3.1. Synthesis of Benzoxazine Monomers Based on Diamines

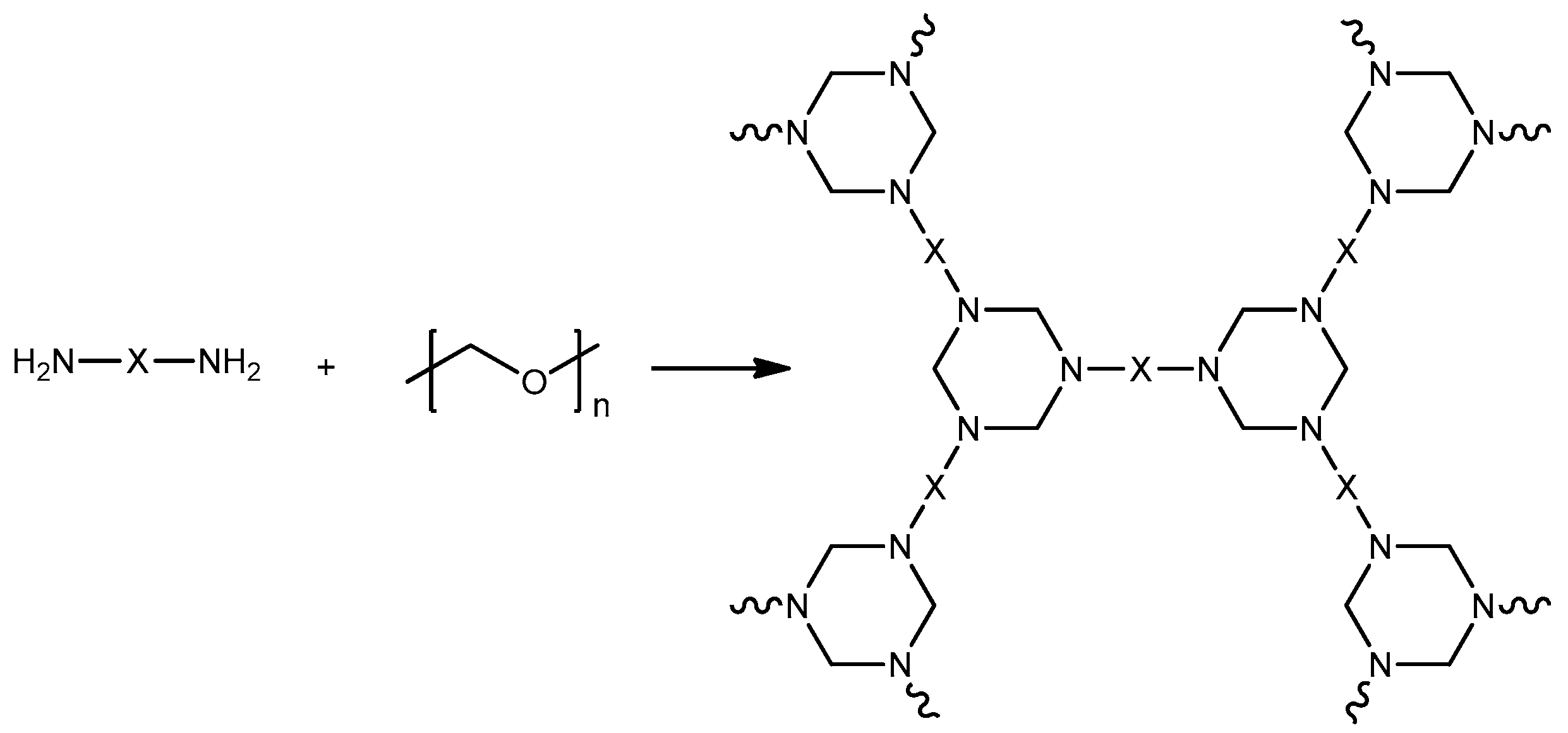

The preparation of benzoxazines based on di- and polyamines is complicated by the peculiarity of the first stage of the reaction. The formation of hyperbranched triazine chains (

Figure 1), which can lead to the reaction mass gelation [

16], either leading to a decrease in the yield of the main product, or complete impossibility of one-step synthesis of benzoxazines based on diamines.

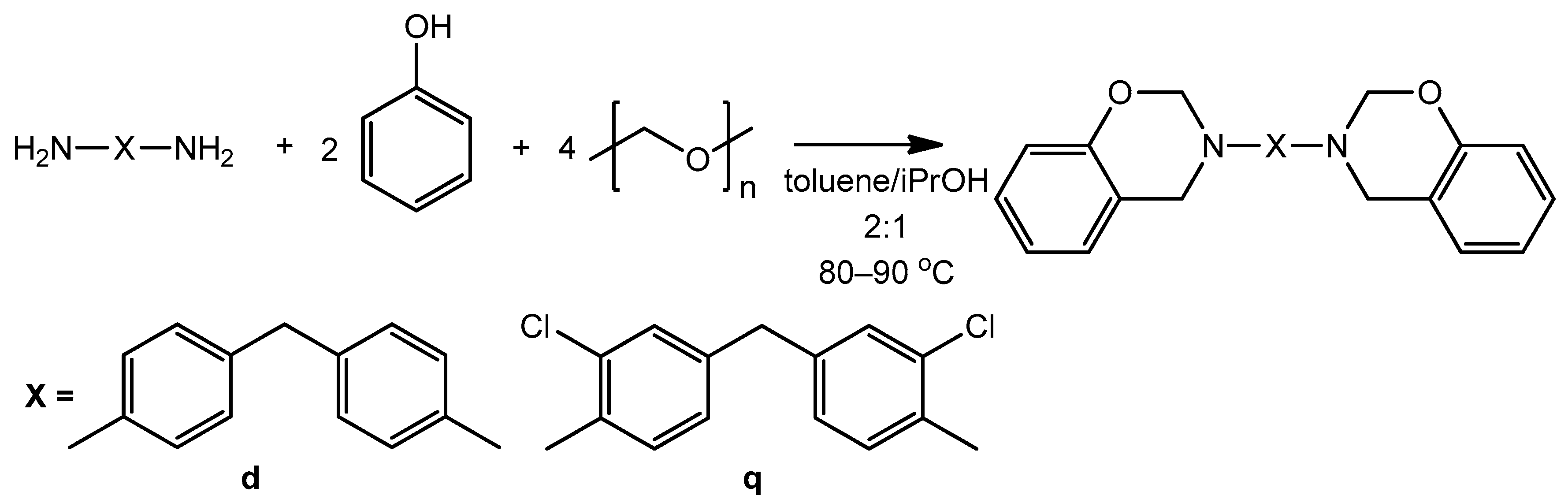

Despite the aforementioned fact, benzoxazines based on 4,4′-diaminodiphenylmethane/quamine, phenol and paraformaldehyde were obtained successfully (

Figure 2) by two methods: in toluene and in a mixture of toluene and isopropanol according to the scheme below (

Figure 2). The structure of the obtained benzoxazine monomers was characterized using

1H and

13C NMR spectroscopy.

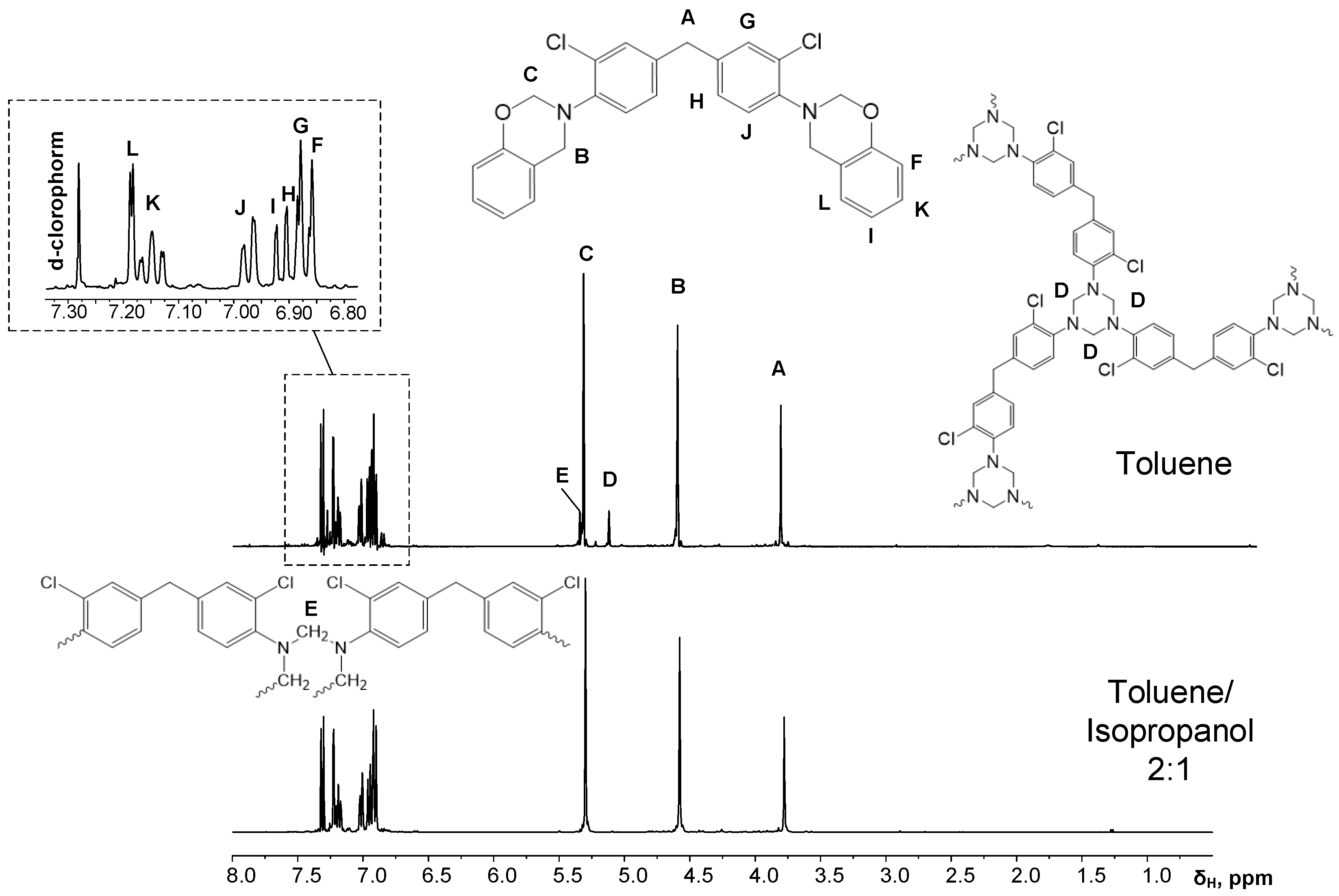

A low-intensity signal with a chemical shift at δ

H = 5.1 ppm in the

1H NMR spectra of the products obtained via this method (

Figure 3,

Table 2) indicates a small number of triazine structures.

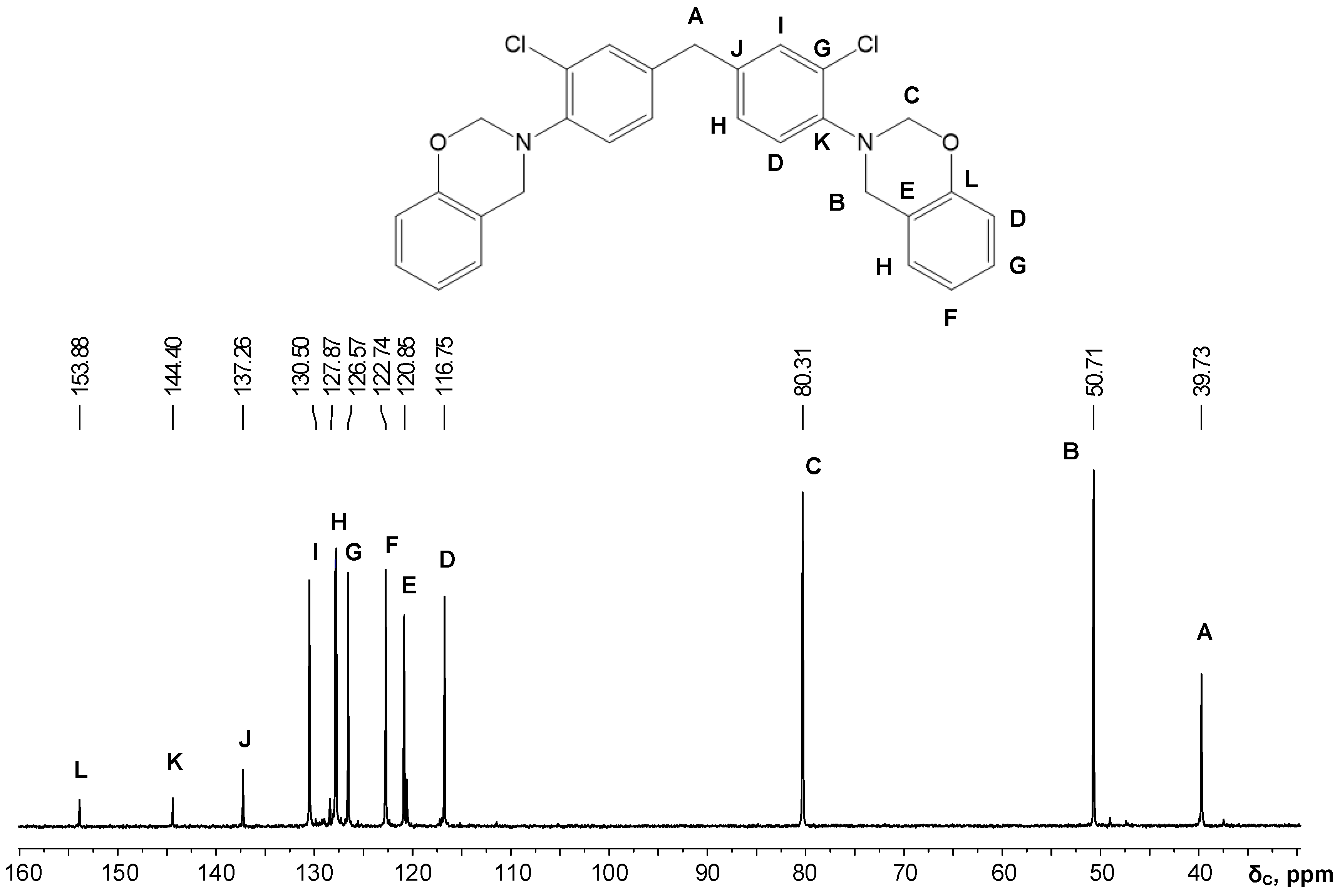

In the second method, a toluene/isopropanol mixture with 2:1 volume ratio was used. Due to the hydroxyl groups affinity to isopropanol and increased general solvation, triazine structures are not formed (

Figure 3 and

Figure 4,

Table 2) [

35].

The yields of benzoxazines in the two preparation methods were up to 90–95%. To exclude the formation of compounds with the Mannich bridge, a 10% excess of paraformaldehyde was used, its loading was carried out gradually and only after complete dissolution of quamine and phenol, the optimal reaction temperature was used (80–90 °C).

Benzoxazine monomer based on 4,4′-diaminodiphenylmethane (P-d) was obtained by the analogous method in toluene/isopropanol solvents mixture.

Based on the data obtained from

1H NMR spectroscopy, it can be concluded that some branched triazine structures insoluble in toluene are formed. Thus, carrying out the reaction in a toluene/isopropanol solvent mixture gives a much cleaner product than in pure toluene medium. However, unlike a number of halogen-free diamines [

14,

17,

18,

19,

20,

21], the direct synthesis of P-q from quamine, phenol and paraformaldehyde in toluene medium is still possible despite the presence of a slightly larger number of byproducts in comparison with the toluene/ethanol solvent mixture.

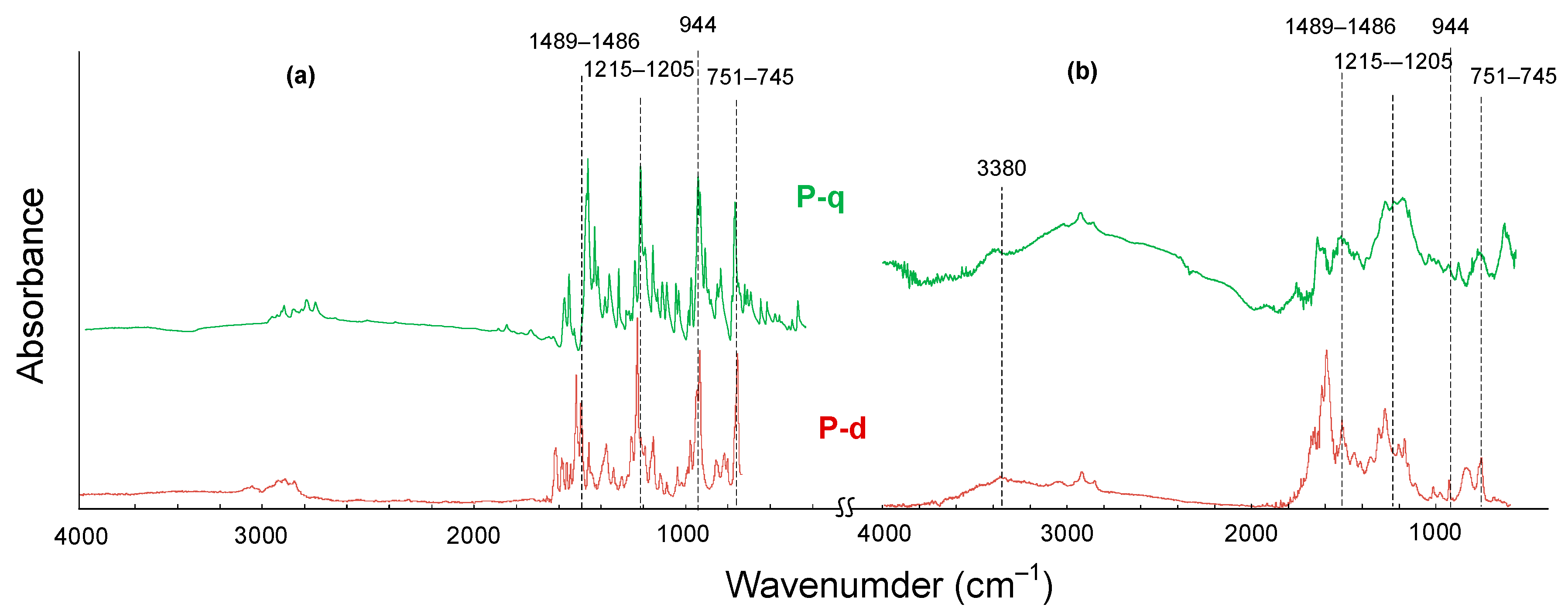

The structures of the obtained monomers and polymers were confirmed using FTIR spectroscopy and elemental analysis (

Table 3). In the FTIR spectra of monomers (

Figure 5), the absorption bands correspond to various vibrations in the oxazine ring: at 944 and 1215–1205 cm

−1 –to the stretching vibrations of the C–N–C and C–O–C bonds, respectively; in the region of 1489–1486 cm

−1 –to the stretching vibrations of the C–H bonds in the –CH

2– groups; at 751–745 cm

−1 –to the bending vibrations of –CH

2– groups. In the FTIR spectra of polybenzoxazines, the intensities of these bands decrease significantly, and a broadened band at 3600–3380 cm

−1 appears, corresponding to the stretching vibrations of phenolic hydroxyl groups linked by hydrogen bonds. The absorption bands in the FTIR spectra of benzoxazine and related polybenzoxazines correspond well to the literature data [

36,

37,

38,

39].

The content of elements in benzoxazine monomers (

Table 3), taking into account the measurement error, converges with the theoretical calculation, therefore, pure monomers were obtained.

The obtained benzoxazine monomers are polymerized by the thermal method with the formation of an insoluble thermosetting polymer according to the scheme shown in Figure 8 (

Figure S3 in Supplementary Materials).

3.2. Properties of Diamine-Based Benzoxazine Monomers

The curing kinetics of various diamine-based benzoxazine monomers was investigated by using differential scanning calorimetry (DSC) (Figure 8 and

Figure S3,

Table 4). The curves show that P-d polymerization proceeds under milder conditions than P-q. This may be due to the fact that the aromatic rings of the diamine in P-q are deactivated by chlorine atoms; therefore, the addition to the ortho position relative to the nitrogen atom will be somewhat difficult both sterically and energetically.

This statement is in a good agreement with early studies by Ishida and colleagues [

40,

41], who showed that benzoxazine monomers based on bisphenol A and aromatic amines polymerize not only according to the standard scheme with the formation of phenolic polymers with a Mannich bridge, but also with the participation of the p-position of the aromatic amine residue. The structure of the aromatic amine is important here. Amines with an activated aromatic ring (that is, with electron-donor substituents that increase the electron density in the o- and p-positions relative to the amino group) significantly increase the network density, while deactivated amines with a methyl group in the o- and p- positions, on the contrary, noticeably reduce it (

Figure 6, Figure 8 and

Figure S3) [

42]. In other words, if benzoxazine monomer has an electron-donor substituent in the m-position relative to the nitrogen atom or has no substituents in the aromatic ring of the diamine, then polymerization proceeds under milder conditions (lower temperature of the onset of polymerization and lower enthalpy of the curing reaction) and higher cross-link density and glass transition temperature are achieved in the resulting polymer (Figure 14).

In this case the P-q monomer has an electron-withdrawing chlorine in o-position and as a result polyP-q has reduced T

g of 182 °C compared to polyP-d’s 190 °C. Studies [

43,

44] report that the presence of electro-acceptor groups in amine or phenol aromatic ring can significantly affect the conditions for obtaining the benzoxazine monomer, and also can increase the polymerization temperature, which is observed during the curing of P-q, too.

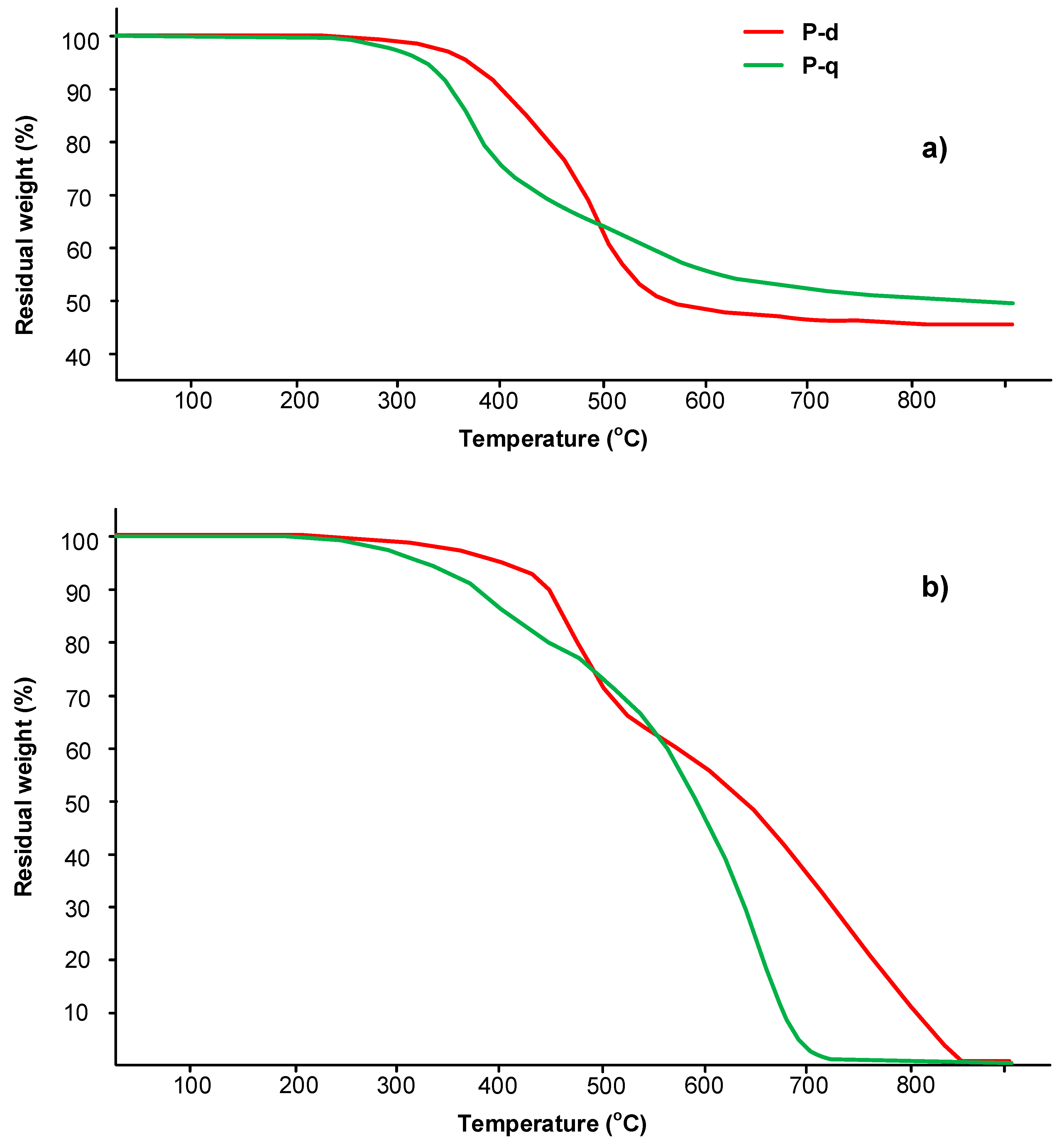

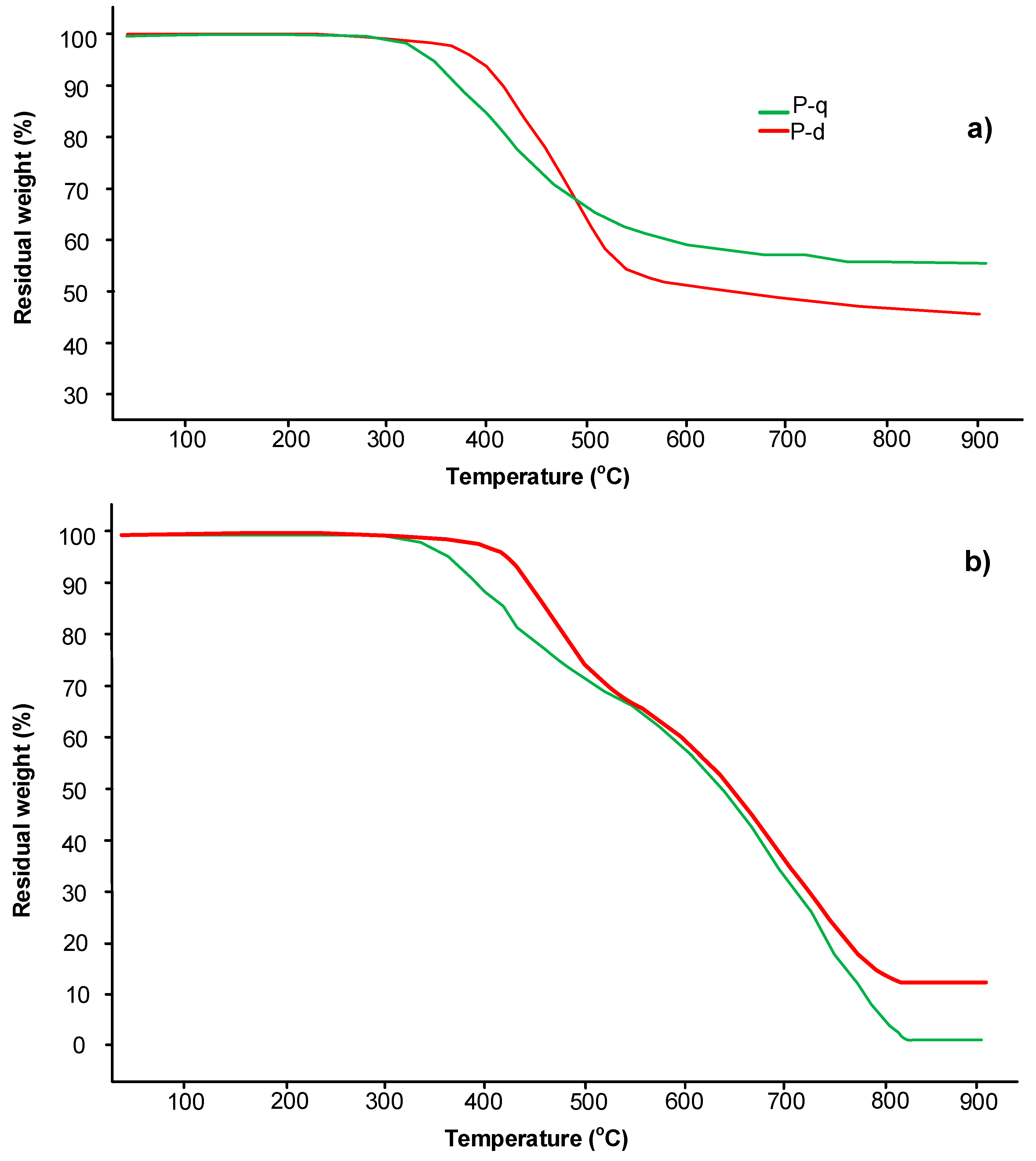

To confirm the stability of the benzoxazine monomers during curing in the selected mode, a thermogravimetric analysis both in air and argon atmosphere was carried out (

Figure 7).

Figure 8 and

Figure 9 show that the temperature of 5% mass loss for monomers P-d and P-q in air 407 °C and 333 °C, respectively, and in argon, 366 °C and 327 °C, respectively. These temperatures indicate the stability of the materials under the selected curing mode. The char yield at 800 °C for P-d and P-q in argon was 45 and 50%, respectively; in air, both monomers burned out without residue at 800 °C.

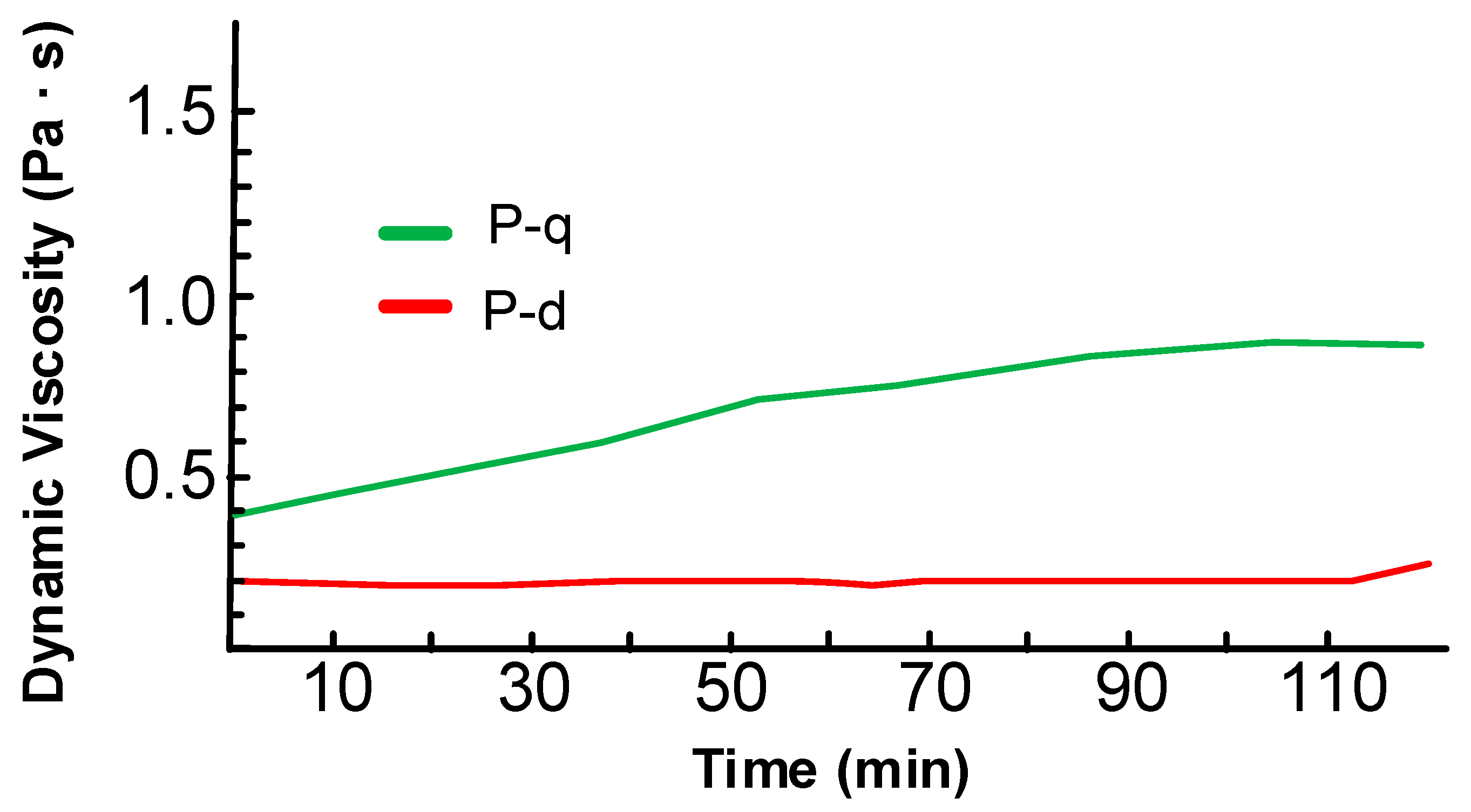

To determine the optimal curing mode of the obtained P-q, as well as the possibility of using it in the production of polymer composite materials and the processing method, we measured temperature profile of viscosity at a heating rate of 2 °C/min (

Figure 8). It can be seen that the obtained benzoxazine monomer has a rather wide technological window (115–225 °C) at a low viscosity (<1 Pa·s), which makes it possible to process this monomer by the vacuum infusion method.

Figure 8 represents the comparison of the viscosity and DSC curves at the same heating rate of 2 °C/min. The dramatic increase in viscosity that corresponds to the gelation is observed right after the peak of DSC curve.

To evaluate the melting stability of P-q, viscosity curves were obtained in rotational mode at 130 °C for 2 h at a shear rate 200 rpm.

Figure 9 shows that the P-q viscosity increase 2 times within 2 h; however, its values still remain below 1 Pa∙s. While viscosity of P-d monomer was not altered in a distinguishable way. This aspect contributes to the possibility of the vacuum infusion processing of monomers having P-d base more preferred than P-q.

3.3. Thermal Properties and Fire Resistance of Diamine-Based Polybenzoxazines

Benzoxazine monomers were cured according to the following regime: 2 h at 180 °C, 4 h at 200 °C, 2 h at 220 °C; all samples were degassed at 130 °C for 1 h before curing. The polymerization scheme is shown in

Figure 10. The oxazine rings are opened to form a crosslinked polymer under the high temperature.

Elemental analysis of the obtained polymers (

Table 5) showed that the only target polymerization reaction takes place during polymerization; that is to say, destruction does not occur with the release of byproducts.

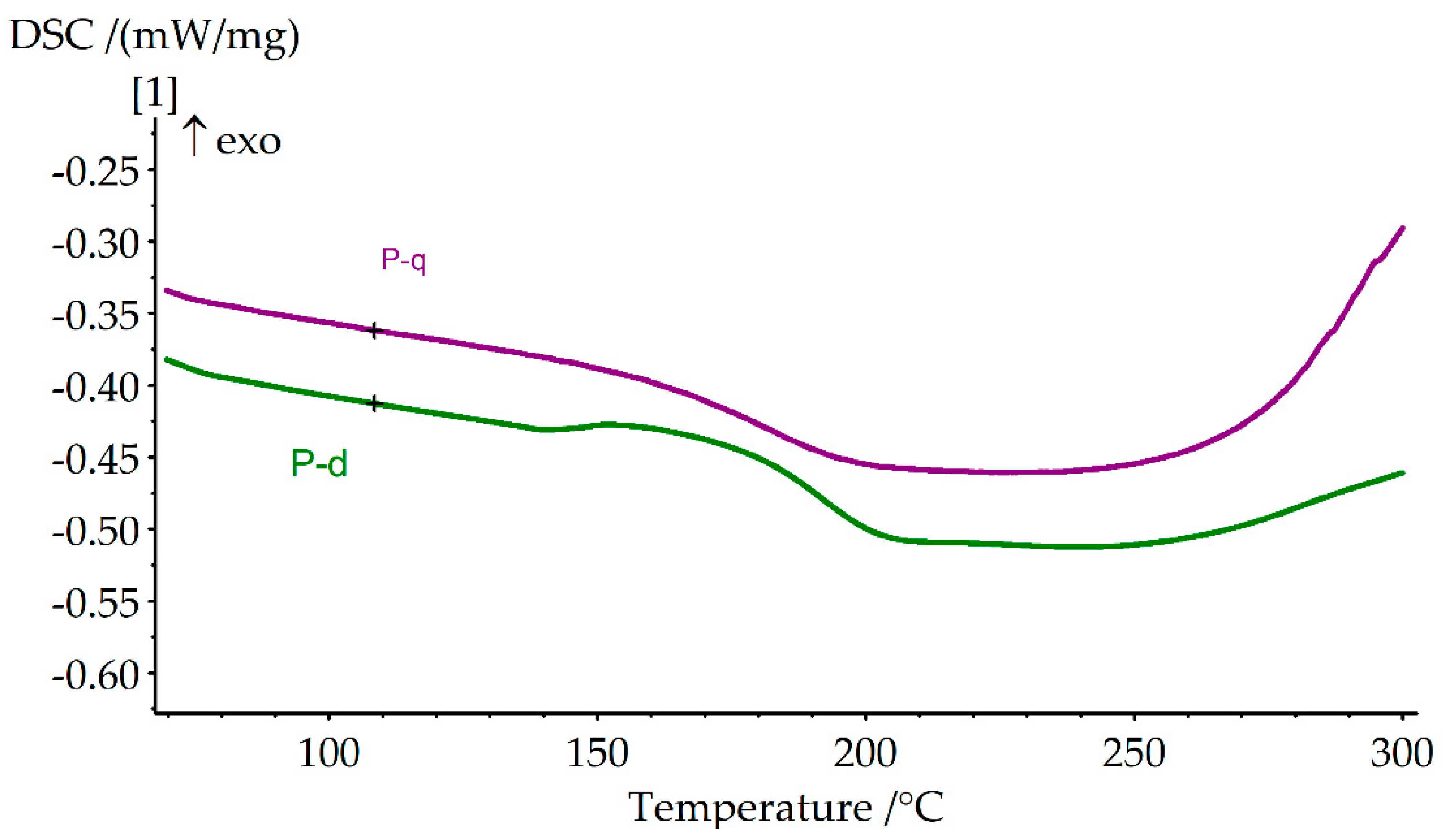

The glass transition temperatures (T

g) of the obtained cured samples were measured by DSC at a heating rate 10 °C/min. It turned out that T

g for P-d is higher than for P-q, being 190 °C and 182 °C, respectively (

Figure 11). By the character of DSC curves we could define that the beginnings of the thermal destruction of the P-q and P-d polymers are very close to each other in the region of 250 °C. However, the dramatic rise of DSC heat flow of P-q indicates that thermal stability of P-q at temperatures 250–300 °C is lower than that of P-d.

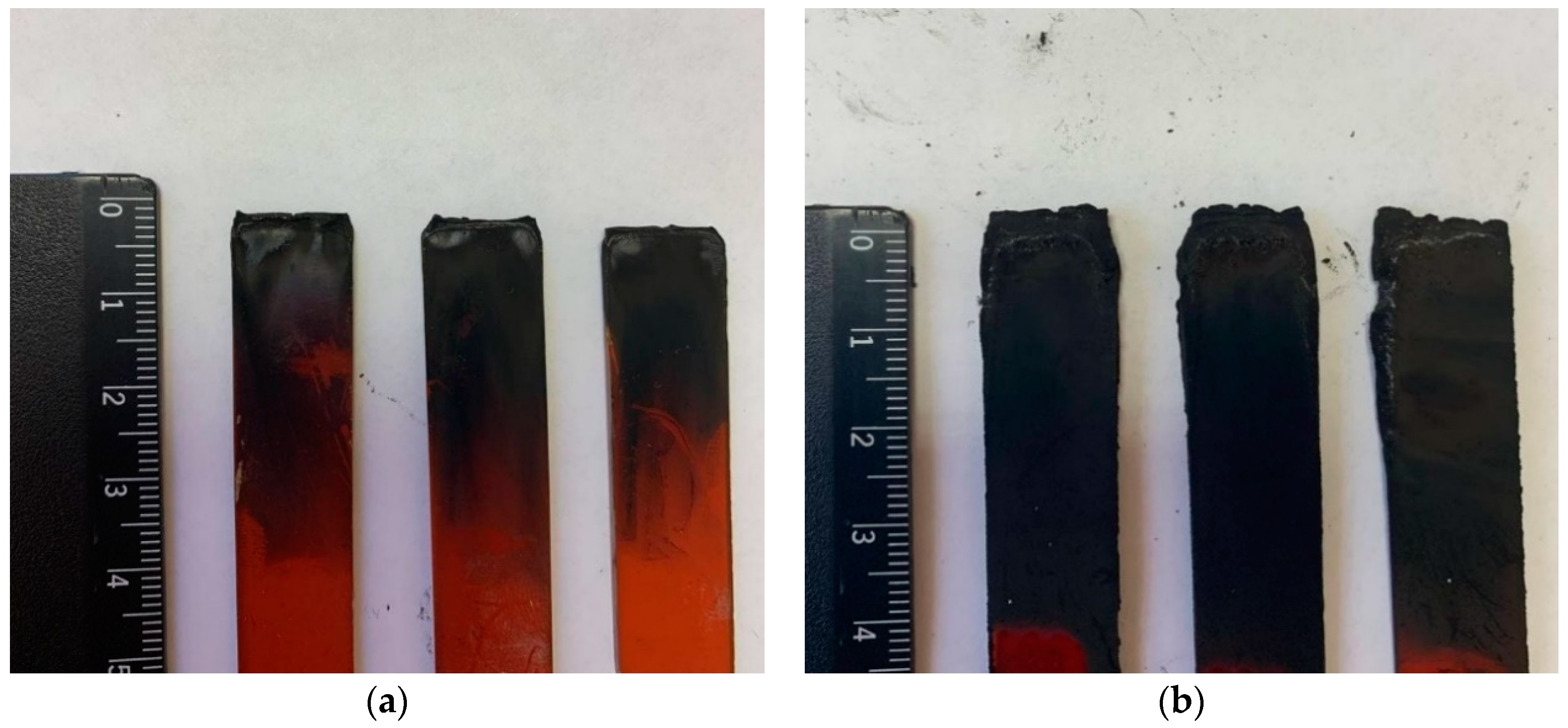

The determination of the fire-resistance according to the UL-94 standard showed that polyP-d has a category V-1, while polyP-q has an increased resistance to burning and so can be classified in the V-0 category (

Table 6). In comparison with polyP-d, the quamine-based polymer is characterized by near-zero burning times, even after several flame applications. The examples of the tested samples are presented in

Figure 12. The multicellular foam on the surface of the polyP-q samples seems to an the insulating effect resulting in the limitation of the diffusion of oxygen to the surface of the underlying material. The obtained flammability experimental data are in good agreement with the calculated data on the limiting oxygen index (LOI) according to the Van Crevelen–Hovtyzer rule [

45] (1):

where CY is the coke yield according to the TGA data.

One of the limiting factors of plastics’ high-temperature usage is their tendency not only to soften, but also to undergo the thermally induced degradation. Thermal degradation is the upper limit of the polymer’s operating temperature; above this temperature polymers can degrade with the formation of low-molecular-weight products that can change their properties.

The study of polybenzoxazines’ decomposition allows us to understand nature of the thermal stability of the material and prompt us to create new structures with greater thermal resistance.

It was proposed that the thermal decomposition of polybenzoxazines occurs stepwise [

46,

47,

48]. At the first stage of the destruction, aromatic compounds are formed (benzene, derivatives of phenol, aniline). In the second step—low-molecular compounds (hydrocarbons, carbon dioxide, aliphatic amines, etc.), followed by carbonization.

In the present work, thermogravimetric analysis with a mass-detector was carried out. According to the TGA data (

Figure 13 and

Table 6), the 5% and 10% mass-loss of polyP-q occurs at lower temperatures compared to polyP-d. However, probably due to the presence of chlorine atoms, polyP-q has a higher char yield.

The structures formed during thermal destruction of polyP-q are described below (

Table 7).

The result obtained is generally in satisfactory agreement with previously published studies. It can be noted that, both in air and in an inert atmosphere in the range of 300–500 °C, the destruction of benzoxazine cycles occurs predominantly and a small amount of potentially toxic chlorine-containing substances is released. As can be seen from

Table 5, at low temperatures from 343 °C and 700 °C in air, compounds are formed containing chlorine: HClO and CH

3Cl are formed with fractions 0.04% and 0.11%, respectively. More compounds containing chlorine are formed in an argon atmosphere at different temperatures (373–445 °C). For example, CH

3Cl (26.86%),

+CH

2CH

2Cl (3.93%), CH

3CH

2Cl (4.59%), CH

3OCl (5.5%),

+CH

2CH

2NH

3Cl (4.59%). Above 500 °C, there is almost no mass loss in the inert atmosphere. In air, thermo-oxidative destruction is most intense at 700 °C.

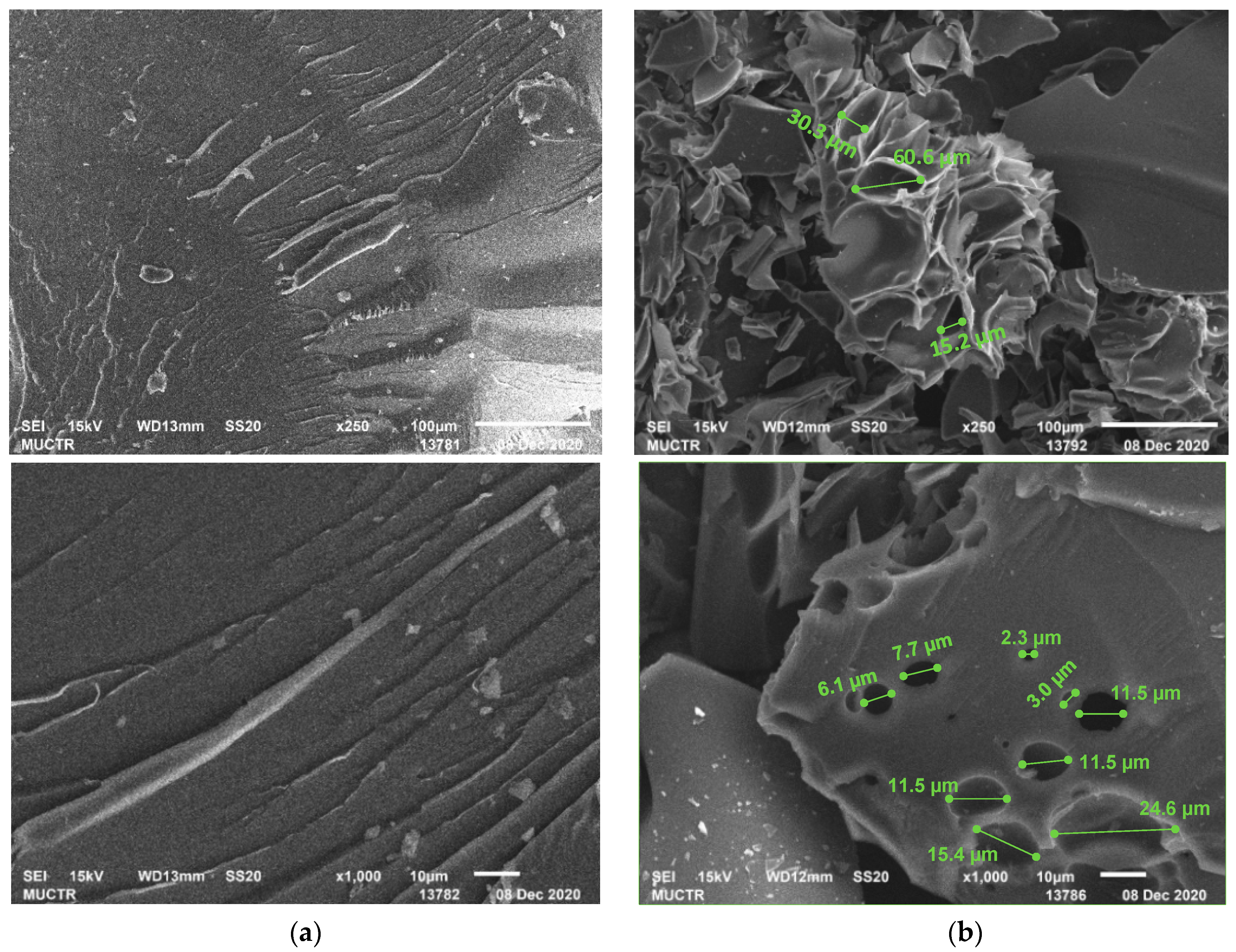

The surface of the fractured polymer sample and char yield were examined using SEM.

Figure 14a shows that the polymer has glassy bulky surface with no specific morphological features. The SEM image of the char residue (

Figure 14b) showed that during the burning of polybenzoxazine, a dense foam protective layer with a pore diameter from 2.3 to 60.6 µm is formed, which prevents the polymer from further burning.

It is also known that halogen radicals compete for the radical species HO· and H· that are critical for flame propagation [

49,

50]. Thus, the higher fire resistance of polyP-q compared to polyP-d can be explained by two factors. The first factor is the release of low molecular weight products, such as CO

2, NO

2, CH

3Cl and HClO, which cause system cooling and removing of high-energy HO· and H· radicals. The second factor is the formation of the char layer on the polymer surface, which prevents oxygen penetration into the bulk of the sample and thereby stops combustion.

The notable feature of polyP-q is its higher thermal resistance in air, compared to the results in argon (

Figure 13). This behavior usually occurs when thermo-oxidative reactions with the participation of atmospheric oxygen occur additionally in air, leading to the formation of densely crosslinked products. This is also confirmed by the results of TGA-MS analysis (

Table 7). In an oxygen atmosphere at a temperature of about 340 °C, active particles (cations) are formed, which can additionally cross-link the polymer network. In an argon atmosphere, these particles are also formed, but already at higher temperatures. The formation of a char layer and small pores can be observed in the SEM images of the samples tested according to the UL-94 standard and the surface of the char residue examined using SEM (

Figure 12 and

Figure 14).

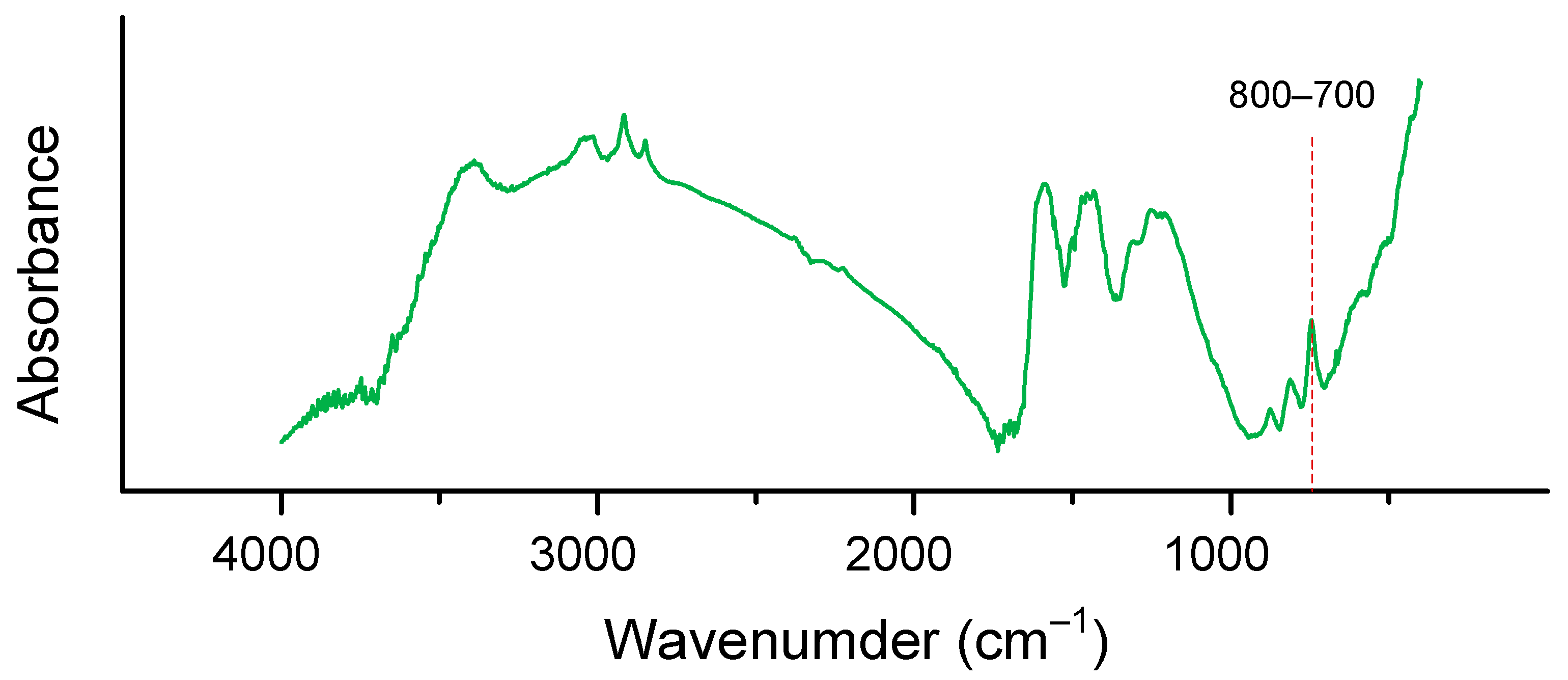

Quamine-based polybenzoxazine char residue was investigated by FTIR (

Figure 15). It showed stretching vibrations of the C–Cl (800–700 cm

−1) bond after burning of the polymer sample. This observation is consistent with relatively low content of chlorine-containing ions during TGA and with the formation of a dense char residue in the UL-94 vertical test and presumably indicates the cessation of combustion on the sample surface without the flame penetrating deep into the sample.

Based on the data of elemental analysis and IR spectroscopy of the coke residue (

Table 5,

Figure 15), it can be seen that the residue contains a small amount of chlorine atoms. According to the TGA-MS data in air (

Table 7), it can be seen that only 0.11% and 0.04% of the chlorine-containing products CH

3Cl and HClO are formed, respectively. The data obtained indicate a low lability of chlorine atoms in the composition of polybenzoxazine, which is a positive factor in terms of safety and environmental friendliness.

The lower temperature of the onset of polyP-q decomposition in an inert atmosphere is most likely due to the easier cleavage of bonds in the polymer due to the presence of electron-withdrawing chlorine atoms in the diamine structure. On the contrary, the higher thermal resistance of polyP-q in air indicates a greater proportion of crosslinking and resulted char formation. This fact is indirectly confirmed by the presence of a significant amount of residual chlorine in the char residue, as well as a relatively low chlorine content in the combustion products.

Thus, the formation of char probably plays a major role in the mechanism of combustion and thermooxidative destruction of polyP-q.