Effects of Fabrication Methods on the Performance of Luminescent Solar Concentrators Based on Doped Polymer Optical Fibers

Abstract

1. Introduction

2. Experimental

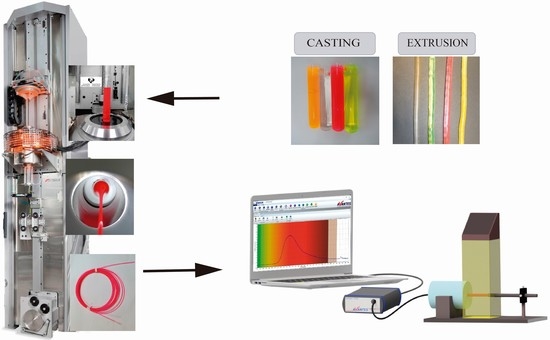

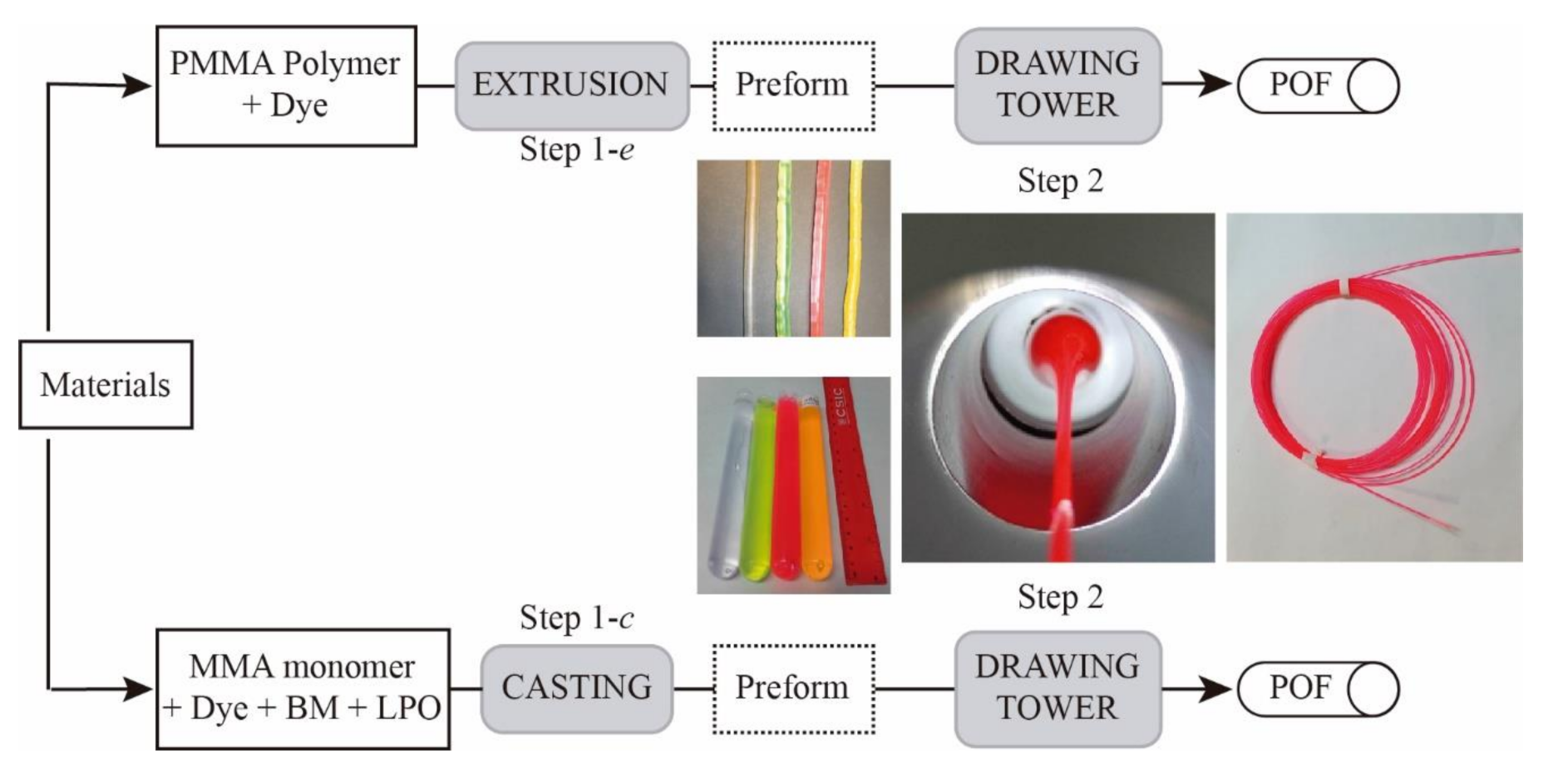

2.1. Fabrication of POFs

2.2. Characterization Methods

3. Results and Discussion

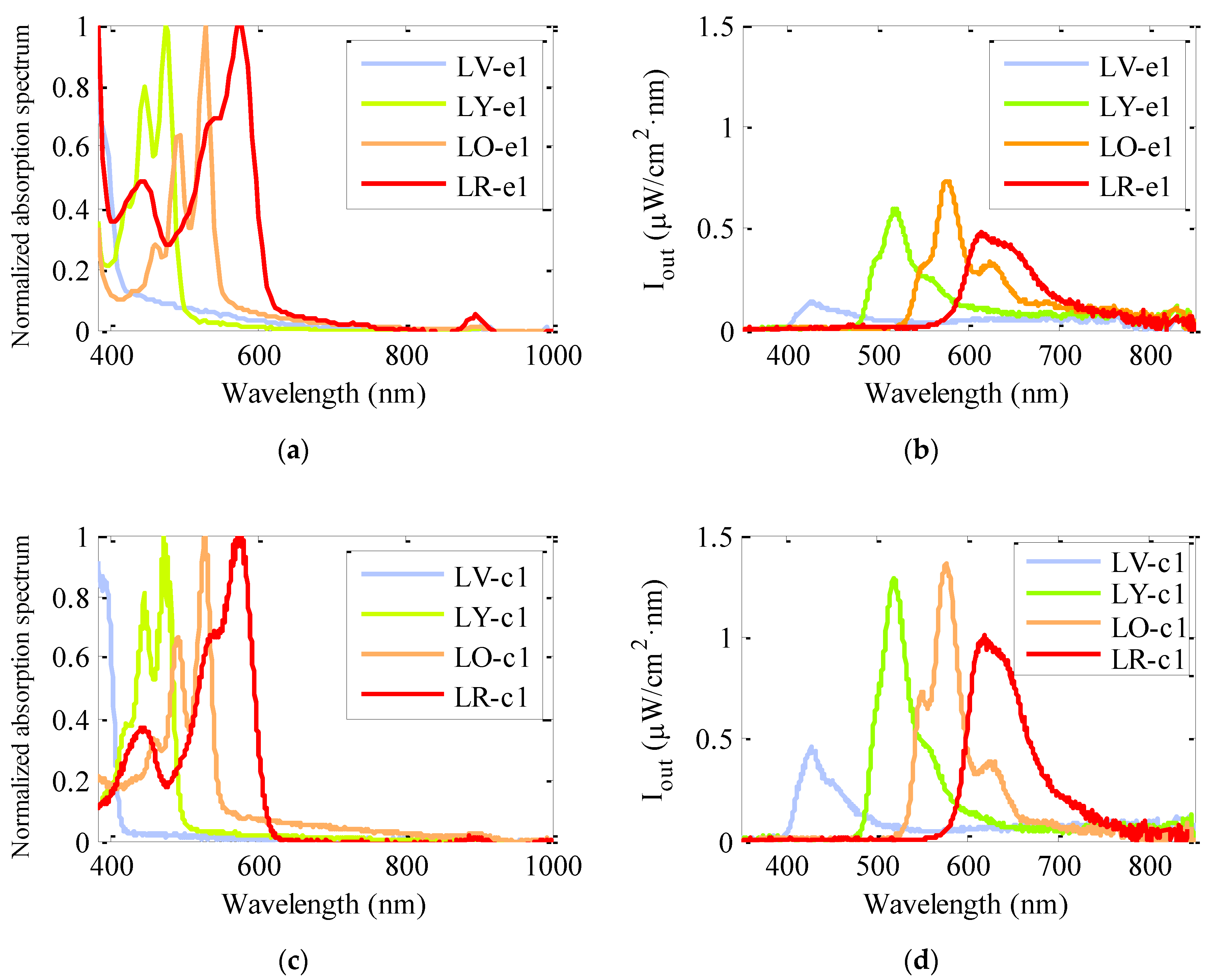

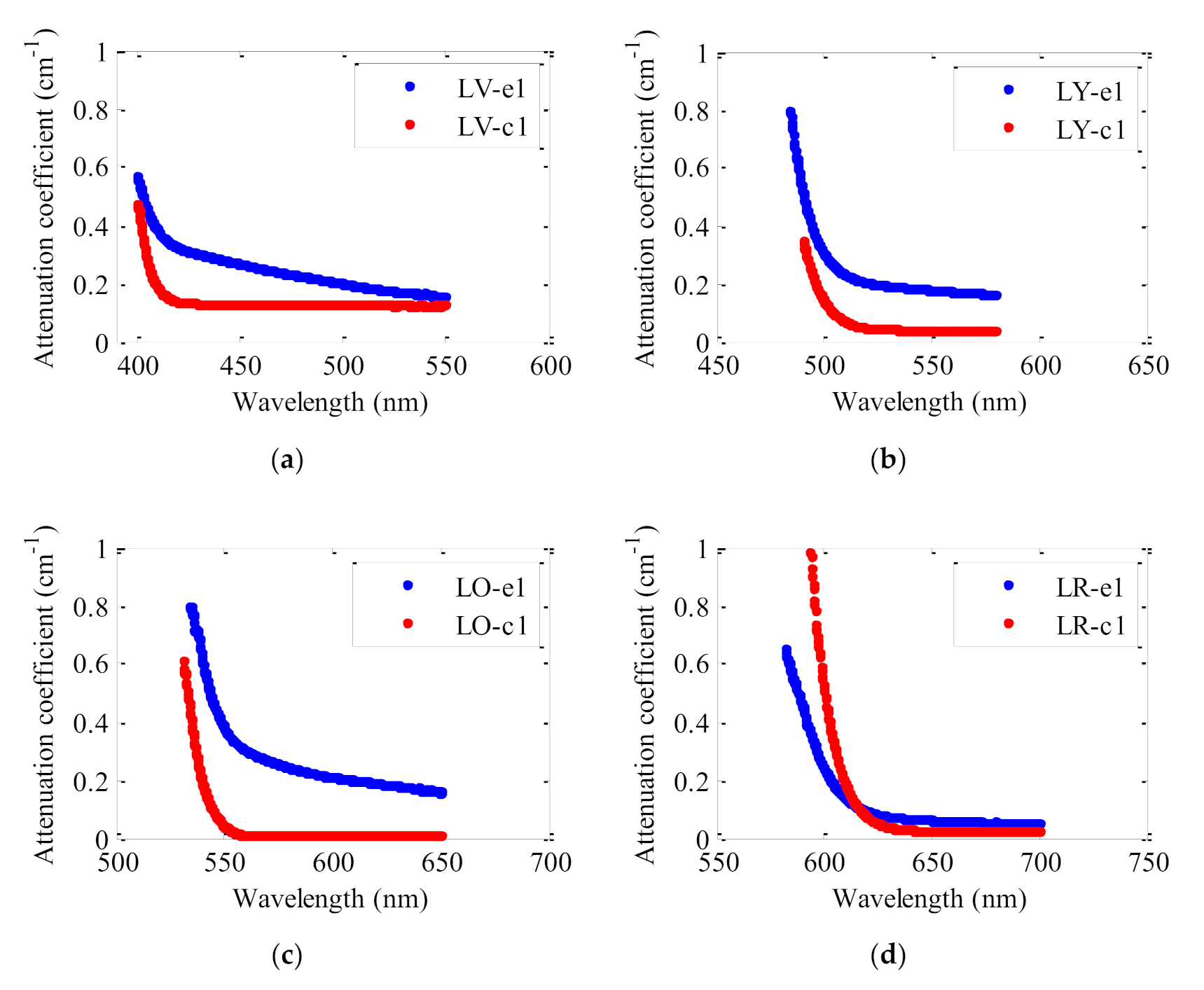

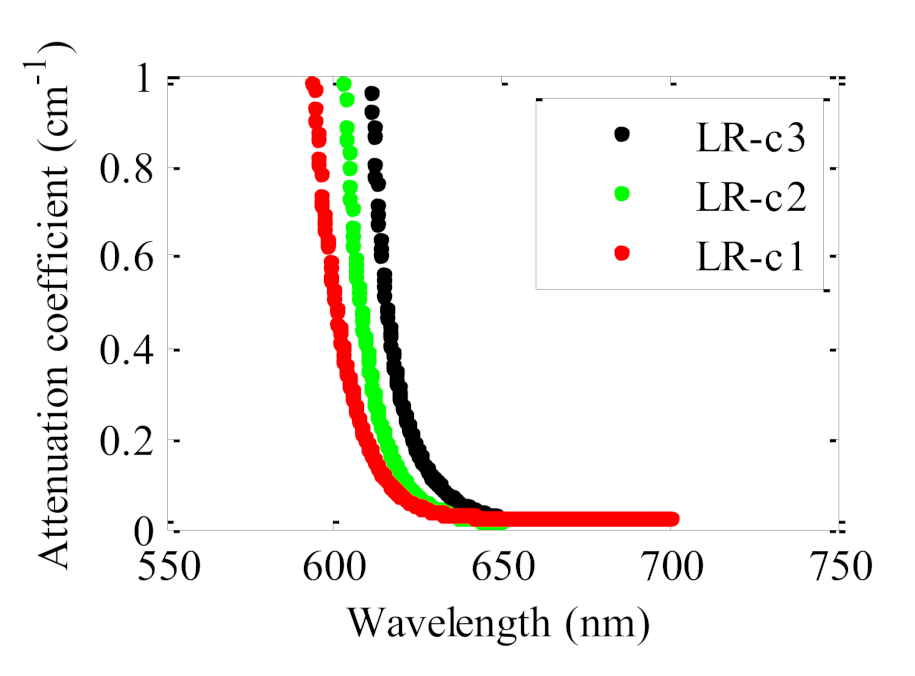

3.1. Absorption and Emission Spectra

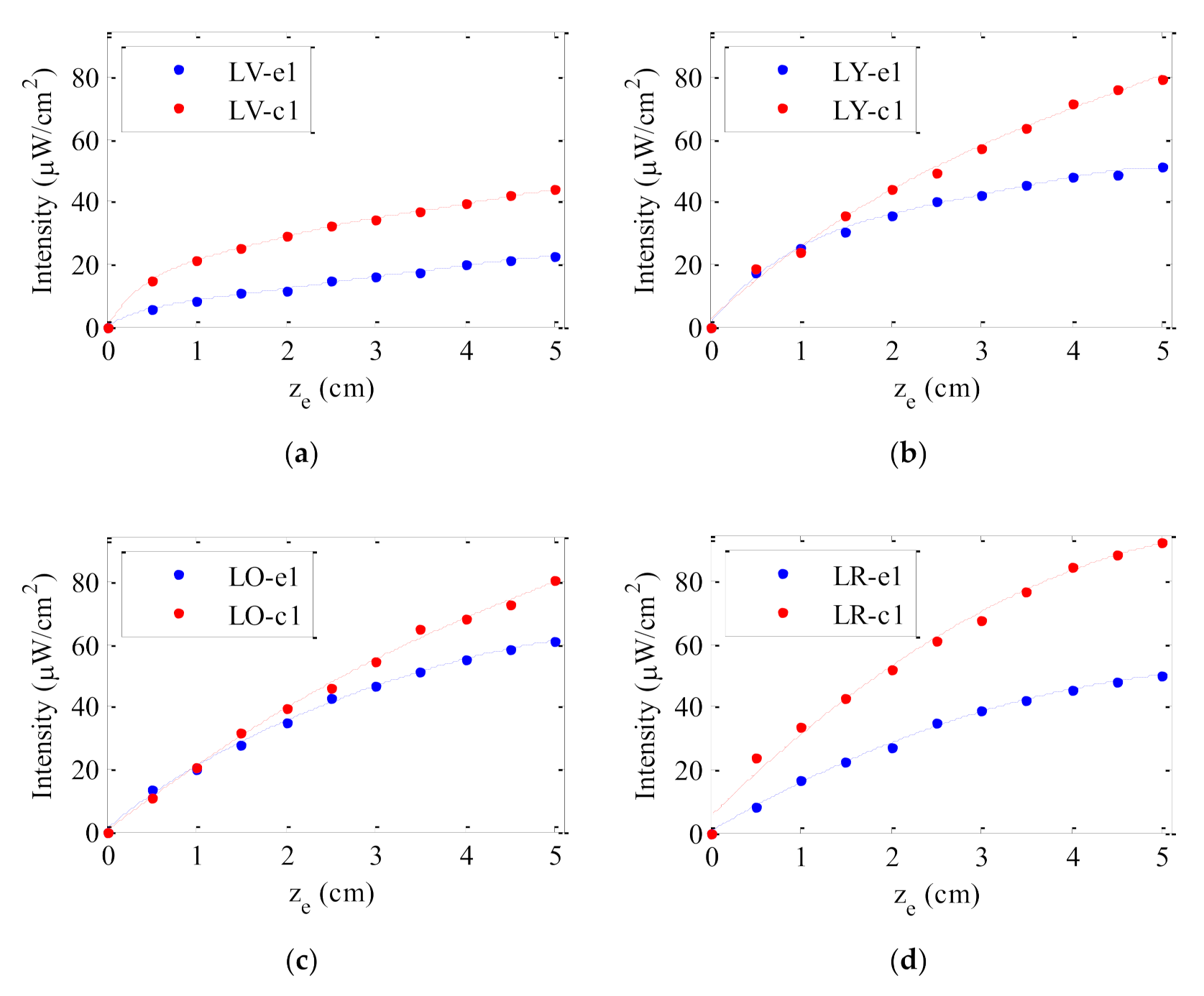

3.2. Performance under Calibrated Solar-Simulator

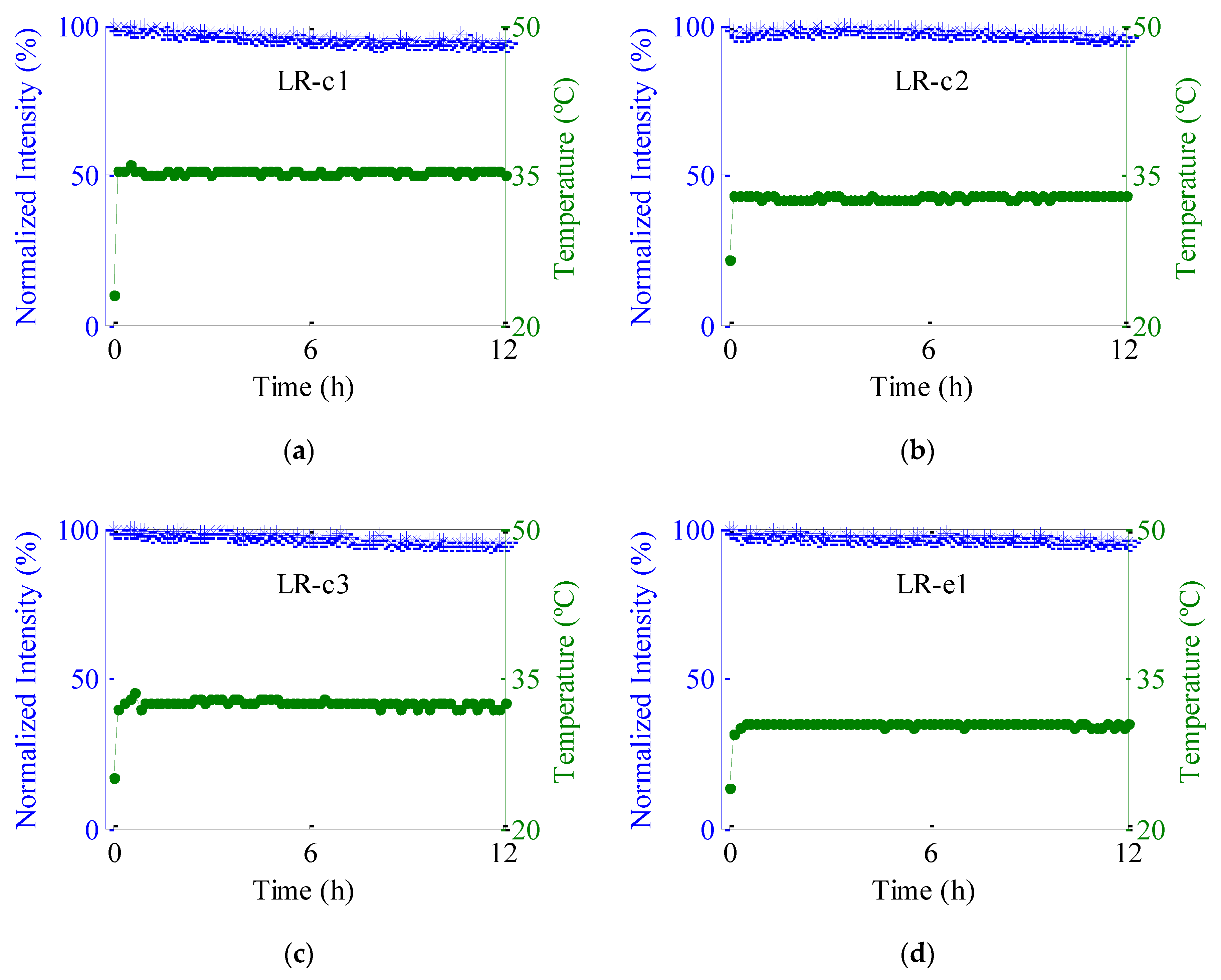

3.3. Photostability under Calibrated Solar-Simulator

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Clark, J.; Lanzani, G. Organic Photonics for Communications. Nat. Photonics 2010, 4, 438–446. [Google Scholar] [CrossRef]

- Arrue, J.; Jiménez, F.; Ayesta, I.; Illarramendi, M.A.; Zubia, J. Polymer-Optical-Fiber Lasers and Amplifiers Doped with Organic Dyes. Polymers 2011, 3, 1162–1180. [Google Scholar] [CrossRef]

- Koike, Y. Fundamentals of Plastic Optical Fibers, 1st ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2015. [Google Scholar]

- Kuzyk, M.G. Polymer Fiber Optics: Materials, Physics, and Applications; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Weber, W.H.; Lambe, J. Luminescent Greenhouse Collector for Solar Radiation. Appl. Opt. 1976, 15, 2299. [Google Scholar] [CrossRef] [PubMed]

- McIntosh, K.R.; Yamada, N.; Richards, B.S. Theoretical Comparison of Cylindrical and Square-Planar Luminescent Solar Concentrators. Appl. Phys. B Lasers Opt. 2007, 88, 285–290. [Google Scholar] [CrossRef]

- Correia, S.F.H.; Lima, P.P.; André, P.S.; Ferreira, M.R.S.; Carlos, L.A.D. High-Efficiency Luminescent Solar Concentrators for Flexible Waveguiding Photovoltaics. Sol. Energy Mater. Sol. Cells 2015, 138, 51–57. [Google Scholar] [CrossRef]

- Wang, T.; Yu, B.; Chen, B.; Hu, Z.; Luo, Y.; Zou, G.; Zhang, Q. A Theoretical Model of a Cylindrical Luminescent Solar Concentrator with a Dye-Doping Coating. J. Opt. 2013, 15. [Google Scholar] [CrossRef]

- Vishwanathan, B.; Reinders, A.H.M.E.; de Boer, D.K.G.; Desmet, L.; Ras, A.J.M.; Zahn, F.H.; Debije, M.G. A Comparison of Performance of Flat and Bent Photovoltaic Luminescent Solar Concentrators. Sol. Energy 2015, 112, 120–127. [Google Scholar] [CrossRef]

- Inman, R.H.; Shcherbatyuk, G.V.; Medvedko, D.; Gopinathan, A.; Ghosh, S. Cylindrical Luminescent Solar Concentrators with Near-Infrared Quantum Dots. Opt. Express 2011, 19, 24308. [Google Scholar] [CrossRef]

- Banaei, E.-H.; Abouraddy, A.F. Design of a Polymer Optical Fiber Luminescent Solar Concentrator. Prog. Photovolt. Res. Appl. 2015, 23, 403–416. [Google Scholar] [CrossRef]

- Mateen, F.; Oh, H.; Kang, J.; Lee, S.Y.; Hong, S.-K. Improvement in the Performance of Luminescent Solar Concentrator Using Array of Cylindrical Optical Fibers. Renew. Energy 2019, 138, 691–696. [Google Scholar] [CrossRef]

- Jakubowski, K.; Huang, C.-S.; Gooneie, A.; Boesel, L.F.; Heuberger, M.; Hufenus, R. Luminescent Solar Concentrators Based on Melt-Spun Polymer Optical Fibers. Mater. Des. 2020, 189, 108518. [Google Scholar] [CrossRef]

- Chen, J.-Y.; Chiu, Y.-C.; Shih, C.-C.; Wu, W.-C.; Chen, W.-C. Electrospun Nanofibers with Dual Plasmonic-Enhanced Luminescent Solar Concentrator Effects for High-Performance Organic Photovoltaic Cells. J. Mater. Chem. A 2015, 3, 15039–15048. [Google Scholar] [CrossRef]

- Papakonstantinou, I.; Portnoi, M.; Debije, M.G. The Hidden Potential of Luminescent Solar Concentrators. Adv. Energy Mater. 2020, 11, 2002883. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, X.; Zhang, Y.; Dong, R.; Luscombe, C.K. Review on the Role of Polymers in Luminescent Solar Concentrators. J. Polym. Sci. Part A Polym. Chem. 2019, 57, 201–215. [Google Scholar] [CrossRef]

- Roncali, J. Luminescent Solar Collectors: Quo Vadis? Adv. Energy Mater. 2020, 10, 2001907. [Google Scholar] [CrossRef]

- Debije, M.G.; Verbunt, P.P.C. Thirty Years of Luminescent Solar Concentrator Research: Solar Energy for the Built Environment. Adv. Energy Mater. 2012, 2, 12–35. [Google Scholar] [CrossRef]

- Meinardi, F.; Ehrenberg, S.; Dhamo, L.; Carulli, F.; Mauri, M.; Bruni, F.; Simonutti, R.; Kortshagen, U.; Brovelli, S. Highly Efficient Luminescent Solar Concentrators Based on Earth-Abundant Indirect-Bandgap Silicon Quantum Dots. Nat. Photonics 2017, 11, 177–185. [Google Scholar] [CrossRef]

- Verbunt, P.P.C.; Debije, M.G. Progress in Luminescent Solar Concentrator Research: Solar Energy for the Built Environmen. In Proceedings of the World Renewable Energy Congress, Linköping, Sweden, 8–13 May 2011; pp. 2751–2758. [Google Scholar] [CrossRef]

- BASF. Lumogen® F. Available online: http://www2.basf.us/additives/pdfs/p3201e.pdf (accessed on 3 January 2021).

- Arrospide, E.; Durana, G.; Azkune, M.; Aldabaldetreku, G.; Bikandi, I.; Ruiz-Rubio, L.; Zubia, J. Polymers beyond Standard Optical Fibres—Fabrication of Microstructured Polymer Optical Fibres. Polym. Int. 2018, 67, 1155–1163. [Google Scholar] [CrossRef]

- Parola, I.; Arrospide, E.; Recart, F.; Illarramendi, M.; Durana, G.; Guarrotxena, N.; García, O.; Zubia, J. Fabrication and Characterization of Polymer Optical Fibers Doped with Perylene-Derivatives for Fluorescent Lighting Applications. Fibers 2017, 5, 28. [Google Scholar] [CrossRef]

- Parola, I.; Illarramendi, M.A.; Jakobs, F.; Kielhorn, J.; Zaremba, D.; Johannes, H.-H.; Zubia, J. Characterization of Double-Doped Polymer Optical Fibers as Luminescent Solar Concentrators. Polymers 2019, 11, 1187. [Google Scholar] [CrossRef]

- Ayesta, I.; Illarramendi, M.; Arrue, J.; Parola, I.; Jiménez, F.; Zubia, J.; Tagaya, A.; Koike, Y. Optical Characterization of Doped Thermoplastic and Thermosetting Polymer-Optical-Fibers. Polymers 2017, 9, 90. [Google Scholar] [CrossRef] [PubMed]

- Parola, I.; Zaremba, D.; Evert, R.; Kielhorn, J.; Jakobs, F.; Illarramendi, M.A.; Zubia, J.; Kowalsky, W.; Johannes, H.-H. High Performance Fluorescent Fiber Solar Concentrators Employing Double-doped Polymer Optical Fibers. Sol. Energy Mater. Sol. Cells 2018, 178, 20–28. [Google Scholar] [CrossRef]

- Bikandi, I.; Illarramendi, M.A.; Zubia, J.; Arrue, J.; Jiménez, F. Side-Illumination Fluorescence Critical Angle: Theory and Application to F8BT-Doped Polymer Optical Fibers. Opt. Express 2012, 20, 4630. [Google Scholar] [CrossRef] [PubMed]

- Albers, P.T.M.; Bastiaansen, C.W.M.; Debije, M.G. Dual Waveguide Patterned Luminescent Solar Concentrators. Sol. Energy 2013, 95, 216–223. [Google Scholar] [CrossRef]

- Bergren, M.R.; Makarov, N.S.; Ramasamy, K.; Jackson, A.; Guglielmetti, R.; McDaniel, H. High-Performance CuInS2 Quantum Dot Laminated Glass Luminescent Solar Concentrators for Windows. ACS Energy Lett. 2018, 3, 520–525. [Google Scholar] [CrossRef]

- Griffini, G.; Levi, M.; Turri, S. Novel Crosslinked Host Matrices Based on Fluorinated Polymers for Long-Term Durability in Thin-Film Luminescent Solar Concentrators. Sol. Energy Mater. Sol. Cells 2013, 118, 36–42. [Google Scholar] [CrossRef]

- Meinardi, F.; Colombo, A.; Velizhanin, K.A.; Simonutti, R.; Lorenzon, M.; Beverina, L.; Viswanatha, R.; Klimov, V.I.; Brovelli, S. Large-Area Luminescent Solar Concentrators Based on “Stokes-Shift-Engineered” Nanocrystals in a Mass-Polymerized PMMA Matrix. Nat. Photonics 2014, 8, 392–399. [Google Scholar] [CrossRef]

- Bikandi, I.; Illarramendi, M.A.; Zubia, J.; Aldabaldetreku, G.; Bazzana, L. Effects of Cladding on the Emission of Doped Plastic Optical Fibres. Phys. Status Solidi C 2011, 8, 2931–2934. [Google Scholar] [CrossRef]

- Cerdán, L.; Costela, A.; Durán-Sampedro, G.; García-Moreno, I.; Calle, M.; Juan-y-Seva, M.; de Abajo, J.; Turnbull, G.A. New Perylene-Doped Polymeric Thin Films for Efficient and Long-Lasting Lasers. J. Mater. Chem. 2012, 22, 8938–8947. [Google Scholar] [CrossRef]

| Fiber Code | Type | Host | Dye | Concentration (wt%) | Diameter (2r) (mm) |

|---|---|---|---|---|---|

| LV-e1 | SI Uncladded | PMMA | Lumogen F Violet 570 | 0.003 | 0.95 ± 0.03 |

| LY-e1 | SI Uncladded | PMMA | Lumogen F Yellow 083 | 0.003 | 0.81 ± 0.01 |

| LO-e1 | SI Uncladded | PMMA | Lumogen F Orange 240 | 0.003 | 1.00 ± 0.03 |

| LR-e1 | SI Uncladded | PMMA | Lumogen F Red 305 | 0.003 | 0.95 ± 0.05 |

| LV-c1 | SI Uncladded | PMMA | Lumogen F Violet 570 | 0.003 | 0.74 ± 0.01 |

| LY-c1 | SI Uncladded | PMMA | Lumogen F Yellow 083 | 0.003 | 0.87 ± 0.01 |

| LO-c1 | SI Uncladded | PMMA | Lumogen F Orange 240 | 0.003 | 0.99 ± 0.01 |

| LR-c1 | SI Uncladded | PMMA | Lumogen F Red 305 | 0.003 | 0.91 ± 0.01 |

| LR-c2 | SI Uncladded | PMMA | Lumogen F Red 305 | 0.01 | 1.01 ± 0.01 |

| LR-c3 | SI Uncladded | PMMA | Lumogen F Red 305 | 0.03 | 0.93 ± 0.01 |

| Fiber Code | Iout (μW/cm2) | Pout (μW) | ηopt (%) | C |

|---|---|---|---|---|

| LV-e1 | 22.72 | 0.16 | 3.39 × 10−4 | 2.27 × 10−4 |

| LV-c1 | 44.07 | 0.19 | 5.12 × 10−4 | 4.41 × 10−4 |

| LY-e1 | 51.66 | 0.27 | 6.57 × 10−4 | 5.17 × 10−4 |

| LY-c1 | 79.80 | 0.47 | 1.09 × 10−3 | 7.98 × 10−4 |

| LO-e1 | 61.37 | 0.48 | 9.64 × 10−4 | 6.14 × 10−4 |

| LO-c1 | 80.97 | 0.62 | 1.26 × 10−3 | 8.10 × 10−4 |

| LR-e1 | 50.34 | 0.36 | 7.51 × 10−4 | 5.03 × 10−4 |

| LR-c1 | 92.64 | 0.72 | 1.46 × 10−3 | 9.26 × 10−4 |

| LR-c2 | 196.55 | 1.33 | 2.87 × 10−3 | 1.97 × 10−3 |

| LR-c3 | 397.23 | 3.12 | 6.24 × 10−3 | 3.97 × 10−3 |

| a | b | a + b | τ (min) | R2 | |

|---|---|---|---|---|---|

| 1st period | 95.2 ± 0.3 | 4.9 ± 0.3 | 100.1 ± 0.6 | 450 ± 60 | 0.89 |

| 2nd period | 94 ± 1 | 3.1 ± 0.9 | 97 ± 2 | 900 ± 400 | 0.68 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arrospide, E.; Illarramendi, M.A.; Ayesta, I.; Guarrotxena, N.; García, O.; Zubia, J.; Durana, G. Effects of Fabrication Methods on the Performance of Luminescent Solar Concentrators Based on Doped Polymer Optical Fibers. Polymers 2021, 13, 424. https://doi.org/10.3390/polym13030424

Arrospide E, Illarramendi MA, Ayesta I, Guarrotxena N, García O, Zubia J, Durana G. Effects of Fabrication Methods on the Performance of Luminescent Solar Concentrators Based on Doped Polymer Optical Fibers. Polymers. 2021; 13(3):424. https://doi.org/10.3390/polym13030424

Chicago/Turabian StyleArrospide, Eneko, María Asunción Illarramendi, Igor Ayesta, Nekane Guarrotxena, Olga García, Joseba Zubia, and Gaizka Durana. 2021. "Effects of Fabrication Methods on the Performance of Luminescent Solar Concentrators Based on Doped Polymer Optical Fibers" Polymers 13, no. 3: 424. https://doi.org/10.3390/polym13030424

APA StyleArrospide, E., Illarramendi, M. A., Ayesta, I., Guarrotxena, N., García, O., Zubia, J., & Durana, G. (2021). Effects of Fabrication Methods on the Performance of Luminescent Solar Concentrators Based on Doped Polymer Optical Fibers. Polymers, 13(3), 424. https://doi.org/10.3390/polym13030424