Structure–Property Relationship of Polymerized Ionic Liquids for Solid-State Electrolyte Membranes

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Polymerisation Equipment

2.3. Measurements

3. Results and Discussion

3.1. Preparation of the Polymer Films

3.2. Structure–Property Relationship of the Polymerized Ionic Liquids

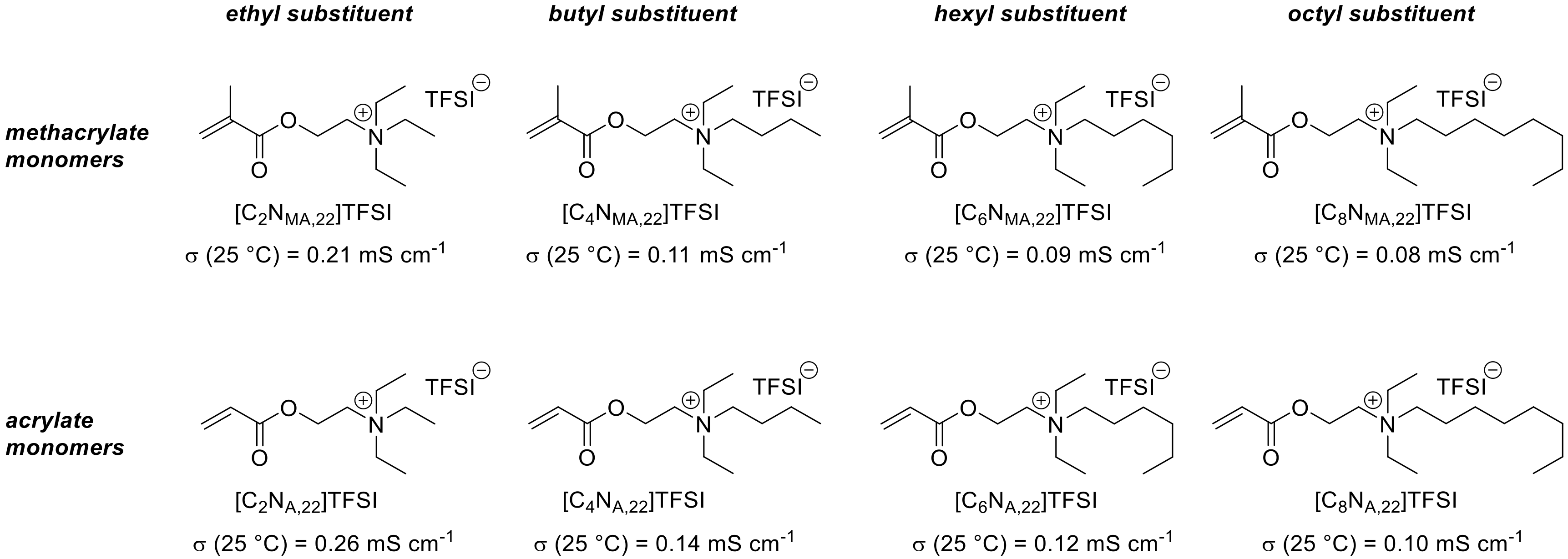

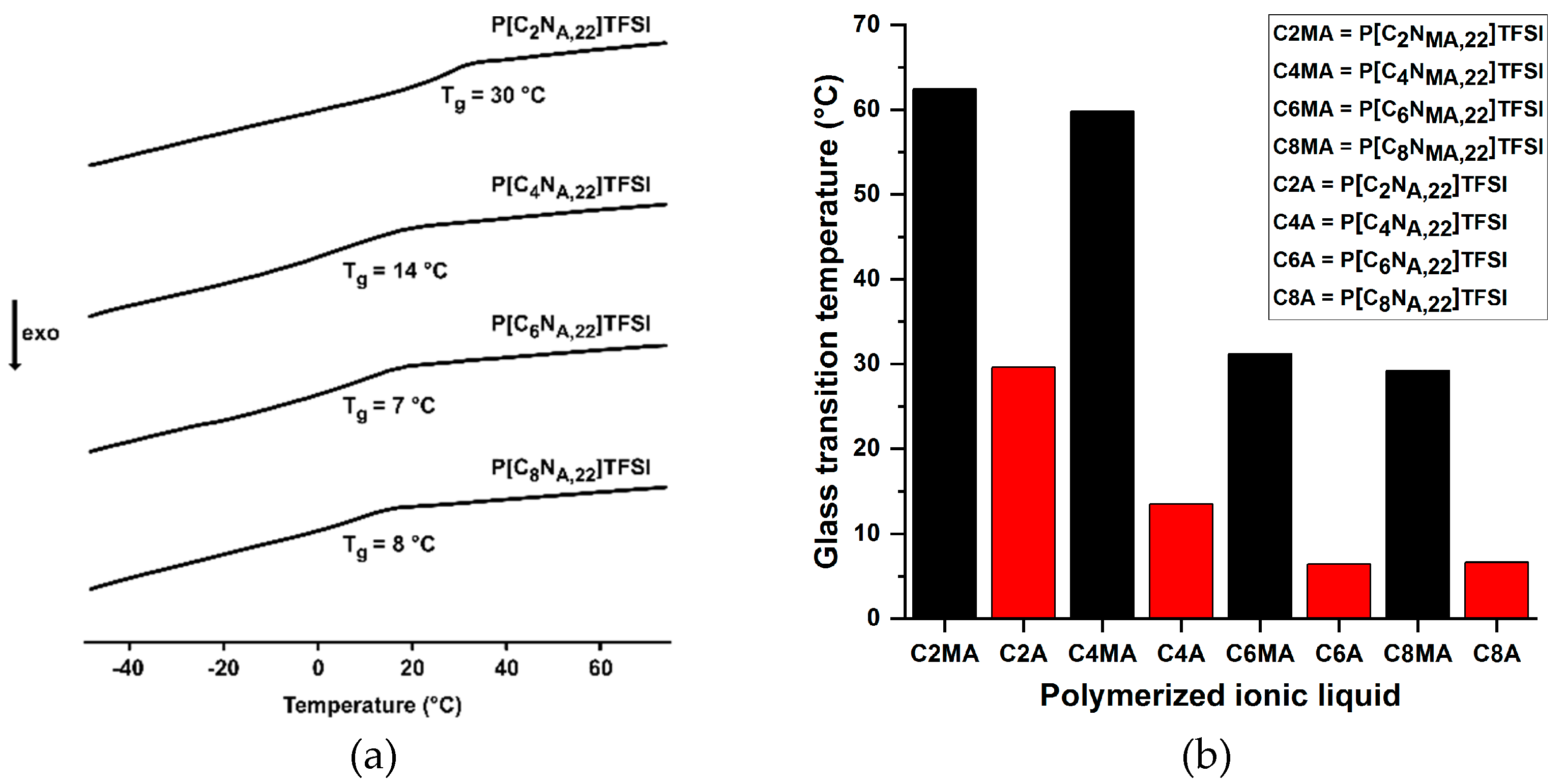

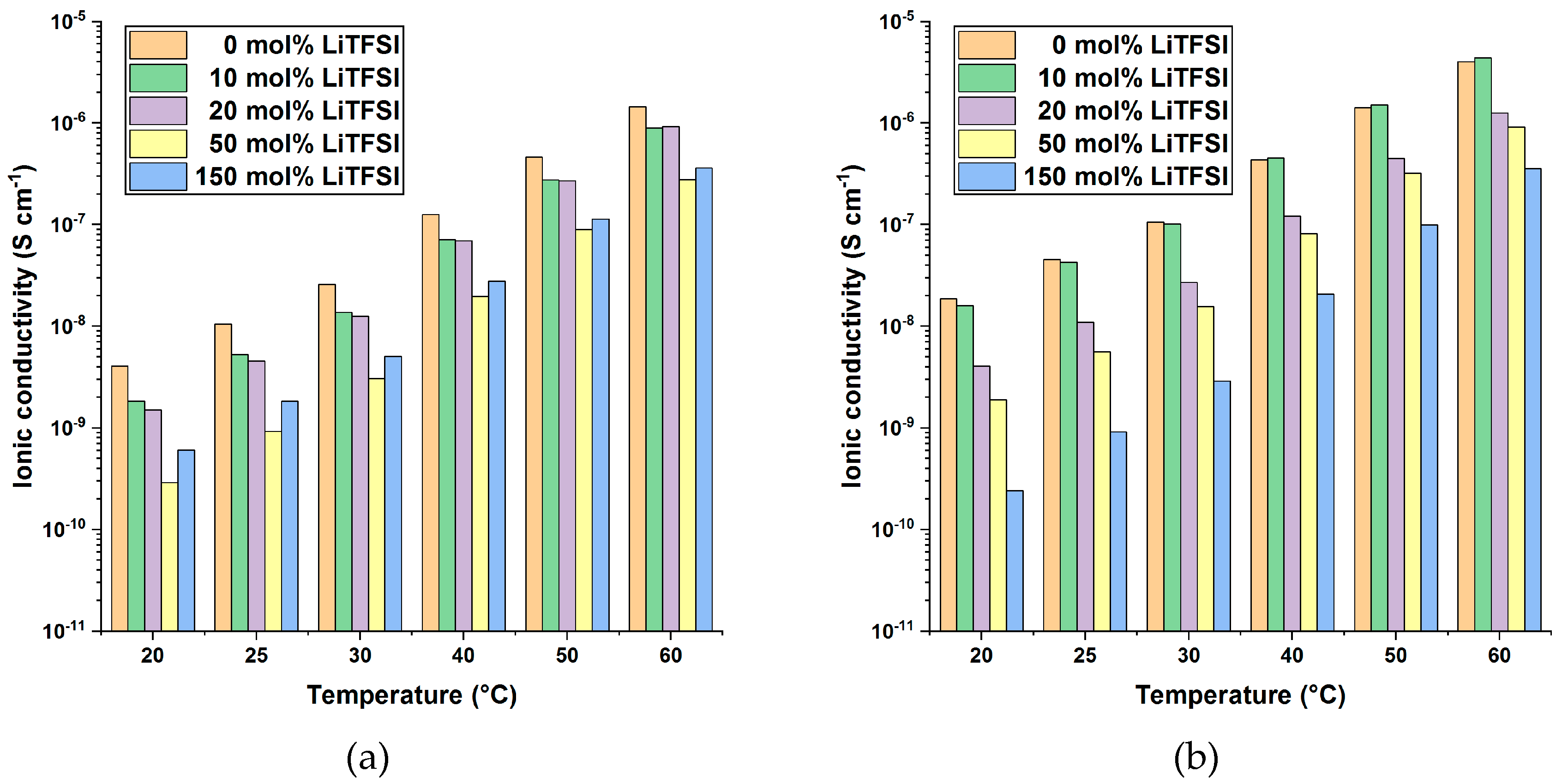

3.3. Influence of the Conducting Salt

4. Conclusions

- Acrylate PILs feature lower Tg and higher ionic conductivity values than methacrylate PILs with same side chain length;

- Longer side chains lead to reduced Tg and increasing ionic conductivity values (within the studied range from C2 to C8 alkyl chains);

- A higher content of conducting salt reduces Tg and the ionic conductivity but increases the 7Li diffusion coefficient.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Le Bideau, J.; Viau, L.; Vioux, A. Ionogels, ionic liquid based hybrid materials. Chem. Soc. Rev. 2011, 40, 907–925. [Google Scholar] [CrossRef]

- Ohno, H. Functional Design of Ionic Liquids. Bull. Chem. Soc. Jpn. 2006, 79, 1665–1680. [Google Scholar] [CrossRef]

- Ohno, H. Molten salt type polymer electrolytes. Electrochimica Acta 2001, 46, 1407–1411. [Google Scholar] [CrossRef]

- Ohno, H.; Ito, K. Room-Temperature Molten Salt Polymers as a Matrix for Fast Ion Conduction. Chem. Lett. 1998, 27, 751–752. [Google Scholar] [CrossRef]

- Tseng, S.-K.; Wang, R.-H.; Wu, J.-L.; Jyothibasu, J.P.; Wang, T.-L.; Chu, C.-Y.; Lee, R.-H. Synthesis of a series of novel imidazolium-containing ionic liquid copolymers for dye-sensitized solar cells. Polym. 2020, 210, 123074. [Google Scholar] [CrossRef]

- Tang, J.; Sun, W.; Tang, H.; Radosz, M.; Shen, Y. Enhanced CO2 Absorption of Poly(ionic liquid)s. Macromolecules 2005, 38, 2037–2039. [Google Scholar] [CrossRef]

- Wang, A.; Liu, X.; Wang, S.; Chen, J.; Xu, H.; Xing, Q.; Zhang, L. Polymeric ionic liquid enhanced all-solid-state electrolyte membrane for high-performance lithium-ion batteries. Electrochimica Acta 2018, 276, 184–193. [Google Scholar] [CrossRef]

- Costa, L.T.; Sun, B.; Jeschull, F.; Brandell, D. Polymer-ionic liquid ternary systems for Li-battery electrolytes: Molecular dynamics studies of LiTFSI in a EMIm-TFSI and PEO blend. J. Chem. Phys. 2015, 143, 024904. [Google Scholar] [CrossRef] [PubMed]

- Shaplov, A.S.; Marcilla, R.; Mecerreyes, D. Recent Advances in Innovative Polymer Electrolytes based on Poly(ionic liquid)s. Electrochimica Acta 2015, 175, 18–34. [Google Scholar] [CrossRef]

- Löwe, R.; Hanemann, T.; Hofmann, A. Polymerizable Ionic Liquids for Solid-State Polymer Electrolytes. Molecule 2019, 24, 324. [Google Scholar] [CrossRef] [PubMed]

- Atkins, P.W.; de Paula, J.; Bär, M. Physikalische Chemie, 5. ed.; Wiley-VCH Verl.: Weinheim, Deutschland, 2013; ISBN 9783527332472. [Google Scholar]

- Tanner, J.E. Use of the Stimulated Echo in NMR Diffusion Studies. J. Chem. Phys. 1970, 52, 2523–2526. [Google Scholar] [CrossRef]

- Stejskal, E.O.; Tanner, J.E. Spin Diffusion Measurements: Spin Echoes in the Presence of a Time-Dependent Field Gradient. J. Chem. Phys. 1965, 42, 288–292. [Google Scholar] [CrossRef]

- Zhang, H.; Li, L.; Feng, W.; Zhou, Z.; Nie, J. Polymeric ionic liquids based on ether functionalized ammoniums and perfluorinated sulfonimides. Polym. 2014, 55, 3339–3348. [Google Scholar] [CrossRef]

- Ogihara, W.; Washiro, S.; Nakajima, H.; Ohno, H. Effect of cation structure on the electrochemical and thermal properties of ion conductive polymers obtained from polymerizable ionic liquids. Electrochimica Acta 2006, 51, 2614–2619. [Google Scholar] [CrossRef]

- Ohno, H.; Yoshizawa, M.; Ogihara, W. Development of new class of ion conductive polymers based on ionic liquids. Electrochimica Acta 2004, 50, 255–261. [Google Scholar] [CrossRef]

- Appetecchi, G.B.; Montanino, M.; Zane, D.; Carewska, M.; Alessandrini, F.; Passerini, S. Effect of the alkyl group on the synthesis and the electrochemical properties of N-alkyl-N-methyl-pyrrolidinium bis(trifluoromethanesulfonyl)imide ionic liquids. Electrochimica Acta 2009, 54, 1325–1332. [Google Scholar] [CrossRef]

- Shin, J.-H.; Henderson, W.A.; Tizzani, C.; Passerini, S.; Jeong, S.-S.; Kim, K.-W. Characterization of Solvent-Free Polymer Electrolytes Consisting of Ternary PEO–LiTFSI–PYR[sub 14] TFSI. J. Electrochem. Soc. 2006, 153, A1649–A1654. [Google Scholar] [CrossRef]

- Bruce, P. Conductivity and transference number measurements on polymer electrolytes. Solid State Ionics 1988, 28–30, 918–922. [Google Scholar] [CrossRef]

- Xue, Z.; He, D.; Xie, X. Poly(ethylene oxide)-based electrolytes for lithium-ion batteries. J. Mater. Chem. A 2015, 3, 19218–19253. [Google Scholar] [CrossRef]

- Stephan, A.M. Review on gel polymer electrolytes for lithium batteries. Eur. Polym. J. 2006, 42, 21–42. [Google Scholar] [CrossRef]

- Diddens, D.; Heuer, A. Simulation Study of the Lithium Ion Transport Mechanism in Ternary Polymer Electrolytes: The Critical Role of the Segmental Mobility. J. Phys. Chem. B 2014, 118, 1113–1125. [Google Scholar] [CrossRef]

- Zhang, Z.; Nasrabadi, A.T.; Aryal, D.; Ganesan, V. Mechanisms of Ion Transport in Lithium Salt-Doped Polymeric Ionic Liquid Electrolytes. Macromolecules 2020, 53, 6995–7008. [Google Scholar] [CrossRef]

- Long, L.; Wang, S.; Xiao, M.; Meng, Y. Polymer electrolytes for lithium polymer batteries. J. Mater. Chem. A 2016, 4, 10038–10069. [Google Scholar] [CrossRef]

- Qian, J.; Jin, B.; Li, Y.; Zhan, X.; Hou, Y.; Zhang, Q. Research progress on gel polymer electrolytes for lithium-sulfur batteries. J. Energy Chem. 2021, 56, 420–437. [Google Scholar] [CrossRef]

| Polymer | σ [S·cm−1] at 25 °C | σ [S·cm−1] at 60 °C | Tg [°C] | TDec (Onset) [°C] | TDec (98 wt%) [°C] |

|---|---|---|---|---|---|

| P[C2NMA,22]TFSI | 2.7 × 10−9 | 4.5 × 10−7 | 62 | 333 | 323 |

| P[C4NMA,22]TFSI | 3.4 × 10−9 | 7.5 × 10−7 | 60 | 329 | 325 |

| P[C6NMA,22]TFSI | 4.8 × 10−9 | 7.9 × 10−7 | 31 | 330 | 329 |

| P[C8NMA,22]TFSI | 1.1 × 10−8 | 1.5 × 10−6 | 29 | 335 | 332 |

| P[C2NA,22]TFSI | 7.3 × 10−9 | 2.1 × 10−6 | 30 | 347 | 333 |

| P[C4NA,22]TFSI | 1.3 × 10−8 | 2.4 × 10−6 | 14 | 354 | 319 |

| P[C6NA,22]TFSI | 3.0 × 10−8 | 3.6 × 10−6 | 6 | 361 | 334 |

| P[C8NA,22]TFSI | 4.5 × 10−8 | 4.0 × 10−6 | 7 | 358 | 342 |

| PIL | Glass Transition Temperature Tg of PIL Mixture with LiTFSI Content of | ||||

|---|---|---|---|---|---|

| 0 mol% | 10 mol% | 20 mol% | 50 mol% | 150 mol% | |

| P[C2NMA,22]TFSI | 62 | 31 | 29 | 20 | −27 |

| P[C4NMA,22]TFSI | 60 | 14 | 8 | 7 | −27 |

| P[C6NMA,22]TFSI | 31 | 3 | −13 | 6 | −43 |

| P[C8NMA,22]TFSI | 29 | −3 | −2 | −2 | −24 |

| P[C2NA,22]TFSI | 30 | 17 | 11 | −7 | −30 |

| P[C4NA,22]TFSI | 14 | 6 | −1 | −13 | −35 |

| P[C6NA,22]TFSI | 6 | 6 | 0 | −8 | −40 |

| P[C8NA,22]TFSI | 7 | 0 | −1 | −11 | −35 |

| Polymer | σ [S·cm−1] at 20 °C | σ [S·cm−1] at 60 °C |

|---|---|---|

| P[C2NA,22]TFSI (neat) | 2.2 × 10−9 | 2.1 ×10−6 |

| P[C2NA,22]TFSI + 10 mol% LiTFSI | 2.4 × 10−9 | 2.7 × 10−6 |

| P[C2NA,22]TFSI + 20 mol% LiTFSI | 1.8 × 10−9 | 2.3 × 10−6 |

| P[C2NA,22]TFSI + 50 mol% LiTFSI | 1.8 × 10−10 | 7.9 × 10−7 |

| P[C2NA,22]TFSI + 150 mol% LiTFSI | 2.6 × 10−10 | 7.0 × 10−7 |

| PEO10LiTFSI [18] | 1.5 × 10−5 | 4.1 × 10−4 |

| PEO20LiTFSI [18] | 7.0 × 10−6 | 3.7 × 10−4 |

| Membrane | Ionic Conductivity at 25 °C [S·cm−1]C | 7Li Diffusion Coefficient at 25 °C [m2·s−1] |

|---|---|---|

| P[C2NA,22]TFSI + 20 mol% LiTFSI | 6.9 × 10−9 | <10−14 * |

| P[C2NA,22]TFSI + 150 mol% LiTFSI | 1.2 × 10−9 | 4.3 ± 0.1 × 10−14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Löwe, R.; Hanemann, T.; Zinkevich, T.; Hofmann, A. Structure–Property Relationship of Polymerized Ionic Liquids for Solid-State Electrolyte Membranes. Polymers 2021, 13, 792. https://doi.org/10.3390/polym13050792

Löwe R, Hanemann T, Zinkevich T, Hofmann A. Structure–Property Relationship of Polymerized Ionic Liquids for Solid-State Electrolyte Membranes. Polymers. 2021; 13(5):792. https://doi.org/10.3390/polym13050792

Chicago/Turabian StyleLöwe, Robert, Thomas Hanemann, Tatiana Zinkevich, and Andreas Hofmann. 2021. "Structure–Property Relationship of Polymerized Ionic Liquids for Solid-State Electrolyte Membranes" Polymers 13, no. 5: 792. https://doi.org/10.3390/polym13050792

APA StyleLöwe, R., Hanemann, T., Zinkevich, T., & Hofmann, A. (2021). Structure–Property Relationship of Polymerized Ionic Liquids for Solid-State Electrolyte Membranes. Polymers, 13(5), 792. https://doi.org/10.3390/polym13050792