Towards Next-Generation Sustainable Composites Made of Recycled Rubber, Cenospheres, and Biobinder

Abstract

1. Introduction

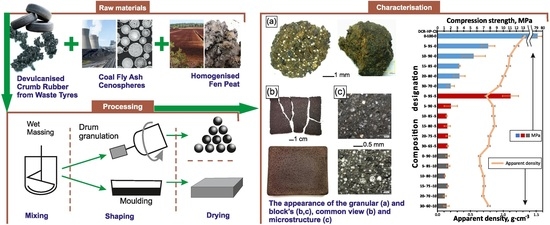

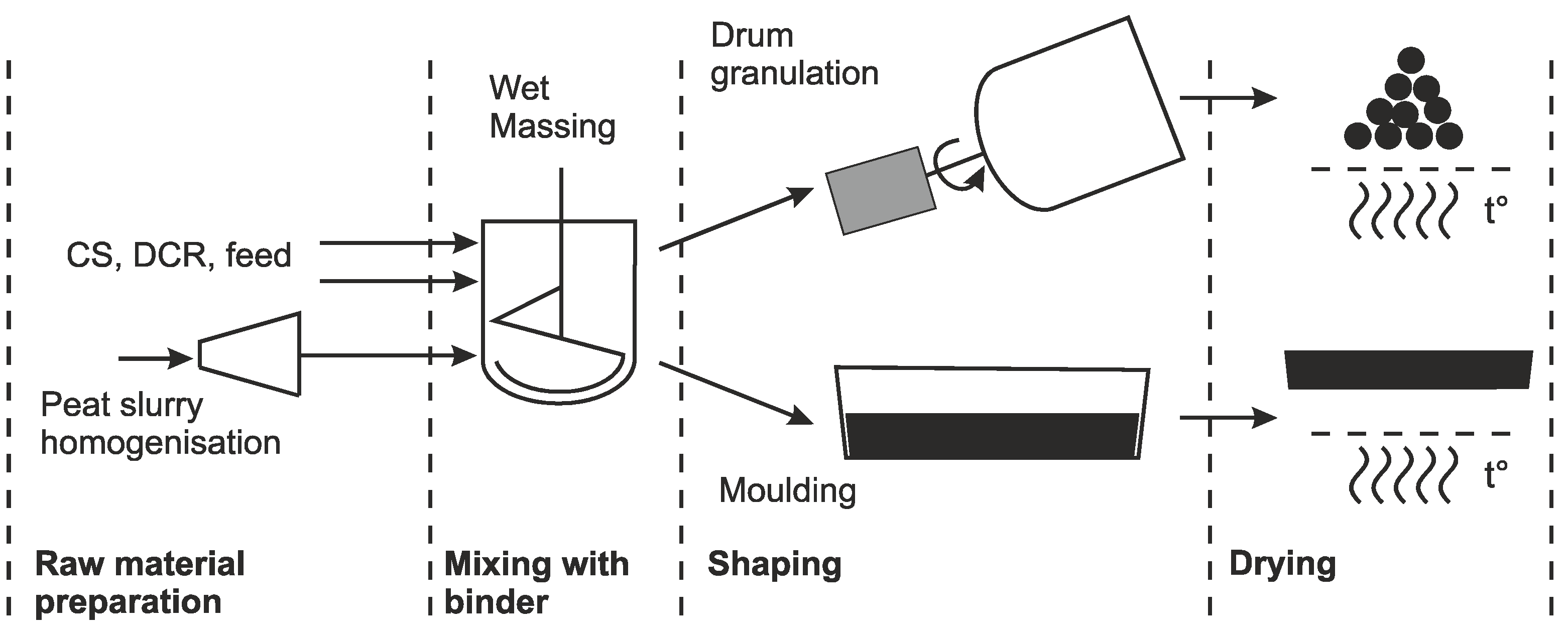

2. Materials and Methods

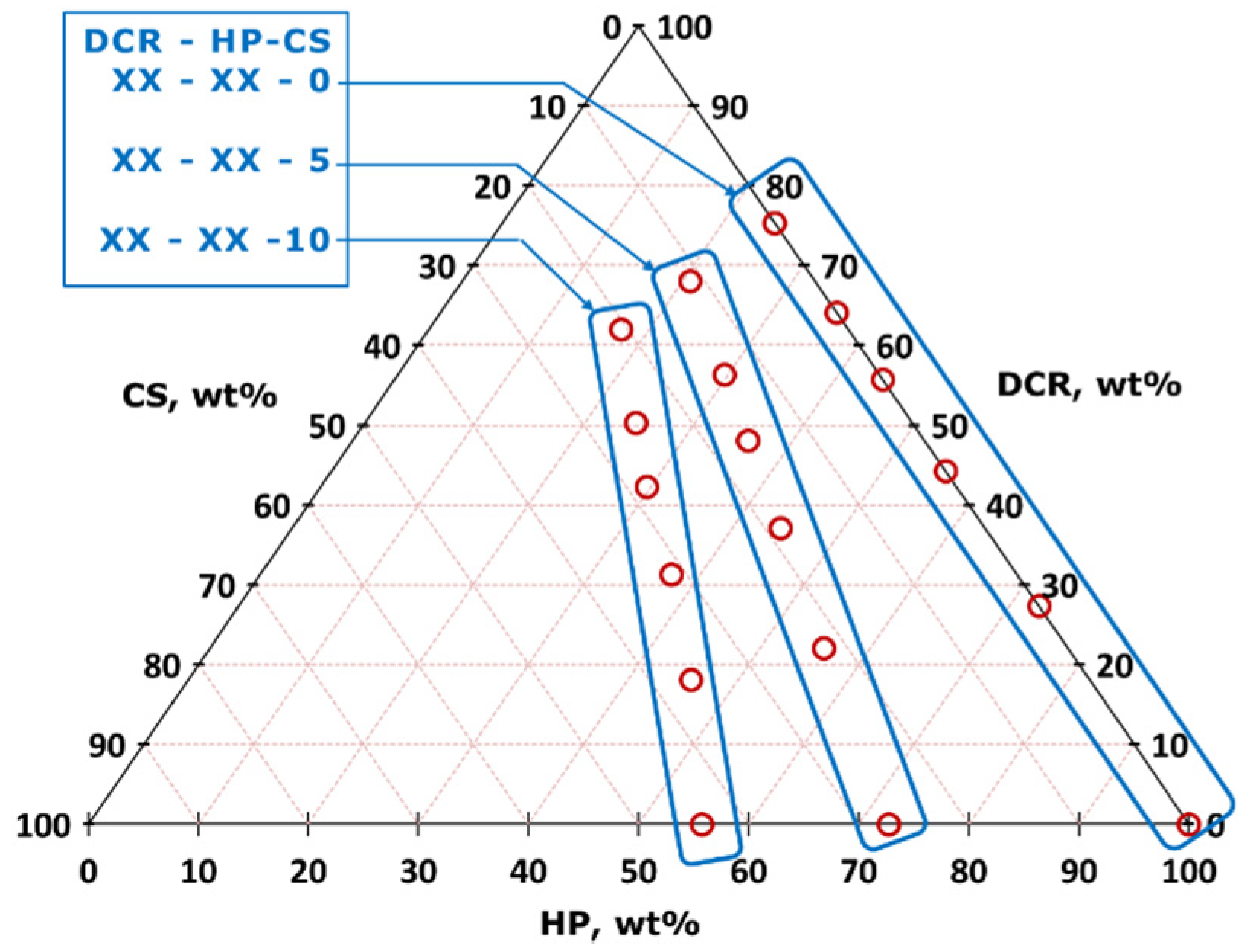

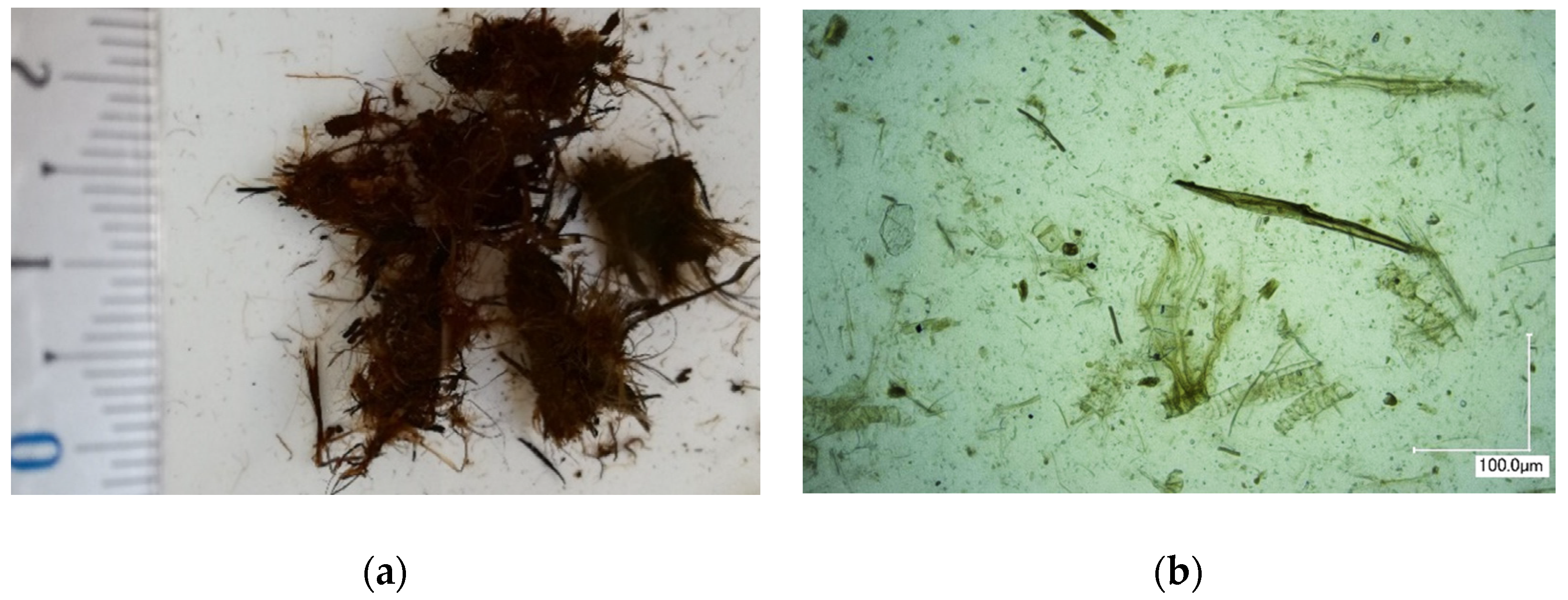

2.1. Raw Materials and Compositions

2.2. Characterisation Methods

Liquid Adsorption

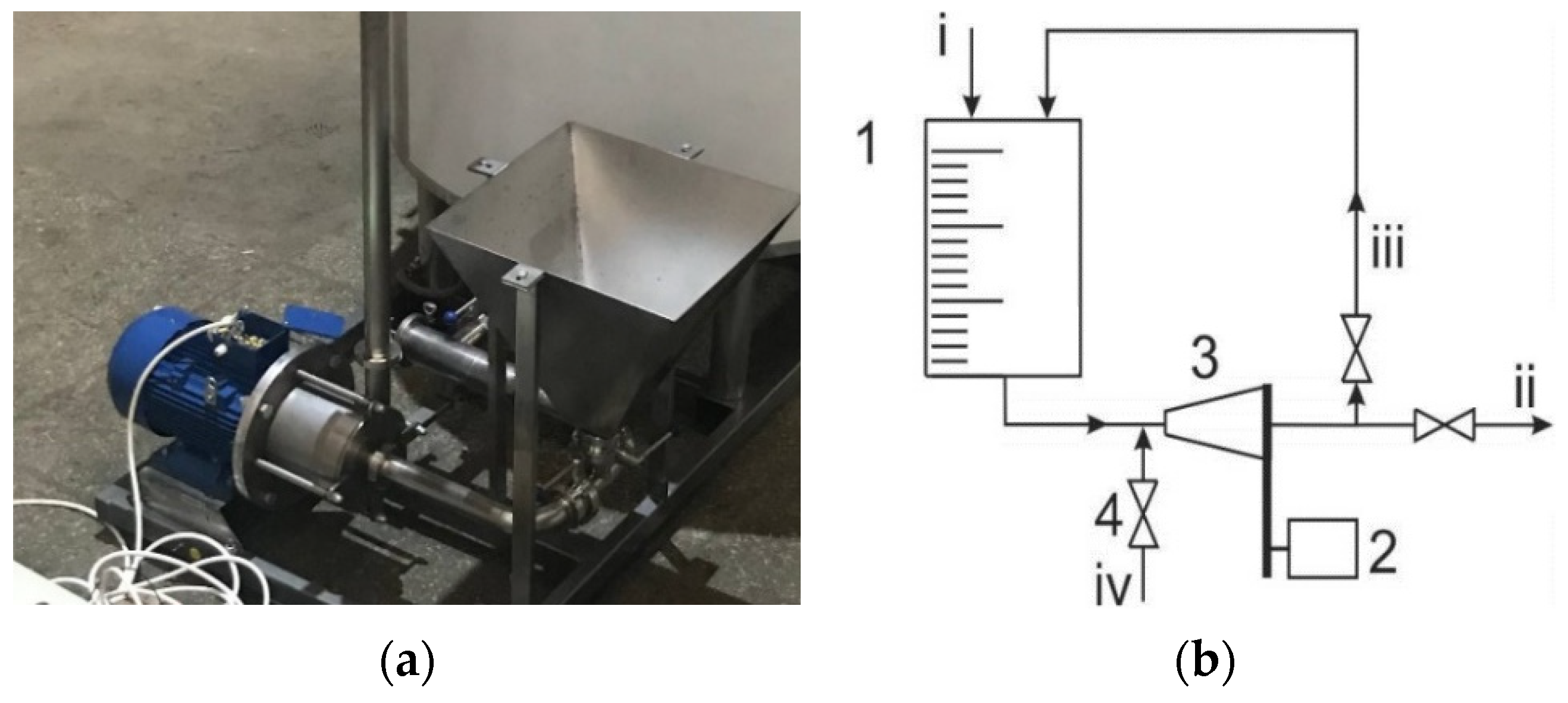

2.3. Used Equipment and Measurement Devices

3. Results

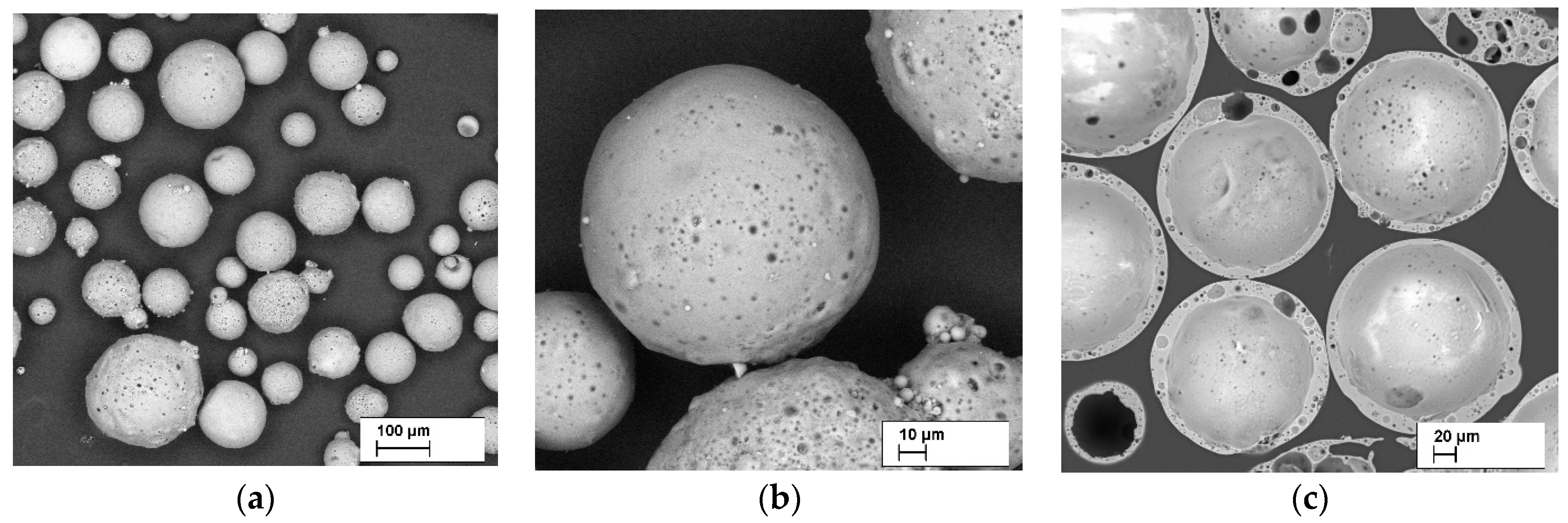

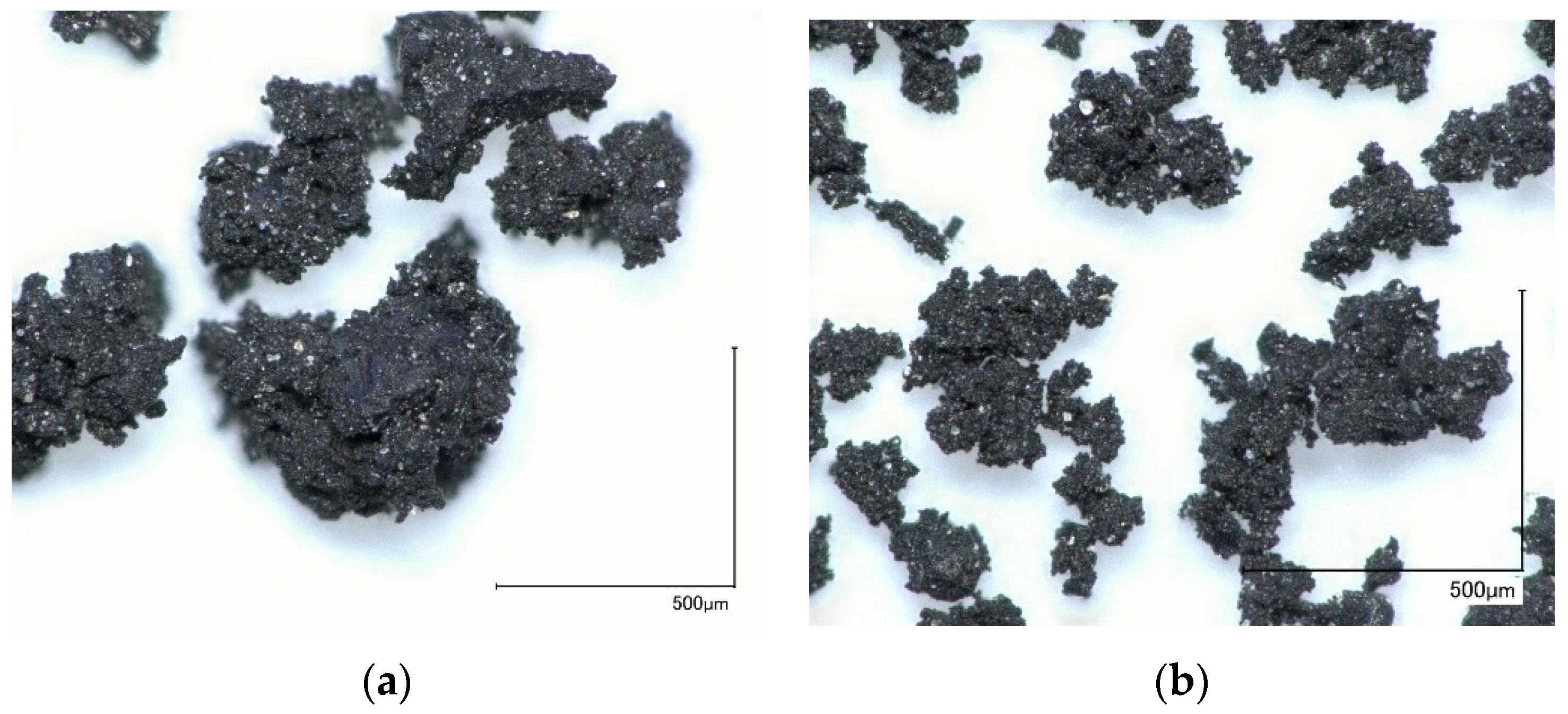

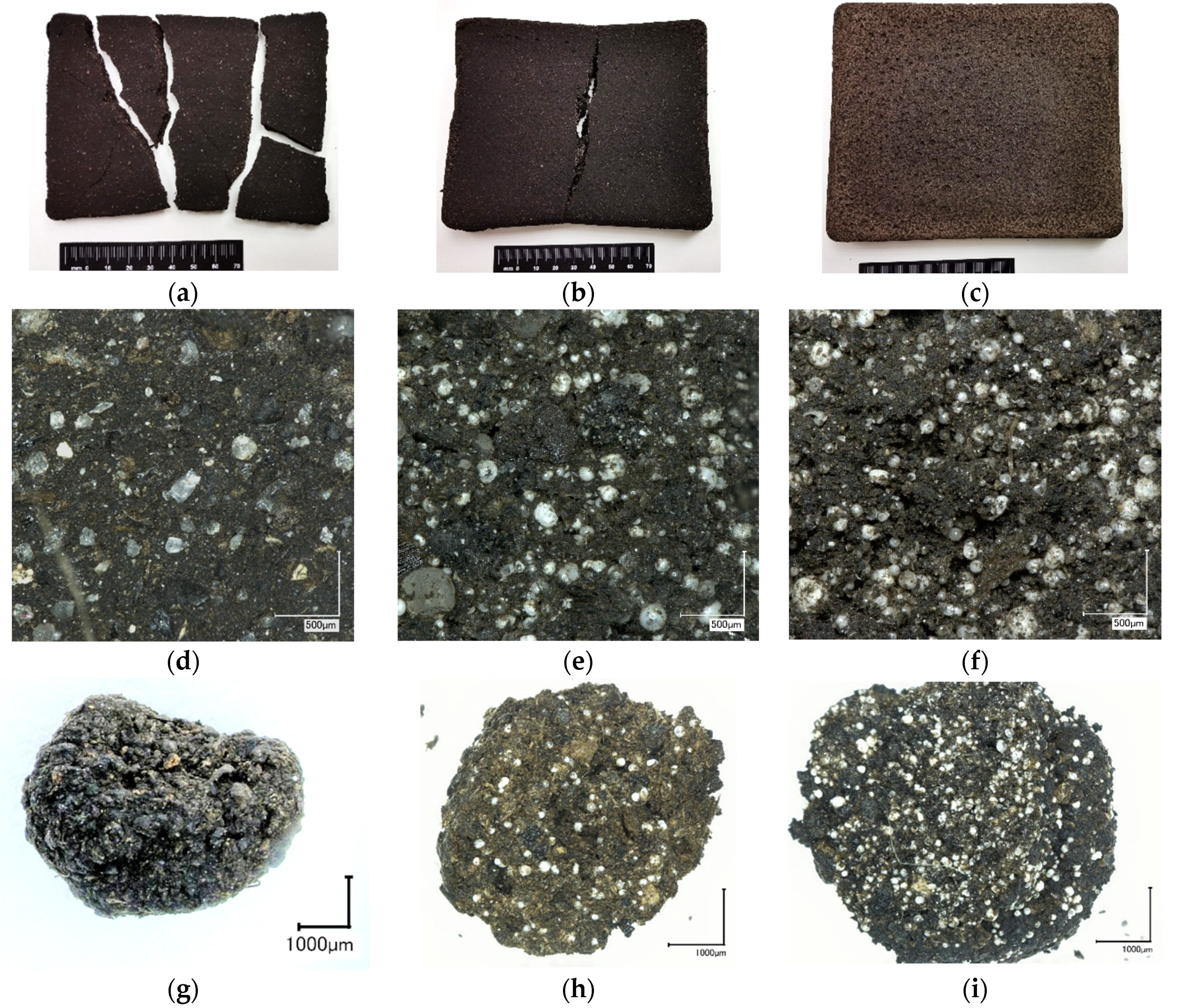

3.1. Morphology of the Obtained Biocomposite Block and Granules

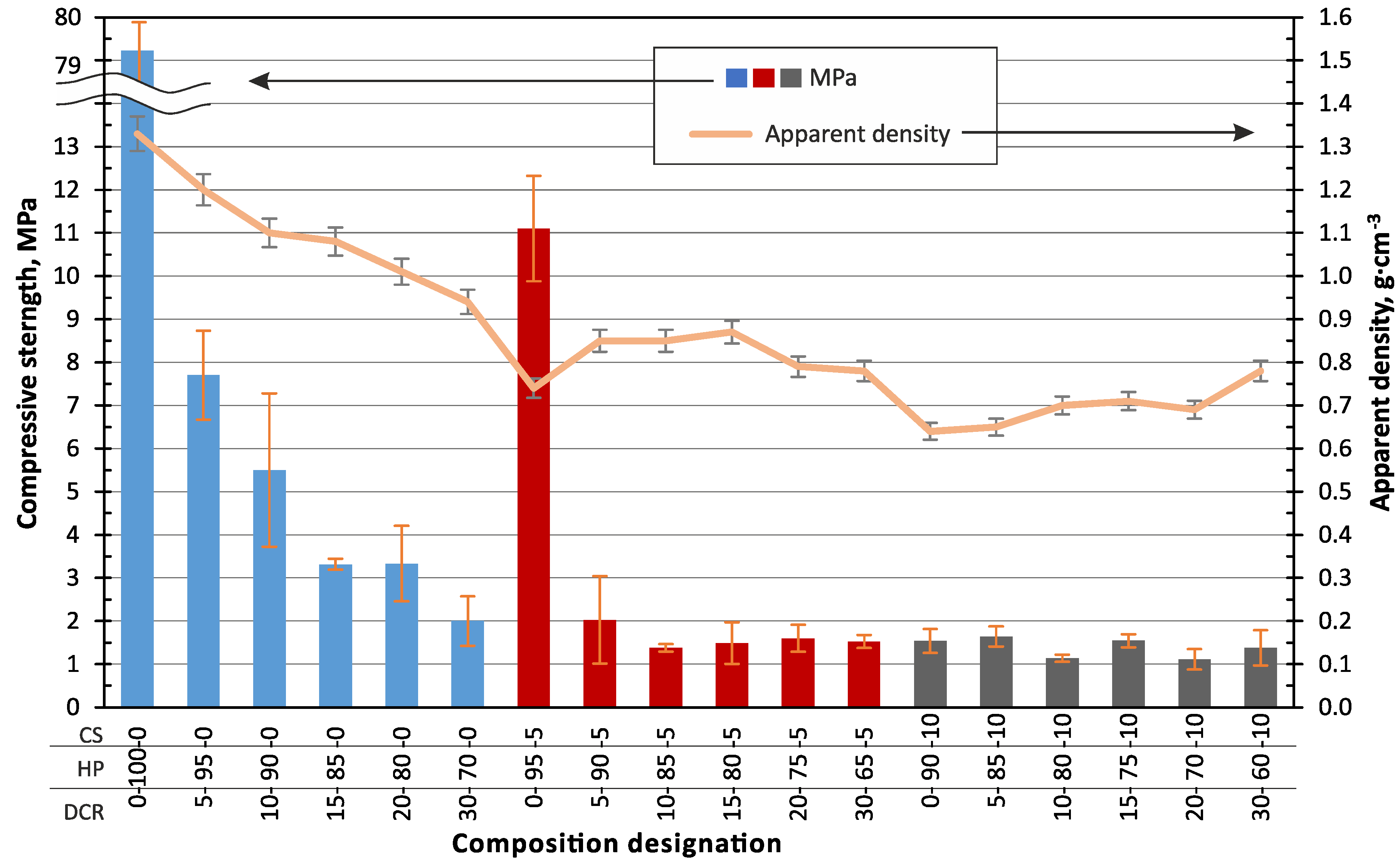

3.2. Mechanical Properties and Density of the Obtained Biocomposite Block and Granules

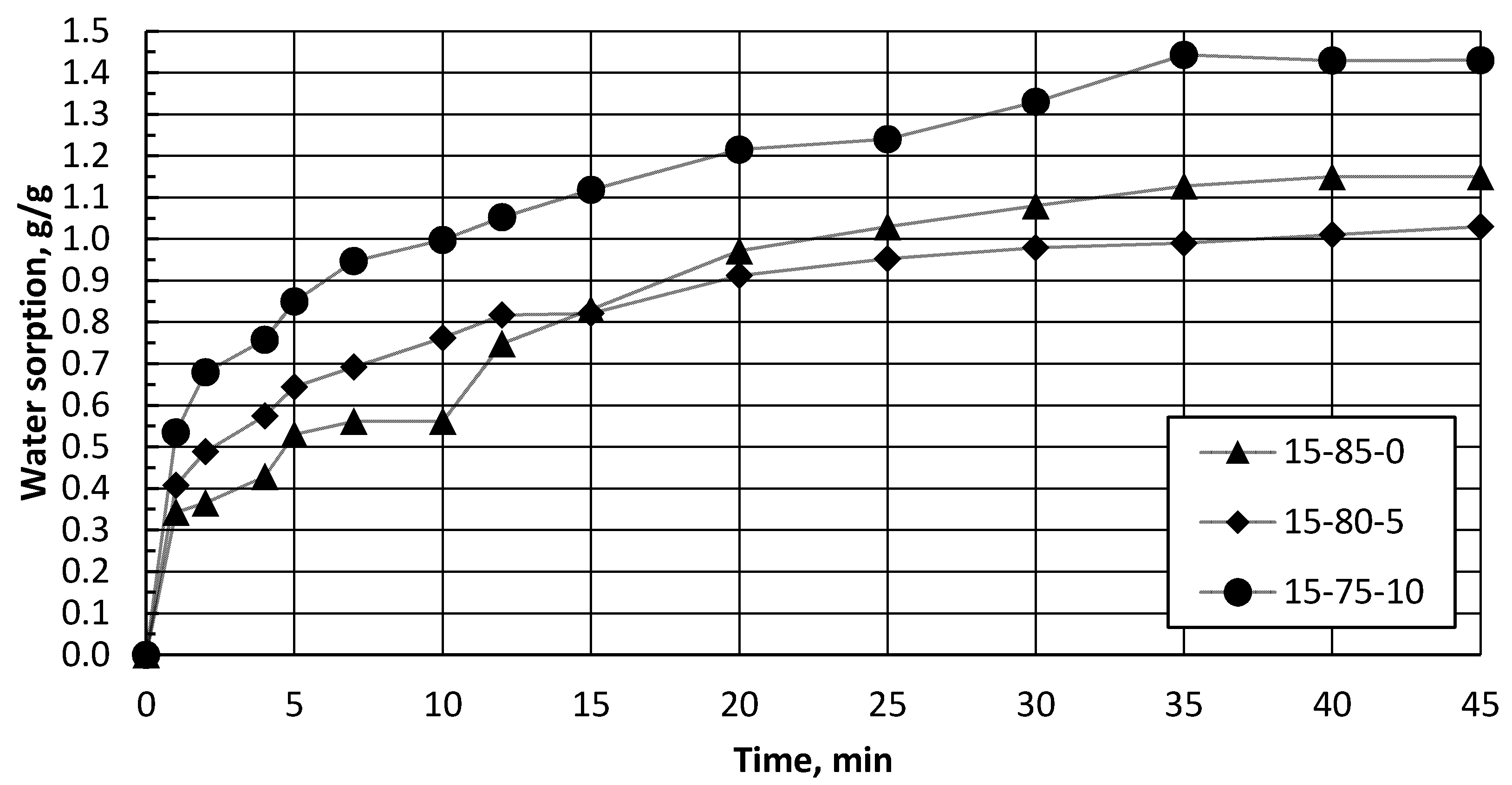

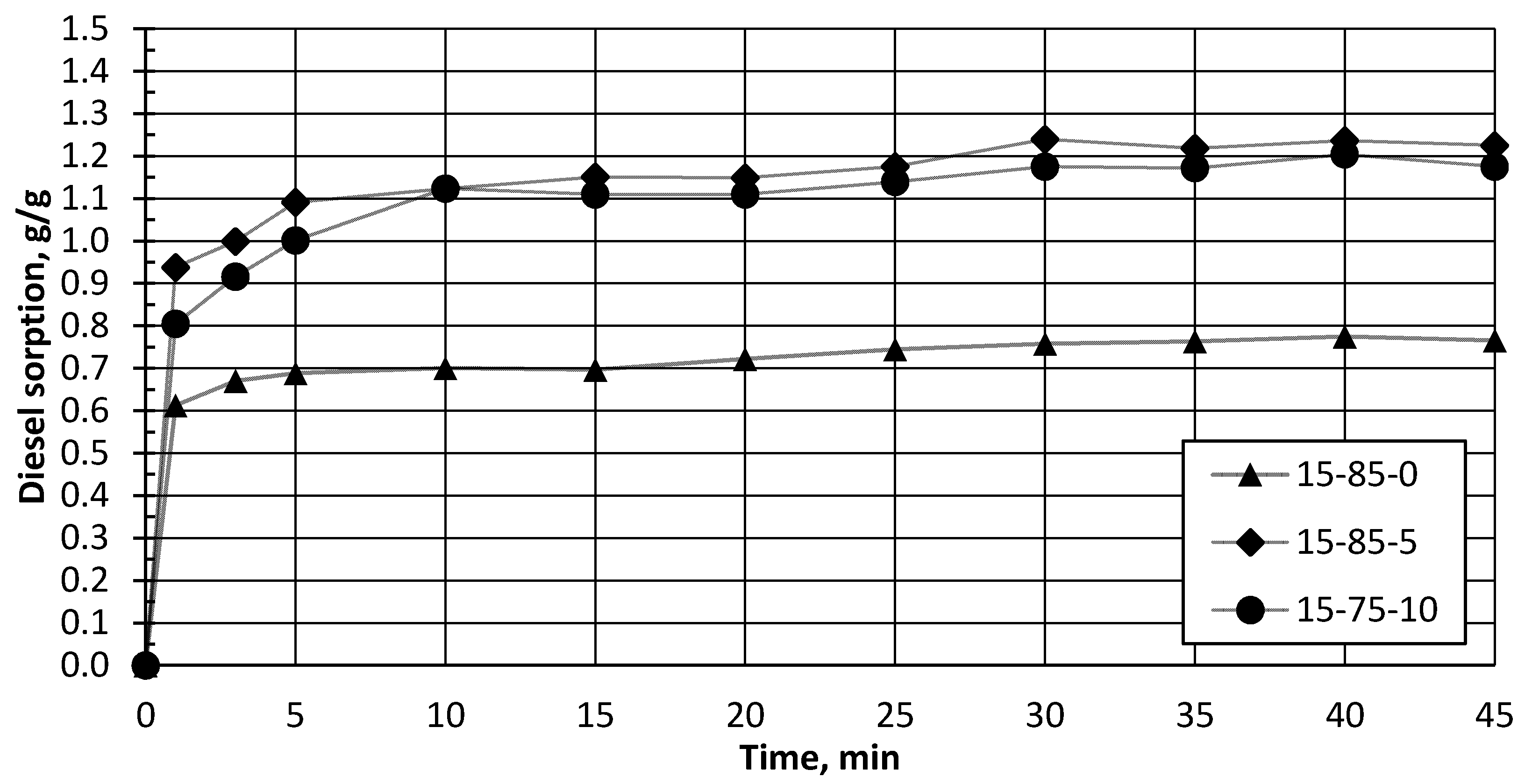

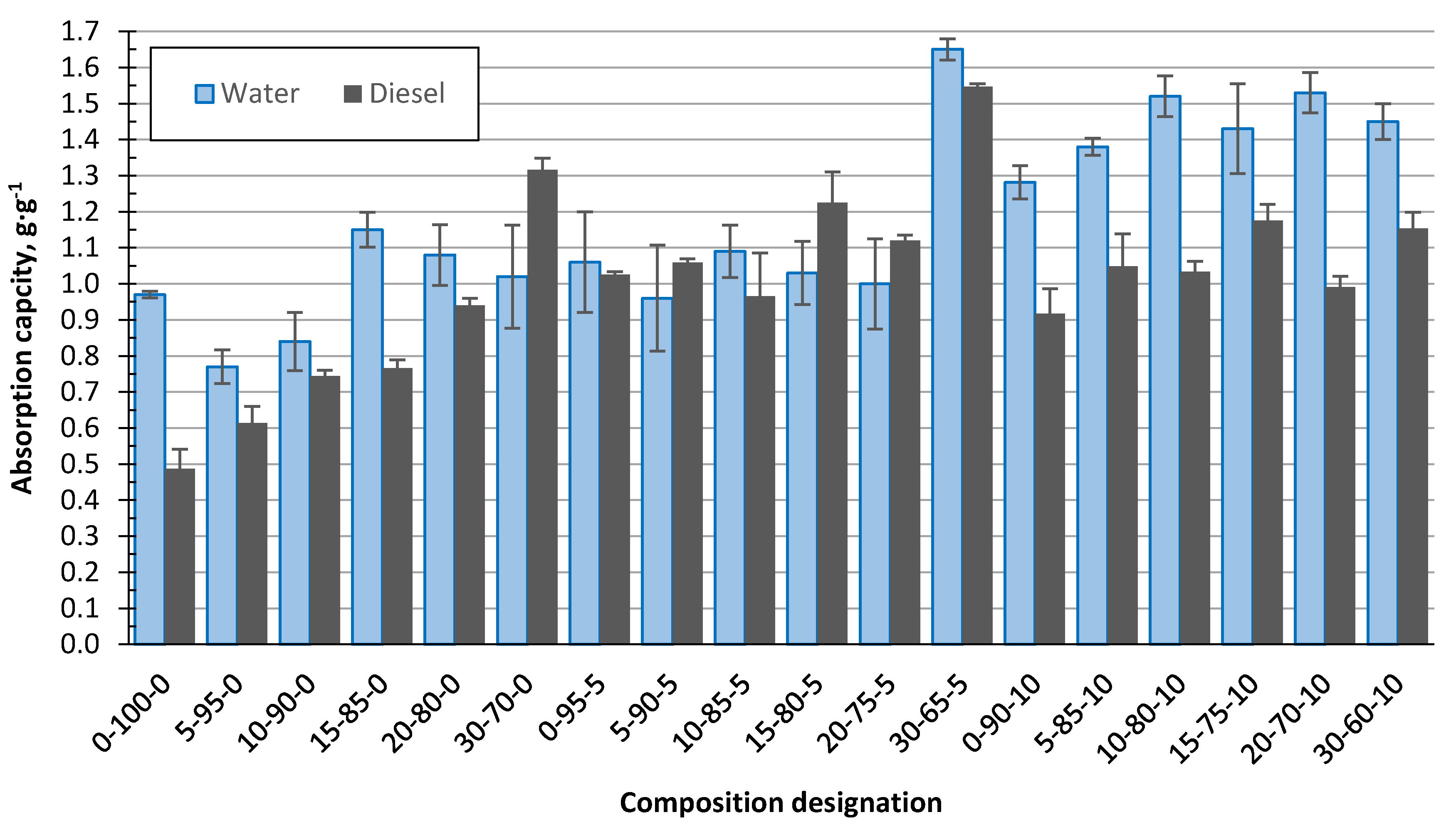

3.3. Sorption of Liquids in the Structure of the Granulated Biocomposites

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ranjbar, N.; Kuenzel, C. Cenospheres: A review. Fuel 2017, 207, 1–12. [Google Scholar] [CrossRef]

- Rugele, K.; Lehmhus, D.; Hussainova, I.; Peculevica, J.; Lisnanskis, M.; Shishkin, A. Effect of Fly-Ash Cenospheres on Properties of Clay-Ceramic Syntactic Foams. Materials 2017, 10, 828. [Google Scholar] [CrossRef]

- Shishkin, A.; Mironov, V.; Zemchenkov, V.; Antonov, M.; Hussainova, I. Hybrid Syntactic Foams of Metal—Fly Ash Cenosphere—Clay. Key Eng. Mater. 2016, 674, 35–40. [Google Scholar] [CrossRef]

- Santa Maria, J.A.; Schultz, B.F.; Ferguson, J.B.; Gupta, N.; Rohatgi, P.K. Effect of hollow sphere size and size distribution on the quasi-static and high strain rate compressive properties of Al-A380–Al2O3 syntactic foams. J. Mater. Sci. 2014, 49, 1267–1278. [Google Scholar] [CrossRef]

- Tatarinov, A.; Shishkin, A.; Mironovs, V. Correlation between ultrasound velocity, density and strength in metal-ceramic composites with added hollow spheres. IOP Conf. Ser. Mater. Sci. Eng. 2019, 660, 012040. [Google Scholar] [CrossRef]

- Jiang, F.; Zhang, L.; Mukiza, E.; Qi, Z.; Cang, D. Formation mechanism of high apparent porosity ceramics prepared from fly ash cenosphere. J. Alloys Compd. 2018, 749, 750–757. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C.; Panicker, V.J. Recycling of waste tire rubber as aggregate in concrete: Durability-related performance. J. Clean. Prod. 2016, 112, 504–513. [Google Scholar] [CrossRef]

- Nehdi, M.; Khan, A. Cementitious Composites Containing Recycled Tire Rubber: An Overview of Engineering Properties and Potential Applications. Cem. Concr. Aggreg. 2001, 1, 3–10. [Google Scholar] [CrossRef]

- Ferronato, N.; Torretta, V. Waste Mismanagement in Developing Countries: A Review of Global Issues. Int. J. Environ. Res. Public Health 2019, 16, 1060. [Google Scholar] [CrossRef]

- Sridhar, V.; Xiu, Z.Z.; Xu, D.; Lee, S.H.; Kim, J.K.; Kang, D.J.; Bang, D.-S. Fly ash reinforced thermoplastic vulcanizates obtained from waste tire powder. Waste Manag. 2009, 29, 1058–1066. [Google Scholar] [CrossRef] [PubMed]

- Mucsi, G.; Szenczi, Á.; Nagy, S. Fiber reinforced geopolymer from synergetic utilisation of fly ash and waste tire. J. Clean. Prod. 2018, 178, 429–440. [Google Scholar] [CrossRef]

- Llompart, M.; Sanchez-Prado, L.; Pablo Lamas, J.; Garcia-Jares, C.; Roca, E.; Dagnac, T. Hazardous organic chemicals in rubber recycled tire playgrounds and pavers. Chemosphere 2013, 90, 423–431. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Ali, A.H.; Karim, M.R.; Abdelaziz, M. A Review on Using Crumb Rubber in Reinforcement of Asphalt Pavement. Sci. World J. 2014, 2014, 1–21. [Google Scholar] [CrossRef]

- Vincevica-Gaile, Z.; Stankevica, K.; Irtiseva, K.; Shishkin, A.; Obuka, V.; Celma, S.; Ozolins, J.; Klavins, M. Granulation of fly ash and biochar with organic lake sediments—A way to sustainable utilisation of waste from bioenergy production. Biomass Bioenergy 2019, 23–33. [Google Scholar] [CrossRef]

- Obuka, V.; Šinka, M.; Kļaviņš, M.; Stankeviča, K.; Korjakins, A. Sapropel as a binder: Properties and application possibilities for composite materials. Mater. Sci. Eng. 2015, 96, 012026. [Google Scholar] [CrossRef]

- Obuka, V.; Sinka, M.; Nikolajeva, V.; Kostjukova, S.; Lazdina, L.; Klavins, M. Sapropel and lime as binders for development of composite materials. In Proceedings of the European Biomass Conference and Exhibition, Stockholm, Sweden, 12–15 June 2017. [Google Scholar]

- Kļaviņš, M. Kūdra un Sapropelis—Ražošanas, Zinātnes un Vides Sinerģija Resursu Efektīvas Izmantošanas Kontekstā; Kļaviņš, M., Ozola, R., Eds.; ResProd: Riga, Latvia, 2017; ISBN 978-9934-18-207-5. [Google Scholar]

- Christian, S.J. Natural fibre-reinforced noncementitious composites (biocomposites). Nonconv. Vernac. Constr. Mater. 2020, 169–187. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Haraguchi, K. Biocomposites. In Encyclopedia of Polymeric Nanomaterials; Springer: Berlin/Heidelberg, Germany, 2015; pp. 124–130. [Google Scholar]

- Bocci, E.; Prosperi, E.; Mair, V.; Bocci, M. Ageing and Cooling of Hot-Mix-Asphalt during Hauling and Paving—A Laboratory and Site Study. Sustainability 2020, 12, 8612. [Google Scholar] [CrossRef]

- Piao, Y.; Jiang, Q.; Li, H.; Matsumoto, H.; Liang, J.; Liu, W.; Pham-Huu, C.; Liu, Y.; Wang, F. Identify Zr Promotion Effects in Atomic Scale for Co-Based Catalysts in Fischer–Tropsch Synthesis. ACS Catal. 2020, 10, 7894–7906. [Google Scholar] [CrossRef]

- Wang, F.; Xie, Z.; Liang, J.; Fang, B.; Piao, Y.; Hao, M.; Wang, Z. Tourmaline-Modified FeMnTiO x Catalysts for Improved Low-Temperature NH 3 -SCR Performance. Environ. Sci. Technol. 2019, 53, 6989–6996. [Google Scholar] [CrossRef]

- Ouyang, J.; Zhao, Z.; Yang, H.; Zhang, Y.; Tang, A. Large-scale synthesis of sub-micro sized halloysite-composed CZA with enhanced catalysis performances. Appl. Clay Sci. 2018, 152, 221–229. [Google Scholar] [CrossRef]

- Asokan, P.; Firdoous, M.; Sonal, W. Properties and potential of bio fibres, bio binders, and bio composites. Rev. Adv. Mater. Sci. 2012, 30, 254–261. [Google Scholar]

- Pellis, A.; Malinconico, M.; Guarneri, A.; Gardossi, L. Renewable polymers and plastics: Performance beyond the green. N. Biotechnol. 2021, 60, 146–158. [Google Scholar] [CrossRef]

- Müller, C.; Kües, U.; Schöpper, C.; Kharazipour, A. Natural Binders. In Wood Production, Wood Technology, and Biotechnological Impacts; Universitaetsverlag Goettingen: Göttingen, Germany, 2007; pp. 347–381. ISBN 13 978-3-940344-11-3. [Google Scholar]

- Kajikawa, S.; Horikoshi, M.; Tanaka, S.; Umemura, K.; Kanayama, K. Molding of wood powder with a natural binder. Procedia Eng. 2017, 207, 113–118. [Google Scholar] [CrossRef]

- Shishkin, A.; Drozdova, M.; Kozlov, V.; Hussainova, I.; Lehmhus, D. Vibration-Assisted Sputter Coating of Cenospheres: A New Approach for Realising Cu-Based Metal Matrix Syntactic Foams. Metals 2017, 7, 16. [Google Scholar] [CrossRef]

- Ozernovs, O.; Jevmenovs, I. Method for Devulcanisation of Rubber and Devulcanisation Catalyst for Such Purpose. Patent Application PCT/IB2014/066580, 6 November 2015. [Google Scholar]

- Lapkovskis, V.; Mironovs, V.; Irtiseva, K.; Goljandin, D.; Shishkin, A. Investigation of Devulcanised Crumb Rubber Milling and Deagglomeration in Disintegrator System. Key Eng. Mater. 2019, 800, 216–220. [Google Scholar] [CrossRef]

- Polyakov, A.; Mironovs, V.; Shishkin, A.; Baronins, J. Preparation of Coal-Water Slurries Using a High—Speed Mixer—Disperser. In Proceedings of the 4th International Scientific Conference Civil Engineering’ 13, Jelgava, Latvia, 16–17 May 2013; pp. 77–81. [Google Scholar]

- Shishkin, A.; Mironovs, V.; Vu, H.; Novak, P.; Baronins, J.; Polyakov, A.; Ozolins, J. Cavitation-Dispersion Method for Copper Cementation from Wastewater by Iron Powder. Metals 2018, 8, 920. [Google Scholar] [CrossRef]

- Polyakov, A.; Polykova, E. Mixser-Disperser. Latvia Patent LV 13592B, 20 September 2007. [Google Scholar]

- Zong, Y.; Wan, Q.; Cang, D. Preparation of anorthite-based porous ceramics using high-alumina fly ash microbeads and steel slag. Ceram. Int. 2019, 45, 22445–22451. [Google Scholar] [CrossRef]

- Huo, W.; Zhang, X.; Chen, Y.; Lu, Y.; Liu, J.; Yan, S.; Wu, J.-M.; Yang, J. Novel mullite ceramic foams with high porosity and strength using only fly ash hollow spheres as raw material. J. Eur. Ceram. Soc. 2018, 38, 2035–2042. [Google Scholar] [CrossRef]

- Zaccaron, A.; de Souza Nandi, V.; Bernardin, A.M. Fast drying for the manufacturing of clay ceramics using natural clays. J. Build. Eng. 2021, 33, 101877. [Google Scholar] [CrossRef]

- Ashby, M.F. Materials Selection in Mechanical Design, 4th ed.; Butterworth Heinemann: Oxford, UK, 2010; ISBN 978-1-85617-663-7. [Google Scholar]

| Designation of the Composition | ||||||||||||

| 0–100–0 | 5–95–0 | 10–90–0 | 15–85–0 | 20–80–0 | 30–70–0 | 0–95–5 | 5–90–5 | 10–85–5 | 15–80–5 | 20–75–5 | 30–65–5 | |

| Wet mixture composition [wt.%] | ||||||||||||

| DCR | 0.0 | 5.0 | 10.0 | 15.0 | 20.0 | 30.0 | 0.0 | 5.0 | 10.0 | 15.0 | 20.0 | 30.0 |

| HP | 100 | 95.0 | 90.0 | 85.0 | 80.0 | 70.0 | 95.0 | 90.0 | 85.0 | 80.0 | 75.0 | 65.0 |

| CS | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 5.0 | 5.0 | 5.0 | 5.0 | 5.0 | 5.0 |

| Dried composite material formulation [wt.%] | ||||||||||||

| DCR | 0.0 | 27.3 | 44.2 | 55.8 | 64.1 | 75.4 | 0.0 | 22.1 | 37.2 | 48.1 | 56.3 | 68.0 |

| HP | 100 | 72.7 | 55.8 | 44.2 | 35.9 | 24.6 | 72.7 | 55.8 | 44.2 | 35.9 | 29.6 | 20.6 |

| CS | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 27.3 | 22.1 | 18.6 | 16.0 | 14.1 | 11.3 |

| Designation of the Composition | ||||||

| 0–90–10 | 5–85–10 | 10–80–10 | 15–75–10 | 20–70–10 | 30–60–10 | |

| Wet mixture composition [wt.%] | ||||||

| DCR | 0.0 | 5.0 | 10.0 | 15.0 | 20.0 | 30.0 |

| HP | 90.0 | 85.0 | 80.0 | 75.0 | 70.0 | 60.0 |

| CS | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 |

| Dried composite material formulation [wt.%] | ||||||

| DCR | 0.0 | 18.6 | 32.1 | 42.3 | 50.3 | 62.0 |

| HP | 55.8 | 44.2 | 35.9 | 29.6 | 24.6 | 17.4 |

| CS | 44.2 | 37.2 | 32.1 | 28.2 | 25.1 | 20.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Irtiseva, K.; Lapkovskis, V.; Mironovs, V.; Ozolins, J.; Thakur, V.K.; Goel, G.; Baronins, J.; Shishkin, A. Towards Next-Generation Sustainable Composites Made of Recycled Rubber, Cenospheres, and Biobinder. Polymers 2021, 13, 574. https://doi.org/10.3390/polym13040574

Irtiseva K, Lapkovskis V, Mironovs V, Ozolins J, Thakur VK, Goel G, Baronins J, Shishkin A. Towards Next-Generation Sustainable Composites Made of Recycled Rubber, Cenospheres, and Biobinder. Polymers. 2021; 13(4):574. https://doi.org/10.3390/polym13040574

Chicago/Turabian StyleIrtiseva, Kristine, Vjaceslavs Lapkovskis, Viktors Mironovs, Jurijs Ozolins, Vijay Kumar Thakur, Gaurav Goel, Janis Baronins, and Andrei Shishkin. 2021. "Towards Next-Generation Sustainable Composites Made of Recycled Rubber, Cenospheres, and Biobinder" Polymers 13, no. 4: 574. https://doi.org/10.3390/polym13040574

APA StyleIrtiseva, K., Lapkovskis, V., Mironovs, V., Ozolins, J., Thakur, V. K., Goel, G., Baronins, J., & Shishkin, A. (2021). Towards Next-Generation Sustainable Composites Made of Recycled Rubber, Cenospheres, and Biobinder. Polymers, 13(4), 574. https://doi.org/10.3390/polym13040574