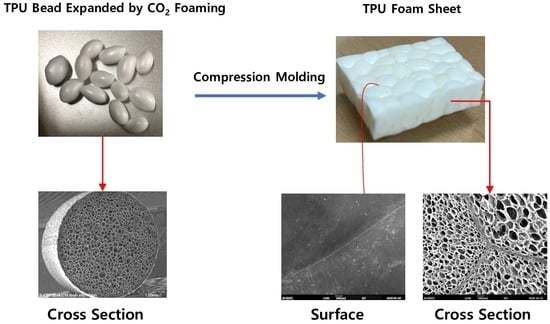

Compression Molding of Thermoplastic Polyurethane Foam Sheets with Beads Expanded by Supercritical CO2 Foaming

Abstract

1. Introduction

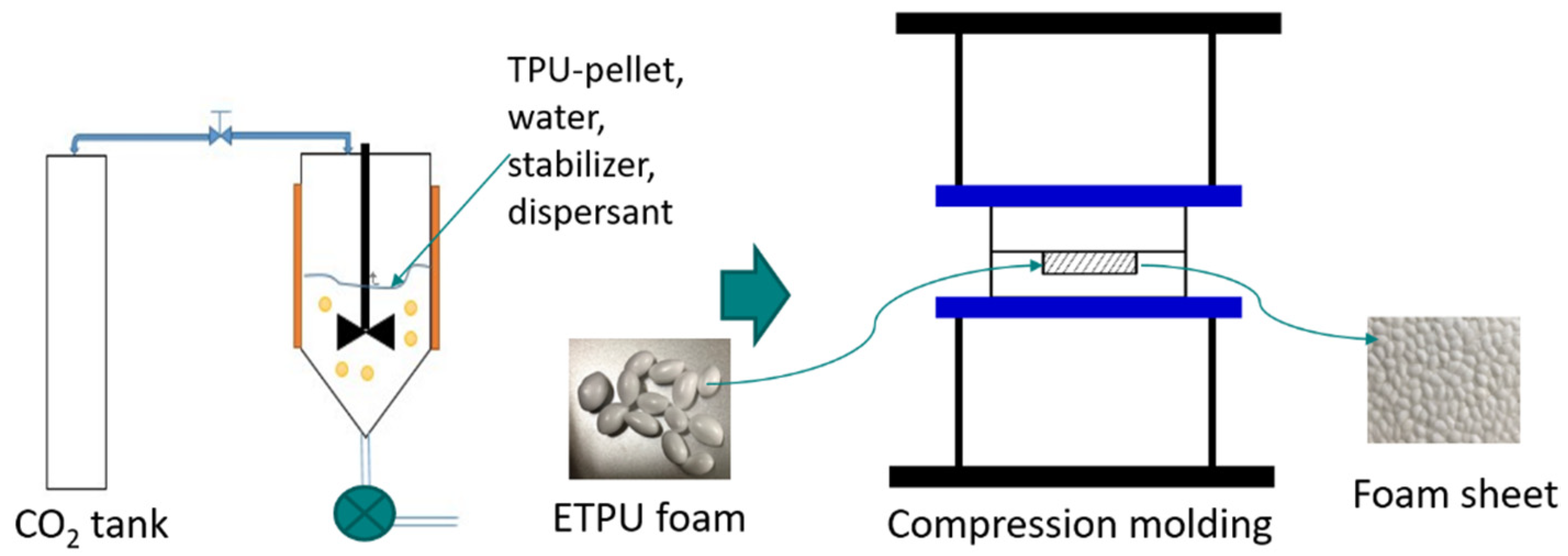

2. Materials and Methods

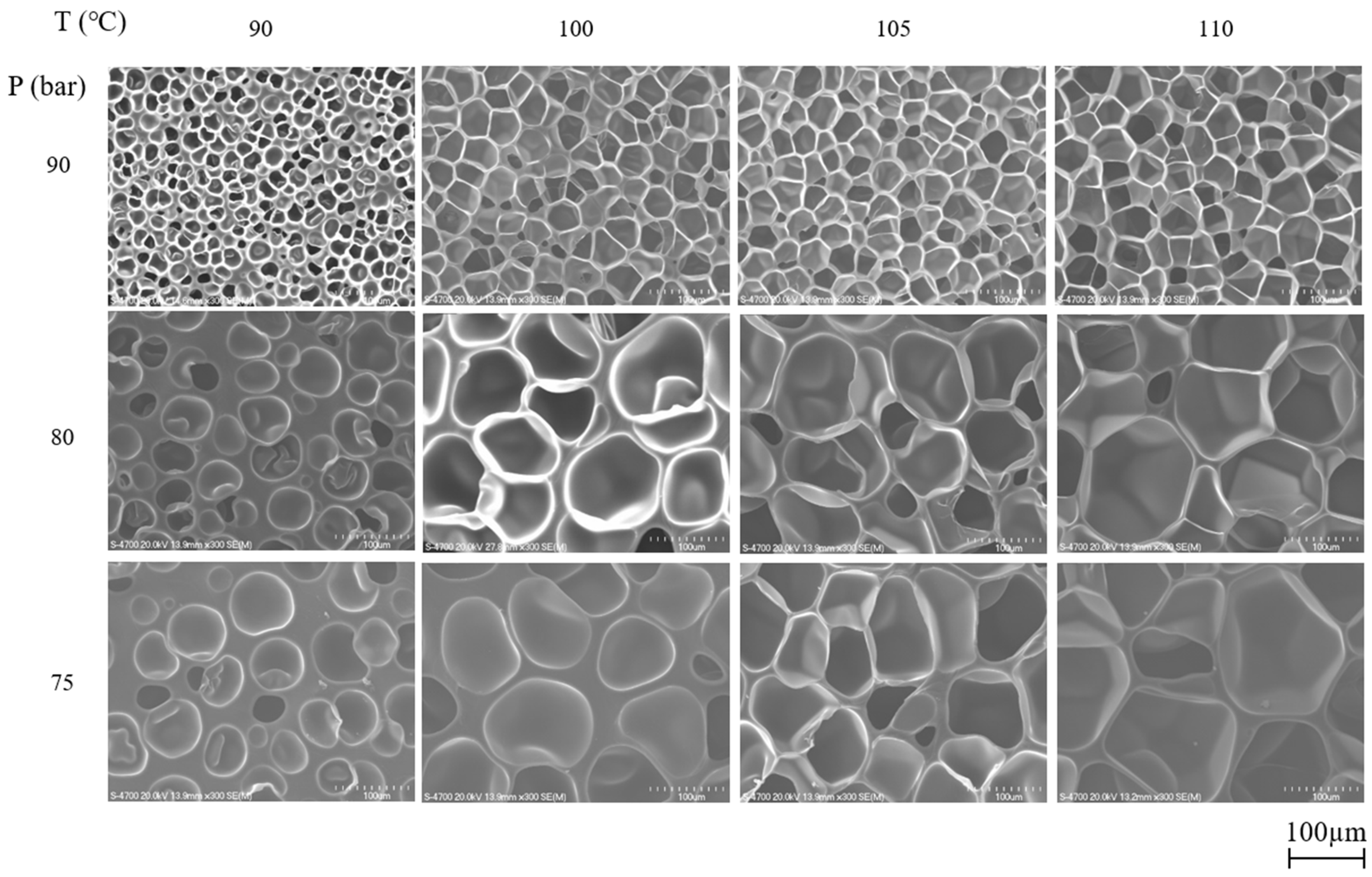

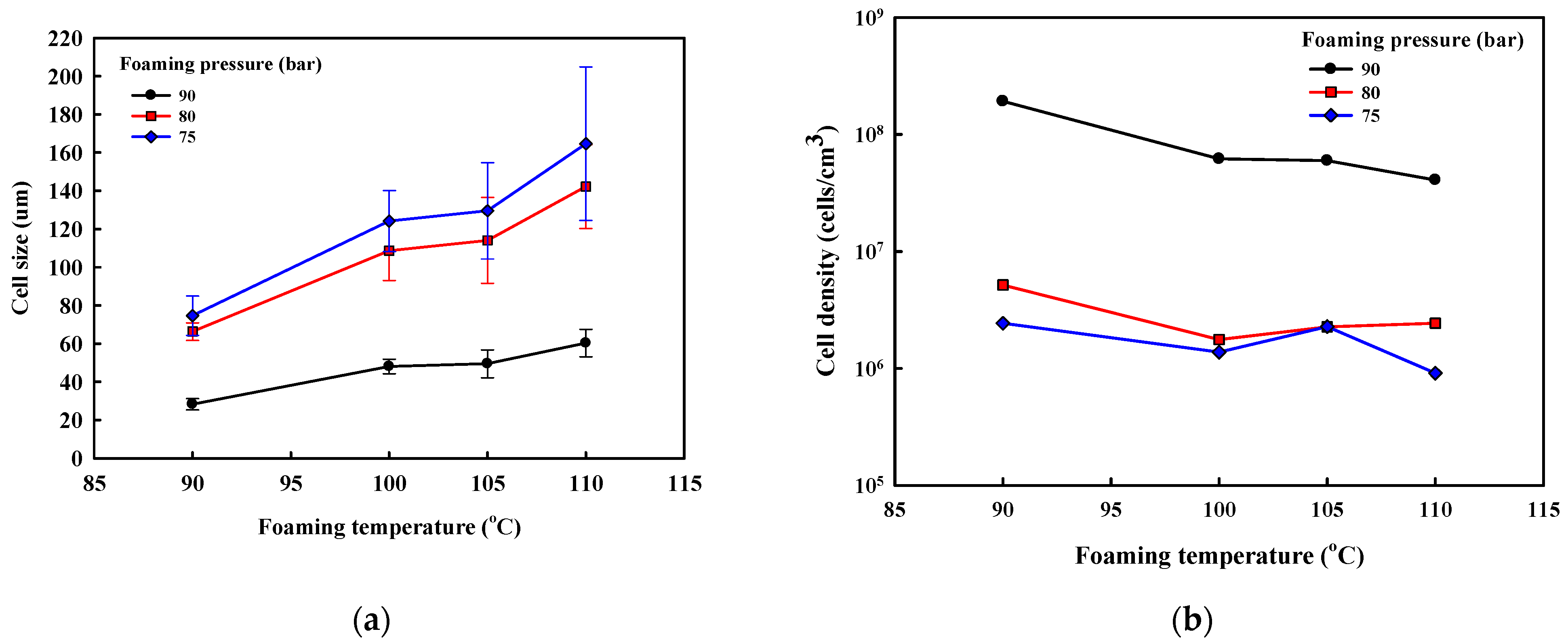

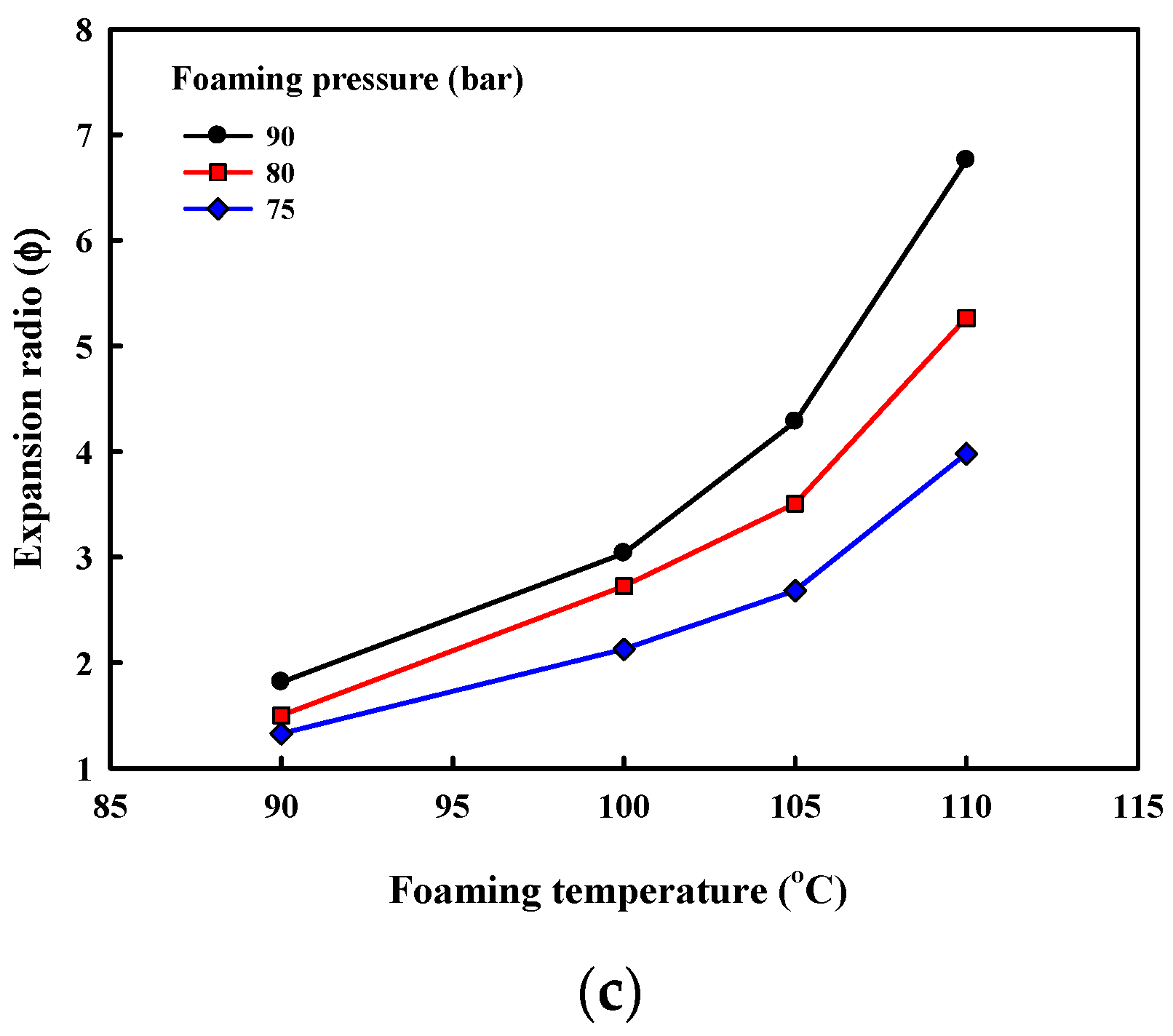

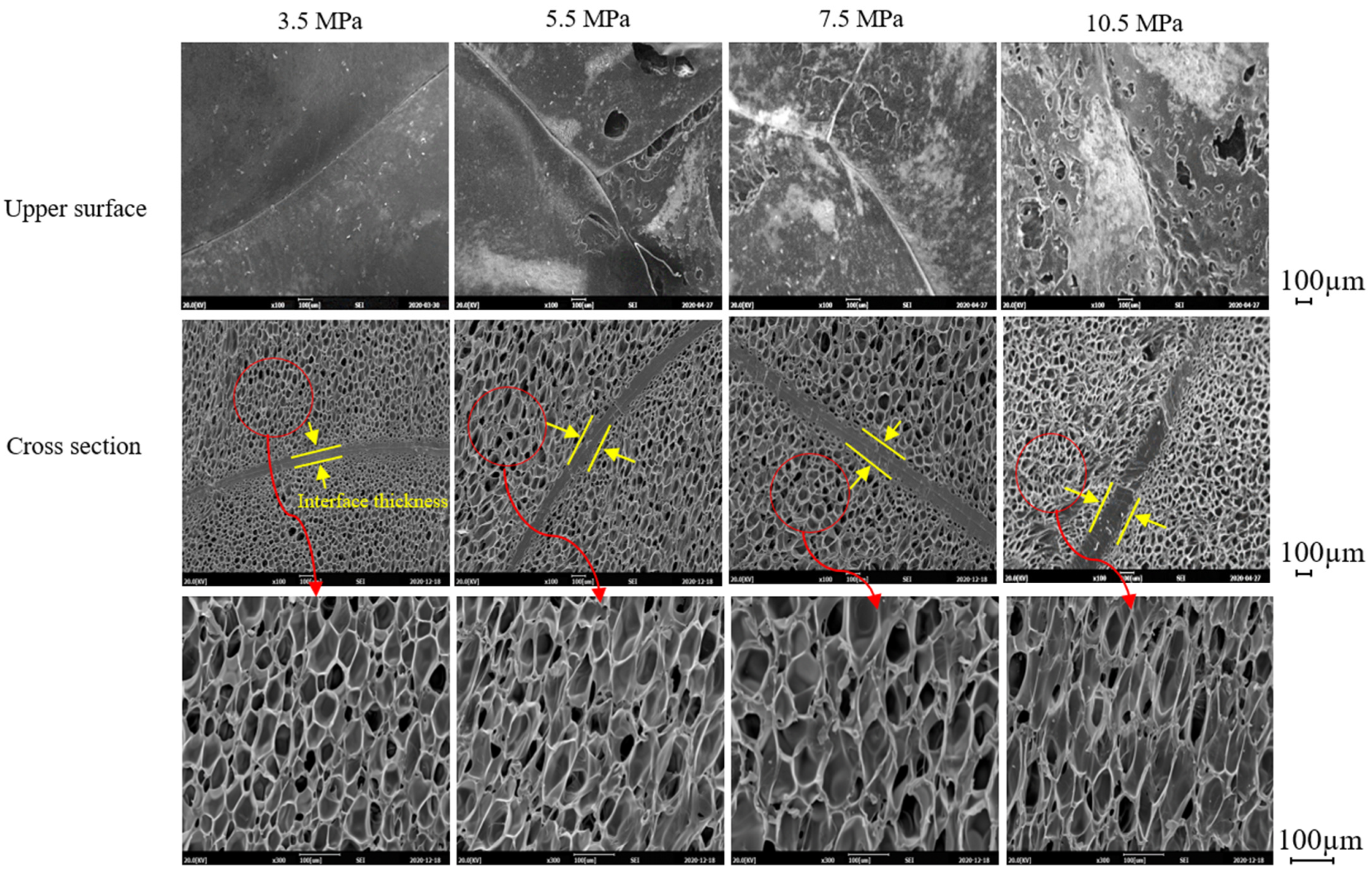

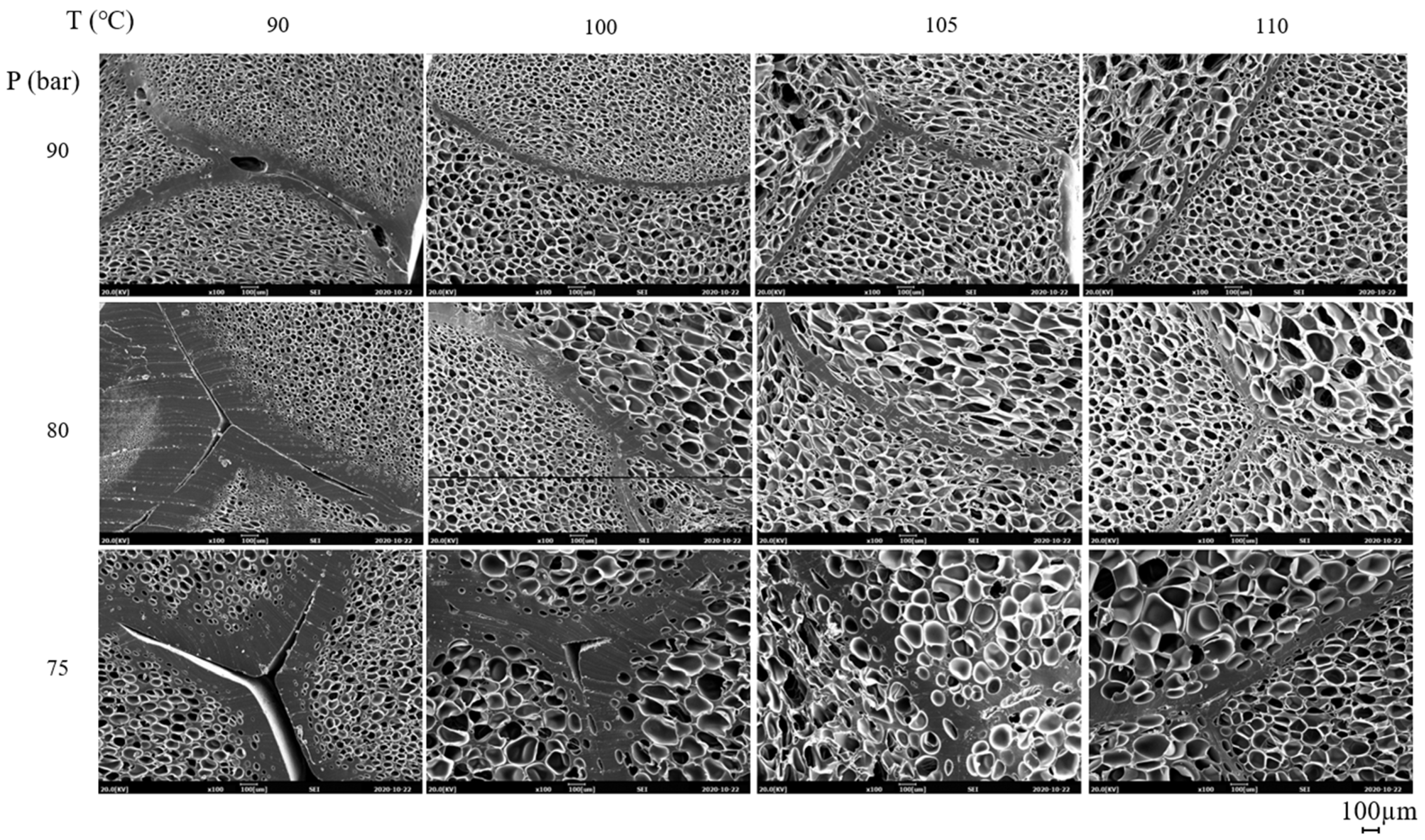

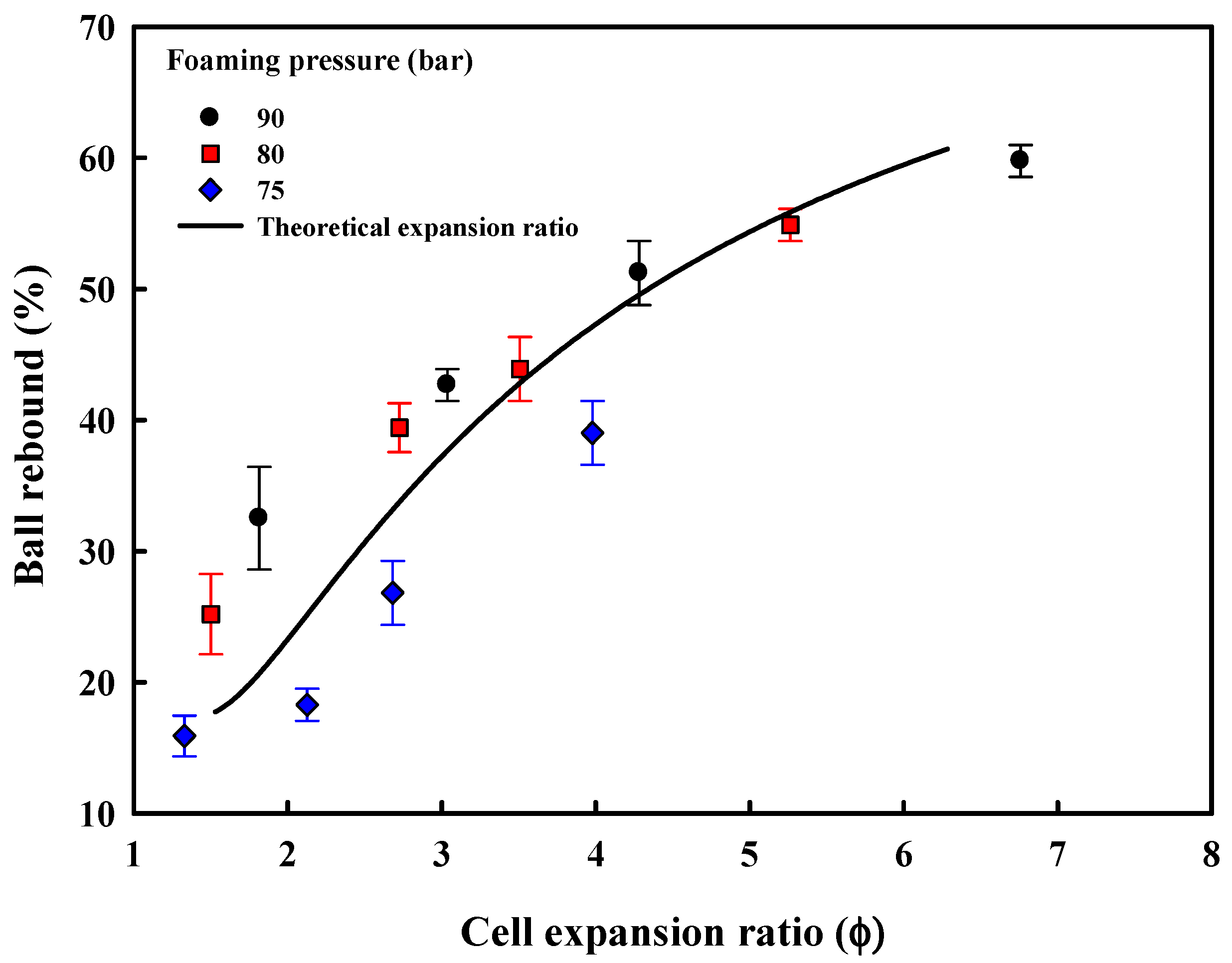

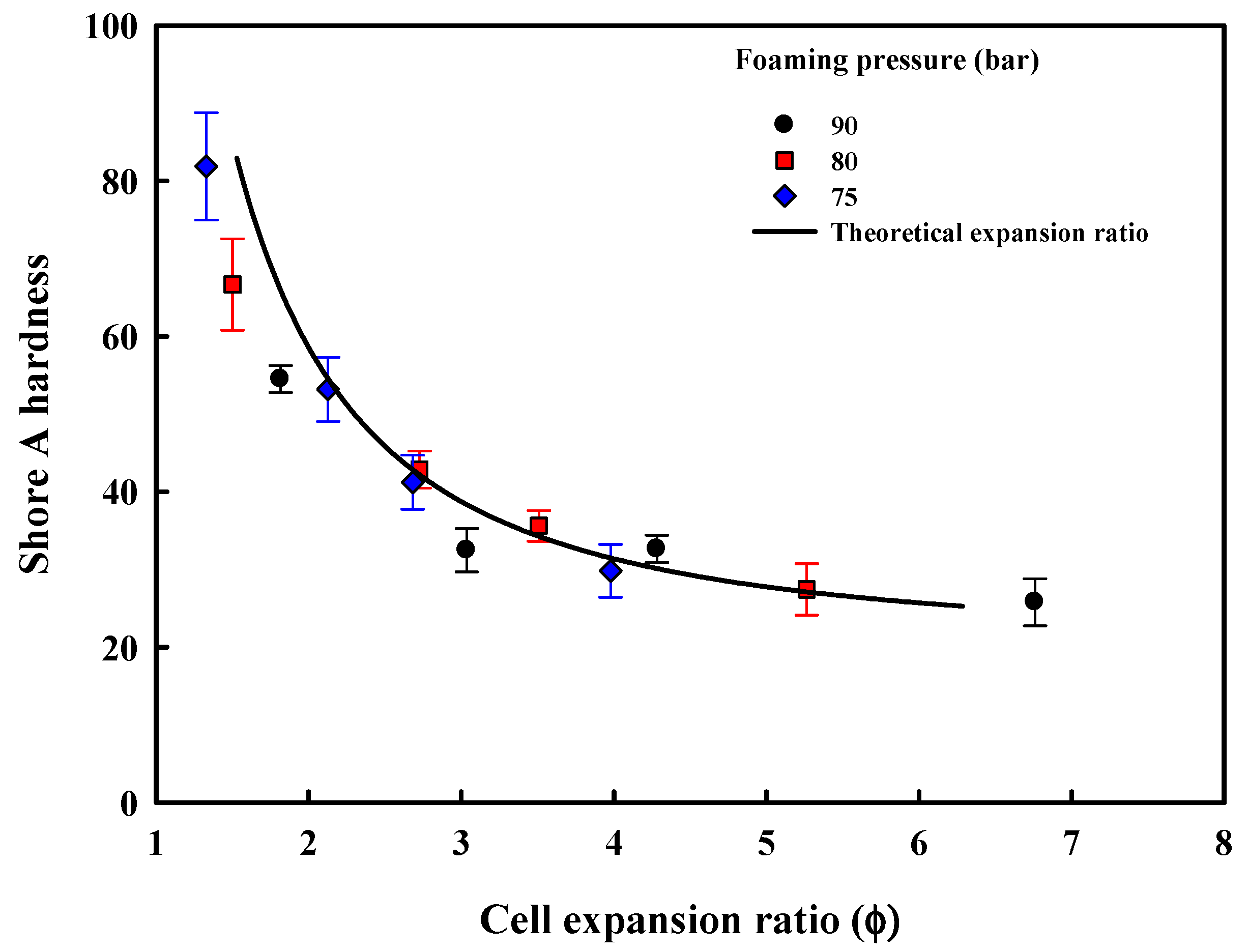

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mills, N.J. Chapter 1–Introduction to polymer foam microstructure. In Polymer Foams Handbook: Engineering and Biomechanics Application and Design Guide, 1st ed.; Butterworth-Heinemannn Ltd.: Oxford, UK, 2007; pp. 1–18. [Google Scholar]

- Han, X.M.; Zeng, C.C.; Lee, L.J.; Koelling, K.W.; Tomasko, D.L. Extrusion of Polystyrene Nanocomposite Foams With Supercritical CO2. Poly. Eng. Sci. 2003, 43, 1261–1275. [Google Scholar] [CrossRef]

- Hayashi, H.; Mori, T.; Okamoto, M.; Yamasaki, S.; Hayami, H. Polyethylene ionomer-based nano-composite foams prepared by a batch process and MuCell® injection molding. Mater. Sci. Eng. C 2010, 30, 62–70. [Google Scholar] [CrossRef]

- Gomez-Monterde, J.; Hain, J.; Sanchez-Soto, M.; Maspoch, M.L. Microcellular injection moulding: A comparison between MuCell process and the novel micro-foaming technology IQ Foam. J. Mater. Process. Technol. 2019, 268, 162–170. [Google Scholar] [CrossRef]

- Raps, D.; Hossieny, N.; Park, C.B.; Altstadt, V. Past and present developments in polymer bead foams and bead foaming technology. Polymer 2015, 56, 5–19. [Google Scholar] [CrossRef]

- Nofar, M.; Ameli, A.; Park, C.B. A novel technology to manufacture biodegradable polylactide bead foam products. Mater. Des. 2015, 83, 413–421. [Google Scholar] [CrossRef]

- Kang, D.H.; Oh, S.S.; Kim, H.I. Improvement of Physical Properties of Polypropylene Chemical Foam by Glass Fiber Reinforcement. Polym. Korea 2019, 43, 589–594. [Google Scholar] [CrossRef]

- Li, Q.; Matuana, L.M. Foam extrusion of high density polyethylene/wood-flour composites using chemical foaming agents. J. Appl. Polym. Sci. 2003, 28, 3139–3150. [Google Scholar] [CrossRef]

- Shin, J.H.; Lee, H.K.; Song, K.B.; Lee, K.H. Characterization of Poly(lactic acid) Foams Prepared with Supercritical Carbon Dioxode. Polym. Korea 2013, 37, 685–693. [Google Scholar] [CrossRef][Green Version]

- Sun, Y.; Usda, Y.; Suganaga, H.; Haruki, M.; Kihara, S.; Takishima, S. Pressure drop threshold in the foaming of low density polyethylene, polystyrene, and polypropylene using CO2 and N2 as foaming agents. J. Supercrit. Fluid. 2015, 103, 38–47. [Google Scholar] [CrossRef]

- He, J.; Gao, Q.; Song, X.; Bu, X.; He, J. Effect of foaming agent on physical and mechanical properties of alkali-activated slag foamed concrete. Constr. Build. Mater. 2019, 226, 280–287. [Google Scholar] [CrossRef]

- Zhang, R.; Huang, K.; Hu, S.F.; Liu, Q.T.; Zhao, X.; Liu, Y. Improved cell morphology and reduced shrinkage ratio of ETPU beads by reactive blending. Polym. Test. 2017, 63, 38–46. [Google Scholar] [CrossRef]

- Standau, T.; Hadelt, B.; Schreier, P.; Altstadt, V. Development a Bead Foam from an Engineering Polymer with Addition of Chain Extender: Expanded Polybutylene Terephthalate. Ind. Eng. Chem. Res. 2018, 57, 17170–17176. [Google Scholar] [CrossRef]

- Shen, J.; Cao, X.; Lee, L.J. Synthesis and foaming of water expandable polystyrene-clay nanocomposites. Polymer 2006, 47, 6303–6310. [Google Scholar] [CrossRef]

- Wali, K.F.; Bhavnani, H.; Overfelt, R.A.; Sheldon, D.S.; Williams, K. Investigation of the Performance of an Expandable Polystyrene Injector for Use on the Lost-Foam Casting Process. Metall. Mater. Trans. B 2003, 34, 843–851. [Google Scholar] [CrossRef]

- Ruiz, J.A.R.; Vincent, M.; Agassant, J.F.; Sadik, T.; Caroline, P. Polymer foaming with chemical blowing agents: Experiment and modeling. Polym. Eng. Sci. 2015, 55, 2018–2029. [Google Scholar] [CrossRef]

- Hossieny, N.J.; Barzegari, M.R.; Nofar, M.; Mahmood, S.H.; Park, C.B. Crystallization of hard segment domains with the presence of butane for microcellular thermoplastic polyurethane foams. Polymer 2014, 55, 651–662. [Google Scholar] [CrossRef]

- Guo, Y.; Hossieny, N.; Chu, R.K.M.; Park, C.B.; Zhou, N. Critical processing parameters for foamed bead manufacturing in a lab-scale autoclave system. Chem. Eng. J. 2013, 214, 180–188. [Google Scholar] [CrossRef]

- Naduib, H.E.; Park, C.B.; Reichelt, N. Fundamental Foaming Mechanisms Governing the Volume Expansion of Extruded Polypropylene Foams. J. Appl. Polym. Sci. 2004, 91, 2661–2668. [Google Scholar]

- Ji, W.; Wang, D.; Guo, J.; Fei, B.; Gu, X.; Li, H.; Sun, J.; Zhang, S. The preparation of starch derivatives reacted with urea-phosphoric acid and effect on fire performance of expandable polystyrene foams. Carbohydr. Polymers 2020, 233, 115841. [Google Scholar]

- Nofar, M.; Guo, Y.; Park, C.B. Double Crystal Melting Peak Generation for Expanded Polypropylene Bead Foam Manufacturing. Ind. Eng. Chem. Res. 2013, 52, 2297–2303. [Google Scholar] [CrossRef]

- Sulong, N.H.R.; Mustapa, S.A.S.; Rashid, M.K.A. Application of expanded polystyrene (EPS) in buildings and constructions: A review. J. Appl. Polym. Sci. 2019, 136, 47529–47539. [Google Scholar] [CrossRef]

- Guo, P.; Xu, Y.; Lu, M.; Zhang, S. Expanded Linear Low- Density Polyethylene Beads: Fabrication, Melt Strength, and Foam Morphology. Ind. Eng. Chem. Res. 2016, 55, 8104–8113. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, G.; Wang, C.; Park, C.B. Ultra-lightweight, super thermal-insulation and strong PP/CNT microcellular foams. Compos. Sci. Technol. 2020, 191, 108084–108095. [Google Scholar] [CrossRef]

- Srivastava, V.; Srivastava, R. A Review on Manufacturing, Properties and Application of Expanded Polypropylene. MIT. Int. J. Mech. Eng. 2014, 4, 22–28. [Google Scholar]

- Ge, C.B.; Wang, S.P.; Zheng, W.G.; Zhai, W.T. Preparation of Microcellular Thermoplastic Polyurethane (TPU) Foam and Its Tensile Property. Polym. Eng. Sci. 2018, 58, E158–E166. [Google Scholar] [CrossRef]

- Jiang, X.; Zhao, L.; Feng, L.; Chen, C. Microcellular Thermoplastic Polyurethanes and their flexible properties prepared by mold foaming process with supercritical CO2. J. Cell. Plast. 2019, 55, 615–631. [Google Scholar] [CrossRef]

- Zhai, W.T.; Kim, Y.W.; Jung, D.W.; Park, C.B. Steam-Chest Molding of Expanded Polypropylene Foams. 2. Mechanism of Interbead Bonding. Ind. Eng. Chem. Res. 2011, 50, 5523–5531. [Google Scholar] [CrossRef]

- Hossieny, N.; Ameli, A.; Park, C.B. Characterization of Expanded Polypropylene Bead Foams with Modified Steam-Chest Molding. Ind. Eng. Chem. Res. 2013, 52, 8236–8247. [Google Scholar] [CrossRef]

- Ge, C.B.; Een, Q.; Wang, S.P.; Zheng, W.G.; Zhai, W.T.; Park, C.B. Steam-chest molding of expanded thermoplastic polyurethane bead foams and their mechanical properties. Chem. Eng. Sci. 2017, 174, 337–346. [Google Scholar] [CrossRef]

- Zhao, D.; Wang, G.J.; Wang, M.H. Investigation of the effect of foaming process parameters on expanded thermoplastic polyurethane bead foams properties using response surface methodology. J. Appl. Polym. Sci. 2018, 135, 46327–46337. [Google Scholar] [CrossRef]

- Okolieocha, C.; Raps, D.; Subramanianm, K.; Altstadt, V. Microcellular to nanocellular polymer foams: Progress (2004–2015) and future directions-A review. Eur. Polym. J. 2015, 73, 500–519. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, T.; Lee, S.-J.; Yoo, Y.H.; Park, K.-H.; Kang, H.-J. Compression Molding of Thermoplastic Polyurethane Foam Sheets with Beads Expanded by Supercritical CO2 Foaming. Polymers 2021, 13, 656. https://doi.org/10.3390/polym13040656

Zhang T, Lee S-J, Yoo YH, Park K-H, Kang H-J. Compression Molding of Thermoplastic Polyurethane Foam Sheets with Beads Expanded by Supercritical CO2 Foaming. Polymers. 2021; 13(4):656. https://doi.org/10.3390/polym13040656

Chicago/Turabian StyleZhang, Tao, Seung-Jun Lee, Yong Hwan Yoo, Kyu-Hwan Park, and Ho-Jong Kang. 2021. "Compression Molding of Thermoplastic Polyurethane Foam Sheets with Beads Expanded by Supercritical CO2 Foaming" Polymers 13, no. 4: 656. https://doi.org/10.3390/polym13040656

APA StyleZhang, T., Lee, S.-J., Yoo, Y. H., Park, K.-H., & Kang, H.-J. (2021). Compression Molding of Thermoplastic Polyurethane Foam Sheets with Beads Expanded by Supercritical CO2 Foaming. Polymers, 13(4), 656. https://doi.org/10.3390/polym13040656