Fabrication of Recycled Polycarbonate Fibre for Thermal Signature Reduction in Camouflage Textiles

Abstract

:1. Introduction

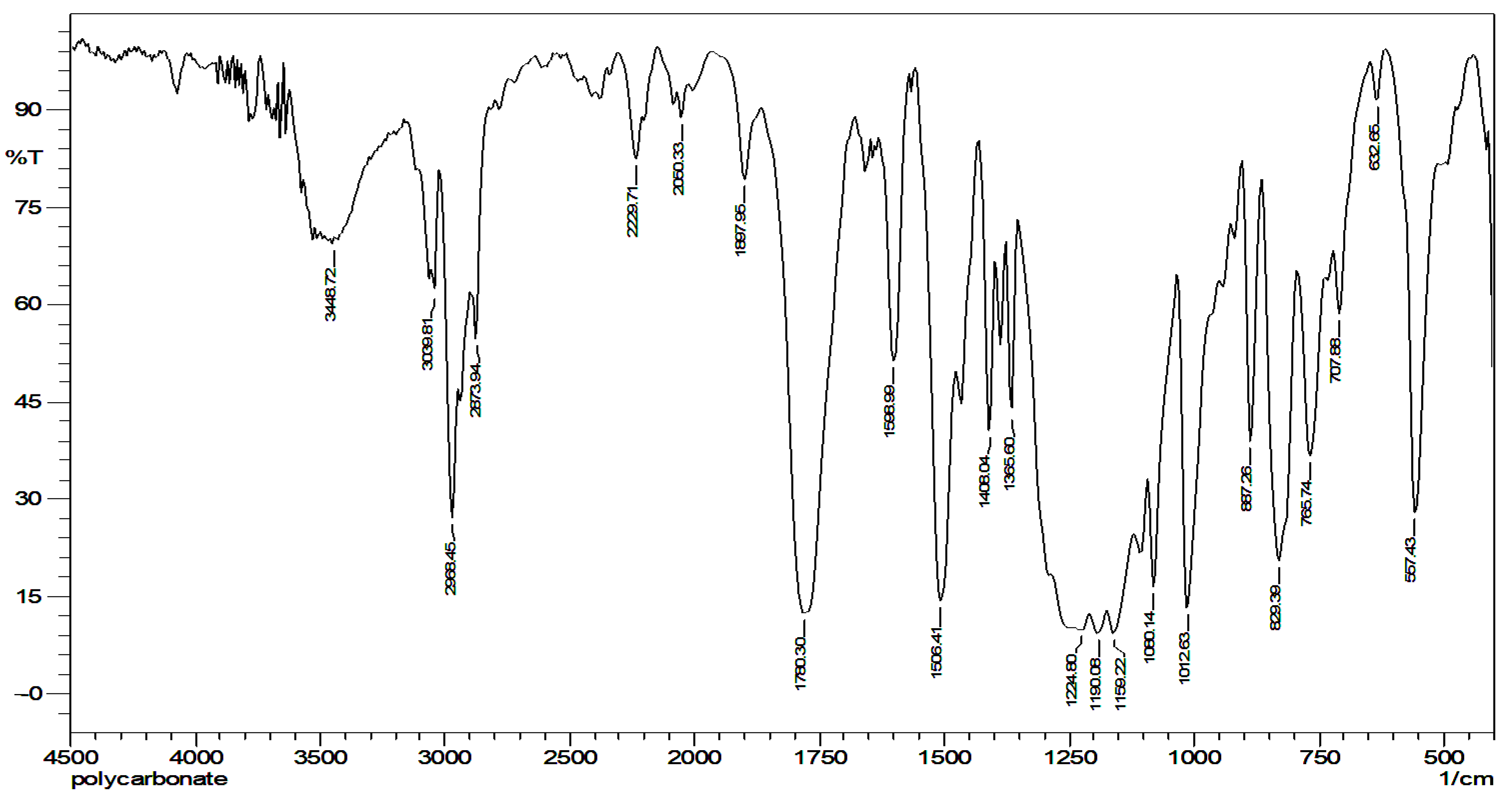

2. Materials and Methods

3. Results and Discussion

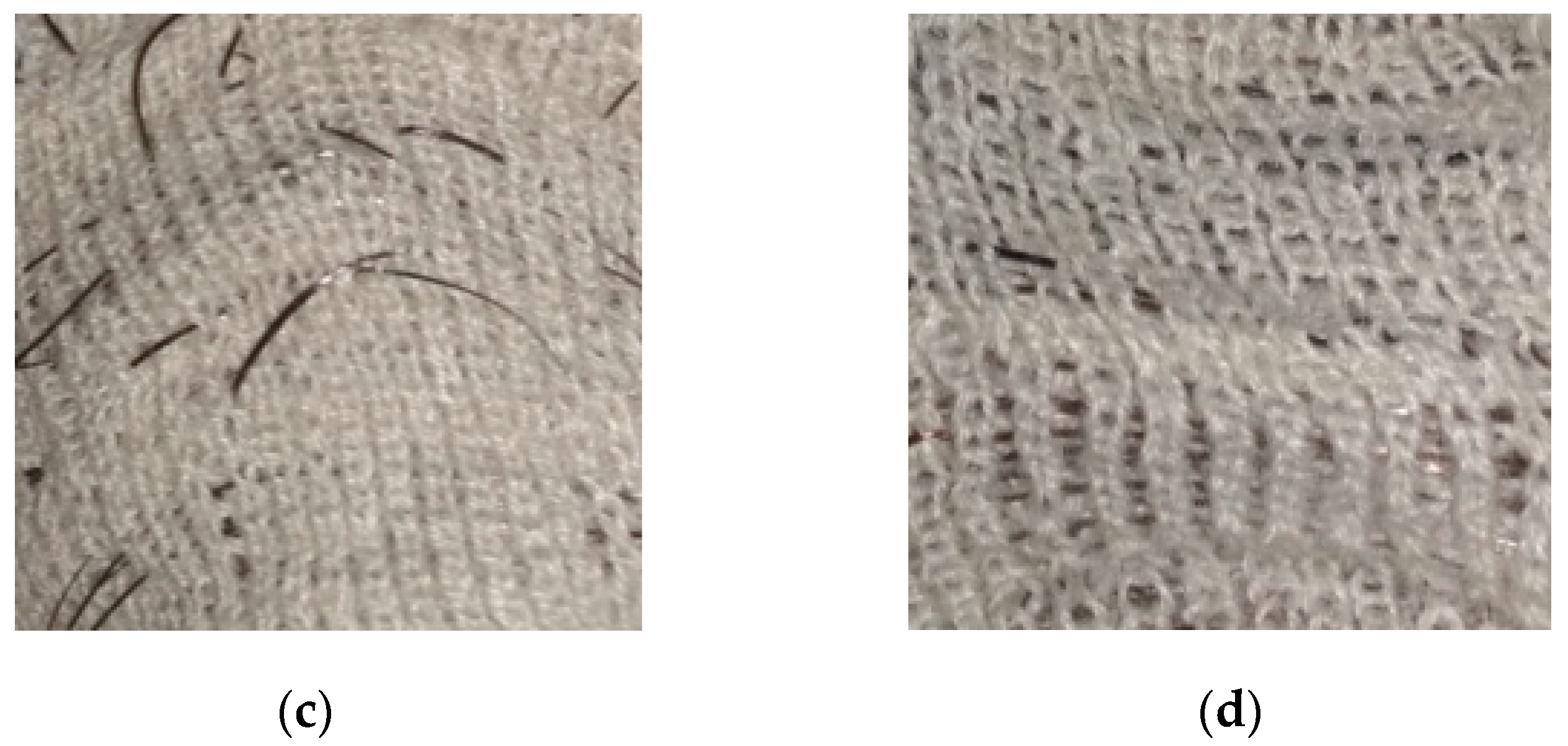

3.1. Fabrication of Polyacrylic–Polycarbonate Fabric

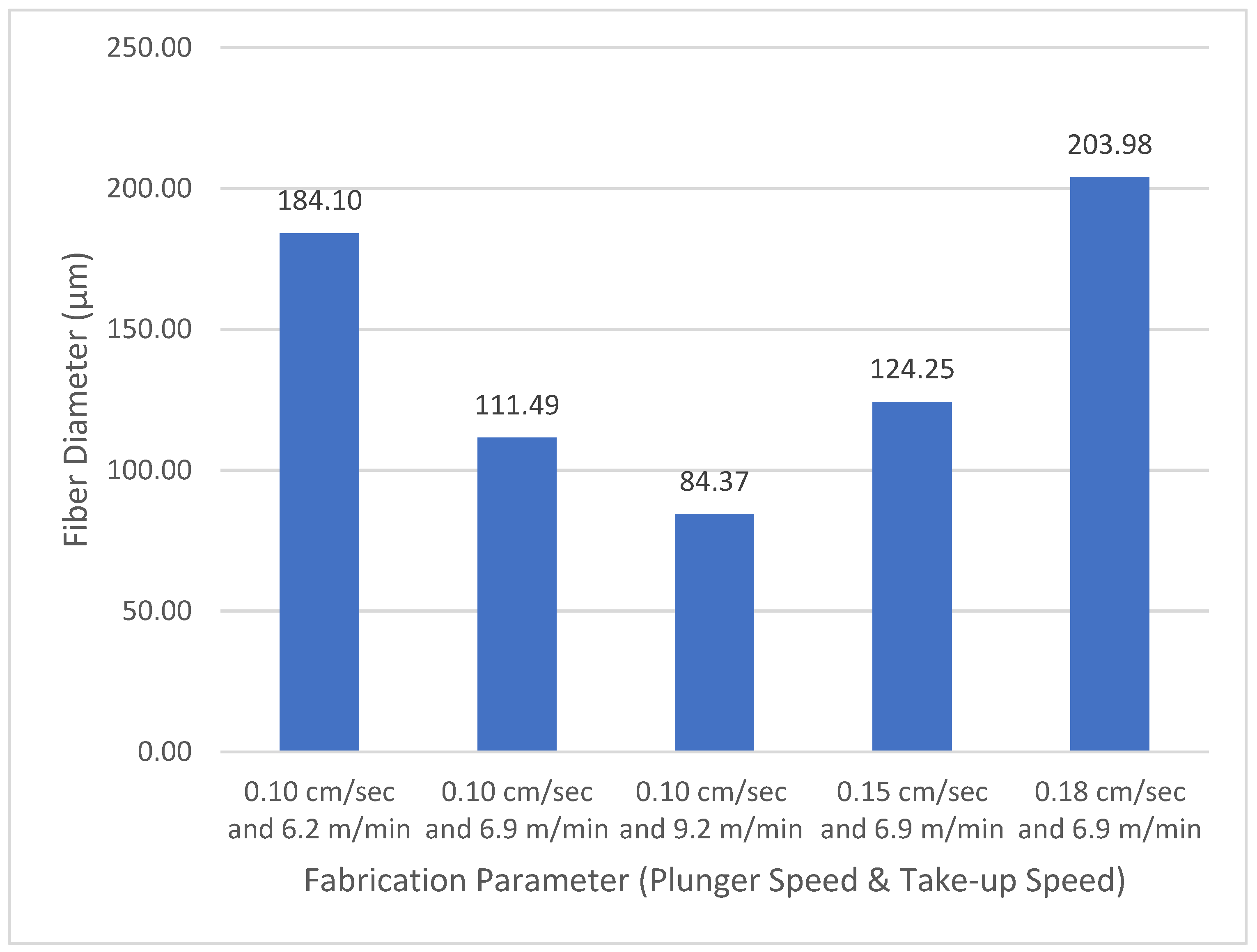

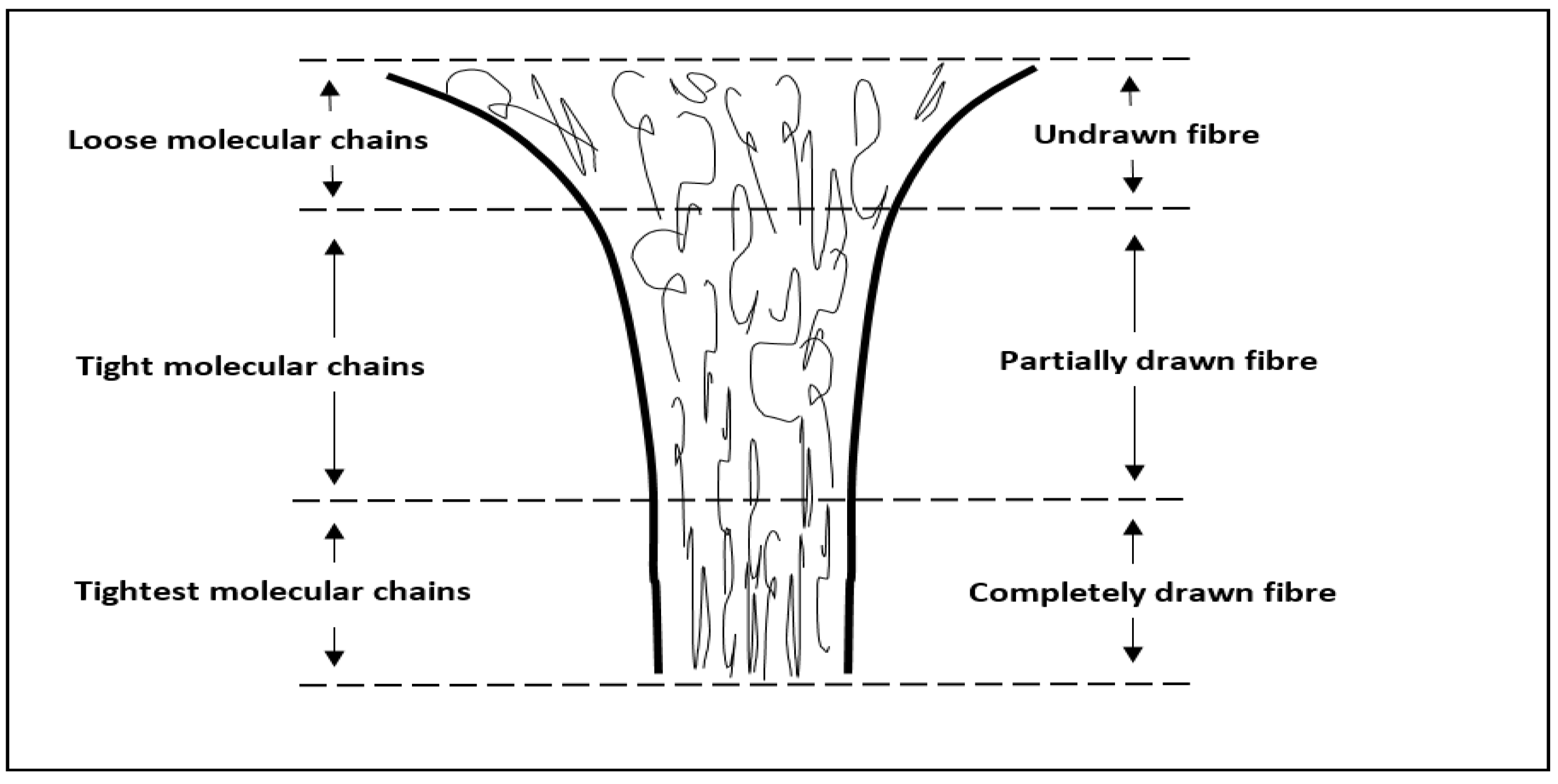

3.2. Fibre Diameter

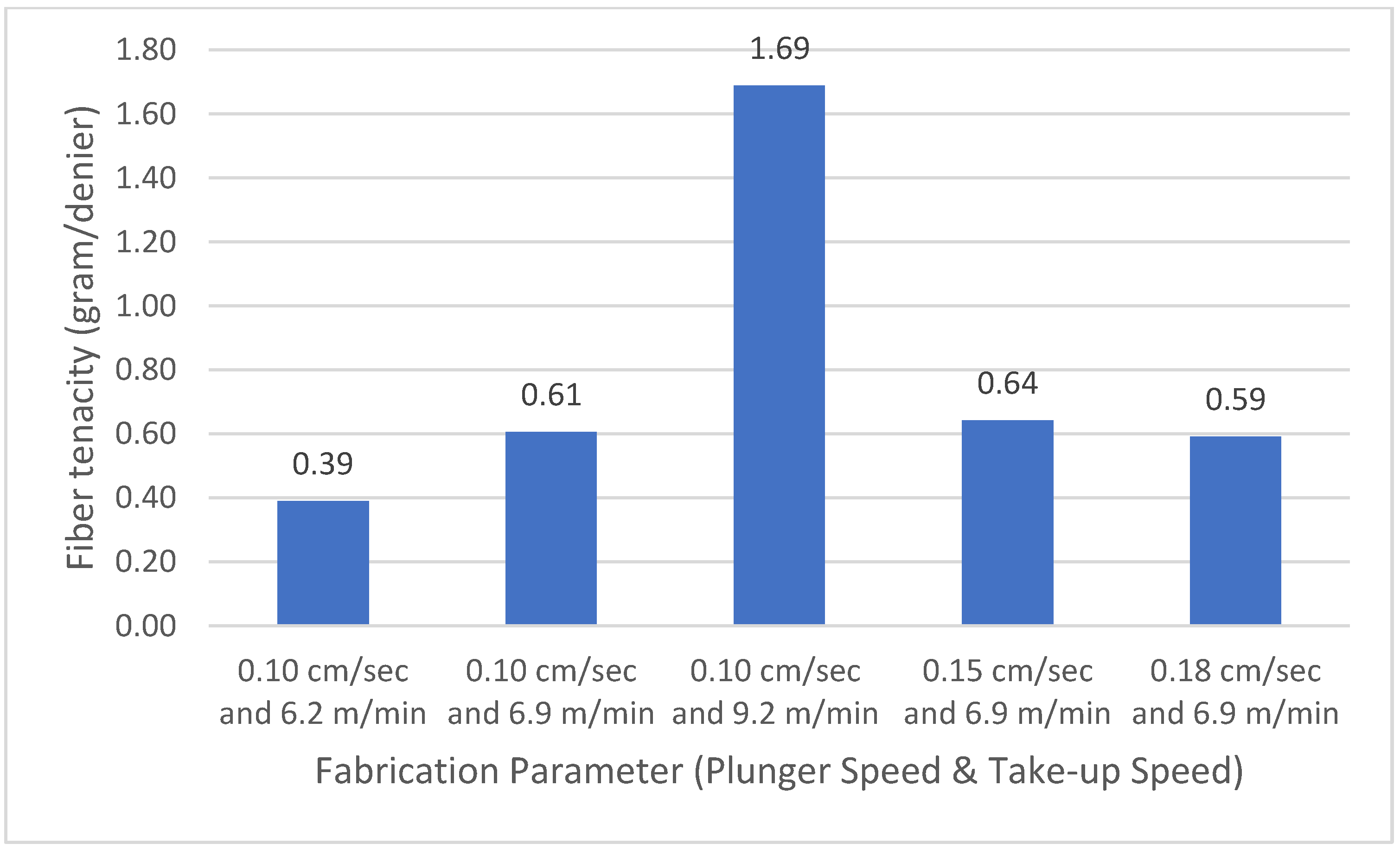

3.3. Fibre Tenacity

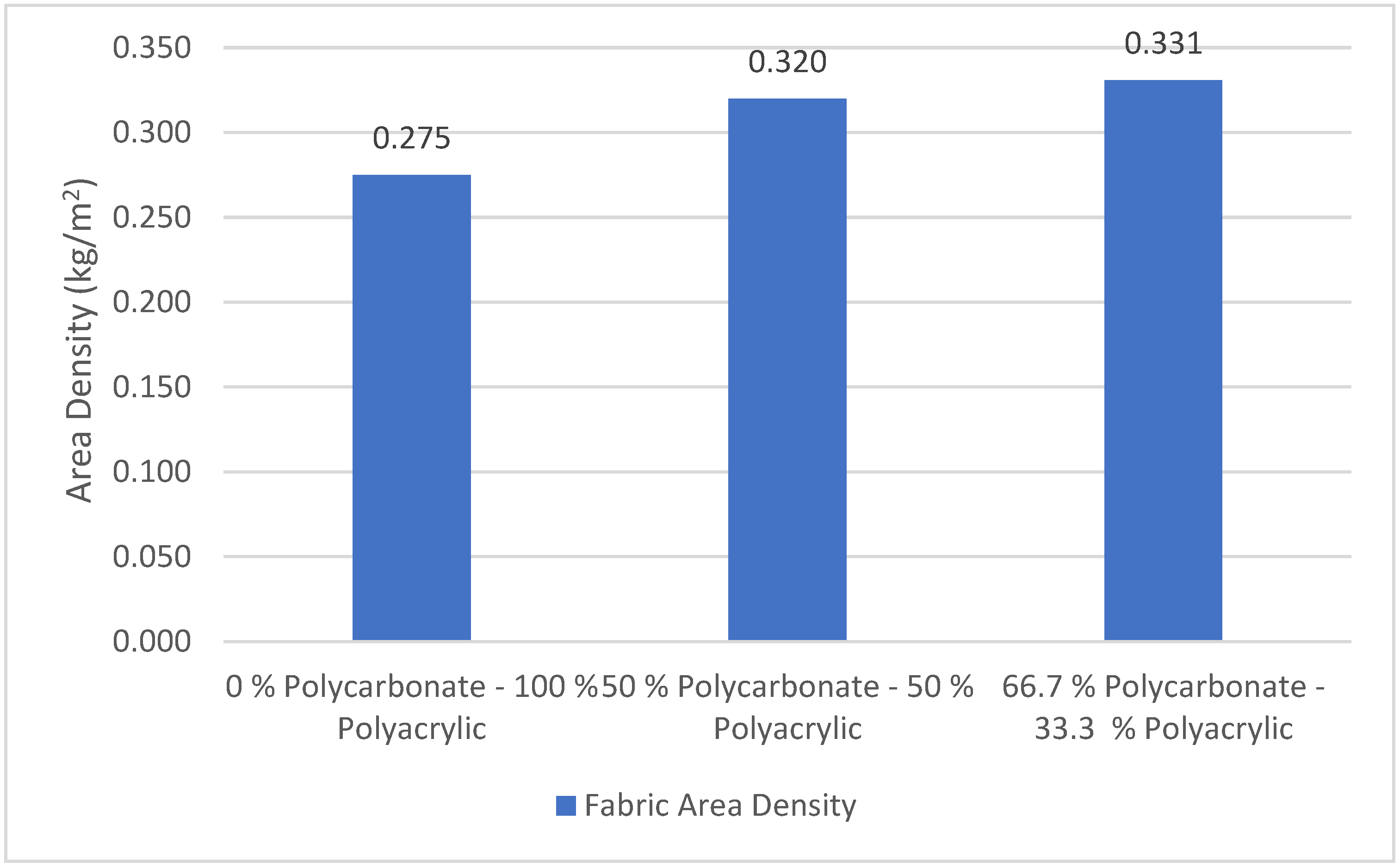

3.4. Fabric Areal Density

3.5. Bursting Strength

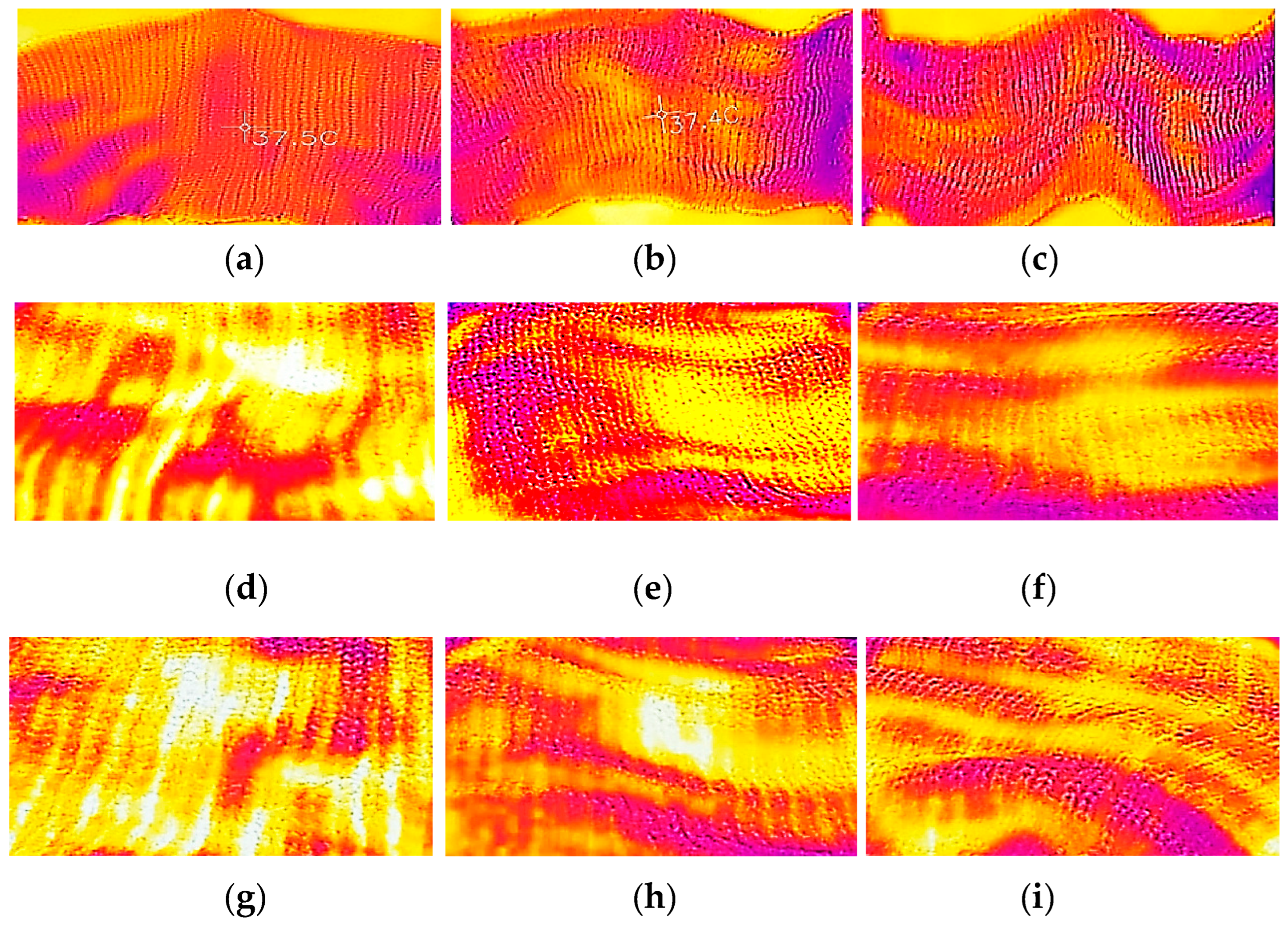

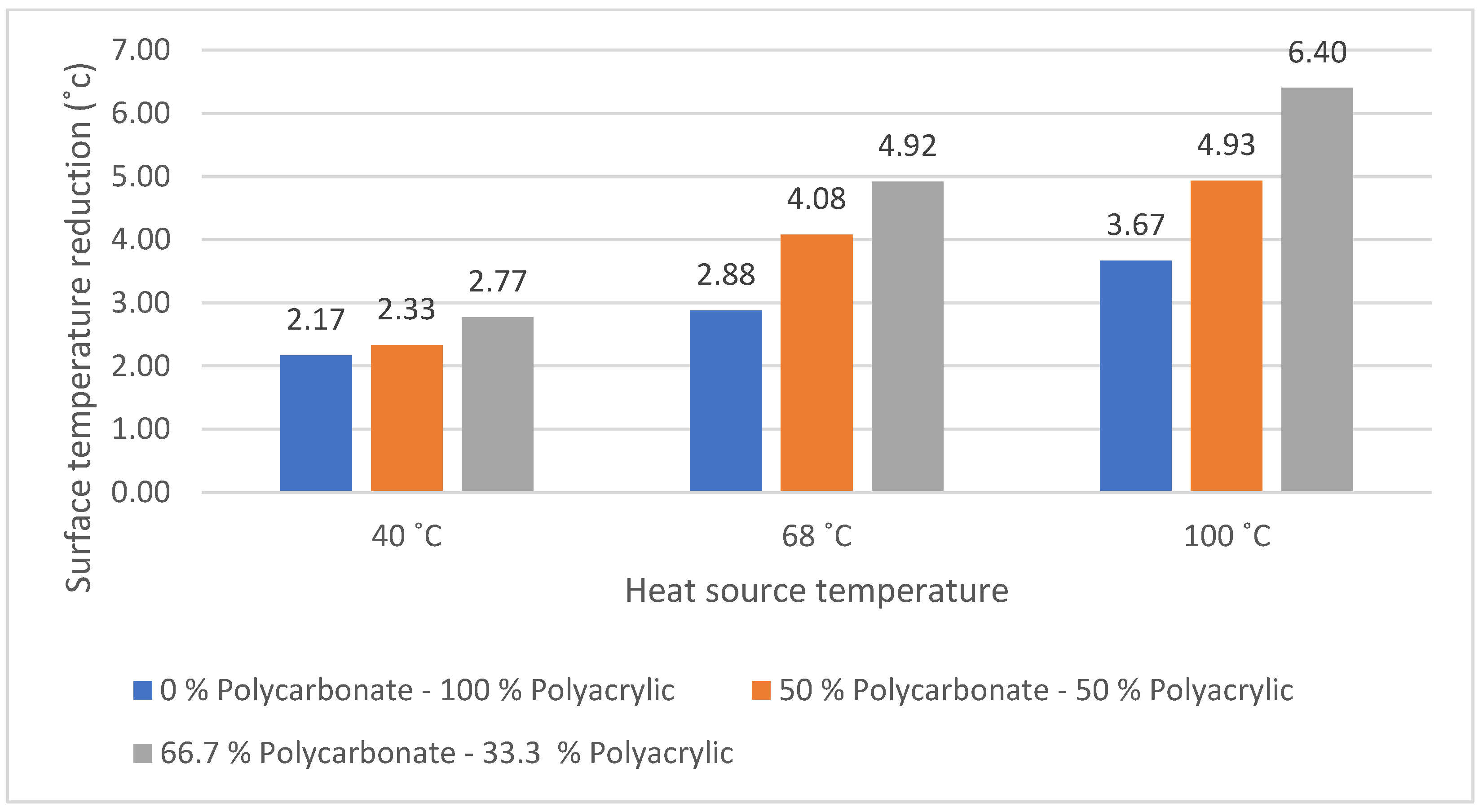

3.6. Thermal Signature Reduction

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dai, G.; Shang, J.; Huang, J. Theory of Transformation Thermal Convection for Creeping Flow in Porous Media: Cloaking, Concentrating, and Camouflage. Phys. Rev. E 2018, 97, 022129. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Negied, N.K.A.-W.; Hemayed, E.B.; Fayek, M. HSBS: A Human’s Heat Signature and Background Subtraction Hybrid Approach for Crowd Counting and Analysis. Int. J. Pattern Recognit. Artif. Intell. 2016, 30, 1655025. [Google Scholar] [CrossRef]

- Dev, O.; Dayal, S.; Dubey, A.; Abbas, S.M. Multi-Layered Textile Structure for Thermal Signature Suppression of Ground Based Targets. Infrared Phys. Technol. 2020, 105, 103175. [Google Scholar] [CrossRef]

- Rubežienė, V.; Padleckienė, I.; Žuravliova, S.V.; Baltušnikaitė, J. Reduction of Thermal Signature Using Fabrics with Conductive Additives. Mater. Sci. 2013, 19, 409–414. [Google Scholar] [CrossRef] [Green Version]

- Hixson, J.G.; Jacobs, E.L.; Vollmerhausen, R.H. Target Detection Cycle Criteria When Using the Targeting Task Performance Metric; Driggers, R.G., Huckridge, D.A., Eds.; International Society for Optics and Photonics: London, UK, 2004; p. 275. [Google Scholar]

- Holst, G.C. Common Sense Approach to Thermal Imaging; SPIE: Bellingham, WA, USA, 2000; ISBN 978-0-8194-3722-8. [Google Scholar]

- Liu, Q.; Zhuang, J.; Ma, J. Robust and Fast Pedestrian Detection Method for Far-Infrared Automotive Driving Assistance Systems. Infrared Phys. Technol. 2013, 60, 288–299. [Google Scholar] [CrossRef]

- Bertozzi, M.; Broggi, A.; Caraffi, C.; Del Rose, M.; Felisa, M.; Vezzoni, G. Pedestrian Detection by Means of Far-Infrared Stereo Vision. Comput. Vis. Image Underst. 2007, 106, 194–204. [Google Scholar] [CrossRef]

- Fang, Y.; Yamada, K.; Ninomiya, Y.; Horn, B.K.P.; Masaki, I. A Shape-Independent Method for Pedestrian Detection with Far-Infrared Images. IEEE Trans. Veh. Technol. 2004, 53, 1679–1697. [Google Scholar] [CrossRef]

- Li, J.; Gong, W.; Li, W.; Liu, X. Robust Pedestrian Detection in Thermal Infrared Imagery Using the Wavelet Transform. Infrared Phys. Technol. 2010, 53, 267–273. [Google Scholar] [CrossRef]

- Olmeda, D.; de la Escalera, A.; Armingol, J.M. Contrast Invariant Features for Human Detection in Far Infrared Images. In Proceedings of the 2012 IEEE Intelligent Vehicles Symposium, Alcal de Henares, Madrid, Spain, 3–7 June 2012; IEEE: Alcal de Henares, Madrid, Spain, 2012; pp. 117–122. [Google Scholar]

- Kyriacos, D. Polycarbonates. In Brydson’s Plastics Materials; Elsevier: Amsterdam, The Netherlands, 2017; pp. 457–485. ISBN 978-0-323-35824-8. [Google Scholar]

- Muhamad, M.S.; Salim, M.R.; Lau, W.J.; Yusop, Z. A Review on Bisphenol a Occurrences, Health Effects and Treatment Process via Membrane Technology for Drinking Water. Environ. Sci. Pollut. Res. 2016, 23, 11549–11567. [Google Scholar] [CrossRef]

- Kraus, R.G.; Emmons, E.D.; Thompson, J.S.; Covington, A.M. Infrared Absorption Spectroscopy of Polycarbonate at High Pressure. J. Polym. Sci. Part B Polym. Phys. 2008, 46, 734–742. [Google Scholar] [CrossRef]

- Fasano, A.; Woyessa, G.; Stajanca, P.; Markos, C.; Stefani, A.; Nielsen, K.; Rasmussen, H.K.; Krebber, K.; Bang, O. Fabrication and Characterization of Polycarbonate Microstructured Polymer Optical Fibers for High-Temperature-Resistant Fiber Bragg Grating Strain Sensors. Opt. Mater. Express 2016, 6, 649. [Google Scholar] [CrossRef] [Green Version]

- Pötschke, P.; Brünig, H.; Janke, A.; Fischer, D.; Jehnichen, D. Orientation of Multiwalled Carbon Nanotubes in Composites with Polycarbonate by Melt Spinning. Polymer 2005, 46, 10355–10363. [Google Scholar] [CrossRef]

- Bautista-Quijano, J.R.; Pötschke, P.; Brünig, H.; Heinrich, G. Strain Sensing, Electrical and Mechanical Properties of Polycarbonate/Multiwall Carbon Nanotube Monofilament Fibers Fabricated by Melt Spinning. Polymer 2016, 82, 181–189. [Google Scholar] [CrossRef]

- Polycarbonates Demand Worldwide from 2011 to 2024. Available online: https://www.statista.com/statistics/750965/polycarbonates-demand-worldwide/ (accessed on 22 November 2021).

- Polycarbonate Market Research Report. Marketresearchfuture 2021. Available online: https://www.marketresearchfuture.com/reports/polycarbonate-market-1080 (accessed on 22 November 2021).

- A New Way to Recycle Polycarbonates That Prevents BPA Leaching. Available online: https://phys.org/news/2016-06-recycle-polycarbonates-bpa-leaching.html (accessed on 22 November 2021).

- Degenstein, L.M.; Sameoto, D.; Hogan, J.D.; Asad, A.; Dolez, P.I. Smart Textiles for Visible and IR Camouflage Application: State-of-the-Art and Microfabrication Path Forward. Micromachines 2021, 12, 773. [Google Scholar] [CrossRef] [PubMed]

- Frequently Asked Questions: Thermal Imaging for Elevated Skin Temperature Screening. Available online: https://www.flir.com/discover/public-safety/faq-about-thermal-imaging-for-elevated-body-temperature-screening/ (accessed on 27 April 2022).

- Ghassemi, P.; Pfefer, T.J.; Casamento, J.P.; Simpson, R.; Wang, Q. Best Practices for Standardized Performance Testing of Infrared Thermographs Intended for Fever Screening. PLoS ONE 2018, 13, e0203302. [Google Scholar] [CrossRef] [Green Version]

- Singhal, K.; Mishra, S.; Kumar, B. A Study of Curling in Rib-Knit Constructions. J. Text. Inst. 2021, 112, 666–675. [Google Scholar] [CrossRef]

- Nakajima, T.; Kajiwara, K. (Eds.) Advanced Fiber Spinning Technology; Woodhead Publishing: Cambridge, UK, 1994; ISBN 978-1-85573-182-0. [Google Scholar]

- Teke, S.; Altun, S. CFD Modeling of the Melt Spinning of Poly (Ethylene Terepthalate) at Low Take-up Velocities. Sci. Res. Essays 2012, 7, 372–386. [Google Scholar]

- Groover, M.P. Fundamentals of Modern Manufacturing, 4th ed.; Hohn Wilery & Sons, Inc.: Danver, CO, USA, 2010; pp. 40–49. [Google Scholar]

- Eichhorn, S.J.; Hearle, J.W.S. Handbook of Textile Fibre Structure; Woodhead Publishing Limited: Cambridge, UK, 2009; pp. 217–219. [Google Scholar]

- Kumar, V.; Sampath, V.R. Investigation on the Physical and Dimensional Properties of Single Jersey Fabrics made from Cotton Sheath—Elastomeric Core Spun. Fibres Text. East. Eur. 2003, 21, 73–75. [Google Scholar]

- Arbataitis, E.; Mikucioniene, D.; Halavska, L. Flexible Theoretical Calculation of Loop Length and Area Density of Weft-Knitted Structures: Part I. Materials 2021, 14, 3059. [Google Scholar] [CrossRef]

- Khalil, E. Effect of Stitch Length on Physical and Mechanical Properties of Single Jersey Cotton Knitted Fabric. Int. J. Sci. Res. IJSR 2012, 3, 4. [Google Scholar]

- Rahman, S.; Smriti, S.A. Investigation on the Changes of Areal Density of Knit Fabric with Stitch Length Variation on the Increment of Tuck Loop Percentages. J. Polym. Text. Eng. 2015, 2, 1–14. [Google Scholar]

- Chowdhary, U. Bursting Strength and Extension for Jersey, Interlock and Pique Knits. Trends Text. Eng. Fash. Technol. 2018, 1, 19–27. [Google Scholar] [CrossRef] [Green Version]

- Degirmenci, Z.; Çelik, N. Relation between extension and bursting strength properties of the denim viewed knitted fabrics produced by cellulosic fibers. Fibres Text. East. Eur. 2016, 24, 101–106. [Google Scholar] [CrossRef]

- Rashid, M.R.; Ahmed, F.; Azad, A.K. Bursting Strength and Pilling Properties of Weft Knitted Fabrics Made from Conventional Ring and Compact Spun Yarn. Available online: https://www.researchgate.net/publication/328419424_Bursting_Strength_and_Piling_Properties_of_Weft_Knitted_Fabrics_Made_from_Conventional_Ring_and_Compact_Spun_Yarn (accessed on 7 April 2022).

- Adanur, S.; Tewari, A. An Overview of Military Textiles; NIScPR: New Delhi, India, 1997; pp. 348–352. [Google Scholar]

- Steffens, F.; Gralha, S.E.; Ferreira, I.L.S.; Oliveira, F.R. Military Textiles—An Overview of New Developments. Key Eng. Mater. 2019, 812, 120–126. [Google Scholar] [CrossRef]

- Zhu, H.; Li, Q.; Zheng, C.; Hong, Y.; Xu, Z.; Wang, H.; Shen, W.; Kaur, S.; Ghosh, P.; Qiu, M. High-Temperature Infrared Camouflage with Efficient Thermal Management. Light Sci. Appl. 2020, 9, 60. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Weingart, N.; Raps, D.; Kuhnigk, J.; Klein, A.; Altstädt, V. Expanded Polycarbonate (EPC)—A New Generation of High-Temperature Engineering Bead Foams. Polymers 2020, 12, 2314. [Google Scholar] [CrossRef]

- Tian, L.; Yuanyuan, Z.; Yingying, M.; Ran, H. Fabrication of Functional Silver Loaded Montmorillonite/Polycarbonate with Superhydrophobicity. Appl. Clay Sci. 2015, 118, 337–343. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soekoco, A.; Rehman, A.U.; Fauzi, A.; Tasya, H.; Diandra, P.; Tasa, I.; Nugraha; Yuliarto, B. Fabrication of Recycled Polycarbonate Fibre for Thermal Signature Reduction in Camouflage Textiles. Polymers 2022, 14, 1972. https://doi.org/10.3390/polym14101972

Soekoco A, Rehman AU, Fauzi A, Tasya H, Diandra P, Tasa I, Nugraha, Yuliarto B. Fabrication of Recycled Polycarbonate Fibre for Thermal Signature Reduction in Camouflage Textiles. Polymers. 2022; 14(10):1972. https://doi.org/10.3390/polym14101972

Chicago/Turabian StyleSoekoco, Asril, Ateeq Ur Rehman, Ajisetia Fauzi, Hamdi Tasya, Purnama Diandra, Islami Tasa, Nugraha, and Brian Yuliarto. 2022. "Fabrication of Recycled Polycarbonate Fibre for Thermal Signature Reduction in Camouflage Textiles" Polymers 14, no. 10: 1972. https://doi.org/10.3390/polym14101972

APA StyleSoekoco, A., Rehman, A. U., Fauzi, A., Tasya, H., Diandra, P., Tasa, I., Nugraha, & Yuliarto, B. (2022). Fabrication of Recycled Polycarbonate Fibre for Thermal Signature Reduction in Camouflage Textiles. Polymers, 14(10), 1972. https://doi.org/10.3390/polym14101972