Elaboration of Design and Optimization Methods for a Newly Developed CFRP Sandwich-like Structure Validated by Experimental Measurements and Finite Element Analysis

Abstract

:1. Introduction

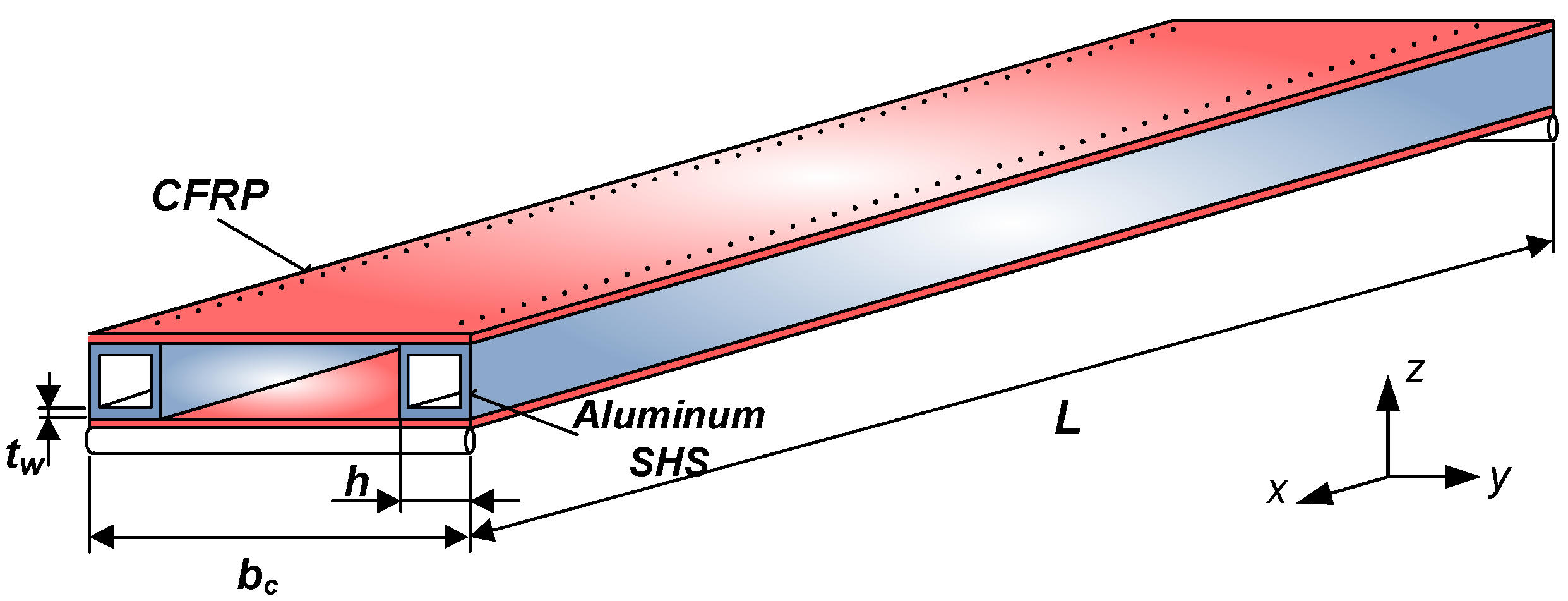

2. Materials and Methods—Structural Components of the Analyzed Sandwich-like Structure

2.1. CFRP Face Sheets as Structural Elements

2.1.1. CFRP Face Sheets—Calculated Elasticity Modulus and Flexural Modulus

2.1.2. CFRP Face Sheets—Measured Elasticity Modulus and Flexural Modulus

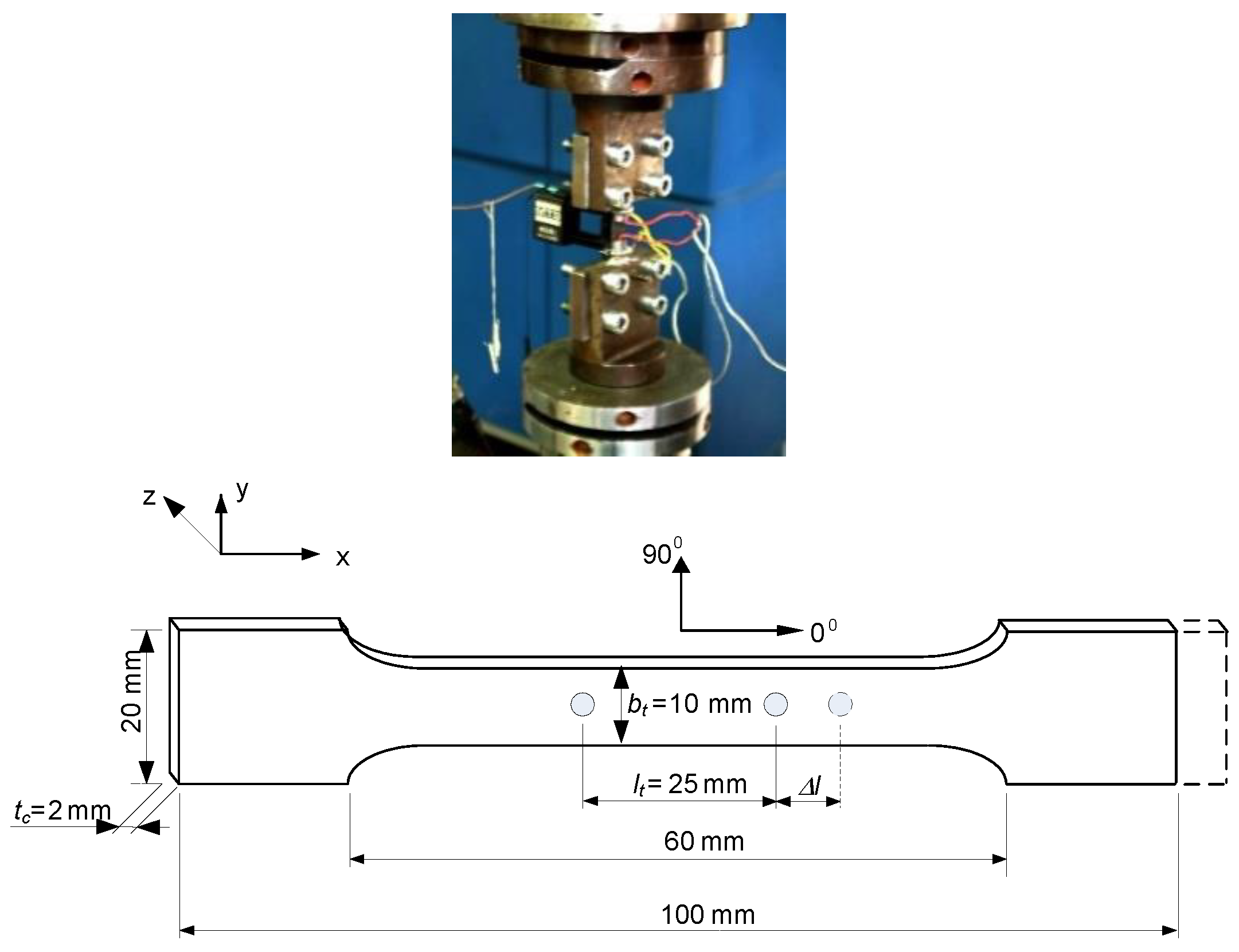

Determination of Elasticity Modulus Using Tensile Test

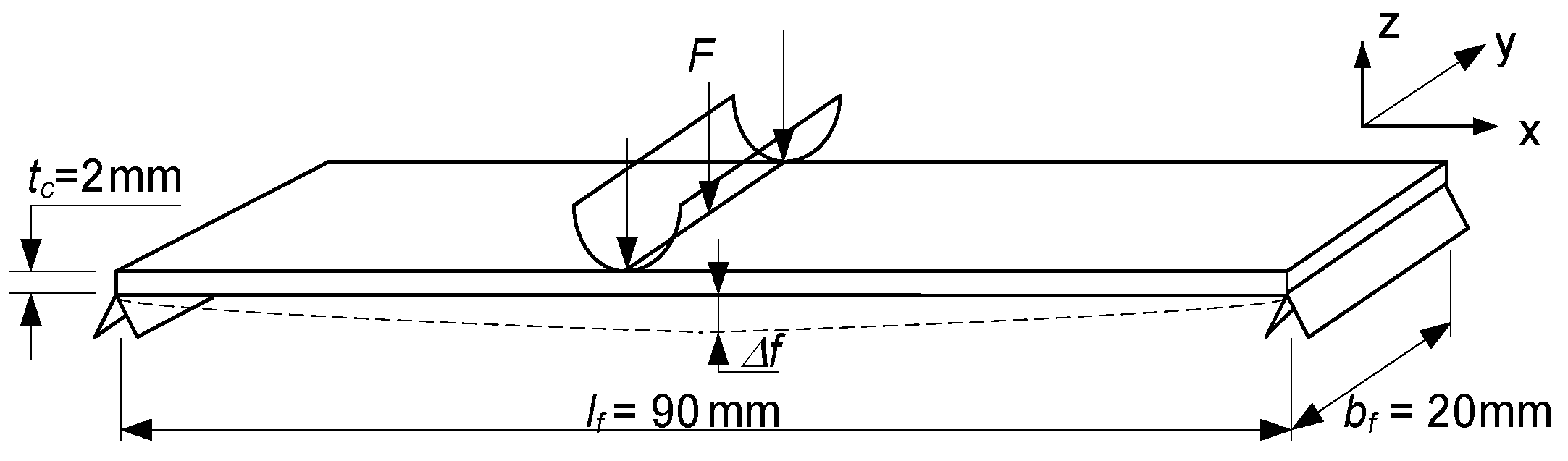

Determination of Flexural Modulus Using Three-Point Bending Test

2.1.3. Comparison of the Calculated and Measured Data

2.2. Aluminum Square Hollow Section Stiffeners as Structural Element

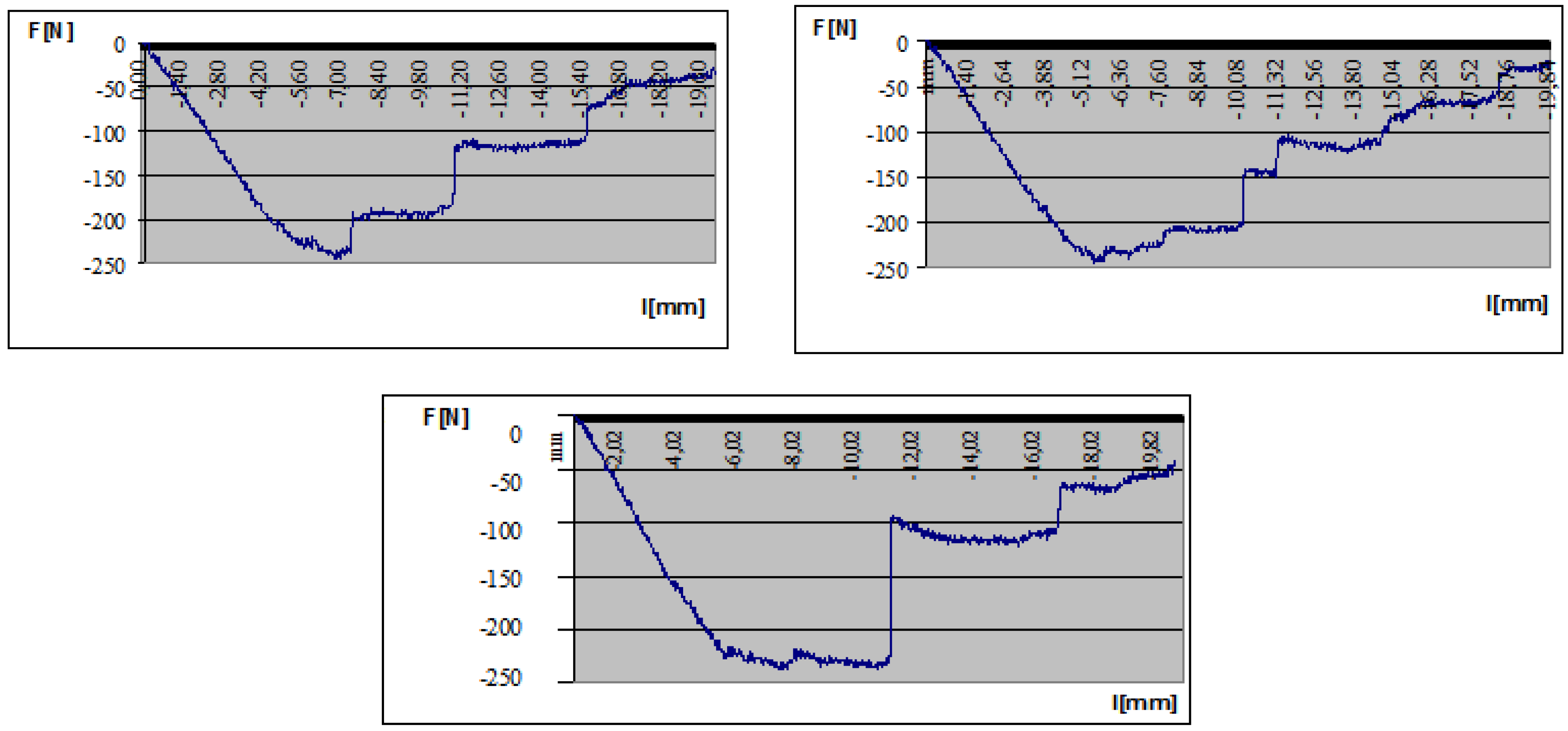

2.3. Rivets for Joining the CFRP Face Sheets and the Al Stiffeners—Shear Test of Rivets

3. Results—The Elaborated Calculation Methods for the Investigated Sandwich-like Structure and Validation by Experimental Measurements and Finite Element Analysis

3.1. Calculation Methods for the Investigated Sandwich-like Structure

3.1.1. Calculation of the Middle Deflection of the Sandwich-like Structure

3.1.2. Calculation of Stresses Occurred in the Structural Components of the Analyzed Sandwich-like Structure

3.2. Experimental Tests Relating to the Investigated Sandwich-like Structure

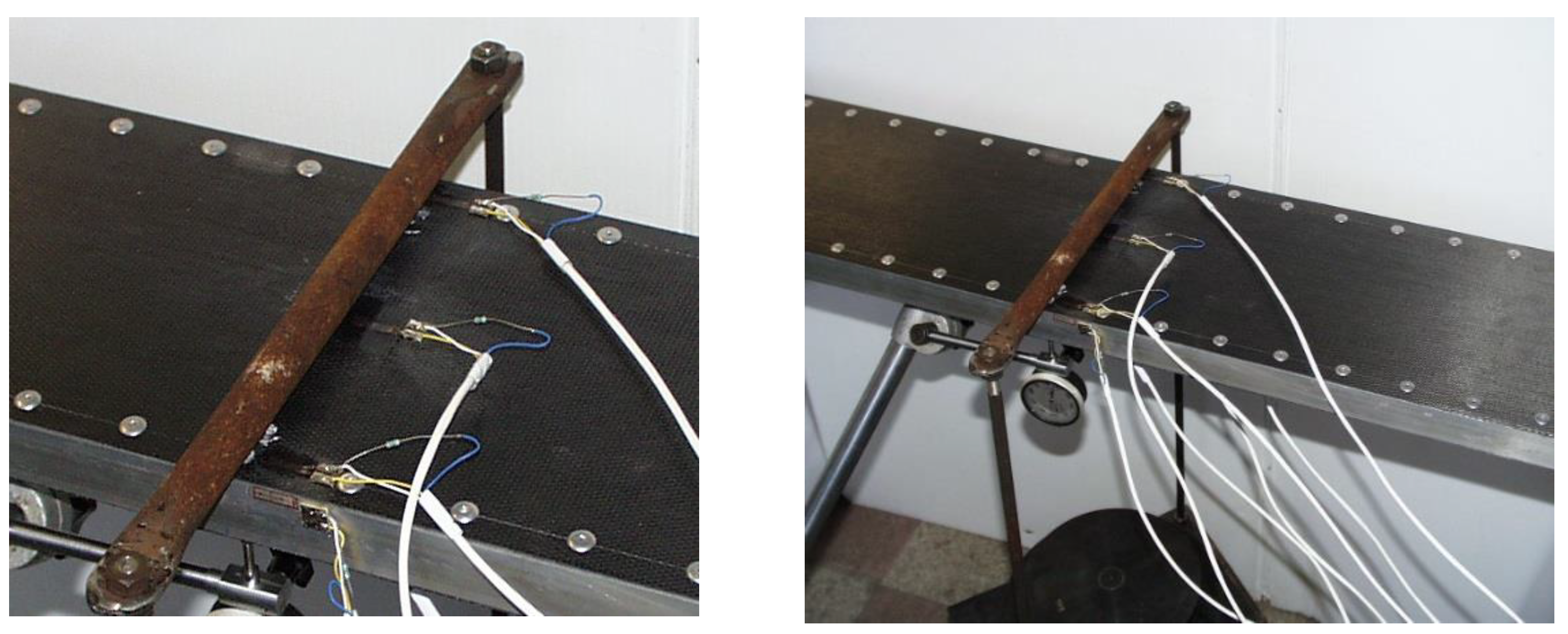

3.2.1. Experimental Tests Relating to the Sandwich-like Structure’s Deflection

3.2.2. Experimental Tests Relating to the Stresses Occurred in the Structural Elements of the Sandwich-like Structure

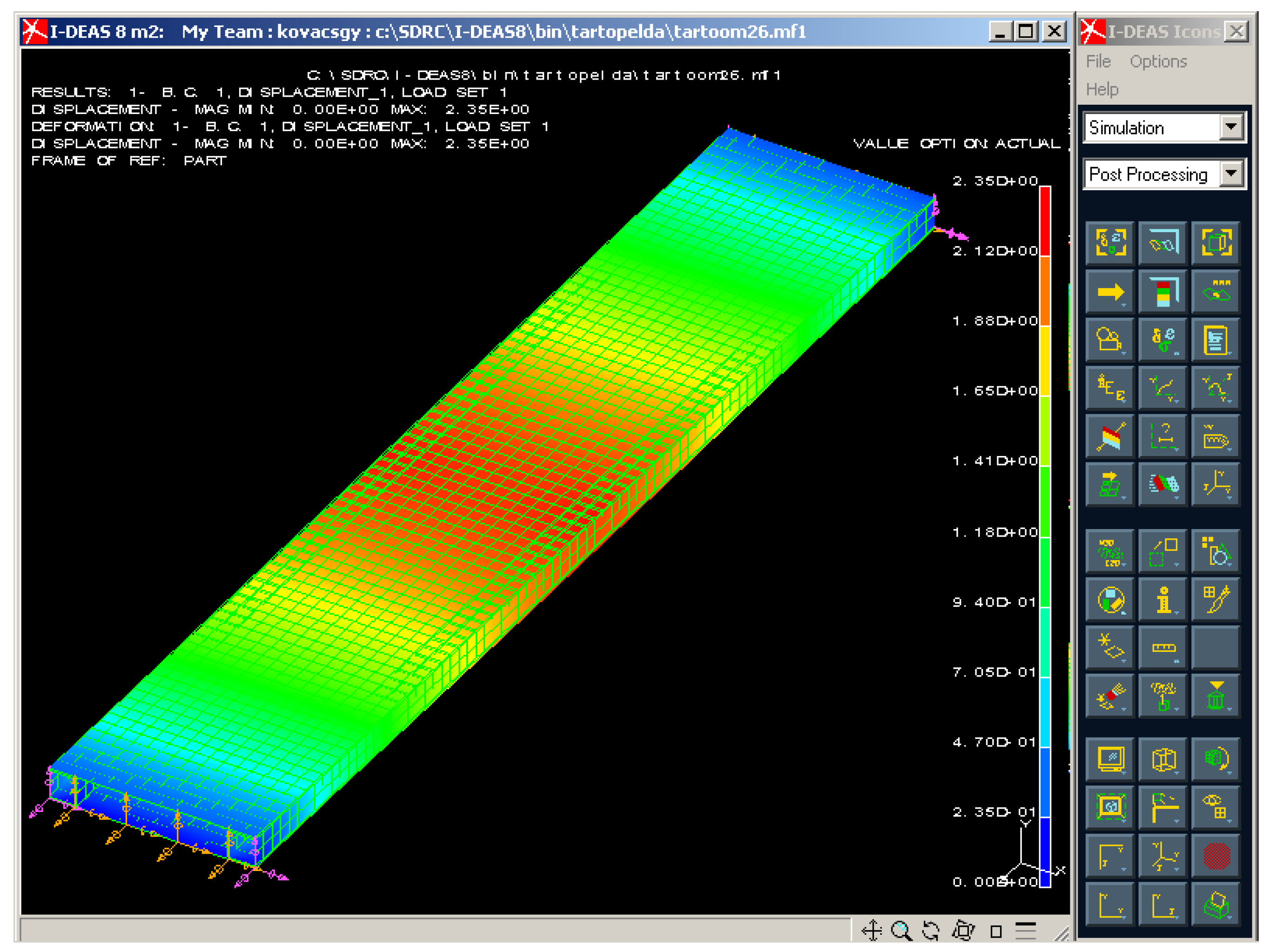

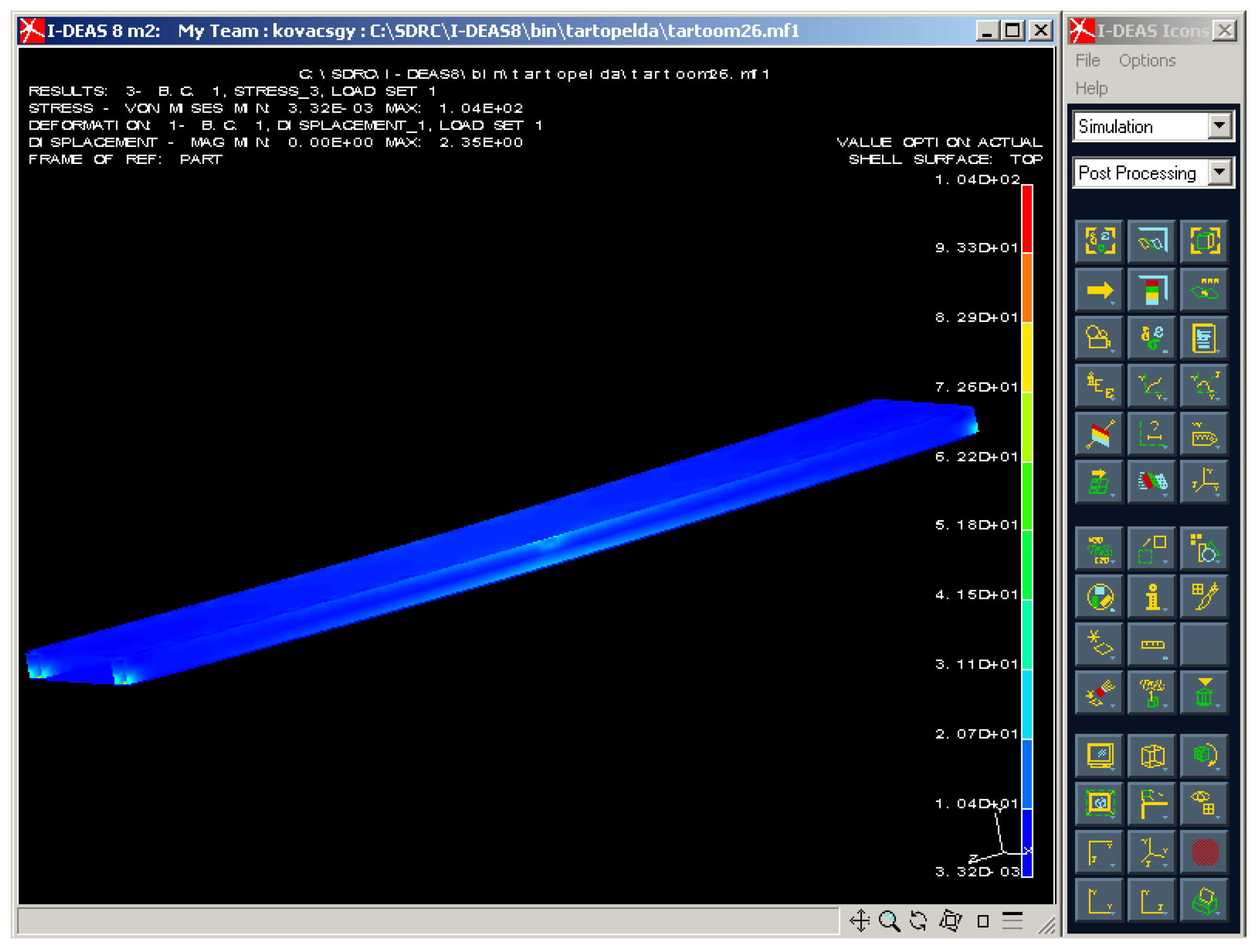

3.3. Finite Element Analysis of the Examined Sandwich-like Structure

3.4. Comparison of Measured, Calculated and FEM Data Relating to the Investigated Sandwich-like Structure

4. Structural Optimization of the Investigated Sandwich-like Construction

4.1. Cost Objective Function

4.2. Mass Objective Function

4.3. Design Constraints

4.4. Flexible Tolerance Optimization Algorithm

4.5. Results of the Structural Optimization for Different Face Sheets’ Layer Sequences

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Smith, W.F.; Hashemi, J. Foundations of Materials Science and Engineering, 6th ed.; McGraw-Hill Education: New York, NY, USA, 2019. [Google Scholar]

- Callister, W.D.; Rethwisch, D.G. Materials Science and Engineering: An Introduction, 8th ed.; John Wiley & Sons: New York, NY, USA, 2018. [Google Scholar]

- Hollaway, L.C. A review of the present and future utilisation of FRP composites in the civil infrastructure with reference to their important in-service properties. Constr. Build. Mater. 2010, 24, 2419–2445. [Google Scholar] [CrossRef]

- Todor, M.P.; Bulei, C.; Kiss, I. An overview on fiber-reinforced composites used in the automotive industry. Ann. Fac. Eng. Huned.-Int. J. Eng. 2017, 15, 181–184. [Google Scholar]

- Ismail, N.; Kot, S.; Aziz, A.S.A.; Rajiani, I. From innovation to market: Integrating university and industry perspectives towards commercialising research output. Forum Sci. Oecon. 2020, 8, 99–115. [Google Scholar]

- Ferreira, A.D.B.L.; Nóvoa, P.R.O.; Marques, A.T. Multifunctional material systems: A state-of-the-art review. Compos. Struct. 2016, 151, 3–35. [Google Scholar] [CrossRef]

- Serrano-Garcia, W.; Jayathilaka, W.A.D.M.; Chinnappan, A.; Tran, T.Q.; Baskar, C.; Thomas, S.W.; Ramakrishna, S. Nanocomposites for electronic applications that can be embedded for textiles and wearables. Sci. China Technol. Sci. 2019, 62, 895–902. [Google Scholar] [CrossRef]

- Tran, T.Q.; Lee, J.K.Y.; Chinnappan, A.; Jayathilaka, W.A.D.M.; Ji, D.; Kumar, V.V.; Ramakrishna, S. Strong, lightweight, and highly conductive CNT/Au/Cu wires from sputtering and electroplating methods. J. Mater. Sci. Technol. 2020, 40, 99–106. [Google Scholar] [CrossRef]

- Salahuddin, B.; Faisal, S.N.; Baigh, T.A.; Alghamdi, M.N.; Islam, M.S.; Song, B.; Zhang, X.; Gao, S.; Aziz, S. Carbonaceous materials coated carbon fibre reinforced polymer matrix composites. Polymers 2021, 13, 2771. [Google Scholar] [CrossRef] [PubMed]

- Maros, Z.; Felhő, C.; Vass, Z.; Maros, M.B. Application of 2D-3D surface geometrical features in tribological analysis of ceramics and ceramic layers. Mater. Sci. Forum 2015, 812, 435–440. [Google Scholar] [CrossRef]

- Houmat, A. Optimal lay-up design of variable stiffness laminated composite plates by a layer-wise optimization technique. Eng. Optimiz. 2018, 50, 205–217. [Google Scholar] [CrossRef]

- Blasques, J.P.; Stolpe, M. Maximum stiffness and minimum weight optimization of laminated composite beams using continuous fiber angles. Struct. Multidiscip. Optim. 2011, 43, 573–588. [Google Scholar] [CrossRef]

- Peng, W.; Chen, J.; Wei, J.; Tu, W. Optimal strength design for fiber-metal laminates and fiber-reinforced plastic laminates. J. Compos. Mater. 2010, 45, 237–254. [Google Scholar] [CrossRef]

- Kollár, L.P.; Springer, G.S. Mechanics of Composite Structures; Cambridge University Press: London, UK, 2003. [Google Scholar]

- Gillet, A.; Francescato, P.; Saffre, P. Single-and multi-objective optimization of composite structures: The influence of design variables. J. Compos. Mater. 2010, 44, 457–480. [Google Scholar] [CrossRef]

- Nikbakt, S.; Kamarian, S.; Shakeri, M. A review on optimization of composite structures Part I: Laminated composites. Compos. Struct. 2018, 195, 158–185. [Google Scholar] [CrossRef]

- Sohouli, A.; Yildiz, M.; Suleman, A. Design optimization of thin-walled composite structures based on material and fiber orientation. Compos. Struct. 2017, 176, 1081–1095. [Google Scholar] [CrossRef]

- Vo-Duy, T.; Duong-Gia, D.; Ho-Huu, V.; Vu-Do, H.C.; Nguyen-Thoi, T. Multi-objective optimization of laminated composite beam structures using NSGA-II algorithm. Compos. Struct. 2017, 16, 498–509. [Google Scholar] [CrossRef] [Green Version]

- Chen, S.; Zhu, W.; Cheng, Y. Multi-objective optimization of acoustic performances of polyurethane foam composites. Polymers 2018, 10, 788. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Al-Fakher, U.; Manalo, A.; Ferdous, W.; Aravinthan, T.; Zhuge, Y.; Bai, Y.; Edoo, A. Bending behaviour of precast concrete slab with externally flanged hollow FRP tubes. Eng. Struct. 2021, 241, 112433. [Google Scholar] [CrossRef]

- Alajarmeh, O.; Manalo, A.; Benmokrane, B.; Ferdous, W.; Mohammed, A.; Abousnina, R.; Elchalakani, M.; Edoo, A. Behavior of circular concrete columns reinforced with hollow composite sections and GFRP bars. Mar. Struct. 2020, 72, 102785. [Google Scholar] [CrossRef]

- Yuguo, W.; Haoji, W.; Jinhua, W.; Bin, L.; Jingyu, X.; Sheng, F. Finite element analysis of grinding process of long fiber reinforced ceramic matrix woven composites: Modeling, experimental verification and material removal mechanism. Cerami. Int. 2019, 45, 15920–15927. [Google Scholar]

- Dong, C.; Davies, I.J. Optimal design for the flexural behavior of glass and carbon fiber reinforced polymer hybrid composites. Mater. Des. 2012, 37, 450–457. [Google Scholar] [CrossRef]

- Kundrák, J.; Karpuschewski, B.; Pálmai, Z.; Felhő, C.; Makkai, T.; Borysenko, D. The energetic characteristics of milling with changing cross-section in the definition of specific cutting force by FEM method. CIRP J. Manuf. Techn. 2021, 32, 61–69. [Google Scholar] [CrossRef]

- Wang, J.; Shi, C.; Yang, N.; Sun, H.; Liu, Y.; Song, B. Strength, stiffness, and panel peeling strength of carbon fiber-reinforced composite sandwich structures with aluminium honeycomb cores for vehicle body. Compos. Struct. 2018, 184, 1189–1196. [Google Scholar] [CrossRef]

- Soheil, G.; Shokrollah, S.; Colin, B.; Saeed, M.; Mohammadreza, I.; Peter, T. Localized failure analysis of internally pressurized laminated ellipsoidal woven GFRP composite domes: Analytical, numerical, and experimental studies. Arch. Civ. Mech. Eng. 2019, 45, 1235–1250. [Google Scholar]

- Kundrák, J.; Molnár, V.; Makkai, T.; Dági, T. Analysis of material removal efficiency in face milling of aluminum alloy. In MANUFACTURING 2019: Advances in Manufacturing II, Proceedings of the International Scientific-Technical Conference MANUFACTURING, Poznan, Poland, 19–22 May, 2019; Lecture Notes in Mechanical Engineering; Gapiński, B., Szostak, M., Ivanov, V., Eds.; Springer: Cham, Switzerland, 2019; Volume 4, pp. 393–404. [Google Scholar]

- Kot, S.; Haque, A.U.; Kozlovski, E. Strategic scm’s mediating effect on the sustainable operations: Multinational perspective. Organizacija 2019, 52, 219–235. [Google Scholar] [CrossRef] [Green Version]

- Pereira, A.B.; Fernandes, F.A. Sandwich panels bond with advanced adhesive films. J. Compos. Sci. 2019, 3, 79. [Google Scholar] [CrossRef] [Green Version]

- Yan, J.; Wang, G.; Li, Q.; Zhang, L.; Yan, J.D.; Chen, C.; Fang, Z. A comparative study on damage mechanism of sandwich structures with different core materials under lightning strikes. Energies 2017, 10, 1594. [Google Scholar] [CrossRef] [Green Version]

- Doluk, E.; Rudawska, A.; Kuczmaszewski, J.; Pieśko, P. Influence of cutting parameters on the surface quality of two-layer sandwich structures. Materials 2020, 13, 1664. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Baca Lopez, D.M.; Ahmad, R. Tensile mechanical behaviour of multi-polymer sandwich structures via fused deposition modelling. Polymers 2020, 12, 651. [Google Scholar] [CrossRef] [Green Version]

- Adel, I.S.; Steven, L.D. Weight and cost multi-objective optimization of hybrid composite sandwich structures. Int. J. Comp. Met. Exp. Meas. 2017, 5, 200–210. [Google Scholar]

- Craig, A.S. Optimizing sandwich beam for strength and stiffness. J. Sand. Struct. Mater. 2012, 14, 573–595. [Google Scholar]

- Xiang, L.; Gangyan, L.; Chun, H.W.; Min, Y. Optimum design of composite sandwich structures subjected to combined torsion and bending loads. Appl. Compos. Mater. 2012, 19, 315–331. [Google Scholar]

- Wang, D.; Abdalla, M.M.; Zhang, W. Buckling optimization design of curved stiffeners for grid-stiffened composite structures. Compos. Struct. 2017, 159, 656–666. [Google Scholar] [CrossRef]

- Todor, M.P.; Kiss, I. Systematic approach on materials selection in the automotive industry for making vehicles lighter, safer and more fuel-efficient. Appl. Eng. Lett. 2016, 1, 91–97. [Google Scholar]

- Virág, Z.; Szirbik, S. Modal analysis of optimized trapezoidal stiffened plates under lateral pressure and uniaxial compression. Appl. Mech. 2021, 2, 681–693. [Google Scholar]

- Karpuschewski, B.; Kundrák, J.; Felhő, C.; Varga, G.; Sztankovics, I.; Makkai, T.; Borysenko, D. Preliminary investigations for the effect of cutting tool edge geometry in high-feed face milling. In Vehicle and Automotive Engineering 2. VAE 2018; Lecture Notes in Mechanical Engineering; Jármai, K., Bolló, B., Eds.; Springer: Cham, Switzerland, 2018; pp. 241–254. ISBN 9783319756769. [Google Scholar]

- Virág, Z.; Jármai, K. Optimum design of stiffened plates for static or dynamic loadings using different ribs. Struct. Eng. Mech. 2020, 74, 255–266. [Google Scholar]

- Barbero, E.J. Introduction to Composite Materials Design; Taylor & Francis: Boca Raton, FL, USA, 2011. [Google Scholar]

- EuroCode 3 1992: Design of Steel Structures. Part 1.1; CEN European Committee for Standardization: Brussels, Belgium, 1992.

- Himmelblau, D.M. Applied Nonlinear Programming; McGraw-Hill: New York, NY, USA, 1972. [Google Scholar]

- Lima, A.M.; Kwong, W.H.; Cruz, A.J.G. An improved flexible tolerance method for solving nonlinear constrained optimization problems: Application in mass integration. Chin. J. Chem. Eng. 2017, 25, 617–631. [Google Scholar] [CrossRef]

| Calculated | Measured | Difference (%) | |

|---|---|---|---|

| Elastic modulus | 38,490 MPa | 41,650 MPa | 8.2 |

| Flexural modulus | 41,710 MPa | 42,478 MPa | 1.84 |

| Loading Conditions (N) | |||||

|---|---|---|---|---|---|

| Middle Deflection (mm) | 300 N | 400 N | 500 N | 600 N | 700 N |

| 1st Al stiffener | 1.61 | 1.96 | 2.3 | 2.65 | 3.0 |

| Face sheet midpoint | 1.78 | 2.19 | 2.59 | 2.98 | 3.41 |

| 2nd Al stiffener | 1.8 | 2.2 | 2.65 | 3.0 | 3.43 |

| Average in Al stiffener | 1.705 ± 0.095 | 2.08 ± 0.12 | 2.475 ± 0.175 | 2.825 ± 0.175 | 3.215 ± 0.215 |

| Loading Conditions (N) | ||||

|---|---|---|---|---|

| Stresses (MPa) | 300 N | 400 N | 500 N | 600 N |

| Channel 1 | −7.172 | −9.73 | −12.208 | −14.97 |

| Channel 2 | −6.647 | −8.568 | −10.291 | −11.302 |

| Channel 3 | −4.915 | −6.346 | −7.788 | −9.242 |

| Channel 4 | −5.097 | −6.667 | −8.381 | −9.358 |

| Channel 5 | 5.072 | 7.015 | 8.859 | 10.503 |

| Channel 6 | 4.624 | 6.111 | 7.622 | 9.024 |

| Channel 7 | 4.796 | 6.497 | 8.259 | 9.993 |

| Middle Deflection (mm) | Ratio | Difference (%) | |

|---|---|---|---|

| Measured | 2.475 | 100% | 0 |

| Calculated | 2.56 | 103.43% | +3.43 |

| FEM | 2.35 | 94.95% | −5.05 |

| Location | Stress (MPa) | Ratio | Difference (%) | |

|---|---|---|---|---|

| Measured | Stress in the CFRP face sheet | 8.559 MPa | 100% | 0 |

| Stress in the Al stiffener | 12.208 MPa | 100% | 0 | |

| Calculated | Stress in the CFRP face sheet | 8.434 MPa | 98.54% | −1.46% |

| Stress in the Al stiffener | 11.503 MPa | 94.22% | −5.78% | |

| FEM | Stress in the CFRP face sheet | 9.305 MPa | 108.72% | −8.72% |

| Stress in the Al stiffener | 11.12 MPa | 91.09% | −8.9% |

| Layer Sequence of the Face Sheet | Optimal Al Geometries | Total Mass (kg) | Total Cost (USD) | Cost Components | ||

|---|---|---|---|---|---|---|

| h (mm) | tw (mm) | |||||

| [0°, +45°, −45°, 0°]s | 25 | 1.5 | 2.498 | 410.002 | 270.4 | CFRP face sheets |

| 4.802 | Al stiffeners | |||||

| 4 | Heat treatment | |||||

| 130.8 | Manufacturing | |||||

| [0°, 90°]s | 60 | 4 | 6.598 | 191.633 | 54.912 | CFRP face sheets |

| 30.721 | Al stiffeners | |||||

| 4 | Heat treatment | |||||

| 102 | Manufacturing | |||||

| [0°, 90°, 0°] | 80 | 4 | 8.474 | 180.958 | 41.184 | CFRP face sheets |

| 40.974 | Al stiffeners | |||||

| 4 | Heat treatment | |||||

| 94.8 | Manufacturing | |||||

| [0°, 0°] | 100 | 5 | 12.708 | 183.078 | 27.456 | CFRP face sheets |

| 64.022 | Al stiffeners | |||||

| 4 | Heat treatment | |||||

| 87.6 | Manufacturing | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kovács, G. Elaboration of Design and Optimization Methods for a Newly Developed CFRP Sandwich-like Structure Validated by Experimental Measurements and Finite Element Analysis. Polymers 2021, 13, 4348. https://doi.org/10.3390/polym13244348

Kovács G. Elaboration of Design and Optimization Methods for a Newly Developed CFRP Sandwich-like Structure Validated by Experimental Measurements and Finite Element Analysis. Polymers. 2021; 13(24):4348. https://doi.org/10.3390/polym13244348

Chicago/Turabian StyleKovács, György. 2021. "Elaboration of Design and Optimization Methods for a Newly Developed CFRP Sandwich-like Structure Validated by Experimental Measurements and Finite Element Analysis" Polymers 13, no. 24: 4348. https://doi.org/10.3390/polym13244348

APA StyleKovács, G. (2021). Elaboration of Design and Optimization Methods for a Newly Developed CFRP Sandwich-like Structure Validated by Experimental Measurements and Finite Element Analysis. Polymers, 13(24), 4348. https://doi.org/10.3390/polym13244348