Is the Polylactic Acid Fiber in Green Compost a Risk for Lumbricus terrestris and Triticum aestivum?

Abstract

1. Introduction

2. Materials and Methods

Experimental Design

3. Results

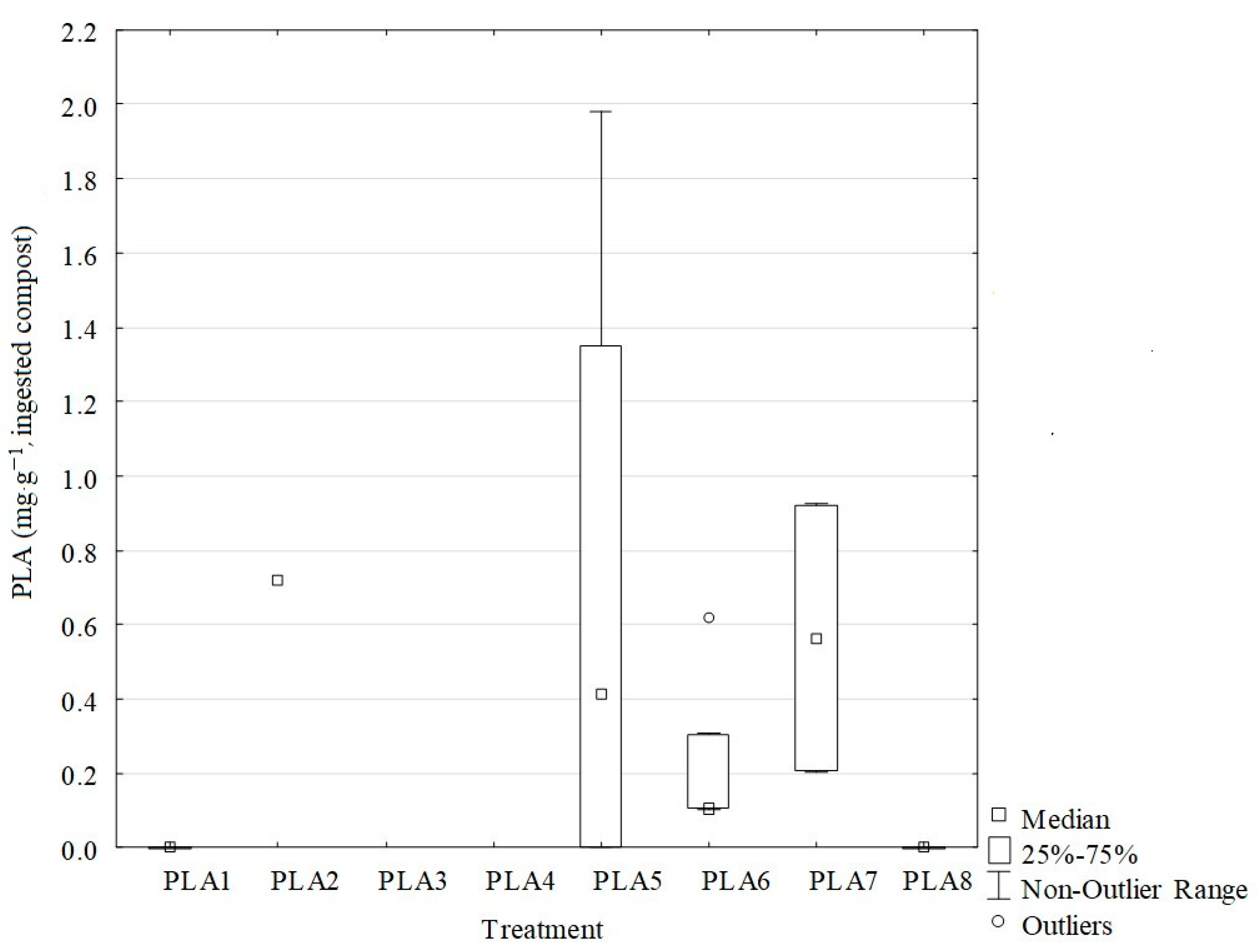

3.1. PLA Residues in Composts Exposed to Different Types of Composting Treatments

3.2. Ecotoxicological Effects of PLA Residues in Composts

3.2.1. Ecotoxicological Effects of PLA Residues on Earthworms

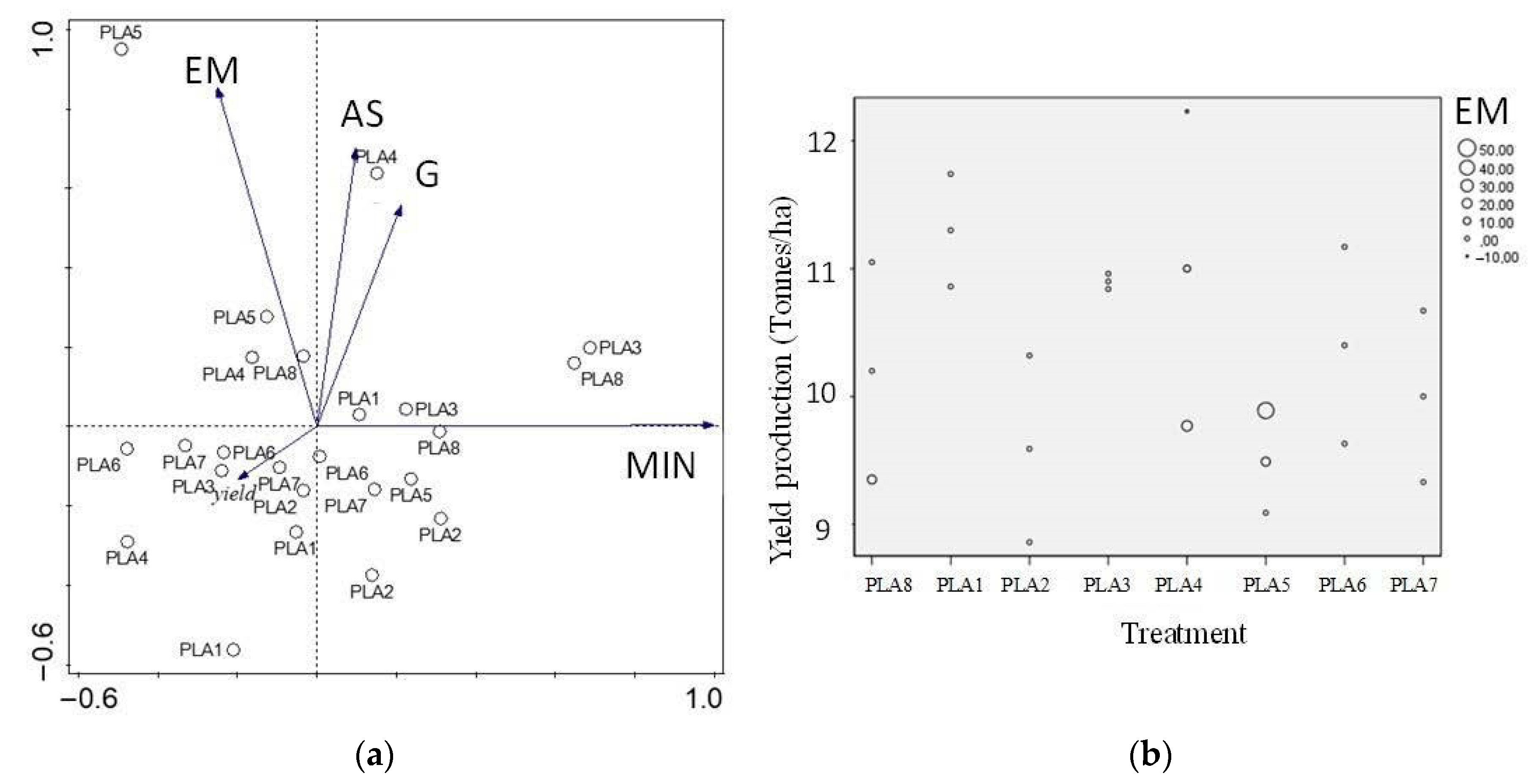

3.2.2. Ecotoxicological Effects of PLA on Plant Growth

3.2.3. Effects of PLA on Soil Physicochemical Conditions

3.2.4. Effects of PLA on Earthworm Burrows

3.2.5. Relationship between All Response Variables

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Haider, T.P.; Völker, C.; Kramm, J.; Landfester, K.; Wurm, F.R.A. Plastics of the Future? The Impact of Biodegradable Polymers on the Environment and on Society. Chem. Int. Ed. 2019, 58, 50. [Google Scholar]

- Gross, R.A.; Kalra, B. Biodegradable polymers for the environment. Science 2002, 297, 803–807. [Google Scholar] [CrossRef] [PubMed]

- Karamanlioglu, M.; Preziosi, R.; Robson, G.D. Abiotic and biotic environmental degradation of the bioplastic polymer poly(lactic acid): A review. Polym. Degrad. Stab. 2017, 137, 122–130. [Google Scholar] [CrossRef]

- European Bioplastics 2105; Composts Standarizations: Berlin, Germany, 2018.

- Weithmann, N.; Möller, J.N.; Löder, M.G.; Piehl, S.; Laforsch, C.; Freitag, R. Organic fertilizer as a vehicle for the entry of microplastic into the environment. Sci. Adv. 2018, 4, eaap8060. [Google Scholar] [CrossRef] [PubMed]

- Sarasa, J.; Gracia, J.M.; Javierr, C. Study of the biodisintegration of a bioplastic material waste. Bioresour. Technol. 2009, 100, 3764–3768. [Google Scholar] [CrossRef] [PubMed]

- Brodhagen, M.; Golberger, J.R.; Hayes, D.G.; Inglis, D.A.; Marsh, T.L.; Miles, C. Policy considerations for limiting unintended residual plastic in agricultural soils. Environ. Sci. Policy 2017, 69, 81–84. [Google Scholar] [CrossRef]

- GESAMP. Sources, Fate and Effects of Microplastics in the Marine Environment: A Global Assessment; International Maritime Organization: London, UK, 2015. [Google Scholar]

- Lwanga, E.H.; Gertsen, H.; Gooren, H.; Peters, P.; Salánki, T.; van der Ploeg, M.; Besseling, E.; Koelmans, A.A.; Geissen, V. Incorporation of microplastics from litter into burrows of Lumbricus terrestris. Environ. Pollut. 2017, 220, 523–531. [Google Scholar] [CrossRef]

- Maaß, S.; Daphi, D.; Lehmann, A.; Rillig, M.A. Transport of microplastics by two collembolan species. Environ. Pollut. 2017, 225, 456–459. [Google Scholar] [CrossRef]

- Qi, Y.; Ossowicki, A.; Yang, X.; Lwanga, E.H.; Dini-Andreote, F.; Geissen, V.; Garbeva, P. Effects of plastic mulch film residues on wheat rhizosphere and soil properties. J. Hazard. Mater. 2020, 387, 121711. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.X.; Liu, W.; Wang, E.; Zhou, T.; Xin, P. Residual plastic mulch fragments effects on soil physical properties and water flow behavior in the Minqin Oasis, northwester China. Soil Tillage Res. 2017, 166, 100–107. [Google Scholar] [CrossRef]

- Unmar, G.; Mohee, R. Assessing the effect of biodegradable and degradable plastics on the composting of green wastes and compost quality. Bioresour. Technol. 2008, 99, 6738–6744. [Google Scholar] [CrossRef]

- Beriot, N.; Peek, J.; Zornoza, R.; Geissen, V.; Lwanga, E.H. Low density-microplastics detected in sheep faeces and soil: A case study from the intensive vegetable farming in Southeast Spain. Sci. Total Environ. 2021, 755, 142653. [Google Scholar] [CrossRef] [PubMed]

- Lwanga, E.H.; Vega, J.M.; Quej, V.K.; de los Angeles Chi, J.; Del Cid, L.S.; Chi, C.; Segura, G.E.; Gertsen, H.; Salánki, T.; van der Ploeg, M.; et al. Field evidence for transfer of plastic debris along a terrestrial food chain. Sci. Rep. Nat. 2017, 7, 14071. [Google Scholar] [CrossRef]

- Sharma, S.; Chatterjee, S. Microplastic pollution, a threat to marine ecosystem and human health: A short review. Environ. Sci. Pollut. Res. 2017, 24, 21530–21547. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, X.; Gertsen, H.; Peters, P.; Salánki, T.; Geissen, V. Simple method for the extraction and identification of light density microplastics from soil. Sci. Total Environ. 2018, 1056–1065. [Google Scholar] [CrossRef] [PubMed]

- ECN. Sustainable Compost Application in Agriculture; ECN: Badden-Wuttenberg, German, 2008. [Google Scholar]

- OECD. Guideline for Testing of Chemicals No. 207. Earthworm, Acute Toxicity Test; OECD: Paris, France, 1984. [Google Scholar]

- OECD. Test No. 222: Earthworm Reproduction Test (Eisenia fetida/Eisenia andrei), OECD Guidelines for the Testing of Chemicals, Section 2; OECD: Paris, France, 2016. [Google Scholar] [CrossRef]

- Blake, G.R.; Hartge, K.H.; Klute, A. (Eds.) Methods of Soil Analysis, Part 1: Physical and Mineralogical Methods; Soil Science Society of America: Madison, WI, USA, 1986; pp. 363–368. [Google Scholar]

- USDA. Soil Quality Test Kit Guide; United States Department of Agriculture; Agricultural Research Service; Natural Resources Conservation Service: Washington, DC, USA, July 2001; p. 82. [Google Scholar]

- Decagon. Mini Disk Infiltrometer; Decagon Devices Inc.: Pullman, WA, USA, 2014; 21p. [Google Scholar]

- ISO/DIS 14238. Soil Quality-Determination of Nitrogen Mineralisation and Nitrification in Soils and the Influence of Chemicals on These Processes; Technical Committee ISO/TC 190/SC 4: Soil Quality-Biological Methods: Geneva, Zwitzerland, 1995. [Google Scholar]

- OECD. Test Guidelines for the Chemicals. Organisation for Economic Cooperation and Development OECD; OECD: Paris, France, 2000. [Google Scholar]

- Meng, J.; Yang, Y. Symmetrical Two-Dimensional PCA with Image Measures in Face Recognition. Int. J. Adv. Robotic. Syst. 2012, 9, 6. [Google Scholar] [CrossRef]

- Reyes-Torres, E.R.; Oviedo-Ocaña, I.; Dominguez, D.; Komilis, A.; Sánchez, A. Systematic review on the composting of green waste: Feedstock quality and optimization strategies. Waste Manag. 2018, 77, 486–499. [Google Scholar] [CrossRef] [PubMed]

- Qi, Y.; Yang, X.; Mejia, A.; Huerta, E.; Beriot, N.; Gertsen, H. Macro- and micro- plastics in soil-plant system: Effects of plastic mulch film residues on wheat (Triticum aestivum) growth. Sci. Total Environ. 2018, 1048–1056. [Google Scholar] [CrossRef] [PubMed]

- Moreno, M.M.; González-Mora, S.; Villena, J.; Campos, J.A.; Moreno, C. Deterioration pattern of six biodegradable, potentially low-environmental impact mulches in field conditions. J. Environ. Manag. 2017, 200, 490–501. [Google Scholar] [CrossRef] [PubMed]

- Rillig, M.C.; Lehmann, A.; de Souza Machado, A.A.; Yang, G. Microplastic effects on plants. New Phytol. 2018, 223, 1066–1070. [Google Scholar] [CrossRef] [PubMed]

| Stage | Treatment | Description | Assessment |

|---|---|---|---|

| 1 | 2 wkT | 2 wk tunnel (70 °C) | Green compost |

| 1 | 2 wk T + n | 2 wk tunnel+O | Green compost |

| 2 and 3 | PLA1 | 0.1 % PLA | Earthworms, plants, soil |

| 2 and 3 | PLA2 | 0.25 % PLA | Earthworms, plants, soil |

| 2 and 3 | PLA3 | 0.50 % PLA | Earthworms, plants, soil |

| 2 and 3 | PLA4 | 0.75 % PLA | Earthworms, plants, soil |

| 2 and 3 | PLA5 | 1 % PLA | Earthworms, plants, soil |

| 2 and 3 | PLA6 | 3 % PLA | Earthworms, plants, soil |

| 2 and 3 | PLA7 | 5 % PLA | Earthworms, plants, soil |

| 2 and 3 | PLA8 | 0 % PLA | Earthworms, plants, soil |

| Treatment | Biomass Change (%) Means (SD) | Mortality (%) Means (SD) |

|---|---|---|

| PLA1 | −17.4 (6.35) | 0 (0) |

| PLA 2 | −11.9 (3.19) | 0 (0) |

| PLA 3 | −15.4 (10.0) | 0 (0) |

| PLA 4 | −3.87 (8.42) | 8.33 (14.4) |

| PLA 5 | −2.36 (12.1) | 16.7 (28.9) |

| PLA 6 | −14.8 (6.86) | 0 (0) |

| PLA 7 | −11.6 (7.68) | 0 (0) |

| PLA 8 | −14.3 (12.2) | 16.7 (14.4) |

| Treatment | Parameters | |||||

|---|---|---|---|---|---|---|

| Number Grain/Ear | Weight/Grain (g) (n.s.) | Weight Grain/Ear (g) | Number of Tillers (m2) | Plant Dry Matter (g/m2) | Yield Grain (t/ha) | |

| PLA1 | 34.2 (3.71) | 0.04 (0.001) | 1.33 (0.14) | 1004 (67.7) | 1091 (129) | 11.3 (0.44) |

| PLA 2 | 31.3 (0.87) | 0.04 (0.001) | 1.15 (8.05) | 1023 (35.6) | 1039 (128) | 9.59 (0.73) |

| PLA3 | 35.5 (1.93) | 0.04 (0.001) | 1.36 (0.06) | 940 (44.3) | 1030 (34.1) | 10.9 (0.06) |

| PLA 4 | 33.0 (2.02) | 0.04 (0.001) | 1.35 (0.11) | 950 (32.9) | 1161 (87.3) | 11.0 (1.23) |

| PLA 5 | 33.6 (3.10) | 0.04 (0.002) | 1.22 (0.05) | 917 (11.9) | 1017 (56.4) | 9.49 (0.40) |

| PLA 6 | 34.4 (0.63) | 0.04 (0.002) | 1.35 (0.11) | 904 (47.1) | 1069 (127) | 10.4 (0.77) |

| PLA 7 | 34.4 (2.12) | 0.04 (0.001) | 1.30 (0.09) | 910 (57.2) | 1002 (84.3) | 10.0 (0.67) |

| PLA 8 | 34.9 (3.32) | 0.04 (0.001) | 1.29 (0.13) | 928 (25.1) | 1065 (63.5) | 10.2 (0.85) |

| Treatment | Parameters | |||||

|---|---|---|---|---|---|---|

| Aggregates >250 µm (%) | Unsaturated * Hydraulic Conductivity (cm h−1) | Bulk Density (g cm−3) | Time Cero: N-(NO3+NO2) (mg/kg soil) | 28 days Incubation: N-(NO3+NO2) (mg/kg soil) | Rate of Mineralization N (%) | |

| PLA1 | 53.3 (16.9) | 0.43 (0.03) | 1.12 (0.04) | 19.9 (1.76) | 65.5 (3.46) | 231 (41.3) |

| PLA 2 | 52.8 (7.42) | 0.16 (0.07) | 1.17 (0.02) | 20.0 (2.80) | 75.5 (1.00) | 281 (45.3) |

| PLA 3 | 70.5 (5.37) | 0.12 (0.05) | 1.12 (0.03) | 19.8 (3.08) | 77.7 (16.0) | 303 (121.0) |

| PLA 4 | 71.2 (6.39) | 0.19 (0.05) | 1.15 (0.05) | 24.2 (9.87) | 69.2 (16.2) | 202 (82.4) |

| PLA 5 | 65.5 (5.47) | 0.12 (0.03) | 1.13 (0.03) | 22.8 (3.31) | 69.3 (11.8) | 212 (94.5) |

| PLA 6 | 67.8 (2.72) | 0.10 (0.14) | 1.12 (0.04) | 27.3 (3.18) | 76.7 (13.3) | 183 (63.4) |

| PLA 7 | 64.09 (5.31) | 0.16 (0.10) | 1.07 (0.08) | 21.00 (3.13) | 66.0 (3.28) | 220 (62.3) |

| PLA 8 | 66.15 (7.48) | 0.15 (0.06) | 1.15 (0.02) | 20.0 (3.90) | 83.3 (13.8) | 325 (88.7) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huerta-Lwanga, E.; Mendoza-Vega, J.; Ribeiro, O.; Gertsen, H.; Peters, P.; Geissen, V. Is the Polylactic Acid Fiber in Green Compost a Risk for Lumbricus terrestris and Triticum aestivum? Polymers 2021, 13, 703. https://doi.org/10.3390/polym13050703

Huerta-Lwanga E, Mendoza-Vega J, Ribeiro O, Gertsen H, Peters P, Geissen V. Is the Polylactic Acid Fiber in Green Compost a Risk for Lumbricus terrestris and Triticum aestivum? Polymers. 2021; 13(5):703. https://doi.org/10.3390/polym13050703

Chicago/Turabian StyleHuerta-Lwanga, Esperanza, Jorge Mendoza-Vega, Oriana Ribeiro, Henny Gertsen, Piet Peters, and Violette Geissen. 2021. "Is the Polylactic Acid Fiber in Green Compost a Risk for Lumbricus terrestris and Triticum aestivum?" Polymers 13, no. 5: 703. https://doi.org/10.3390/polym13050703

APA StyleHuerta-Lwanga, E., Mendoza-Vega, J., Ribeiro, O., Gertsen, H., Peters, P., & Geissen, V. (2021). Is the Polylactic Acid Fiber in Green Compost a Risk for Lumbricus terrestris and Triticum aestivum? Polymers, 13(5), 703. https://doi.org/10.3390/polym13050703