Strain-Induced Form Transition and Crystallization Behavior of the Transparent Polyamide

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Samples

2.3. In Situ X-ray Diffraction Measurements

2.4. Tensile Testing

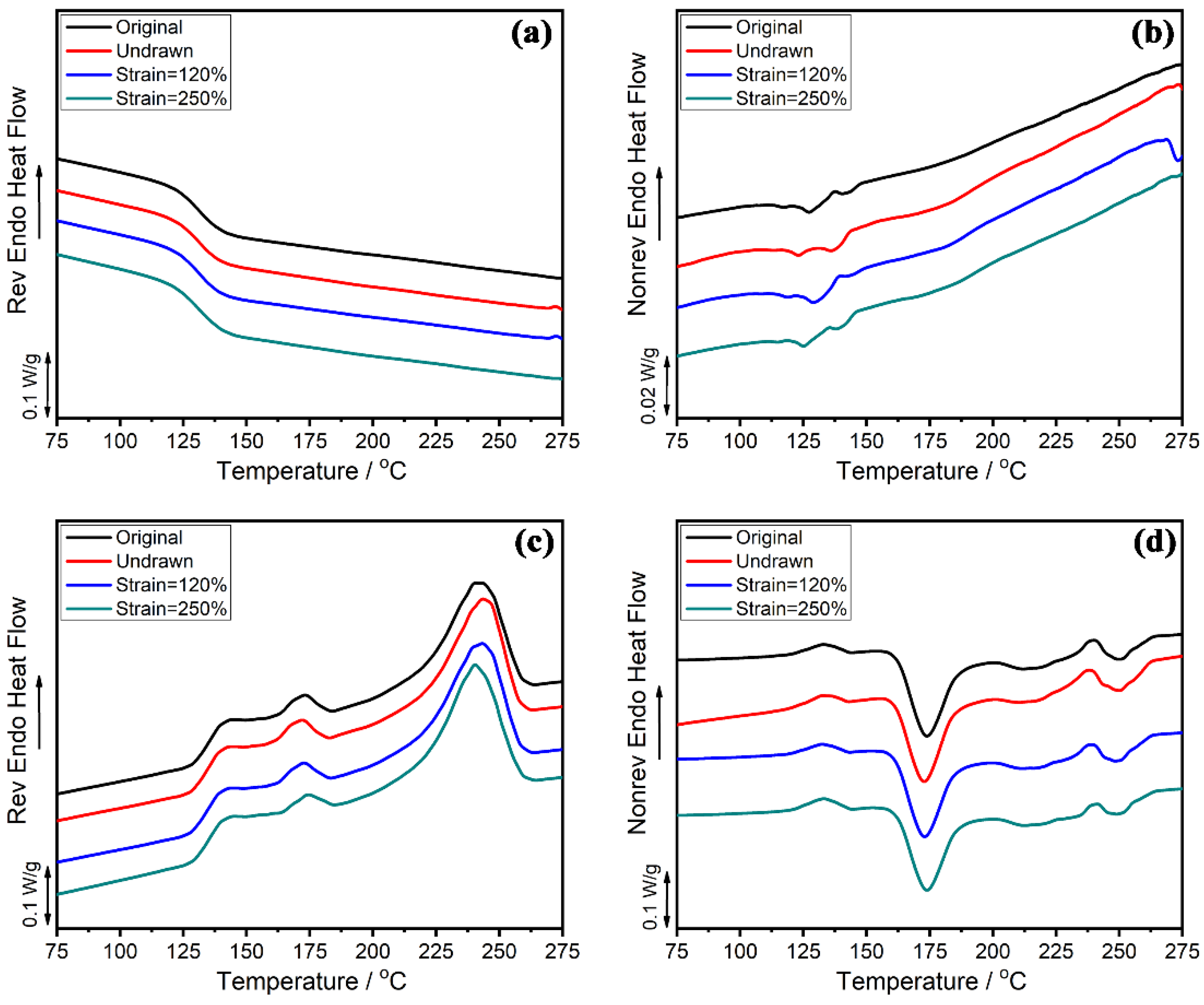

2.5. Thermal Properties of Tensile Samples

3. Results and Discussion

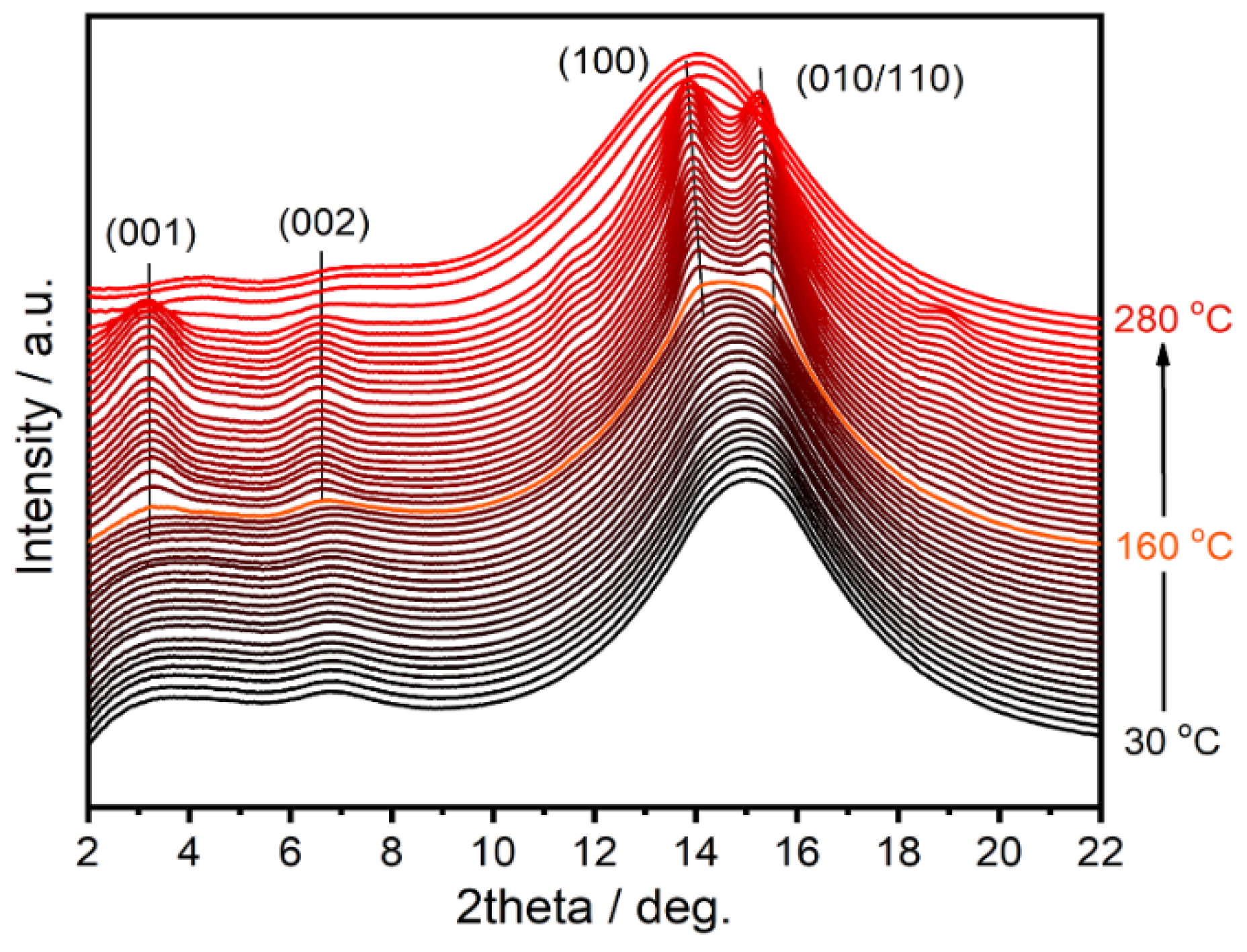

3.1. Cold Crystallization in Heating Process

3.2. Isothermal Crystallization

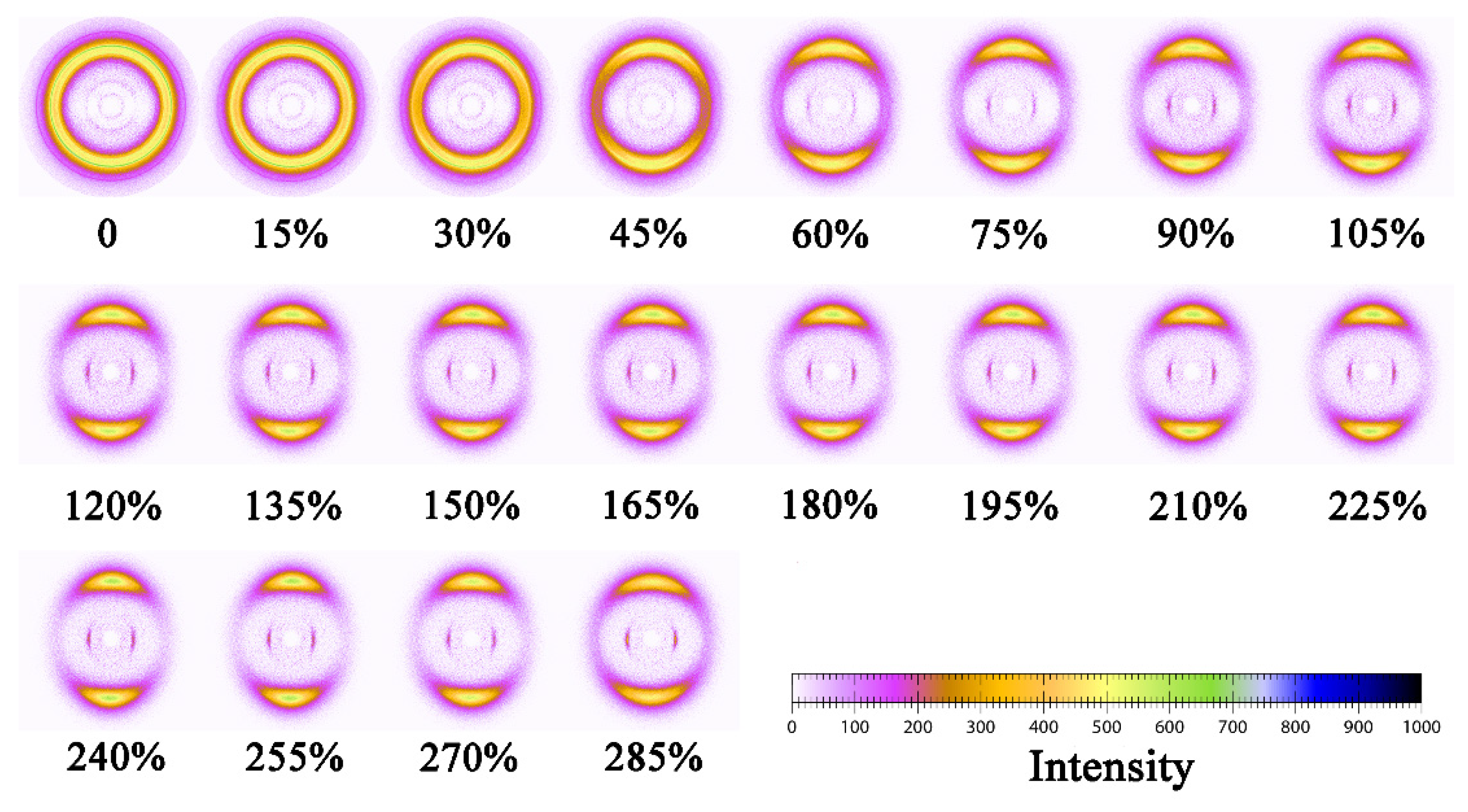

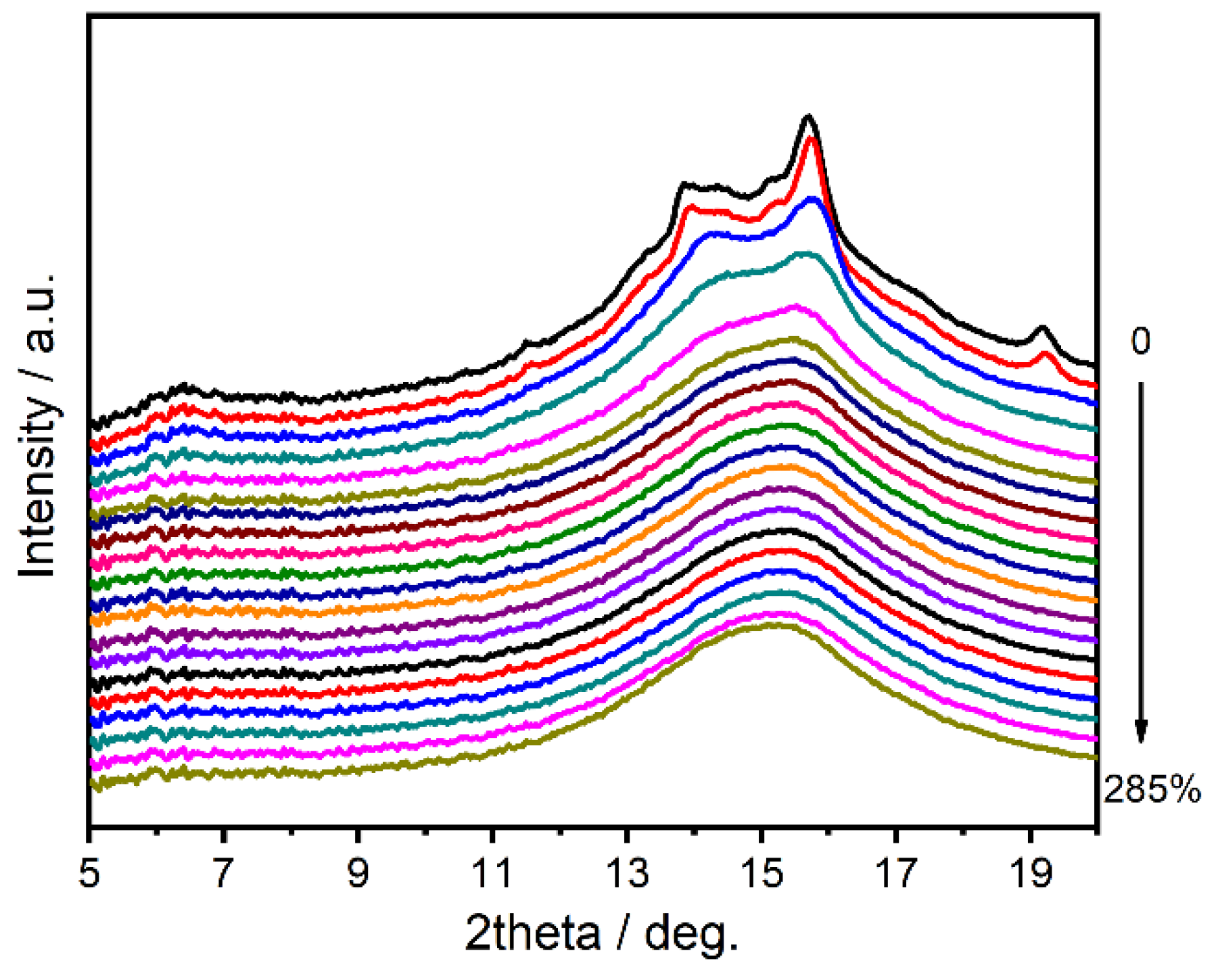

3.3. Crystal Form Transition Induced by Strain

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dasgupta, S.; Hammond, W.B.; Goddard, W.A. Crystal structures and properties of nylon polymers from theory. J. Am. Chem. Soc. 1999, 118, 139–174. [Google Scholar] [CrossRef]

- Jones, N.A.; Atkins, E.D.T.; Hill, M.J.; Cooper, S.J.; Franco, L. Polyamides with a choice of structure and crystal surface chemistry. Studies of chain-folded lamellae of Nylons 8 10 and 10 12 and comparison with the other 2N 2(N+1) Nylons 4 6 and 6 8. Macromolecules 1997, 30, 3569–3578. [Google Scholar] [CrossRef]

- Wang, L.L.; Dong, X.; Gao, Y.Y.; Huang, M.M.; Han, C.C.; Zhu, S.N.; Wang, D.J. Transamidation determination and mechanism of long chain-based aliphatic polyamide alloys with excellent interface miscibility. Polymer 2015, 59, 16–25. [Google Scholar] [CrossRef]

- Liu, X.R.; Huang, M.M.; Zhu, P.; Dong, S.Y.; Dong, X.; Wang, D.J. Shape memory property and underlying mechanism by the phase separation control of poly(ϵ-caprolactone)/poly(ether-b-amide). Polym. Int. 2018, 67, 1291–1301. [Google Scholar] [CrossRef]

- Liu, X.R.; Wang, Y.; Wang, Z.; Cavallo, D.; Müller, A.J.; Zhu, P.; Zhao, Y.; Dong, X.; Wang, D.J. The origin of memory effects in the crystallization of polyamides: Role of hydrogen bonding. Polymer 2020, 188, 122117. [Google Scholar] [CrossRef]

- Liu, X.R.; Wang, Y.; Liu, L.Y.; Dong, X.; Wang, D.J. Time and Temperature Dependence of the Structural Evolution for Polyamide 1012. Chin. J. Polym. Sci. 2020, 38, 993–998. [Google Scholar] [CrossRef]

- Chen, L.; Chen, W.; Zhou, W.; Li, J.; Liu, Y.; Qi, Z.; Li, L. In Situ microscopic infrared imaging study on deformation-induced spatial orientation and phase transition distributions of PA12. J. Appl. Polym. Sci. 2014, 131, 40703. [Google Scholar] [CrossRef]

- Zhang, W.J.; He, J.H.; Yin, X.Z.; Wang, L.N.; Chen, R.Y.; Wang, Y.D.; Pang, X. One-pot double in-situ fabrication of transparent semi-aromatic polyamide nanocomposites with upconversion nanoparticles. Compos. Commun. 2020, 20, 100361. [Google Scholar] [CrossRef]

- Liu, F.L.; He, J.J.; Yang, H.X.; Yang, S.Y. Improved Properties of Aromatic Polyamide Tape-casting Films. Chin. J. Polym. Sci. 2020, 38, 1345–1354. [Google Scholar] [CrossRef]

- Zou, G.J.; Wang, P.L.; Feng, W.T.; Ren, Z.L.; Ji, J.H. Bio-based transparent polyamide 10T/10I/1012 with high performance. J. Appl. Polym. Sci. 2019, 136, 47305. [Google Scholar] [CrossRef]

- Dong, S.Y.; Zhu, P.; Liu, J.G.; Wang, D.J.; Dong, X. Thermal Treatment Effects on the Microstructure and Tensile Properties of Transparent Polyamides. Acta Polym. Sin. 2019, 50, 189–198. [Google Scholar]

- Chen, J.; Qu, L.; Li, X.; Jiang, A.; Niu, M.; Wang, J. Rheological behavior of semi-aromatic transparent polyamide. J. Appl. Polym. Sci. 2005, 97, 1586–1589. [Google Scholar] [CrossRef]

- Zhang, G.; Zhou, Y.X.; Kong, Y.; Li, Z.M.; Long, S.R.; Yang, J. Semiaromatic polyamides containing ether and different numbers of methylene (2–10) units: Synthesis and properties. RSC Adv. 2014, 4, 63006–63015. [Google Scholar] [CrossRef]

- Gies, A.P.; Nonidez, W.K. A technique for obtaining matrix-assisted laser desorption/ionization time-of-flight mass spectra of poorly soluble and insoluble aromatic polyamides. Anal. Chem. 2004, 76, 1991–1997. [Google Scholar] [CrossRef]

- Zhou, C.X.; Qi, S.X.; Zhu, P.; Zhao, Y.; Xu, Y.Z.; Dong, X.; Wang, D.J. The methylene infrared vibration and dielectric behavior monitored by amide group arrangement for long chain polyamides. Polymer 2020, 190, 122231. [Google Scholar] [CrossRef]

- Yemni, T.; Boyd, R.H. Dielectric-relaxation in the odd-numbered polyamides: Nylon 7-7 and Nylon 11. J. Polym. Sci. Polym. Phys. Ed. 1979, 17, 741–751. [Google Scholar] [CrossRef]

- Martino, L.; Basilissi, L.; Farina, H.; Ortenzi, M.A.; Zini, E.; Di Silvestro, G.; Scandola, M. Bio-based polyamide 11: Synthesis, rheology and solid-state properties of star structures. Eur. Polym. J. 2014, 59, 69–77. [Google Scholar] [CrossRef]

- Bunn, C.W.; Garner, E.V. The crystal structures of two polyamides. Proc. R. Soc. A Math. Phys. Sci. 1997, 189, 39–68. [Google Scholar]

- Kinoshita, Y. An Investigation of the Structures of Polyamide Series. Makromol. Chem. 1959, 33, 1–20. [Google Scholar] [CrossRef]

- Brill, R. Über das Verhalten von Polyamiden beim Erhitzen. J. Prakt. Chem. 1942, 161, 49–64. [Google Scholar] [CrossRef]

- Jones, N.A.; Cooper, S.J.; Atkins, E.D.T.; Hill, M.J.; Franco, L. Temperature-induced changes in chain-folded lamellar crystals of aliphatic polyamides. Investigation of nylons 2 6, 2 8, 2 10, and 2 12. J. Polym. Sci. Pol. Phys. 1997, 35, 675–688. [Google Scholar] [CrossRef]

- Cooper, S.J.; Atkins, E.D.T.; Hill, M.J. Temperature-induced changes in lamellar crystals of monodisperse nylon 6 and nylon 6 6 oligoamides. Macromolecules 1998, 31, 8947–8956. [Google Scholar] [CrossRef]

- Yoshioka, Y.; Tashiro, K.; Ramesh, C. Structural change in the Brill transition of Nylon m/n (2) conformational disordering as viewed from the temperature-dependent infrared spectral measurements. Polymer 2003, 44, 6407–6417. [Google Scholar] [CrossRef]

- Cui, X.W.; Yan, D.Y. Polymorphism and crystalline transitions of the novel even-odd nylons derived from undecanedioic acid. J. Polym. Sci. Part B Polym. Phys. 2010, 43, 2048–2060. [Google Scholar] [CrossRef]

- Huang, Y.; Weihua, L.I.; Yan, D. Crystalline transition behaviors of nylons 12 20 and 10 20. Eur. Polym. J. 2003, 39, 1133–1140. [Google Scholar] [CrossRef]

- Yan, D.Y.; Li, Y.J.; Zhu, X.Y. Brill transition in Nylon 10 12 investigated by variable temperature XRD and real time FT-IR. Macromol. Rapid Commun. 2000, 21, 1040–1043. [Google Scholar] [CrossRef]

- Song, J.B.; Zhang, H.L.; Ren, M.Q.; Chen, Q.Y.; Sun, X.H.; Wang, S.Y.; Zhang, H.F.; Mo, Z.S. Crystal transition of nylon-12,12 under drawing and annealing. Macromol. Rapid Commun. 2005, 26, 487–490. [Google Scholar] [CrossRef]

- Wang, L.L.; Dong, X.; Huang, M.M.; Wang, D.J. Transient microstructure in long alkane segment polyamide: Deformation mechanism and its temperature dependence. Polymer 2016, 97, 217–225. [Google Scholar] [CrossRef]

- Ruehle, D.A.; Perbix, C.; Castañeda, M.; Dorgan, J.R.; Mittal, V.; Halley, P.; Martin, D. Blends of biorenewable polyamide-11 and polyamide-6,10. Polymer 2013, 54, 6961–6970. [Google Scholar] [CrossRef]

- Quarti, C.; Milani, A.; Civalleri, B.; Orlando, R.; Castiglioni, C. Ab Initio Calculation of the Crystalline Structure and IR Spectrum of Polymers: Nylon 6 Polymorphs. J. Phys. Chem. B 2012, 116, 8299–8311. [Google Scholar] [CrossRef]

- Wang, D.; Shao, C.; Zhao, B.; Bai, L.; Wang, X.; Yan, T.; Li, J.; Pan, G.; Li, L. Deformation-Induced Phase Transitions of Polyamide 12 at Different Temperatures: An in Situ Wide-Angle X-ray Scattering Study. Macromolecules 2010, 43, 2406–2412. [Google Scholar] [CrossRef]

- Wang, L.L.; Dong, X.; Huang, M.M.; Müller, A.J.; Wang, D.J. The effect of microstructural evolution during deformation on the post-yielding behavior of self-associated polyamide blends. Polymer 2017, 117, 231–242. [Google Scholar] [CrossRef]

- Zhou, C.X.; Zhu, P.; Liu, X.R.; Dong, X.; Wang, D.J. The toughening mechanism of core-shell particles by the interface interaction and crystalline transition in polyamide 1012. Compos. Part B Eng. 2021, 206, 108539. [Google Scholar] [CrossRef]

- Zhu, P.; Dong, X.; Wang, D.J. Strain-Induced Crystallization of Segmented Copolymers: Deviation from the Classic Deformation Mechanism. Macromolecules 2017, 50, 3912–3922. [Google Scholar] [CrossRef]

- Wang, L.L.; Dong, X.; Huang, M.M.; Muller, A.J.; Wang, D.J. Self-Associated Polyamide Alloys with Tailored Polymorphism Transition and Lamellar Thickening for Advanced Mechanical Application. ACS Appl. Mater. Interfaces 2017, 9, 19238–19247. [Google Scholar] [CrossRef]

- Zhu, P.; Dong, X.; Cao, Y.Y.; Wang, L.L.; Liu, X.R.; Wang, Z.F.; Wang, D.J. The Brill transition in polyether-b-amide segmented copolymers and composition dependence. Eur. Polym. J. 2017, 93, 334–346. [Google Scholar] [CrossRef]

- Zhou, C.X.; Dong, S.Y.; Zhu, P.; Liu, J.G.; Dong, X.; Wang, D.J. Effects of Linear Alicyclic Polyamide Chemical Structure on the Mechanical and Optical Properties. Acta Polym. Sin. 2021, 52, 297–303. [Google Scholar]

- Wang, L.L.; Zhu, P.; Dong, X.; Wang, D.J. Strain-induced Crystallization of Long Chain Polyamide and Its Copolymers. Acta Polym. Sin. 2020, 51, 1–11. [Google Scholar]

| Polyamide | The Fastest Mass Loss Temperature a Tpeak/°C | Glass Transition Temperature b Tg/°C | Cold Crystallization Temperature b Tcc/°C | Melting Temperature b Tm/°C |

|---|---|---|---|---|

| PAPACM12 | 482.1 | 136.4 | 174.2 | 244.7 |

| 2θ (°) | d-Space/nm | Assigned Lattice Plane |

|---|---|---|

| 3.2 | 2.18 | (001) |

| 6.5 | 1.09 | (002) |

| 13.9 | 0.51 | (100) |

| 15.3 | 0.46 | (010)/(110) |

| 2θ (°) | d-Space/nm | Assigned Lattice |

|---|---|---|

| 6.5 | 1.09 | (002) |

| 13.7 | 0.52 | (100) |

| 15.2 | 0.47 | (010)/(110) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, C.; Dong, S.; Zhu, P.; Liu, J.; Wang, D.; Dong, X. Strain-Induced Form Transition and Crystallization Behavior of the Transparent Polyamide. Polymers 2021, 13, 1028. https://doi.org/10.3390/polym13071028

Zhou C, Dong S, Zhu P, Liu J, Wang D, Dong X. Strain-Induced Form Transition and Crystallization Behavior of the Transparent Polyamide. Polymers. 2021; 13(7):1028. https://doi.org/10.3390/polym13071028

Chicago/Turabian StyleZhou, Chenxu, Siyuan Dong, Ping Zhu, Jiguang Liu, Dujin Wang, and Xia Dong. 2021. "Strain-Induced Form Transition and Crystallization Behavior of the Transparent Polyamide" Polymers 13, no. 7: 1028. https://doi.org/10.3390/polym13071028

APA StyleZhou, C., Dong, S., Zhu, P., Liu, J., Wang, D., & Dong, X. (2021). Strain-Induced Form Transition and Crystallization Behavior of the Transparent Polyamide. Polymers, 13(7), 1028. https://doi.org/10.3390/polym13071028