Recent Advances in Renewable Polymer Production from Lignin-Derived Aldehydes

Abstract

1. Introduction

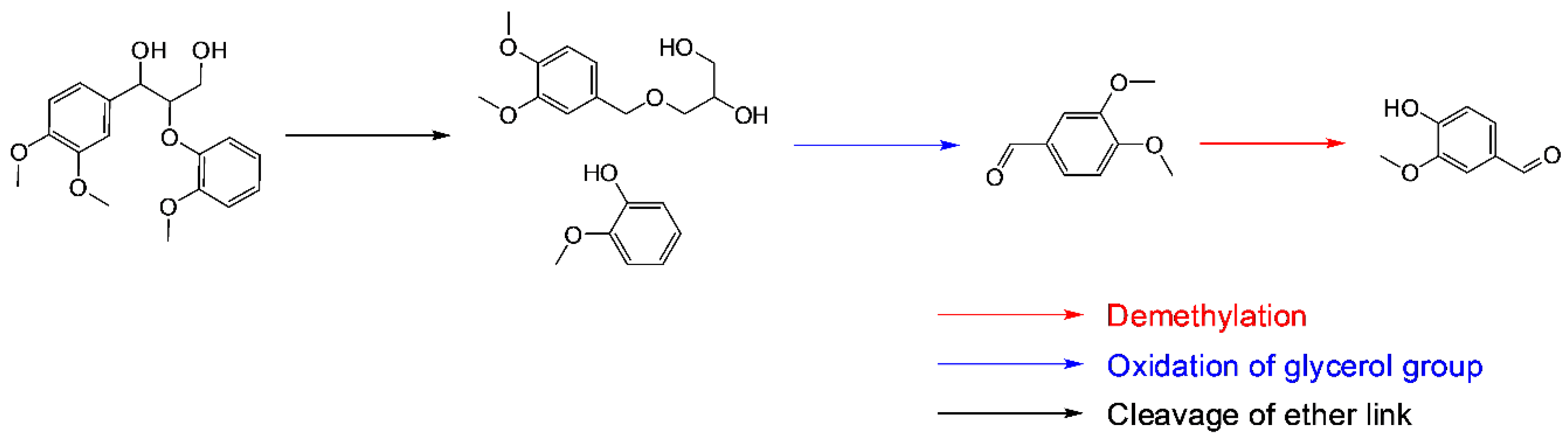

2. Production of Aromatic Aldehydes from Lignin

| Entry | Lignin Type | Product | Reaction | Catalyst | Reaction Conditions | Yield | Ref. |

|---|---|---|---|---|---|---|---|

| 1 | Swollen residual enzyme lignin | Vanillin, Syringaldehyde | Alkaline nitrobenzene oxidation | - | 170 °C; 3 h | Vanillin: 13.39% Syringaldehyde: 14.19% | Wang et al. [46] |

| 2 | Double enzymatic lignin | Vanillin, Syringaldehyde | Alkaline nitrobenzene oxidation | - | 170 °C; 3 h | Vanillin: 9.17% Syringaldehyde: 15.99% | Wang et al. [46] |

| 3 | Kraft lignin | Vanillin, Syringaldehyde | Alkaline nitrobenzene oxidation | - | 170 °C; 3 h | Vanillin: 2.51% Syringaldehyde: 2.92% | Wang et al. [46] |

| 4 | Alkali lignin | Vanillin, Syringaldehyde | Alkaline nitrobenzene oxidation | - | 170 °C; 3 h | Vanillin: 6.52% Syringaldehyde: 4.16% | Wang et al. [46] |

| 5 | Kraft lignin | Vanillin | Oxidation | - | 120–125 °C; 10 bar; 130 min | 3.5–7.6% | Araújo et al. [27] |

| 6 | Oil palm empty fruit bunches lignin | Vanillin | Nitrobenzene oxidation | - | 165 °C; 3 h | 1.6% | Mohamad Ibrahim et al. [47] |

| 7 | Lignosulfonates | Vanillin | Oxidation | 185 °C; 11 atm; 85 min | 7.2% | Bjørsvik and Minisci [31] | |

| 8 | Kraft lignin | Vanillin | Chemical oxidation | - | 133 °C; 2.8 bar O2; 35 min | 10.8% | Fargues et al. [25] |

| 9 | Pine kraft lignin | Vanillin | Oxidation | - | 120 °C; 5.5 bar N2, 9.3 bar O2; 60 min | 10% | Mathias and Rodrigues [34] |

| 10 | Pine wood lignin | Vanillin | Oxidation | - | 160 °C; 0.9 MPa O2; 20 min | 23.1% | Taraban’ko et al. [48] |

| 11 | Poplar lignin | Vanillin, Syringaldehyde | Alkaline aerobic lignin oxidation | 175 °C; 5 bar O2, 15 bar He; 10 min | Vanillin: 7% Syringaldehyde: 13% | Schutyser et al. [42] | |

| 12 | Eucalyptus globulus dioxane lignin | Vanillin, Syringaldehyde | Nitrobenzene oxidation | - | 170 °C; 4 h | Vanillin: 5.66% Syringaldehyde: 33.2% | Rodrigues Pinto et al. [28] |

| 13 | Lignosulfonates | Vanillin, Syringaldehyde | Oxidation | CuSO4 | 150 °C; 10 bar O2; 20 min; CuSO4 loading of 20% | Vanillin: 4.5% Syringaldehyde: 16.1% | Santos et al. [32] |

| 14 | Pine lignin | Vanillin, Syringaldehyde | Oxygen delignification | - | 100 °C; 0.7 MPa O2; 60 min | Vanillin: 8.8% Syringaldehyde: 0.72% | Wong et al. [49] |

| 15 | Eucalyptus pulp lignin | Vanillin, Syringaldehyde | Oxygen delignification | - | 100 °C; 0.7 MPa O2; 60 min | Vanillin: 4.62% Syringaldehyde: 7.85% | Wong et al. [49] |

| 16 | Cornstalk lignin | Syringaldehyde | Catalytic oxidation | LaFe0.8Cu0.2O3 | 120 °C; 5 bar O2; 30 min; LaFe0.8Cu0.2O3 loading of 5% | 11.5% | Zhang et al. [50] |

| 17 | Softwood lignin | Vanillin | Alkaline wet oxidation | - | 140 °C; 10 bar O2; 280 min | 3% | Gomes and Rodrigues [51] |

| 18 | Dealkali lignin | Syringaldehyde | Catalytic oxidation | LaFe0.2Cu0.8O3 | 160 °C; 0.8 MPa O2; 2.5 h; LaFe0.8Cu0.2O3 loading of 5% | 10% | Li et al. [52] |

| 19 | Kraft lignin | Vanillin | Alkaline wet oxidation | CuMn (1:3) | 150 °C; atmospheric pressure; 60 min; CuMn loading of 0.2% | 6.7% | Jeon et al. [53] |

| 20 | Native softwood lignin | Vanillin | Aerobic oxidation | - | 120 °C; 72 h | 21% | Maeda et al. [54] |

| 21 | Kraft lignin | Vanillin | Alkaline wet oxidation | - | 140 °C; 10 bar O2; 2 h | 4.3% | Gomes and Rodrigues [55] |

| 22 | Lignin from Kraft cooking liquor | Vanillin | Alkaline nitrobenzene oxidation | - | 170 °C; 3 h, | 3.9% | Gitaari et al. [56] |

| 23 | Kraft lignin | Vanillin | Oxidation | - | 160 °C; 1 MPa O2; 1 h | 21.1% | Zhu et al. [57] |

| 24 | Kraft lignin | Vanillin | Catalytic oxidation | CuSO4 | 140 °C; 1 h; CuSO4 loading of 10% | 10.9% | Zhang et al. [58] |

| 25 | Organosolv lignin | Vanillin, Syringaldehyde | Electro-oxidation | - | Room temperature; 1 h | 17.5% | Yan et al. [59] |

| 26 | Kraft lignin | Vanillin | Oxidative depolymerization | - | 180–220 °C; 1–2 atm O2; 1–2 h | 1.8–5.2% | Liu et al. [60] |

| 27 | Eucalyptus lignin | Vanillin, Syringaldehyde | Alkaline nitrobenzene oxidation | - | 170 °C; 4 h | Vanillin: 7.3% Syringaldehyde: 29.3% | Ninomiya et al. [61] |

3. Production of Polymers from the Lignin-Derived Aromatic Aldehydes

3.1. Production of Vanillin- and Syringaldehyde-Derived Polymers

3.2. Properties of Vanillin- and Syringaldehyde-Derived Polymers

| Entry | Monomers | Polymerization Method | Final Polymer | Glass Transition Temperature (°C) | Degradation Temperature (°C) | Other Properties | Ref. |

|---|---|---|---|---|---|---|---|

| 1 | Vanillin, syringaldehyde | Epoxidation; curing at 80 °C for 8 h | Epoxy resin | 82–167 a | T5% = 220–269 b | - | Zhao et al. [107] |

| 2 | Vanillin | Epoxidation; curing at 160 °C for 2 h | Epoxy resin | 166–214 c | T5% = 286–356 d | - | Wang et al. [94] |

| 3 | Vanillin methacrylate | Suspension polymerization; curing at 65 °C for 6 h | Polyvanillin methacrylate | 102 c | Degradation T range = 250–480 b | - | Zhang et al. [102] |

| 4 | Vanillin, syringaldehyde | Free radical polymerization | (Meth)acrylate-type polymers | 95–180 c | Tmax = 340–360 b | Mn = 7600–14,600 g mol−1; Đ = 1.89–4.07 | Zhou et al. [100] |

| 5 | Vanillin | Electrochemical reductive polymerization | Polyvanillin | - | T50% = 440 d | Mn = 9850–11,784 g mol−1; Đ = 1.42–1.58 | Amarasekara et al. [86] |

| 6 | Vanillin | Reversible addition-fragmentation chain-transfer (RAFT) polymerization | Methacrylate-type polymers | 111–139 | Tmax = 281–327 | Mn = 15,000–41,000 g mol−1; Đ = 1.12–1.39 | Holmberg et al. [109] |

| 7 | Syringyl methacrylate | RAFT polymerization | Poly(syringyl methacrylate) | 114–205 e | Initial degradation T = 256–303 d | Mn = 11000–38,000 g mol−1; Đ = 1.32–1.74 | Holmberg et al. [110] |

| 8 | Vanillin-derived bis-benzoxazine monomer | Ring opening polymerization | Poly(bisbenzoxazine) | 202–255 e | Degradation T range = 220–450 b | - | Sini et al. [111] |

| 9 | Vanillin | - | Divanillin-ethanol amine conjugate-based polyurethane | −68.1 to −67.2 c | T5% = 329.6–341.5 b | - | Gang et al. [93] |

| 10 | Vanillin, syringaldehyde, etc. | - | Polyvinyl acetals | 114–157 | T95% = 185–308 b | Mn = 22,300–46,000 g mol−1 | Rostagno et al. [97] |

| 11 | Vanillin | - | Poly (ether benzoxazole) | - | >400 b | - | Sun et al. [112] |

| 12 | Vanillin-based monomers | Phosphonite-mediated multicomponent polymerization | Fluorescent polymers | - | - | Mn = 3000–12,700 g mol−1; Đ = 1.8–2.3 | Kayser et al. [108] |

| 13 | Vanillyl alcohol | - | Polyurethane | 59 | T5% = 178 b | Mw = 32,000 g mol−1 | Tachibana and Abe [113] |

| 14 | Vanillin | - | Polyurethane (PU-3) | 80.4 c | T5% = 229 b | Mn = 4000 g mol−1 | Zhao et al. [114] |

| 15 | Vanillin | - | Cured epoxy resins | - | T5% = 394 b | - | Shibata and Ohkita [115] |

| 16 | Vanillin | Phthalonitrile functionalization | Phthalonitrile resins | >500 c | T5% = 477–482 b | - | Han et al. [116] |

| 17 | Hydrovanilloin | Electrochemical dimerization | Hydrovanilloin—Diglycidyl Ether Phenoxy Resin | 135 | T = 255 d | - | Amarasekara et al. [117] |

| 18 | Vanillin methacrylate | Free radical solution homo-polymerization | Vanillin-derived polymer (PVMA) | - | - | Mn = 17,900 g mol−1 | Zhao et al. [118] |

4. Summary and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- De Bhowmick, G.; Sarmah, A.K.; Sen, R. Lignocellulosic biorefinery as a model for sustainable development of biofuels and value added products. Bioresour. Technol. 2018, 247, 1144–1154. [Google Scholar] [CrossRef] [PubMed]

- Kwon, E.E.; Lee, T.; Ok, Y.S.; Tsang, D.C.W.; Park, C.; Lee, J. Effects of calcium carbonate on pyrolysis of sewage sludge. Energy 2018, 153, 726–731. [Google Scholar] [CrossRef]

- Jung, J.-M.; Oh, J.-I.; Baek, K.; Lee, J.; Kwon, E.E. Biodiesel production from waste cooking oil using biochar derived from chicken manure as a porous media and catalyst. Energy Convers. Manag. 2018, 165, 628–633. [Google Scholar] [CrossRef]

- Kim, S.; Kwon, E.E.; Kim, Y.T.; Jung, S.; Kim, H.J.; Huber, G.W.; Lee, J. Recent advances in hydrodeoxygenation of biomass-derived oxygenates over heterogeneous catalysts. Green Chem. 2019, 21, 3715–3743. [Google Scholar] [CrossRef]

- Park, C.; Lee, J. Recent achievements in CO2-assisted and CO2-catalyzed biomass conversion reactions. Green Chem. 2020, 22, 2628–2642. [Google Scholar] [CrossRef]

- Cagnon, B.; Py, X.; Guillot, A.; Stoeckli, F.; Chambat, G. Contributions of hemicellulose, cellulose and lignin to the mass and the porous properties of chars and steam activated carbons from various lignocellulosic precursors. Bioresour. Technol. 2009, 100, 292–298. [Google Scholar] [CrossRef]

- Schutyser, W.; Renders, T.; Van den Bosch, S.; Koelewijn, S.F.; Beckham, G.T.; Sels, B.F. Chemicals from lignin: An interplay of lignocellulose fractionation, depolymerisation, and upgrading. Chem. Soc. Rev. 2018, 47, 852–908. [Google Scholar] [CrossRef]

- Sun, Z.; Fridrich, B.; de Santi, A.; Elangovan, S.; Barta, K. Bright side of lignin depolymerization: Toward new platform chemicals. Chem. Rev. 2018, 118, 614–678. [Google Scholar] [CrossRef]

- Rinaldi, R.; Jastrzebski, R.; Clough, M.T.; Ralph, J.; Kennema, M.; Bruijnincx, P.C.A.; Weckhuysen, B.M. Paving the way for lignin valorisation: Recent advances in bioengineering, biorefining and catalysis. Angew. Chem. Int. Ed. 2016, 55, 8164–8215. [Google Scholar] [CrossRef]

- Gillet, S.; Aguedo, M.; Petitjean, L.; Morais, A.R.C.; da Costa Lopes, A.M.; Łukasik, R.M.; Anastas, P.T. Lignin transformations for high value applications: Towards targeted modifications using green chemistry. Green Chem. 2017, 19, 4200–4233. [Google Scholar] [CrossRef]

- Shuai, L.; Saha, B. Towards high-yield lignin monomer production. Green Chem. 2017, 19, 3752–3758. [Google Scholar] [CrossRef]

- Renders, T.; Van den Bosch, S.; Koelewijn, S.F.; Schutyser, W.; Sels, B.F. Lignin-first biomass fractionation: The advent of active stabilisation strategies. Energy Environ. Sci. 2017, 10, 1551–1557. [Google Scholar] [CrossRef]

- Gierer, J. Chemistry of delignification. Wood Sci. Technol. 1985, 19, 289–312. [Google Scholar] [CrossRef]

- Sturgeon, M.R.; Kim, S.; Lawrence, K.; Paton, R.S.; Chmely, S.C.; Nimlos, M.; Foust, T.D.; Beckham, G.T. A mechanistic investigation of acid-catalyzed cleavage of aryl-ether linkages: Implications for lignin depolymerization in acidic environments. ACS Sustain. Chem. Eng. 2014, 2, 472–485. [Google Scholar] [CrossRef]

- Pu, Y.; Hu, F.; Huang, F.; Ragauskas, A.J. Lignin structural alterations in thermochemical pretreatments with limited delignification. Bioenerg. Res. 2015, 8, 992–1003. [Google Scholar] [CrossRef]

- Liu, S.; Bai, L.; van Muyden, A.P.; Huang, Z.; Cui, X.; Fei, Z.; Li, X.; Hu, X.; Dyson, P.J. Oxidative cleavage of β-O-4 bonds in lignin model compounds with a single-atom Co catalyst. Green Chem. 2019, 21, 1974–1981. [Google Scholar] [CrossRef]

- Lora, J. Industrial commercial lignins: Sources, properties and applications. In Monomers, Polymers and Composites from Renewable Resources; Belgacem, M.N., Gandini, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2008; pp. 225–241. [Google Scholar] [CrossRef]

- Ragauskas, A.J.; Beckham, G.T.; Biddy, M.J.; Chandra, R.; Chen, F.; Davis, M.F.; Davison, B.H.; Dixon, R.A.; Gilna, P.; Keller, M.; et al. Lignin valorization: Improving lignin processing in the biorefinery. Science 2014, 344, 1246843. [Google Scholar] [CrossRef]

- Davis, R.; Tao, L.; Tan, E.; Biddy, M.; Beckham, G.; Scarlata, C.; Jacobson, J.; Cafferty, K.; Ross, J.; Lukas, J. Process Design and Economics for the Conversion of Lignocellulosic Biomass to Hydrocarbons: Dilute-Acid and Enzymatic Deconstruction of Biomass to Sugars and Biological Conversion of Sugars to Hydrocarbons; Report NREL/TP-5100-60223; National Renewable Energy Laboratory: Golden, CO, USA, 2013.

- Zhu, Y.; Romain, C.; Williams, C.K. Sustainable polymers from renewable resources. Nature 2016, 540, 354–362. [Google Scholar] [CrossRef]

- Delidovich, I.; Hausoul, P.J.C.; Deng, L.; Pfützenreuter, R.; Rose, M.; Palkovits, R. Alternative monomers based on lignocellulose and their use for polymer production. Chem. Rev. 2016, 116, 1540–1599. [Google Scholar] [CrossRef]

- Cheng, C.; Wang, J.; Shen, D.; Xue, J.; Guan, S.; Gu, S.; Luo, K.H. Catalytic oxidation of lignin in solvent systems for production of renewable chemicals: A review. Polymers 2017, 9, 240. [Google Scholar] [CrossRef]

- Rodrigues Pinto, P.C.; Borges da Silva, E.A.; Rodrigues, A.E. Lignin as source of fine chemicals: Vanillin and syringaldehyde. In Biomass Conversion: The Interface of Biotechnology, Chemistry and Materials Science; Baskar, C., Baskar, S., Dhillon, R.S., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 381–420. [Google Scholar] [CrossRef]

- Fache, M.; Boutevin, B.; Caillol, S. Vanillin production from lignin and its use as a renewable chemical. ACS Sustain. Chem. Eng. 2016, 4, 35–46. [Google Scholar] [CrossRef]

- Fargues, C.; Mathias, Á.; Rodrigues, A. Kinetics of vanillin production from Kraft lignin oxidation. Ind. Eng. Chem. Res. 1996, 35, 28–36. [Google Scholar] [CrossRef]

- Villar, J.C.; Caperos, A.; García-Ochoa, F. Oxidation of hardwood Kraft-lignin to phenolic derivatives with oxygen as oxidant. Wood Sci. Technol. 2001, 35, 245–255. [Google Scholar] [CrossRef]

- Araújo, J.D.P.; Grande, C.A.; Rodrigues, A.E. Vanillin production from lignin oxidation in a batch reactor. Chem. Eng. Res. Des. 2010, 88, 1024–1032. [Google Scholar] [CrossRef]

- Rodrigues Pinto, P.C.; Borges da Silva, E.A.; Rodrigues, A.E. Insights into oxidative conversion of lignin to high-added-value phenolic aldehydes. Ind. Eng. Chem. Res. 2011, 50, 741–748. [Google Scholar] [CrossRef]

- Pinto, P.C.R.; Costa, C.E.; Rodrigues, A.E. Oxidation of lignin from Eucalyptus globulus pulping liquors to produce syringaldehyde and vanillin. Ind. Eng. Chem. Res. 2013, 52, 4421–4428. [Google Scholar] [CrossRef]

- Tarabanko, V.E.; Fomova, N.A.; Kuznetsov, B.N.; Ivanchenko, N.M.; Kudryashev, A.V. On the mechanism of vanillin formation in the catalytic oxidation of lignin with oxygen. React. Kinet. Catal. Lett. 1995, 55, 161–170. [Google Scholar] [CrossRef]

- Bjørsvik, H.-R.; Minisci, F. Fine chemicals from lignosulfonates. 1. Synthesis of vanillin by oxidation of lignosulfonates. Org. Process Res. Dev. 1999, 3, 330–340. [Google Scholar] [CrossRef]

- Santos, S.G.; Marques, A.P.; Lima, D.L.D.; Evtuguin, D.V.; Esteves, V.I. Kinetics of Eucalypt lignosulfonate oxidation to aromatic aldehydes by oxygen in alkaline medium. Ind. Eng. Chem. Res. 2011, 50, 291–298. [Google Scholar] [CrossRef]

- Pacek, A.W.; Ding, P.; Garrett, M.; Sheldrake, G.; Nienow, A.W. Catalytic conversion of sodium lignosulfonate to vanillin: Engineering aspects. Part 1. Effects of processing conditions on vanillin yield and selectivity. Ind. Eng. Chem. Res. 2013, 52, 8361–8372. [Google Scholar] [CrossRef]

- Mathias, A.L.; Rodrigues, A.E. Production of vanillin by oxidation of pine Kraft lignins with oxygen. Holzforschung 1995, 49, 273–278. [Google Scholar] [CrossRef]

- Tarabanko, V.E.; Petukhov, D.V. Study of mechanism and improvement of the process of oxidative cleavage of lignins into the aromatic aldehydes. Chem. Sustain. Dev. 2003, 11, 655–667. [Google Scholar]

- Tarabanko, V.E.; Petukhov, D.V.; Selyutin, G.E. New mechanism for the catalytic oxidation of lignin to vanillin. Kinet. Catal. 2004, 45, 569–577. [Google Scholar] [CrossRef]

- Hosoya, T.; Yamamoto, K.; Miyafuji, H.; Yamada, T. Selective production of bio-based aromatics by aerobic oxidation of native soft wood lignin in tetrabutylammonium hydroxide. RSC Adv. 2020, 10, 19199–19210. [Google Scholar] [CrossRef]

- Wu, G.; Heitz, M. Catalytic mechanism of Cu2+ and Fe3+ in alkaline O2 oxidation of lignin. J. Wood Chem. Technol. 1995, 15, 189–202. [Google Scholar] [CrossRef]

- Araújo, J.D.P.; Grande, C.A.; Rodrigues, A.E. Structured packed bubble column reactor for continuous production of vanillin from Kraft lignin oxidation. Catal. Today 2009, 147, S330–S335. [Google Scholar] [CrossRef]

- Constant, S.; Wienk, H.L.J.; Frissen, A.E.; Peinder, P.d.; Boelens, R.; Van Es, D.S.; Grisel, R.J.H.; Weckhuysen, B.M.; Huijgen, W.J.J.; Gosselink, R.J.A.; et al. New insights into the structure and composition of technical lignins: A comparative characterisation study. Green Chem. 2016, 18, 2651–2665. [Google Scholar] [CrossRef]

- Ekielski, A.; Mishra, P.K. Lignin for bioeconomy: The present and future role of technical lignin. Int. J. Mol. Sci. 2021, 22, 63. [Google Scholar] [CrossRef]

- Schutyser, W.; Kruger, J.S.; Robinson, A.M.; Katahira, R.; Brandner, D.G.; Cleveland, N.S.; Mittal, A.; Peterson, D.J.; Meilan, R.; Román-Leshkov, Y.; et al. Revisiting alkaline aerobic lignin oxidation. Green Chem. 2018, 20, 3828–3844. [Google Scholar] [CrossRef]

- Silva, E.A.B.D.; Zabkova, M.; Araújo, J.D.; Cateto, C.A.; Barreiro, M.F.; Belgacem, M.N.; Rodrigues, A.E. An integrated process to produce vanillin and lignin-based polyurethanes from Kraft lignin. Chem. Eng. Res. Des. 2009, 87, 1276–1292. [Google Scholar] [CrossRef]

- Mota, M.I.F.; Rodrigues Pinto, P.C.; Loureiro, J.M.; Rodrigues, A.E. Recovery of vanillin and syringaldehyde from lignin oxidation: A review of separation and purification processes. Sep. Purif. Rev. 2016, 45, 227–259. [Google Scholar] [CrossRef]

- Mabrouk, A.; Erdocia, X.; Alriols, M.G.; Labidi, J. Economic analysis of a biorefinery process for catechol production from lignin. J. Clean. Prod. 2018, 198, 133–142. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, S.; Li, F.; Cao, X.; Sun, R. Production of vanillin from lignin: The relationship between β-O-4 linkages and vanillin yield. Ind. Crops Prod. 2018, 116, 116–121. [Google Scholar] [CrossRef]

- Mohamad Ibrahim, M.N.; Nadiah, M.Y.N.; Norliyana, M.S.; Sipaut, C.S.; Shuib, S. Separation of vanillin from oil palm empty fruit bunch lignin. Clean (Weinh.) 2008, 36, 287–291. [Google Scholar] [CrossRef]

- Taraban’ko, V.E.; Koropatchinskaya, N.V.; Kudryashev, A.V.; Kuznetsov, B.N. Influence of lignin origin on the efficiency of the catalytic oxidation of lignin into vanillin and syringaldehyde. Russ. Chem. Bull. 1995, 44, 367–371. [Google Scholar] [CrossRef]

- Wong, Z.; Chen, K.; Li, J. Formation of vanillin and syringaldehyde in an oxygen delignification process. Bioresources 2010, 5, 1509–1516. [Google Scholar]

- Zhang, J.; Deng, H.; Lin, L. Wet aerobic oxidation of lignin into aromatic aldehydes catalysed by a perovskite-type oxide: LaFe1-xCuxO3 (x=0, 0.1, 0.2). Molecules 2009, 14, 2747–2757. [Google Scholar] [CrossRef]

- Gomes, E.D.; Rodrigues, A.E. Lignin biorefinery: Separation of vanillin, vanillic acid and acetovanillone by adsorption. Sep. Purif. Technol. 2019, 216, 92–101. [Google Scholar] [CrossRef]

- Li, Y.-X.; Zhu, J.-P.; Zhang, Z.-J.; Qu, Y.-S. Preparation of syringaldehyde from lignin by catalytic oxidation of perovskite-type oxides. ACS Omega 2020, 5, 2107–2113. [Google Scholar] [CrossRef]

- Jeon, W.; Choi, I.-H.; Park, J.-Y.; Lee, J.-S.; Hwang, K.-R. Alkaline wet oxidation of lignin over Cu-Mn mixed oxide catalysts for production of vanillin. Catal. Today 2020, 352, 95–103. [Google Scholar] [CrossRef]

- Maeda, M.; Hosoya, T.; Yoshioka, K.; Miyafuji, H.; Ohno, H.; Yamada, T. Vanillin production from native softwood lignin in the presence of tetrabutylammonium ion. J. Wood Sci. 2018, 64, 810–815. [Google Scholar] [CrossRef]

- Gomes, E.D.; Rodrigues, A.E. Recovery of vanillin from kraft lignin depolymerization with water as desorption eluent. Sep. Purif. Technol. 2020, 239, 116551. [Google Scholar] [CrossRef]

- Gitaari, N.; Benard, K.; Gichuki, J.; Kareru, P. Synthesis of vanillin from lignin. Chem. Sci. Int. J. 2019, 27, 1–5. [Google Scholar] [CrossRef]

- Zhu, Y.; Liao, Y.; Lv, W.; Liu, J.; Song, X.; Chen, L.; Wang, C.; Sels, B.F.; Ma, L. Complementing vanillin and cellulose production by oxidation of lignocellulose with stirring control. ACS Sustain. Chem. Eng. 2020, 8, 2361–2374. [Google Scholar] [CrossRef]

- Zhang, R.; Maltari, R.; Guo, M.; Kontro, J.; Eronen, A.; Repo, T. Facile synthesis of vanillin from fractionated Kraft lignin. Ind. Crops Prod. 2020, 145, 112095. [Google Scholar] [CrossRef]

- Yan, K.; Zhang, Y.; Tu, M.; Sun, Y. Electrocatalytic valorization of organosolv lignin utilizing a nickel-based electrocatalyst. Energy Fuels 2020, 34, 12703–12709. [Google Scholar] [CrossRef]

- Liu, S.; Das, L.; Blauch, D.N.; Veronee, C.; Dou, C.; Gladden, J.; Sun, N.; Socha, A.M. Statistical design of experiments for production and purification of vanillin and aminophenols from commercial lignin. Green Chem. 2020, 22, 3917–3926. [Google Scholar] [CrossRef]

- Ninomiya, K.; Ochiai, K.; Eguchi, M.; Kuroda, K.; Tsuge, Y.; Ogino, C.; Taima, T.; Takahashi, K. Oxidative depolymerization potential of biorefinery lignin obtained by ionic liquid pretreatment and subsequent enzymatic saccharification of eucalyptus. Ind. Crops Prod. 2018, 111, 457–461. [Google Scholar] [CrossRef]

- Westwood, N.J.; Panovic, I.; Lancefield, C.S. Chemical modification of lignin for renewable polymers or chemicals. In Production of Biofuels and Chemicals from Lignin; Fang, Z., Smith, J.R.L., Eds.; Springer: Singapore, 2016; pp. 183–216. [Google Scholar] [CrossRef]

- Upton, B.M.; Kasko, A.M. Strategies for the conversion of lignin to high-value polymeric materials: Review and perspective. Chem. Rev. 2016, 116, 2275–2306. [Google Scholar] [CrossRef]

- Sen, S.; Patil, S.; Argyropoulos, D.S. Thermal properties of lignin in copolymers, blends, and composites: A review. Green Chem. 2015, 17, 4862–4887. [Google Scholar] [CrossRef]

- Faruk, O.; Sain, M. Lignin in Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Llevot, A.; Grau, E.; Carlotti, S.; Grelier, S.; Cramail, H. From lignin-derived aromatic compounds to novel biobased polymers. Macromol. Rapid Commun. 2016, 37, 9–28. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Zhao, X.; Wang, A.; Huber, G.W.; Zhang, T. Catalytic transformation of lignin for the production of chemicals and fuels. Chem. Rev. 2015, 115, 11559–11624. [Google Scholar] [CrossRef] [PubMed]

- Fache, M.; Boutevin, B.; Caillol, S. Vanillin, a key-intermediate of biobased polymers. Eur. Polym. J. 2015, 68, 488–502. [Google Scholar] [CrossRef]

- Fache, M.; Darroman, E.; Besse, V.; Auvergne, R.; Caillol, S.; Boutevin, B. Vanillin, a promising biobased building-block for monomer synthesis. Green Chem. 2014, 16, 1987–1998. [Google Scholar] [CrossRef]

- Fache, M.; Viola, A.; Auvergne, R.; Boutevin, B.; Caillol, S. Biobased epoxy thermosets from vanillin-derived oligomers. Eur. Polym. J. 2015, 68, 526–535. [Google Scholar] [CrossRef]

- Fache, M.; Auvergne, R.; Boutevin, B.; Caillol, S. New vanillin-derived diepoxy monomers for the synthesis of biobased thermosets. Eur. Polym. J. 2015, 67, 527–538. [Google Scholar] [CrossRef]

- Harvey, B.G.; Guenthner, A.J.; Meylemans, H.A.; Haines, S.R.L.; Lamison, K.R.; Groshens, T.J.; Cambrea, L.R.; Davis, M.C.; Lai, W.W. Renewable thermosetting resins and thermoplastics from vanillin. Green Chem. 2015, 17, 1249–1258. [Google Scholar] [CrossRef]

- Stanzione Iii, J.F.; Sadler, J.M.; La Scala, J.J.; Reno, K.H.; Wool, R.P. Vanillin-based resin for use in composite applications. Green Chem. 2012, 14, 2346–2352. [Google Scholar] [CrossRef]

- Mirzakhanian, Z.; Faghihi, K.; Geravi, H.A.; Mahdieh, M. Semi-aromatic polyimide/Ag nanocomposite derived from vanillin. J. Appl. Polym. Sci. 2016, 133, 44001. [Google Scholar] [CrossRef]

- Chauhan, N.P.S.; Kataria, P.; Chaudhary, J.; Ameta, S.C. Synthesis, Characterization, and Thermal Studies of Terpolymers Derived from Vanillin, Furfural, and Halo-Substituted Acetophenones. Int. J. Polym. Mater. Polym. Biomater. 2012, 61, 57–71. [Google Scholar] [CrossRef]

- Chauhan, N.P.S. Preparation and characterization of bio-based terpolymer derived from vanillin oxime, formaldehyde, and p-hydroxyacetophenone. Des. Monomers Polym. 2014, 17, 176–185. [Google Scholar] [CrossRef]

- Sini, N.K.; Bijwe, J.; Varma, I.K. Renewable benzoxazine monomer from Vanillin: Synthesis, characterization, and studies on curing behavior. J. Polym. Sci. Part A Polym. Chem. 2014, 52, 7–11. [Google Scholar] [CrossRef]

- Nishimura, R.T.; Giammanco, C.H.; Vosburg, D.A. Green, enzymatic syntheses of divanillin and diapocynin for the organic, biochemistry, or advanced general chemistry laboratory. J. Chem. Educ. 2010, 87, 526–527. [Google Scholar] [CrossRef]

- Llevot, A.; Grau, E.; Carlotti, S.; Grelier, S.; Cramail, H. Renewable (semi)aromatic polyesters from symmetrical vanillin-based dimers. Polym. Chem. 2015, 6, 6058–6066. [Google Scholar] [CrossRef]

- Llevot, A.; Grau, E.; Carlotti, S.; Grelier, S.; Cramail, H. Selective laccase-catalyzed dimerization of phenolic compounds derived from lignin: Towards original symmetrical bio-based (bis) aromatic monomers. J. Mol. Catal. B Enzym. 2016, 125, 34–41. [Google Scholar] [CrossRef]

- Savonnet, E.; Grau, E.; Grelier, S.; Defoort, B.; Cramail, H. Divanillin-based epoxy precursors as DGEBA substitutes for biobased epoxy thermosets. ACS Sustain. Chem. Eng. 2018, 6, 11008–11017. [Google Scholar] [CrossRef]

- Yamamoto, H.; Hoshino, T.; Uchiyama, T. Convenient preparation and quantification of 5,5′-diferulic acid. Biosci. Biotechnol. Biochem. 1999, 63, 390–394. [Google Scholar] [CrossRef]

- Kelly, D.R.; Baker, S.C.; King, D.S.; de Silva, D.S.; Lord, G.; Taylor, J.P. Studies of nitrile oxide cycloadditions, and the phenolic oxidative coupling of vanillin aldoxime by Geobacillus sp. DDS012 from Italian rye grass silage. Org. Biomol. Chem. 2008, 6, 787–796. [Google Scholar] [CrossRef]

- Delomenède, M.; Bedos-Belval, F.; Duran, H.; Vindis, C.; Baltas, M.; Nègre-Salvayre, A. Development of novel antiatherogenic biaryls: Design, synthesis, and reactivity. J. Med. Chem. 2008, 51, 3171–3181. [Google Scholar] [CrossRef]

- Fang, Z.; Nikafshar, S.; Hegg, E.L.; Nejad, M. Biobased divanillin as a precursor for formulating biobased epoxy resin. ACS Sustain. Chem. Eng. 2020, 8, 9095–9103. [Google Scholar] [CrossRef]

- Amarasekara, A.S.; Wiredu, B.; Razzaq, A. Vanillin based polymers: I. An electrochemical route to polyvanillin. Green Chem. 2012, 14, 2395–2397. [Google Scholar] [CrossRef]

- Maiorana, A.; Reano, A.F.; Centore, R.; Grimaldi, M.; Balaguer, P.; Allais, F.; Gross, R.A. Structure property relationships of biobased n-alkyl bisferulate epoxy resins. Green Chem. 2016, 18, 4961–4973. [Google Scholar] [CrossRef]

- Amarasekara, A.S.; Razzaq, A. Vanillin-based polymers—Part II: Synthesis of Schiff base polymers of divanillin and their chelation with metal ions. ISRN Polym. Sci. 2012, 2012, 532171. [Google Scholar] [CrossRef]

- Fache, M.; Boutevin, B.; Caillol, S. Epoxy thermosets from model mixtures of the lignin-to-vanillin process. Green Chem. 2016, 18, 712–725. [Google Scholar] [CrossRef]

- Zhao, S.; Abu-Omar, M.M. Recyclable and malleable epoxy thermoset bearing aromatic imine bonds. Macromolecules 2018, 51, 9816–9824. [Google Scholar] [CrossRef]

- Forsythe, W.G.; Garrett, M.D.; Hardacre, C.; Nieuwenhuyzen, M.; Sheldrake, G.N. An efficient and flexible synthesis of model lignin oligomers. Green Chem. 2013, 15, 3031–3038. [Google Scholar] [CrossRef]

- Llevot, A.; Grau, E.; Carlotti, S.; Grelier, S.; Cramail, H. ADMET polymerization of bio-based biphenyl compounds. Polym. Chem. 2015, 6, 7693–7700. [Google Scholar] [CrossRef]

- Gang, H.; Lee, D.; Choi, K.-Y.; Kim, H.-N.; Ryu, H.; Lee, D.-S.; Kim, B.-G. Development of high performance polyurethane elastomers using vanillin-based green polyol chain extender originating from lignocellulosic biomass. ACS Sustain. Chem. Eng. 2017, 5, 4582–4588. [Google Scholar] [CrossRef]

- Wang, S.; Ma, S.; Xu, C.; Liu, Y.; Dai, J.; Wang, Z.; Liu, X.; Chen, J.; Shen, X.; Wei, J.; et al. Vanillin-derived high-performance flame retardant epoxy resins: Facile synthesis and properties. Macromolecules 2017, 50, 1892–1901. [Google Scholar] [CrossRef]

- Hernandez, E.D.; Bassett, A.W.; Sadler, J.M.; La Scala, J.J.; Stanzione, J.F. Synthesis and characterization of bio-based epoxy resins derived from vanillyl alcohol. ACS Sustain. Chem. Eng. 2016, 4, 4328–4339. [Google Scholar] [CrossRef]

- An, E.S.; Cho, D.H.; Choi, J.W.; Kim, Y.H.; Song, B.K. Peroxidase-catalyzed copolymerization of syringaldehyde and bisphenol A. Enzyme Microb. Technol. 2010, 46, 287–291. [Google Scholar] [CrossRef]

- Rostagno, M.; Shen, S.; Ghiviriga, I.; Miller, S.A. Sustainable polyvinyl acetals from bioaromatic aldehydes. Polym. Chem. 2017, 8, 5049–5059. [Google Scholar] [CrossRef]

- Kwon, J.; Kim, J.; Park, S.; Khang, G.; Kang, P.M.; Lee, D. Inflammation-responsive antioxidant nanoparticles based on a polymeric prodrug of vanillin. Biomacromolecules 2013, 14, 1618–1626. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Lepoittevin, B.; Roddier, C.; Guerineau, V.; Bech, L.; Herry, J.-M.; Bellon-Fontaine, M.-N.; Roger, P. Facile synthesis and promising antibacterial properties of a new guaiacol-based polymer. Polymer 2011, 52, 1908–1916. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, H.; Deng, J.; Wu, Y. High glass-transition temperature acrylate polymers derived from biomasses, syringaldehyde, and vanillin. Macromol. Chem. Phys. 2016, 217, 2402–2408. [Google Scholar] [CrossRef]

- Kakuchi, R.; Yoshida, S.; Sasaki, T.; Kanoh, S.; Maeda, K. Multi-component post-polymerization modification reactions of polymers featuring lignin-model compounds. Polym. Chem. 2018, 9, 2109–2115. [Google Scholar] [CrossRef]

- Zhang, H.; Yong, X.; Zhou, J.; Deng, J.; Wu, Y. Biomass vanillin-derived polymeric microspheres containing functional aldehyde groups: Preparation, characterization, and application as adsorbent. ACS Appl. Mater. Interfaces 2016, 8, 2753–2763. [Google Scholar] [CrossRef]

- Zhang, H.; Deng, J.; Wu, Y. Biobased magnetic microspheres containing aldehyde groups: Constructed by vanillin-derived polymethacrylate/Fe3O4 and recycled in adsorbing amine. ACS Sustain. Chem. Eng. 2017, 5, 658–666. [Google Scholar] [CrossRef]

- Ma, S.; Li, T.; Liu, X.; Zhu, J. Research progress on bio-based thermosetting resins. Polym. Int. 2016, 65, 164–173. [Google Scholar] [CrossRef]

- Ratna, D. Handbook of Thermoset Resins; iSmithers: Shawbury, UK, 2009. [Google Scholar]

- Auvergne, R.; Caillol, S.; David, G.; Boutevin, B.; Pascault, J.-P. Biobased thermosetting epoxy: Present and future. Chem. Rev. 2014, 114, 1082–1115. [Google Scholar] [CrossRef]

- Zhao, S.; Abu-Omar, M.M. Renewable thermoplastics based on lignin-derived polyphenols. Macromolecules 2017, 50, 3573–3581. [Google Scholar] [CrossRef]

- Kayser, L.V.; Hartigan, E.M.; Arndtsen, B.A. Multicomponent coupling approach to cross-conjugated polymers from vanillin-based monomers. ACS Sustain. Chem. Eng. 2016, 4, 6263–6267. [Google Scholar] [CrossRef]

- Holmberg, A.L.; Nguyen, N.A.; Karavolias, M.G.; Reno, K.H.; Wool, R.P.; Epps, T.H. Softwood lignin-based methacrylate polymers with tunable thermal and viscoelastic properties. Macromolecules 2016, 49, 1286–1295. [Google Scholar] [CrossRef]

- Holmberg, A.L.; Reno, K.H.; Nguyen, N.A.; Wool, R.P.; Epps, T.H. Syringyl methacrylate, a hardwood lignin-based monomer for high-Tg polymeric materials. ACS Macro Lett. 2016, 5, 574–578. [Google Scholar] [CrossRef] [PubMed]

- Sini, N.K.; Bijwe, J.; Varma, I.K. Thermal behaviour of bis-benzoxazines derived from renewable feed stock ‘vanillin’. Polym. Degrad. Stab. 2014, 109, 270–277. [Google Scholar] [CrossRef]

- Sun, H.; Young, Y.D.; Kanehashi, S.; Tsuchiya, K.; Ogino, K.; Sim, J.-H. Synthesis and characterization of biobased poly (ether benzoxazole) derived from vanillin. J. Fiber Sci. Technol. 2016, 72, 89–95. [Google Scholar] [CrossRef]

- Tachibana, K.; Abe, H. Studies on thermo-mechanical and thermal degradation properties of bio-based polyurethanes synthesized from vanillin-derived diol and lysine diisocyanate. Polym. Degrad. Stab. 2019, 167, 283–291. [Google Scholar] [CrossRef]

- Zhao, C.; Huang, C.; Chen, Q.; Ingram, I.D.V.; Zeng, X.; Ren, T.; Xie, H. Sustainable aromatic aliphatic polyesters and polyurethanes prepared from vanillin-derived diols via green catalysis. Polymers 2020, 12, 586. [Google Scholar] [CrossRef]

- Shibata, M.; Ohkita, T. Fully biobased epoxy resin systems composed of a vanillin-derived epoxy resin and renewable phenolic hardeners. Eur. Polym. J. 2017, 92, 165–173. [Google Scholar] [CrossRef]

- Han, Y.; Tang, D.-H.; Wang, G.-X.; Sun, Y.-N.; Guo, Y.; Zhou, H.; Qiu, W.-F.; Zhao, T. Phthalonitrile resins derived from vanillin: Synthesis, curing behavior, and thermal properties. Chin. J. Polym. Sci. 2020, 38, 72–83. [Google Scholar] [CrossRef]

- Amarasekara, A.S.; Garcia-Obergon, R.; Thompson, A.K. Vanillin-based polymers: IV. Hydrovanilloin epoxy resins. J. Appl. Polym. Sci. 2019, 136, 47000. [Google Scholar] [CrossRef]

- Zhao, R.; Yong, X.; Pan, M.; Deng, J.; Pan, K. Aldehyde-containing nanofibers electrospun from biomass vanillin-derived polymer and their application as adsorbent. Sep. Purif. Technol. 2020, 246, 116916. [Google Scholar] [CrossRef]

- Shuai, L.; Amiri, M.T.; Questell-Santiago, Y.M.; Héroguel, F.; Li, Y.; Kim, H.; Meilan, R.; Chapple, C.; Ralph, J.; Luterbacher, J.S. Formaldehyde stabilization facilitates lignin monomer production during biomass depolymerization. Science 2016, 354, 329–333. [Google Scholar] [CrossRef] [PubMed]

- Deuss, P.J.; Scott, M.; Tran, F.; Westwood, N.J.; De Vries, J.G.; Barta, K. Aromatic monomers by in situ conversion of reactive intermediates in the acid-catalyzed depolymerization of lignin. J. Am. Chem. Soc. 2015, 137, 7456–7467. [Google Scholar] [CrossRef] [PubMed]

- Lahive, C.W.; Deuss, P.J.; Lancefield, C.S.; Sun, Z.; Cordes, D.B.; Young, C.M.; Tran, F.; Slawin, A.M.Z.; De Vries, J.G.; Kamer, P.C.J.; et al. Advanced model compounds for understanding acid-catalyzed lignin depolymerization: Identification of renewable aromatics and a lignin-derived solvent. J. Am. Chem. Soc. 2016, 138, 8900–8911. [Google Scholar] [CrossRef]

- Deuss, P.J.; Lancefield, C.S.; Narani, A.; De Vries, J.G.; Westwood, N.J.; Barta, K. Phenolic acetals from lignins of varying compositions via iron(iii) triflate catalysed depolymerisation. Green Chem. 2017, 19, 2774–2782. [Google Scholar] [CrossRef]

- Galkin, M.V.; Samec, J.S.M. Lignin valorization through catalytic lignocellulose fractionation: A fundamental platform for the future biorefinery. ChemSusChem 2016, 9, 1544–1558. [Google Scholar] [CrossRef]

- Tarabanko, V.E.; Tarabanko, N. Catalytic oxidation of lignins into the aromatic aldehydes: General process trends and development prospects. Int. J. Mol. Sci. 2017, 18, 2421. [Google Scholar] [CrossRef]

- Kim, S.; Tsang, Y.F.; Kwon, E.E.; Lin, K.-Y.A.; Lee, J. Recently developed methods to enhance stability of heterogeneous catalysts for conversion of biomass-derived feedstocks. Korean J. Chem. Eng. 2019, 36, 1–11. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, N.; Kim, Y.T.; Lee, J. Recent Advances in Renewable Polymer Production from Lignin-Derived Aldehydes. Polymers 2021, 13, 364. https://doi.org/10.3390/polym13030364

Lee N, Kim YT, Lee J. Recent Advances in Renewable Polymer Production from Lignin-Derived Aldehydes. Polymers. 2021; 13(3):364. https://doi.org/10.3390/polym13030364

Chicago/Turabian StyleLee, Nahyeon, Yong Tae Kim, and Jechan Lee. 2021. "Recent Advances in Renewable Polymer Production from Lignin-Derived Aldehydes" Polymers 13, no. 3: 364. https://doi.org/10.3390/polym13030364

APA StyleLee, N., Kim, Y. T., & Lee, J. (2021). Recent Advances in Renewable Polymer Production from Lignin-Derived Aldehydes. Polymers, 13(3), 364. https://doi.org/10.3390/polym13030364