138

APA StyleBae, B.-I., & Choi, H.-K. (2022). Experimental Study on the Flexural Behavior of Lap-Spliced Ultra-High-Performance Fiber-Reinforced Concrete Beams. Polymers, 14(11), 2138. https://doi.org/10.3390/polym14112138