Exploring the Potential to Repurpose Flexible Moulded Polyurethane Foams as Acoustic Insulators

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

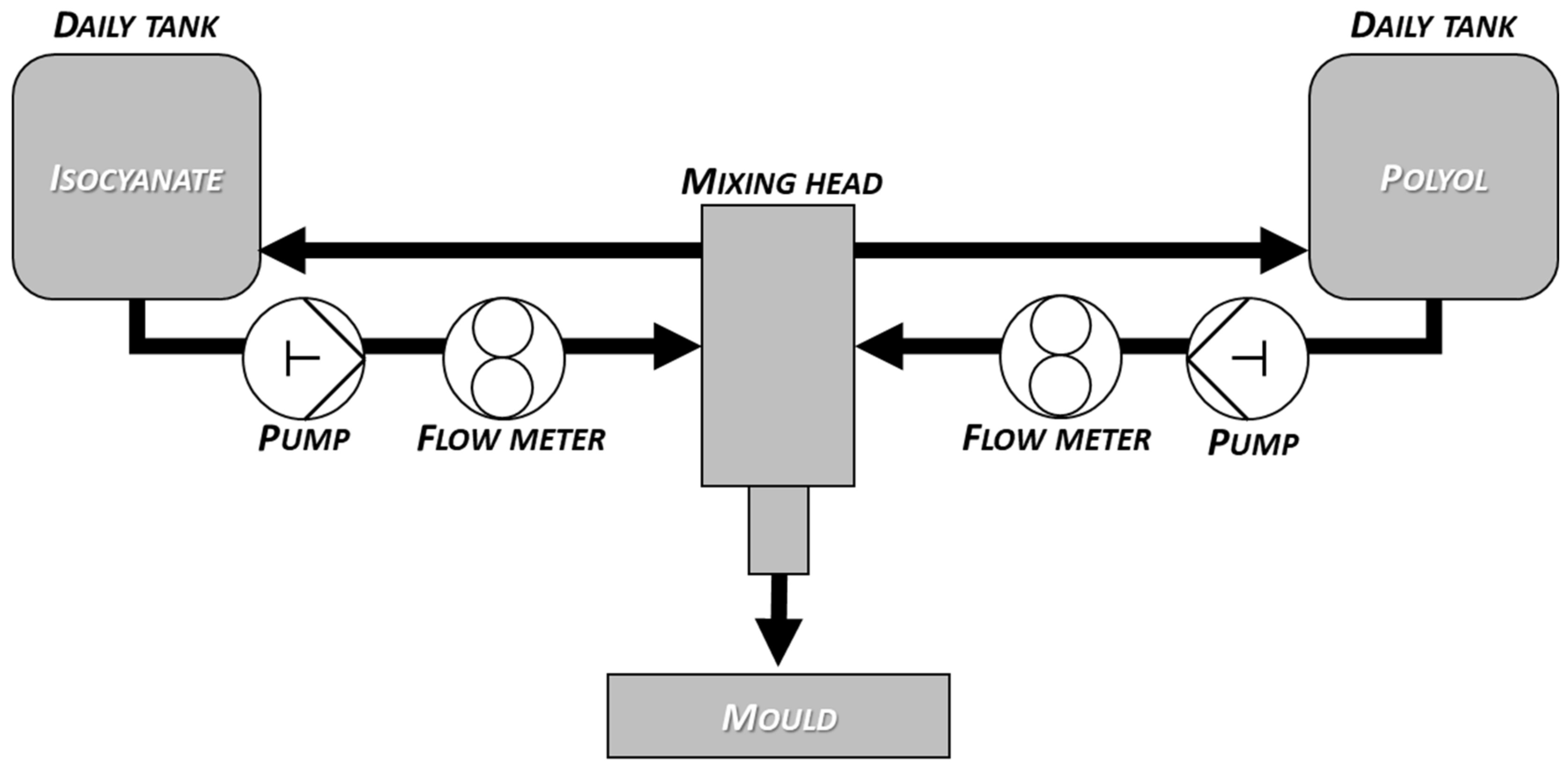

2.2. Flexible Polyurethane Foam Production

2.3. Mechanical Measurements

2.4. Aging Tests

2.5. Micro-CT Measurements

2.6. Acoustic Measurements

3. Results and Discussion

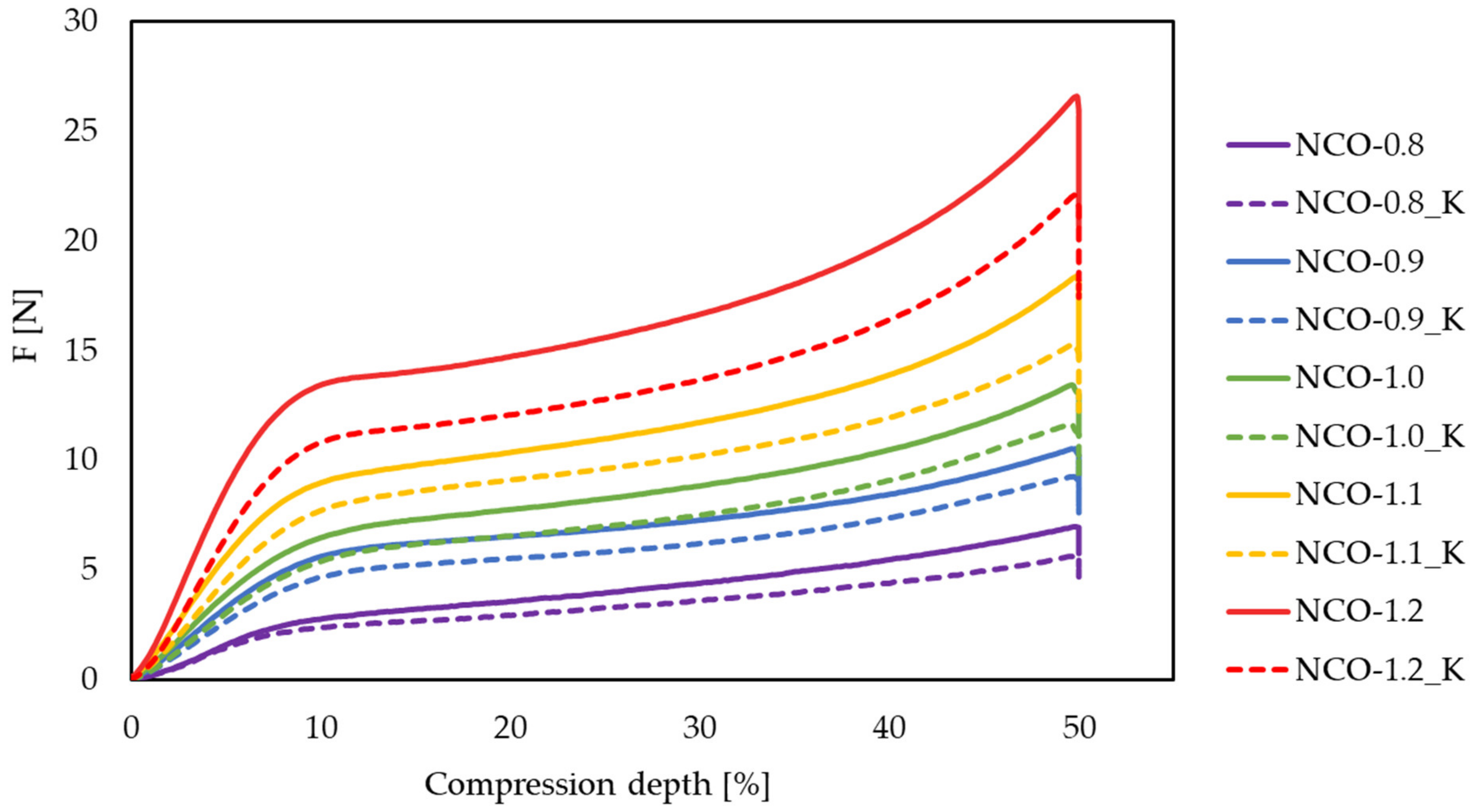

3.1. Mechanical Tests

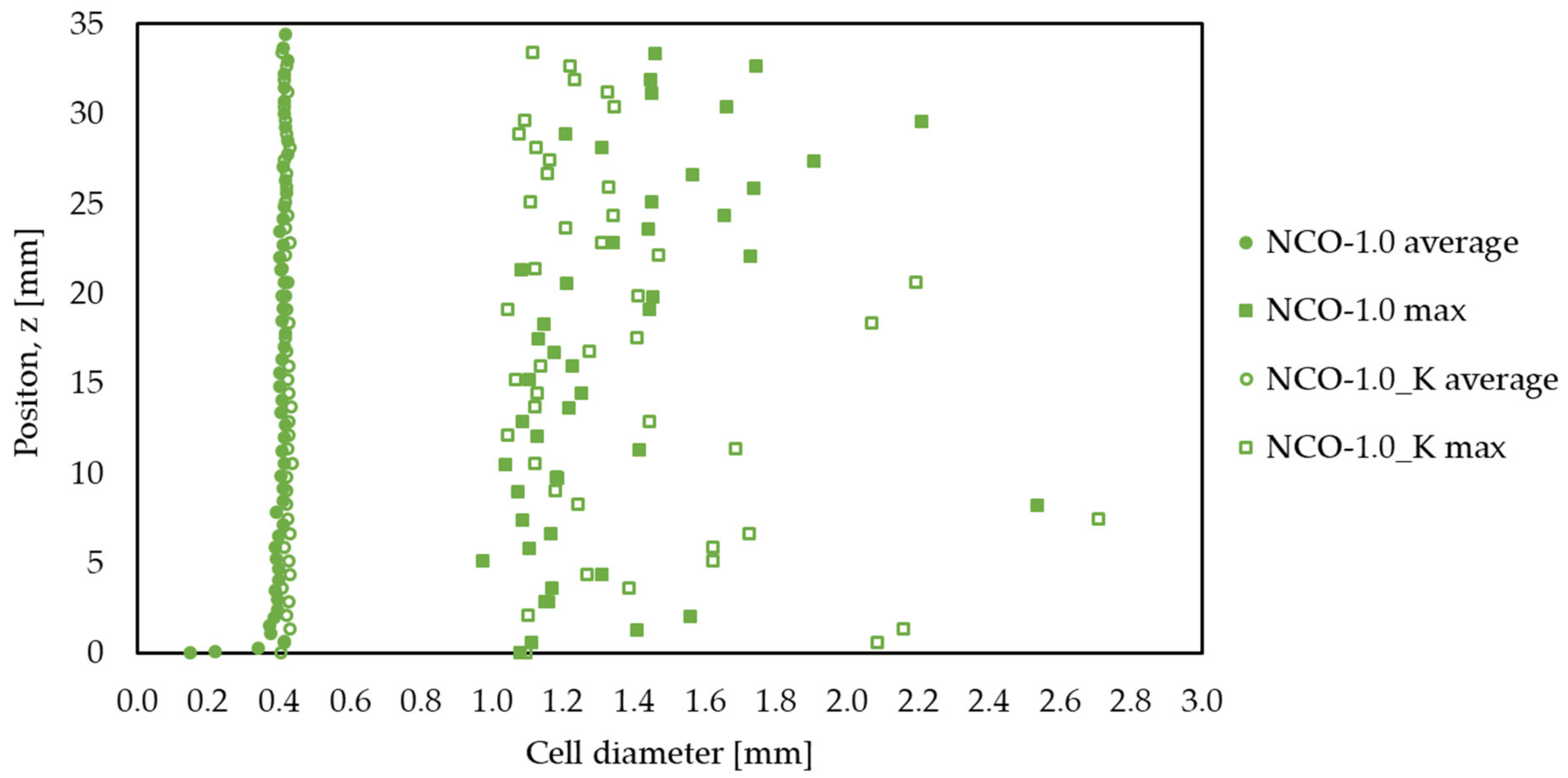

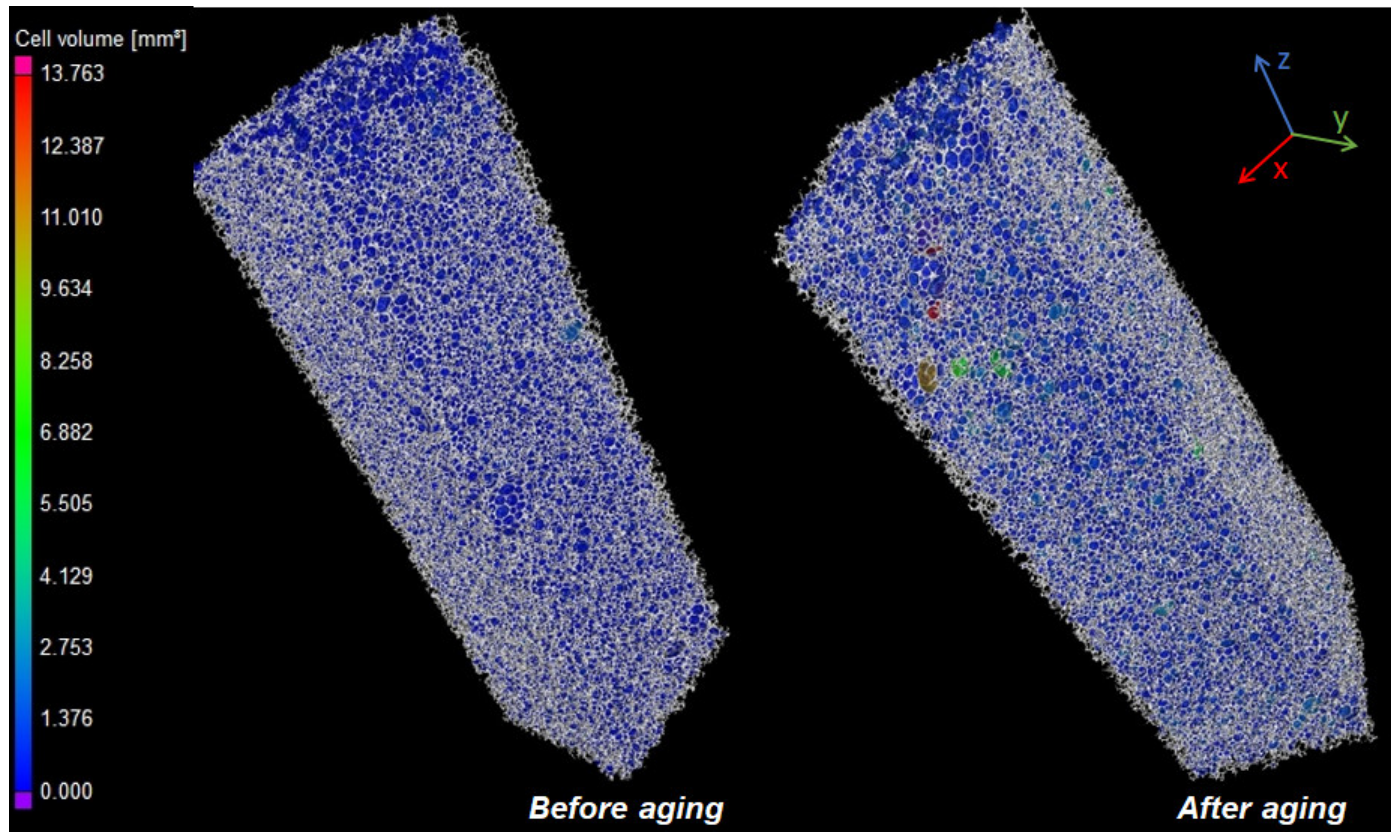

3.2. Results of the Micro-CT Measurements

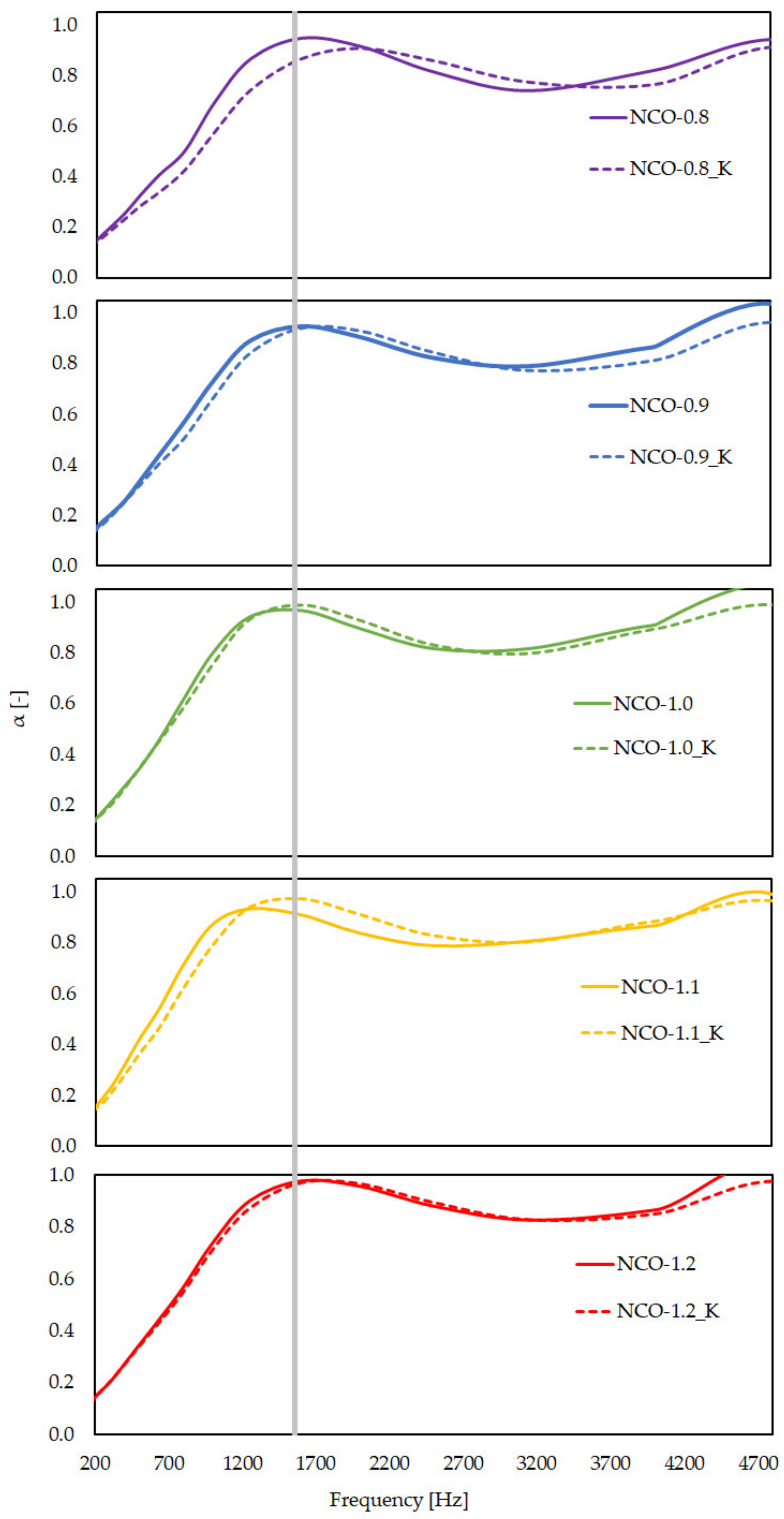

3.3. Acoustic Measurements

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Suleman, S.; Khan, S.M.; Gull, N.; Aleem, W.; Shafiq, M.; Jamil, T. A Comprehensive Short Review on Polyurethane Foam. Int. J. Innov. Sci. Res. 2014, 12, 165–169. [Google Scholar]

- Akindoyo, J.O.; Beg, M.D.H.; Ghazali, S.; Islam, M.R.; Jeyaratnam, N.; Yuvaraj, A.R. Polyurethane types, synthesis and applications—A review. RSC Adv. 2016, 6, 114453–114482. [Google Scholar] [CrossRef] [Green Version]

- Gama, N.; Ferreira, A.; Barros-Timmons, A. Polyurethane Foams: Past, Present, and Future. Materials 2018, 11, 1841. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- He, Y.; Xie, D.; Zhang, X. The structure, microphase-separated morphology, and property of polyurethanes and polyureas. J. Mater. Sci. 2014, 49, 7339–7352. [Google Scholar] [CrossRef]

- Sung, G.; Choe, H.; Choi, Y.; Kim, J.H. Morphological, acoustical, and physical properties of free-rising polyurethane foams depending on the flow directions. Korean J. Chem. Eng. 2018, 35, 1045–1052. [Google Scholar] [CrossRef]

- Woods, G. Flexible Polyurethane Foams: Chemistry and Technology; Applied Science Publishers: London, UK, 1982. [Google Scholar]

- Gibson, L.J.; Ashby, M.F. Cellular Solids, 2nd ed.; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- Ebe, K.; Griffin, M.J. Factors affecting static seat cushion comfort. Ergonomics 2001, 44, 901–921. [Google Scholar] [CrossRef] [PubMed]

- Shan, C.W.; Ghazali, M.I.; Idris, M.I. Improved vibration characteristics of flexible polyurethane foam via composite formation. Int. J. Automot. Mech. Eng. 2013, 7, 1031–1042. [Google Scholar] [CrossRef]

- Shafigullin, L.N.; Yurasov, S.Y.; Shayakhmetova, G.R.; Shafigullina, A.N.; Zharin, E.D. Sound-absorbing polyurethane foam for the auto industry. Russ. Eng. Res. 2017, 37, 372–374. [Google Scholar] [CrossRef]

- Zhang, C.; Li, J.; Hu, Z.; Zhu, F.; Huang, Y. Correlation between the acoustic and porous cell morphology of polyurethane foam: Effect of interconnected porosity. Mater. Des. 2012, 41, 319–325. [Google Scholar] [CrossRef]

- Kuczmarski, M.A.; Johnston, J.C. Acoustic Absorption in Porous Materials; NASA: Washington, DC, USA, 2011; pp. 1–20. [Google Scholar]

- Andersson, A.; Lundmark, S.; Magnusson, A.; Maurer, F.H.J. Vibration and Acoustic Damping of Flexible Polyurethane Foams Modified with a Hyperbranched Polymer. J. Cell. Plast. 2010, 46, 73–93. [Google Scholar] [CrossRef]

- Imai, Y.; Asano, T. Studies of acoustical absorption of flexible polyurethane foam. J. Appl. Polym. Sci. 1982, 27, 183–195. [Google Scholar] [CrossRef]

- Gayathri, R.; Vasanthakumari, R.; Padmanabhan, C. Sound absorption, Thermal and Mechanical behavior of Polyurethane foam modified with Nano silica, Nano clay and Crumb rubber fillers. Int. J. Sci. Eng. Res. 2013, 4, 301–308. [Google Scholar]

- Eling, B.; Tomović, Ž.; Schädler, V. Current and Future Trends in Polyurethanes: An Industrial Perspective. Macromol. Chem. Phys. 2020, 221, 2000114. [Google Scholar] [CrossRef]

- Mosanenzadeh, S.G.; Naguib, H.E.; Park, C.B.; Atalla, N. Development of polylactide open-cell foams with bimodal structure for high-acoustic absorption. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Kurańska, M.; Barczewski, R.; Barczewski, M.; Prociak, A.; Polaczek, K. Thermal insulation and sound absorption properties of open-cell polyurethane foams modified with bio-polyol based on used cooking oil. Materials 2020, 13, 5673. [Google Scholar] [CrossRef] [PubMed]

- Tzanakis, I.; Hadfield, M.; Thomas, B.; Noya, S.M.; Henshaw, I.; Austen, S. Future perspectives on sustainable tribology. Renew. Sustain. Energy Rev. 2012, 16, 4126–4140. [Google Scholar] [CrossRef] [Green Version]

- Datta, J.; Włoch, M. Recycling of Polyurethanes. In Polyurethane Polymers: Blends Interpenetrating Polymer Networks; Elsevier: Amsterdam, The Netherlands, 2017; pp. 323–358. [Google Scholar]

- Zia, K.M.; Bhatti, H.N.; Bhatti, I.A. Methods for polyurethane and polyurethane composites, recycling and recovery: A review. React. Funct. Polym. 2007, 67, 675–692. [Google Scholar] [CrossRef]

- Kemona, A.; Piotrowska, M. Polyurethane Recycling and Disposal: Methods and Prospects. Polymers 2020, 12, 1752. [Google Scholar] [CrossRef] [PubMed]

- Moon, J.; Kwak, S.B.; Lee, J.Y.; Oh, J.S. Recent Development in Polyurethanes for Automotives. Elastomers Compos. 2017, 52, 249–256. [Google Scholar]

- TopLine HK—User’s Manual; Hennecke Gmbh: Sankt Augustin, Germany, 2013.

- ASTM D3574; Standard Test Methods for Flexible Cellular Materials—Slab, Bonded, and Molded Urethane Foams. ASTM Standard Test Methods; ASTM: West Conshohocken, PA, USA, 2013; pp. 1–29. [CrossRef]

- ISO 10534-2:1998; Acoustics—Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes—Part 2: Transfer-Function Method; ISO: Geneva, Switzerland, 1998; Available online: https://www.iso.org/standard/22851.html (accessed on 18 September 2021).

- ASTM E1050-19; Standard Test Method for Impedance and Absorption of Acoustical Materials Using a Tube, Two Microphones and a Digital Frequency Analysis System; ASTM: West Conshohocken, PA, USA, 2019; Available online: https://www.astm.org/Standards/E1050.htm (accessed on 18 September 2021).

- ASTM E2611-19; Standard Test Method for Normal Incidence Determination of Porous Material Acoustical Properties Based on the Transfer Matrix Method; ASTM: West Conshohocken, PA, USA, 2019; Available online: https://www.astm.org/Standards/E2611.htm (accessed on 18 September 2021).

| NCO-Index | Original Samples | F50%,0 (N) | h0 (mm) | Samples after Aging | F50%,1 (N) | h1 (mm) | ΔF50% (%) | Δh (%) | ΔF50%, Average (%) |

|---|---|---|---|---|---|---|---|---|---|

| 0.8 | NCO-0.8_1 | 5.76 | 33.10 | NCO-0.8_1_K | 4.49 | 33.00 | 22.14 | 0.29 | 17.67 |

| NCO-0.8_2 | 5.74 | 34.00 | NCO-0.8_2_K | 4.91 | 33.80 | 14.49 | −0.29 | ||

| NCO-0.8_3 | 5.57 | 33.99 | NCO-0.8_3_K | 4.66 | 33.69 | 16.39 | 0.60 | ||

| 0.9 | NCO-0.9_1 | 8.93 | 34.48 | NCO-0.9_1_K | 7.48 | 34.48 | 16.21 | 0.00 | |

| NCO-0.9_2 | 9.15 | 34.04 | NCO-0.9_2_K | 8.11 | 34.12 | 11.36 | −0.24 | 12.65 | |

| NCO-0.9_3 | 8.11 | 34.03 | NCO-0.9_3_K | 7.26 | 34.03 | 10.39 | −0.01 | ||

| 1.0 | NCO-1.0_1 | 11.09 | 34.90 | NCO-1.0_1_K | 9.46 | 35.07 | 14.77 | −0.51 | 14.66 |

| NCO-1.0_2 | 11.00 | 34.27 | NCO-1.0_2_K | 9.19 | 34.43 | 16.49 | −0.45 | ||

| NCO-1.0_3 | 11.21 | 34.24 | NCO-1.0_3_K | 9.78 | 34.39 | 12.73 | −0.44 | ||

| 1.1 | NCO-1.1_1 | 14.90 | 33.79 | NCO-1.1_1_K | 12.48 | 33.83 | 16.24 | −0.12 | 16.72 |

| NCO-1.1_2 | 15.08 | 33.99 | NCO-1.1_2_K | 12.52 | 34.23 | 16.99 | −0.70 | ||

| NCO-1.1_3 | 14.08 | 33.92 | NCO-1.1_3_K | 11.70 | 33.94 | 16.93 | −0.05 | ||

| 1.2 | NCO-1.2_1 | 20.20 | 33.90 | NCO-1.2_1_K | 16.90 | 33.94 | 16.33 | −0.13 | 17.42 |

| NCO-1.2_2 | 21.36 | 33.84 | NCO-1.2_2_K | 17.60 | 33.78 | 17.63 | 0.16 | ||

| NCO-1.2_3 | 20.44 | 34.05 | NCO-1.2_3_K | 16.70 | 34.12 | 18.30 | −0.19 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mester, E.; Pecsmány, D.; Jálics, K.; Filep, Á.; Varga, M.; Gráczer, K.; Viskolcz, B.; Fiser, B. Exploring the Potential to Repurpose Flexible Moulded Polyurethane Foams as Acoustic Insulators. Polymers 2022, 14, 163. https://doi.org/10.3390/polym14010163

Mester E, Pecsmány D, Jálics K, Filep Á, Varga M, Gráczer K, Viskolcz B, Fiser B. Exploring the Potential to Repurpose Flexible Moulded Polyurethane Foams as Acoustic Insulators. Polymers. 2022; 14(1):163. https://doi.org/10.3390/polym14010163

Chicago/Turabian StyleMester, Enikő, Dániel Pecsmány, Károly Jálics, Ádám Filep, Miklós Varga, Kitti Gráczer, Béla Viskolcz, and Béla Fiser. 2022. "Exploring the Potential to Repurpose Flexible Moulded Polyurethane Foams as Acoustic Insulators" Polymers 14, no. 1: 163. https://doi.org/10.3390/polym14010163

APA StyleMester, E., Pecsmány, D., Jálics, K., Filep, Á., Varga, M., Gráczer, K., Viskolcz, B., & Fiser, B. (2022). Exploring the Potential to Repurpose Flexible Moulded Polyurethane Foams as Acoustic Insulators. Polymers, 14(1), 163. https://doi.org/10.3390/polym14010163