The Multiple Uses of Polypropylene/Polyethylene Terephthalate Microfibrillar Composite Structures to Support Waste Management—Composite Processing and Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Blending and Filament Processing

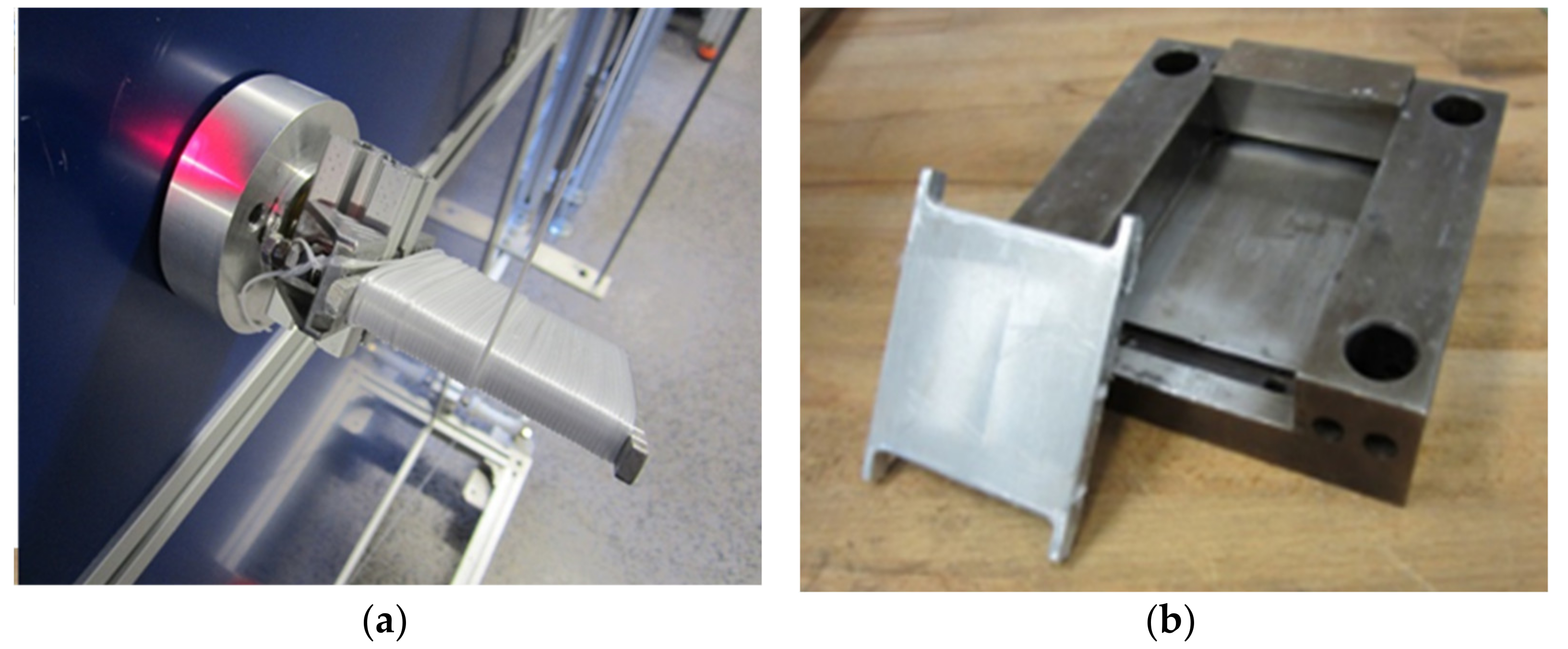

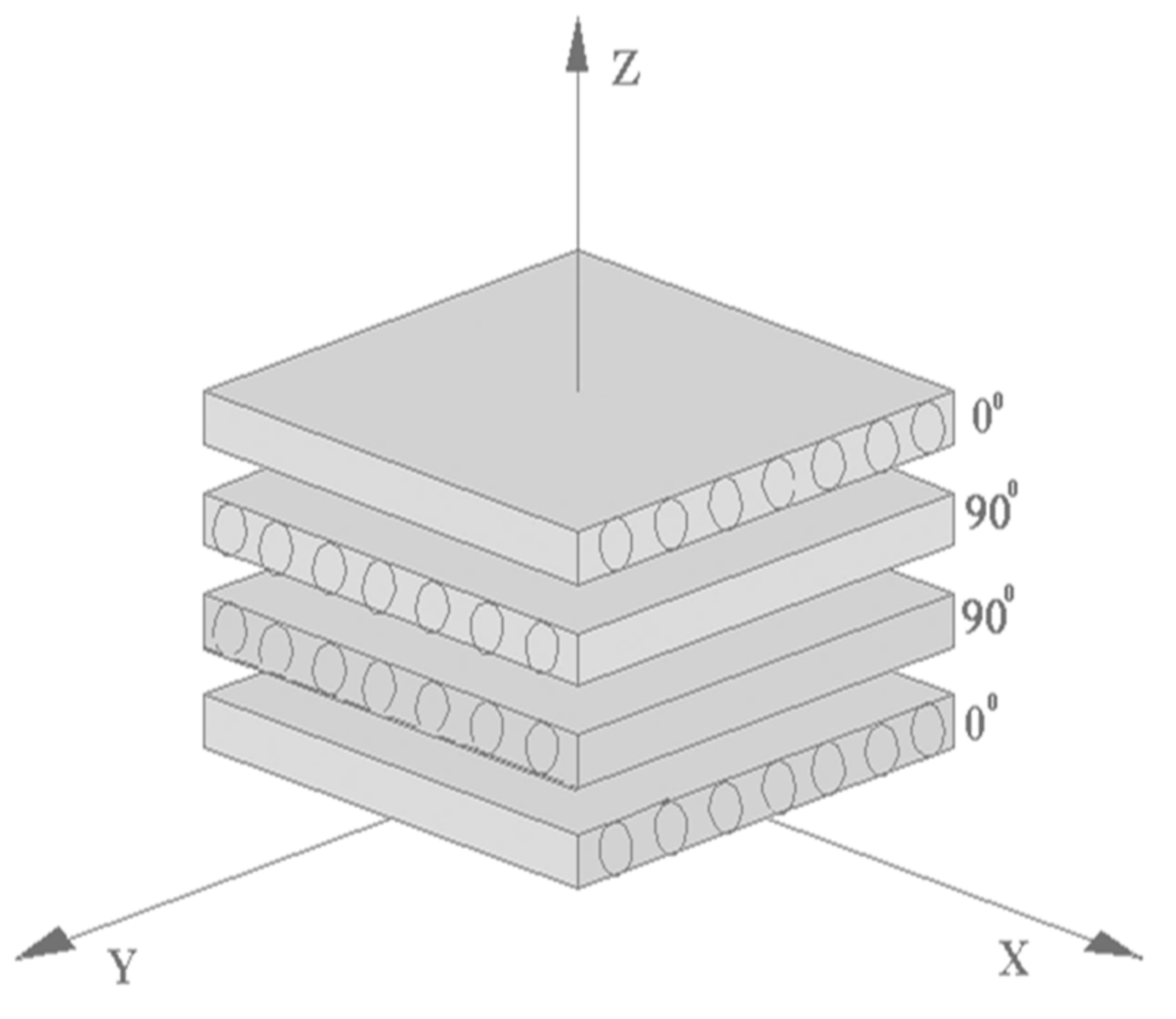

2.3. Composite Processing

2.4. Mechanical Characterization

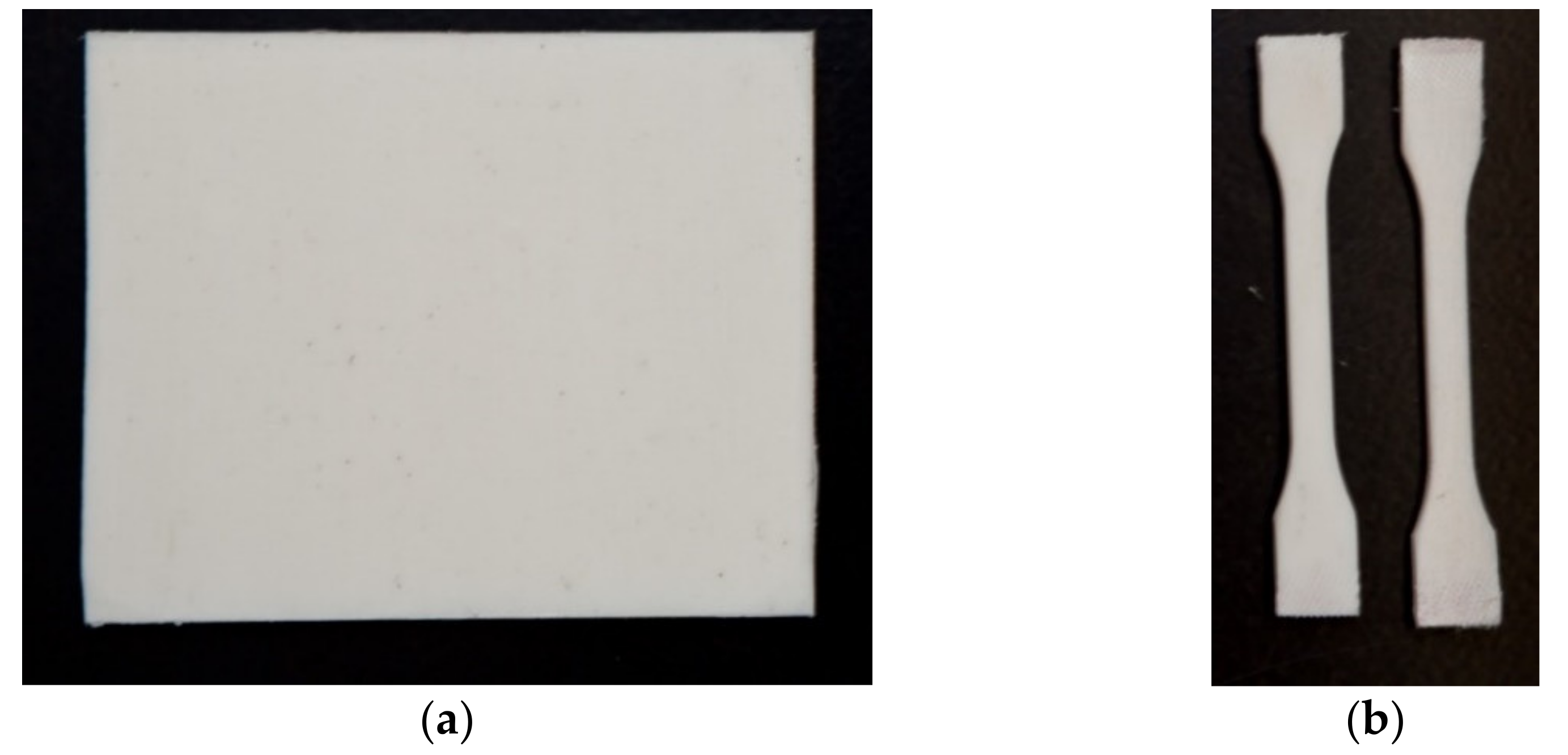

2.4.1. Tensile Test

2.4.2. Impact/Falling Weight Test

3. Results and Discussion

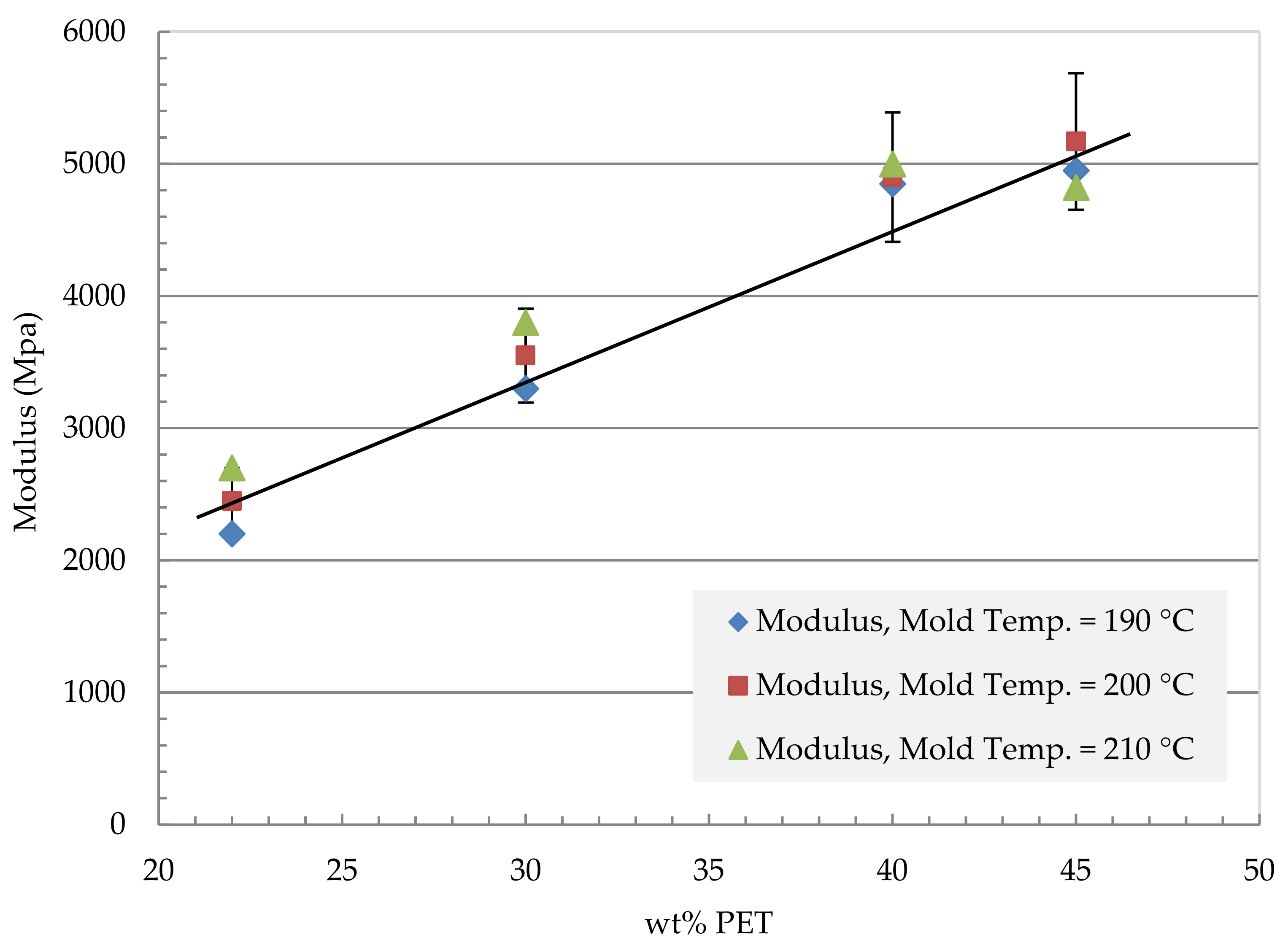

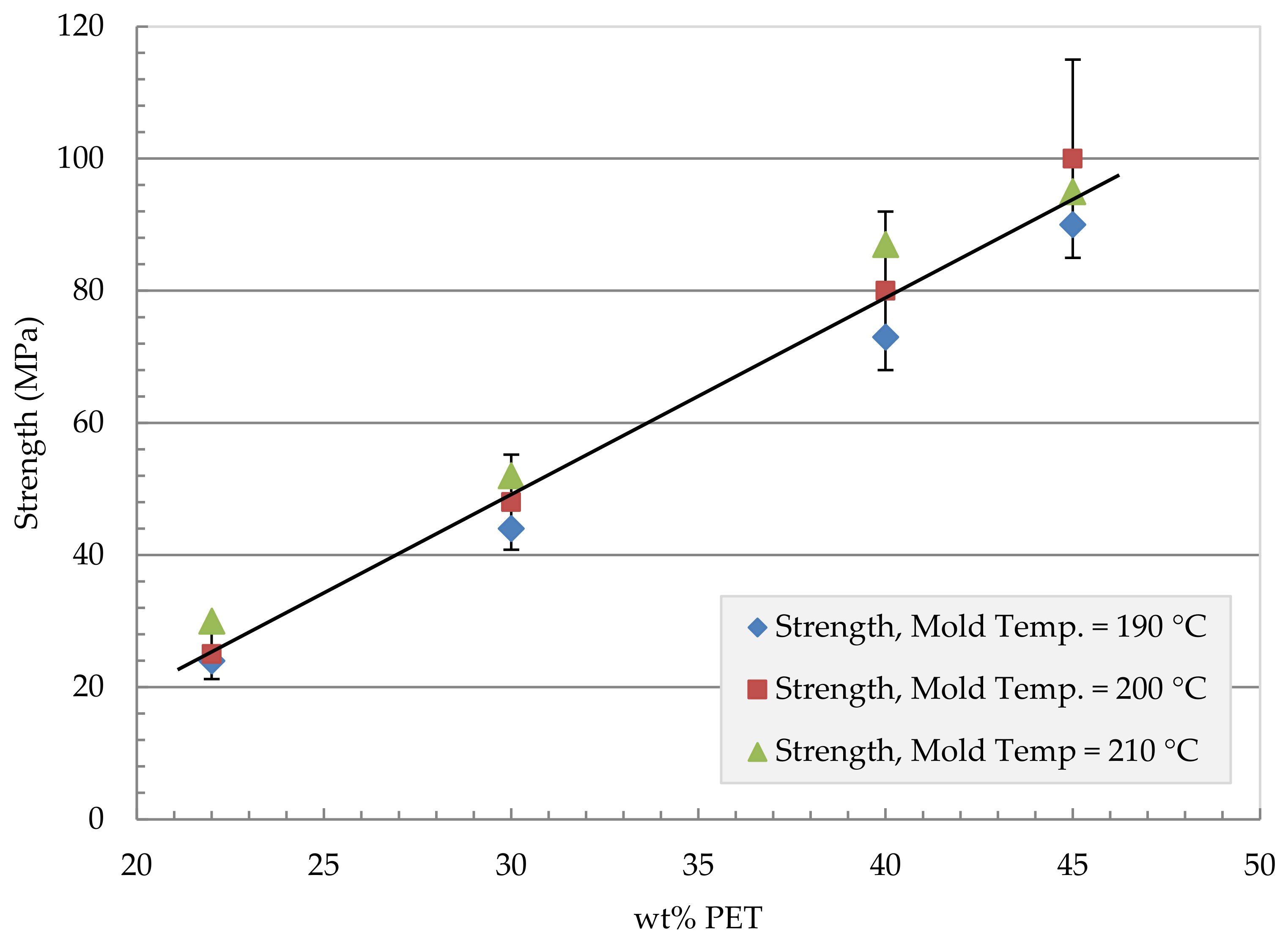

3.1. Tensile Test

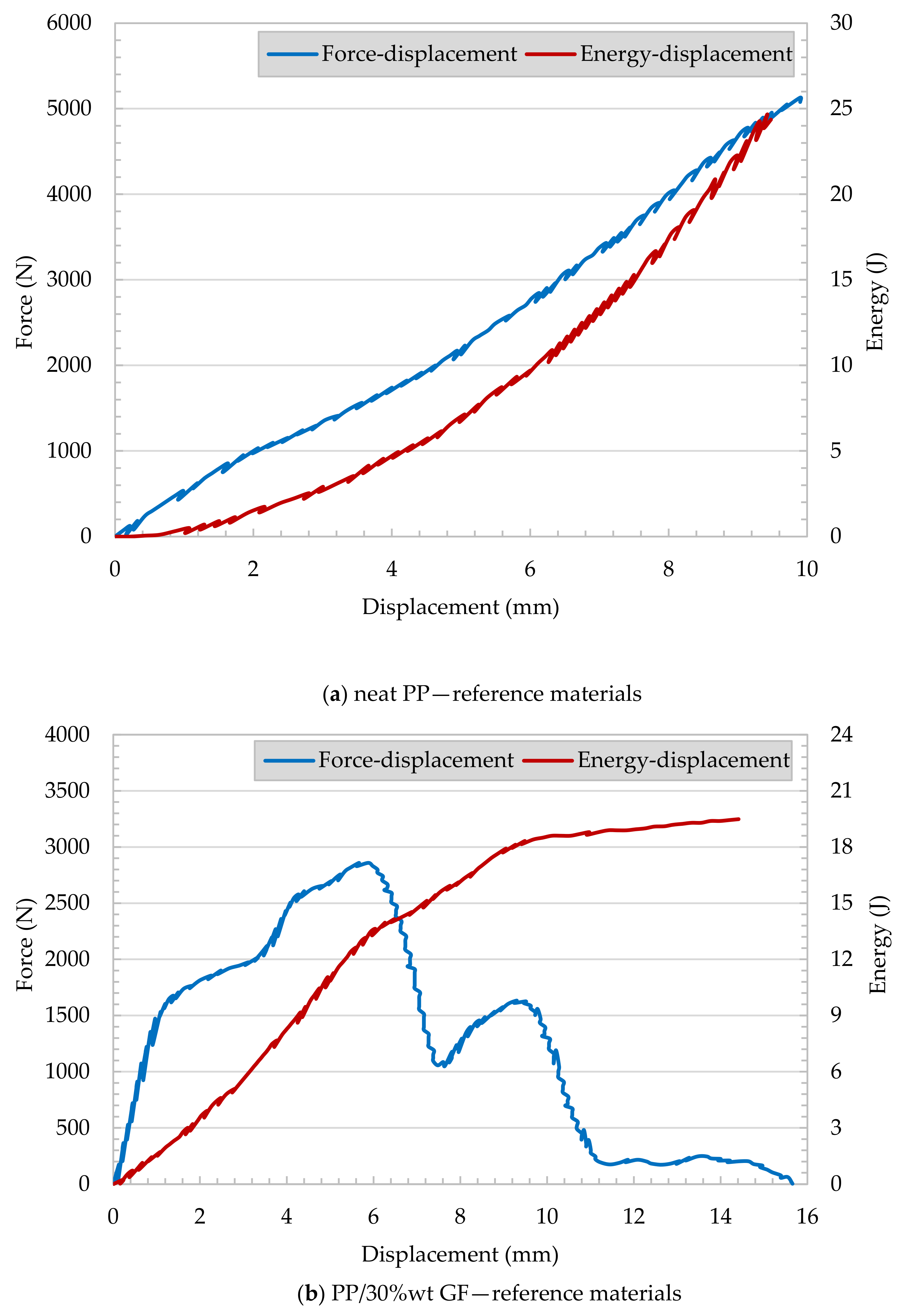

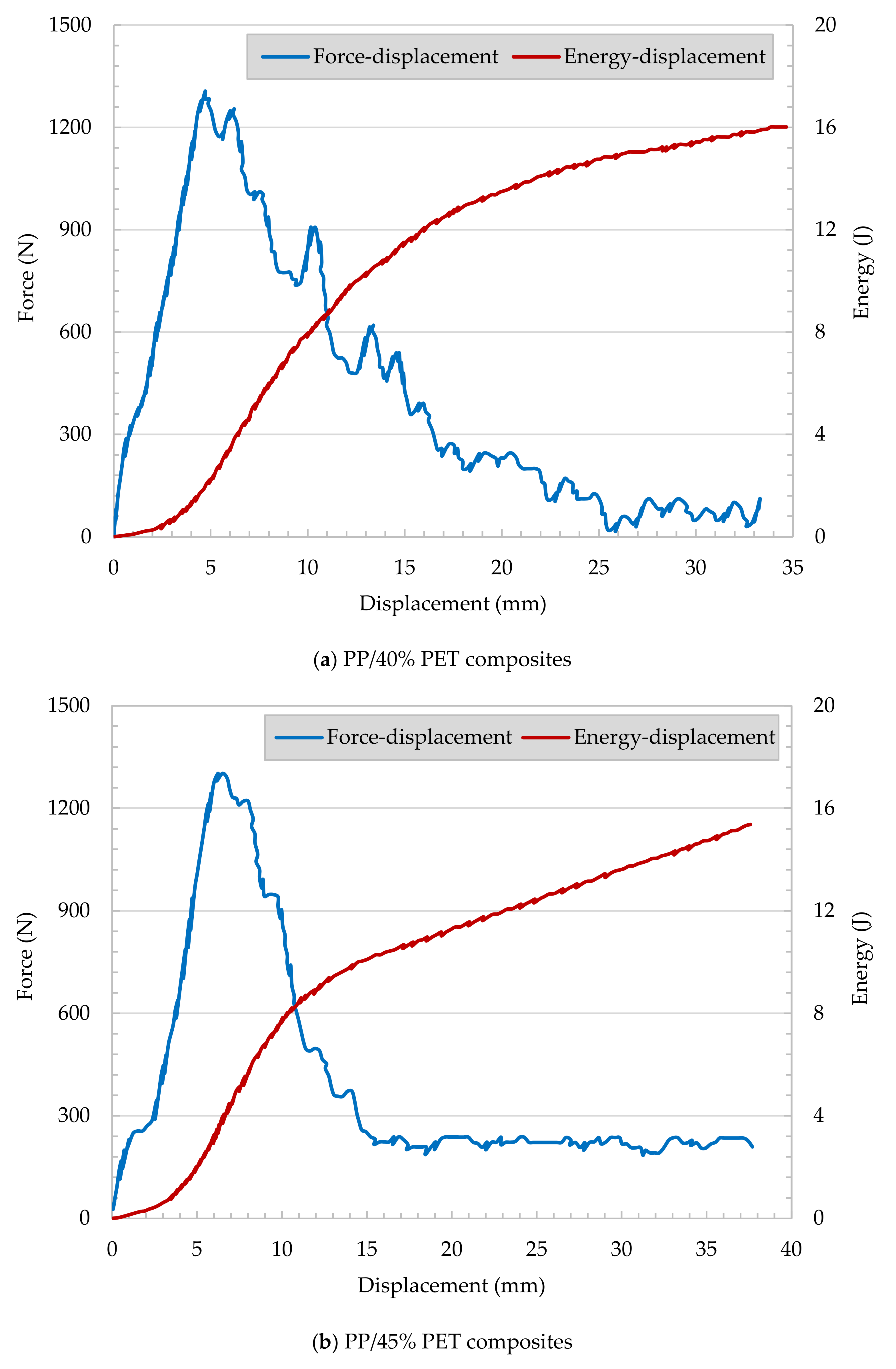

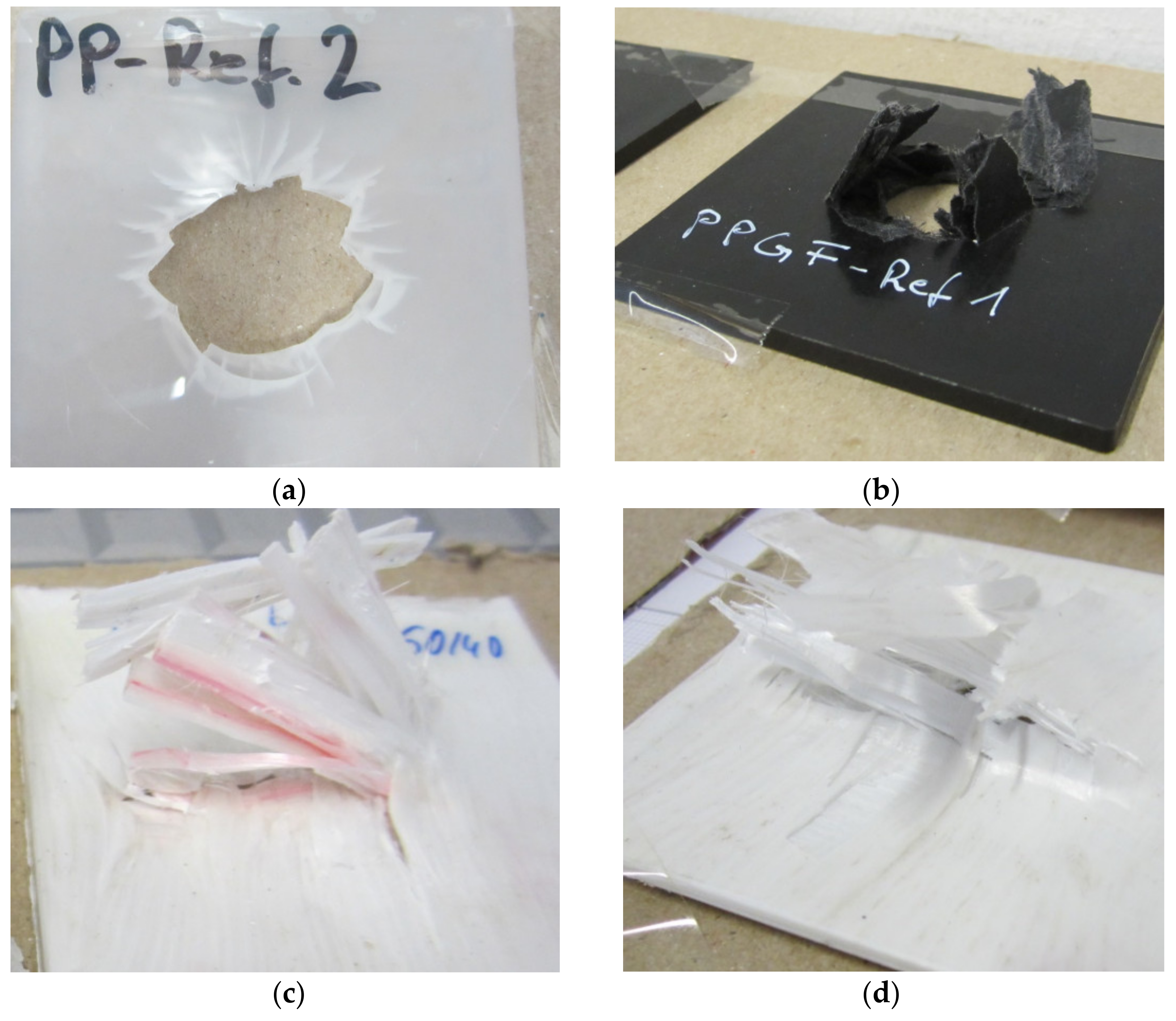

3.2. Impact/Falling Weight Test

3.2.1. Sample Preparation

3.2.2. Impact/Falling Weight Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Directive 2000/53/EC of the European Parliament and of the Council. 2000. Available online: http://eurlex.europa.eu/LexUriServ/LexUriServ.do?uri=CONSLEG:2000L0053:20050701:EN:PDF (accessed on 7 January 2005).

- Mazda Develops Automatic Bumper Recycling Process. 2009. Available online: http://green.autoblog.com/2009/03/23/mazdadevelops-automatic-bumper-recycling-process (accessed on 23 March 2009).

- Mishra, R.K.; Verma, K.; Chaudhary, R.G.; Lambat, T.; Joseph, K. An efficient fabrication of polypropylene hybrid nanocomposites using carbon nanotubes and PET fibrils. Mater. Today Proc. 2020, 29, 794–800. [Google Scholar] [CrossRef]

- Narula, C.K.; Allison, J.E.; Bauer, D.R.; Gandhi, H.S. Materials Chemistry Issues Related to Advanced Materials Applications in the Automotive Industry. Chem. Mater. 1996, 8, 984–1003. [Google Scholar] [CrossRef]

- Evstatiev, M.; Fakirov, S. Microfibrillar Reinforcement of Polymer Blends. Polymer 1992, 33, 877–880. [Google Scholar] [CrossRef]

- Mehta, A.; Isayev, A. Rheology, morphology, and mechanical characteristics of poly(etherether keton)-liquid crystalline polymer. Polym. Eng. Sci. 1991, 31, 971–980. [Google Scholar] [CrossRef]

- Tjong, S.C.; Liu, S.L.; Li, R.K.Y. Structure and mechanical properties of the extruded blends of a liquid crystalline polymer with polypropylene. J. Mater. Sci. 1995, 30, 353–360. [Google Scholar] [CrossRef]

- Tjong, S.C.; Liu, S.L.; Li, R.K.Y. Mechanical properties of injection moulded blend of polypropylene with thermotropic liquid crystalline polymer. J. Mater. Sci. 1996, 31, 479–484. [Google Scholar] [CrossRef]

- Varga, L.J.; Bárány, T. Development of Polypropylene-Based Single-Polymer Composites with Blends of Amorphous Poly-Alpha-Olefin and Random Polypropylene Copolymer. Polymers 2020, 12, 1429. [Google Scholar] [CrossRef]

- Kim, T.K.; Kim, B.K.; Lee, S.Y.; Cho, Y.L.; Kim, M.S.; Jeong, H.M. Thermoplastic polyurethane elastomer/thermoplastic polyolefin elastomer blends compatibilized with a polyolefinic segment in TPU. Macromol. Res. 2010, 18, 177–184. [Google Scholar] [CrossRef]

- Li, J.-L.; Wang, X.-F.; Yang, C.-J.; Yang, J.-H.J.; Wang, Y.; Ahang, J.-H. Toughening modification of polycarbonate/poly(butylene terephthalate) blends achieved by simultaneous addition of elastomer particles and carbon nanotubes. Compos. Part A Appl. Sci. Manuf. 2016, 90, 200–210. [Google Scholar] [CrossRef]

- Evstatiev, M.; Fakirov, S.; Evstatiev, O.; Friedrich, K. Effect of Blend Composition on the Structure-Properties Relationship of Nanostructured Polymer Composites from Polycondensate/Polyolefin Blends. Int. J. Polym. Mater. 2004, 53, 211–228. [Google Scholar]

- Pilipović, A.; Ilinčić, P.; Petruša, J.; Domitran, Z. Influence of Polymer Composites and Memory Foam on Energy Absorption in Vehicle Application. Polymers 2020, 12, 1222. [Google Scholar] [CrossRef]

- Sathishkumar, T.P.; Satheeshkumar, S.; Naveen, J. Glass fiber-reinforced polymer composites—A review. J. Reinf. Plast. Compos. 2014, 33, 1258–1275. [Google Scholar] [CrossRef]

- Davoodi, M.M.; Sapuan, S.M.; Ahmed, D.; Ali, A.; Khalina, A.; Jonoobi, M. Mechanical properties of hybrid kenaf/glass reinforced epoxy composite for passenger car bumper beam. Mater. Des. 2010, 31, 4927–4932. [Google Scholar] [CrossRef]

- Ramasubbu, R.; Madasamy, S. Fabrication of Automobile Component Using Hybrid Natural Fiber Reinforced Polymer Composite. J. Nat. Fibers 2020. [Google Scholar] [CrossRef]

- El Hajj, N.; Seif, S.; Zgheib, N. Recycling of poly(propylene)-based car bumpers as carrier resin for short glass fiber composites. J. Mater. Cycles Waste Manag. 2021, 23, 288–300. [Google Scholar] [CrossRef]

- Fakirov, S.; Bhattacharyya, D.; Shields, R.J. Nanofibril reinforced composites from polymer blends. Colloids Surf. A Physicochem. Eng. Asp. 2008, 313–314, 2–8. [Google Scholar] [CrossRef]

- Evstatiev, M.; Fakirov, S.; Bechtold, G.; Friedrich, K. Structure-property relationships of injection—And compression-molded microfibrillar-reinforced PET/PA-6 composites. Adv. Polym. Technol. 2000, 19, 249–259. [Google Scholar] [CrossRef]

- Evstatiev, M.; Fakirov, S.; Krasteva, B.; Friedrich, K.; Covas, J.; Cunha, A. Recycling of poly(ethylene terephthalate) as polymer-polymer composites. Polym. Eng. Sci. 2002, 42, 826–835. [Google Scholar] [CrossRef]

- Nakagaito, A.; Fujimura, A.; Sasaki, T.; Hama, Y.; Yano, H. Production of microfibrillated cellulose (MFC)-reinforced polylactic acid (PLA) nanocomposites from sheets obtained by a papermaking-like process. Compos. Sci. Technol. 2009, 69, 1293–1297. [Google Scholar] [CrossRef]

- Evstatiev, M.; Simeonova, S.; Friedrich, K.; Pei, X.-O.; Formanek, P. MFC-structured biodegradable poly(l-lactide)/poly(butylene adipate-co-terephatalate) blends with improved mechanical and barrier properties. J. Mater. Sci. 2013, 48, 6312–6330. [Google Scholar] [CrossRef]

- Friedrich, K.; Evstatiev, M.; Fakirov, S.; Evstatiev, O.; Ishii, M.; Harrass, M. Microfibrillar reinforced composites from PET/PP blends: Processing, morphology and mechanical properties. Compos. Sci. Technol. 2005, 65, 107–116. [Google Scholar] [CrossRef]

- Kuzmanović, M.; Delva, L.; Cardon, L.; Ragaert, K. Relationship between the Processing, Structure, and Properties of Microfibrillar Composites. Adv. Mater. 2020, 32, 2003938. [Google Scholar] [CrossRef] [PubMed]

- Fakirov, S.; Kamo, H.; Evstatiev, M.; Friedrich, K. Microfibrillar Reinforced Composites from PET/LDPE Blend: Morphology and Mechanical properties. J. Macromol. Sci. Part B Phys. 2004, 43, 775–789. [Google Scholar] [CrossRef]

- Kuzmanovi, M.; Delva, L.; Mi, D.; Martins, C.I.; Cardon, L.; Ragaert, K. Development of Crystalline Morphology and Its Relationship with Mechanical Properties of PP/PET Microfibrillar Composites Containing POE and POE-g-MA. Polymers 2018, 10, 291. [Google Scholar] [CrossRef] [PubMed]

- Machiels, A.G.C.; Dam, J.V.; Boer, A.P.D.; Norder, B. Stability of blends of thermoplastic liquid crystalline polymers with thermoplastic polymers. Polym. Eng. Sci. 1997, 37, 1512–1525. [Google Scholar] [CrossRef]

- Friedrich, K.; Ueda, E.; Kamo, H.; Evstatiev, M.; Fakirov, S. Direct Electron Microscopic Observation of Transcrystalline Layers in Microfibrillar Reinforced Polymer-Polymer Composites. J. Mater. Sci. 2002, 37, 4299–4306. [Google Scholar] [CrossRef]

- Krumova, M.; Michler, G.H.; Evstatiev, M.; Friedrich, K.; Stribeck, N.; Fakirov, S. Transcrystallisation with reorientation of polypropylene in drawn PET/PP and PA66/PP blends. Part 2. Electron microscopic observations on the PET/PP blend. In Scattering Methods and the Properties of Polymer Materials; Stribeck, N., Smarsly, B., Eds.; Progress in Colloid and Polymer Science 130; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Almajid, A.; Walter, R.; Kroos, T.; Junaidi, H.; Gurka, M.; Abdelrazek Khalil, K. Development of Polypropylene/Polyethylene Terephthalate Microfibrillar Composites Filament to Support Waste Management. Polymers 2021, 13, 233. [Google Scholar] [CrossRef]

- Hartikainen, J.; Lindner, M.; Harmia, T.; Friedrich, K. Mechanical properties of polypropylene composites reinforced with long glass fibres and mineral fillers. Plast. Rubber Compos. 2004, 33, 77–84. [Google Scholar] [CrossRef]

- Mi, D.; Wang, Y.; Kuzmanovic, M.; Delva, L.; Jiang, Y.; Cardon, L.; Zhang, J.; Ragaert, K. Effects of Phase Morphology on Mechanical Properties: Oriented/Unoriented PP Crystal Combination with Spherical/Microfibrillar PET Phase. Polymers 2019, 11, 248. [Google Scholar] [CrossRef]

- Krumova, M.; Flores, A.; Baltá Calleja, F.; Fakirov, S. Elastic properties of oriented polymers, blends and reinforced composites using the microindentation technique. Colloid Polym. Sci. 2002, 280, 591–598. [Google Scholar] [CrossRef]

| Polymer Type | Polymer Grade | Manufacturer | Density (g/cm3) | MFR (dg/min) | Intrinsic Viscosity (dL/g) | |

|---|---|---|---|---|---|---|

| Bulk | Crystalline | |||||

| PET | BC111 | Sabic | 0.838 | 1.39 | - | 0.74–0.78 |

| PP | 500P | Sabic | - | 0.905 | 3 | - |

| % PET | Densityg/cm3 | Thickness(mm) | Fmax (N) | Standard Deviation, Fmax | Displ. at Fmax (mm) | Standard Deviation, Disp. | Energy at Fmax (J/mm) | Etot (J/mm) | Specific Etot (J/g) | Ductility Index (DI) |

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 0.905 | 3.9 | 5440 | ±200 | 11.3 | ±1.3 | 8.4 | 8.52 | 0.23 | 0.02 |

| 40 | 1.1 | 4.07 | 1449 | ±50 | 7.0 | ±0.5 | 2.42 | 6.59 | 0.147 | 0.61 |

| 45 | 1.12 | 3.08 | 1309 | ±40 | 6.3 | ±0.4 | 2.49 | 7.76 | 0.223 | 0.67 |

| 30 wt% GF | 1.15 | 4.0 | 3388 | ±120 | 5.2 | ±0.27 | 4.58 | 9.07 | 0.197 | 0.48 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almajid, A.; Walter, R.; Kroos, T.; Junaedi, H.; Gurka, M.; Khalil, K.A. The Multiple Uses of Polypropylene/Polyethylene Terephthalate Microfibrillar Composite Structures to Support Waste Management—Composite Processing and Properties. Polymers 2021, 13, 1296. https://doi.org/10.3390/polym13081296

Almajid A, Walter R, Kroos T, Junaedi H, Gurka M, Khalil KA. The Multiple Uses of Polypropylene/Polyethylene Terephthalate Microfibrillar Composite Structures to Support Waste Management—Composite Processing and Properties. Polymers. 2021; 13(8):1296. https://doi.org/10.3390/polym13081296

Chicago/Turabian StyleAlmajid, Abdulhakim, Rolf Walter, Tim Kroos, Harri Junaedi, Martin Gurka, and Khalil Abdelrazek Khalil. 2021. "The Multiple Uses of Polypropylene/Polyethylene Terephthalate Microfibrillar Composite Structures to Support Waste Management—Composite Processing and Properties" Polymers 13, no. 8: 1296. https://doi.org/10.3390/polym13081296

APA StyleAlmajid, A., Walter, R., Kroos, T., Junaedi, H., Gurka, M., & Khalil, K. A. (2021). The Multiple Uses of Polypropylene/Polyethylene Terephthalate Microfibrillar Composite Structures to Support Waste Management—Composite Processing and Properties. Polymers, 13(8), 1296. https://doi.org/10.3390/polym13081296