Theoretical Determination of High-Energy Photon Attenuation and Recommended Protective Filler Contents for Flexible and Enhanced Dimensionally Stable Wood/NR and NR Composites

Abstract

1. Introduction

2. Simulation Setup and Determination of High-Energy Photon Shielding Properties

2.1. Simulation Setup

2.2. Determination of µ and HVL

2.3. Determination of Recommended Bi2O3, Bi2S3, and Pb Contents

3. Results and Discussion

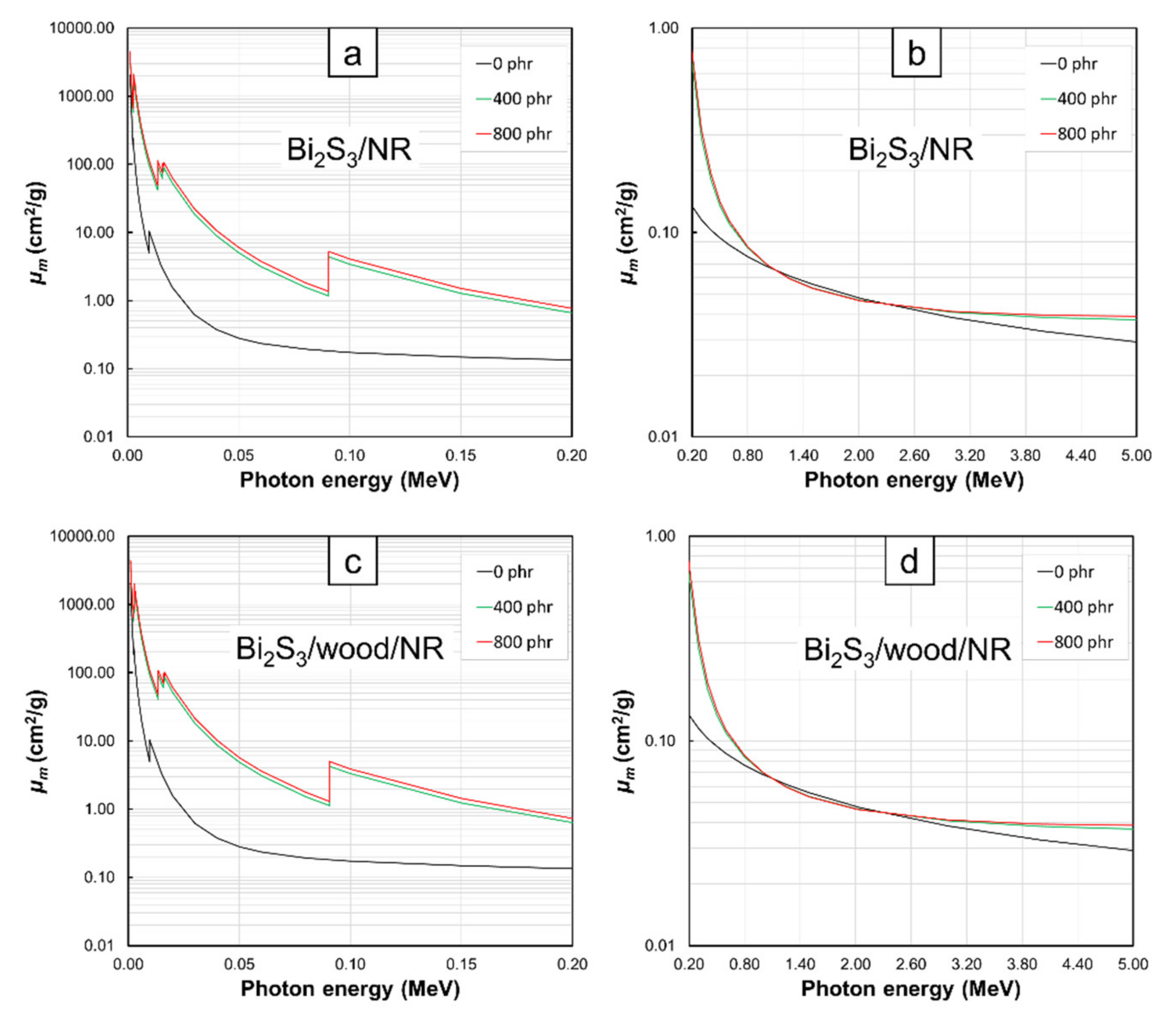

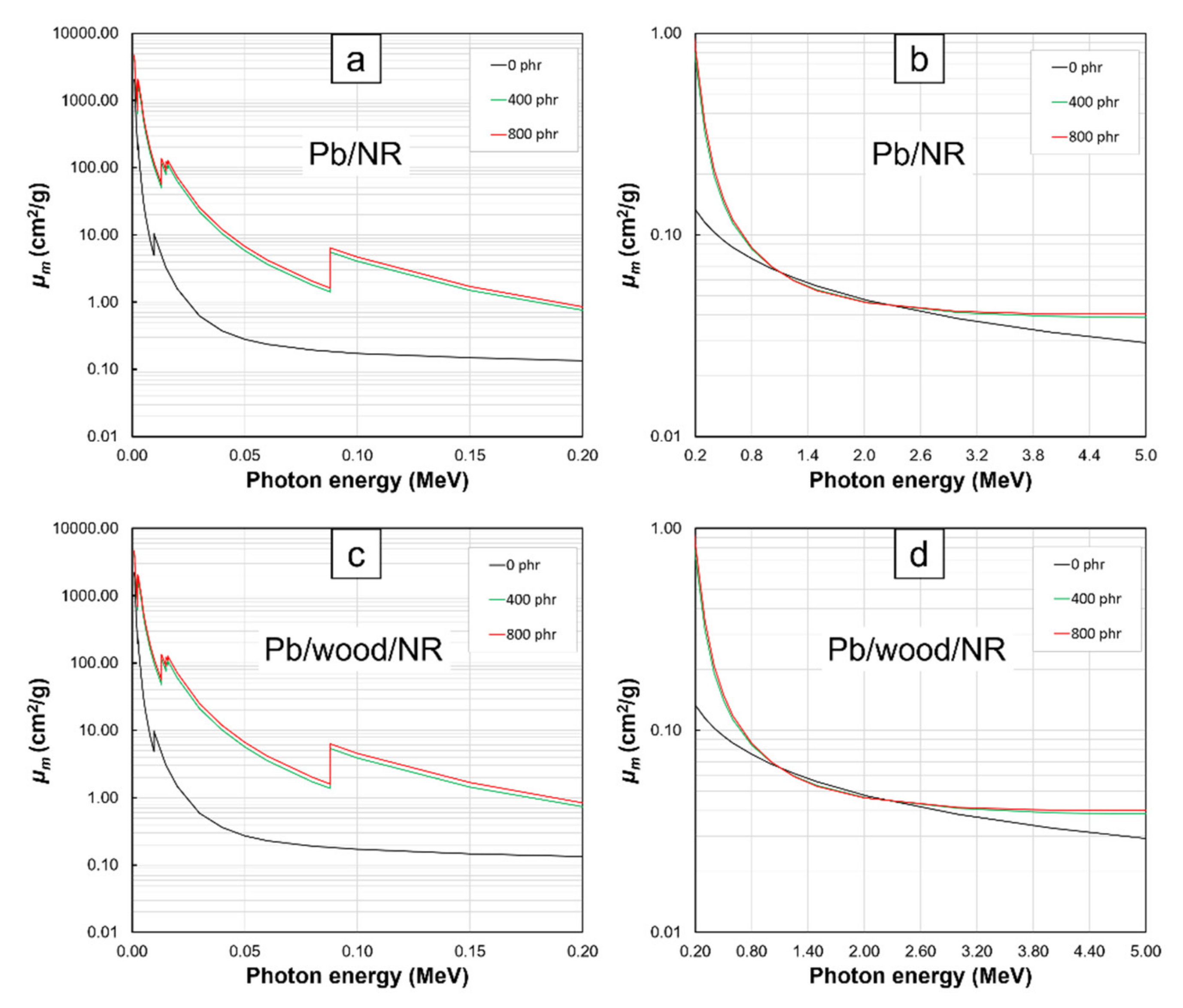

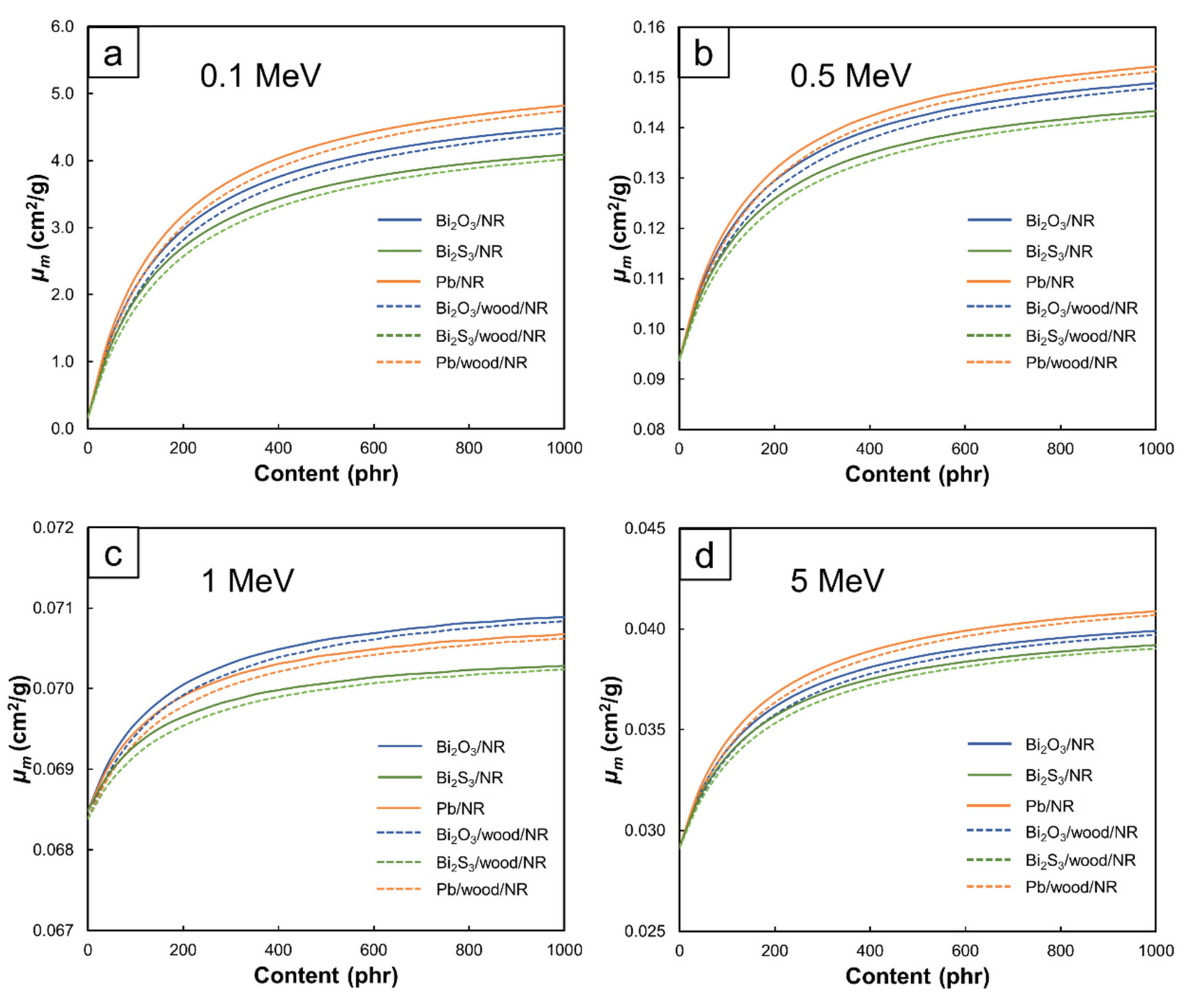

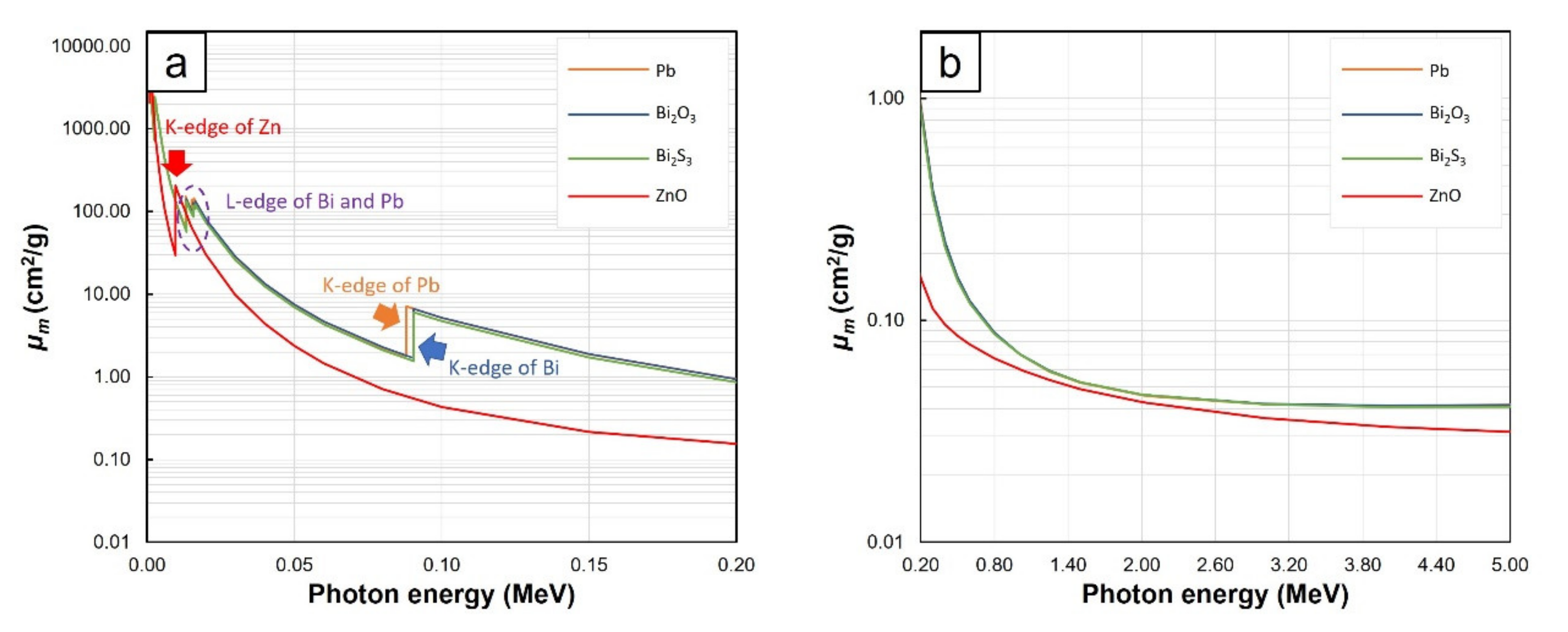

3.1. Mass Attenuation Coefficient (µm)

| Filler Type | Content (phr) | Photon Energy (MeV) | µm (cm2/g) | Reference | ||

|---|---|---|---|---|---|---|

| XCOM | Literature Value | Difference (%) | ||||

| Pb | 0 | 0.122 | 0.162 | 0.159 | 1.9 | [30] |

| 40 | 0.943 | 0.813 | 13.8 | |||

| 80 | 1.459 | 1.198 | 17.9 | |||

| Pb | 0 | 0.356 | 0.108 | 0.106 | 1.9 | [30] |

| 40 | 0.149 | 0.142 | 4.7 | |||

| 80 | 0.176 | 0.166 | 5.7 | |||

| Pb | 0 | 0.662 | 0.084 | 0.086 | 2.4 | [30] |

| 40 | 0.090 | 0.089 | 1.1 | |||

| 80 | 0.094 | 0.091 | 3.2 | |||

| Pb | 100 | 0.662 | 0.095 | 0.085 | 10.5 | [22] |

| 300 | 0.103 | 0.094 | 8.7 | |||

| 500 | 0.106 | 0.096 | 9.4 | |||

| 1000 | 0.110 | 0.092 | 16.4 | |||

| Pb | 0 | 1.173 | 0.063 | 0.064 | 1.6 | [30] |

| 40 | 0.063 | 0.063 | 0.0 | |||

| 80 | 0.063 | 0.063 | 0.0 | |||

| Pb | 100 | 1.250 | 0.060 | 0.051 | 15.0 | [22] |

| 300 | 0.060 | 0.052 | 13.3 | |||

| 500 | 0.059 | 0.056 | 5.1 | |||

| 1000 | 0.059 | 0.051 | 13.6 | |||

| Pb | 0 | 1.332 | 0.059 | 0.059 | 0.0 | [30] |

| 40 | 0.059 | 0.058 | 1.7 | |||

| 80 | 0.059 | 0.058 | 1.7 | |||

| Bi2O3 | 0 | 0.223 | 0.129 | 0.130 | 0.2 | [31] |

| 20 | 0.206 | 0.225 | 8.8 | |||

| 40 | 0.255 | 0.289 | 13.4 | |||

| 80 | 0.342 | 0.382 | 11.8 | |||

| 150 | 0.463 | 0.469 | 1.4 | |||

| Bi2O3 | 0 | 0.253 | 0.124 | 0.123 | 0.8 | [31] |

| 20 | 0.183 | 0.190 | 3.8 | |||

| 40 | 0.220 | 0.237 | 7.7 | |||

| 80 | 0.286 | 0.304 | 6.3 | |||

| 150 | 0.379 | 0.371 | 2.1 | |||

| Bi2O3 | 0 | 0.341 | 0.110 | 0.112 | 1.8 | [31] |

| 20 | 0.134 | 0.138 | 3.0 | |||

| 40 | 0.148 | 0.163 | 10.1 | |||

| 80 | 0.175 | 0.188 | 7.4 | |||

| 150 | 0.212 | 0.216 | 1.9 | |||

| Bi2O3 | 0 | 0.482 | 0.095 | 0.096 | 1.1 | [31] |

| 20 | 0.104 | 0.106 | 1.9 | |||

| 40 | 0.109 | 0.116 | 6.4 | |||

| 80 | 0.119 | 0.124 | 4.2 | |||

| 150 | 0.132 | 0.137 | 3.8 | |||

| Bi2O3 | 0 | 0.662 | 0.083 | 0.083 | 0.0 | [31] |

| 20 | 0.087 | 0.088 | 1.2 | |||

| 40 | 0.089 | 0.091 | 2.3 | |||

| 80 | 0.092 | 0.095 | 3.3 | |||

| 150 | 0.098 | 0.097 | 1.0 | |||

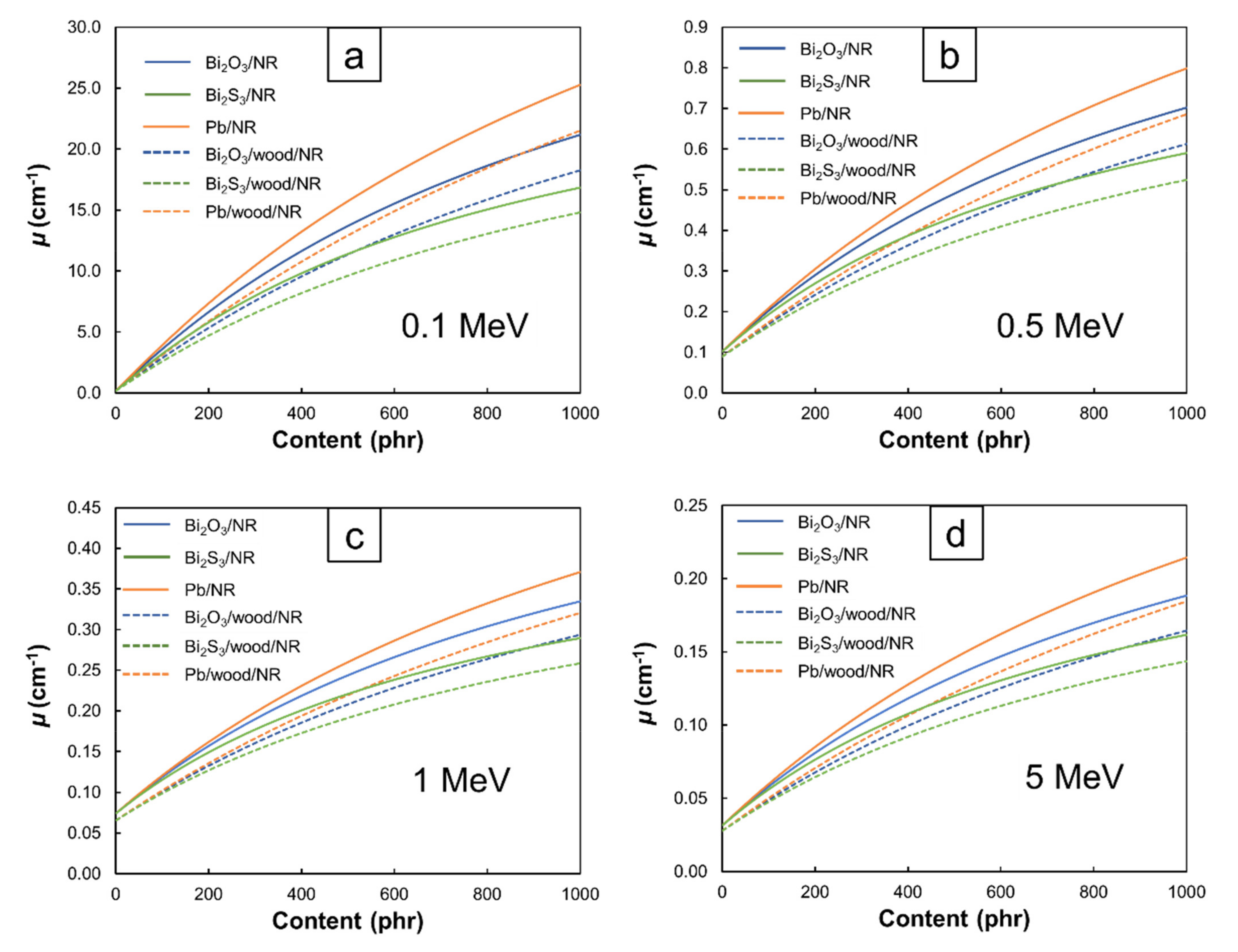

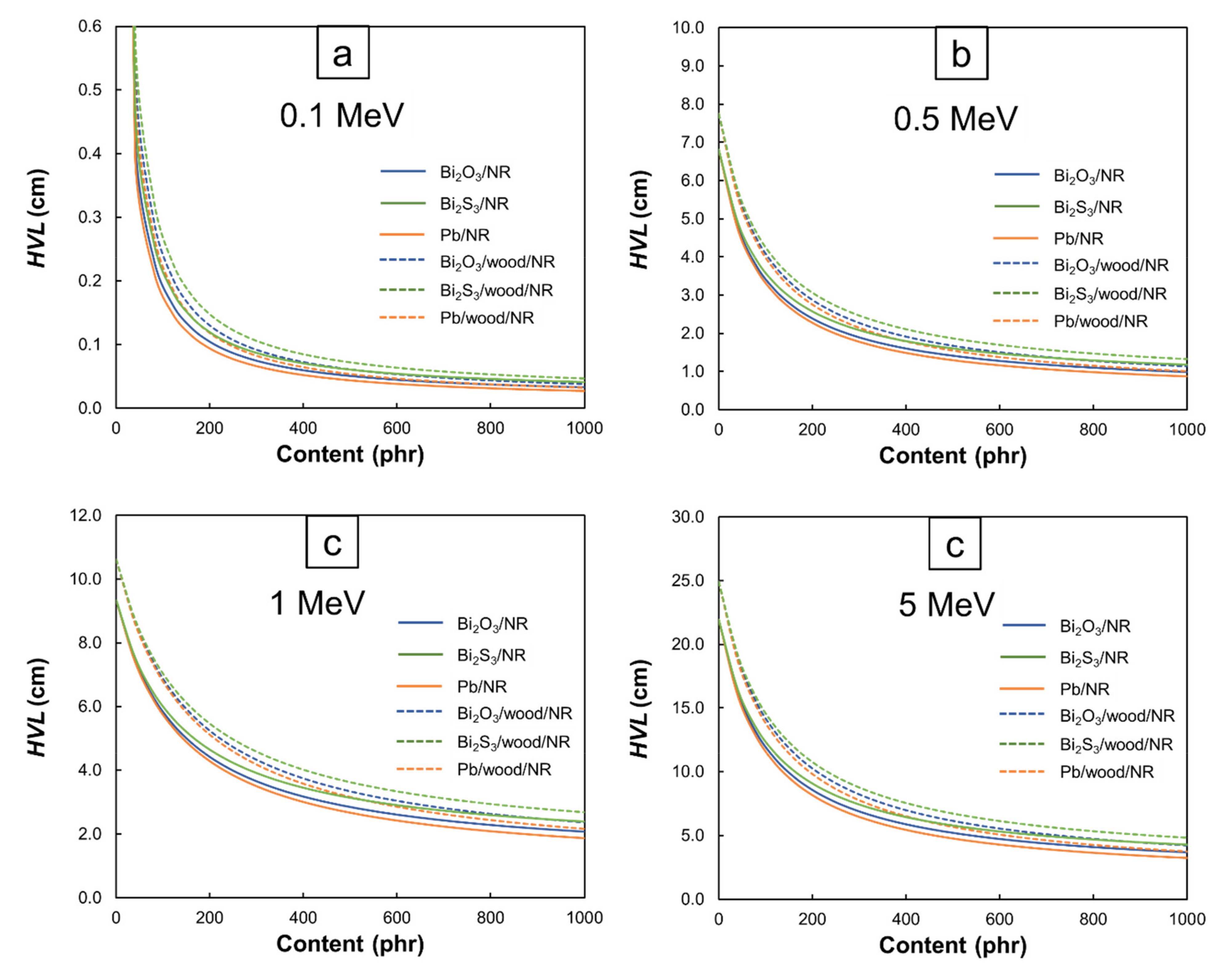

3.2. Linear Attenuation Coefficients (µ) and Half Value Layer (HVL)

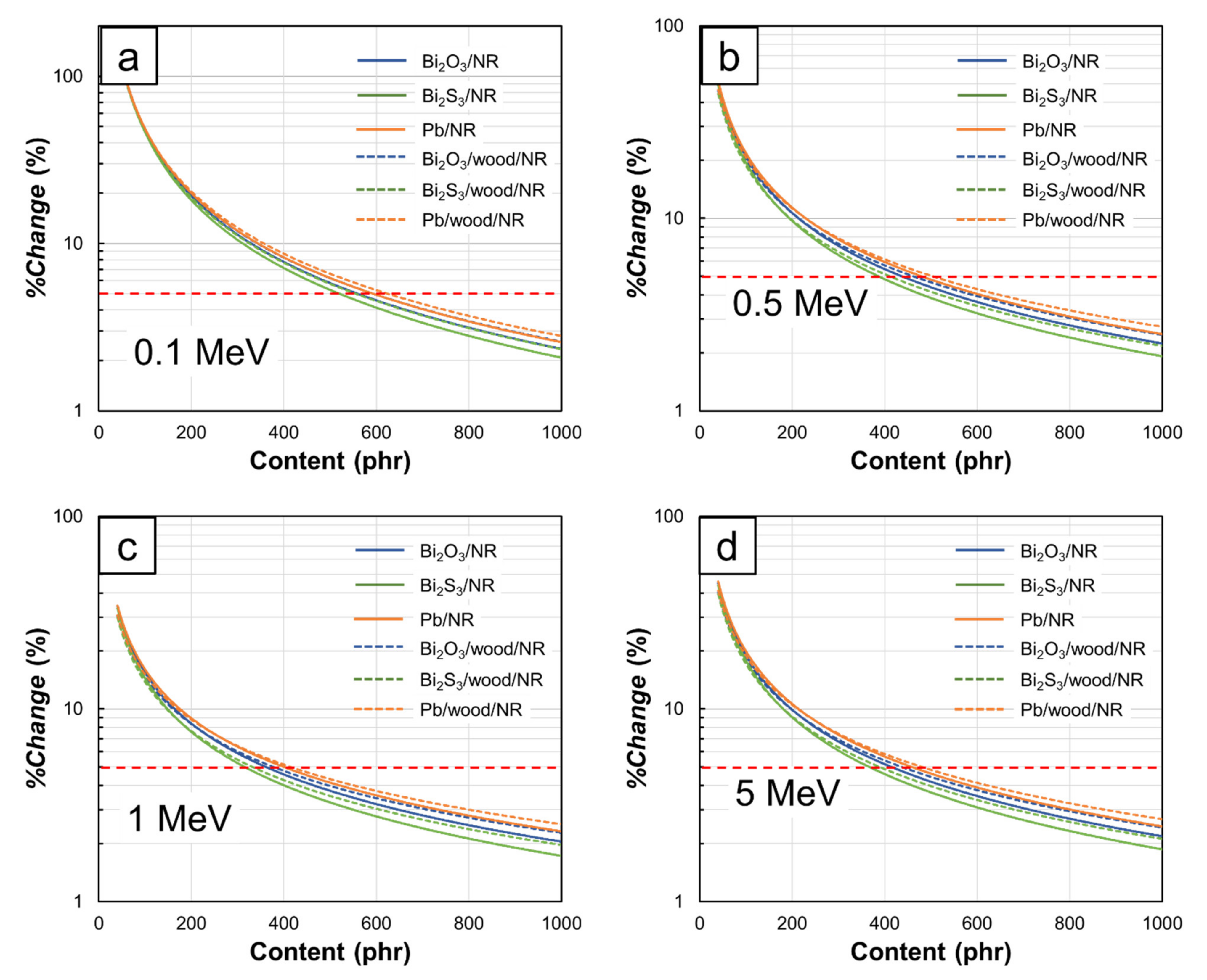

3.3. Recommended Contents of Bi2O3, Bi2S3, and Pb in NR and Wood/NR Composites

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sakdinawat, A.; Attwood, D. Nanoscale X-ray imaging. Nat. Photon. 2010, 4, 840–848. [Google Scholar] [CrossRef]

- Zhao, C.; Fezzaa, K.; Cunningham, R.W.; Wen, H.; De Carlo, F.; Chen, L.; Rollett, A.D.; Sun, T. Real-time monitoring of laser powder bed fusion process using high-speed X-ray imaging and diffraction. Sci. Rep. 2017, 7, 3602. [Google Scholar] [CrossRef] [PubMed]

- Smeets, J.; Roellinghoff, F.; Prieels, D.; Stichelbaut, F.; Benilov, A.; Busca, P.; Fiorini, C.; Peloso, R.; Basilavecchia, M.; Frizzi, T.; et al. Prompt gamma imaging with a slit camera for real-time range control in proton therapy. Phys. Med. Biol. 2012, 57, 3371–3405. [Google Scholar] [CrossRef] [PubMed]

- Fan, F.; Gao, S.; Ji, S.; Fu, Y.; Zhang, P.; Xu, H. Gamma radiation-responsive side-chain tellurium-containing polymer for cancer therapy. Mater. Chem. Front. 2018, 2, 2109–2115. [Google Scholar] [CrossRef]

- Shin, J.M.; Kim, B.K.; Seol, S.G.; Jeon, S.B.; Kim, J.S.; Jun, B.K.; Kang, S.Y.; Lee, J.S.; Chung, M.N.; Kim, S.H. Mutation breeding of sweet potato by gamma-ray radiation. Afr. J. Agric. Res. 2011, 6, 1447–1454. [Google Scholar]

- El-Taher, A. Elemental analysis of granite by instrumental neutron activation analysis (INAA) and X-ray fluorescence analysis (XRF). Appl. Radiat. Isot. 2012, 70, 350–354. [Google Scholar] [CrossRef] [PubMed]

- Rybkina, V.L.; Bannikova, M.; Adamova, G.V.; Dorr, H.; Scherthan, H.; Azizova, T.V. Immunological markers of chronic occupational radiation exposure. Health Phys. 2018, 115, 108–113. [Google Scholar] [CrossRef] [PubMed]

- Luckey, T.D. Biological effects of ionizing radiation: A perspective for Japan. J. Am. Physicians Surg. 2011, 16, 45–46. [Google Scholar]

- Garau, M.M.; Calduch, A.L.; Lopez, E.C. Radiobiology of the acute radiation syndrome. Rep. Pract. Oncol. Radiother. 2011, 16, 123–130. [Google Scholar] [CrossRef]

- Tiamduangtawan, P.; Kamkaew, C.; Kuntonwatchara, S.; Wimolmala, E.; Saenboonruang, K. Comparative mechanical, self-healing, and gamma attenuation properties of PVA hydrogels containing either nano- or micro-sized Bi2O3 for use as gamma-shielding materials. Radiat. Phys. Chem. 2020, 177, 109164. [Google Scholar] [CrossRef]

- McGiff, T.J.; Danforth, R.A.; Herschaft, E.E. Maintaining radiation exposures as low as reasonably achievable (ALARA) for dental personnel operating portable hand-held X-ray equipment. Health Phys. 2012, 103, S179–S185. [Google Scholar] [CrossRef] [PubMed]

- Bouffler, S.; Ainsbury, E.; Gilvin, P.; Harrison, J. Radiation-induced cataracts: The Health Protection Agency’s response to the ICRP statement on tissue reactions and recommendation on the dose limit for the eye lens. J. Radiol. Prot. 2012, 32, 479–488. [Google Scholar] [CrossRef]

- Poltabtim, W.; Wimolmala, E.; Saenboonruang, K. Properties of lead-free gamma-ray shielding materials from metal oxide/EPDM rubber composites. Radiat. Phys. Chem. 2018, 153, 1–5. [Google Scholar] [CrossRef]

- Toyen, D.; Rittirong, A.; Poltabtim, W.; Saenboonruang, K. Flexible, lead-free, gamma-shielding materials based on natural rubber/metal oxide composites. Iranian Polym. J. 2018, 27, 33–41. [Google Scholar] [CrossRef]

- Hashemi, S.A.; Mousavi, S.M.; Gaghihi, R.; Arjmand, M.; Rahsepar, M.; Bahrani, S.; Ramakrishna, S.; Lai, C.W. Superior X-ray radiation shielding effectiveness of biocompatible polyaniline reinforced with hybrid graphene oxide-iron tungsten nitride flakes. Polymers 2020, 12, 1407. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.; Zhang, X.; Li, M.; Yang, R.; Jiang, T.; Lv, J. Investigation of gamma ray shielding efficiency and mechanical performances of concrete shields containing bismuth oxide as an environmentally friendly additive. Radiat. Phys. Chem. 2016, 127, 188–193. [Google Scholar] [CrossRef]

- Low, D.Y.S.; Supramaniam, J.; Soottitantawat, A.; Charinpanitkul, T.; Tanthapanichakoon, W.; Tan, K.W.; Tang, S.Y. Recent developments in nanocellulose-reinforced rubber matrix composites: A review. Polymers 2020, 13, 550. [Google Scholar] [CrossRef] [PubMed]

- Azeez, A.B.; Mohammed, K.S.; Abdullah, M.M.A.B.; Zulkepli, N.N.; Sandu, A.V.; Hussin, K.; Rahmat, A. Design of flexible green anti-radiation shielding material against gamma-ray. Mater. Plast. 2014, 51, 300–308. [Google Scholar]

- Salimi, M.; Ghal-Eh, N.; Amirabadi, E.A. Characterization of a new shielding rubber for use in neutron–gamma mixed fields. Nucl. Sci. Tech. 2018, 29, 36. [Google Scholar] [CrossRef]

- Ninyong, K.; Wimolmala, E.; Sombatsompop, N.; Saenboonruang, K. Properties of natural rubber (NR) and wood/NR composites as gamma shielding materials. IOP Conf. Ser. Mater. Sci. Eng. 2019, 526, 012038. [Google Scholar] [CrossRef]

- Flora, G.; Gupta, D.; Tiwari, A. Toxicity of lead: A review with recent updates. Interdiscip. Toxicol. 2012, 5, 47–58. [Google Scholar] [CrossRef] [PubMed]

- Gwaily, S.E.; Madani, M.; Hassan, H.H. Lead-Natural rubber composites as gamma radiation shields. II: High concentration. Polym. Compos. 2012, 23, 495–499. [Google Scholar] [CrossRef]

- Ozdemir, T.; Gungor, A.; Reyhancan, I.A. Flexible neutron shielding composite material of EPDM rubber with boron trioxide: Mechanical, thermal investigations and neutron shielding tests. Radiat. Phys. Chem. 2017, 131, 7–12. [Google Scholar] [CrossRef]

- Ninyong, K.; Wimolmala, E.; Sombatsompop, N.; Saenboonruang, K. Potential use of NR and wood/NR composites as thermal neutron shielding materials. Polym. Test. 2017, 59, 336–343. [Google Scholar] [CrossRef]

- Berger, M.J.; Hubbell, J.H.; Seltzer, S.M.; Chang, J.; Coursey, J.S.; Sukumar, R.; Zucker, D.S.; Olsen, K. XCOM: Photon Cross Section Database (Version 1.5); National Institute of Standards and Technology: Gaithersburg, MD, USA, 2010. Available online: http://physics.nist.gov/xcom (accessed on 30 January 2021).

- Livet, F.; Sutton, M. X-ray coherent scattering in metal physics. C. R. Phys. 2012, 13, 227–236. [Google Scholar] [CrossRef]

- Hirayama, H. Lecture Note on Photon Interactions and Cross Sections. Available online: http://rcwww.kek.jp/research/shield/photon_r.pdf (accessed on 1 February 2021).

- Bruce, W.B.; Pearson, M.L.; Freedhoff, H.S. The linear energy transfer distributions resulting from primary and scattered X-rays and gamma rays with primary HVL’s from 1.25 mm Cu to 11 mm Pb. Radiat. Res. 1963, 19, 606–620. [Google Scholar] [CrossRef]

- Si-Mohamed, S.; Cormode, D.P.; Bar-Ness, D.; Sigovan, M.; Naha, P.C.; Langlois, J.B.; Chalabreysse, L.; Coulon, P.; Blevis, I.; Roessl, E.; et al. Evaluation of spectral photon counting computed tomography K-edge imaging for determination of gold nanoparticle biodistribution in vivo. Nanoscale 2017, 46, 18246–18257. [Google Scholar] [CrossRef] [PubMed]

- El-Khatib, A.M.; Doma, A.S.; Badawi, M.S.; Abu-Rayan, A.E.; Aly, N.S.; Alzahrani, J.S.; Abbas, M.I. Conductive natural and waste rubbers composites-loaded with lead powder as environmental flexible gamma radiation shielding material. Mater. Res. Express 2020, 7, 105309. [Google Scholar] [CrossRef]

- Intom, S.; Kalkornsurapranee, E.; Johns, J.; Kaewjaeng, S.; Kothan, S.; Hongtong, W.; Chaiphaksa, W.; Kaewkhao, J. Mechanical and radiation shielding properties of flexible material based on natural rubber/ Bi2O3 composites. Radiat. Phys. Chem. 2020, 172, 108772. [Google Scholar] [CrossRef]

- Obaid, S.S.; Sayyed, M.I.; Gaikwad, D.K.; Pawar, P.P. Attenuation coefficients and exposure buildup factor of some rocks for gamma ray shielding applications. Radiat. Phys. Chem. 2018, 148, 86–94. [Google Scholar] [CrossRef]

| Chemical | Chemical Formula | Content (phr *) | Density (g/cm3) |

|---|---|---|---|

| Natural rubber (NR) | C5H8 | 100 | 0.92 |

| Stearic acid | C18H36O2 | 3 | 0.94 |

| Zinc oxide | ZnO | 5 | 5.6 |

| Mercaptobenzothiazole (MBT) | C7H5NS2 | 2 | 1.46 |

| Diphenylguanidine (DPG) | C13H13N3 | 3 | 1.19 |

| Carbon black | C | 40 | 1.95 |

| Sulfur | S | 4 | 2.1 |

| Wood particles (cellulose) | C6H10O5 | 0 or 20 | 0.52 |

| Bismuth oxide, bismuth sulfide, or lead | Bi2O3, Bi2S3 or Pb | 0–1000 | 8.90, 6.78 or 11.35 |

| Content (phr) | Density (g/cm3) | |||||

|---|---|---|---|---|---|---|

| Bi2O3/NR | Bi2S3/NR | Pb/NR | Bi2O3/Wood/NR | Bi2S3/Wood/NR | Pb/Wood/NR | |

| 0 | 1.09 | 1.08 | 1.08 | 0.96 | 0.95 | 0.95 |

| 40 | 1.36 | 1.33 | 1.36 | 1.17 | 1.15 | 1.17 |

| 80 | 1.61 | 1.56 | 1.61 | 1.37 | 1.34 | 1.37 |

| 120 | 1.84 | 1.77 | 1.86 | 1.56 | 1.51 | 1.57 |

| 160 | 2.05 | 1.96 | 2.09 | 1.74 | 1.67 | 1.76 |

| 200 | 2.26 | 2.14 | 2.32 | 1.91 | 1.83 | 1.94 |

| 240 | 2.45 | 2.31 | 2.53 | 2.07 | 1.97 | 2.12 |

| 280 | 2.63 | 2.46 | 2.73 | 2.22 | 2.11 | 2.29 |

| 320 | 2.80 | 2.61 | 2.92 | 2.37 | 2.23 | 2.45 |

| 360 | 2.97 | 2.74 | 3.11 | 2.51 | 2.36 | 2.61 |

| 400 | 3.12 | 2.87 | 3.28 | 2.65 | 2.47 | 2.76 |

| 440 | 3.27 | 2.99 | 3.45 | 2.78 | 2.58 | 2.91 |

| 480 | 3.41 | 3.10 | 3.62 | 2.90 | 2.68 | 3.05 |

| 520 | 3.54 | 3.21 | 3.77 | 3.02 | 2.78 | 3.19 |

| 560 | 3.67 | 3.30 | 3.92 | 3.14 | 2.88 | 3.32 |

| 600 | 3.79 | 3.40 | 4.06 | 3.25 | 2.97 | 3.45 |

| 640 | 3.90 | 3.49 | 4.20 | 3.36 | 3.05 | 3.57 |

| 680 | 4.01 | 3.57 | 4.34 | 3.46 | 3.14 | 3.69 |

| 720 | 4.12 | 3.65 | 4.46 | 3.56 | 3.20 | 3.81 |

| 760 | 4.22 | 3.73 | 4.59 | 3.65 | 3.29 | 3.92 |

| 800 | 4.31 | 3.80 | 4.71 | 3.74 | 3.36 | 4.03 |

| 840 | 4.41 | 3.87 | 4.82 | 3.83 | 3.43 | 4.14 |

| 880 | 4.50 | 3.94 | 4.93 | 3.92 | 3.50 | 4.24 |

| 920 | 4.58 | 4.00 | 5.04 | 4.00 | 3.56 | 4.34 |

| 960 | 4.66 | 4.06 | 5.15 | 4.08 | 3.62 | 4.44 |

| 1000 | 4.74 | 4.12 | 5.25 | 4.16 | 3.68 | 4.54 |

| Composite | Photon Energy (MeV) | Coefficient | Recommended Content (phr) | µ at Recommended Content (cm−1) | Percentage Difference from Composites with Pb (%) * | |

|---|---|---|---|---|---|---|

| A | B | |||||

| Pb/NR | 0.1 | 1.652 × 104 | −1.269 | 593 | 17.8 | n/a ** |

| 0.5 | 1.664 × 103 | −0.941 | 478 | 0.52 | n/a | |

| 1 | 760.3 | −0.839 | 398 | 0.23 | n/a | |

| 5 | 1.312 × 103 | −0.909 | 458 | 0.14 | n/a | |

| Bi2O3/NR | 0.1 | 1.894 × 104 | −1.303 | 557 | 14.9 | 16.3 |

| 0.5 | 1.839 × 103 | −0.972 | 436 | 0.46 | 11.5 | |

| 1 | 869.4 | −0.877 | 358 | 0.21 | 8.7 | |

| 5 | 1.439 × 103 | −0.940 | 413 | 0.12 | 14.3 | |

| Bi2S3/NR | 0.1 | 2.271 × 104 | −1.346 | 521 | 12.8 | 28.4 |

| 0.5 | 2.011 × 103 | −1.007 | 386 | 0.39 | 24.6 | |

| 1 | 985.0 | −0.918 | 316 | 0.18 | 20.1 | |

| 5 | 1.623 × 103 | −0.980 | 365 | 0.11 | 24.8 | |

| Pb/wood/NR | 0.1 | 1.389 × 104 | −1.232 | 624 | 15.3 | n/a |

| 0.5 | 1.199 × 103 | −0.881 | 502 | 0.44 | n/a | |

| 1 | 535.9 | −0.776 | 413 | 0.20 | n/a | |

| 5 | 0.937 × 103 | −0.848 | 476 | 0.12 | n/a | |

| Bi2O3/wood/NR | 0.1 | 1.553 × 104 | −1.259 | 594 | 12.8 | 16.3 |

| 0.5 | 1.303 × 103 | −0.907 | 461 | 0.40 | 9.1 | |

| 1 | 600.5 | −0.808 | 375 | 0.18 | 10.0 | |

| 5 | 1.008 × 103 | −0.874 | 434 | 0.11 | 8.3 | |

| Bi2S3/wood/NR | 0.1 | 1.812 × 104 | −1.297 | 557 | 11.2 | 26.6 |

| 0.5 | 1.402 × 103 | −0.937 | 410 | 0.35 | 21.5 | |

| 1 | 670.5 | −0.844 | 332 | 0.16 | 19.6 | |

| 5 | 1.121 × 103 | −0.908 | 388 | 0.09 | 22.1 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Poltabtim, W.; Toyen, D.; Saenboonruang, K. Theoretical Determination of High-Energy Photon Attenuation and Recommended Protective Filler Contents for Flexible and Enhanced Dimensionally Stable Wood/NR and NR Composites. Polymers 2021, 13, 869. https://doi.org/10.3390/polym13060869

Poltabtim W, Toyen D, Saenboonruang K. Theoretical Determination of High-Energy Photon Attenuation and Recommended Protective Filler Contents for Flexible and Enhanced Dimensionally Stable Wood/NR and NR Composites. Polymers. 2021; 13(6):869. https://doi.org/10.3390/polym13060869

Chicago/Turabian StylePoltabtim, Worawat, Donruedee Toyen, and Kiadtisak Saenboonruang. 2021. "Theoretical Determination of High-Energy Photon Attenuation and Recommended Protective Filler Contents for Flexible and Enhanced Dimensionally Stable Wood/NR and NR Composites" Polymers 13, no. 6: 869. https://doi.org/10.3390/polym13060869

APA StylePoltabtim, W., Toyen, D., & Saenboonruang, K. (2021). Theoretical Determination of High-Energy Photon Attenuation and Recommended Protective Filler Contents for Flexible and Enhanced Dimensionally Stable Wood/NR and NR Composites. Polymers, 13(6), 869. https://doi.org/10.3390/polym13060869