Selected Properties of Cement Bound Spruce and Larch Bark Bio-Aggregates

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation for Hydration Behaviour

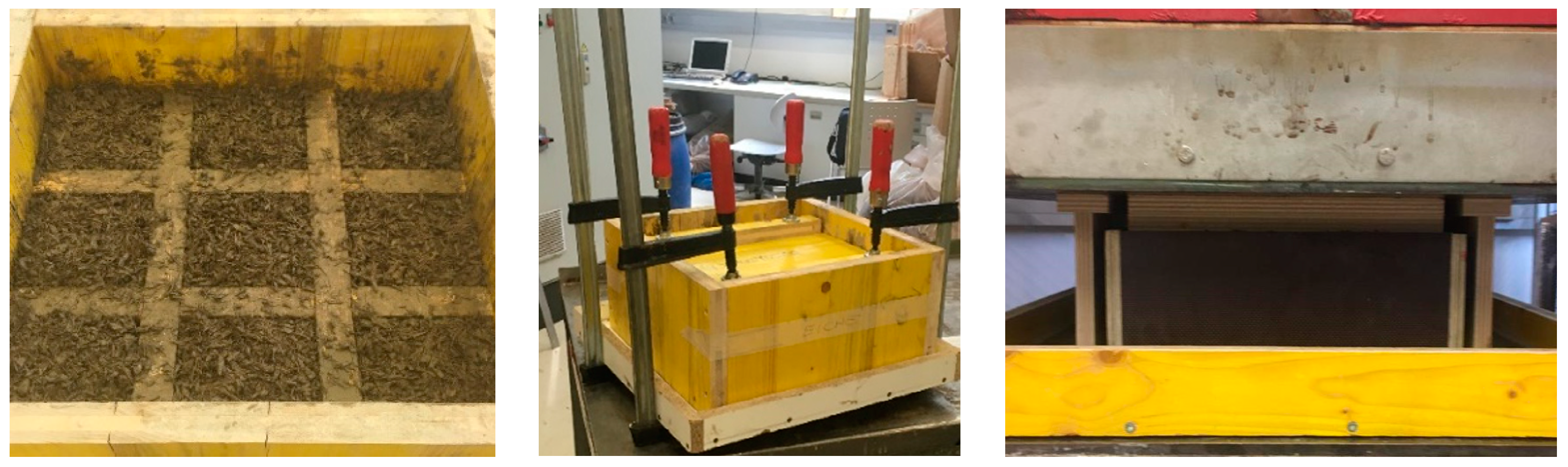

2.2. Sample Preparation for Determination of Density and Compressive Strength

3. Results and Discussion

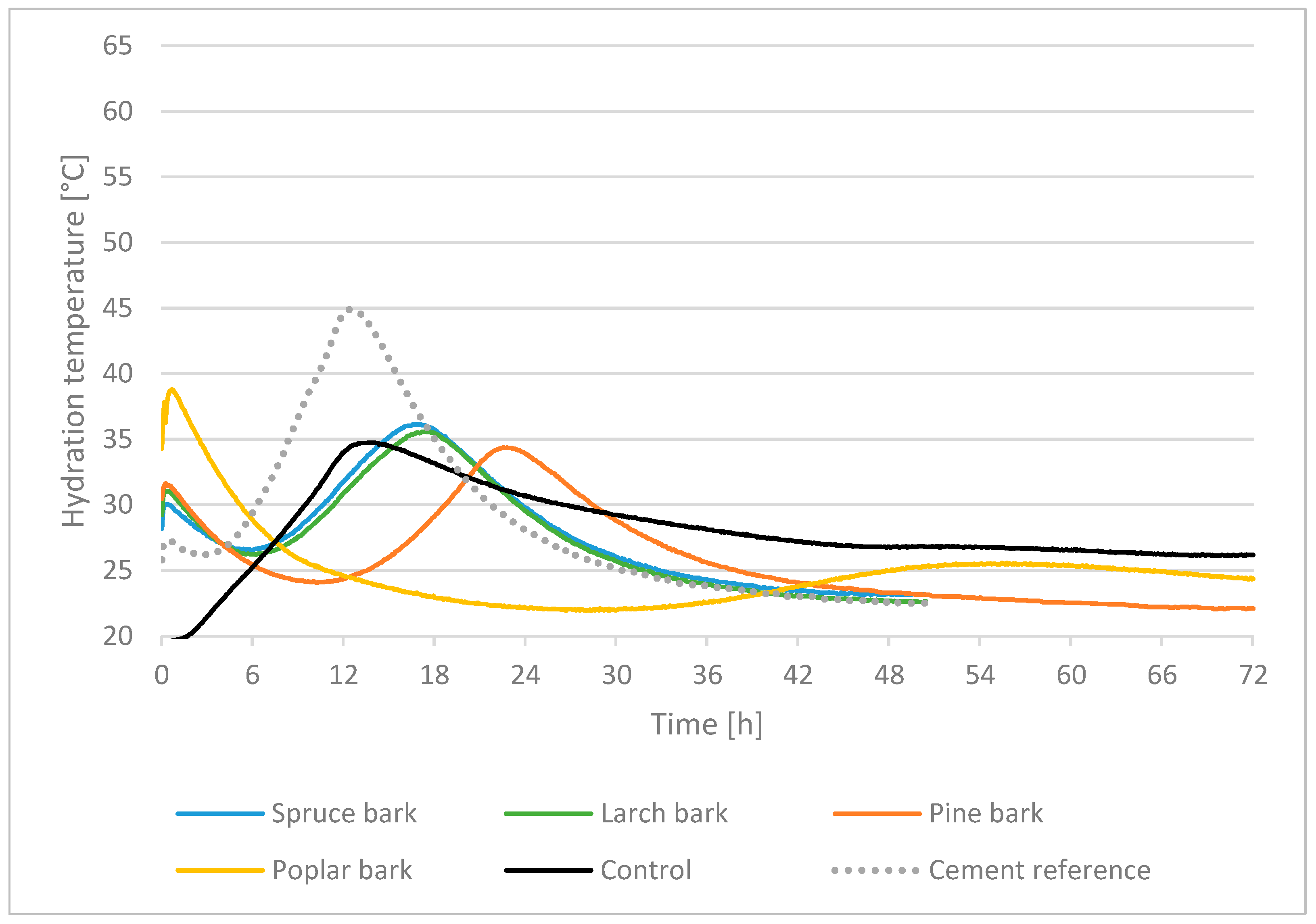

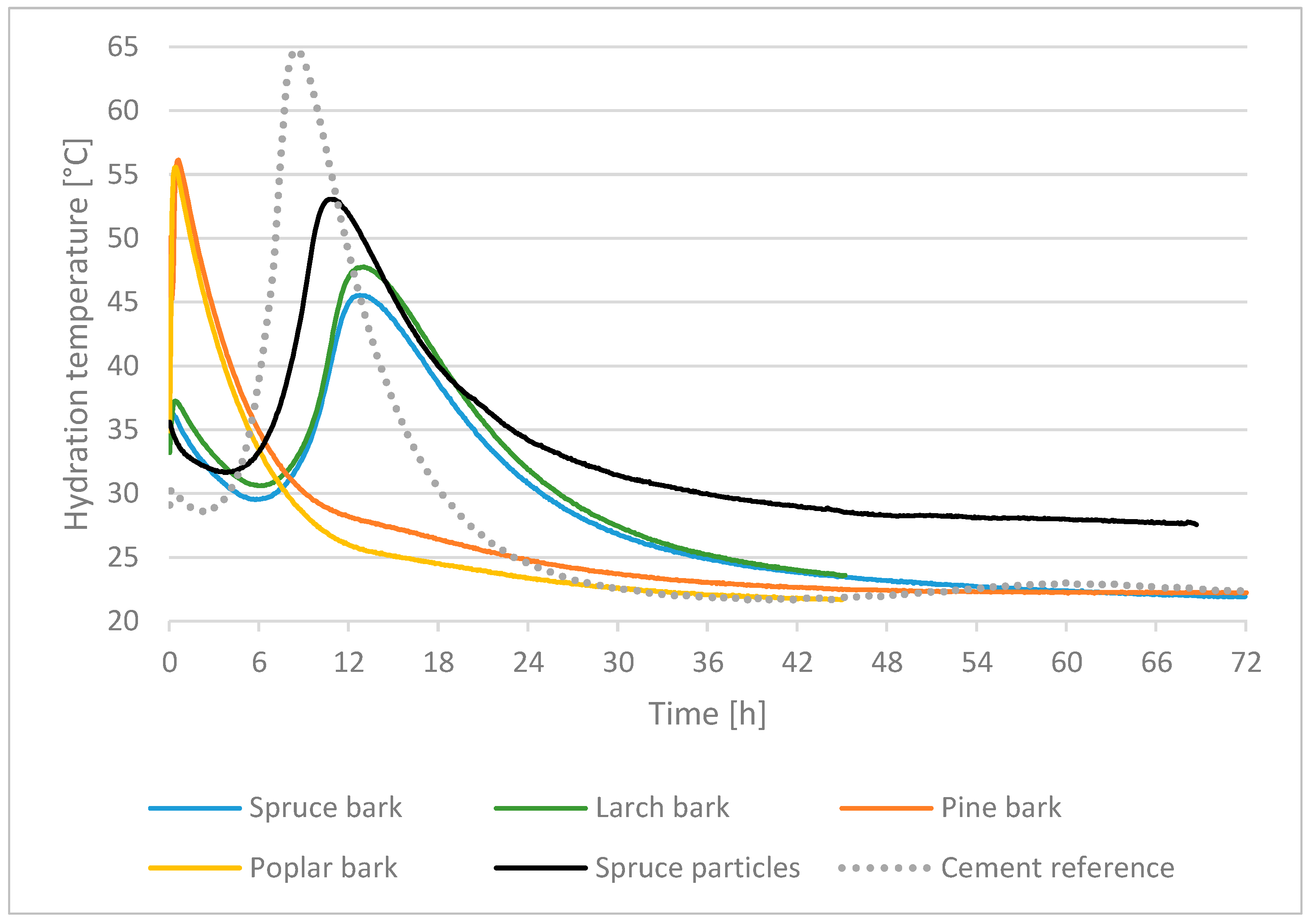

3.1. Hydration Temperature Measurements

- I

- inhibitory index (I-Index)

- time required for the wood–cement mixture to reach maximum temperature [h]

- time required for cement to reach maximum temperature [h]

- maximum temperature of the wood-cement mixture [°C]

- maximum temperature of cement [°C]

- S

- slope of the temperature curve of the wood-cement mixture>

- S’

- slope of the temperature curve of cement

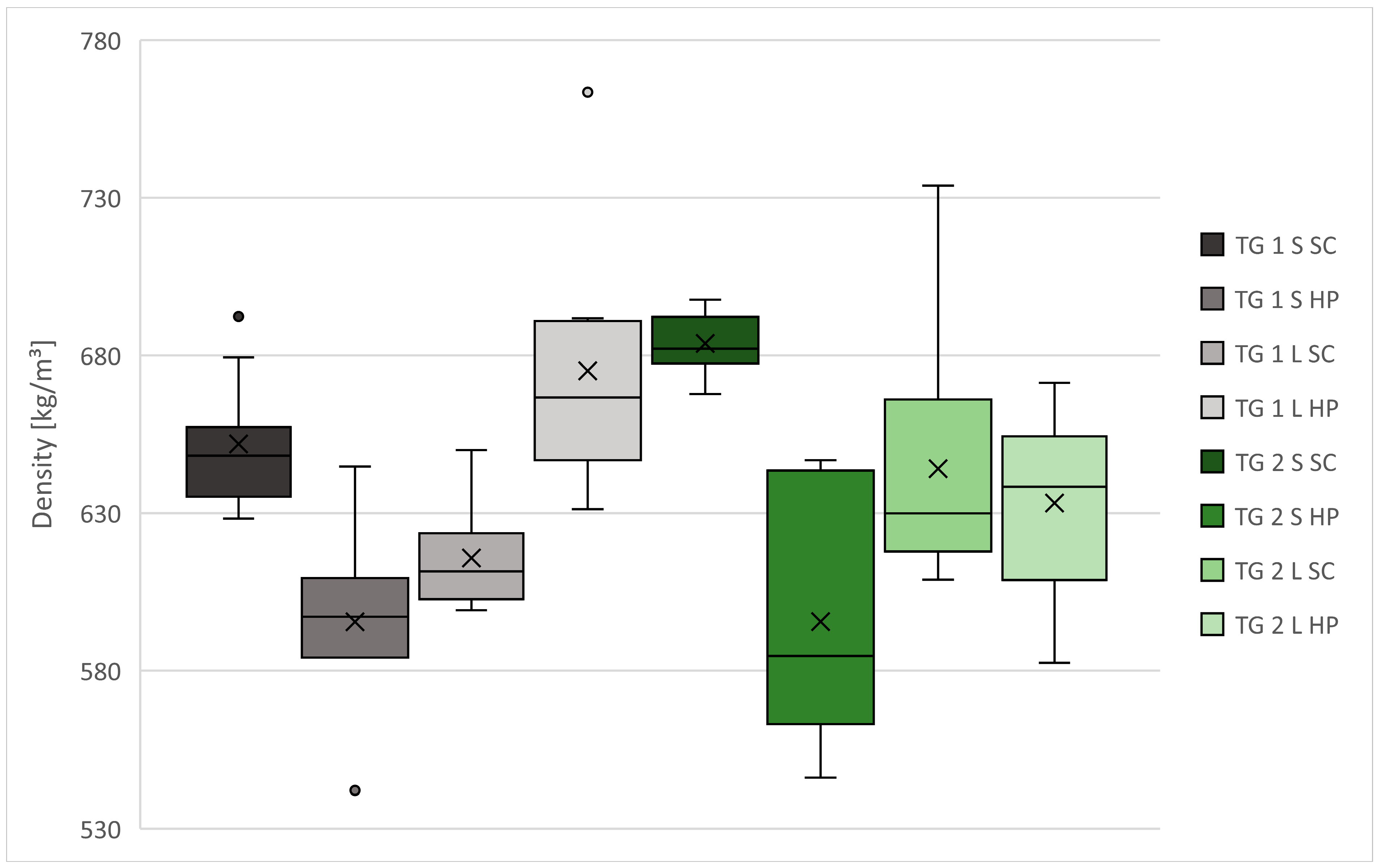

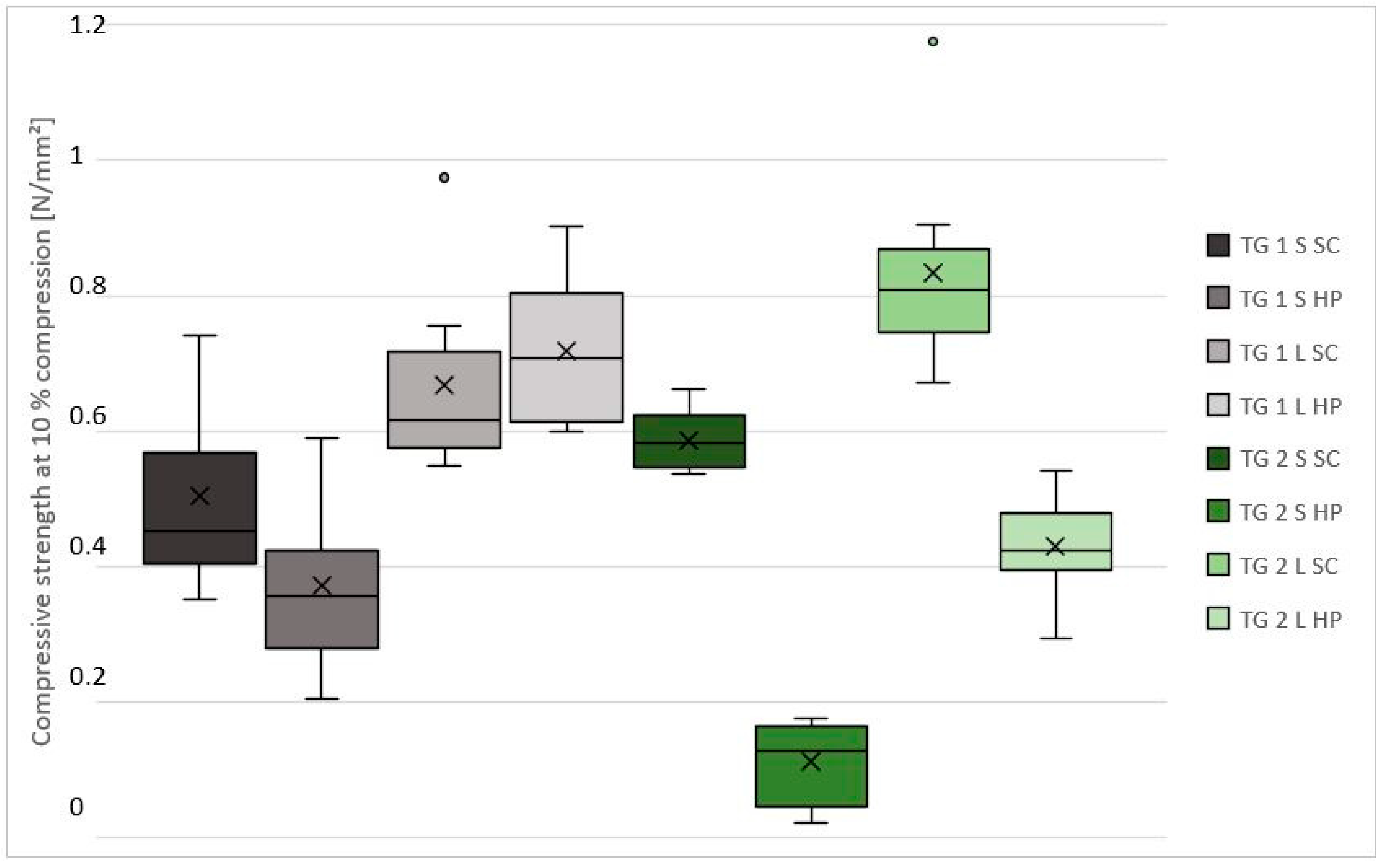

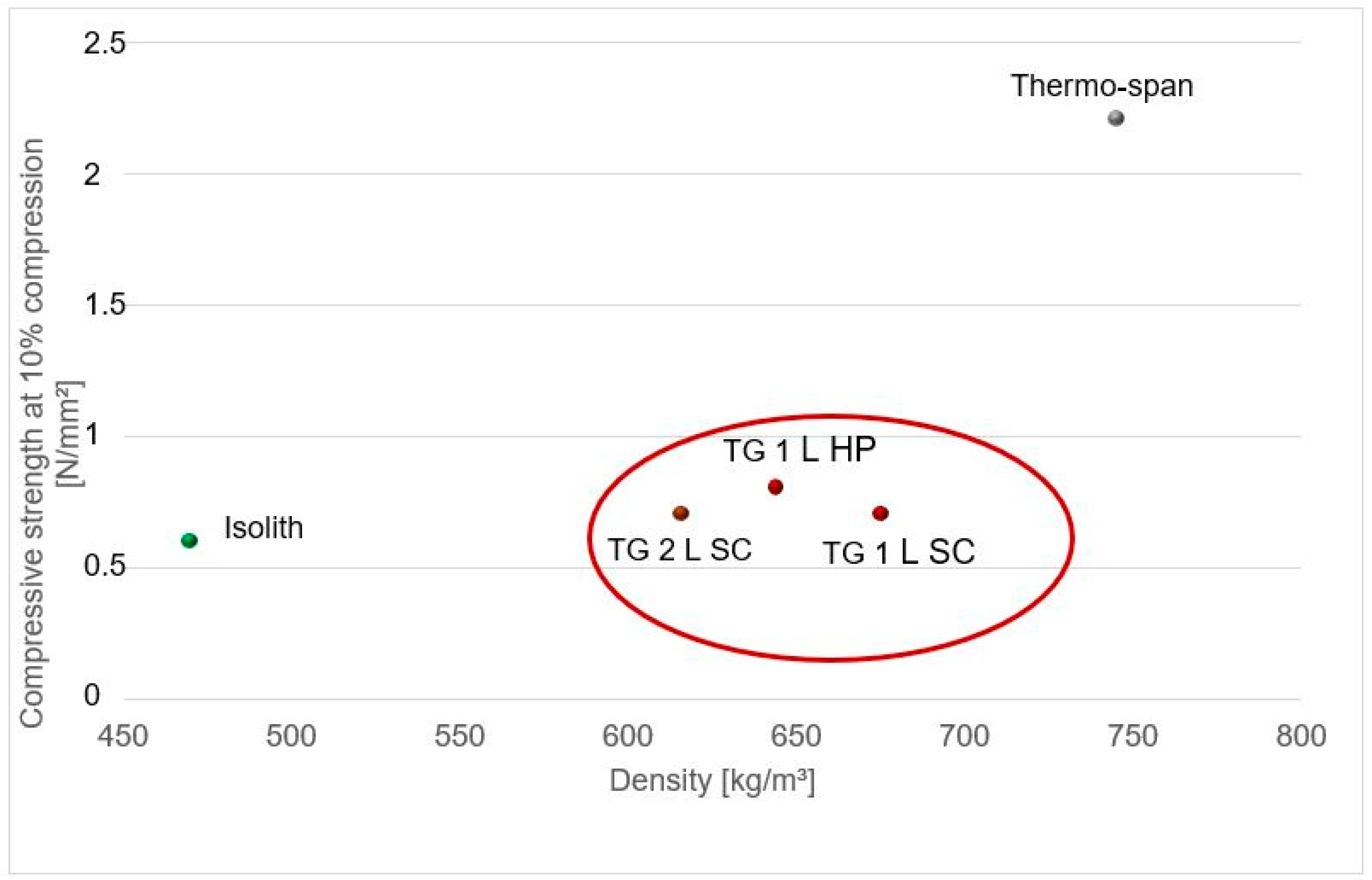

3.2. Densities and Compressive Strengths

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Paulitsch, M.; Barbu, M.C. Holzwerkstoffe der Moderne, 1. Auflage; DRW-Verlag: Leinfelden-Echterdingen, Germany, 2015; ISBN 9783871818912. [Google Scholar]

- Wassilieff, C. Sound absorption of wood-based materials. Appl. Acoust. 1996, 48, 339–356. [Google Scholar] [CrossRef]

- Dunky, M.; Niemz, P. Holzwerkstoffe und Leime: Technologie und Einflussfaktoren; mit 150 Tabellen; Springer: Berlin/Heidelberg, Germany, 2002; ISBN 978-3-540-42980-7. [Google Scholar]

- Botterman, B.; La Doudart de Grée, G.; Hornikx, M.; Yu, Q.L.; Brouwers, H. Modelling and optimization of the sound absorption of wood-wool cement boards. Appl. Acoust. 2018, 129, 144–154. [Google Scholar] [CrossRef]

- Pereira, C.; Caldeira, J.F.; Irle, M.; Ferreira, J.M. Characterizing the setting of cement when mixed with cork, blue gum, or maritime pine, grown in Portugal I: Temperature profiles and compatibility indices. J. Wood Sci. 2006, 52, 311–317. [Google Scholar] [CrossRef]

- Moslemi, A.A.; Lim, Y.T. Compatibility of southern hardwoods with Portland cement. For. Prod. J. 1984, 34, 22–26. [Google Scholar]

- Patel, M.; Patel, K.; Patel, A.; Prajapati, R.; Koshti, U. Study of Sawdust Concrete Properties as Construction Materials. In Proceedings of the 3rd International Conference on Multidisciplinary Research & Practice, Ahmedabad, India, 24 December 2016. [Google Scholar]

- Acharya, S.; Neupane, U.; Adhikari, S. Strength Optimization of Sawdust Concrete through Cement Variation. Proceedings of 8th IOE Graduate Conference, Kathmandu, Nepal, 5–7 June 2020; pp. 730–736. [Google Scholar]

- Plotnikov, N.; Kochetkov, I. Possibility of using sawdust in sawdust concrete. E3S Web Conf. 2021, 244, 4011. [Google Scholar] [CrossRef]

- Sonntag, F. Wandbauten mit Schalungssteinen aus Holzspanbeton; Hochschule für Technik; Wirtschaft und Kultur Leipzig: Leipzig, Germany, 2003. [Google Scholar]

- Vaickelionis, G.; Vaickelioniene, R. Cement hydration in the presence of wood extractives and pozzolan mineral additives. Ceram. Silik. 2006, 50, 115–122. [Google Scholar]

- Frybort, S.; Mauritz, R.; Teischinger, A.; Müller, U. Cement bonded composites—A mechanical review. BioResources 2008, 3, 602–626. [Google Scholar]

- Lin, X.; Silsbee, M.R.; Roy, D.M.; Kessler, K.; Blankenhorn, P.R. Approaches to improve the properties of wood fiber reinforced cementitious composites. Cem. Concr. Res. 1994, 24, 1558–1566. [Google Scholar] [CrossRef]

- Weatherwax, R.C.; Tarkow, H. Effect of Wood on Setting of Portland Cement. For. Prod. J. 1964, 14, 567–570. [Google Scholar]

- Sandermann, W.; Brendel, M. Studien über mineralgebundene Holzwerkstoffe—Zweite Mitteilung: Die „zementvergiftende” Wirkung von Holzinhaltsstoffen und ihre Abhängigkeit von der chemischen Konstitution. Holz als Roh-und Werkstoff 1956, 14, 307–313. [Google Scholar] [CrossRef]

- Hofstrand, A.D.; Moslemi, A.; Garcia, J.F. Curing characteristics of wood particles from nine northern Rocky Mountain species mixed with Portland cement. For. Prod. J. 1984, 34, 57–61. [Google Scholar]

- Garcez, M.R.; Garcez, E.O.; Machado, A.O.; Gatto, D.A. Cement-Wood Composites: Effects of Wood Species, Particle Treatments and Mix Proportion. Int. J. Compos. Mater. 2016, 6, 1–8. [Google Scholar] [CrossRef][Green Version]

- Li, M.; Khelifa, M.; El Ganaoui, M. Mechanical characterization of concrete containing wood shavings as aggregates. Int. J. Sustain. Built Environ. 2017, 6, 587–596. [Google Scholar] [CrossRef]

- Tudor, E.M.; Zwickl, C.; Eichinger, C.; Petutschnigg, A.; Barbu, M.C. Performance of softwood bark comminution technologies for determination of targeted particle size in further upcycling applications. J. Cleaner Prod. 2020, 269, 122412. [Google Scholar] [CrossRef]

- Giannotas, G.; Kamperidou, V.; Barboutis, I. Tree bark utilization in insulating bio-aggregates: A review. Biofuels Bioprod. Biorefin. 2021, 15, 1989–1999. [Google Scholar] [CrossRef]

- Pásztory, Z.; Mohácsiné, I.R.; Gorbacheva, G.; Börcsök, Z. The utilization of tree bark. BioResources 2016, 11, 7859–7888. [Google Scholar] [CrossRef]

- Kain, G.; Tudor, E.M.; Blanchet, P. Bark Thermal Insulation Panels: An Explorative Study on the Effects of Bark Species. Polymers 2020, 12, 2140. [Google Scholar] [CrossRef]

- Gößwald, J.; Barbu, M.C.; Petutschnigg, A.; Tudor, E.M. Binderless Thermal Insulation Panels Made of Spruce Bark Fibres. Polymers 2021, 13, 1799. [Google Scholar] [CrossRef] [PubMed]

- Kristak, L.; Ruziak, I.; Tudor, E.M.; Barbu, M.C.; Kain, G.; Reh, R. Thermophysical Properties of Larch Bark Composite Panels. Polymers 2021, 13, 2287. [Google Scholar] [CrossRef] [PubMed]

- Tudor, E.M.; Dettendorfer, A.; Kain, G.; Barbu, M.C.; Réh, R.; Krišťák, L. Sound-Absorption Coefficient of Bark-Based Insulation Panels. Polymers 2020, 12, 1012. [Google Scholar] [CrossRef] [PubMed]

- Tudor, E.M.; Kristak, L.; Barbu, M.C.; Gergeľ, T.; Němec, M.; Kain, G.; Réh, R. Acoustic Properties of Larch Bark Panels. Forests 2021, 12, 887. [Google Scholar] [CrossRef]

- Tudor, E.M.; Scheriau, C.; Barbu, M.C.; Réh, R.; Krišťák, L.; Schnabel, T. Enhanced Resistance to Fire of the Bark-Based Panels Bonded with Clay. Appl. Sci. 2020, 10, 5594. [Google Scholar] [CrossRef]

- Muszinsky, Z.; McNatt, J. Investigations on the use of spruce bark in the manufacture of particleboard. For. Prod. J. 1984, 34, 28–35. [Google Scholar]

- Calve, L.; Shields, J.; Gravel, M. Maximizing aspen poplar residues utilization for waferboard production. For. Prod. J. 1986, 36, 39–45. [Google Scholar]

- Claude, M.; Yemele, N.; Blanchet, P.; Cloutier, A.; Koubaa, A. Effects of bark content and particle geometry on the physical and mechanical properties of particleboard made from black spruce and trembling aspen bark. For. Prod. J. 2008, 58, 38–46. [Google Scholar]

- Xing, C.; Deng, J.; Zhang, S.Y. Effect of thermo-mechanical refining on properties of MDF made from black spruce bark. Wood Sci. Technol. 2007, 41, 329–338. [Google Scholar] [CrossRef]

- Nishimura, T. Chipboard, oriented strand board (OSB) and structural composite lumber. In Wood Composites; Elsevier: London, UK, 2015; pp. 103–121. ISBN 9781782424543. [Google Scholar]

- Igaz, R.; Krišťák, L.; Ružiak, I.; Gajtanska, M.; Kučerka, M. Thermophysical properties of OSB boards versus equilibrium moisture content. BioResources 2017, 12, 8106–8118. [Google Scholar] [CrossRef]

- Karade, S.R. Potential of Cork Cement Composite as a Thermal Insulation Material. Key Eng. Mater. 2015, 666, 17–29. [Google Scholar] [CrossRef]

- Mansilla, C.; Pradena, M.; Fuentealba, C.; César, A. Evaluation of Mechanical Properties of Concrete Reinforced with Eucalyptus globulus Bark Fibres. Sustainability 2020, 12, 10026. [Google Scholar] [CrossRef]

- Merabti, S.; Kenai, S.; Belarbi, R.; Khatib, J. Thermo-mechanical and physical properties of waste granular cork composite with slag cement. Constr. Build. Mater. 2021, 272, 121923. [Google Scholar] [CrossRef]

- Karade, S.R.; Irle, M.; Maher, K. Influence of granule properties and concentration on cork-cement compatibility. Holz als Roh-und Werkstoff 2006, 64, 281–286. [Google Scholar] [CrossRef]

- Eusebio, D.A.; Yamauchi, H.; Sasaki, H.; Kawai, S. Bark cement composites. In Proceedings of the Third Pacific Rim Bio Based Composites Symposium, Kyoto, Japan, 2–5 December 1996; pp. 274–282. [Google Scholar]

- Wei, Y.M.; Guang, Z.Y.; Tomita, B. Hydration behavior of wood cement-based composite I: Evaluation of wood species effects on compatibility and strength with ordinary Portland cement. J. Wood Sci. 2000, 46, 296–302. [Google Scholar] [CrossRef]

- EN 323:1993. Wood-Based Panels—Determination of Density; European Committee for Standardization: Brussels, Belgium, 1993. [Google Scholar]

- EN 826:2013. Thermal Insulating Products for Building Applications—Determination of Compression Behaviour; European Committee for Standardization: Brussels, Belgium, 2013. [Google Scholar]

- Dhir, R.K.; Ghataora, G.S.; Lynn, C.J. Concrete-Related Applications. In Sustainable Construction Materials; Elsevier: London, UK, 2017; pp. 111–158. ISBN 9780081009871. [Google Scholar]

- Stokke, D.D.; Wu, Q.; Han, G. Introduction to Wood and Natural Fiber Composites; Wiley: Hoboken, NJ, USA, 2014. ISBN 978047071 0913.

- Isolith. Wood-Wool Cement Bonded Boards. 2021. Available online: http://www.isolith.com/ (accessed on 3 December 2021).

- Thermo-Span. Thermo-Span Baustoffwerk. 2021. Available online: http://thermo-span.com/ (accessed on 3 December 2021).

| Bark | Test Samples | Compaction | Cement (%) | Water (%) | Particle Size (%) | Recycling Material (%) | |||

|---|---|---|---|---|---|---|---|---|---|

| <3 mm | 3–7 mm | 7–12 mm | <1–>4 mm | ||||||

| TG 1 <3–12 mm | spruce | n = 17 | SC | 39.26 | 19.64 | 9.86 | 12.30 | 12.30 | 6.64 |

| n = 5 | HP | ||||||||

| larch | n = 9 | SC | |||||||

| n = 9 | HP | ||||||||

| TG 2 <3–7 mm | spruce | n = 9 | SC | 39.26 | 19.64 | 9.86 | 24.60 | - | 6.64 |

| n = 6 | HP | ||||||||

| larch | n = 9 | SC | |||||||

| n = 9 | HP | ||||||||

| Spruce Bark | Larch Bark | Pine Bark | Poplar Bark | Control | Spruce Particles | Cement Reference | ||

|---|---|---|---|---|---|---|---|---|

| CEM II | Tmax (°C) | 36.2 | 35.6 | 34.4 | 38.8 | 34.7 | - | 44.9 |

| tmax (h) | 16.7 | 17.4 | 22.5 | 0.7 | 13.6 | - | 12.3 | |

| I-Index | 3.78 | 4.88 | 8.74 | - | 1.05 | - | - | |

| CEM I | Tmax (°C) | 45.5 | 47.8 | 56.1 | 55.6 | - | 53.1 | 64.8 |

| tmax (h) | 12.8 | 13.0 | 0.6 | 0.5 | - | 10.7 | 8.4 | |

| I-Index | 5.70 | 4.18 | - | - | - | 2.23 | - |

| Bark | Compaction | Test Samples | Density (kg/m3) | Compressive Strength (N/mm2) | |

|---|---|---|---|---|---|

| Test group 1 <3–12 mm | spruce | SC | n = 17 | 652 (21) | 0.504 (0.133) |

| HP | n = 5 | 595 (37) | 0.371 (0.148) | ||

| larch | SC | n = 9 | 616 (16) | 0.669 (0.137) | |

| HP | n = 9 | 675 (39) | 0.719 (0.108) | ||

| Test group 2 <3–7 mm | spruce | SC | n = 9 | 684 (9) | 0.586 (0.043) |

| HP | n = 6 | 596 (41) | 0.111 (0.062) | ||

| larch | SC | n = 9 | 644 (41) | 0.834 (0.145) | |

| HP | n = 9 | 633 (29) | 0.430 (0.070) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Urstöger, J.; Barbu, M.C.; Pacher, T.; Petutschnigg, A.; Jorda, J.; Tudor, E.M. Selected Properties of Cement Bound Spruce and Larch Bark Bio-Aggregates. Polymers 2021, 13, 4438. https://doi.org/10.3390/polym13244438

Urstöger J, Barbu MC, Pacher T, Petutschnigg A, Jorda J, Tudor EM. Selected Properties of Cement Bound Spruce and Larch Bark Bio-Aggregates. Polymers. 2021; 13(24):4438. https://doi.org/10.3390/polym13244438

Chicago/Turabian StyleUrstöger, Johannes, Marius Cătălin Barbu, Thomas Pacher, Alexander Petutschnigg, Johannes Jorda, and Eugenia Mariana Tudor. 2021. "Selected Properties of Cement Bound Spruce and Larch Bark Bio-Aggregates" Polymers 13, no. 24: 4438. https://doi.org/10.3390/polym13244438

APA StyleUrstöger, J., Barbu, M. C., Pacher, T., Petutschnigg, A., Jorda, J., & Tudor, E. M. (2021). Selected Properties of Cement Bound Spruce and Larch Bark Bio-Aggregates. Polymers, 13(24), 4438. https://doi.org/10.3390/polym13244438