Mechanical Properties and Reliability of Parametrically Designed Architected Materials Using Urethane Elastomers

Abstract

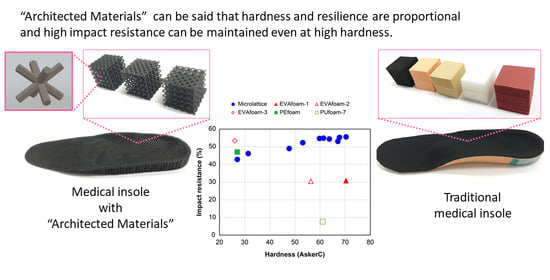

1. Introduction

2. Materials and Methods

2.1. Materials

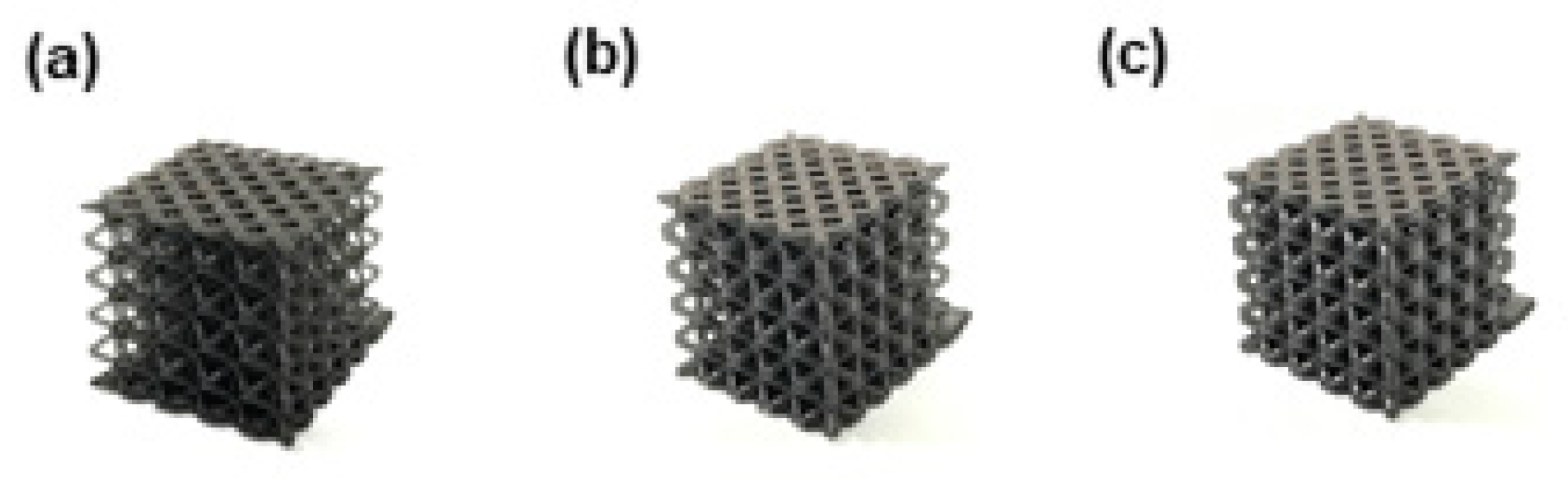

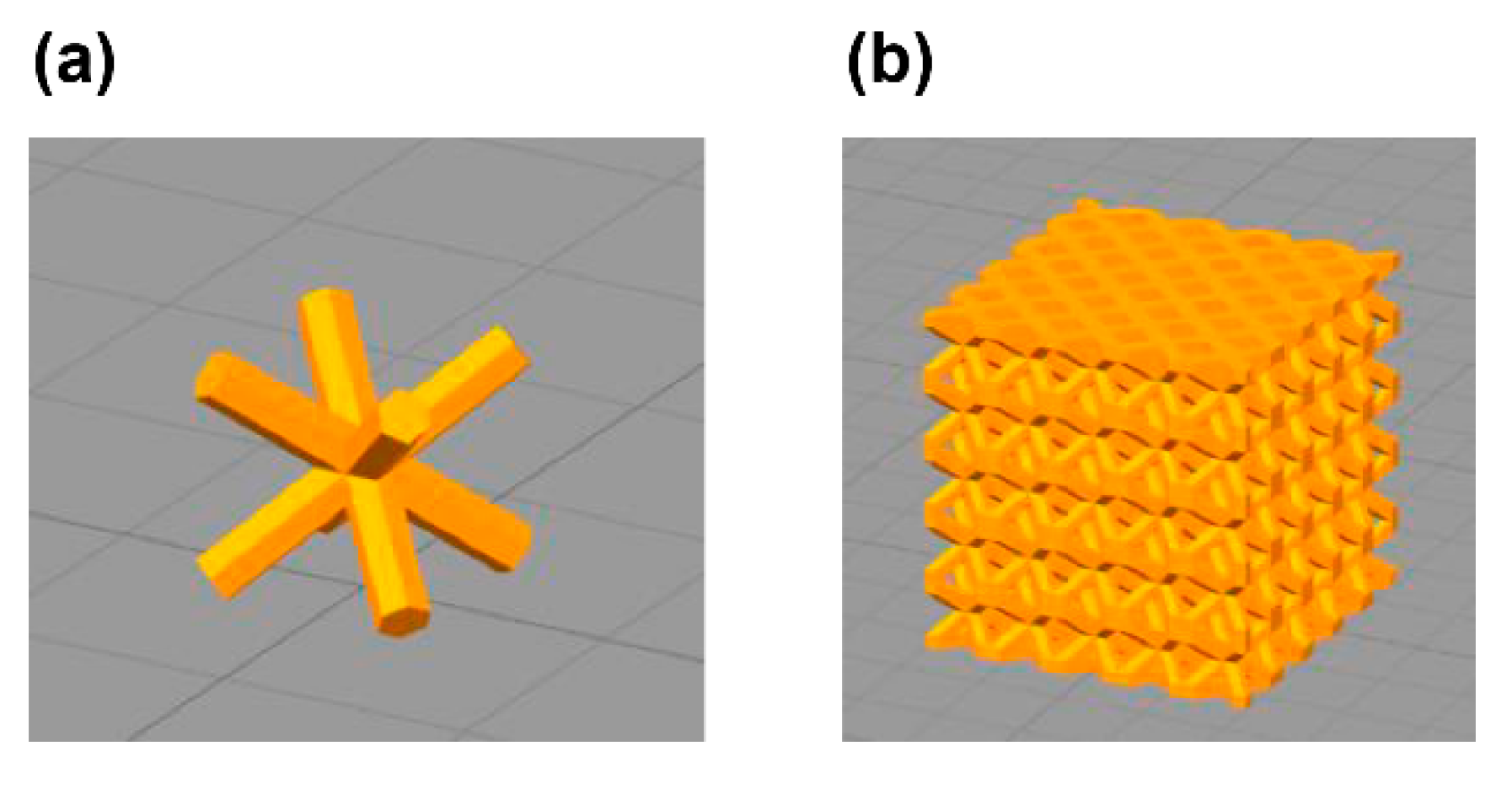

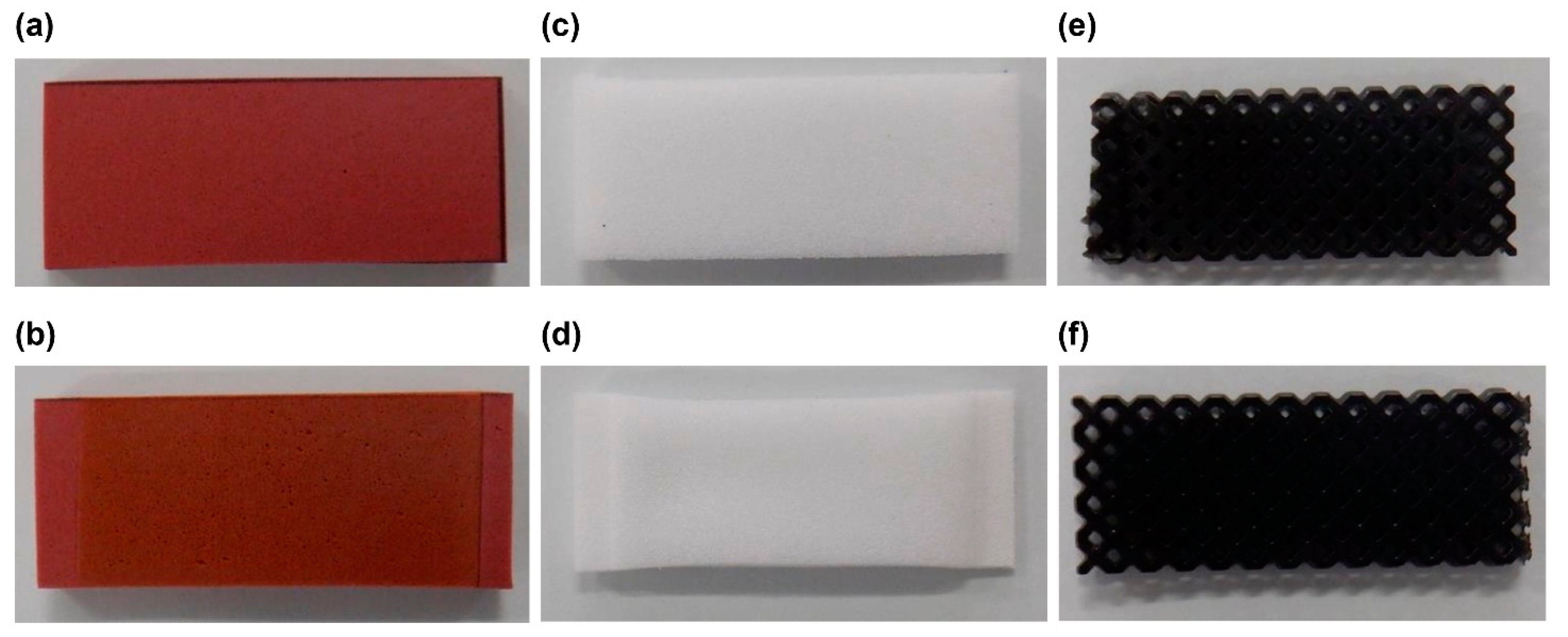

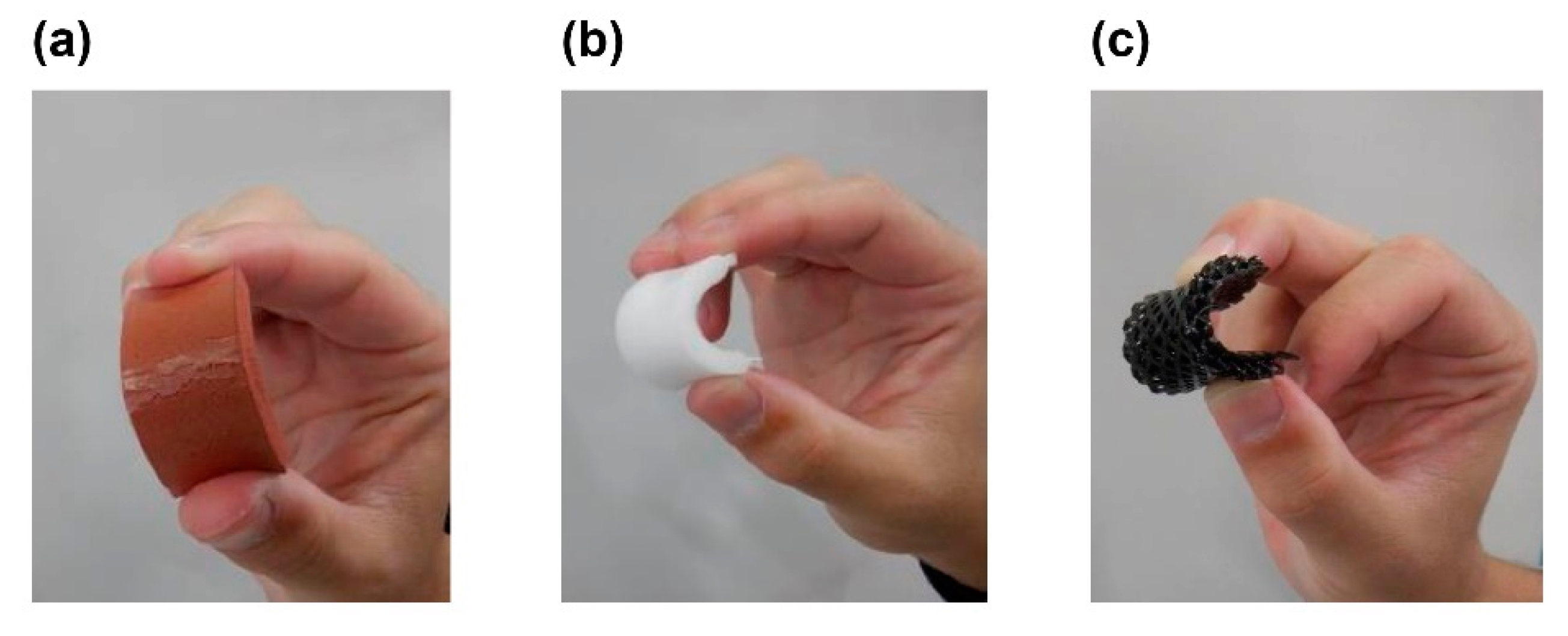

2.1.1. Architected Material 1 (Microlattice)

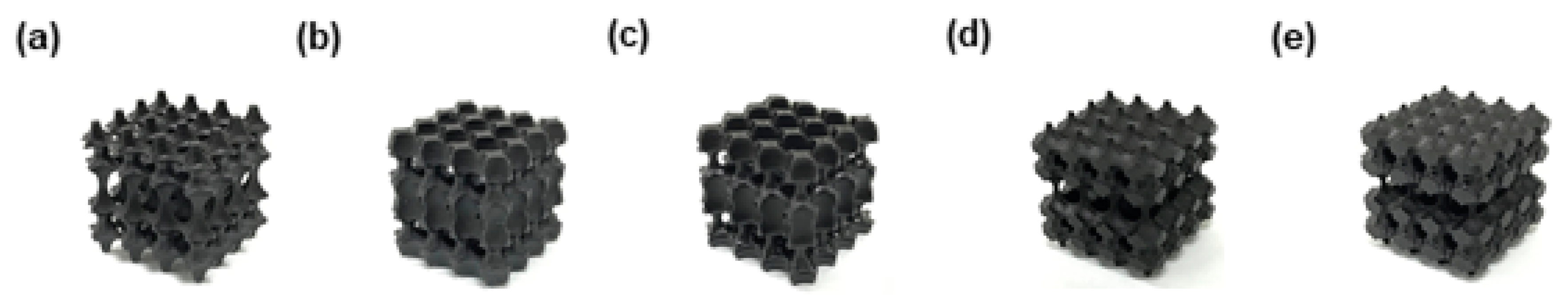

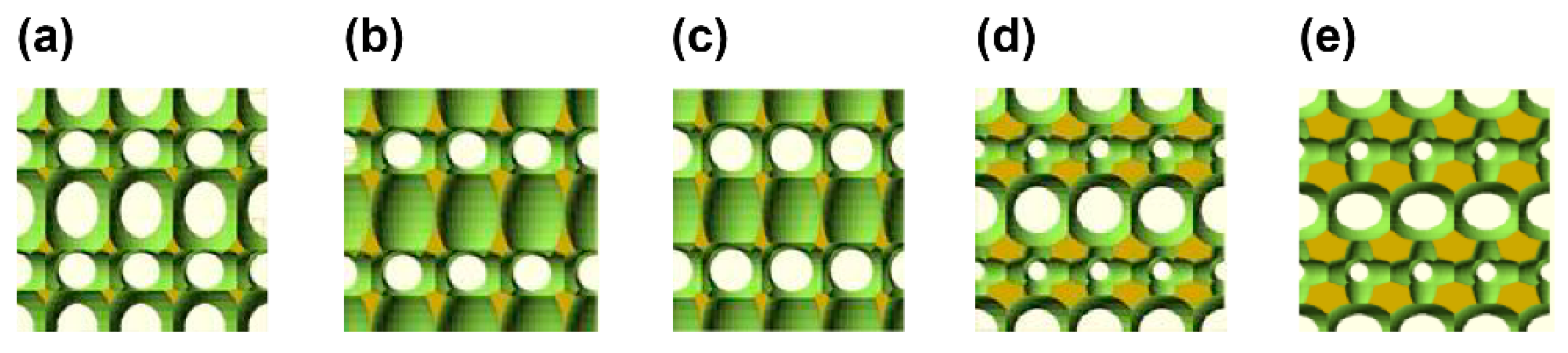

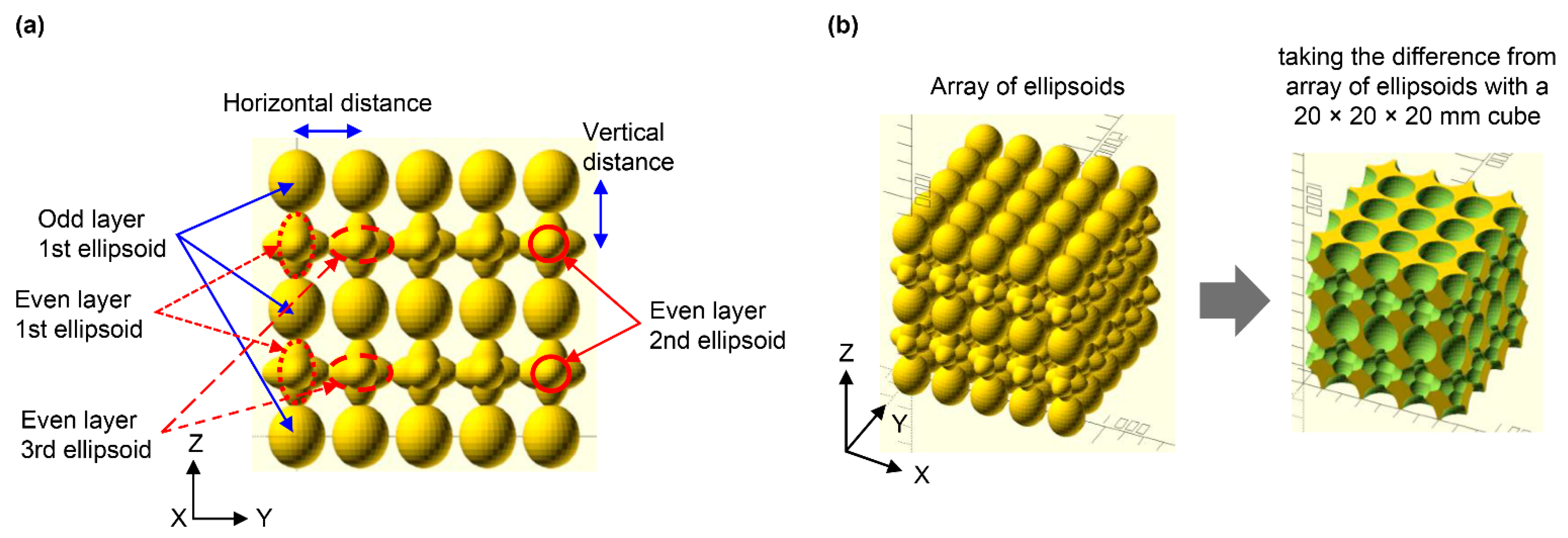

2.1.2. Architected Material 2 (Metafoam)

2.1.3. Polymer Foam

2.2. Methods

2.2.1. Apparent Density and Porosity

2.2.2. Hardness

2.2.3. Rebound Resilience

2.2.4. Frictional Force

2.2.5. Hysteresis Loss

2.2.6. Ultraviolet Light Resistance

2.2.7. Compression Fatigue Test

3. Results and Discussion

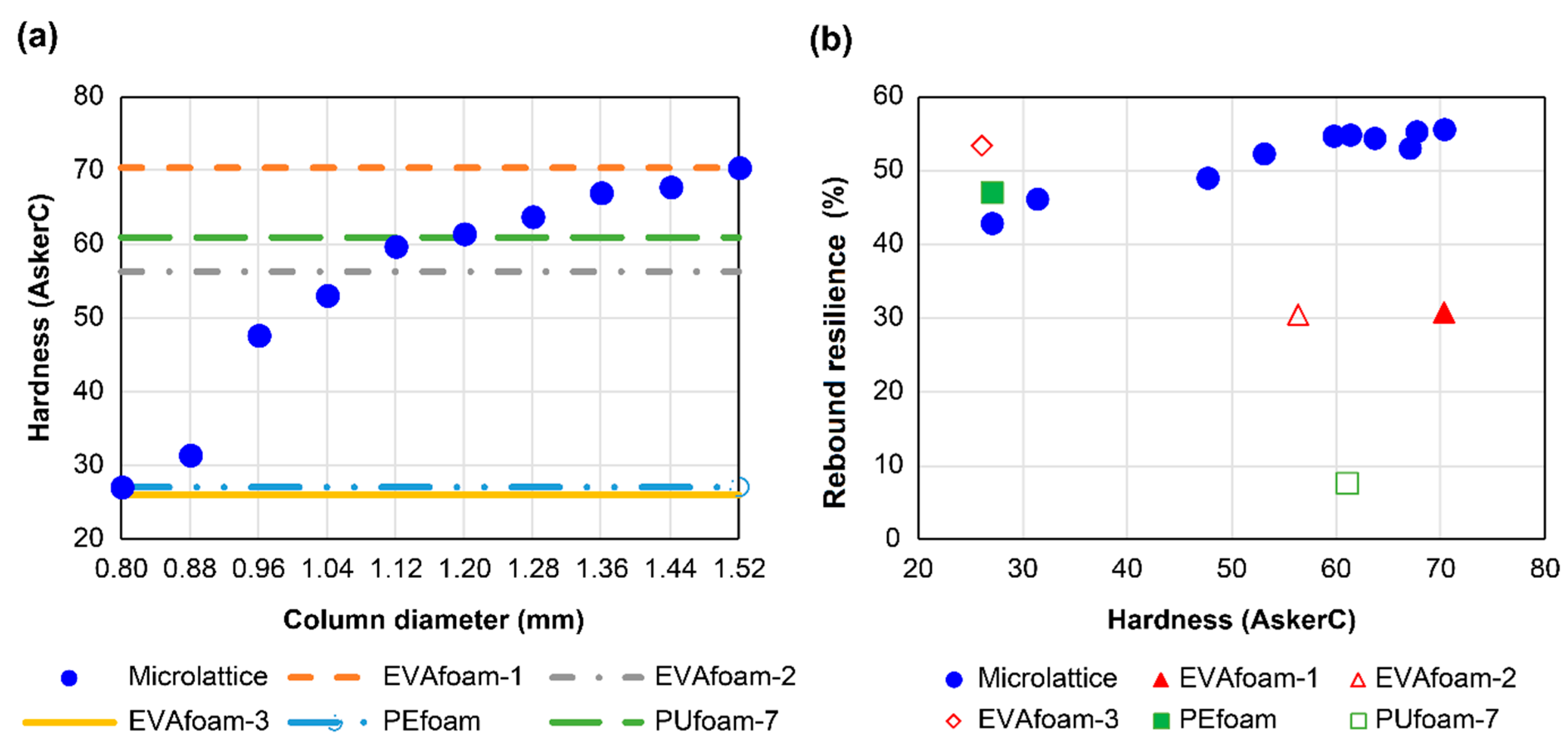

3.1. Microlattice Compared with Plastic Foam

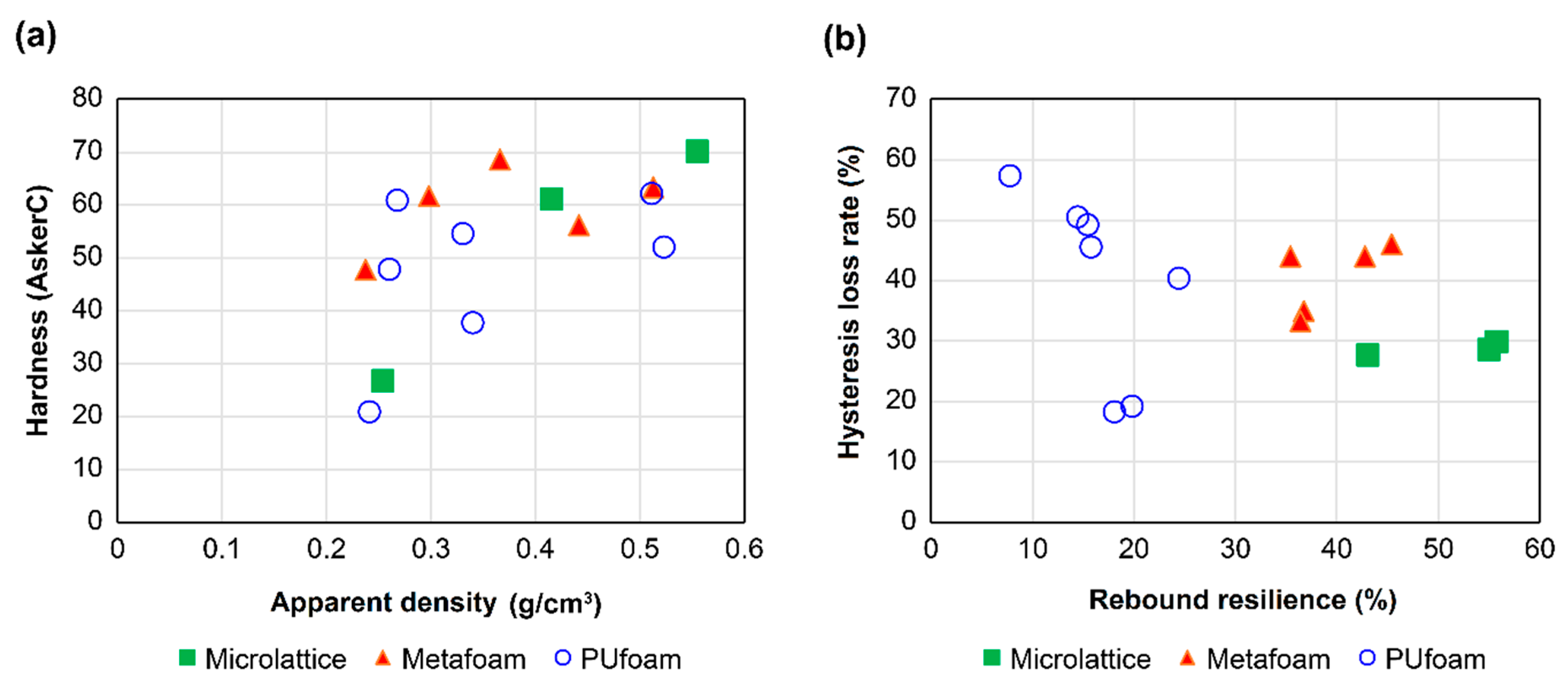

3.2. Metafoam Structure Compared with Microlattice and Urethane Foam

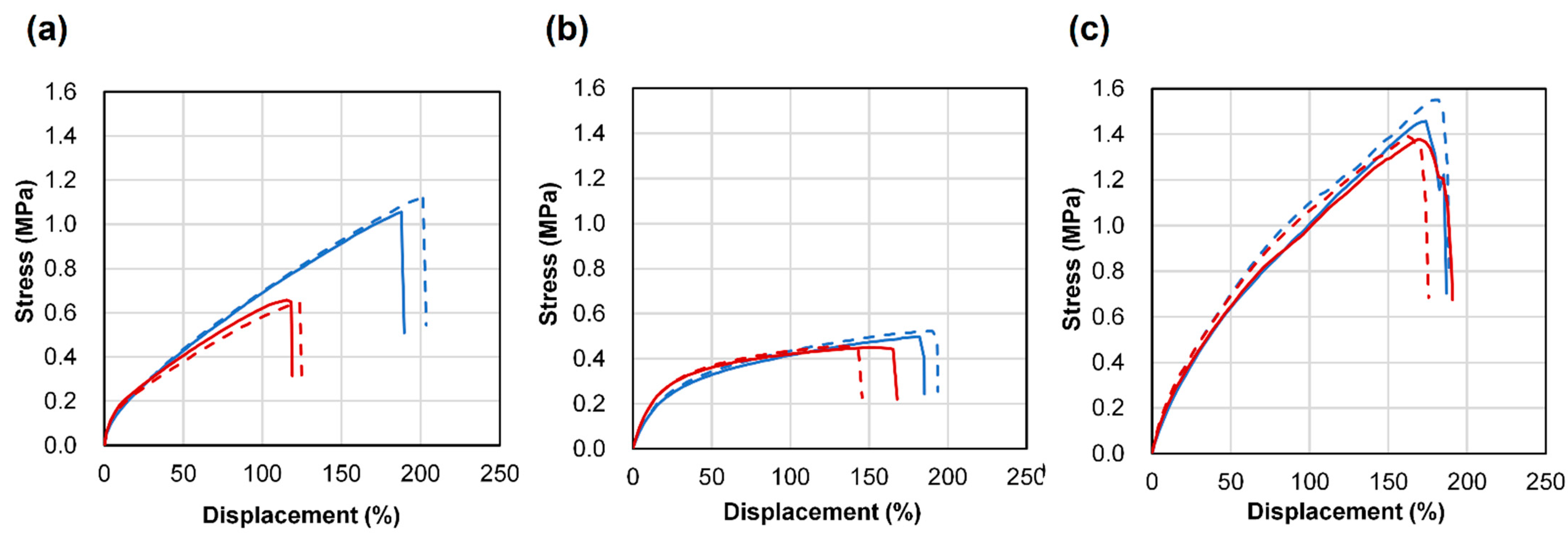

3.3. Durability of Architected Materials and Plastic Foam

3.4. Practicality as Insole Material

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Metafoam Design Parameters

| Component | Size Parameter | (a) MF-1 | (b) MF-2 | (c) MF-3 | (d) MF-4 | (e) MF-5 |

|---|---|---|---|---|---|---|

| Odd Layer ellipsoid | rx | 6.0 | 5.0 | 5.0 | 6.3 | 6.3 |

| Odd Layer ellipsoid | ry | 6.0 | 5.0 | 5.0 | 6.3 | 6.3 |

| Odd Layer ellipsoid | rz | 8.3 | 8.3 | 8.3 | 6.3 | 5.0 |

| Even Layer 1st ellipsoid | lx | 4.0 | 4.0 | 4.8 | 2.5 | 2.5 |

| Even Layer 1st ellipsoid | ly | 4.0 | 4.0 | 4.8 | 2.5 | 2.5 |

| Even Layer 1st ellipsoid | lz | 7.3 | 7.3 | 7.3 | 6.3 | 6.3 |

| Even Layer 2nd ellipsoid | sx | 7.3 | 7.3 | 7.3 | 6.3 | 6.3 |

| Even Layer 2nd ellipsoid | sy | 4.0 | 4.0 | 4.8 | 2.5 | 2.5 |

| Even Layer 2nd ellipsoid | sz | 4.0 | 4.0 | 4.8 | 2.5 | 2.5 |

| Even Layer 3rd ellipsoid | tx | 4.0 | 4.0 | 4.8 | 2.5 | 2.5 |

| Even Layer 3rd ellipsoid | ty | 7.3 | 7.3 | 7.3 | 6.3 | 6.3 |

| Even Layer 3rd ellipsoid | tz | 4.0 | 4.0 | 4.8 | 2.5 | 2.5 |

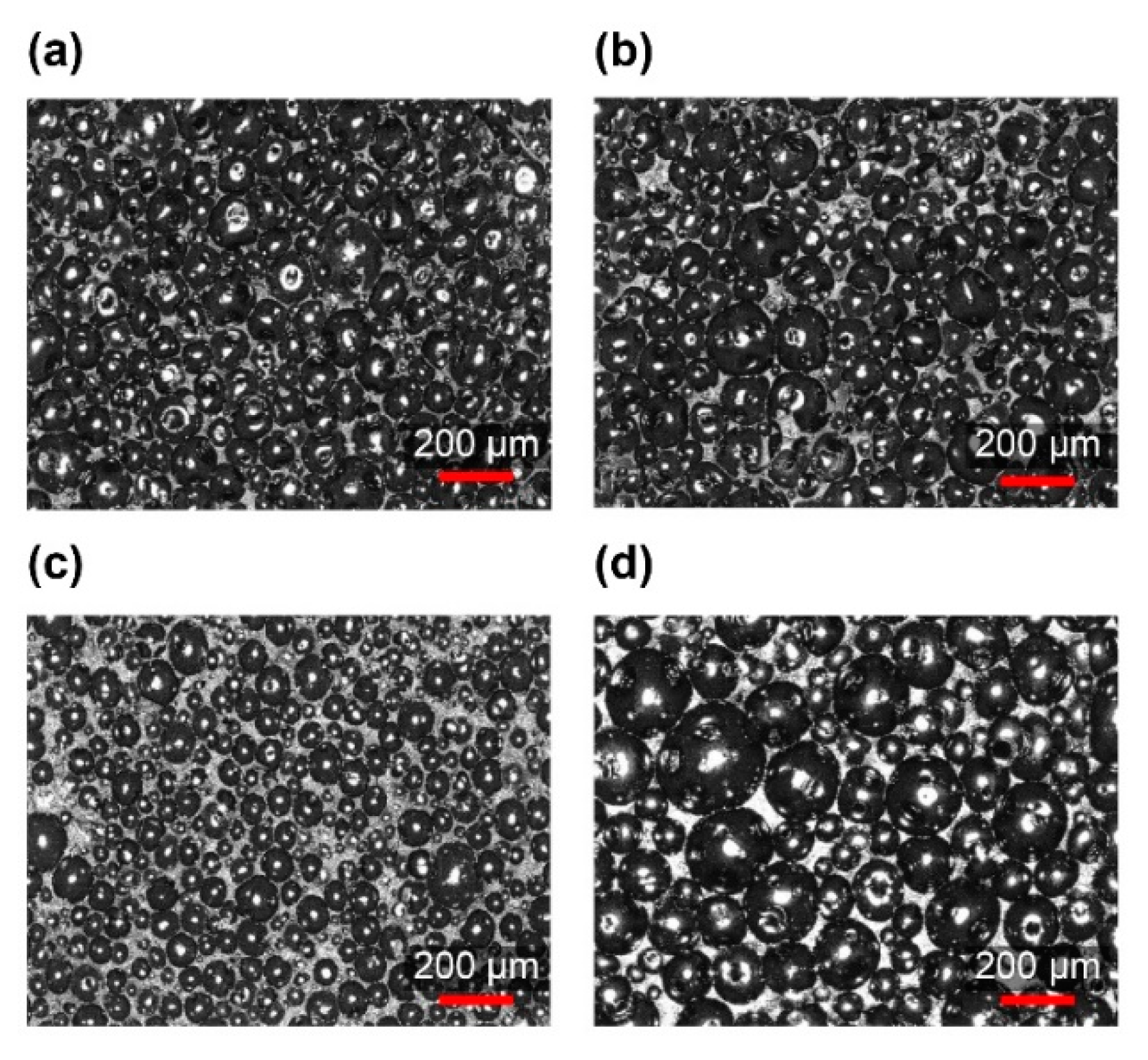

Appendix B. Cross-Section Image of PU Foam Sample

Appendix C. Photograph of Microlattice and Metafoam

Appendix D. Characteristics Table

| Characteristic | (a) ML-1 | (b) ML-2 | (c) ML-3 |

|---|---|---|---|

| Weight (g) | 2.02 | 3.31 | 4.43 |

| Apparent Density (g/cm3) | 0.25 | 0.41 | 0.55 |

| Porosity (%) | 74.8 | 58.7 | 44.9 |

| Characteristic | (a) MF-1 | (b) MF-2 | (c) MF-3 | (d) MF-4 | (e) MF-5 |

|---|---|---|---|---|---|

| Weight (g) | 1.89 | 2.92 | 2.38 | 3.53 | 4.10 |

| Apparent Density (g/cm3) | 0.24 | 0.37 | 0.30 | 0.44 | 0.51 |

| Porosity (%) | 76.4 | 63.6 | 70.4 | 56.0 | 49.0 |

| Characteristic | EVA Foam-1 | EVA Foam-2 | EVA Foam-3 | PE Foam | PU Foam-1 | PU Foam-2 | PU Foam-3 | PU foam-4 | PU Foam-5 | PU Foam-6 | PU Foam-7 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Weight (g) | 2.21 | 1.42 | 0.75 | 0.39 | 1.92 | 2.71 | 2.07 | 2.63 | 4.18 | 4.08 | 2.13 |

| Apparent Density (g/cm3) | 0.28 | 0.18 | 0.09 | 0.05 | 0.24 | 0.34 | 0.26 | 0.33 | 0.52 | 0.51 | 0.27 |

| Hardness (Asker C) | 70 | 56 | 26 | 27 | 21 | 38 | 48 | 55 | 52 | 62 | 61 |

References

- Pham, D.T.; Gault, R.S. A comparison of rapid prototyping technologies. Int. J. Mach. Tools Manuf. 1998, 38, 1257–1287. [Google Scholar] [CrossRef]

- Ventola, C.L. Medical applications for 3D printing: Current and projected uses. Pharm. Ther. 2014, 39, 704–711. [Google Scholar]

- Barrios-Muriel, J.; Romero-Sánchez, F.; Alonso-Sánchez, F.J.; Rodríguez Salgado, D. Advances in orthotic and prosthetic manufacturing: A technology review. Materials 2020, 13, 295. [Google Scholar] [CrossRef]

- Rayna, T.; Striukova, L. From rapid prototyping to home fabrication: How 3D printing is changing business model innovation. Technol. Forecast. Soc. Chang. 2016, 102, 214–224. [Google Scholar] [CrossRef]

- HDürr, H.; Pilz, R.; SaadEleser, N. Rapid tooling of EDM electrodes by means of selective laser sintering. Comput. Ind. 1999, 39, 35–45. [Google Scholar] [CrossRef]

- Tang, Y.; Loh, H.T.; Wong, Y.S.; Fuh, J.Y.H.; Lu, L.; Wang, X. Direct laser sintering of a copper-based alloy for creating three-dimensional metal parts. J. Mater. Process. Technol. 2003, 140, 368–372. [Google Scholar] [CrossRef]

- Shan, S.; Kang, S.H.; Raney, J.R.; Wang, P.; Fang, L.; Lewis, J.A.; Bertoldi, K. Multistable Architected Materials for Trapping Elastic Strain Energy. Adv. Mater. 2015, 27, 4296–4301. [Google Scholar] [CrossRef] [PubMed]

- Shirazi, S.F.S.; Gharehkhani, S.; Mehrali, M.; Yarmand, H.; Metselaar, H.S.C.; Kadri, N.A.; Osman, N.A.A. A review on powder-based additive manufacturing for tissue engineering: Selective laser sintering and inkjet 3D printing. Sci. Technol. Adv. Mater. 2015, 16, 033502. [Google Scholar] [CrossRef]

- Jiang, Y.; Wang, Q. Highly-stretchable 3D-architected Mechanical Metamaterials. Sci. Rep. 2016, 6, 34147. [Google Scholar] [CrossRef]

- Bodaghi, M.; Damanpack, A.R.; Hu, G.F.; Liao, W.H. Large deformations of soft metamaterials fabricated by 3D printing. Mater. Des. 2017, 131, 81–91. [Google Scholar] [CrossRef]

- Weegera, O.; Boddetia, N.; Yeung, S.-K.; Kaijima, S.; Dunn, M.L. Digital design and nonlinear simulation for additive manufacturing of soft lattice structures. Addit. Manuf. 2019, 25, 39–49. [Google Scholar] [CrossRef]

- Saigal, A.; Tumbleston, J.; Vogel, H.; Fox, C.; Mackay, N. Mechanical response of octahedral and octet-truss lattice structures fabricated using the CLIP technology. In Proceedings of the CMSAM2016, Bangkok, Thailand, 24–25 July 2016. 3572-3659-1-SM. [Google Scholar]

- McGregor, D.J.; Tawfick, S.; King, W.P. Mechanical properties of hexagonal lattice structures fabricated using continuous liquid interface production additive manufacturing. Addit. Manuf. 2019, 25, 10–18. [Google Scholar] [CrossRef]

- Morita, J.; Komatsu, S.; Kobe, T.; Nakamura, K.; Kawase, R.; Nakatani, M.; Tanaka, H. A Feeling-based structural design method using architected material. J. Digit. Pract. 2020, 11, 434–455. (In Japanese) [Google Scholar]

- Garcia, A.C.; Durá, J.V.; Ramiro, J.; Hoyos, J.V.; Vera, P. Dynamic study of insole materials simulating real loads. Foot Ankle Int. 1994, 15, 311–323. [Google Scholar] [CrossRef]

- Aguinaldo, A.; Mahar, A. Impact loading in running shoes with cushioning column systems. J. Appl. Biomech. 2003, 19, 353–360. [Google Scholar] [CrossRef][Green Version]

- Mukherjee, M.; Gurusamy-Thangavelu, S.A.; Chelike, D.K.; Alagumalai, A.; Das, B.N.; Jaisankar, S.N.; Mandal, A.B. Biodegradable polyurethane foam as shoe insole to reduce footwear waste: Optimization by morphological physicochemical and mechanical properties. Appl. Surf. Sci. 2020, 499, 143966. [Google Scholar] [CrossRef]

- Demirel, S.; Tuna, B.E. Evaluation of the cyclic fatigue performance of polyurethane foam in different density and category. Polym. Test. 2019, 76, 146–153. [Google Scholar] [CrossRef]

- Lorna, J.G.; Michael, F.A. Cellular Solids: Structure and Properties, 2nd ed.; Cambridge University Press: Cambridge, UK, 1999; pp. 183–231. [Google Scholar]

- Rome, K. A study of the properties of materials used in podiatry. J. Am. Podiatr. Med. Assoc. 1991, 81, 73–83. [Google Scholar] [CrossRef]

- Benard, O. Polymeric Foams Structure-Property-Performance: A Design Guide; William Andrew: New York, NY, USA, 2017; pp. 375–377. [Google Scholar]

- Wioleta, S.; Zbigniew, O.; Boguslaw, W. Analysis of insole material impact on comfort during physical exertion. Fibres Text. East. Eur. 2018, 26, 100–103. [Google Scholar] [CrossRef]

- Szycher, M. Szycher’s Handbook of Polyurethanes, 1st ed.; CRC Press LLC: Boca Raton, FL, USA, 1999; pp. 3–5. [Google Scholar]

- Carl, R.M. Elastomers for Biomedical Applications. Rubber Chem. Technol. 1994, 67, 417–446. [Google Scholar] [CrossRef]

- OpenSCAD the Programmers Solid 3D CAD Modeller. Available online: https://www.openscad.org/ (accessed on 1 February 2021).

- Rosu, D.; Rosu, L.; Cascaval, C.N. IR-change and yellowing of polyurethane as a result of UV irradiation. Polym. Degrad. Stab. 2009, 94, 591–596. [Google Scholar] [CrossRef]

- Gong, L.; Kyriakides, S. Compressive response of open-cell foams. Part I: Morphology and elastic properties. Int. J. Solids Struct. 2005, 42, 1355–1379. [Google Scholar] [CrossRef]

| Material | Hardness (Asker C) | Rebound Resilience (%) | Coefficient of Friction | Carbon Arc Test (48 h) |

|---|---|---|---|---|

| EPU41-Bulk | 85 (0.6) | 53 (0.6) | 1.04 | OK |

| ML-1 | 27 (1.0) | 43 (0.6) | 1.04 | OK |

| ML-2 | 61 (1.2) | 55 (0.6) | 1.04 | OK |

| ML-3 | 70 (0.6) | 56 (0.6) | 1.04 | OK |

| EVAfoam-1 | 71 (1.5) | 31 (1.0) | 0.56 | Shrinking |

| EVAfoam-2 | 57 (1.5) | 31 (0.6) | 0.71 | Shrinking |

| EVAfoam-3 | 27 (0.6) | 53 (0.6) | 1.02 | Shrinking |

| PEfoam | 27 (0.6) | 47 (0.6) | 0.73 | Shrinking |

| PUfoam-7 | 61 (0.6) | 8 (0.6) | 0.23 | Discoloring/Cracking |

| Material | Apparent Density (g/cm3) | Hardness (Asker C) | Rebound Resilience (%) | Hysteresis Loss Rate (%) |

|---|---|---|---|---|

| EPU41-Bulk | 1.00 | 85 (0.6) | 53 (0.6) | 33 |

| ML-1 | 0.25 | 27 (1.0) | 43 (0.6) | 28 |

| ML-2 | 0.41 | 61 (1.2) | 55 (0.6) | 29 |

| ML-3 | 0.55 | 70 (0.6) | 56 (0.6) | 30 |

| MF-1 | 0.24 | 48 (1.5) | 35 (0.6) | 44 |

| MF-2 | 0.37 | 69 (0.6) | 45 (0.6) | 46 |

| MF-3 | 0.30 | 62 (1.7) | 43 (0.6) | 44 |

| MF-4 | 0.44 | 56 (2.1) | 37 (0.6) | 35 |

| MF-5 | 0.51 | 64 (1.7) | 36 (0.6) | 33 |

| PUfoam-1 | 0.24 | 21 (0.6) | 18 (1.0) | 19 |

| PUfoam-2 | 0.34 | 38 (0.6) | 20 (0.6) | 19 |

| PUfoam-3 | 0.26 | 48 (1.0) | 14 (0.6) | 51 |

| PUfoam-4 | 0.33 | 55 (0.6) | 15 (0.6) | 50 |

| PUfoam-5 | 0.52 | 52 (0.6) | 24 (0.6) | 41 |

| PUfoam-6 | 0.51 | 62 (0.6) | 16 (0.6) | 46 |

| PUfoam-7 | 0.27 | 61 (0.6) | 8 (0.6) | 57 |

| Material | Hardness | Rebound Resilience | Coefficient of Friction | UV Resistance | Durability |

|---|---|---|---|---|---|

| ML | Controllable | High | High | Good | Good |

| MF | Controllable | Middle | - | - | Good |

| EVAfoam | Not adjustable | Middle–high | Middle | Poor | Poor |

| PEfoam | Not adjustable | High | Middle | Poor | Poor |

| PUfoam | Not adjustable | Low | Low | Poor | Good |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morita, J.; Ando, Y.; Komatsu, S.; Matsumura, K.; Okazaki, T.; Asano, Y.; Nakatani, M.; Tanaka, H. Mechanical Properties and Reliability of Parametrically Designed Architected Materials Using Urethane Elastomers. Polymers 2021, 13, 842. https://doi.org/10.3390/polym13050842

Morita J, Ando Y, Komatsu S, Matsumura K, Okazaki T, Asano Y, Nakatani M, Tanaka H. Mechanical Properties and Reliability of Parametrically Designed Architected Materials Using Urethane Elastomers. Polymers. 2021; 13(5):842. https://doi.org/10.3390/polym13050842

Chicago/Turabian StyleMorita, Jun, Yoshihiko Ando, Satoshi Komatsu, Kazuki Matsumura, Taisuke Okazaki, Yoshihiro Asano, Masashi Nakatani, and Hiroya Tanaka. 2021. "Mechanical Properties and Reliability of Parametrically Designed Architected Materials Using Urethane Elastomers" Polymers 13, no. 5: 842. https://doi.org/10.3390/polym13050842

APA StyleMorita, J., Ando, Y., Komatsu, S., Matsumura, K., Okazaki, T., Asano, Y., Nakatani, M., & Tanaka, H. (2021). Mechanical Properties and Reliability of Parametrically Designed Architected Materials Using Urethane Elastomers. Polymers, 13(5), 842. https://doi.org/10.3390/polym13050842