Preparation and Stabilization of High Molecular Weight Poly (acrylonitrile-co-2-methylenesuccinamic acid) for Carbon Fiber Precursor

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Synthesis of MLA

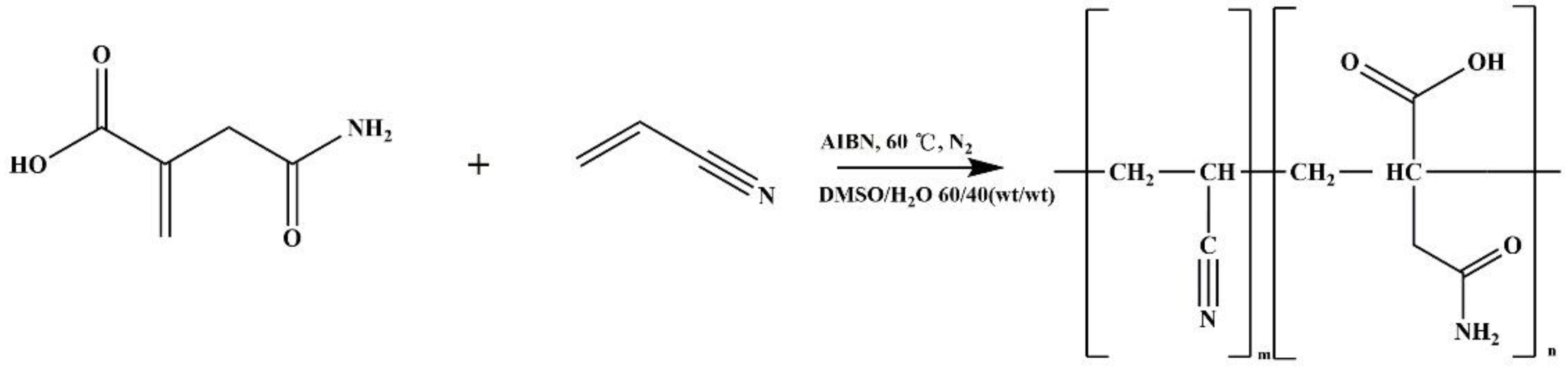

2.3. Preparation of P (AN-co-MLA) in Mixed Solvents

2.4. Polymer Characterization

3. Results and Discussion

3.1. Reactivity Ratio Studies

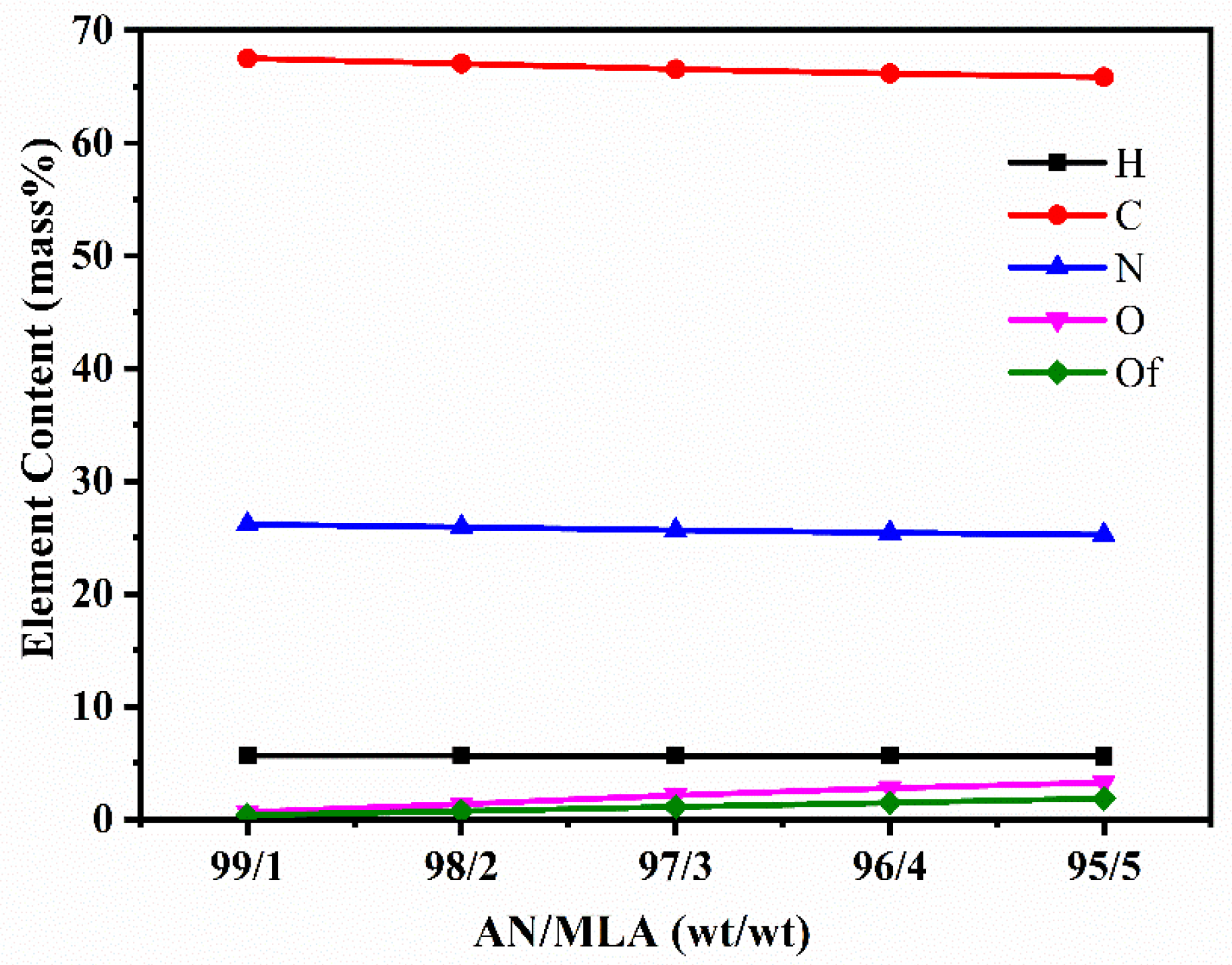

3.2. Molecular Weight and Elemental Analysis Studies

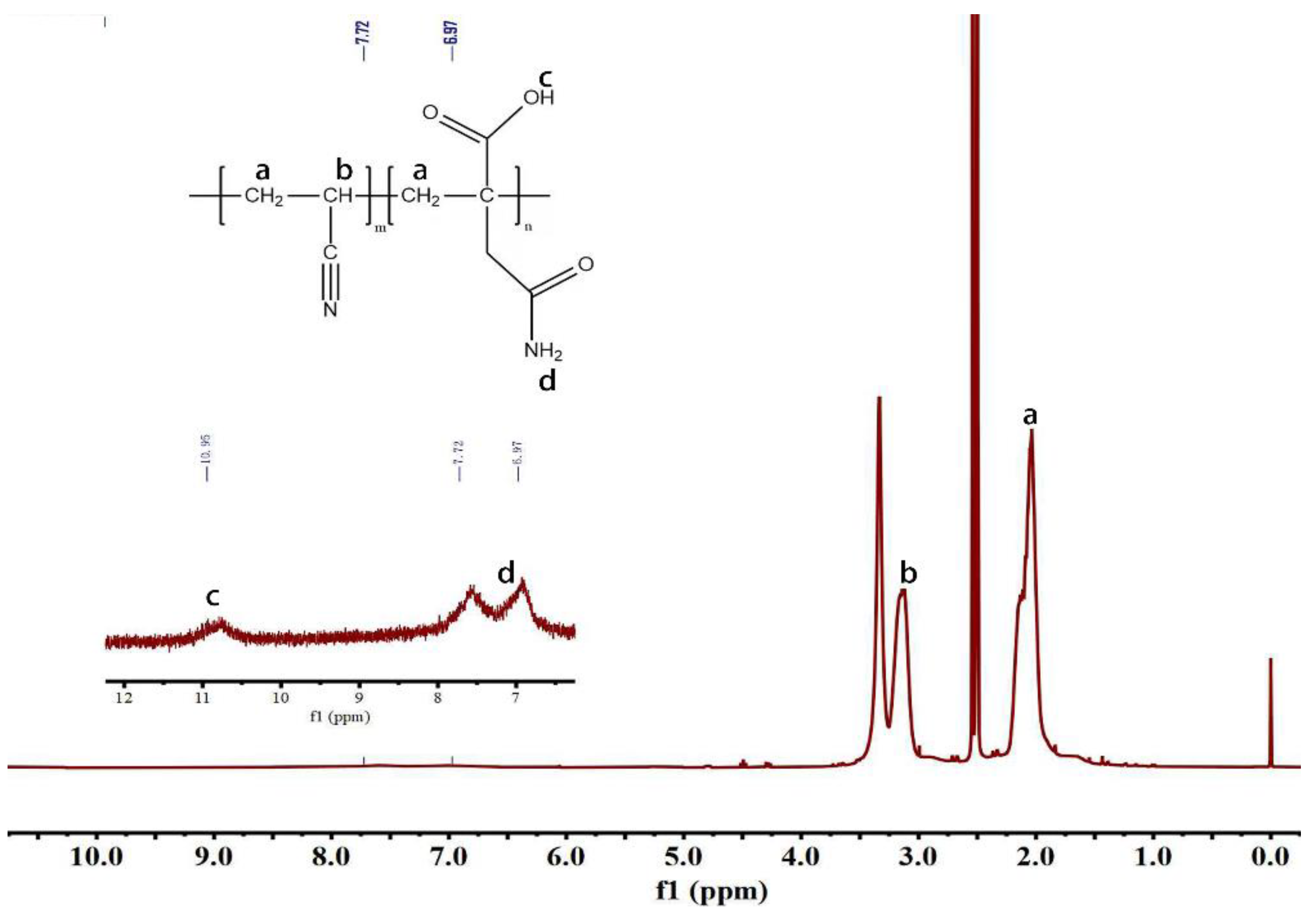

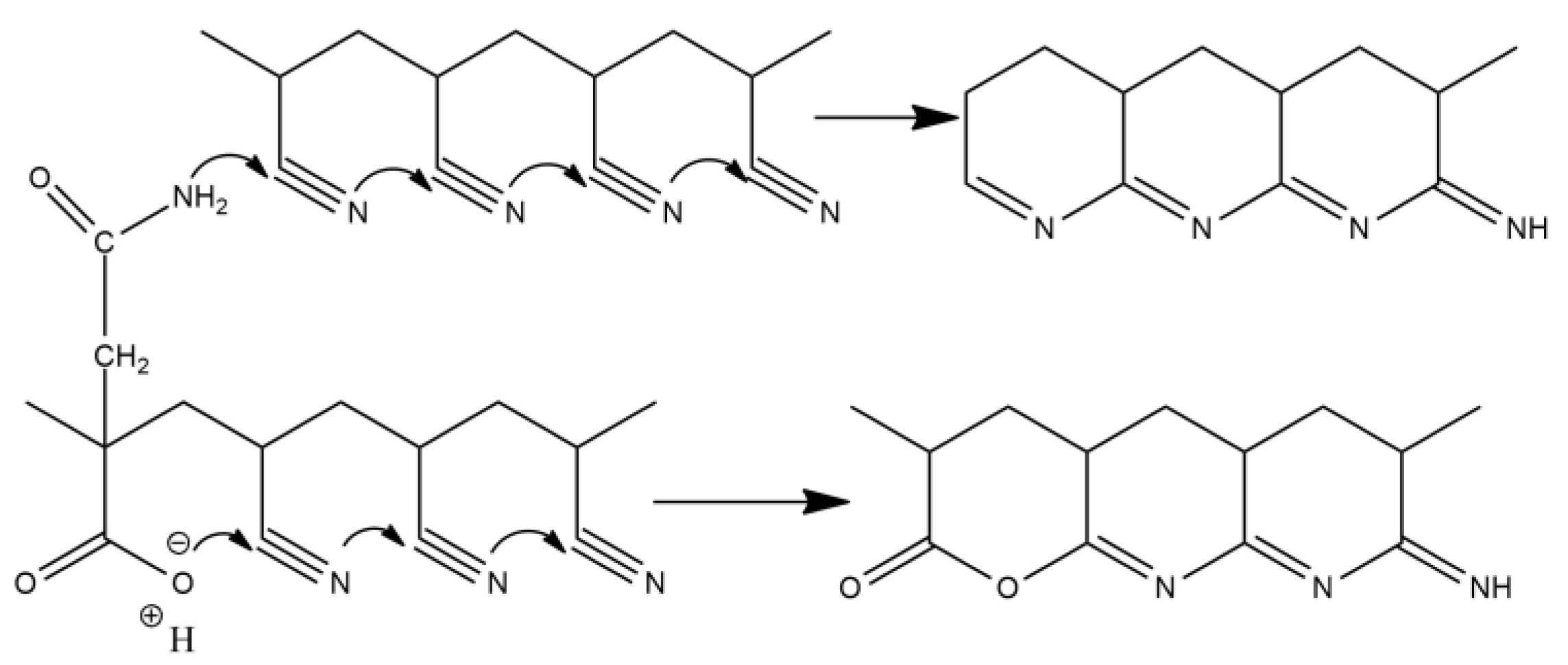

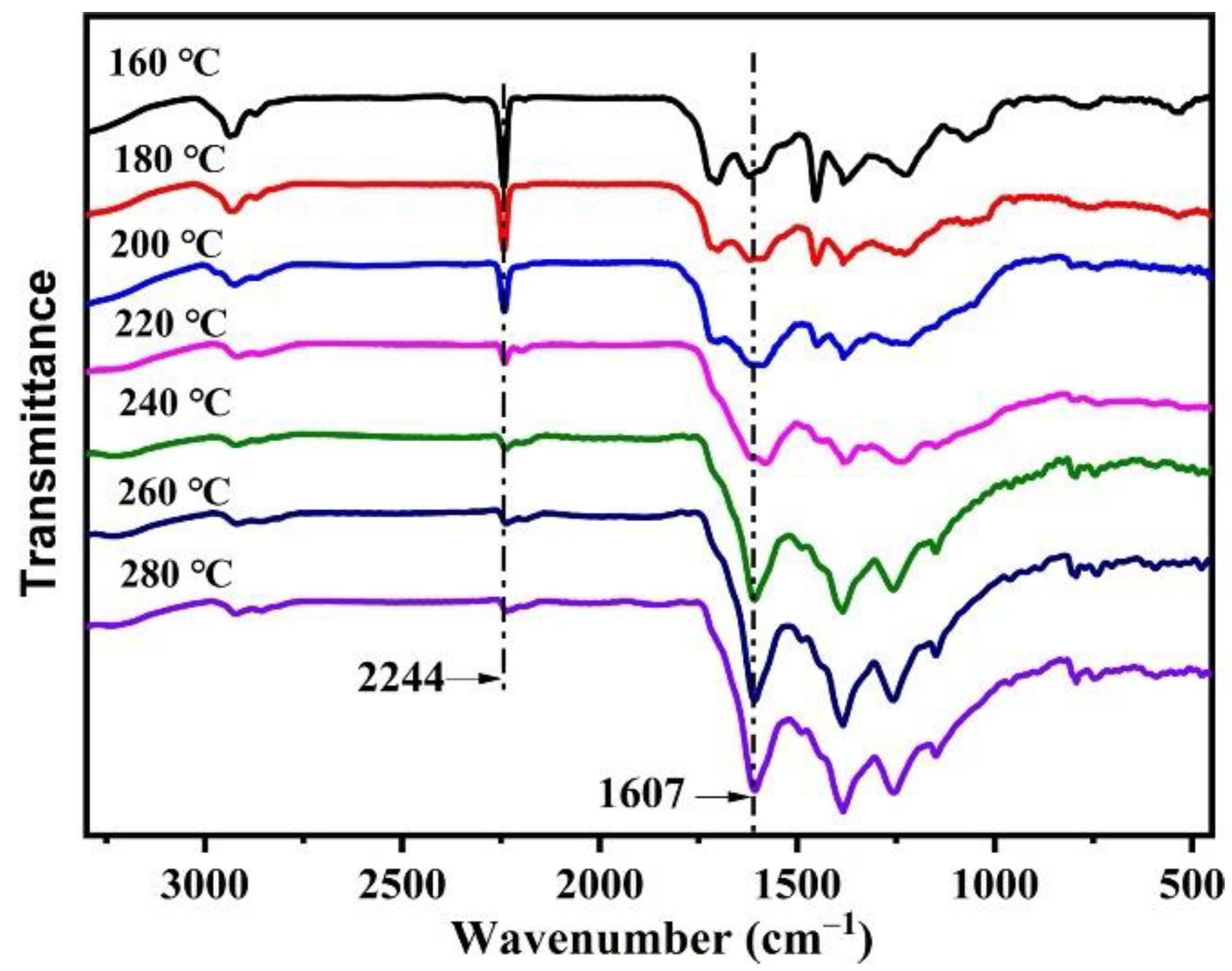

3.3. FTIR and NMR Studies

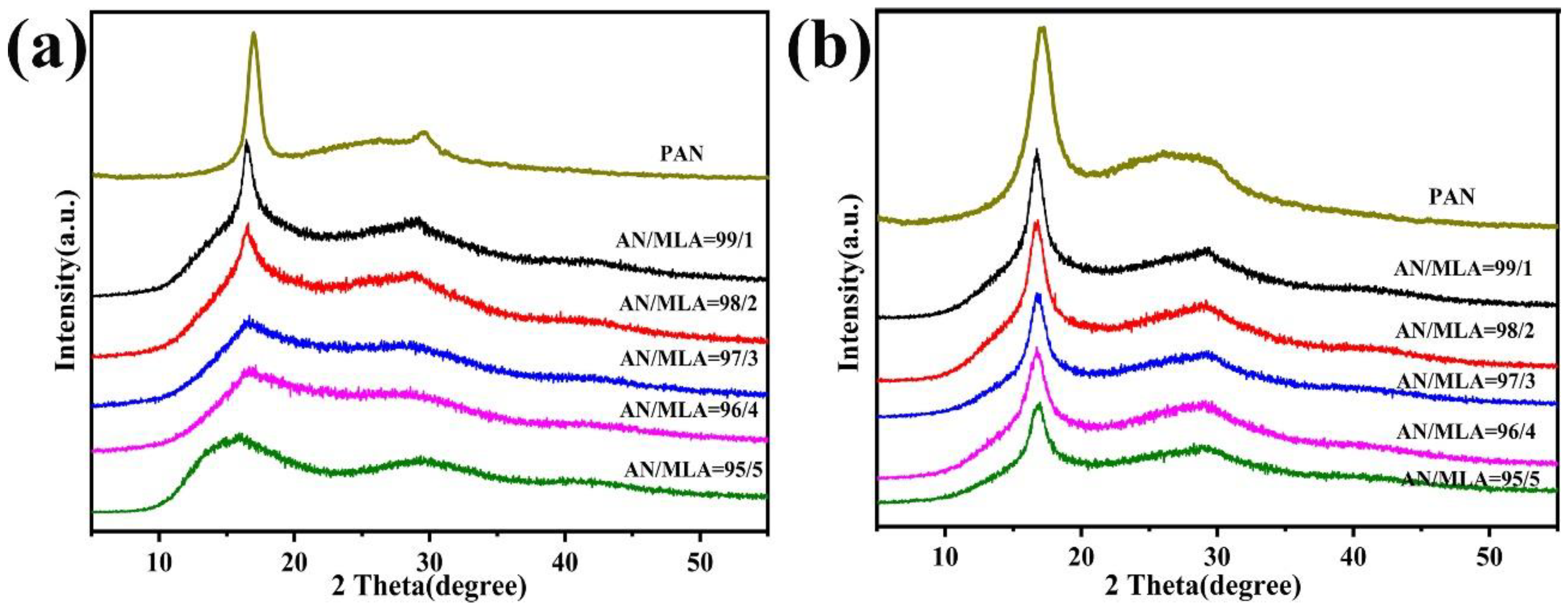

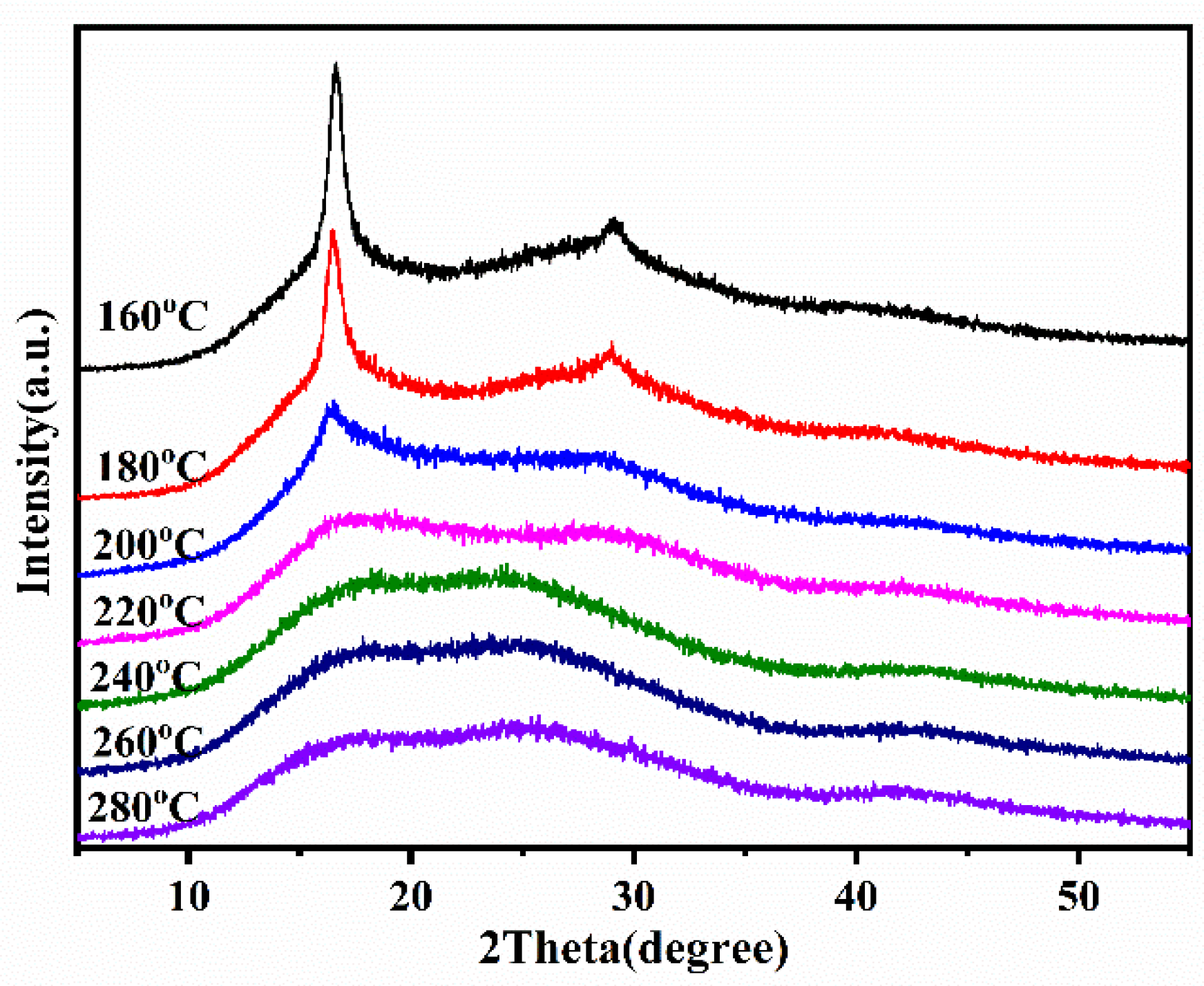

3.4. XRD Studies

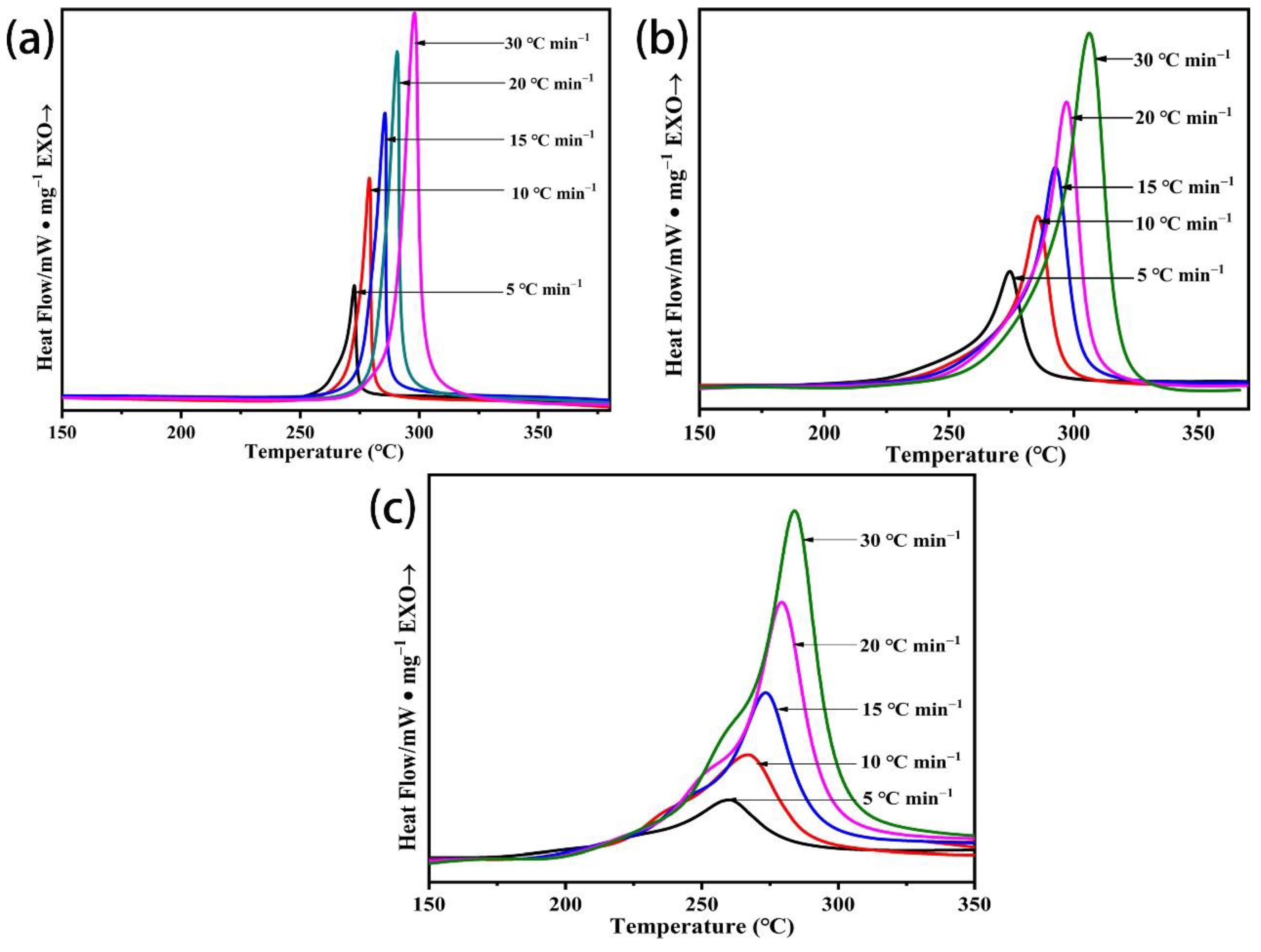

3.5. DSC Analysis

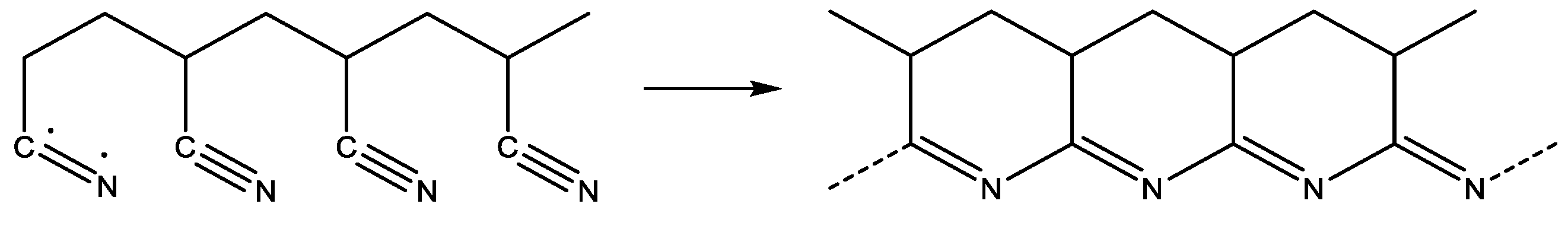

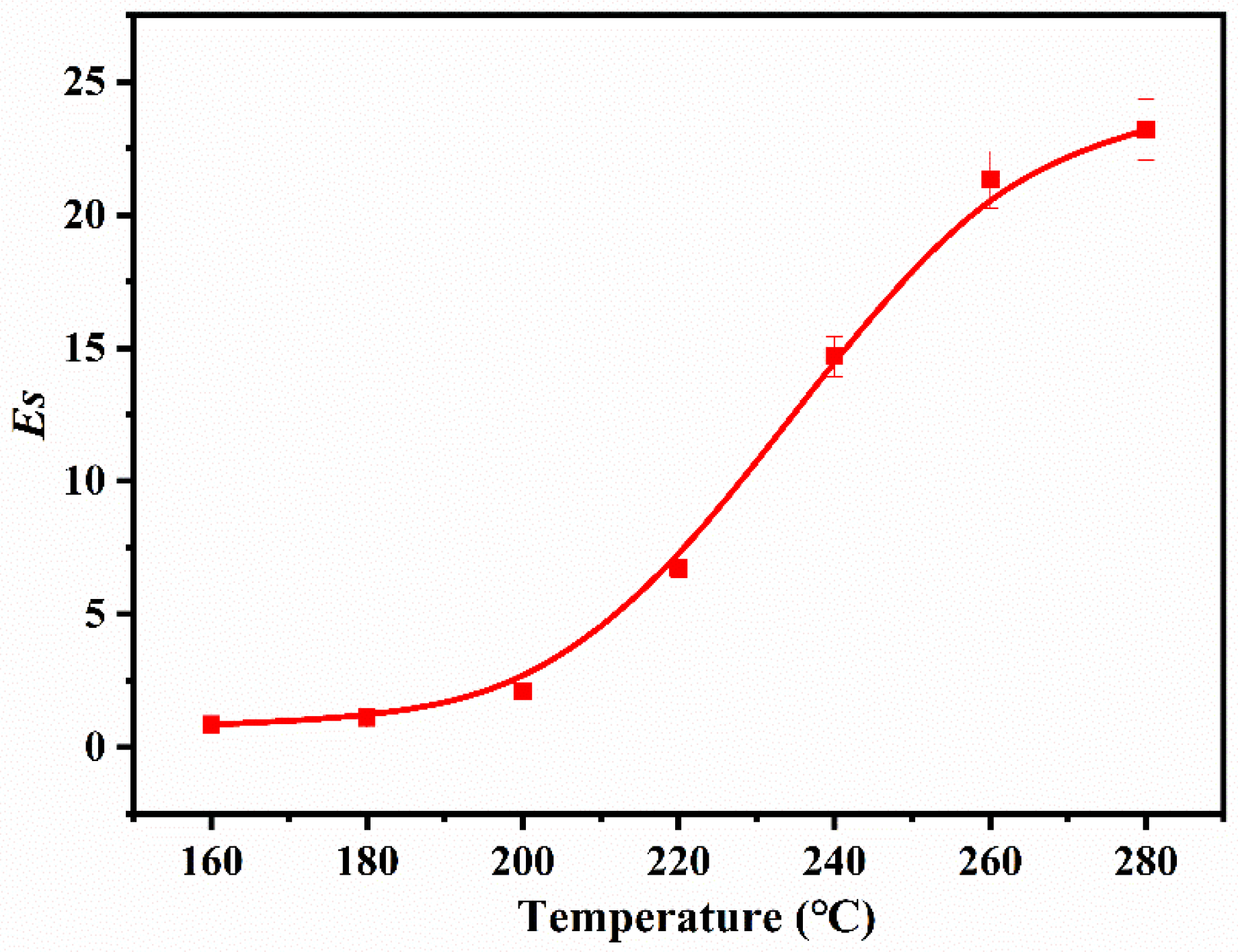

3.6. Evaluation of Activation Energy (Ea) of Cyclization Reactions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ono, M.; Yamane, M.; Tanoue, S.; Uematsu, H.; Yamashita, Y. Mechanical Properties of Thermoplastic Composites Made of Commingled Carbon Fiber/Nylon Fiber. Polymers 2021, 13, 3206. [Google Scholar] [CrossRef]

- Mittal, J.; Mathur, R.B.; Bahl, O.P. Post spinning modification of PAN fibres—A review. Carbon 1997, 35, 1713–1721. [Google Scholar] [CrossRef]

- Shi, L.; Sessim, M.; Tonks, M.R.; Phillpot, S.R. Generation and characterization of an improved carbon fiber model by molecular dynamics. Carbon 2020, 173, 232–244. [Google Scholar] [CrossRef]

- Ahn, H.; Yeo, S.Y.; Lee, B.-S. Designing Materials and Processes for Strong Polyacrylonitrile Precursor Fibers. Polymers 2021, 13, 2863. [Google Scholar] [CrossRef] [PubMed]

- Souto, F.; Calado, V.; Pereira, N. Lignin-based carbon fiber: A current overview. Mater. Res. Express 2018, 5, 232–241. [Google Scholar] [CrossRef]

- Ma, L.; Nie, Y.; Liu, Y.; Huo, F.; Zhang, S. Preparation of Core/Shell Electrically Conductive Fibers by Efficient Coating Carbon Nanotubes on Polyester. Adv. Fibers Mater. 2021, 3, 180–191. [Google Scholar] [CrossRef]

- Xu, T.; Li, X.; Liang, Z.; Amar, V.S.; Hao, F. Carbon Nanofibrous Sponge Made from Hydrothermally Generated Biochar and Electrospun Polymer Nanofibers. Adv. Fibers. Mater. 2020, 2, 74–84. [Google Scholar] [CrossRef] [Green Version]

- Yu, C.; Yan, C.; Shao, J.; Zhang, F. Preparation and properties of rosin-based cationic waterborne polyurethane dispersion. Colloid Polym. Sci. 2021, 299, 1489–1498. [Google Scholar] [CrossRef]

- Devadas, S.; Al-Ajrash, S.; Klosterman, D.A.; Crosson, K.M.; Vasquez, E.S. Fabrication and Characterization of Electrospun Poly(acrylonitrile-co-Methyl Acrylate)/Lignin Nanofibers: Effects of Lignin Type and Total Polymer Concentration. Polymers 2021, 13, 992. [Google Scholar] [CrossRef]

- Zhong, G.; Yue, Z.; Chen, G.; Zhang, L.; Vakili, A.; Wang, Y.; Zhu, L.; Liu, J.; Hao, F. Investigation of post-spinning stretching process on morphological, structural, and mechanical properties of electrospun polyacrylonitrile copolymer nanofibers. Polymers 2011, 52, 519–528. [Google Scholar]

- Lu, T.; Jia, Z.; Kanaev, A.V.; Museur, L. Effect of Light Intensity on the Free Radical Photopolymerization Kinetics of 2-Hydoxyethyl Methacrylate (HEMA): Experiments and Simulations. J. Phys. Chem. B 2020, 29, 445–453. [Google Scholar]

- Zhang, Z.L.; Xu, L.; Zang, C.Y.; Toyoji, K.; Shen, X.D. Precise Synthesis and Thermoresponsive Property of Block Copolymers Consisting of N,N-diethylacrylamide and N,N-dimethylacrylamide. Acta. Polym. Sin. 2019, 50, 384–392. [Google Scholar]

- Lin, M.; Zhao, Q.; Dang, S.; Yang, Z.; Zhang, J. Temperature resistance of AM/AMPS/NVP copolymer microspheres. Iran. Polym. J. 2020, 29, 445–453. [Google Scholar] [CrossRef]

- Jitreewas, P.; Tansiri, P.; Pranee, S.; Khemtong, C.; Seeyangnok, S. Preparation and Application of Poly(Acrylic Acid-co-Acrylamide) on Scale and Corrosion Inhibition. Key Eng. Mater. 2019, 824, 142–148. [Google Scholar] [CrossRef]

- Ju, A.; Yu, H.; Yan, Y.; Cao, M.; Liu, J.; Liu, B. A high molecular weight acrylonitrile copolymer prepared by mixed solvents polymerization: II. effect of DMSO/water ratios on polymerization and stabilization. J. Polym. Res. 2016, 23, 208. [Google Scholar] [CrossRef]

- Gharagheizi, F. Dynamic Simulation and Modelling of Bulk Polymerization of Ethylene Using Bi-functional initiators. E-Polymers 2007, 7, 1–13. [Google Scholar] [CrossRef]

- Zhao, Y.; Liang, J.; Peng, M.; Xu, L.; Shao, Z.; Yang, M. A new process based on mixed-solvent precipitation polymerization to synthesize high molecular weight polyacrylonitrile initiated by ammonium persulphate. Fibers Polym. 2016, 17, 2162–2166. [Google Scholar] [CrossRef]

- Chen, H.; Pan, Y.; Hou, S.; Shao, Z.; Hong, Y.; Ju, A. Poly(acrylonitrile-co-2-methylenesuccinamic acid) as a potential carbon fiber precursor: Preparation and stabilization. RSC Adv. 2017, 7, 54142–54152. [Google Scholar] [CrossRef] [Green Version]

- Han, N.; Zhang, X.X.; Wang, X.C.; Wang, N. Fabrication, structures and properties of Acrylonitrile/Vinyl acetate copolymers and copolymers containing microencapsulated phase change materials. Macromol. Res. 2010, 18, 144–152. [Google Scholar] [CrossRef]

- Muniz, F.; Miranda, M.; Cássio, M.; Sasaki, J.M. The Scherrer equation and the dynamical theory of X-ray diffraction. Acta Cryst. 2016, 72, 385–390. [Google Scholar] [CrossRef] [PubMed]

- Ju, A.; Liu, Z.; Miao, L.; Xu, H.; Ge, M. Molecular design and pre-oxidation mechanism of acrylonitrile copolymer used as carbon fiber precursor. J. Polym. Res. 2013, 20, 318. [Google Scholar] [CrossRef]

- Tüdos, F.; Kelen, T.; Turcsányi, B.; Kennedy, J.P. Analysis of the linear methods for determining copolymerization reactivity ratios. VI. A comprehensive critical reexamination of oxonium ion copolymerizations. J. Polym. Sci. Polym. Chem. Edi. 1981, 19, 1119–1132. [Google Scholar] [CrossRef]

- Jenkins, A.D.; Johnston, R. Chain transfer to a mixture of agents: The anomalous behavior of the acrylonitrile–dimethylformamide–water system. J. Polym. Sci. 1959, 39, 81–86. [Google Scholar] [CrossRef]

- Rwei, S.P.; Way, T.F.; Chiang, W.Y.; Pan, S.Y. Effect of tacticity on the cyclization of polyacrylonitrile copolymers. Colloid Polym. Sci. 2017, 295, 803–815. [Google Scholar] [CrossRef]

- Kost, B.; Basko, M. Synthesis and properties of l-lactide/1,3-dioxolane copolymers: Preparation of polyesters with enhanced acid sensitivity. Polym. Chem. 2021, 12, 2551–2562. [Google Scholar] [CrossRef]

- Ju, A.; Guang, S.; Xu, H. Effect of comonomer structure on the stabilization and spinnability of polyacrylonitrile copolymers. Carbon 2013, 54, 323–335. [Google Scholar] [CrossRef]

- Yang, B.; Xu, L.; Liu, Y.; Liu, B.; Zhang, M. Preparation of monodisperse polystyrene microspheres with different functional groups using soap-free emulsion polymerization. Colloid Polym. Sci. 2021, 299, 1095–1102. [Google Scholar] [CrossRef]

- Min, J.; Wang, C.G.; Qiang, W.; Bai, Y.J.; Bo, Z. Chemical structure evolution and mechanism during pre-carbonization of PAN-based stabilized fiber in the temperature range of 350–600 °C. Polym. Degrad. Stab. 2007, 92, 1737–1742. [Google Scholar]

- Li, C.Q.; Xu, Y.G.; Tong, Y.J.; Xu, L.H. Influences of Metal Ions on Thermal Stabilization of Polyacrylonitrile Fibres. Hi-Tech. Fiber. Appl. 2006, 31, 17–26. [Google Scholar]

- Fitzer, E.; Frohs, W.; Heine, M. Optimization of Stabilization and Carbonization Treatment of PAN-Fibers and Structural Characterization of the Resulting Carbon Fibers. Carbon 1986, 24, 387–395. [Google Scholar] [CrossRef]

- Youe, W.J.; Lee, S.M.; Lee, S.S.; Lee, S.H.; Kim, Y.S. Characterization of carbon nanofiber mats produced from electrospun lignin-g-polyacrylonitrile copolymer. Int. J. Biol. Macromol. 2015, 82, 497–504. [Google Scholar] [CrossRef]

- Huang, J.N.; Cao, Y.H.; Huang, Z.H.; Wang, Z.; Imbraguglio, S.A.; Peng, X.F. Comparatively Thermal and Crystalline Study of Poly(methyl-methacrylate)/Polyacrylonitrile Hybrids: Core–Shell Hollow Fibers, Porous Fibers, and Thin Films. Macromol. Mater. Eng. 2016, 301, 1327–1336. [Google Scholar] [CrossRef] [Green Version]

- Xue, T.J.; McKinney, M.A.; Wilkie, C.A. The thermal degradation of polyacrylonitrile. Polym. Degrad. Stab. 1997, 58, 193–202. [Google Scholar] [CrossRef]

- Yu, M.J.; Bai, Y.J.; Wang, C.G.; Xu, Y.; Guo, P.Z. A new method for the evaluation of stabilization index of polyacrylonitrile fibers. Mater. Lett. 2007, 61, 2292–2294. [Google Scholar] [CrossRef]

- Bajaj, P.; Sreekumar, T.V.; Sen, K. Thermal behaviour of acrylonitrile copolymers having methacrylic and itaconic acid comonomers. Polymer 2001, 42, 1707–1718. [Google Scholar] [CrossRef]

- Han, N.; Zhang, X.X.; Wang, X.C. Fabrication, structures, and properties of acrylonitrile/methyl acrylate copolymers and copolymers containing microencapsulated phase change materials. J. Appl. Polym. Sci. 2007, 103, 2776–2781. [Google Scholar] [CrossRef]

- Liu, C.; Ni, X.; Chen, H.; Yu, H.; Ju, A. High molecular weight poly(acrylonitrile-co-3-aminocarbonyl-3-butenoic acid methyl ester) prepared by mixed solvent polymerization I. effect of monomer feed ratios on polymerization and stabilization. J. Polym. Res. 2019, 26, 276. [Google Scholar] [CrossRef]

- Ju, A.; Zhang, K.; Miao, L.; Ge, M. Poly(acrylonitrile-co-3-ammoniumcarboxylate-3-butenoic acid methyl ester): A better carbon fiber precursor than acrylonitrile terpolymer. J. Polym. Res. 2014, 21, 395. [Google Scholar] [CrossRef]

- Sir, E.I.; Micusik, M.; Gergin, I.; Omastová, M.; Sarac, A.S. Thermal stabilization of poly(acrylonitrile-co-itaconic acid) nanofibers as carbon nanofiber precursor. Polym. Degrad. Stab. 2020, 175, 109142. [Google Scholar]

- Ismar, E.; Sarac, A.S. Synthesis and characterization of poly (acrylonitrile-co-acrylic acid) as precursor of carbon nanofibers. Polym. Adv. Technol. 2016, 27, 1383–1388. [Google Scholar] [CrossRef]

- Ju, A.; Yan, Y.; Wang, D.; Luo, J.; Ge, M.; Li, M. A high molecular weight acrylonitrile copolymer prepared by mixed solvent polymerization: I. effect of monomer feed ratios on polymerization and stabilization. RSC Adv. 2014, 4, 64043–64052. [Google Scholar] [CrossRef]

- Basko, M.; Bednarek, M. Synthesis of functionalized polylactide by cationic activated monomer polymerization. React. Funct. Polym. 2012, 72, 213–220. [Google Scholar] [CrossRef]

- Copolymers of Acrylonitrile and Acrylic Acid: Effect of Composition and Distribution of Chain Units on the Thermal Behavior of Copolymers. Polym. Sci. Ser. B 2020, 62, 102–115. [CrossRef]

- Cetiner, S.; Sen, S.; Arman, B.; Sarac, A.S. Acrylonitrile/vinyl acetate copolymer nanofibers with different vinylacetate content. J. Appl. Polym. Sci. 2012, 127, 3830–3838. [Google Scholar] [CrossRef]

- Yang, R.T.; Steinberg, M. Reaction kinetics and differential thermal analysis. J. Phys. Chem. 1976, 80, 965–968. [Google Scholar] [CrossRef]

- Ozawa, T. A New Method of Analyzing Thermogravimetric Data. Bull. Chem. Soc. Jpn. 1965, 38, 1881–1886. [Google Scholar] [CrossRef] [Green Version]

| AN/MLA (wt/wt) | X (mol/mol−1) | Conversion (%) | O Content in the Copolymers (wt%) | Y (mol/mol−1) |

|---|---|---|---|---|

| 99/1 | 240.89 | 5.14 | 0.64 | 137.21 |

| 98/2 | 119.22 | 6.08 | 1.29 | 67.64 |

| 97/3 | 78.67 | 5.72 | 1.92 | 44.69 |

| 96/4 | 58.39 | 5.94 | 2.54 | 33.12 |

| 95/5 | 46.23 | 6.12 | 3.19 | 25.94 |

| AN/MLA | Mn (kg/mol) | Mw (kg/mol) | PDI |

|---|---|---|---|

| 99/1 | 83.4 | 131.8 | 1.58 |

| 98/2 | 66.7 | 119.9 | 1.79 |

| 97/3 | 64.1 | 124.4 | 1.94 |

| 96/4 | 43.8 | 112.3 | 2.56 |

| 95/5 | 32.4 | 88.8 | 2.74 |

| AN/ MLA (wt/wt) | Peak Intensity (CPS) | D (nm) | Lc (nm) | CI (%) | ||

|---|---|---|---|---|---|---|

| PAN | 17.18 | 5490 | 0.93 | 0.51 | 8.54 | 50.24 |

| 99/1 | 16.72 | 1242 | 0.772 | 0.536 | 10.625 | 49.12 |

| 98/2 | 16.81 | 1146 | 0.854 | 0.523 | 9.610 | 48.92 |

| 97/3 | 16.73 | 1060 | 0.822 | 0.535 | 9.979 | 46.19 |

| 96/4 | 16.73 | 872 | 0.775 | 0.535 | 10.584 | 45.45 |

| 95/5 | 16.97 | 753 | 0.819 | 0.528 | 10.029 | 45.12 |

| AN/MLA (wt/wt) | Peak Intensity I0 (CPS) | Peak Intensity Is (CPS) | SI (%) | |

|---|---|---|---|---|

| PAN | 17.18 | 5345 | 11,415 | −113.56 |

| 99/1 | 16.72 | 1242 | 1396 | −12.40 |

| 98/2 | 16.81 | 1146 | 867 | 24.34 |

| 97/3 | 16.73 | 1060 | 908 | 14.34 |

| 96/4 | 16.73 | 872 | 582 | 33.26 |

| 95/5 | 16.97 | 753 | 492 | 34.66 |

| Heat Treatment Temperature | Peak (°) | Peak Intensity I0 (CPS) | Peak Intensity Is (CPS) | SI (%) |

|---|---|---|---|---|

| 160 °C | 16.64 | 1060 | 1191 | −12.36 |

| 180 °C | 16.50 | 1060 | 909 | 14.25 |

| 200 °C | 16.50 | 1060 | 300 | 71.70 |

| 220 °C | 17.95 | 1060 | 117 | 88.96 |

| 240 °C | 18.43 | 1060 | 103 | 90.28 |

| 260 °C | 24.74 | 1060 | 92 | 91.32 |

| 280 °C | 24.58 | 1060 | 76 | 92.83 |

| AN/MLA (wt/wt) | Ti (°C) | Tp1 (°C) | Tp2 (°C) | Tp3 (°C) | Tf (°C) | ΔT (°C) | ΔH (J g−1) | ΔH/ΔT (J g−1 °C−1) |

|---|---|---|---|---|---|---|---|---|

| PAN | 244.16 | -- | -- | 278.99 | 303.11 | 58.95 | 2004.67 | 34.01 |

| P(AN-AA-MA) | 203.77 | -- | -- | 285.56 | 339.05 | 135.28 | 2054.11 | 15.18 |

| 99/1 | 185.48 | -- | -- | 272.76 | 340.42 | 154.94 | 3003.44 | 19.38 |

| 98/2 | 176.79 | 214.06 | -- | 271.43 | 346.06 | 169.27 | 3381.94 | 19.97 |

| 97/3 | 174.63 | 203.30 | 238.30 | 267.41 | 347.18 | 172.55 | 3346.12 | 19.39 |

| 96/4 | 168.43 | 204.85 | 250.02 | 271.98 | 362.46 | 194.03 | 3999.67 | 20.61 |

| 95/5 | 173.03 | 199.95 | 248.40 | -- | 362.20 | 189.17 | 4408.59 | 23.30 |

| AN/MLA (wt/wt) | Kissinger (kJ mol−1) | Ozawa (kJ mol−1) | ||

|---|---|---|---|---|

| Peak1 | Peak 3 | Peak1 | Peak 3 | |

| PAN | 168.39 | 165.89 | ||

| P (AN-MA-AA) | 141.49 | 140.86 | ||

| 99/1 | 157.14 | 155.25 | ||

| 98/2 | 101.67 | 169.49 | 102.46 | 166.75 |

| 97/3 | 116.98 | 169.47 | 117.21 | 166.72 |

| 96/4 | 122.87 | 216.37 (160.95 peak2) | 122.20 | 211.55 (155.31 peak2) |

| 95/5 | 102.87 | 104.22 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Dang, Y.; Ni, X.; Yuan, C.; Chen, H.; Ju, A. Preparation and Stabilization of High Molecular Weight Poly (acrylonitrile-co-2-methylenesuccinamic acid) for Carbon Fiber Precursor. Polymers 2021, 13, 3862. https://doi.org/10.3390/polym13223862

Zhang S, Dang Y, Ni X, Yuan C, Chen H, Ju A. Preparation and Stabilization of High Molecular Weight Poly (acrylonitrile-co-2-methylenesuccinamic acid) for Carbon Fiber Precursor. Polymers. 2021; 13(22):3862. https://doi.org/10.3390/polym13223862

Chicago/Turabian StyleZhang, Shuxian, Yanjin Dang, Xuepeng Ni, Chunshun Yuan, Huifang Chen, and Anqi Ju. 2021. "Preparation and Stabilization of High Molecular Weight Poly (acrylonitrile-co-2-methylenesuccinamic acid) for Carbon Fiber Precursor" Polymers 13, no. 22: 3862. https://doi.org/10.3390/polym13223862

APA StyleZhang, S., Dang, Y., Ni, X., Yuan, C., Chen, H., & Ju, A. (2021). Preparation and Stabilization of High Molecular Weight Poly (acrylonitrile-co-2-methylenesuccinamic acid) for Carbon Fiber Precursor. Polymers, 13(22), 3862. https://doi.org/10.3390/polym13223862